Patents

Literature

180results about How to "Achieve the purpose of self-cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-cleaning suiting containing nano-functional material and method for making garment products

InactiveCN1824884AExtended service lifeGood social and economic benefitsPhysical treatmentWoolHalothane

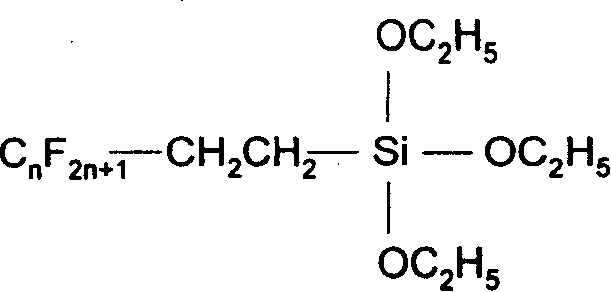

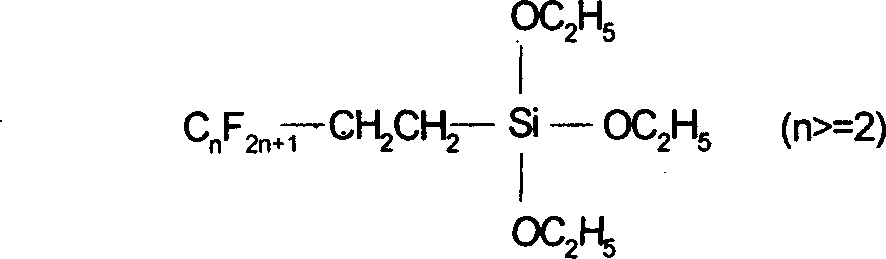

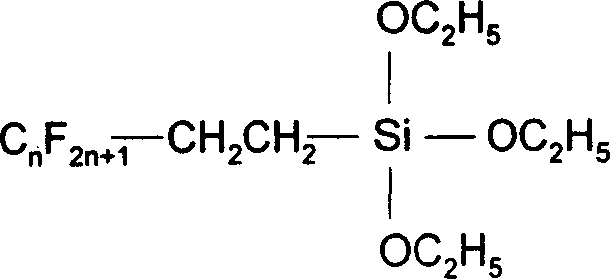

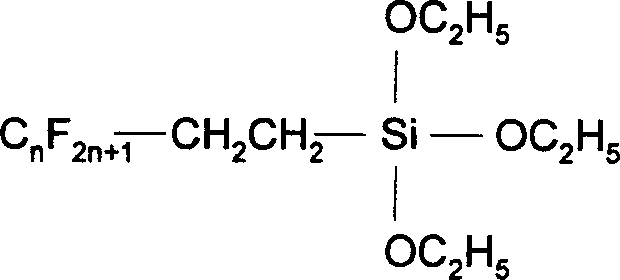

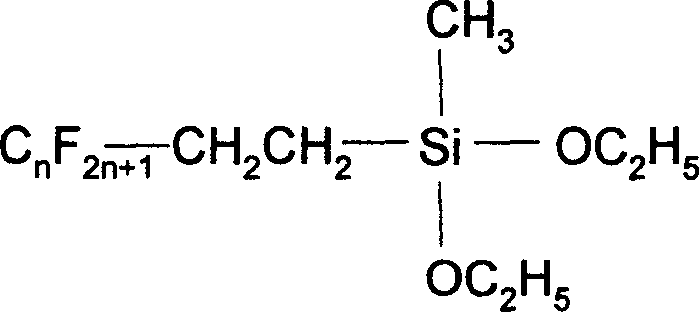

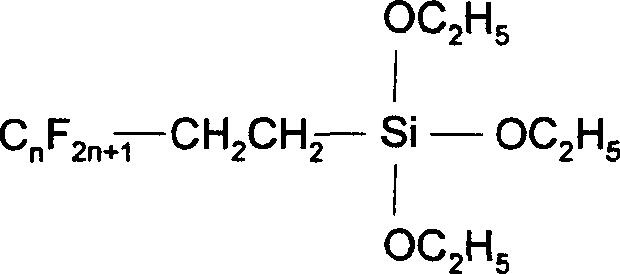

The invention relates to nm functional material self-cleaning suit face fabric that adopts low temperature plasma surface process technology to take dipping or spraying process with halothane residue triethoxy silicane compound containing nm level solid particle to pure wool or wool terylene blending face fabric to make the face fabric has super water discharging and oil discharging feature to achieve the purpose of self-cleaning. The invention could make the face fabric more handsome and prolong useful life, and it also has great social and economic benefits in environment and energy saving aspects.

Owner:中科纳米技术工程中心有限公司

Waterproof ultraviolet-resistant high-strength light and thin fabric and preparation method thereof

ActiveCN106480581AIncreased mechanical strength and electromagnetic shielding performanceExcellent UV resistanceUltrasonic/sonic fibre treatmentWoven fabricsSolventPlain weave

The invention provides a method for preparing a waterproof ultraviolet-resistant high-strength light and thin fabric. The method comprises the following steps: blending ceramic fibers and triangular special-shaped polyester fibers to form warp yarns, blending spandex fibers and titanium-nickel alloy fibers to form weft yarns, weaving plain weaves or basket weaves serving as a fabric structure to form base cloth; adding colloidal silica sol and nanometer titania sol into a solvent, fully stirring, adding graphene oxide solution, dripping a polystyrene high polymer, homogenizing and stirring so as to obtain a coating finishing agent; washing and airing the base cloth, performing low-temperature plasma treatment so as to obtain modified base cloth in a nitrogen atmosphere; spraying deionized water on the surface of the modified base cloth, wetting, repeatedly coating the coating finishing agent, drying, roasting, washing, well-pressing, and performing tenter setting, thereby obtaining the product.

Owner:SHAOXING DAFABRIC CLOTH TRADE

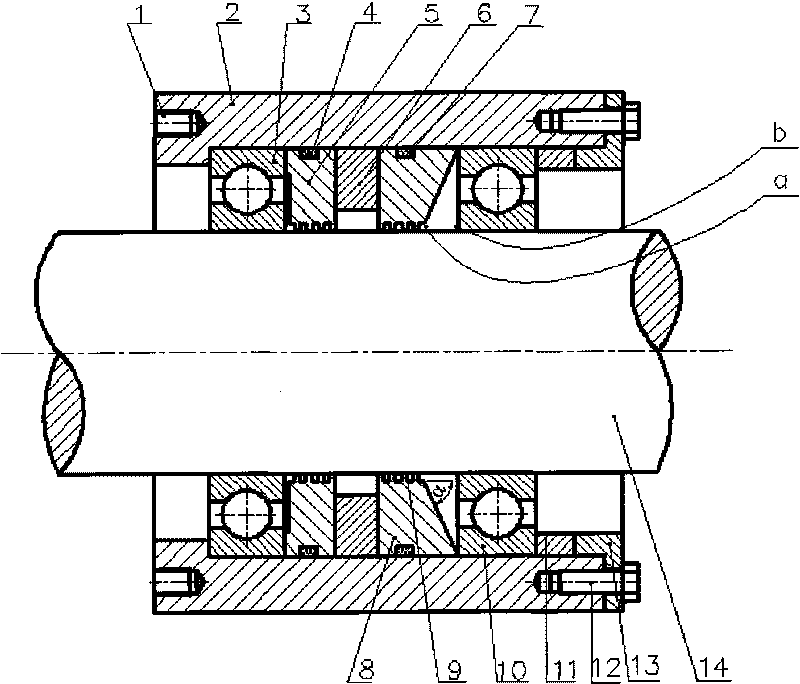

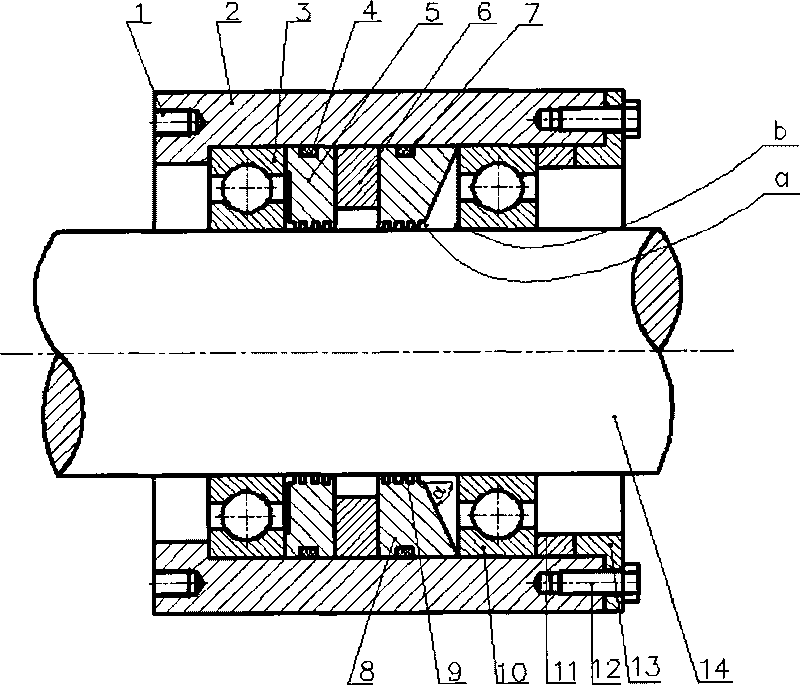

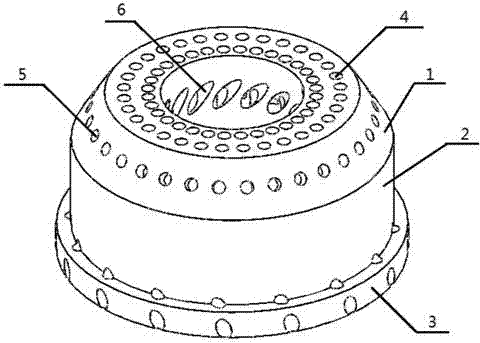

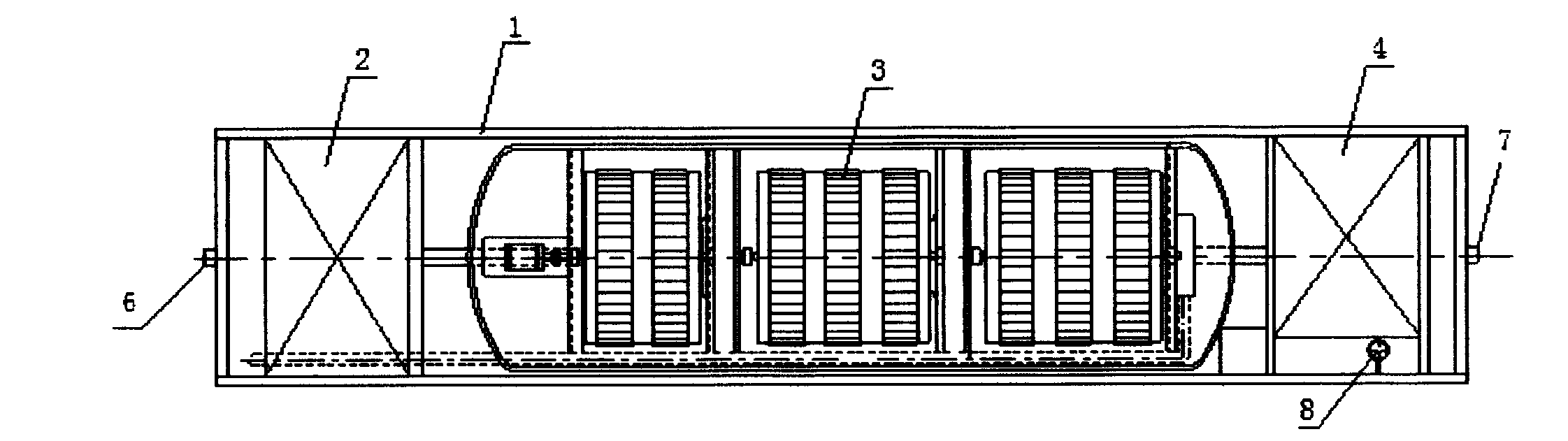

Magnetic liquid sealing device with self-cleaning function

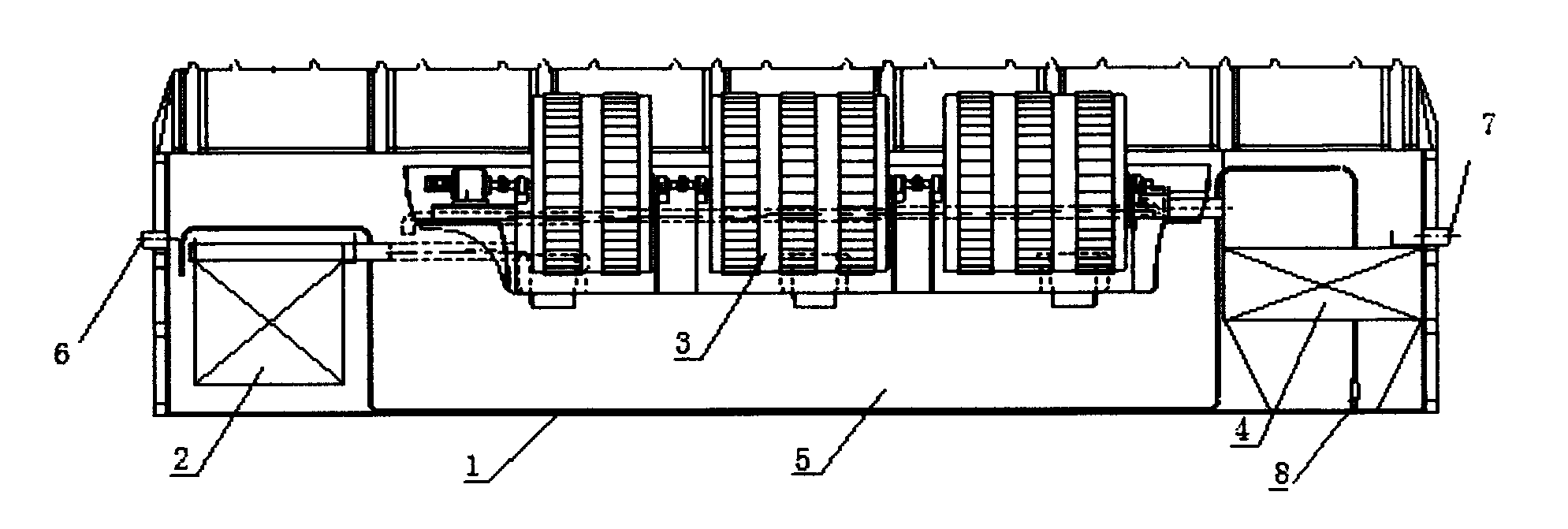

InactiveCN101737499AImprove sealingSeal applicableEngine sealsForeign matterHigh magnetic field strength

The invention discloses a magnetic liquid sealing device with a self-cleaning function, which belongs to the technical field of mechanical engineering sealing and comprises a shell (2), a left bearing (3), a left pole shoe (5) with a rubber seal ring, a permanent magnet (6), a right pole shoe (8) with a rubber seal ring, a right bearing (10), an adjusting gasket (11), a flange disk (13) and a shaft (14). The right end face of the right pole shoe and an axle line form an angle alpha of 10 to 80 degrees to change the shape of the right pole shoe and the magnetic field strength, so that the magnetic field strength on the side a of the right pole shoe is higher than that on the side b. According to Bernoullis equation, the pressure of the granules entering a magnetic liquid from outside on the side with high magnetic field strength is higher that on the side with low magnetic field strength, namely the pressure on the side a is more than that on the side b. The system generates a repulsive force to outside foreign materials so as to fulfil the aim of self cleaning.

