Patents

Literature

536 results about "Plastic pipework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members.

Material for preparing plastic pipeline with high thermal conductivity

The invention relates to a formula of a multi-component plastic material for preparing a plastic pipeline with high thermal conductivity. The material comprises the following components in part by weight: 100 parts of polyolefin, 10 to 200 parts of heat transfer agent, 1 to 100 parts of compatilizer, 0.5 to 5 parts of lubricant and 0.5 to 10 parts of coupling agent. The plastic pipeline made of the material of the invention has the advantages of high heat conduction coefficient, capability of meeting the using requirement of a product, convenient processing, low cost and suitability for popularization and application.

Owner:GUANGDONG LIANSU TECH INDAL

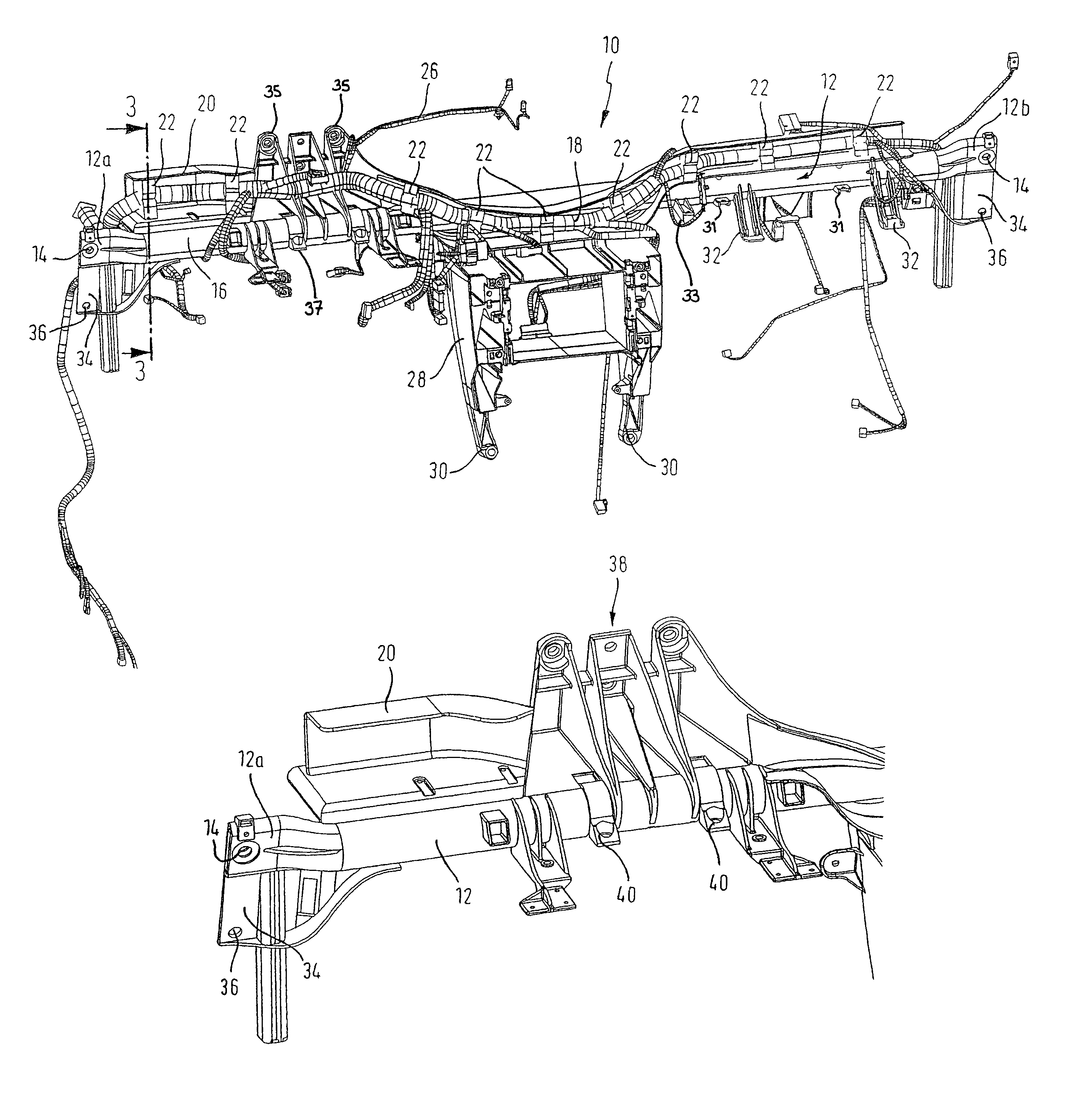

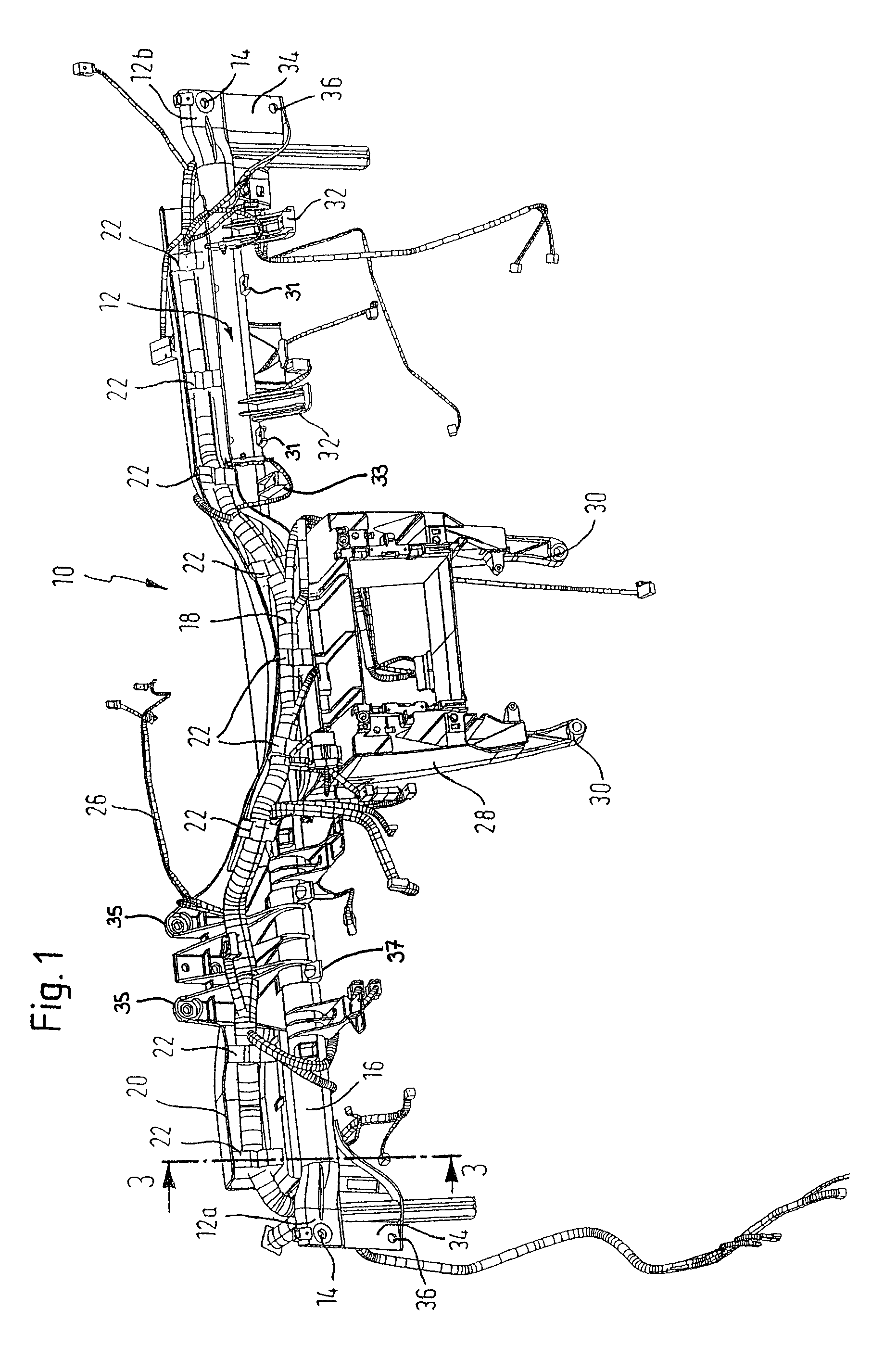

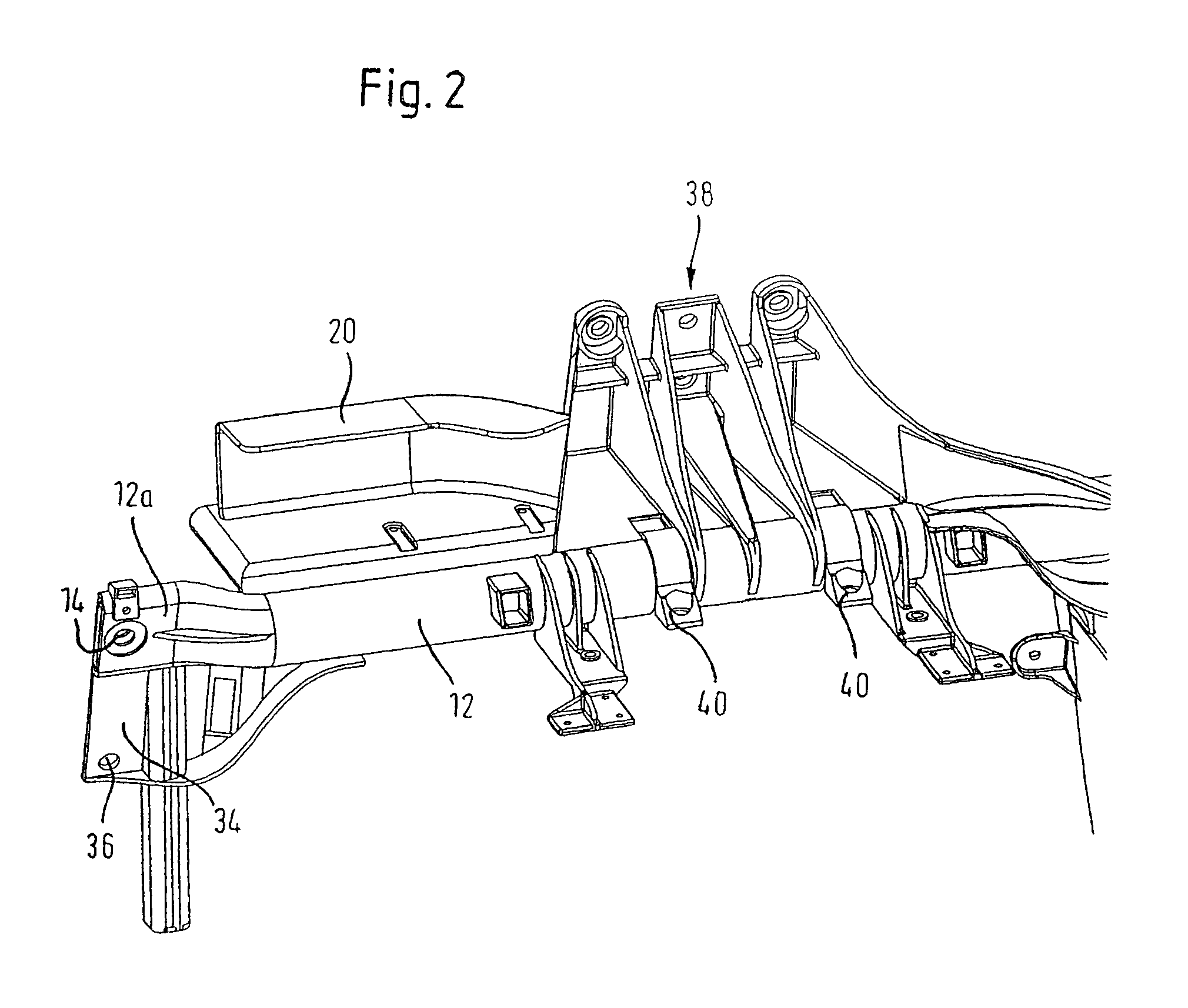

Crossmember module for a motor vehicle

A crossmember module for attachment under an instrument panel of a motor vehicle. The crossmember module includes a metal tube surrounded at least in part with plastic. The metal tube has a central, tubular cross-section and flattened ends. Each flattened end has a first mounting hole and a plastic tab that is injection molded onto each flattened end. The crossmember also has a groove-shaped plastic duct for guiding a wiring harness relative to the metal tube. Different receivers may optionally be molded on in one piece in the plastic enabling the connection of various adjacent components.

