Seawater resistant graphene modified anticorrosive paint and preparation method thereof

A graphene modification and anti-corrosion coating technology, applied in metal anti-corrosion engineering and other metal anti-corrosion fields, can solve problems such as poor compatibility, high surface energy product of graphene, and easy agglomeration

Inactive Publication Date: 2018-09-14

CHANGZHOU UNIV

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Graphene's high surface energy area, strong van der Waals force and π-π interaction make it easy to agglomerate, and cannot form a stable chemical combination with water, organic solvents and polymers, resulting in weak interfacial bonding between graphene and resins , poor compatibility, prone to phase separation, seriously affecting coating performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment example 1

[0047] A marine anti-fouling and anti-corrosion coating material, its raw material composition by mass ratio is:

[0048] A component, 30% epoxy resin;

[0049] 5%Fe 3 o 4 @TiO 2 / rGO composites;

[0050] 20% deionized water;

[0052] 6% zinc phosphate;

[0053] 5% talc;

[0055] 6% water-based dispersant;

[0056] 2% coupling agent;

[0057] 1% other additives;

[0058] Part B, 15% curing agent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

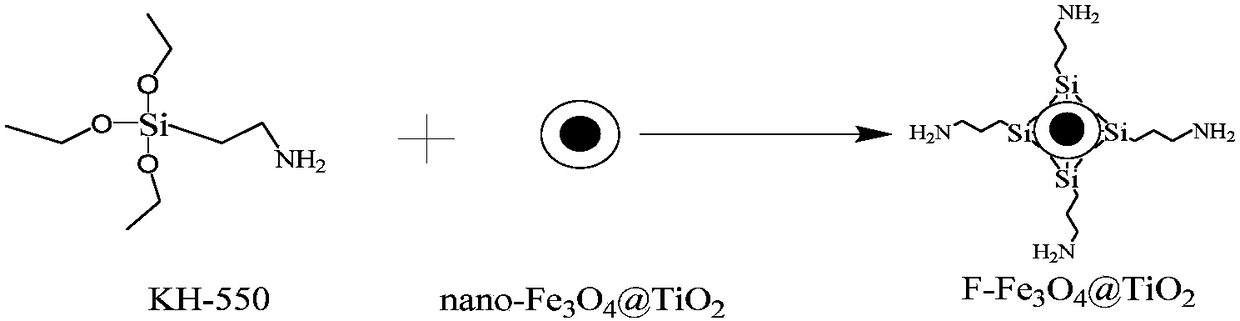

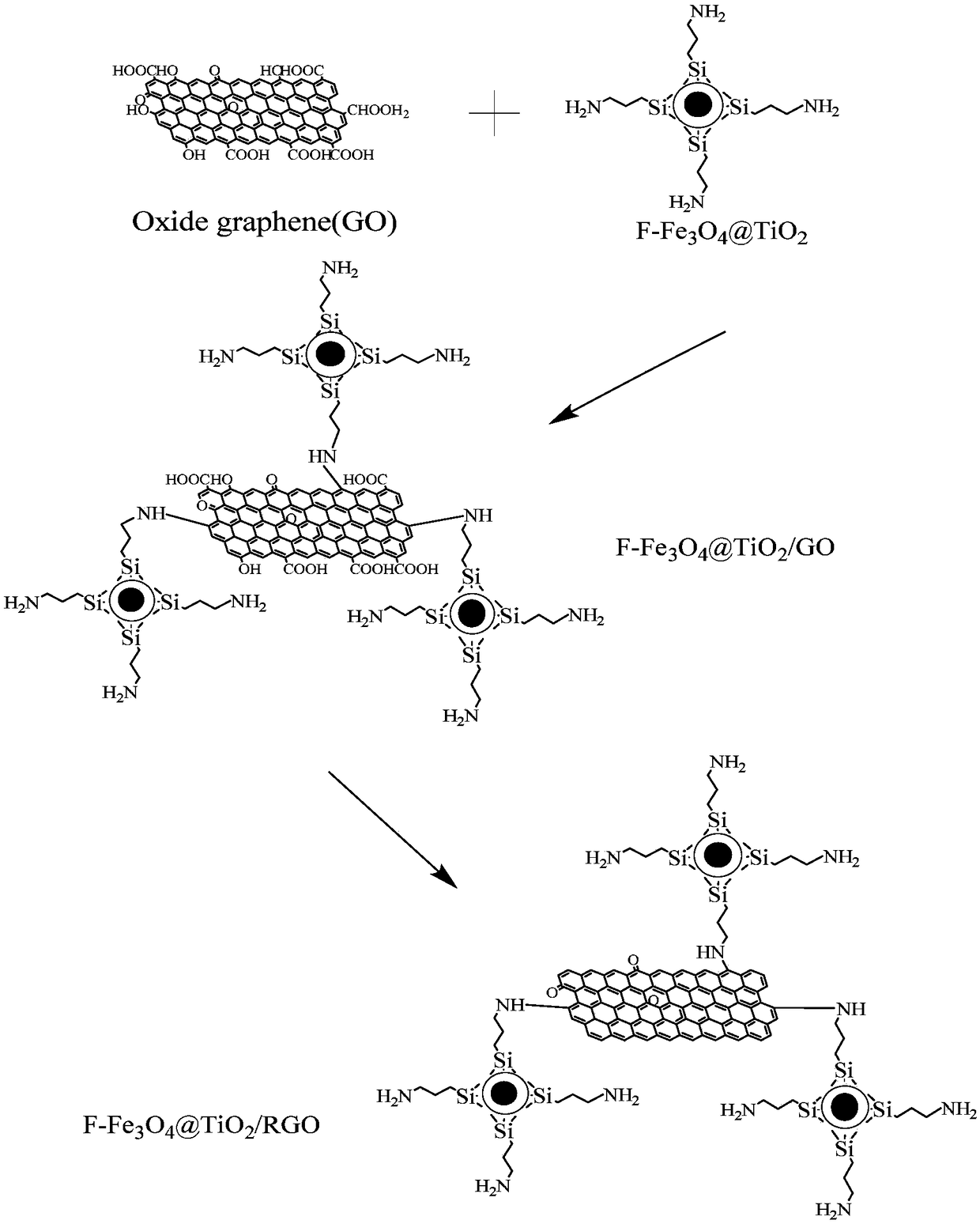

The invention relates to seawater resistant graphene modified anticorrosive paint, which is prepared from the following ingredients in parts by weight: an ingredient A (20 to 30 percent of epoxy resin, 3 to 10 percent of Fe3O4@TiO2 / rGO composite materials, 20 to 30 percent of deionized water, 1 to 5 percent of zinc powder, 5 to 10 percent of zinc phosphate, 5 to 10 percent of talcum powder, 5 to 15 percent of calcium carbonate, 3 to 10 percent of water-based dispersants, 0.5 to 3 percent of coupling agents and 1.5 to 5 percent of other auxiliary agents) and an ingredient B (15 to 30 percent ofcuring agents). The paint has the advantages that the Fe3O4@TiO2 / rGO composite materials are