Owner:BEIJING JIAOTONG UNIV

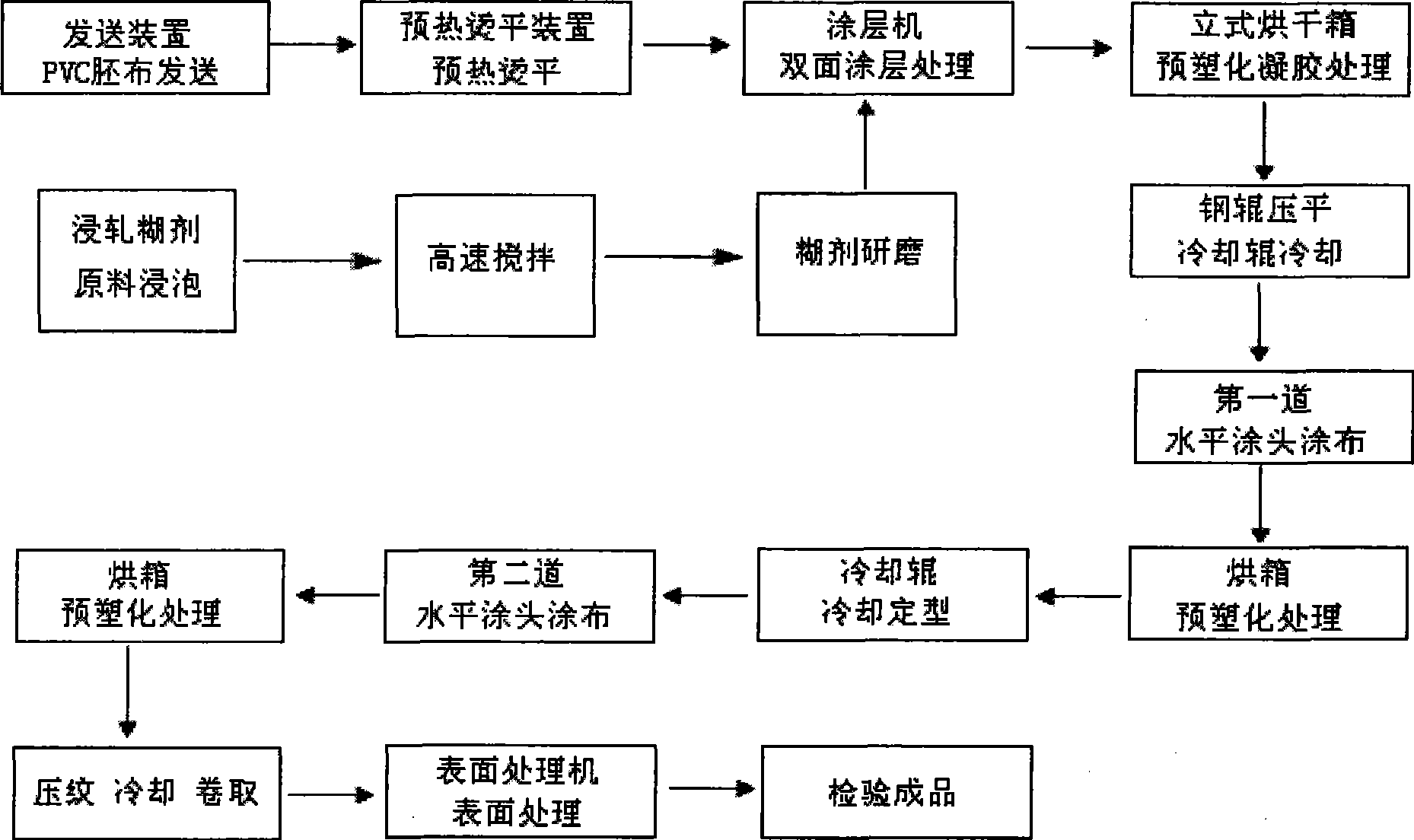

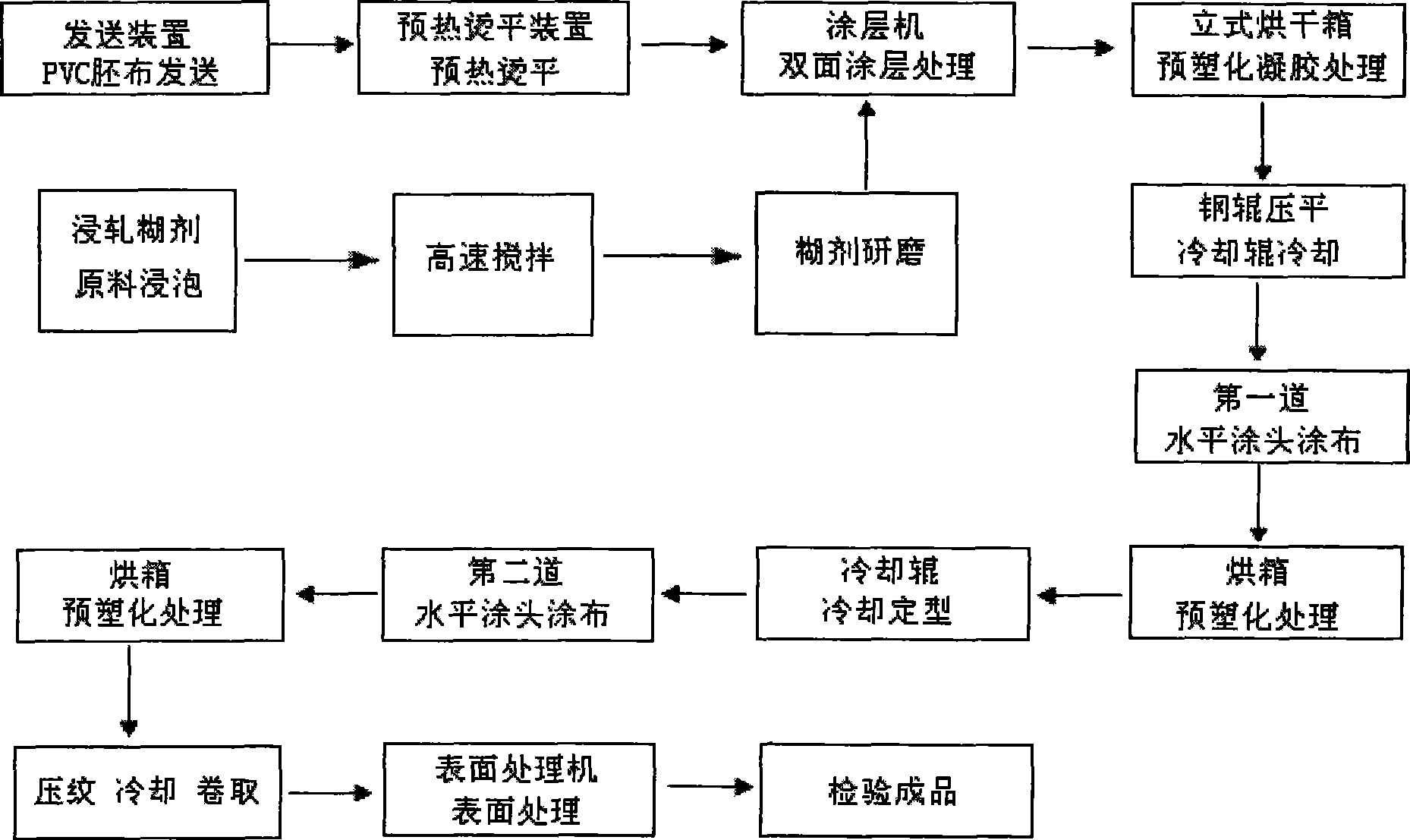

Preparation process for superaqueous surrounding-separating coating material of PVC

InactiveCN101509201AGuarantee processing qualityStay hydratedLiquid surface applicatorsWater cleaningSurface layerEconomic benefits

The invention provides a process for preparing a PVC overwater enclosure coating material, which comprises delivery of PVC grey cloth, preheating and ironing, double-face coating treatment, pre-plasticizing and gelling, planishing and cooling, primary coating of a horizontal coating head, plasticizing treatment, cooling and shaping, secondary coating of the horizontal coating head, plasticizing treatment, embossing, cooling, winding, surface treatment and preparation. The process combines net sandwich cloth coating and surface treatment process, is complete relatively to common coating processing, can process a vertical coating, a surface layer and a bottom layer, reduces the intrusion of ultraviolet rays on the coating by adopting the surface treatment process on the one hand, can prevent plasticizing agent from being transferred to the surface of a product on the other hand so as to achieve the antifouling effect and achieve the aim of self-cleaning by means of rainwater; and the product has good air tightness and superior abrasion-resisting property, is suitable for outdoor application, and has long service life and remarkable economic benefit.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Paper with nano structural surface possessing characters of super hydrophobicity and self-cleaning

InactiveCN1415800ASmall stretch rateMaintain self-cleaning performanceWater-repelling agents additionImpressionabilityEthyl ester

An ultrahydrophobic self-cleaning paper with nano surface structure is made up by using silica gel (703,704, or 705), ethyl acetate, n-butyl acetate and banana oil to prepare an ultrahydrophobic self-cleaning nano layer on the surface of ordinary paper. Its advantages are high impressionability and writability, high water-proof and self-cleaning function.

Owner:HUAZHONG NORMAL UNIV

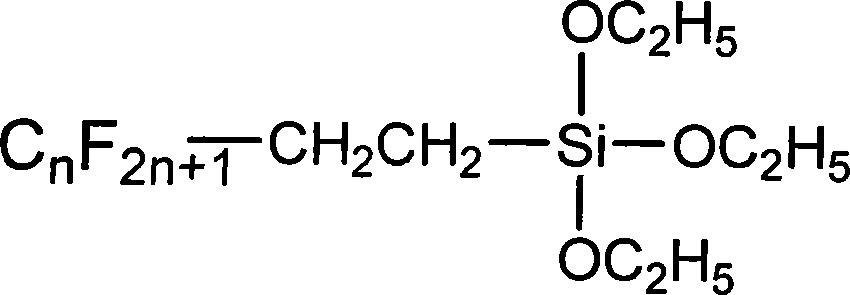

Preparation method of self-cleaning leather or product containing nano functional material

InactiveCN101250596AWith self-cleaning functionSimple processLiquid surface applicatorsCoatingsFiberSpray coating

A preparation process of self-clearing leather or products comprises nano functional material, which comprises mixing nano inorganic solid particles and alcohol solution of fluorine-containing alkyl triethoxy silane compound to prepare mixing solution, then impregnating through the impregnation method or conducting spray coating through the spraying process, and then drying. Since fluorine-containing alkyl triethoxy silane compound is used, therefore the process has high bonding strength to leather fiber, has excellent water repellency and oil repellency without high temperature cross-linking, has simple processing technique to face fabric, and can save energy. Leather is endowed with higher roughness factors through adopting the compounding of nano solid particles, thereby further increasing hydrophobic and oleophobic properties, and making leather have self-clearing function since leather is water free and oil free.

Owner:SHAANXI UNIV OF SCI & TECH

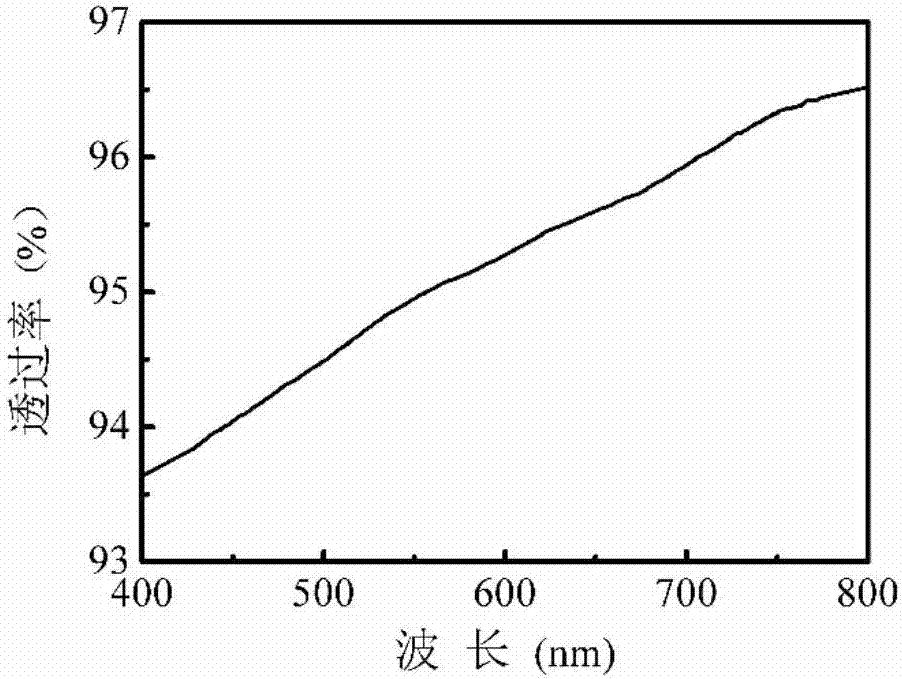

Preparation method of transparent super-hydrophobic coating

InactiveCN103803814AExcellent superhydrophobic propertiesGood light transmissionDip-coatingChemical vapor deposition

The invention relates to a preparation method of a transparent super-hydrophobic coating. The preparation method comprises the steps of (1) preparing boehmite sol; (2) soaking a substrate material in the boehmite sol, and forming a boehmite seed film on the surface of the substrate material through a way of pulling and dip coating; (3) soaking the substrate material coated with the boehmite seed film in a solution containing sodium metaaluminate and urea, and carrying out hydrothermal reaction; and (4) soaking the boehmite seed film-coated substrate material processed by the step (3) in a solution containing a hydrophobic compound, and implementing self-assembly reaction at normal temperature; or carrying out chemical vapor deposition at 100-150 DEG C and implementing self-assembly reaction to obtain the transparent super-hydrophobic coating. The method disclosed by the invention is simple in process, easily available in raw material, low in cost and good in repeatability; the prepared coating is excellent in super-hydrophobicity and light transmission, and is applicable to windshields of automobile, airplane, spacecraft and the like, as well as window glass and curtain walls of buildings and other occasions.