Owner:LISA DRAXLMAIER GMBH

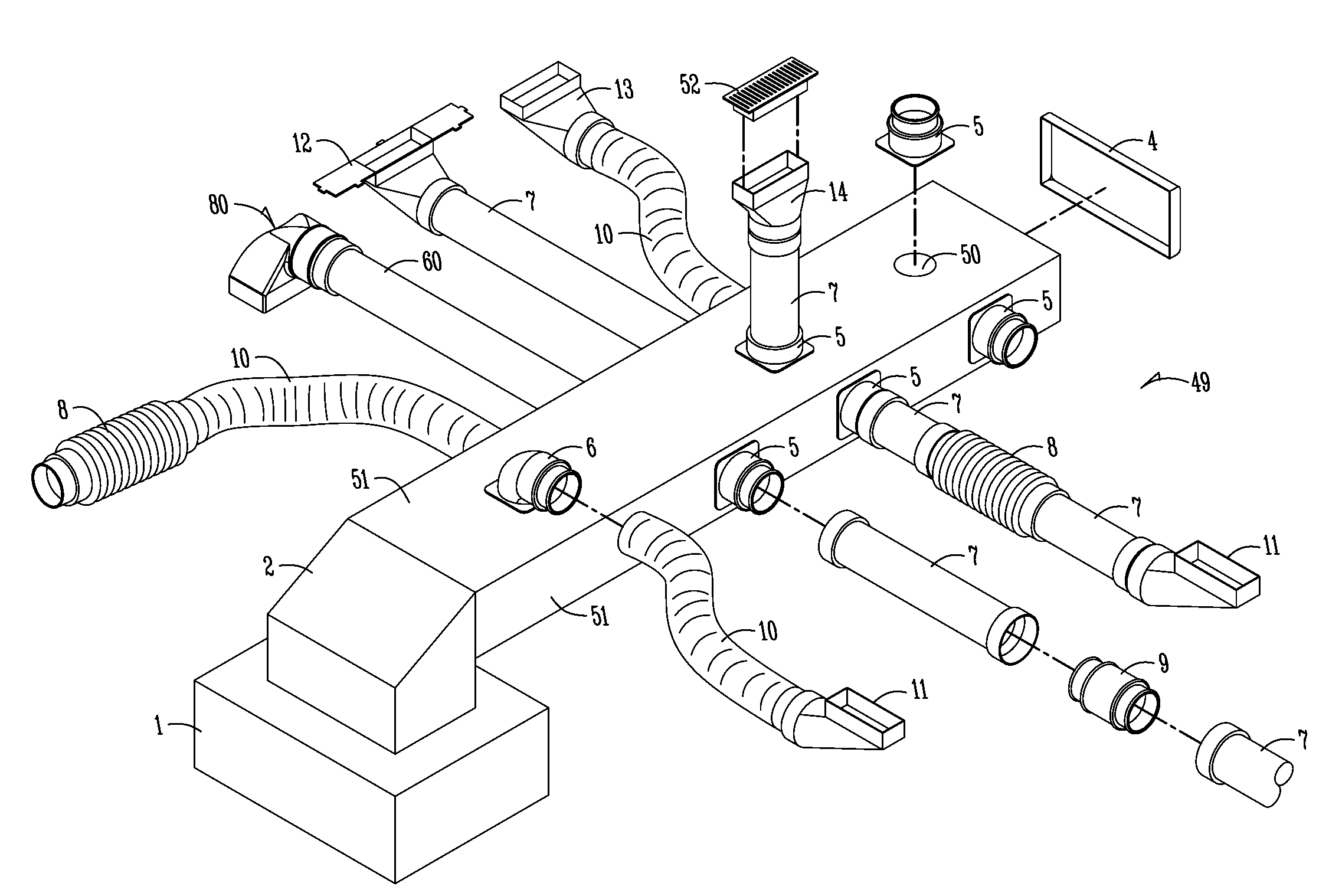

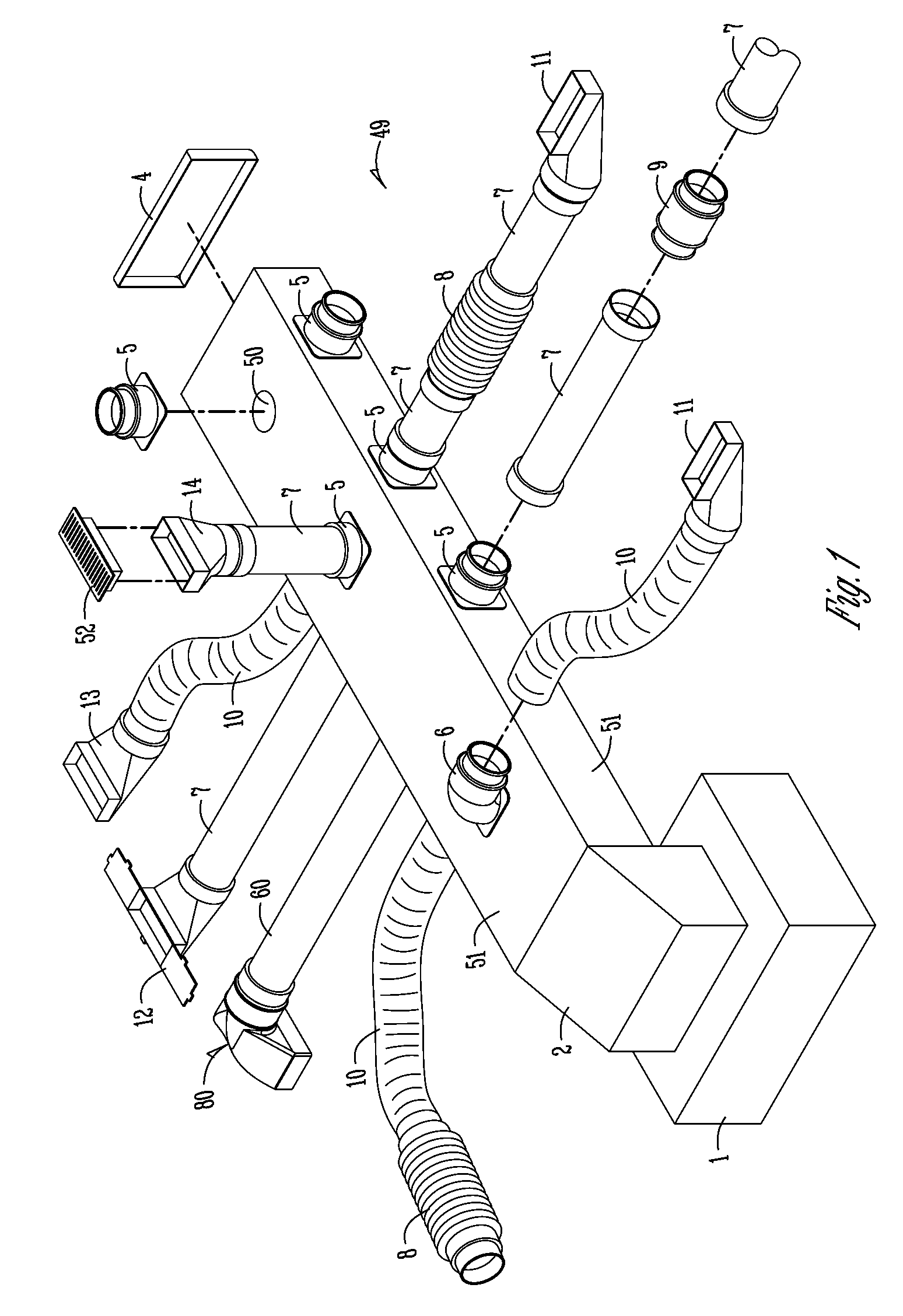

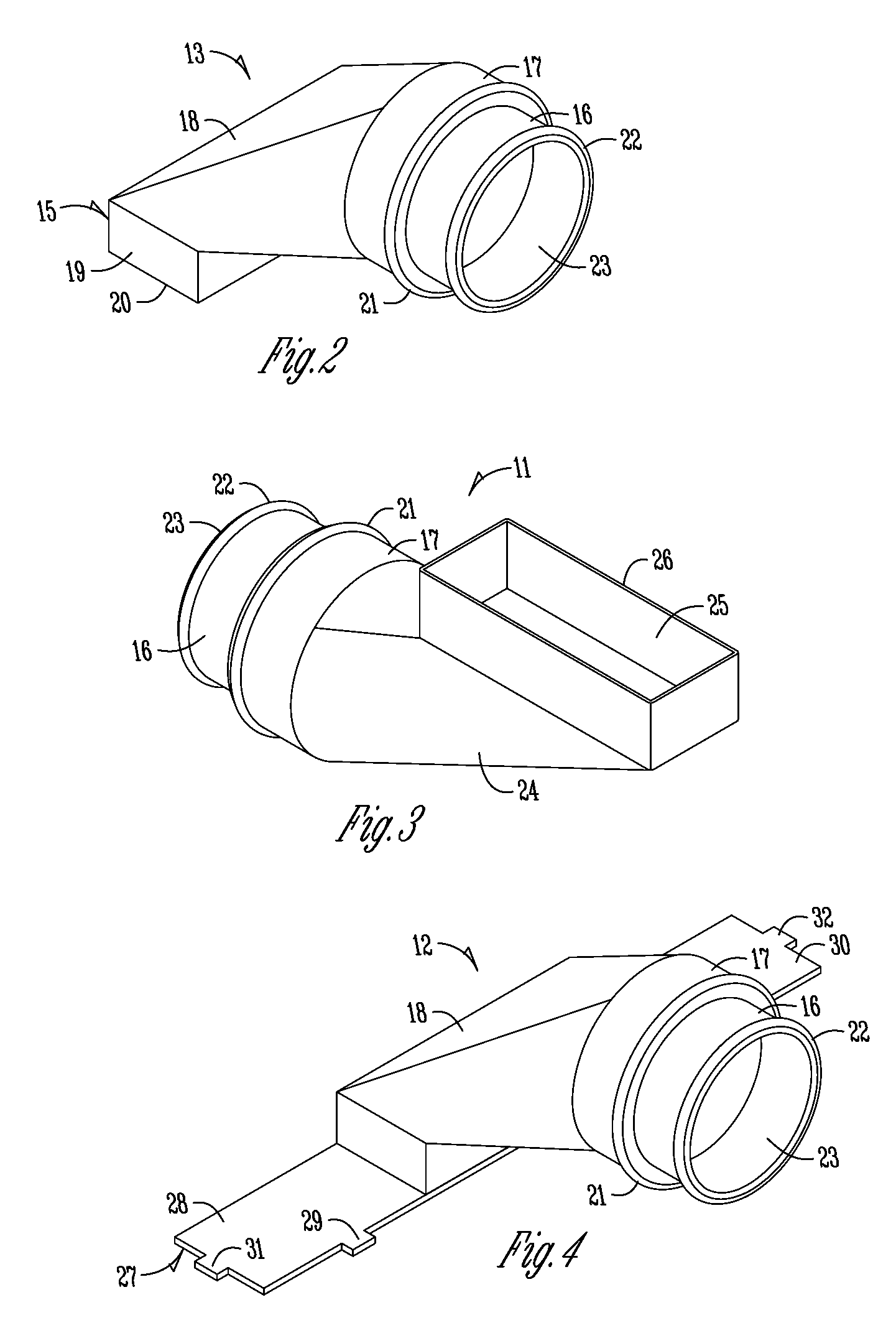

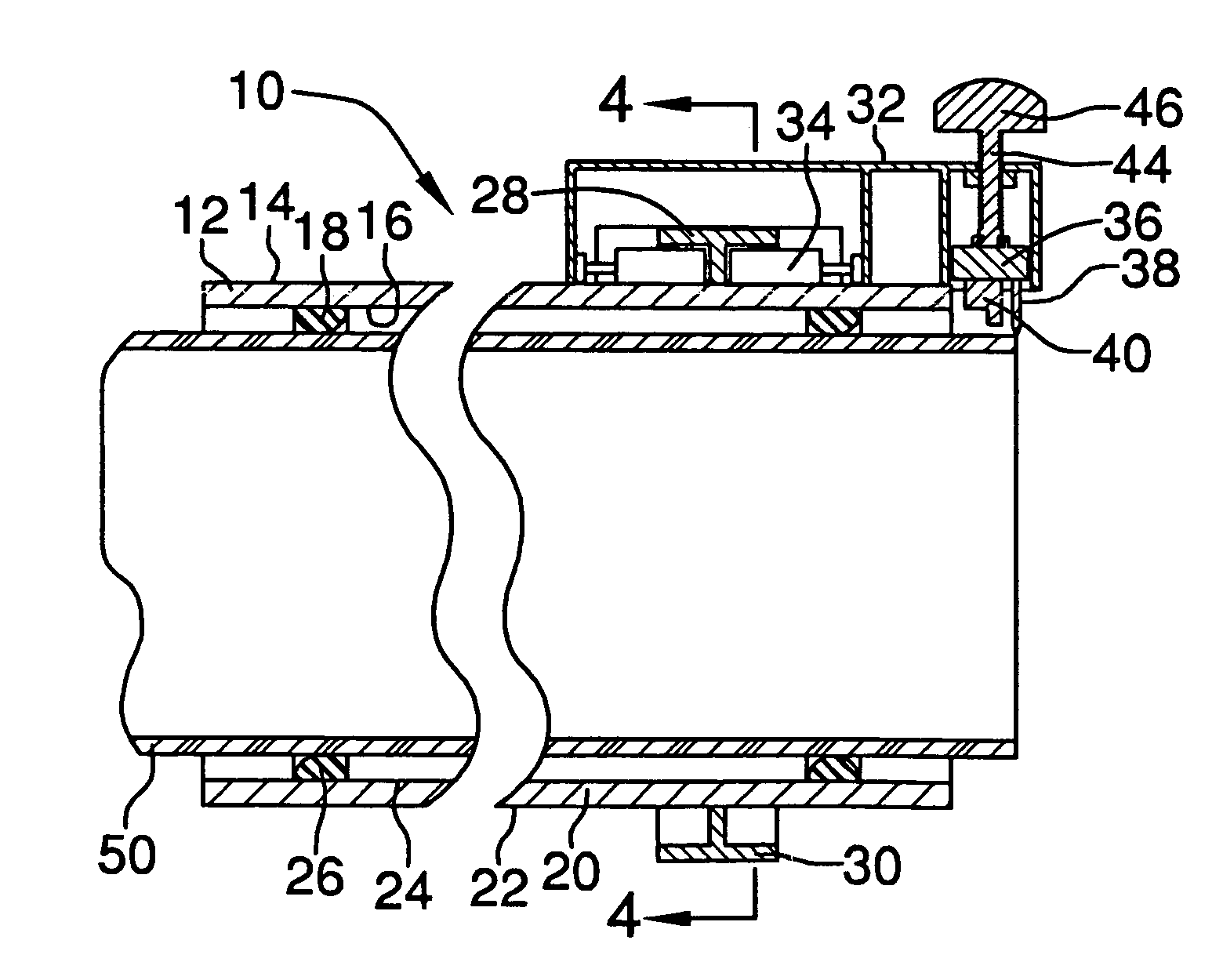

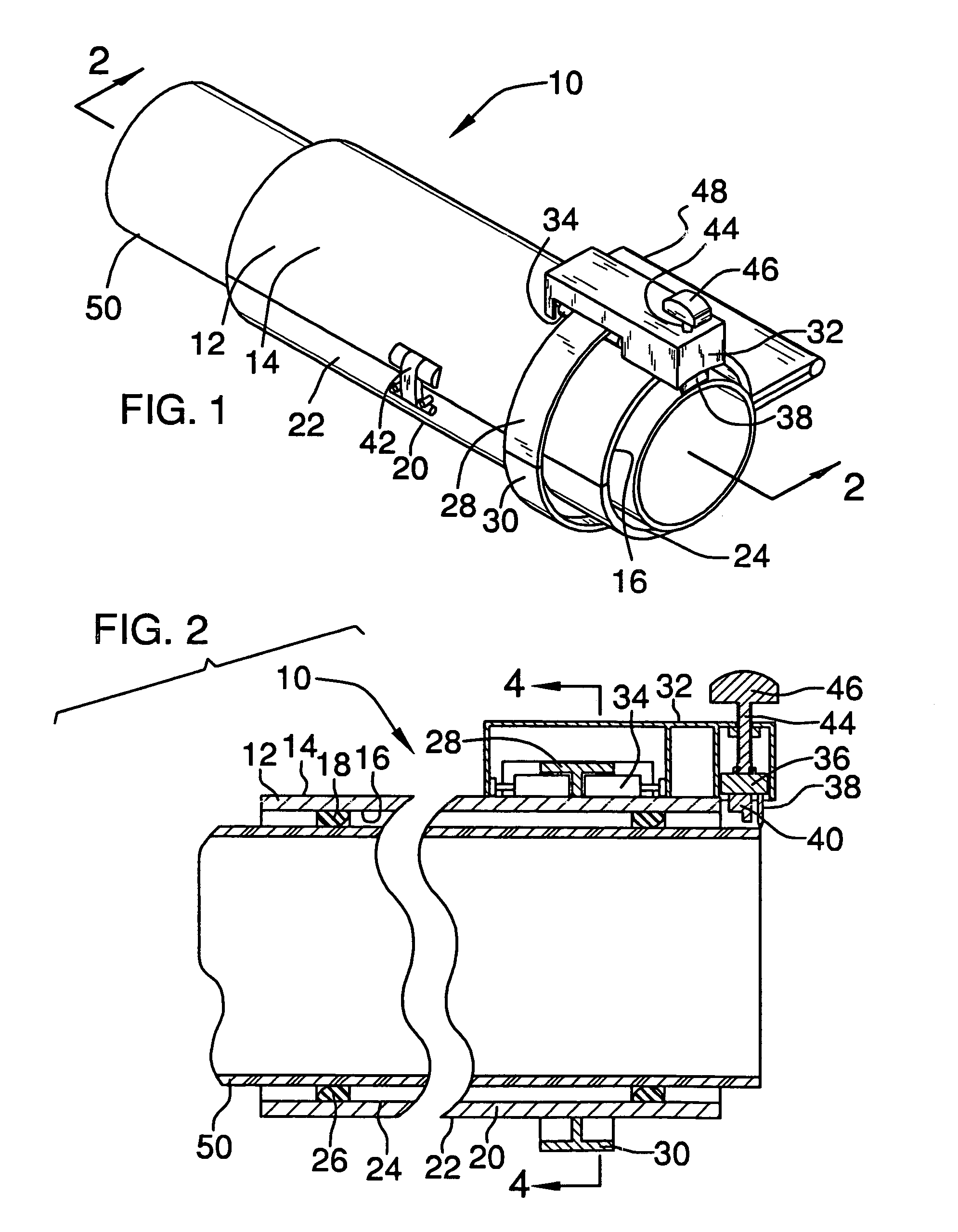