formed at the material surface; Fe3O4@TiO2 nanometer of a core-shell structure has an efficient photocatalysis effect; ocean organic organisms are oxidized and decomposed; meanwhile, the photoinduced cathode protection is realized; the anticorrosive effect is achieved on a base material; rGO is of a unique laminar structure; the adhesive force of the coating can be improved; meanwhile, a physical blocking layer can also be formed; through the performance optimization in various aspects, the paint hasgood antifouling and anticorrosive performance. The seawater resistant graphene modified anticorrosive paint can be widely applied to the fields of facilities such as oil and gas pipelines in marine environment and steel frame structures.

Description

technical field [0001] The invention belongs to the field of metal anticorrosion engineering, in particular to a method for preparing a metal graphene antifouling and anticorrosion coating for marine environments, and can also be applied to other metal anticorrosion fields. Background technique [0002] With the development of the offshore oil and gas field industry, offshore mining, floating facilities (FPSO), and submarine pipelines continue to increase, and they are facing increasingly severe corrosion problems in the marine environment. Steel structures in marine environments are affected by multiple effects such as salt spray, wind, rain, and sunlight, and corrosive water films are easily formed on the surface. The process of atmospheric corrosion caused by the action of thin water film on steel is in line with the law of electrochemical corrosion in electrolyte. The characteristic of this process is that oxygen easily reaches the steel surface, and the corrosion rate ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D5/10C09D7/61C09D7/62

CPCC08K2003/0893C08K2003/2241C08K2003/2275C08K2003/326C08K2003/328C08K2201/011C09D5/106C09D7/61C09D7/62C09D163/00C08K13/06C08K9/06C08K9/02C08K3/22C08K3/042C08K3/08C08K3/32C08K3/34C08K3/26

Inventor 王树立朱建康饶永超赵书华白浩然冯大成才政陈磊黄俊尧陈锋

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com