Owner:DONGHUA UNIV

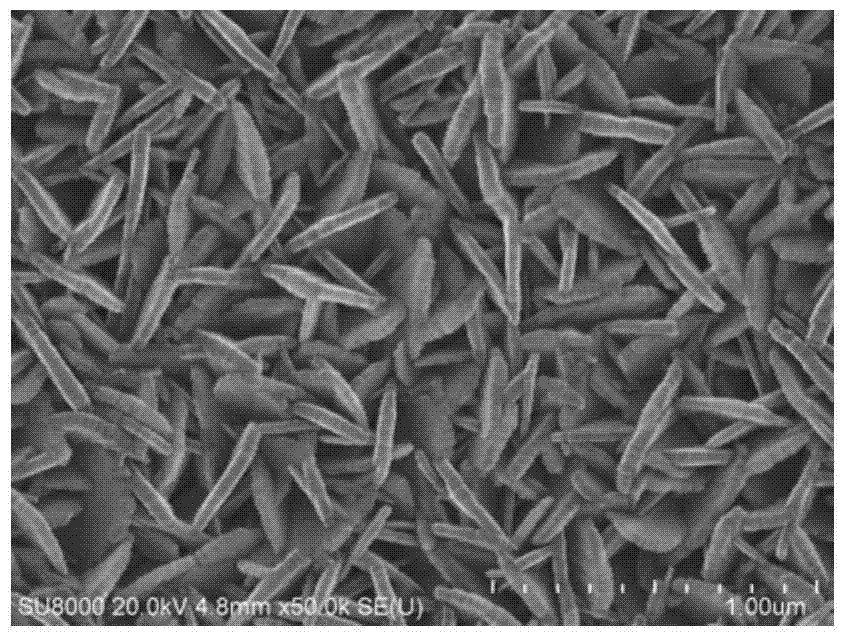

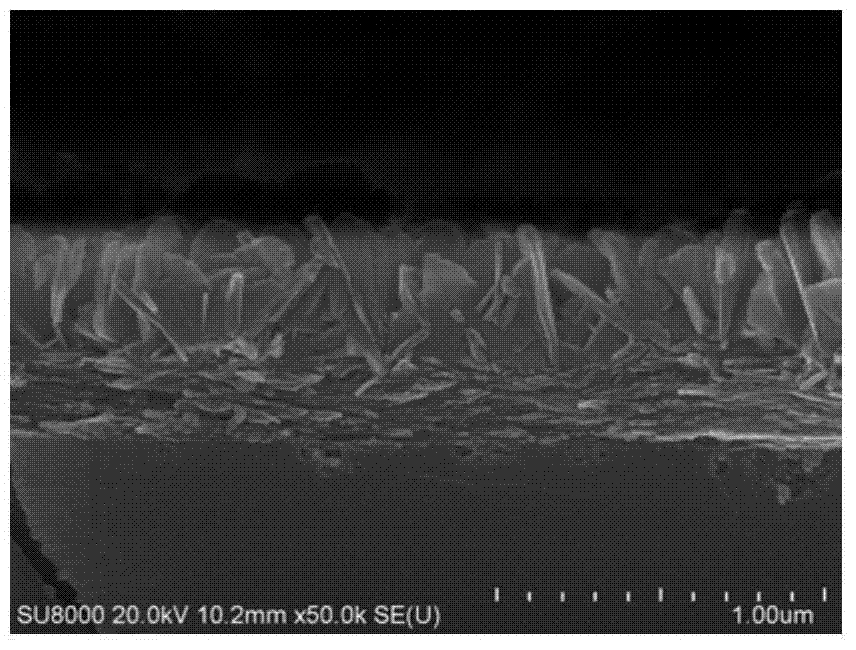

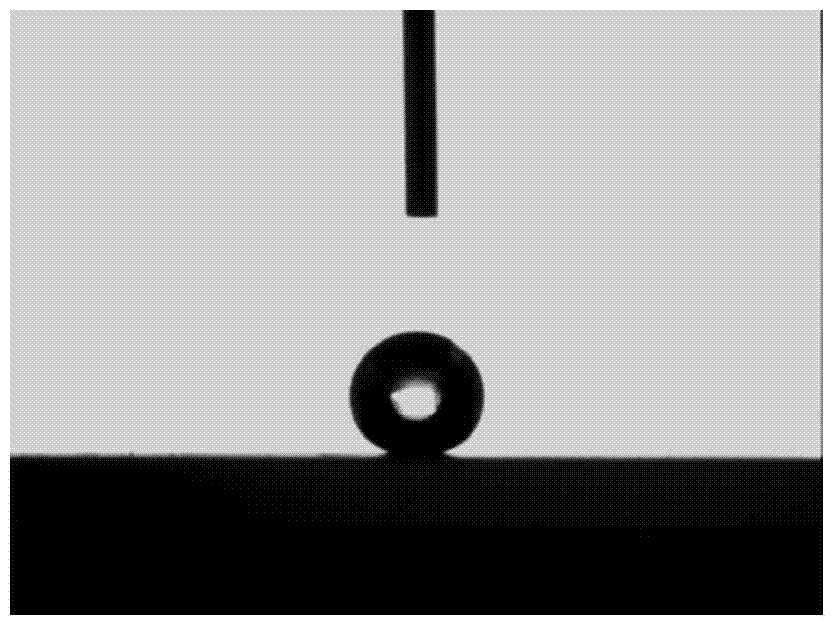

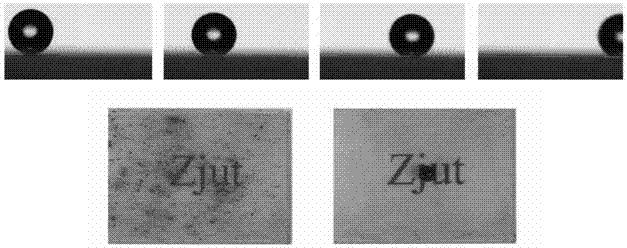

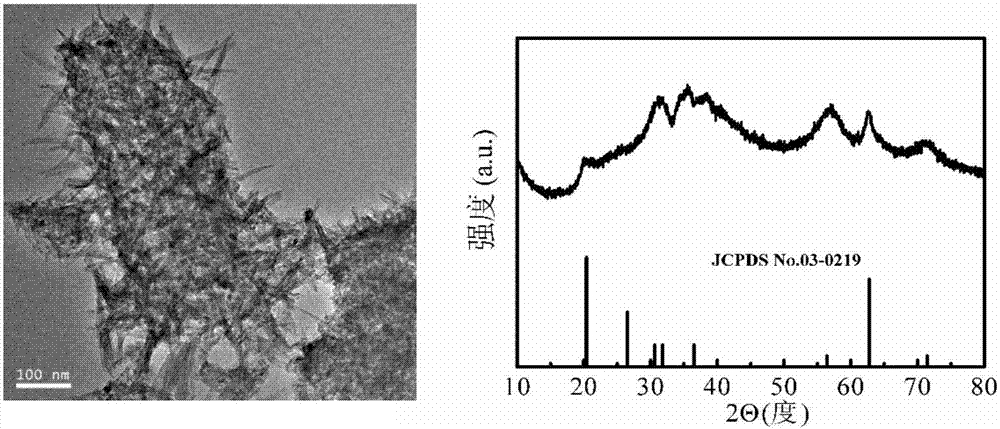

Graphene oxide/copper silicate composite powder, preparation method of composite powder and application thereof in super-hydrophobic coating

InactiveCN107128937ASimple processMild reaction conditionsMaterial nanotechnologyCarbon compoundsMicro nanoUltraviolet lights

The invention discloses graphene oxide / copper silicate composite powder, a preparation method of the composite powder and application thereof in a super-hydrophobic coating. The graphene oxide / copper silicate composite powder with a micro-nano structure on the surface comprises a core formed by flake graphene oxide and a shell layer formed by needle-like nano copper silicate, wherein the needle-like nano copper silicate is arranged on the surface of the core in an array form. The super-hydrophobic coating is prepared by the following steps: coating the surface of a base material with the graphene oxide / copper silicate composite powder with the micro-nano structure on the surface, drying, and performing fluoroalkyl silane low-surface energy treatment, thereby obtaining the product. The preparation method disclosed by the invention is mild in reaction conditions, easy to realize and excellent in process repeatability; the prepared high-transparency, self-cleaning and anticorrosive super-hydrophobic coating has a static water drop contact angle of not less than 150 degrees; the slide angle does not exceed 1 degree; and the light transmissivity is not lower than 90% in a visible-ultraviolet light wave range. The product has excellent corrosion resistance and is expected to be widely applied to the fields of automobiles, spaceflight, solar cells, articles of daily use and the like.

Owner:ZHEJIANG UNIV OF TECH

Clothes dryer and evaporator assembly for clothes dryer

ActiveCN106480676AIncrease profitReduce the number of manual cleaningsTextiles and paperLaundry driersWater flowEngineering

The invention discloses an evaporator assembly for a clothes dryer and the clothes dryer provided with same. The evaporator assembly comprises an evaporator, a water accumulation container, a water storage container, a water draining pipe and a cleaning pipe, wherein an upper end opening and a water accumulation cavity for receiving condensed water flowing from the evaporator are defined in the water accumulation container, the water draining pipe is communicated with the water accumulation container and the water storage container, a water draining pump for driving water in the water accumulation container to flow towards the water storage container is arranged on the water draining pipe, the cleaning pipe is communicated with at least one evaporator in the water accumulation container and the water storage container, and a cleaning pump is arranged on the cleaning pipe and used for driving water in at least one of the water accumulation container and the water storage container to flow towards the evaporator. According to the embodiment, the evaporator assembly for the clothes dryer can achieve condensed water discharge, meanwhile can utilize the condensed water of the clothes dryer to flush dirty flocks and the like on the evaporator so as to achieve the self-cleaning purpose, the water flowing speed and flow are improved, and a cleaning effect is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

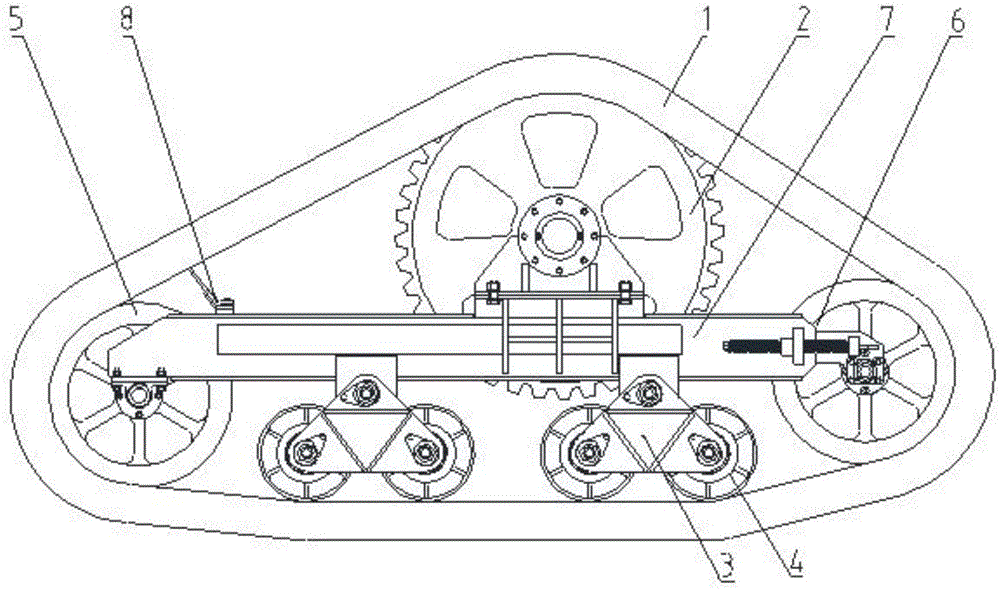

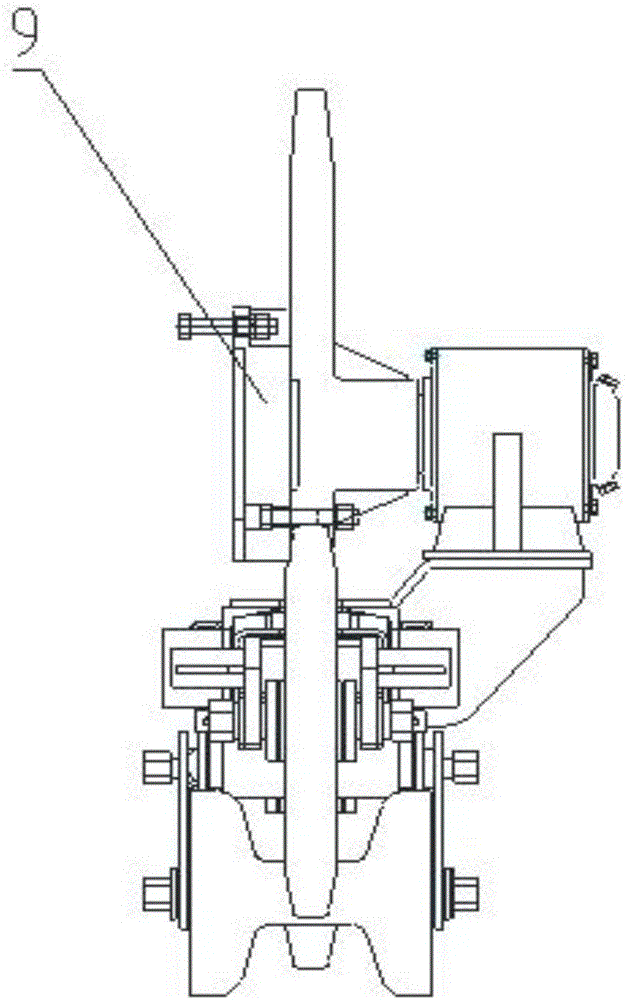

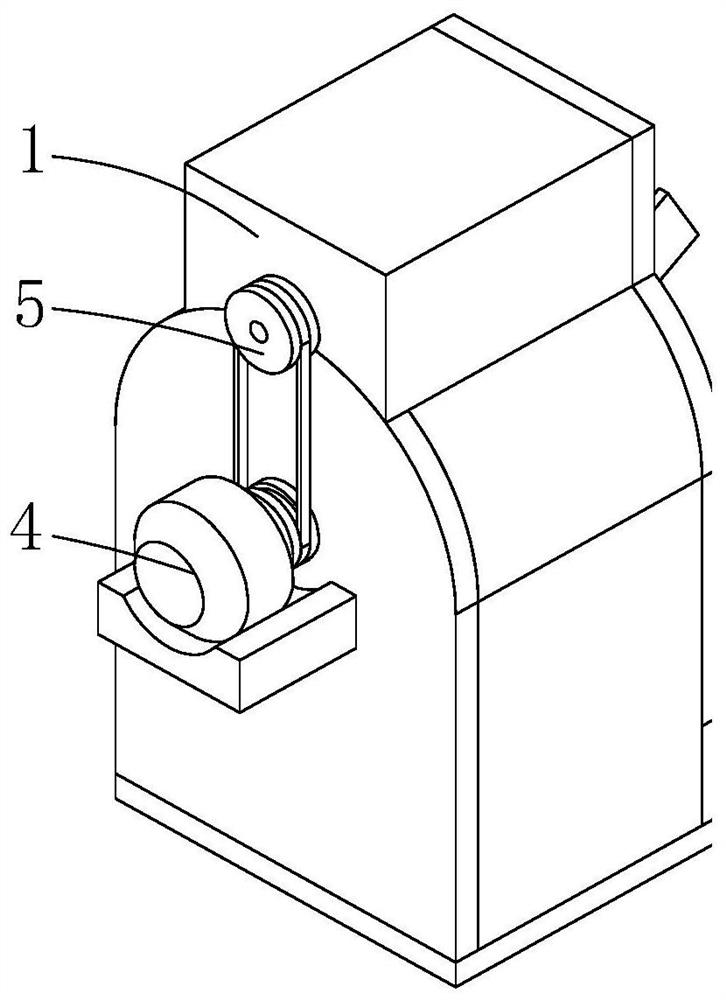

Harvester rubber halftrack traveling device

PendingCN106672096AGood driving maneuverabilityReduce harmEndless track vehiclesDrive wheelGround pressure

The invention discloses a harvester rubber halftrack traveling device. The harvester rubber halftrack traveling device is composed of a rubber track, a driving wheel, swinging arms, thrust wheels, a guiding wheel, a tension wheel and a track bracket; the driving wheel is installed on the upper portion of the track bracket; the thrust wheels are installed on the lower portion of the track bracket; and the guiding wheel and the tension wheel are installed on the two sides of the track bracket correspondingly. The harvester rubber halftrack traveling device disclosed by the invention replaces original vehicle rubber tires, the ground pressure of a whole vehicle is decreased, and the passing ability of the vehicle under severe operating conditions is improved; and the harvester rubber halftrack traveling device has the characteristics of being smooth and steady in traveling, low in noise, capable of saving oil and protecting arable lands, convenient to install and the like.

Owner:黑龙江重兴机械设备有限公司

Nanometer self cleaning cashmere or products thereof

InactiveCN1525001AAchieve the purpose of self-cleaningExtended service lifeFibre treatmentCross-linkChloride

The invention relates to a self-cleaning nano cashmere or products and making method, where the self-cleaning nano cashmere or products is obtained by adopting organic fluorin finishing agent containing nano inorganic solid particles to process the cashmere or products by dipping, coating or spraying. The organic fluorin finishing agent is a water system containing organic fluorin resin 10-70g / L, nano solid particle 5-30g / L, silane coupling agent 0-50g / L, cross-linking agent 0-7g / L, magnesium chloride 0-0.1g / L and isopropanol 0-30g / L. The self-cleaning nano cashmere or products has super -hydrophobic and -oleophobic property, i.e. not stained with both water and oil, thus achieving the self-cleaning purpose.

Owner:BEIJING ERDOS SCI & TECH DEV

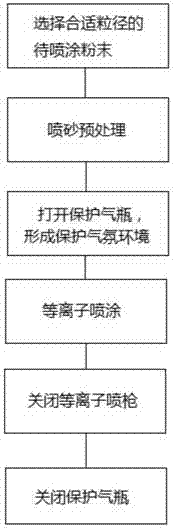

Method for controlling atmospheric plasma spraying of easily-oxidized coating under atmosphere open environment

ActiveCN104213066AImprove antioxidant capacityImprove anti-ablation performanceMolten spray coatingMetallurgyGas cylinder

The invention discloses a method for controlling atmospheric plasma spraying of an easily-oxidized coating under the atmosphere open environment. According to the method, in the plasma spraying process, powder can be effectively prevented from being oxidized, the purity and the property of the coating are ensured, the oxidation-resisting property and the ablation-resisting property of the coating are improved, and the service life of the coating is prolonged. The method specifically comprises the points that before plasma spraying is carried out, an air flow channel is arranged outside a plasma spraying gun muzzle; the air flow channel is connected with a protection air bottle, and therefore the aim that the protection atmosphere environment is formed between the spraying gun opening and a base material can be achieved. Before the coating is sprayed, the protection air bottle is opened in advance, the protection atmosphere environment is formed, and then plasma spraying equipment is controlled to carry out spraying of the easily-oxidized coating. According to the method, manufacturing of a silicide coating under the atmospheric pressure open environment can be achieved, the process is easy to operate, parameters are easy to regulate and control, and the method is a high-efficiency low-cost coating manufacturing process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nanometer self cleaning cashmere or products thereof,and its preparation method

InactiveCN1242114CAchieve the purpose of self-cleaningExtended service lifeFibre treatmentCross-linkChloride

The invention relates to a self-cleaning nano cashmere or products and making method, where the self-cleaning nano cashmere or products is obtained by adopting organic fluorin finishing agent containing nano inorganic solid particles to process the cashmere or products by dipping, coating or spraying. The organic fluorin finishing agent is a water system containing organic fluorin resin 10-70g / L, nano solid particle 5-30g / L, silane coupling agent 0-50g / L, cross-linking agent 0-7g / L, magnesium chloride 0-0.1g / L and isopropanol 0-30g / L. The self-cleaning nano cashmere or products has super -hydrophobic and -oleophobic property, i.e. not stained with both water and oil, thus achieving the self-cleaning purpose.