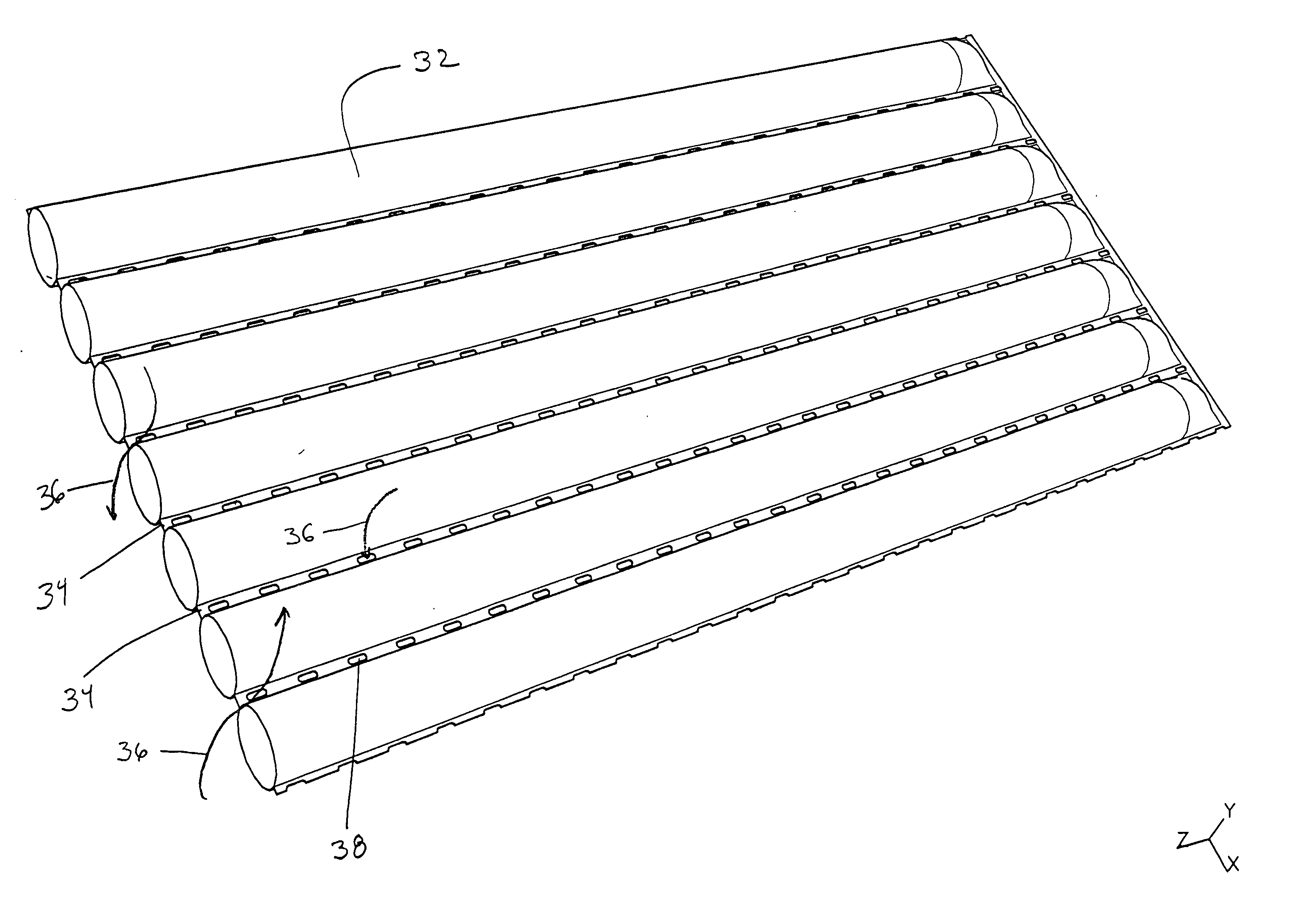

Plastic HVAC component system and method for installing the same

InactiveUS20080318514A1Efficient deliveryReduce lossesDucting arrangementsLighting and heating apparatusPlastic pipeworkEngineering