Owner:BEIJING ERDOS SCI & TECH DEV

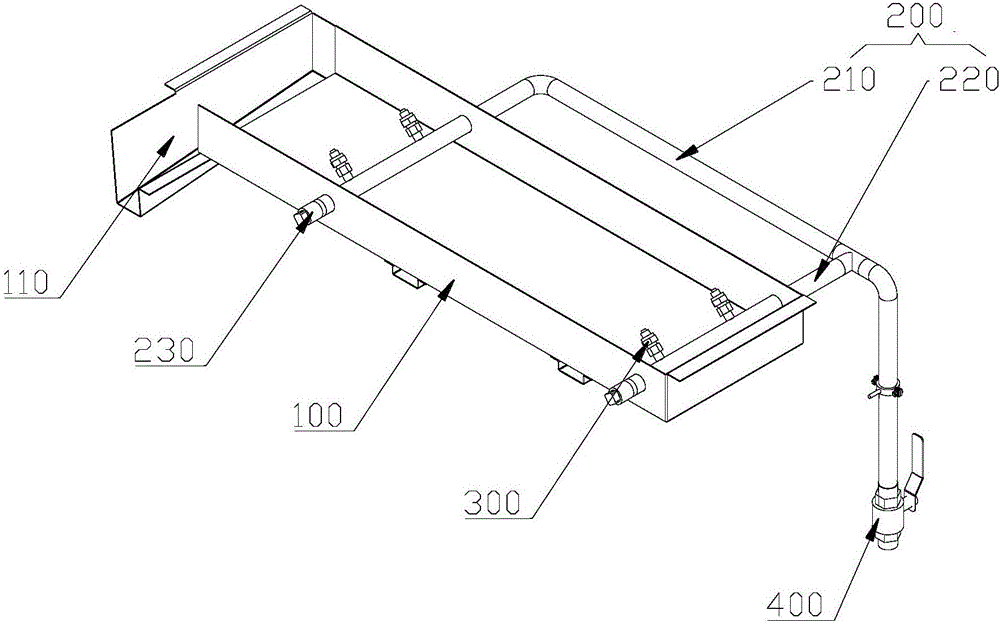

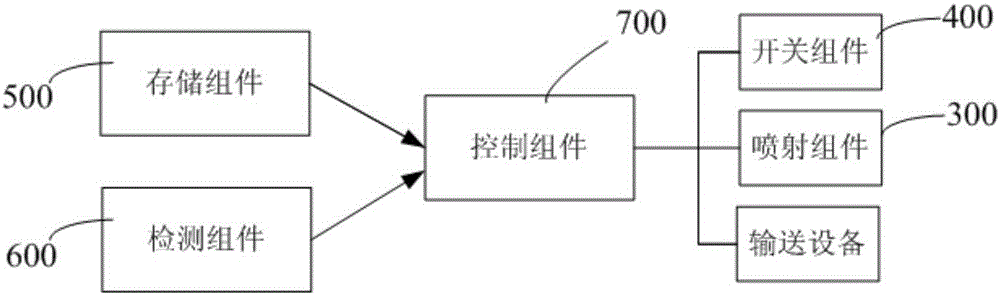

Cleaning device for conveying equipment and conveying equipment

InactiveCN106364869ASimple structureGood decontamination effectCleaningCleaning using liquidsDynamic monitoringEngineering

The invention relates to a cleaning device for conveying equipment and belongs to the field of conveying equipment. The cleaning device comprises a receiving tank, a water supply pipe and spray assemblies. The receiving tank is arranged below the conveying equipment and used for receiving residual materials on the non-working surface of the conveying equipment cleaned by the spray assemblies. The water supply pipe is connected with the spray assemblies and used for conveying liquid materials to the spray assemblies; and the spray assemblies face the conveying equipment. According to the cleaning device for the conveying equipment, the combination of the spray assemblies and mechanisms such as water pipes is adopted to clean the non-working surface of the conveying equipment, the structure is simple, the cleaning effect is good, the operation intensity of a traditional cleaning mode is largely reduced, and the cost is saved; additionally, operation is easy and convenient, as long as a corresponding switch assembly is started and collecting water buckets are placed at the receiving tank and a collecting tank, the fallen residual materials such as grain can be easy to collect and recycle, the cost is reduced, and the cleanliness of an entire factory is improved; and an intelligent control device is adopted to achieve dynamic monitoring on the operating state of the conveying equipment, and the purpose of self-cleaning is achieved.

Owner:HUNAN BONYA INTELLIGENT EQUIP CO LTD

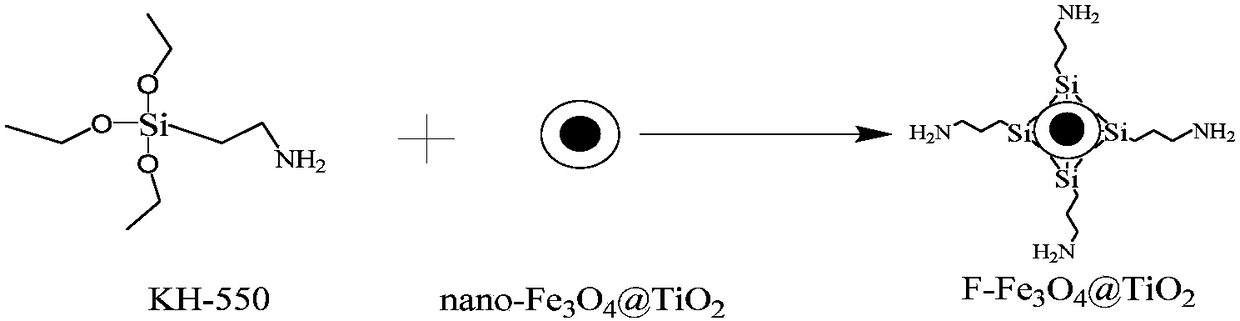

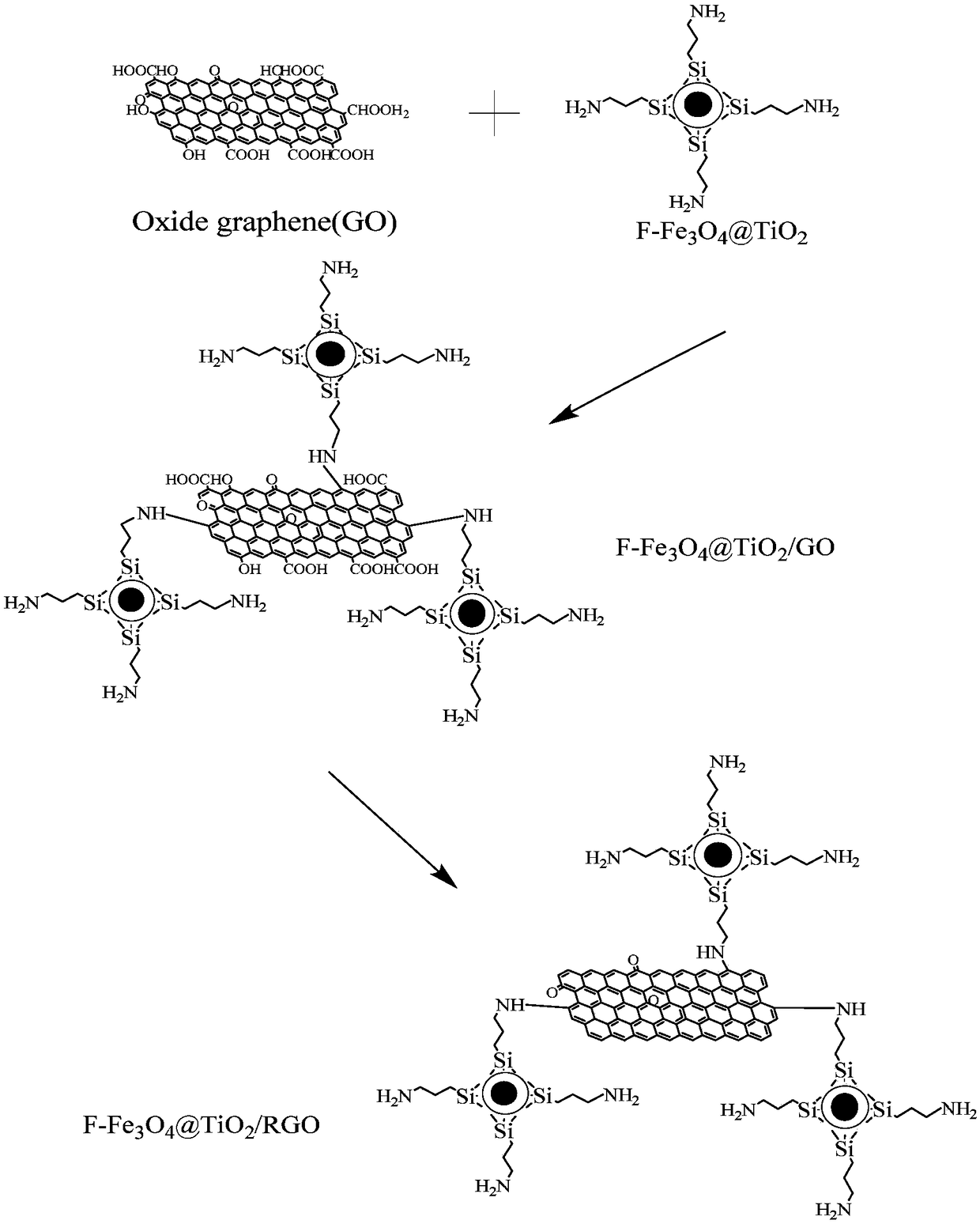

Seawater resistant graphene modified anticorrosive paint and preparation method thereof

InactiveCN108531038AHigh mechanical strengthHigh impact strengthAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention relates to seawater resistant graphene modified anticorrosive paint, which is prepared from the following ingredients in parts by weight: an ingredient A (20 to 30 percent of epoxy resin, 3 to 10 percent of Fe3O4@TiO2 / rGO composite materials, 20 to 30 percent of deionized water, 1 to 5 percent of zinc powder, 5 to 10 percent of zinc phosphate, 5 to 10 percent of talcum powder, 5 to 15 percent of calcium carbonate, 3 to 10 percent of water-based dispersants, 0.5 to 3 percent of coupling agents and 1.5 to 5 percent of other auxiliary agents) and an ingredient B (15 to 30 percent ofcuring agents). The paint has the advantages that the Fe3O4@TiO2 / rGO composite materials are formed at the material surface; Fe3O4@TiO2 nanometer of a core-shell structure has an efficient photocatalysis effect; ocean organic organisms are oxidized and decomposed; meanwhile, the photoinduced cathode protection is realized; the anticorrosive effect is achieved on a base material; rGO is of a unique laminar structure; the adhesive force of the coating can be improved; meanwhile, a physical blocking layer can also be formed; through the performance optimization in various aspects, the paint hasgood antifouling and anticorrosive performance. The seawater resistant graphene modified anticorrosive paint can be widely applied to the fields of facilities such as oil and gas pipelines in marine environment and steel frame structures.

Owner:CHANGZHOU UNIV

Production process for door curtain material

ActiveCN101509202AReduce invasionInhibit migrationLiquid surface applicatorsSynthetic resin layered productsFiberPolyester

The invention provides a process for producing a door curtain material, which comprises delivery of polyester fiber grey cloth, double-face coating treatment, pre-plasticizing and gelling, planishing and cooling, primary coating of a horizontal coating head, plasticizing treatment, cooling and shaping, secondary coating of the horizontal coating head, plasticizing treatment, embossing, cooling, winding, surface treatment and preparation. The process combines net sandwich cloth coating and surface treatment process, is complete relatively to common coating processing, can process a vertical coating, a surface layer and a bottom layer, reduces the intrusion of ultraviolet rays on the coating by adopting the surface treatment process on the one hand, can prevent plasticizing agent from being transferred to the surface of a product on the other hand so as to achieve the antifouling effect and achieve the aim of self-cleaning by means of rainwater; and the product has good air tightness and superior abrasion-resisting property, is suitable for outdoor application, and has long service life and remarkable economic benefit.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Preparation method of feather dress fabric or slopwork productions with nanometer self-cleaning function

InactiveCN100334291CHas superhydrophobic and oleophobic propertiesAchieve the purpose of self-cleaningPhysical treatmentFiberSolid particle

Owner:ZHONGKE BOSIDENG NANOMETER CLOTHING ORNAMENT SUZHOU

Biological rotating disc integrated domestic sewage treatment equipment

InactiveCN103663850ARegulate peak loadAchieve degradationMultistage water/sewage treatmentThree levelPollution

The invention relates to biological rotating disc integrated domestic sewage treatment equipment, belonging to the technical field of domestic sewage treatment equipment. The biological rotating disc integrated domestic sewage treatment equipment comprises an equipment box body, a denitrification tank, a biological treatment unit, a pipe chute secondary sedimentation tank and a mud sump, wherein the skeleton of the equipment box body is welded by carbon steel square tubes, the wall plate of the equipment box body is made of glass fiber reinforced plastics, a three-dimensional elastic packing is installed in the denitrification tank, microorganisms grow on the packing, and the biological treatment unit comprises three levels of (three) rotating biological rotors. According to the biological rotating disc integrated domestic sewage treatment equipment, the problem of environment pollution caused by emission of small-scale domestic sewage is solved, energy consumption for treating water per unit is lowered, and manual operation amount is reduced.

Owner:苏州克莱尔环保科技有限公司

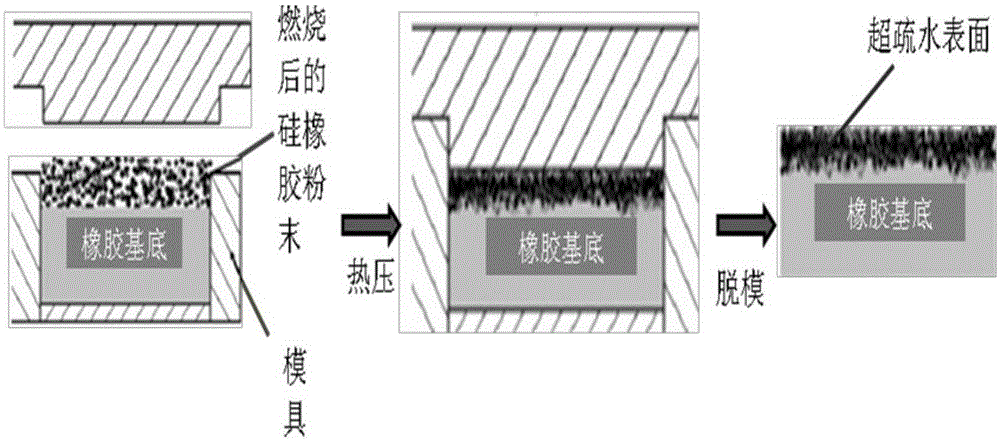

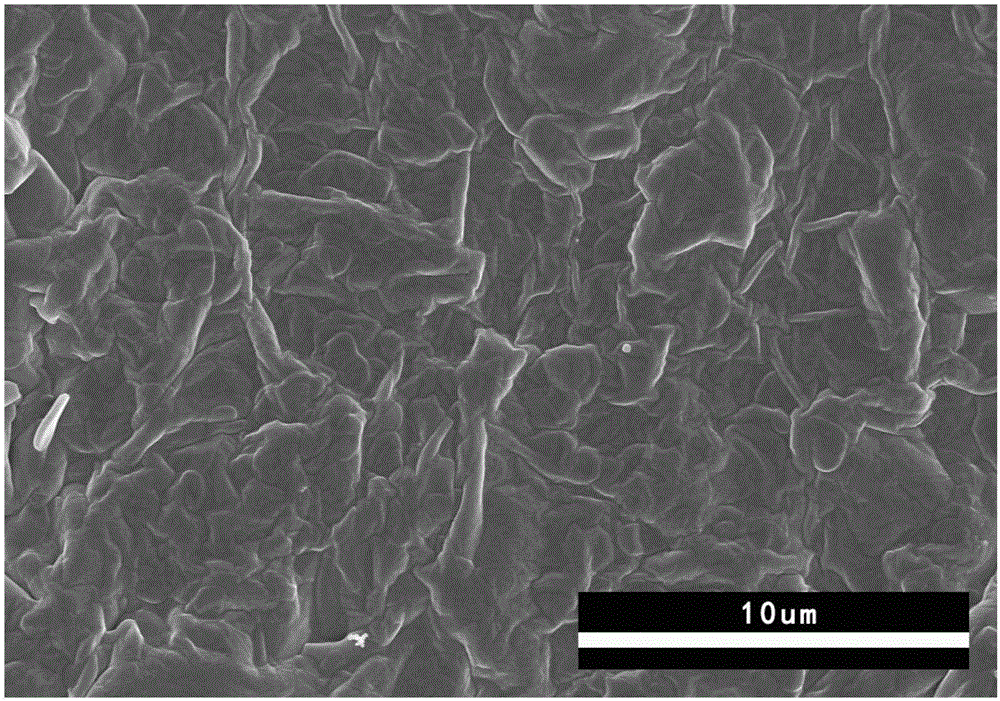

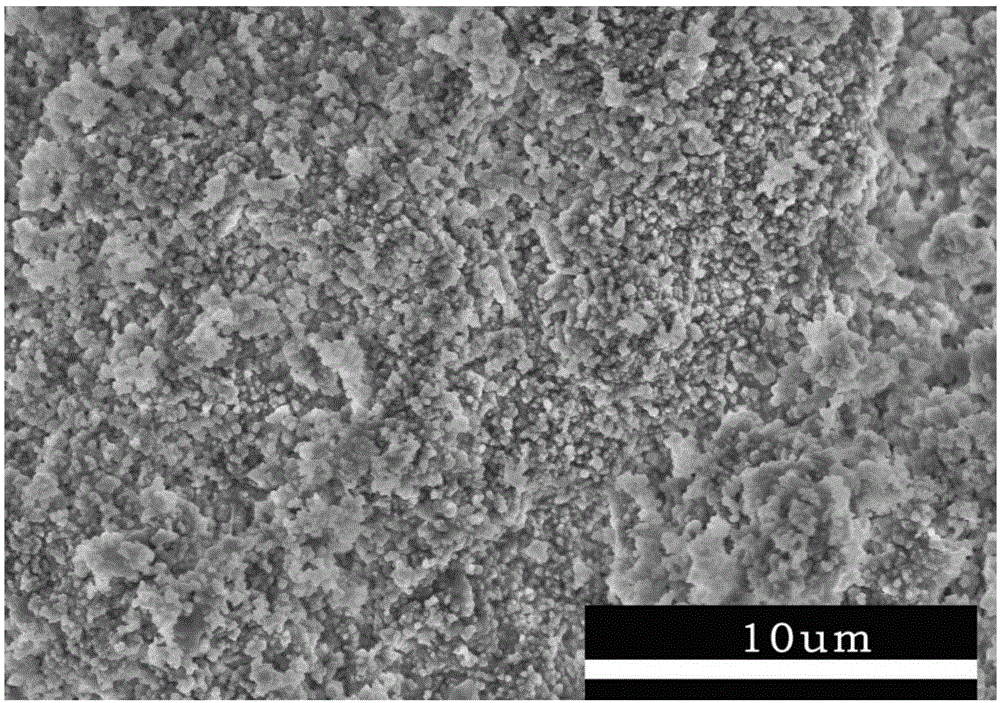

Method for preparing self-cleaning anti-icing rubber surface by use of waste silicone rubber product

Owner:WUXI BOTON TECH CO LTD +1

Composite film glass with infrared reflection and self-cleaning function

InactiveCN1673147AEliminates the process of migrating the barrier layerImprove photocatalytic activityChemical vapor deposition coatingComposite filmOptoelectronics

The present invention discloses one kind of composite film glass with infrared reflection and self-cleaning functions. On the surface of hot float process glass, one transition SiO2 layer is first plated via CVD process, one infrared reflecting SnO2 film is then plated, and one layer of photocatalytically self-cleaning film is finally plated to form the filmed glass with both infrared reflection and self-cleaning functions.