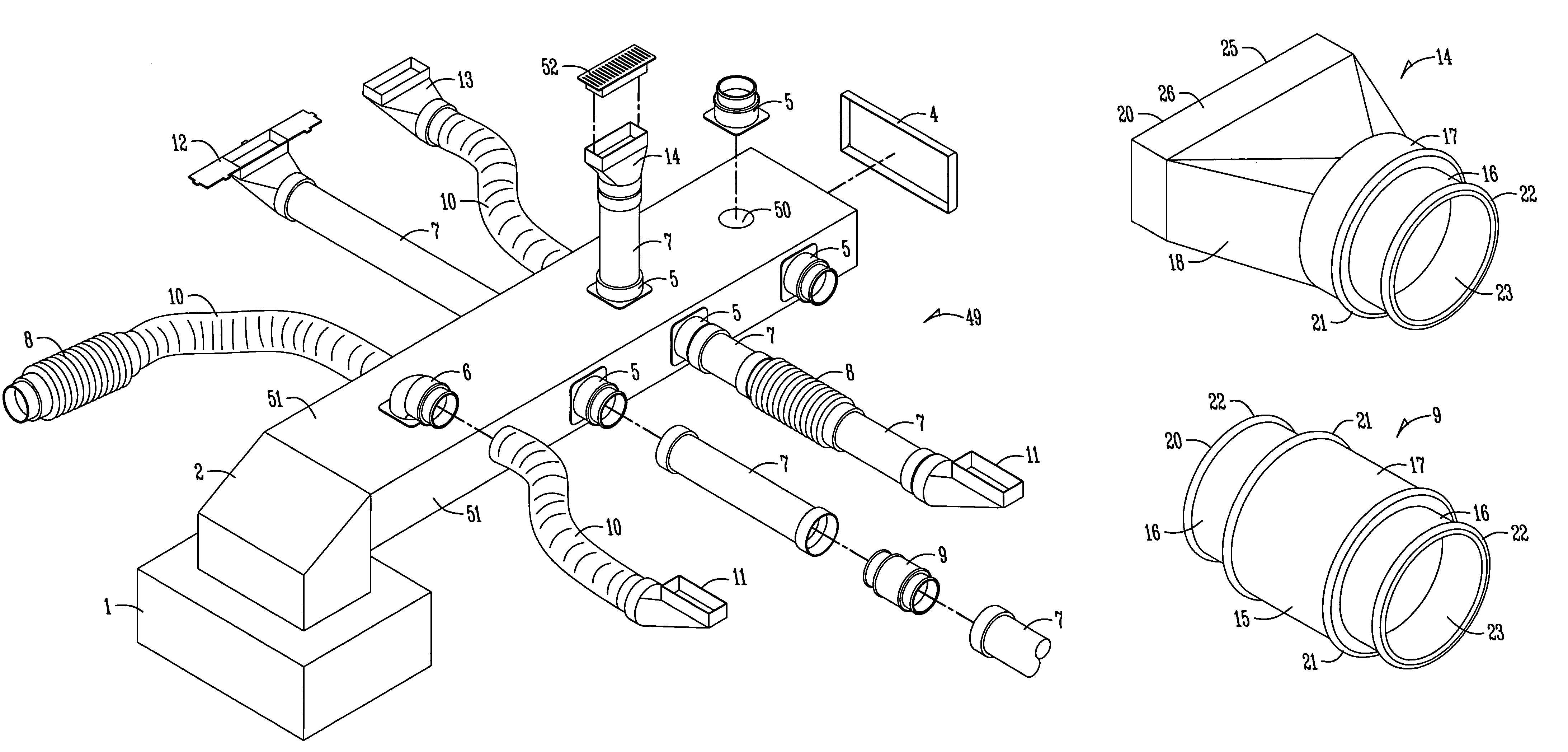

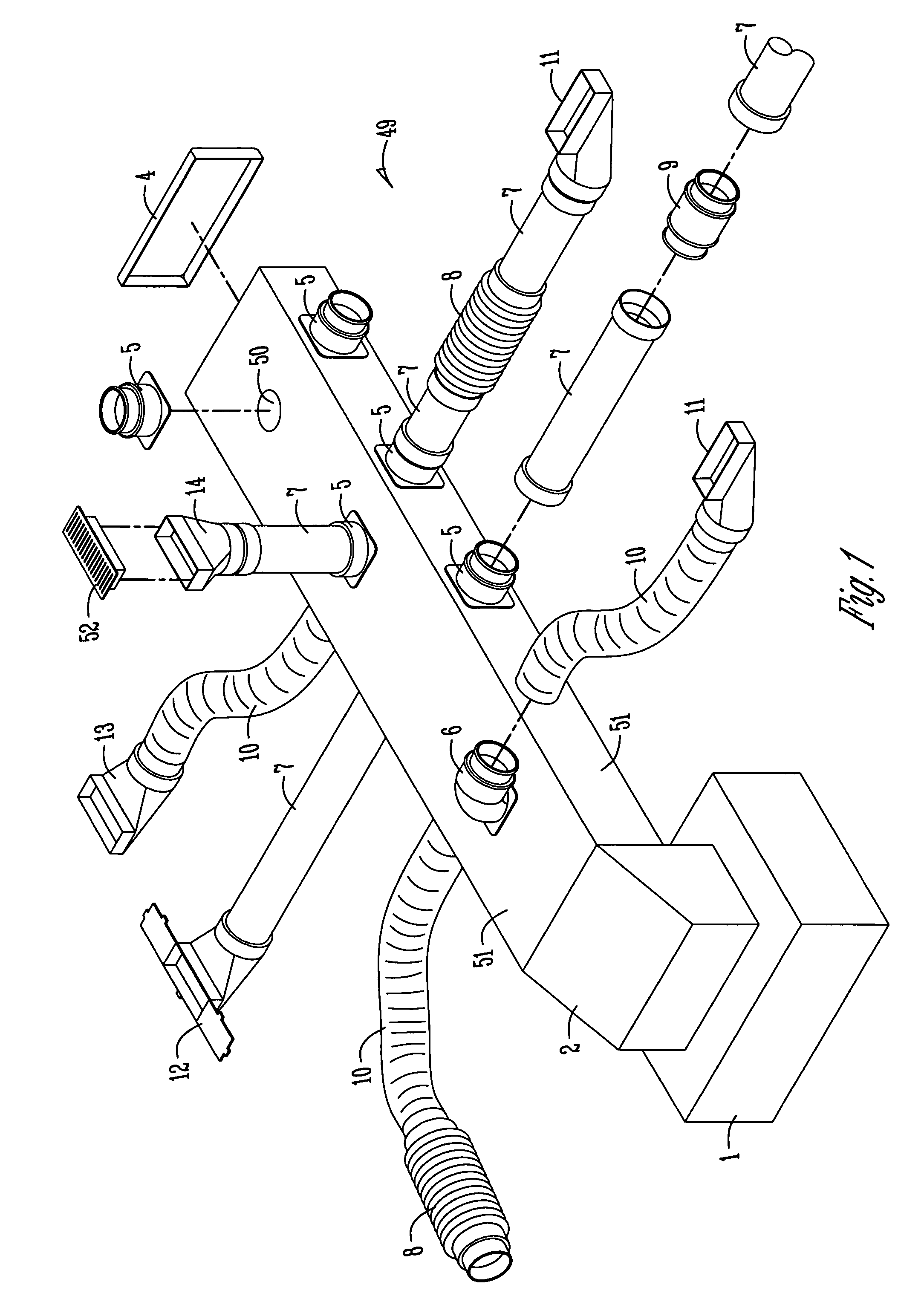

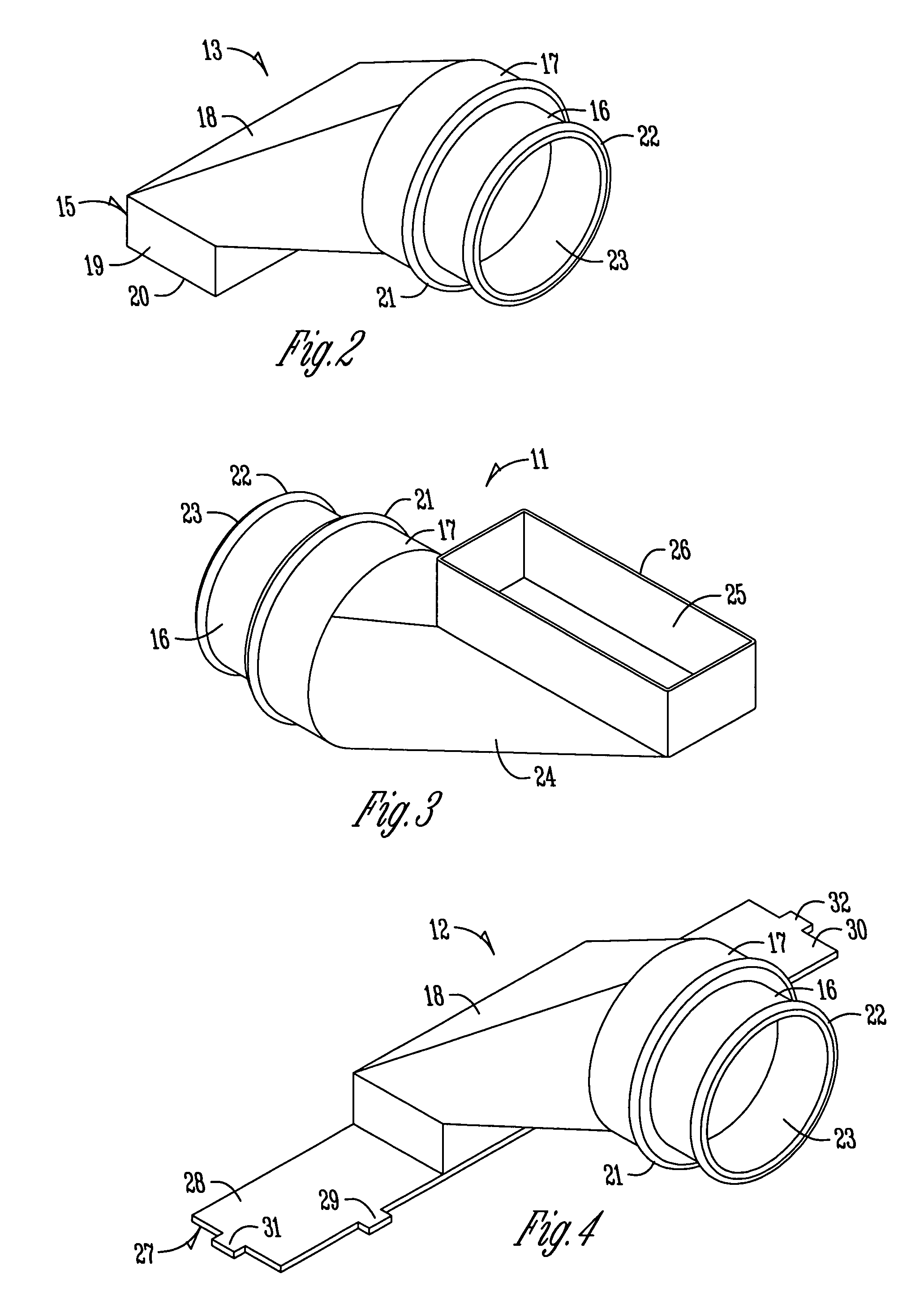

A complete plastic HVAC system assembled using individual plastic components for ensuring the efficient and quiet distribution of air from a central air unit to multiple distribution points and preventing heating and cooling losses, the need for installers to stock multiple sized and shaped components, the accumulation of dust, dirt and pollens during storing, installing and use on the surfaces of the individual components. The fittings have a collar sizable to fit both 6 and 7-inch pipe, whether flexible or rigid. The use of plastic fittings, duct and pipe removes the potential of injury commonly associated with conventional metal ductwork, while providing seamless components that can be configured for any type of installation and insure an air tight connection between adjoining surfaces. The individual fittings include a register boot, torpedo boot, straight boot, rigid and flexible pipe and couplers, straight and 90-degree takeoffs, a plastic duct and duct end cap.

Owner:FETTKETHER

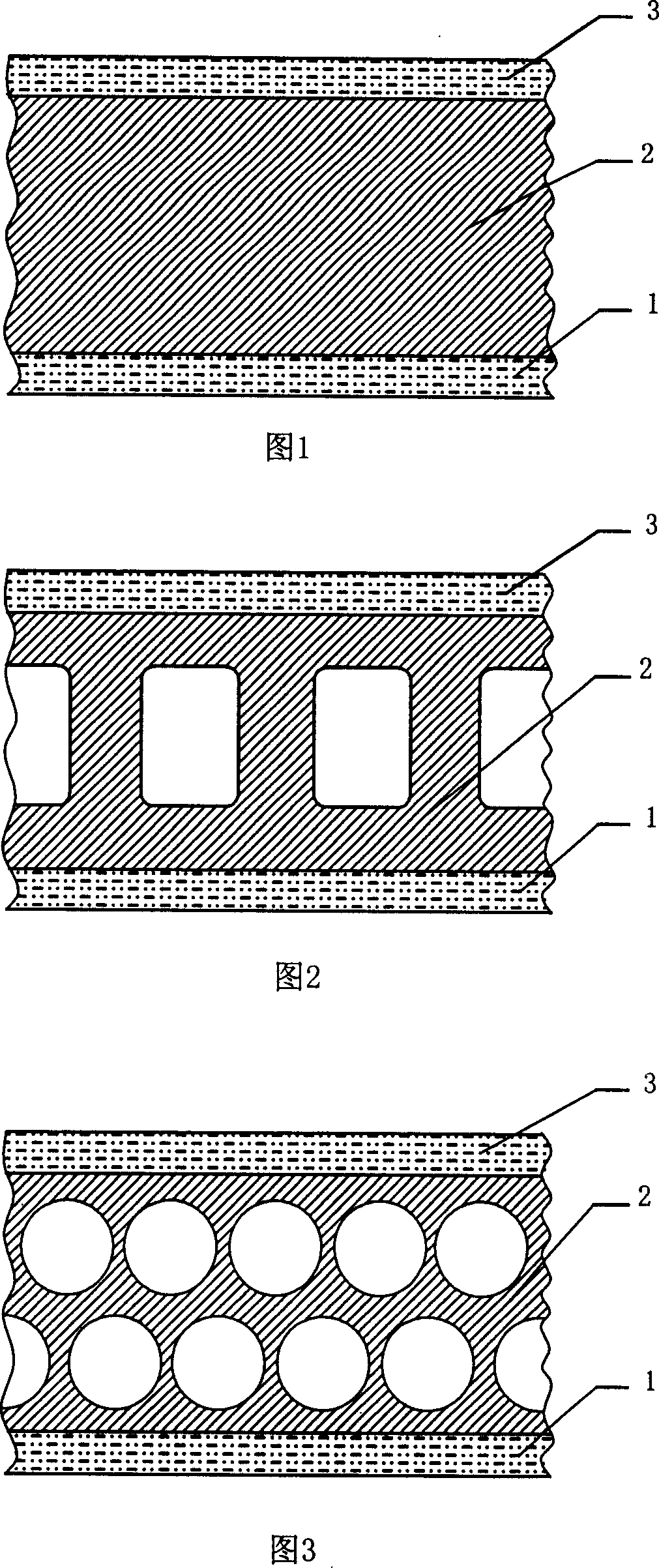

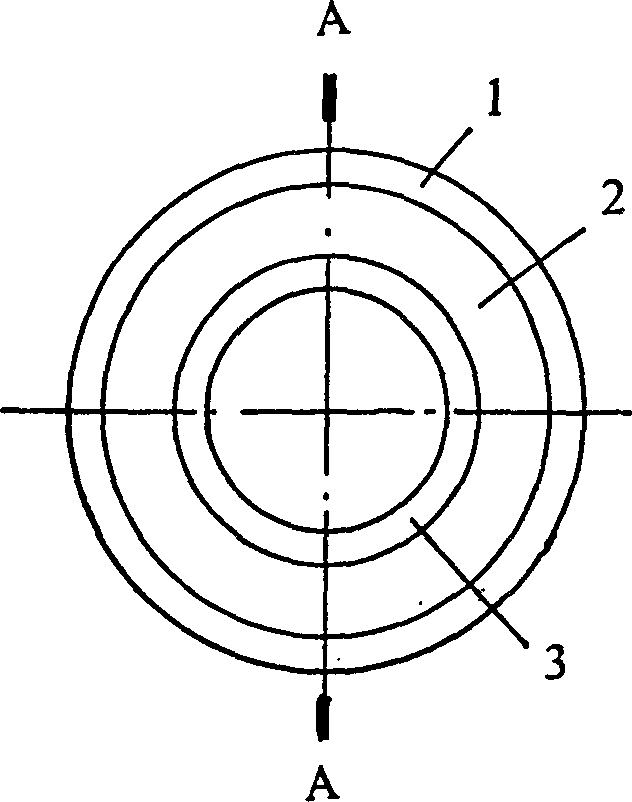

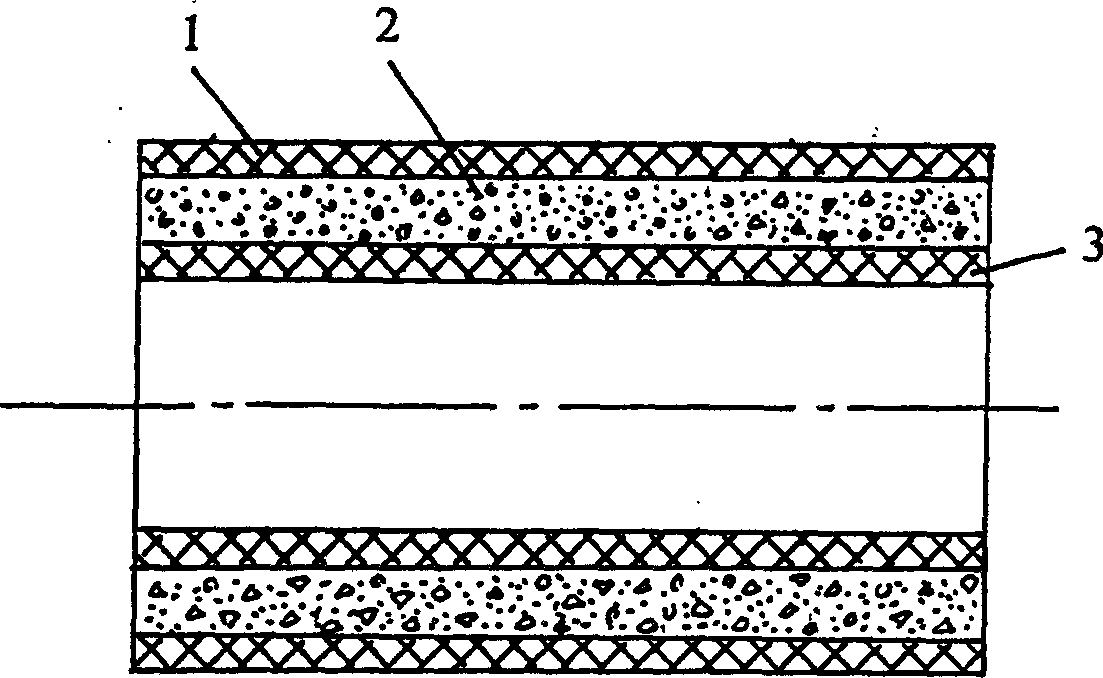

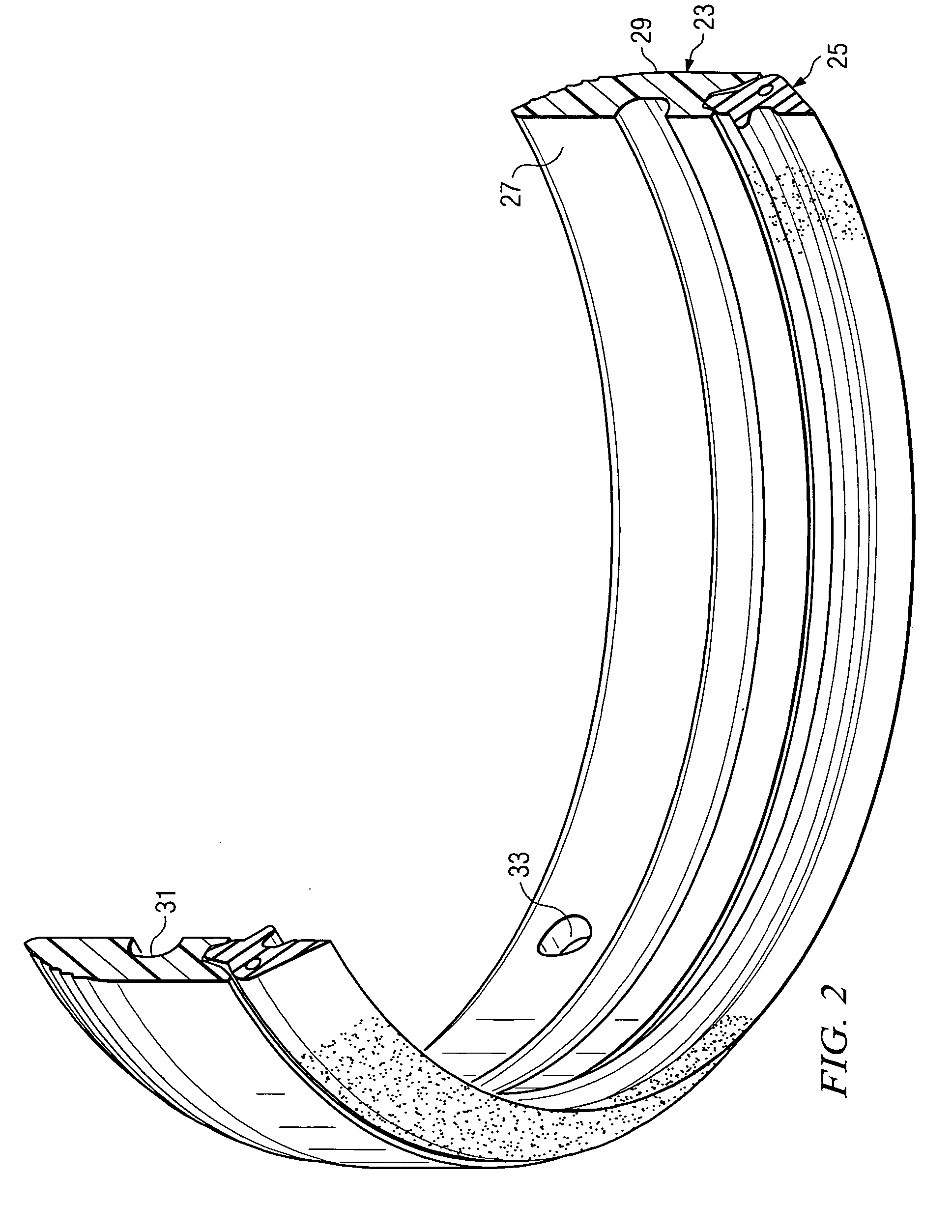

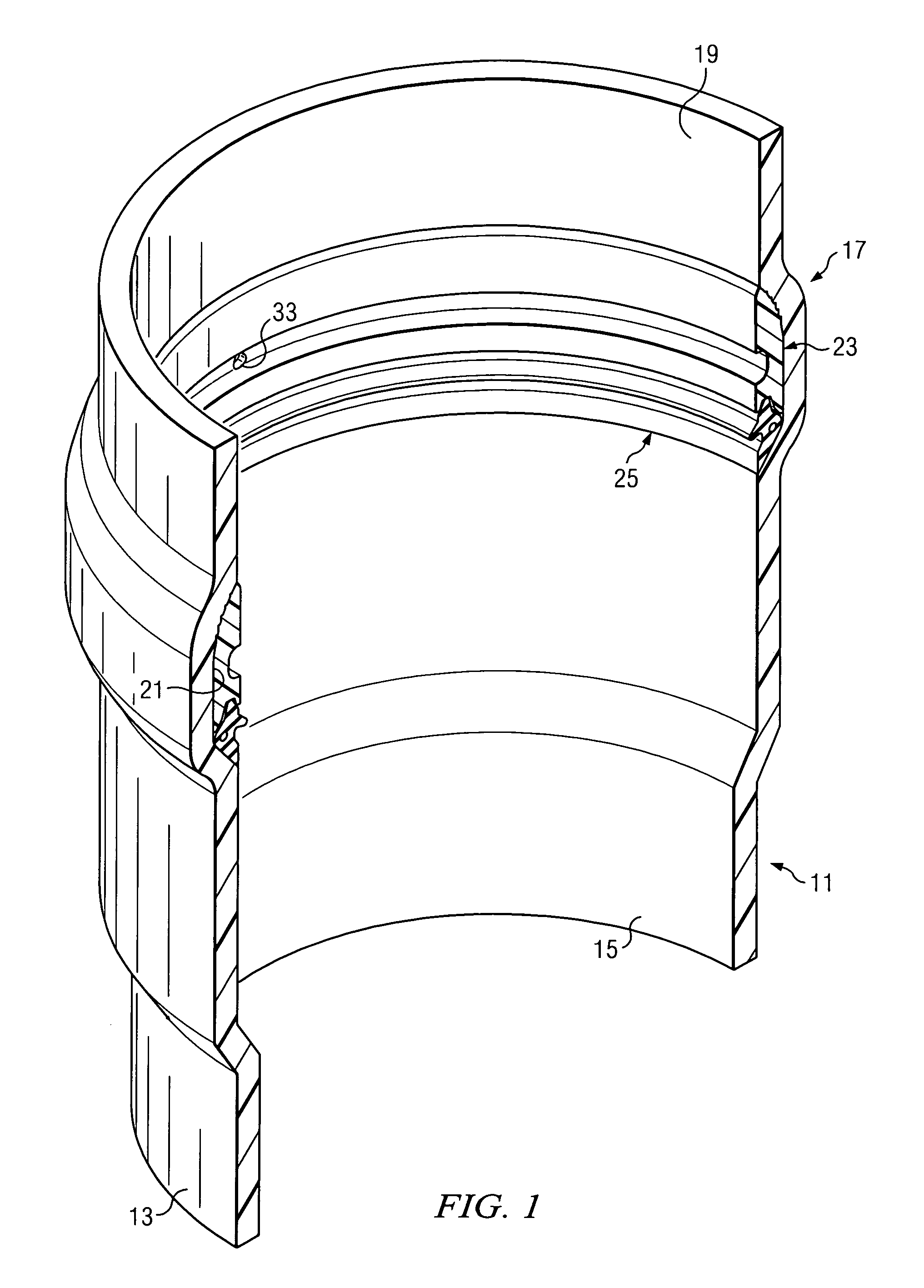

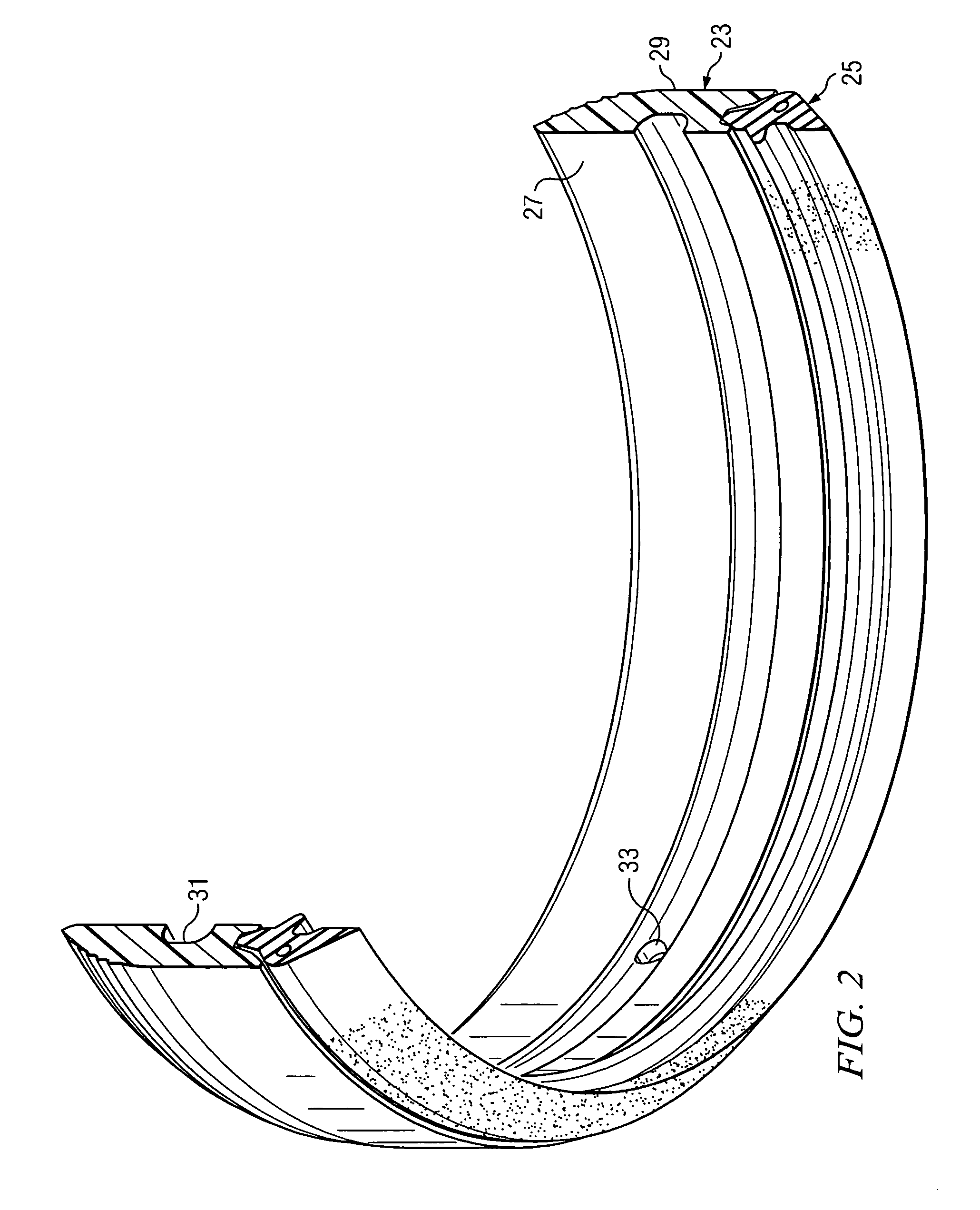

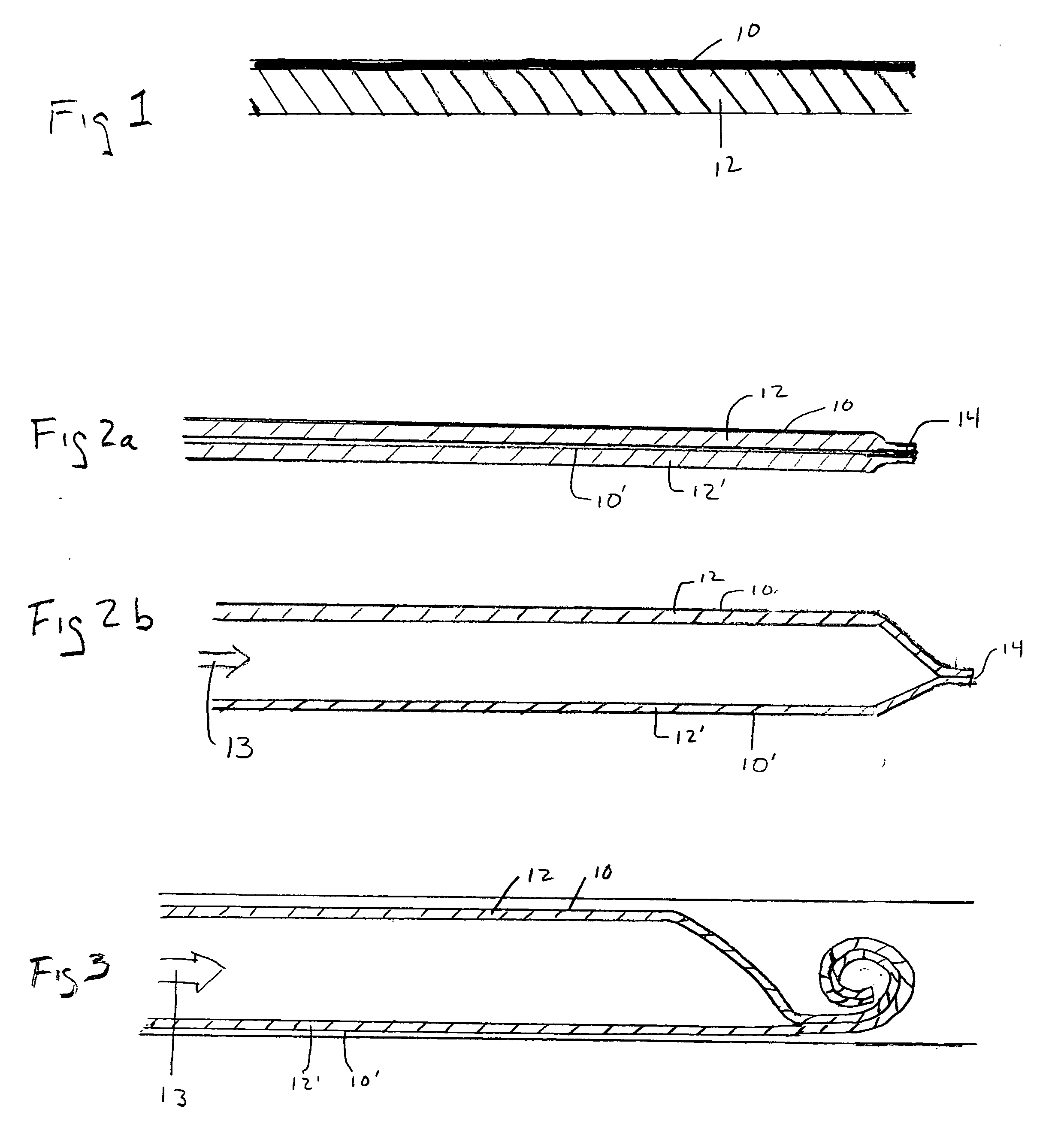

Fiber wrapped pipeline made from composite material

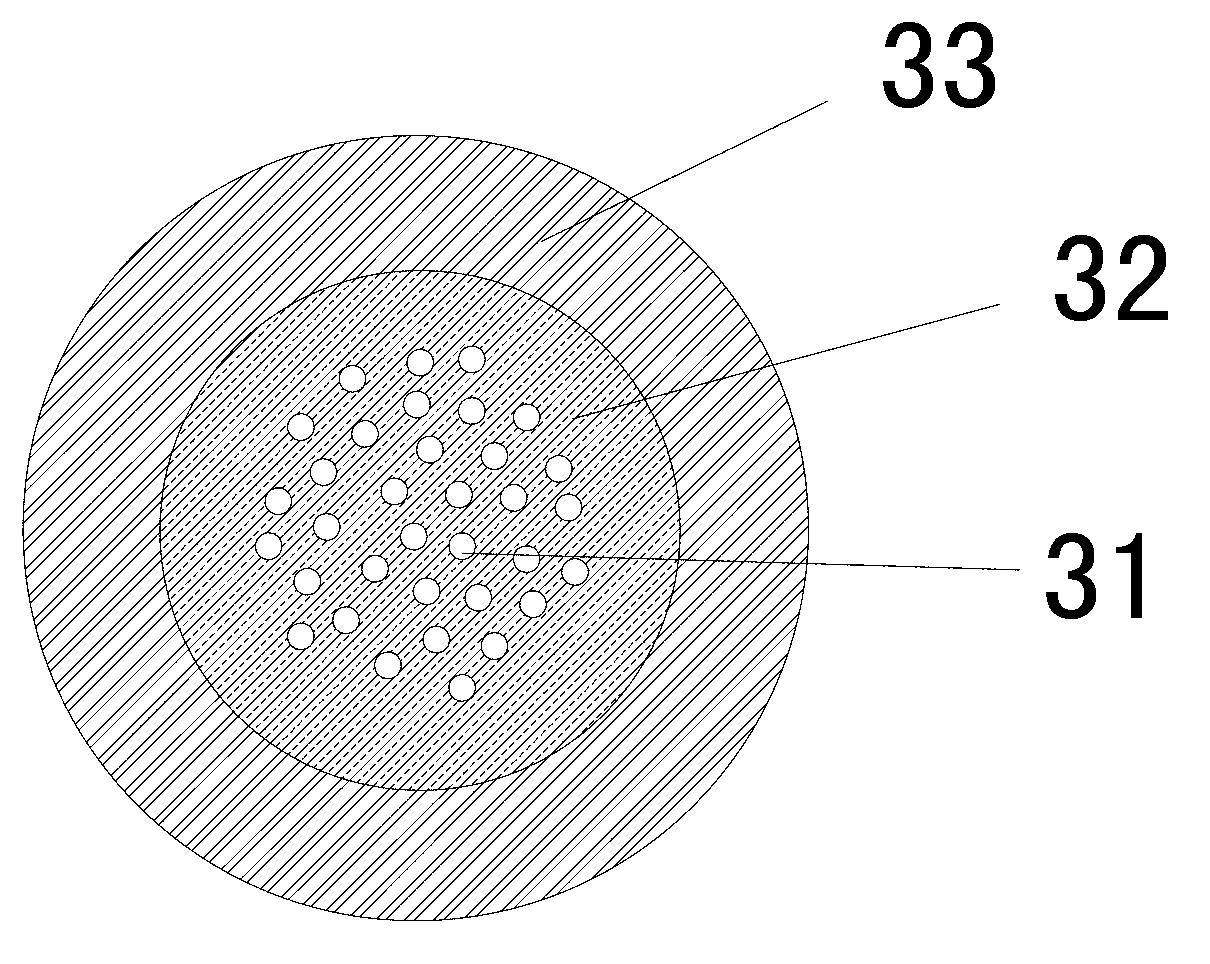

InactiveCN101004230ARetention strengthLow intensityRigid pipesPlastic pipeworkUltimate tensile strength

The present invention relates to a fiber-winded composite material pipe for water supply and drainage. It is characterized by that its pipe wall is divided into three layers, including internal winded layer, intermediate winded layer and external winded layer. Its intermediate winded layer is made up by using thermoplastic composite material, its internal winded layer and external winded layer are made up by using filament and / or continuous fiber reinforced thermoplastic or thermosetting composite material.

Owner:曾建祥

Continuous filament wound and reinforced thermoplastic pipe and manufacturing process thereof

The invention relates to a pipeline structure used for transporting different media such as solid, liquid and gases and a manufacturing process thereof. A continuous filament wound and reinforced thermoplastic pipe is characterized in that a tubular pipeline liner layer, a pipeline structural layer and a pipeline outer protective layer are wound to manufacture a whole structure; the pipeline structural layer is positioned between the pipeline liner layer and the pipeline outer protective layer; the pipeline liner layer and the pipeline outer protective layer are made of thermoplastic plastics; and the pipeline structural layer is made of continuous filaments. The pipeline provided by the invention has better strength, rigidity, shock resistance, fracture toughness, temperature and corrosion resistance, seepage resistance and the like than the traditional thermoplastic or thermosetting pipelines, can be widely applied in the fields such as water supply and sewerage works, petrochemical industry, coal gas and natural gas transportation, seawater desalination and nuclear power and can be suitable for special environments and requirements such as heavy calibre, high rigidity, high strength and high corrosivity.