Owner:江苏凤凰置业投资股份有限公司

Nanometer composite ocean anticorrosion coating and preparation method thereof

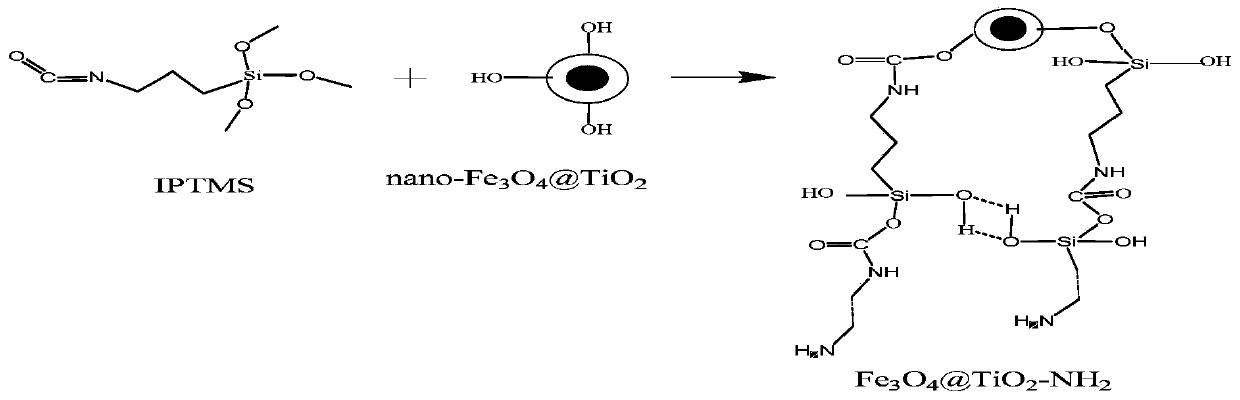

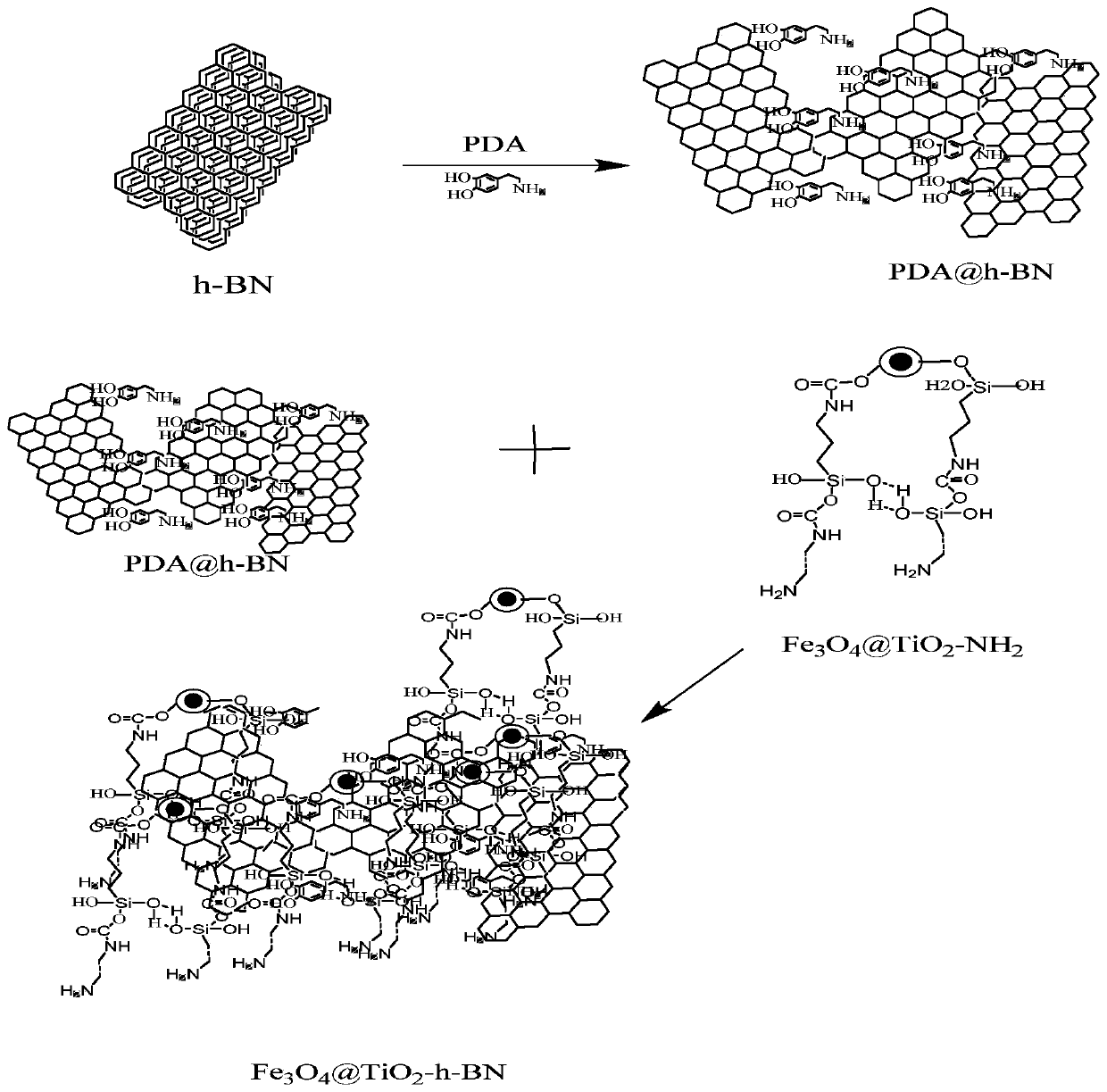

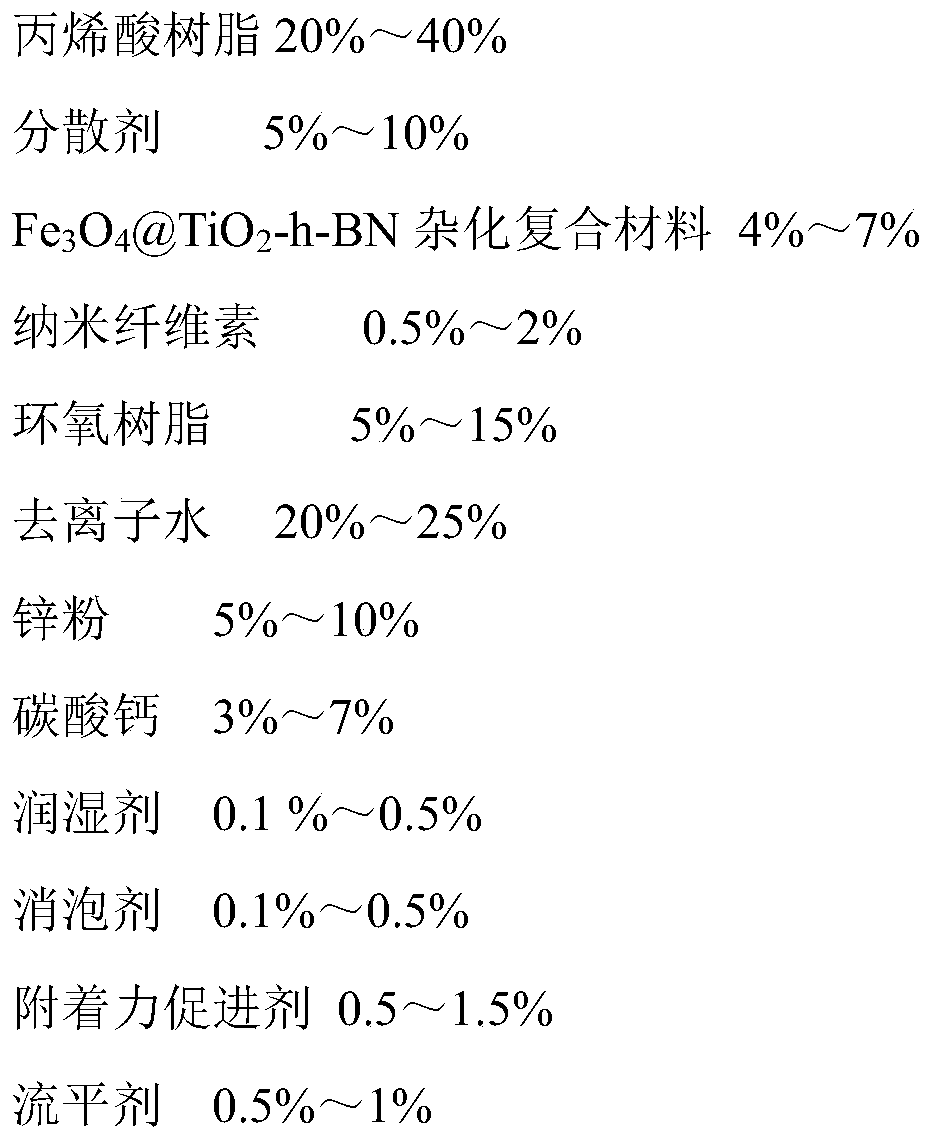

ActiveCN109943169AReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

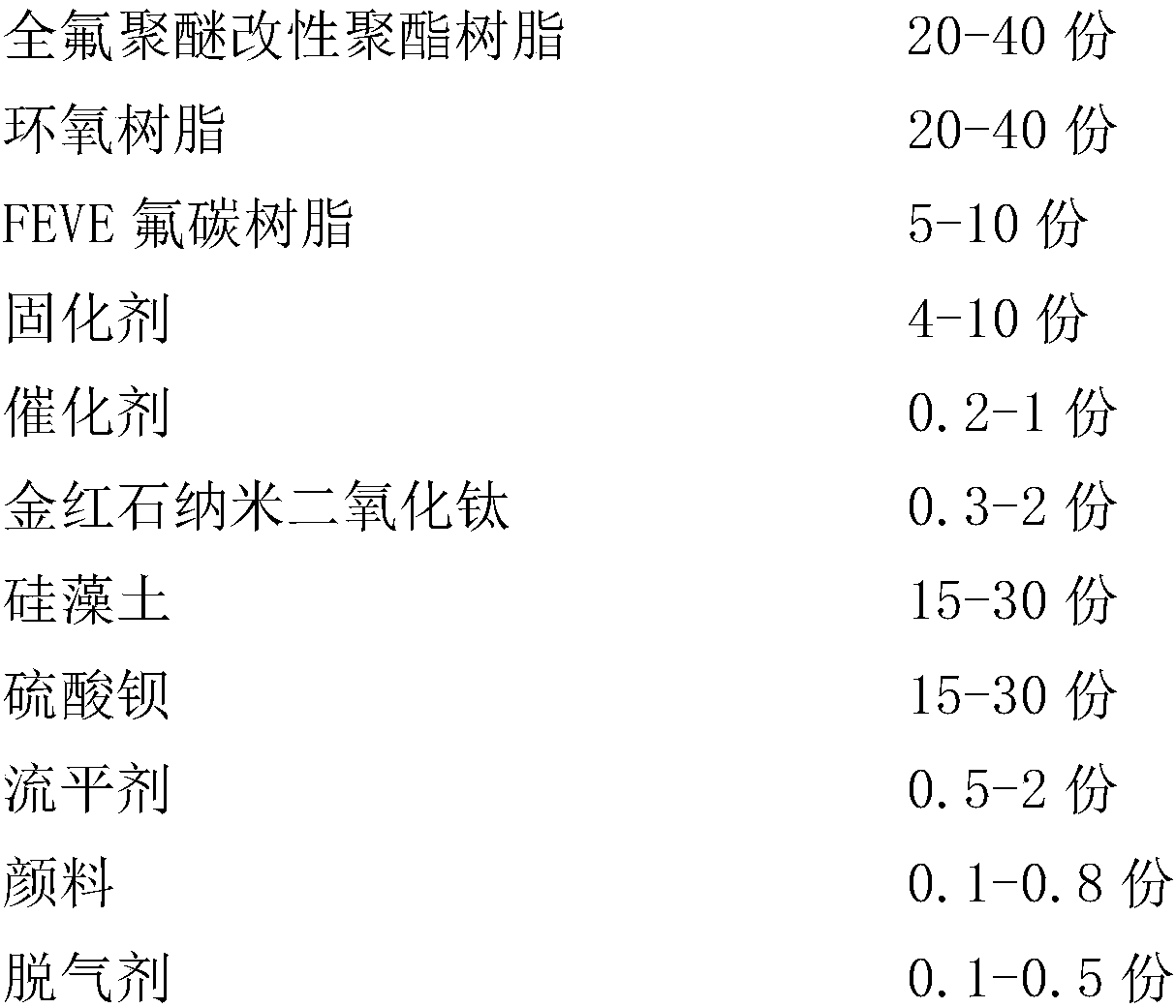

Anti-corrosion thermosetting powder coating

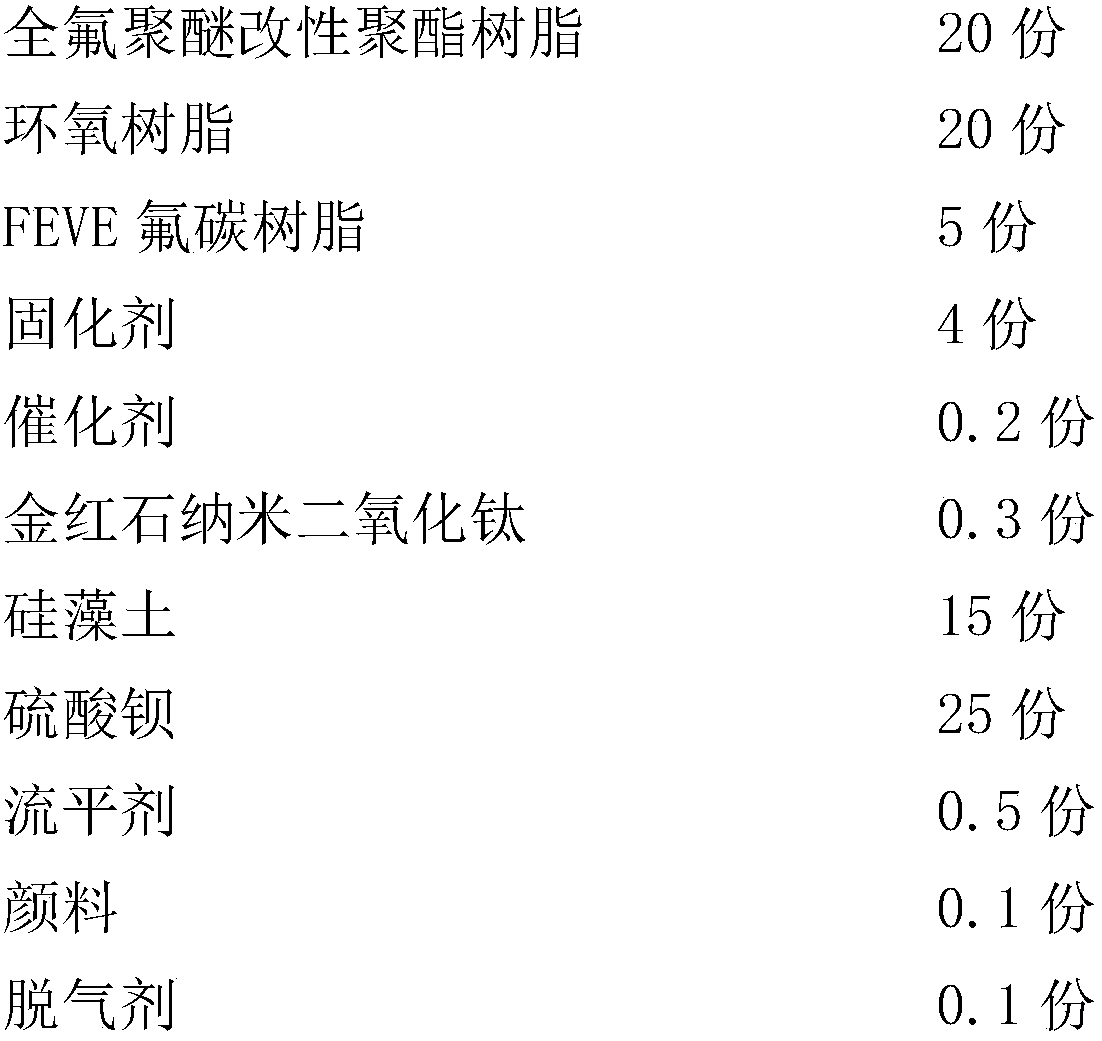

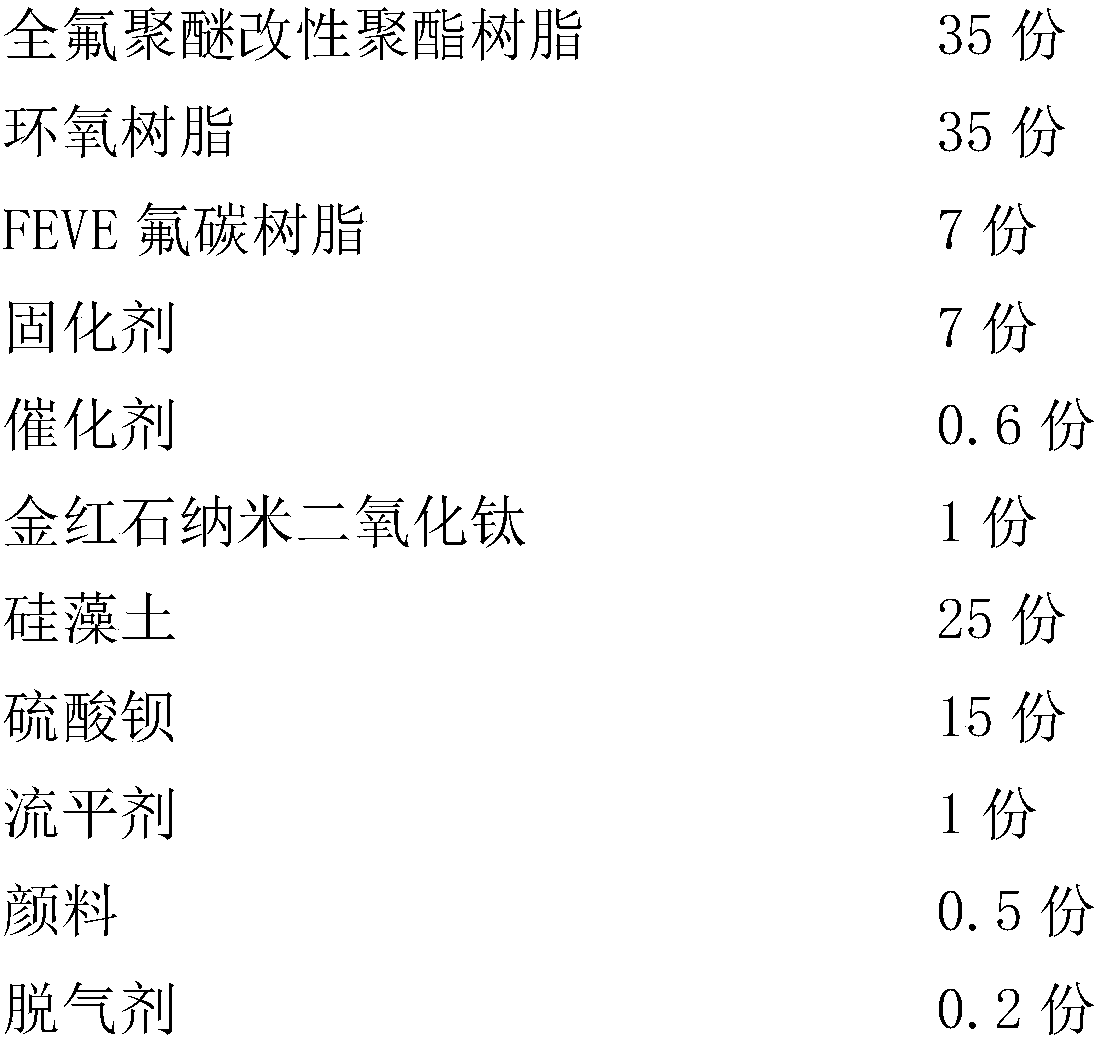

InactiveCN109370392AMake up for weather resistanceImprove wettabilityAnti-corrosive paintsPowdery paintsVinyl etherEpoxy

The invention relates to an anti-corrosion thermosetting powder coating. The anti-corrosion thermosetting powder coating is composed of raw materials including, by weight part, 20-40 parts of perfluoroalkylpolyether modified polyester resin, 20-40 parts of epoxy resin, 5-10 parts of FEVE (fluoroethylene vinyl ether) fluorocarbon resin, 4-10 parts of curing agent, 0.2-1 part of catalyst, 0.3-2 parts of rutile nano-titanium dioxide, 15-30 parts of kieselguhr, 15-30 parts of barium sulfate, 0.5-2 parts of leveling agent, 0.1-0.8 part of pigment and 0.1-0.5 part of degassing agent. The anti-corrosion thermosetting powder coating compounds the perfluoroalkylpolyether modified polyester resin, the epoxy resin and the FEVE fluorocarbon resin to achieve high corrosion resistance, high adhesive force and good wettability.

Owner:宁波爱甬新材料科技有限公司

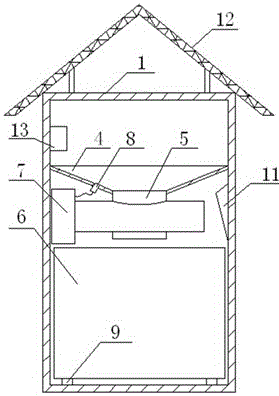

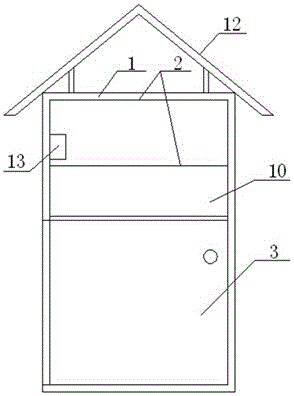

Dustbin used for residential district and capable of improving living comfort degree

PendingCN106144328AAchieve the purpose of self-cleaningImprove the environmentWaste collection and transferRefuse receptaclesUv disinfectionEngineering

The invention discloses a garbage bin for residential quarters capable of improving living comfort, which comprises a box body placed vertically on the ground, a solar panel is arranged on the top of the box body, and the inside of the box body is sequentially arranged from top to bottom There are interconnected trays, air pumps, and trash cans; the upper part of the box is provided with a parabola port connected to the tray, the side wall of the parabolic port is provided with an aroma diffuser, and the lower part of the box is rotatably connected with a trash can The door of the box is equipped with an LED electronic display screen between the parabolic port and the door; a controller and an ultraviolet disinfection lamp are connected to the inner wall of the box between the receiving tray and the trash can, and a distance sensor is installed on the receiving tray. , the controller is respectively connected with the distance sensor, the solar panel, the air pump and the ultraviolet disinfection lamp; the solar panel is connected with the controller, the LED electronic display and the aroma diffuser. The utility model has the advantages of improving the community environment, being able to supply electricity by itself, being able to disinfect garbage, and being suitable for use in residential quarters.

Owner:成都立威讯科技有限公司

Anti-corrosion and anti-blockage drainage pipe and preparation method thereof

ActiveCN109679491AAvoid cloggingReduce contact areaAntifouling/underwater paintsPaints with biocidesFiberPlastic pipework

The invention discloses an anti-corrosion and anti-blockage drainage pipe and a preparation method thereof. The anti-corrosion and anti-blockage drainage pipe drainage pipe comprises a plastic pipe, aself-cleaning layer and an anti-corrosion layer, wherein the anti-corrosion layer is uniformly sprayed on the inner wall of the plastic pipe, and the self-cleaning layer is uniformly sprayed on the surface of the anti-corrosion layer and comprises the following raw materials: nano-silver, glass powder, polystyrene and polydimethylsiloxane; the anti-corrosion layer comprises the following raw materials: polytetrafluoroethylene, carbon fiber, bisphenol A epoxy resin, additives, turpentine and a compatilizer. The pipe has the beneficial effects that a self-cleaning effect can be achieved, dirt in the pipe can be removed to achieve the effect of being in the silt but not imbrued, blockage of the drainage pipe is effectively prevented, and the pipe is provided with the anti-corrosion layer, sothat corrosion resistance and oxidation resistance of the pipe are increased, stability of the pipe is enhanced, and the service life of the pipe is prolonged.