Owner:CHANGSHA XINSHI PIPELINE

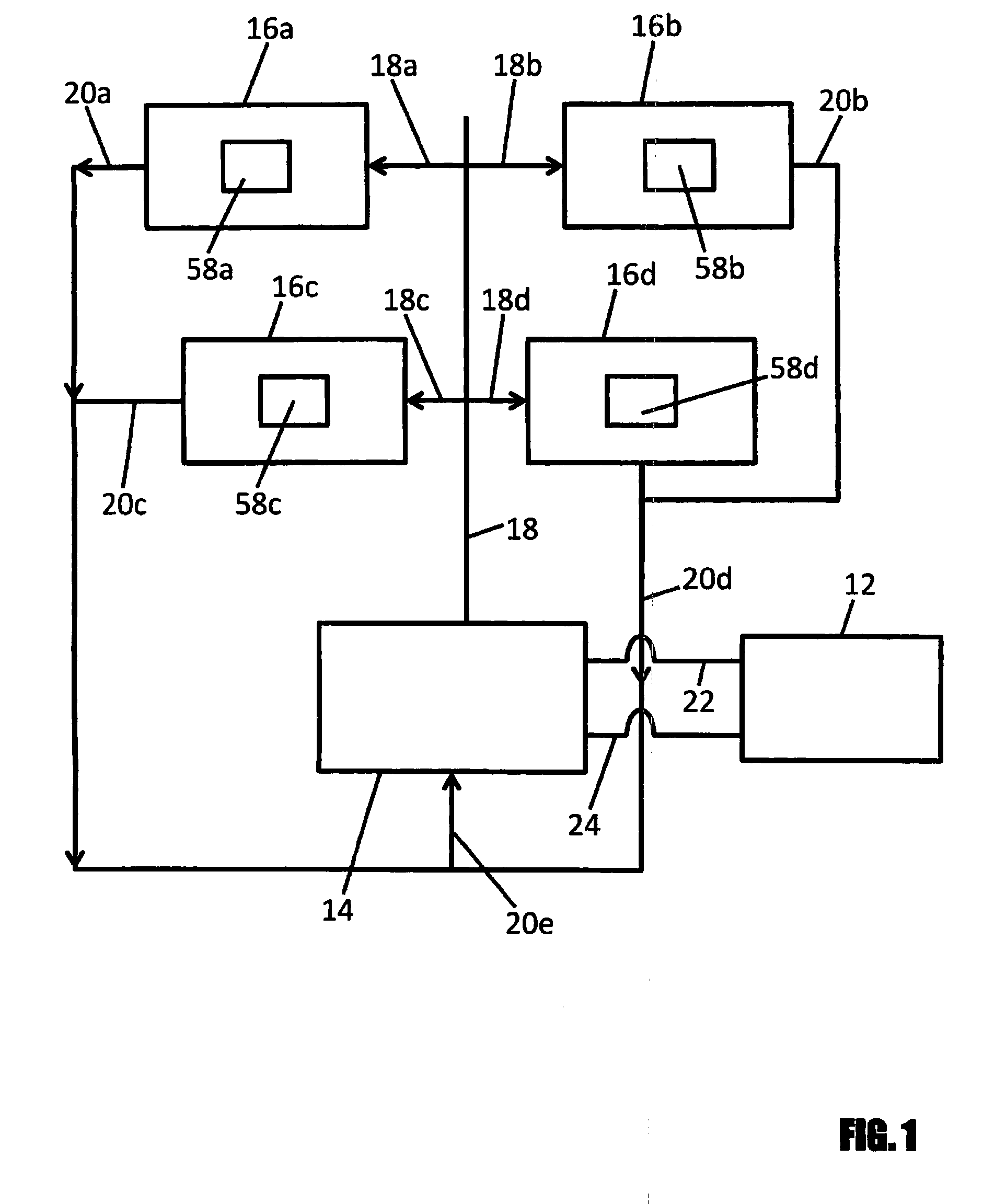

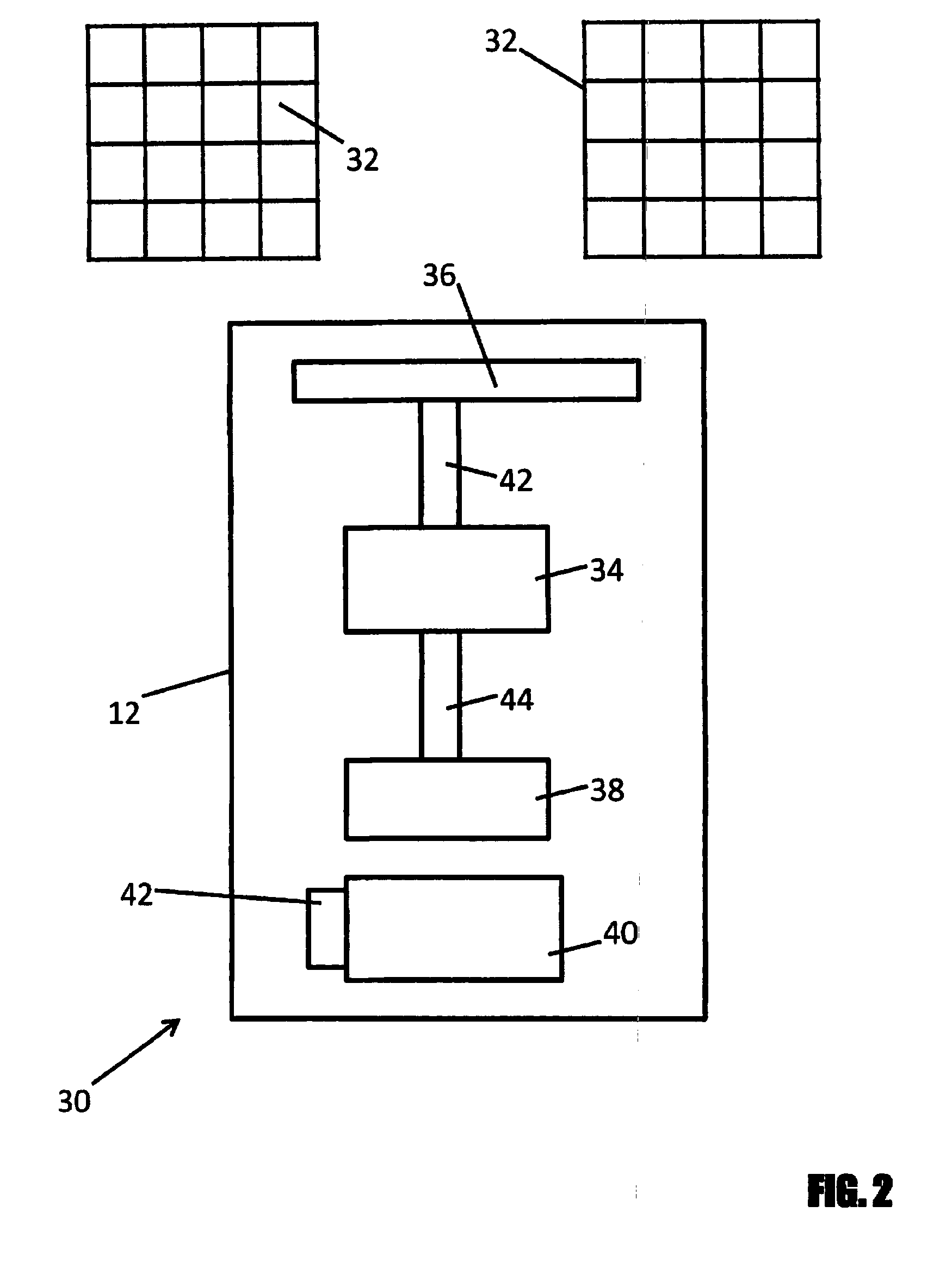

Plastic HVAC component system and method for installing the same

ActiveUS7410416B2Efficient deliveryReduce the amount requiredDucting arrangementsLighting and heating apparatusPlastic pipeworkEngineering

A complete plastic HVAC system assembled using individual plastic components for ensuring the efficient and quiet distribution of air from a central air unit to multiple distribution points and preventing heating and cooling losses, the need for installers to stock multiple sized and shaped components, the accumulation of dust, dirt and pollens during storing, installing and use on the surfaces of the individual components. The fittings have a collar sizable to fit both 6 and 7-inch pipe, whether flexible or rigid. The use of plastic fittings, duct and pipe removes the potential of injury commonly associated with conventional metal ductwork, while providing seamless components that can be configured for any type of installation and insure an air tight connection between adjoining surfaces. The individual fittings include a register boot, torpedo boot, straight boot, rigid and flexible pipe and couplers, straight and 90-degree takeoffs, a plastic duct and duct end cap.

Owner:FETTKETHER

Breathable, waterproof horse blanket

InactiveUS6009693AReduce manufacturing costProtect the backProtection coversGrooming devicesPlastic pipeworkLong segment

An impermeable horse blanket includes mesh material for ventilation of the horse's back while it is covered by the blanket. The mesh material is shielded by a waterproof top cover that protects it and prevents water from wetting the horse while allowing breathing through the openings of the mesh. The front edge of the top cover is attached to the blanket by means of a continuous seam along a front hem that encases a length of plastic piping sufficiently thick to provide a relief structure for raising the front edge of the cover slightly with respect to the blanket and the mesh material. The top cover is also stitched to the blanket at discrete points around its sides and back edge, such that relatively long segments of the side and back perimeter are not attached to the blanket. Thus, an air stream produced by wind or the horse's motion is able to flow between the top cover and the mesh material, thereby producing desirable ventilation while still protecting the back of the horse from rain. The netting material also ensures that insects and debris cannot infiltrate the blanket.