Owner:YANCHENG RUITONG PLASTIC CO LTD

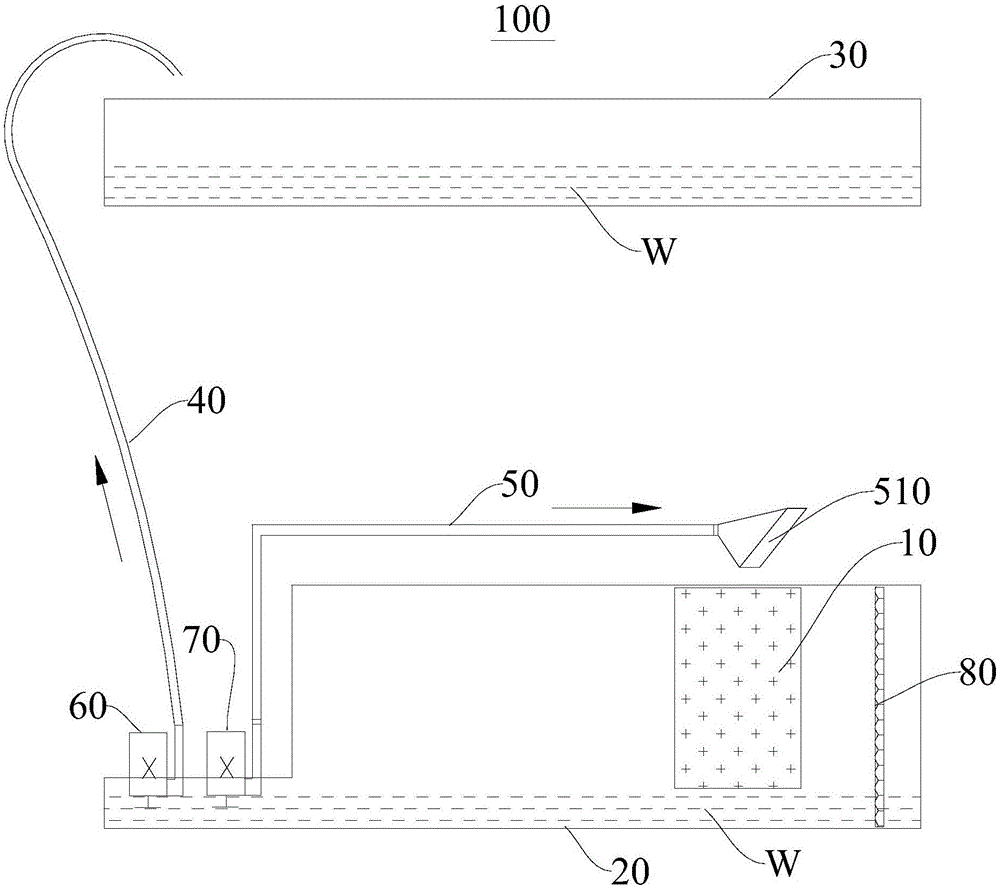

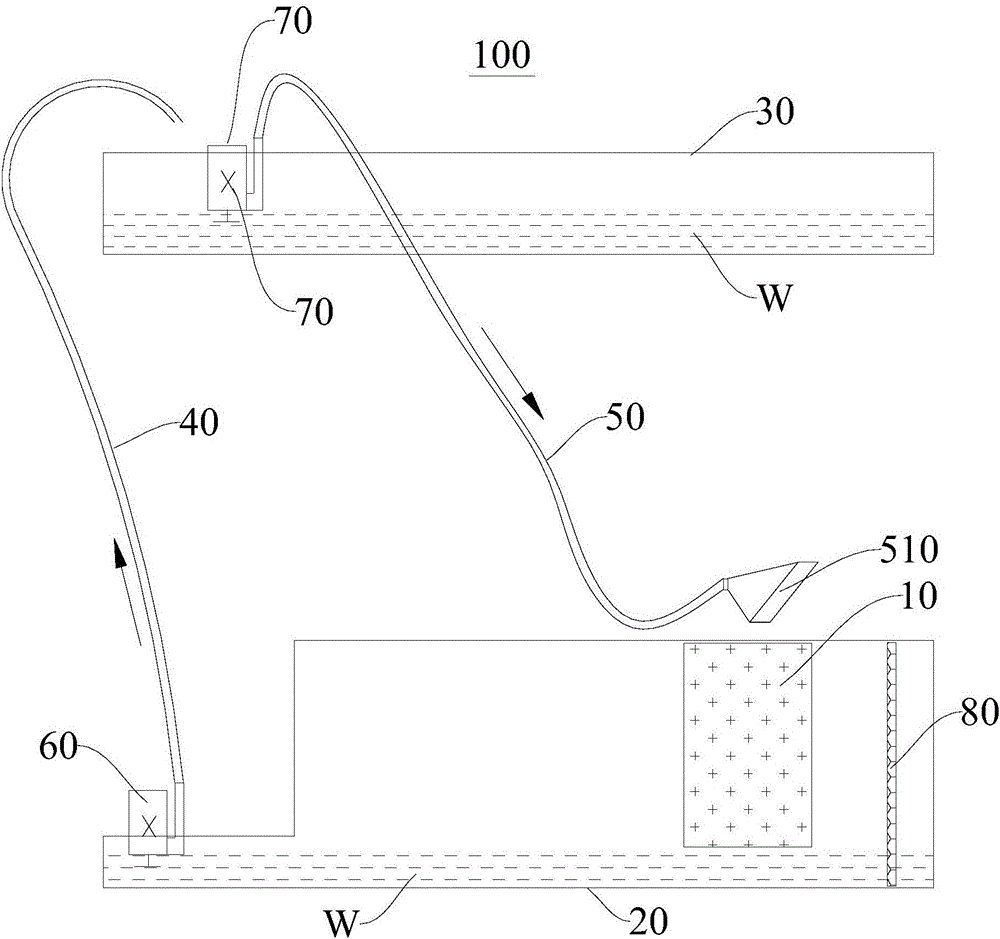

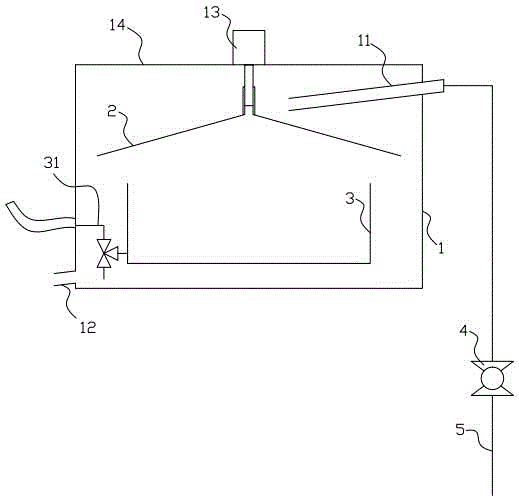

Water quality monitoring and sample feeding device with impurity remover

InactiveCN104597271AExtend your lifeAchieve the purpose of self-cleaningPreparing sample for investigationWater qualityEngineering

The invention discloses a water quality monitoring and sample feeding device with an impurity remover. The water quality monitoring and sample feeding device comprises a covered shell provided with a water inlet tube and a water drainage tube, wherein a collector is arranged at the bottom in the shell, and the collector is communicated with the outside through a sample feeding tube; an umbrella-shaped filter screen is arranged above the collector with a gap, and the centre of the umbrella-shaped filter screen is connected with a motor arranged on the top cover of the shell; the water outlet of the water inlet tube is located close to a place above the umbrella-shaped filter screen. During sample feeding, seawater flows to the umbrella-shaped filter screen through the water inlet tube, impurities are filtered off by the umbrella-shaped filter screen, and a part of the impurities falls off from the edge of an umbrella and enters the water drainage tube to be drained. When many dirt impurities stay on the umbrella-shaped filter screen, the motor is started to enable the umbrella-shaped filter screen to rotate at high speed, and the impurities are cleaned off in combination with the inlet water of the water inlet tube, so as to achieve a self-cleaning purpose. Therefore, the water quality monitoring and sample feeding device disclosed by the invention has the advantage of being capable of primarily removing unrelated impurities in water, prolonging the life of a detection instrument, reducing losses and carrying out self-cleaning.

Owner:ZHEJIANG OCEAN UNIV

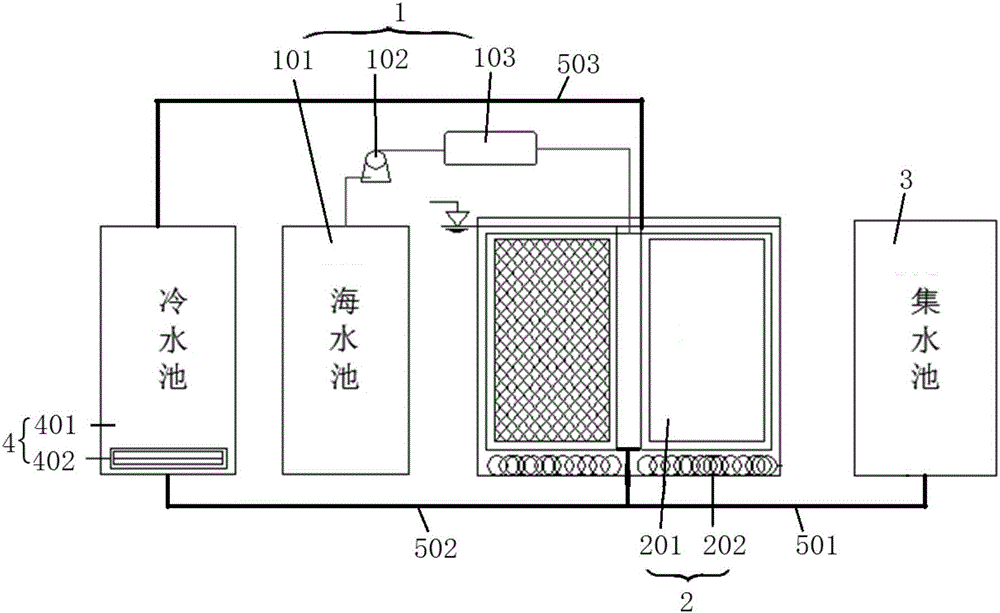

Self-cleaning seawater desalination device and device

ActiveCN106629945AImprove stabilityGood desalination effectWater/sewage treatment by irradiationGeneral water supply conservationWater vaporWater circulation

The invention discloses a self-cleaning seawater desalination device which comprises a water inlet module, a membrane treatment module, a water collecting module, a condensing module and a water circulation module. The water inlet module is used for removing Ca<2+> ions and Mg<2+> ions in the seawater, and the seawater without ions is led to the membrane treatment module. The membrane treatment module adopts a PVDF hydrophobic microporous membrane coated with a nano photocatalyst active layer as a filter membrane, the seawater introduced by the water inlet module is heated by using a heating unit to form water vapor, the water vapor enters a cavity formed by the membrane by penetrating through the PVDF hydrophobic microporous membrane and then is condensed and liquified to form fresh water. The water collecting module is used for collecting the fresh water in the membrane treatment module. The condensing module is used for refrigerating the fresh water led from the membrane treatment module and then forming cold water. The water circulation module is used for water circulation of the whole device. The invention further discloses a self-cleaning seawater desalination method. The self-cleaning seawater desalination device is self-cleaning, low in cost, good in effect, convenient, simple and practical.

Owner:HOHAI UNIV

Durable fabric self-cleaning finishing agent

InactiveCN105625040AExtended service lifeGood social and economic benefitsBiochemical fibre treatmentChemistryChitin

The invention relates to a durable fabric self-cleaning finishing agent. The finishing agent comprises the following raw materials: epoxy resin, nano-titanium dioxide, sodium phosphate dibasic dodecahydrate, polystyrene sulfonate, foamy copper, cellulose ester, butylbenzyl phthalate, barium stearate, luffa cylindrical juice, nano-mica powder, a defoamer, nano-chitin, coco-betaine, an emulsifying wetter, sodium alginate and glycerin abietate. The invention has the advantages that the durable fabric self-cleaning finishing agent is provided; and a fiber fabric is finished by utilizing a fabric self-cleaning finishing agent with special composition, so that the need of developing high-grade self-cleaning textiles can be met.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

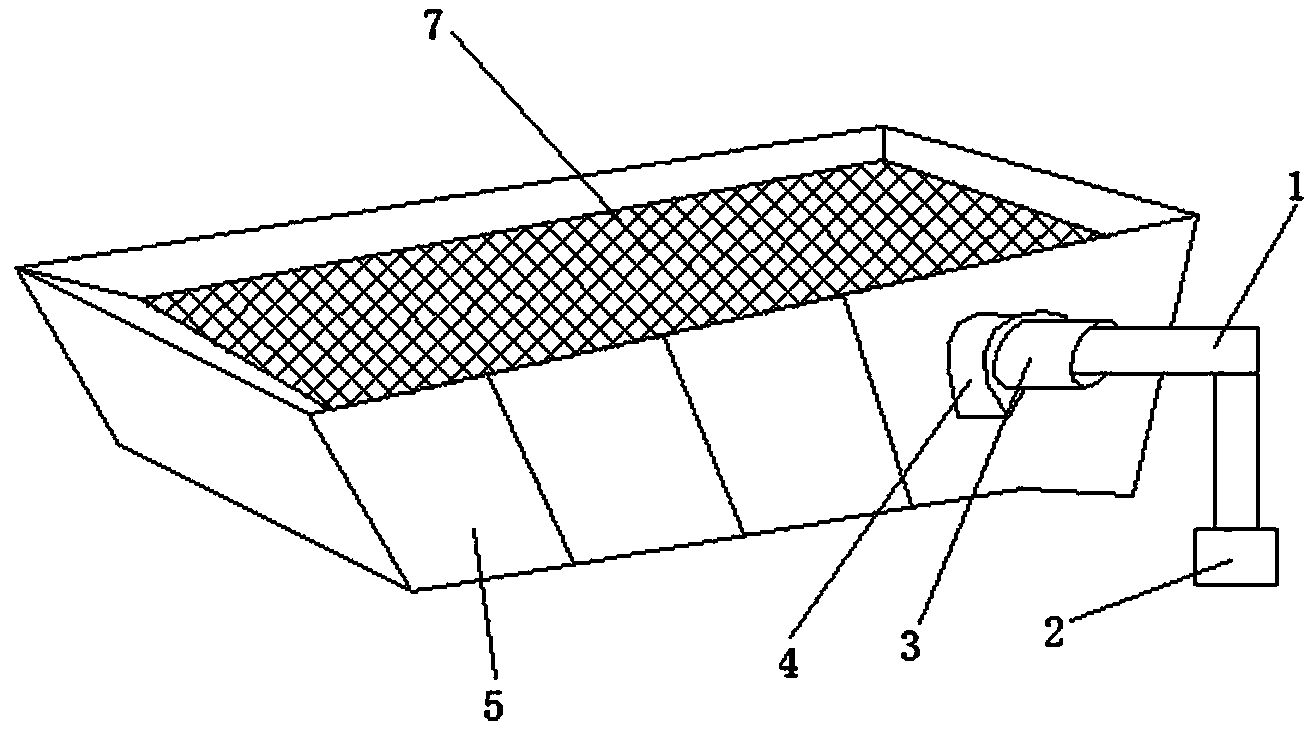

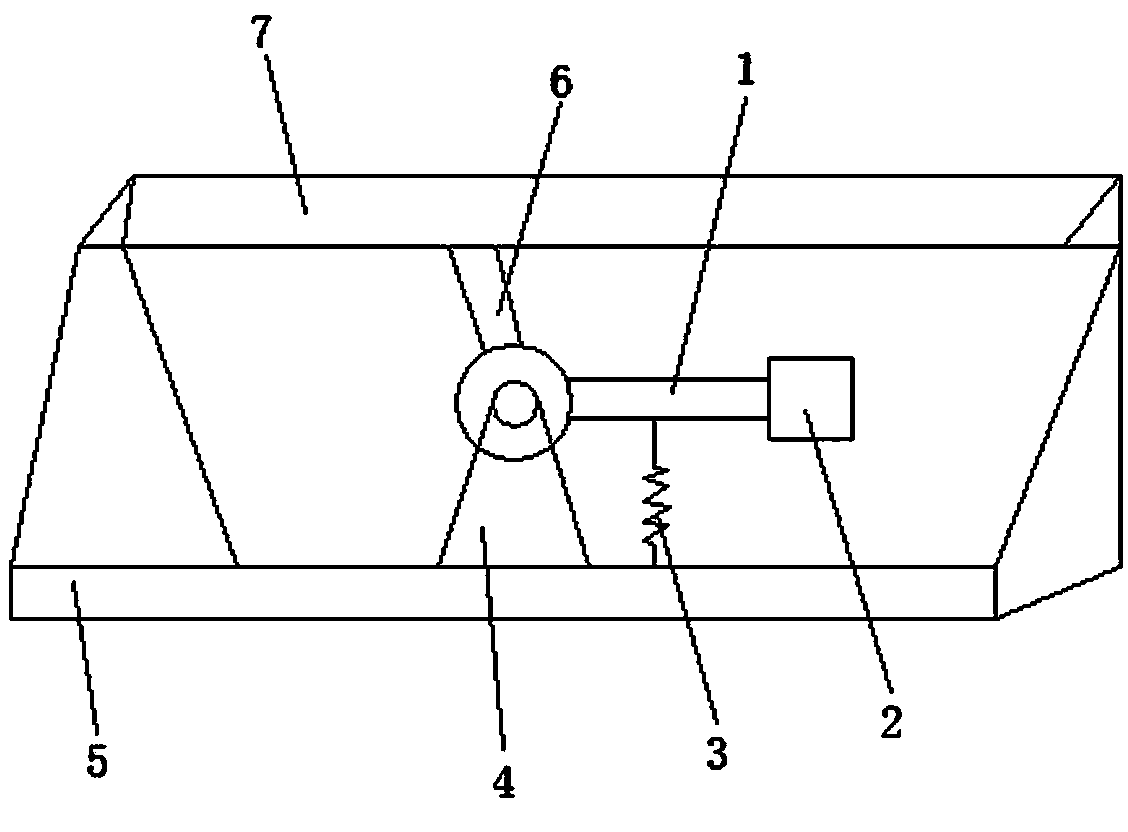

Self-excited screen mesh cleaning device

ActiveCN103639115AAchieve the purpose of self-cleaningEasy to useSievingScreeningChemical industrySelf excited

The invention relates to the technical field of vibratory screening machinery, in particular to a self-excited screen mesh cleaning device which comprises a connecting rod, a heavy punch and an elastic element. The heavy punch is arranged at one end of the connecting rod, the other end of the connecting rod is connected with a screen through a support and connected with a screen mesh through a beating arm, and the elastic element is connected on the connecting rod in a sleeved manner. By the aid of the structure, the self-excited screen mesh cleaning device and the vibratory screen form a resonance system by the aid of kinetic energy provided by reciprocating vibration of the vibratory screen and matching of the elastic element, so that screening is realized, and screen holes are automatically cleaned. Compared with a traditional cleaning device, an additionally connected power supply is omitted, and the self-excited screen mesh cleaning device is convenient to use, high in reliability and fine in cleaning effect. In addition, the self-excited screen mesh cleaning device has the advantages that the cleaning device is reasonable in design and simple in structure, cost is reduced and the like, and the cleaning device is mainly used for screening fine materials and can be widely used for enterprises such as chemical industries and mines.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

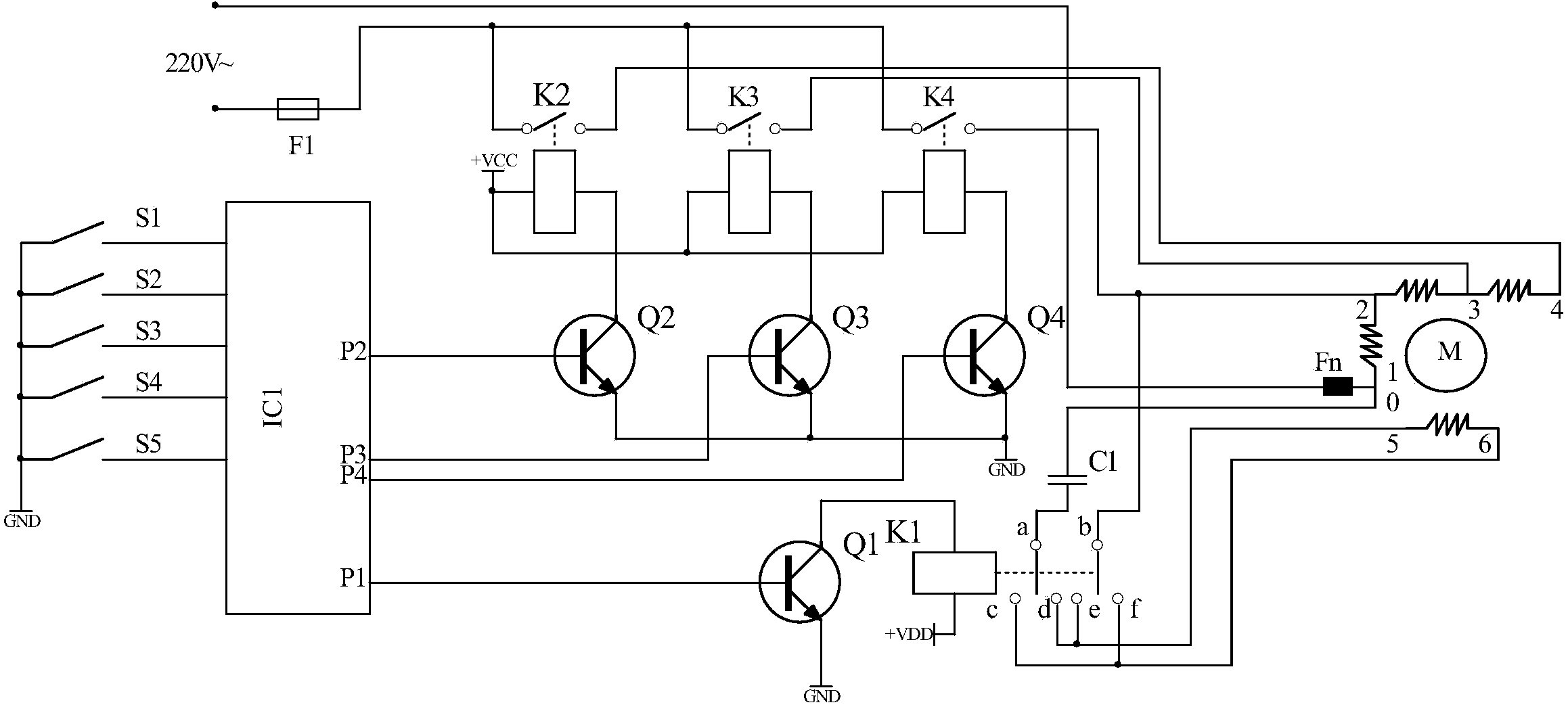

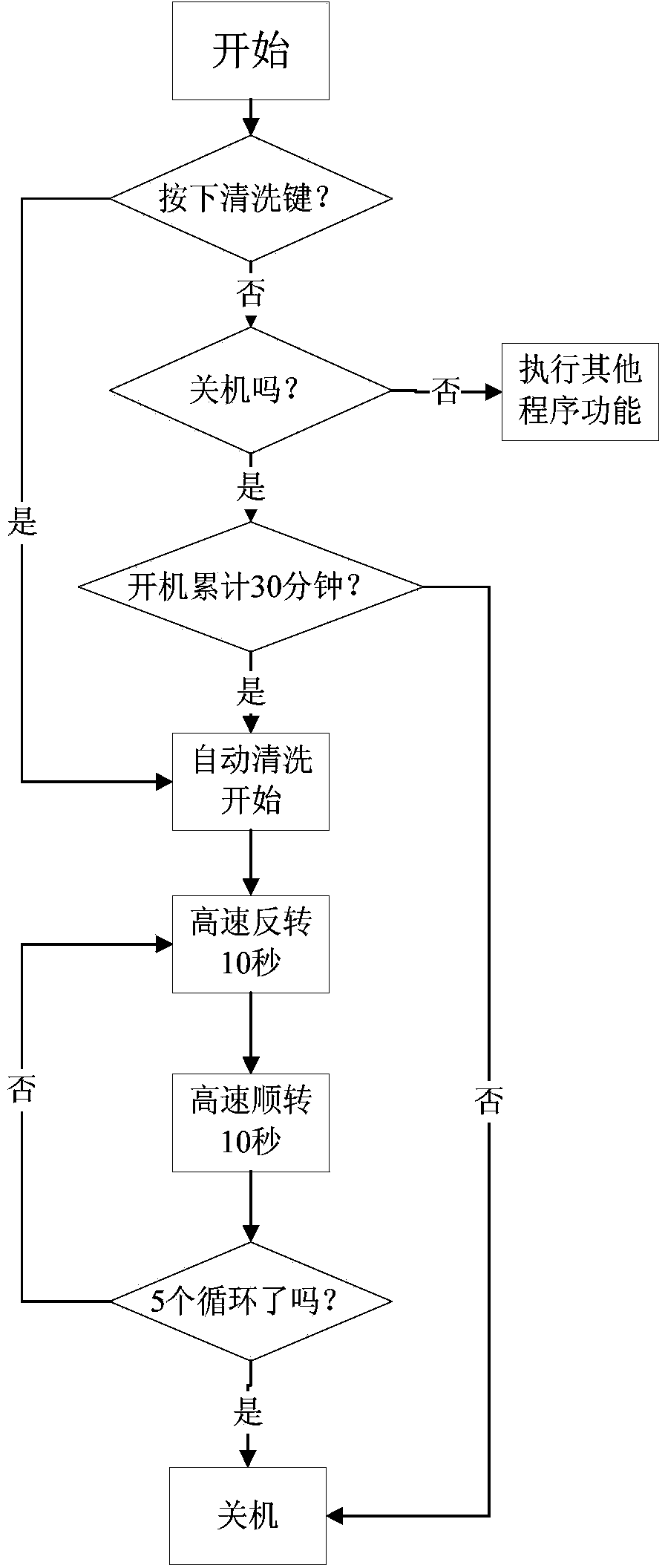

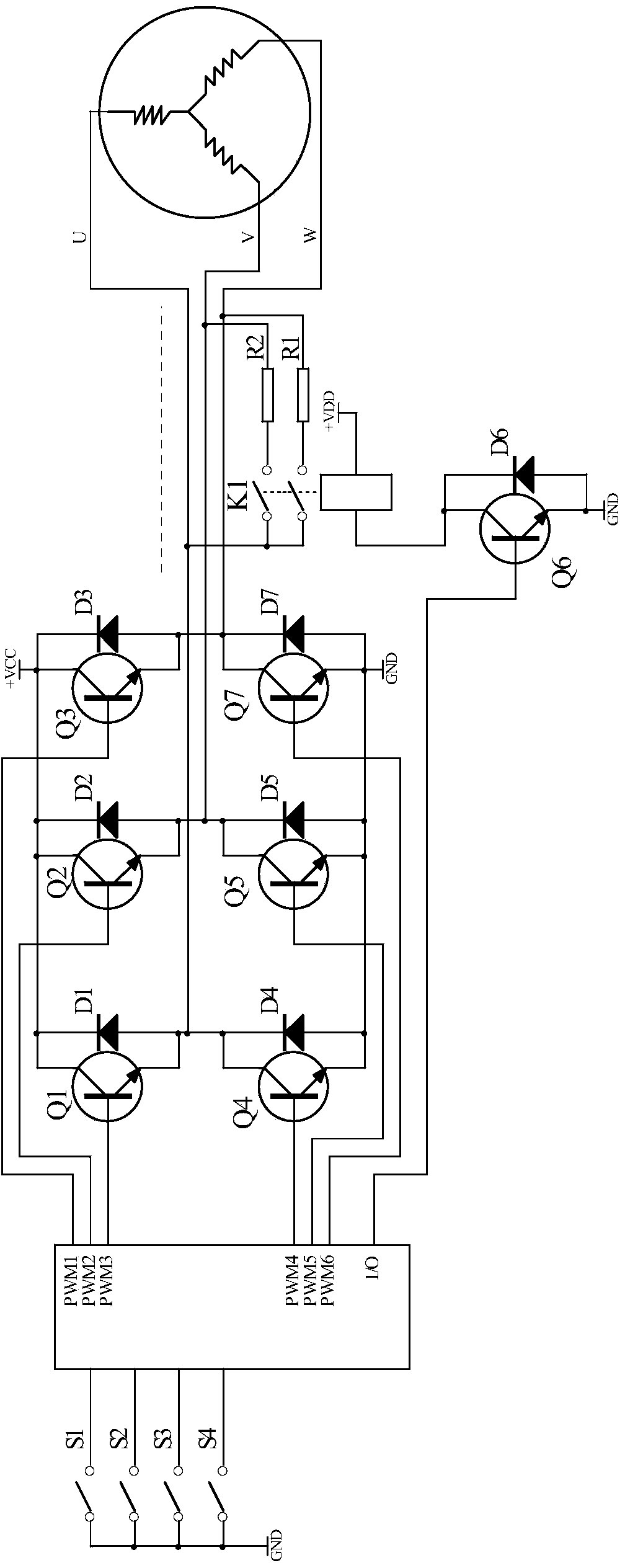

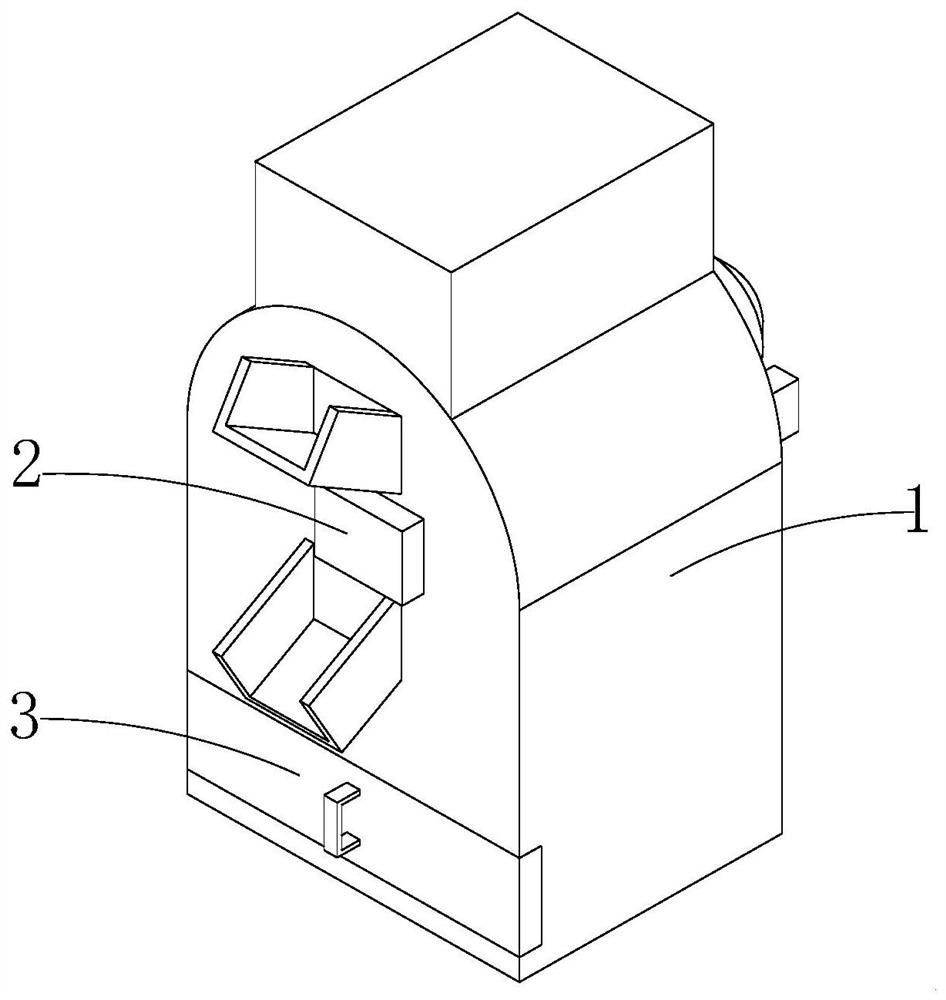

Device and method for automatically cleaning extractor hood

ActiveCN103486637AAchieve the purpose of self-cleaningReduce processing costsDomestic stoves or rangesLighting and heating apparatusImpellerElectric machinery

The invention provides a device for automatically cleaning an extractor hood. The device comprises a motor, a motor forward-reverse rotating control circuit and a controller, wherein the motor is used for driving an impeller, and the controller is used for driving the motor to rotate forward and reversely in an alternating mode within preset periods through the forward-reverse rotating control circuit after the motor operates for the preset time, and then driving the impeller to automatically clean the extractor hood in a centrifuging mode. The device has the advantages that the motor is controlled through the forward-reverse rotating control circuit to circularly rotate forward and reversely in the alternating mode, the motor drives a turbine and blades of the extractor hood to rotate forward and reversely, greasy dirt on the blades fast falls from the blades based on the principle of movement inertia, and accordingly the self-cleaning purpose is achieved; the device is low in machining cost, convenient to operate and reliable in operation.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

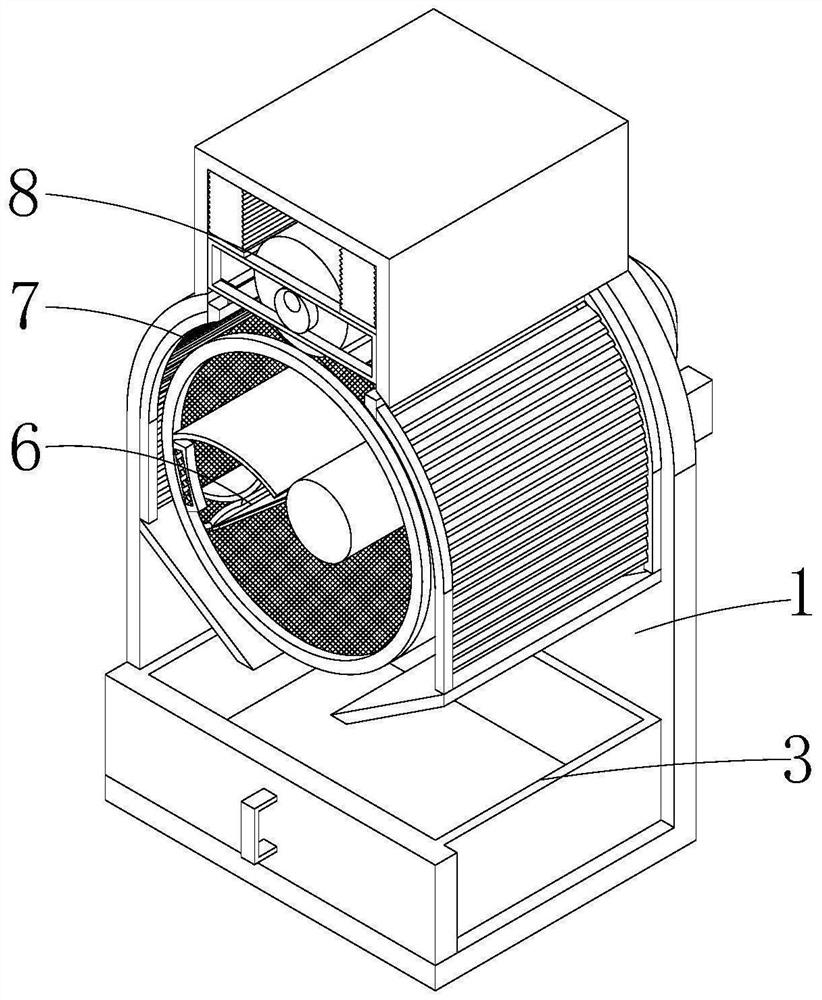

Machining iron scrap treatment equipment

InactiveCN113695977AImprove separation efficiencyAvoid wastingMaintainance and safety accessoriesElectric machineEngineering

The invention discloses machining iron scrap treatment equipment, and relates to the technical field of machining. The equipment comprises an equipment main body, wherein a power-on controller is fixed to the front surface of the equipment main body; a liquid collecting box is mounted below the front surface of the equipment main body in a sliding manner; a motor is fixed to the back face of the equipment main body; a filtering mechanism used for separating iron scraps from cutting liquid is arranged in the equipment main body; an anti-splashing mechanism used for preventing the cutting fluid from splashing is arranged on the inner wall of the equipment main body; and a cleaning mechanism used for cleaning the filtering mechanism is arranged at the top of the filtering mechanism. Through the arrangement of an electromagnet, the cutting fluid in the iron scraps is separated from the iron scraps under the inertia that the iron scraps are bounced by a bouncing plate and the attraction effect of the electromagnet on the iron scraps, so that the problem that a certain amount of cooling fluid exists in the gaps of the iron scraps and cannot be filtered out, so that the cooling fluid is wasted is solved. Therefore, the efficiency of separating the iron scraps from the cutting fluid is improved.

Owner:杨丰年

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com