Owner:EASTWEST INT TAIWAN ENTERPRISES

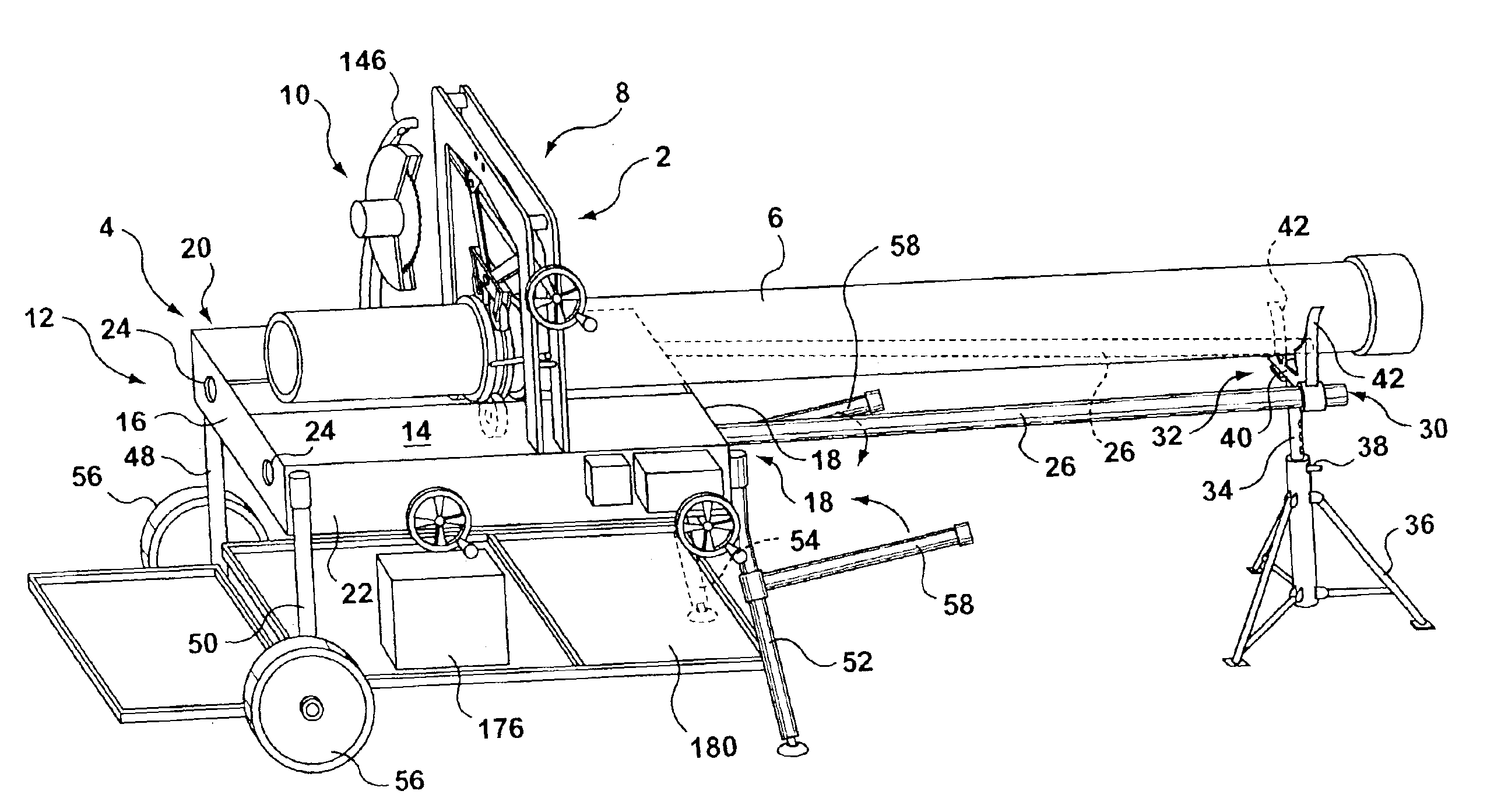

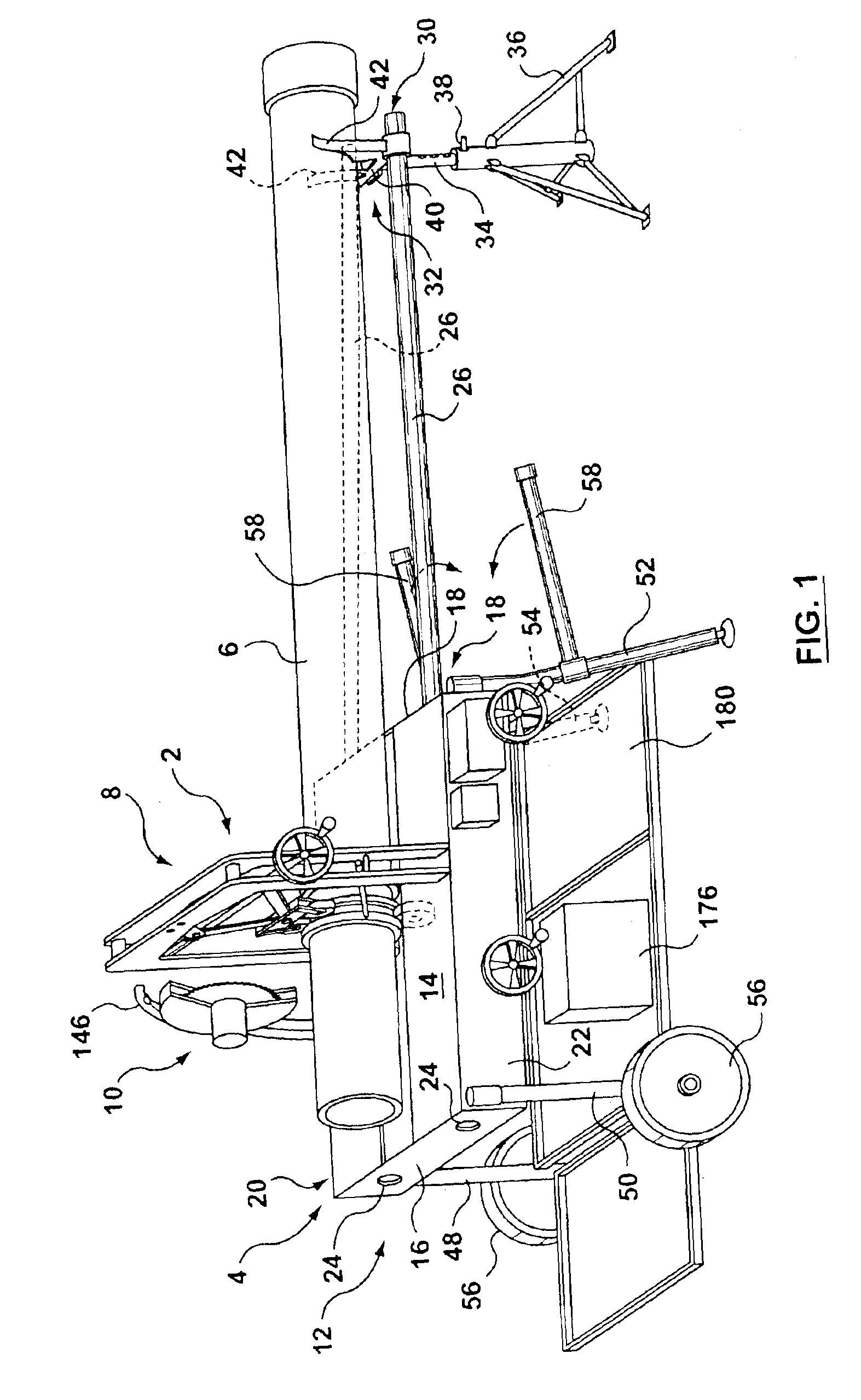

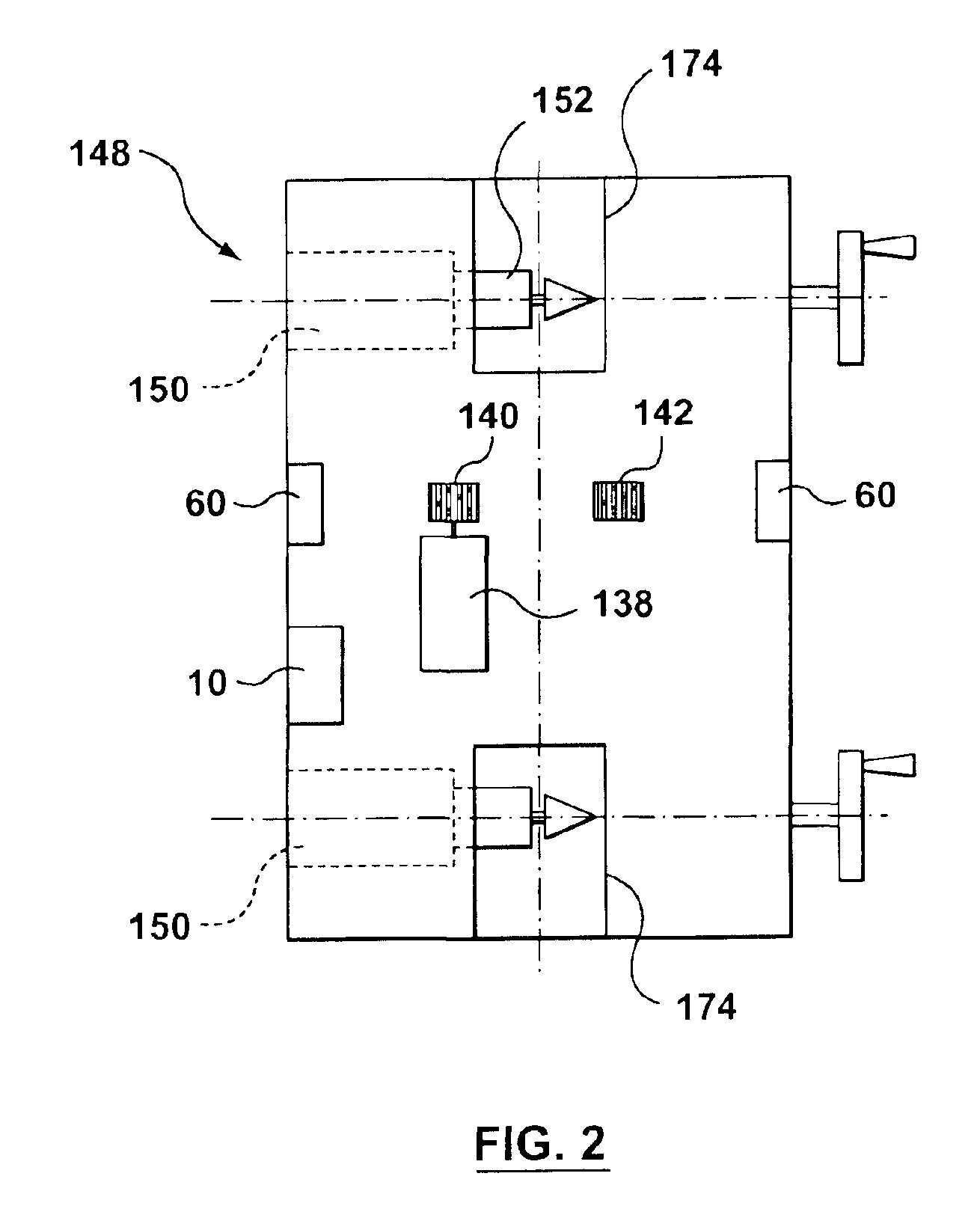

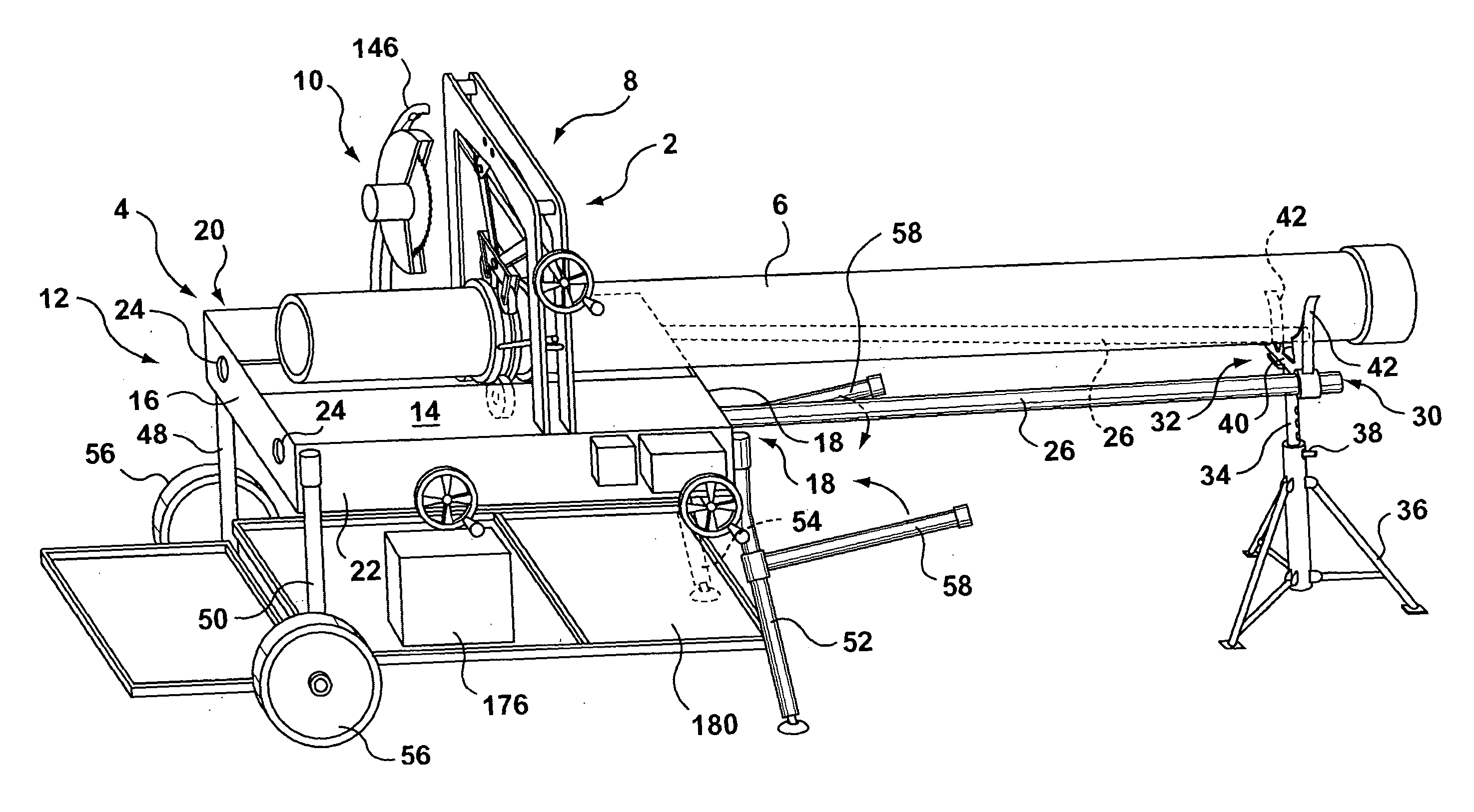

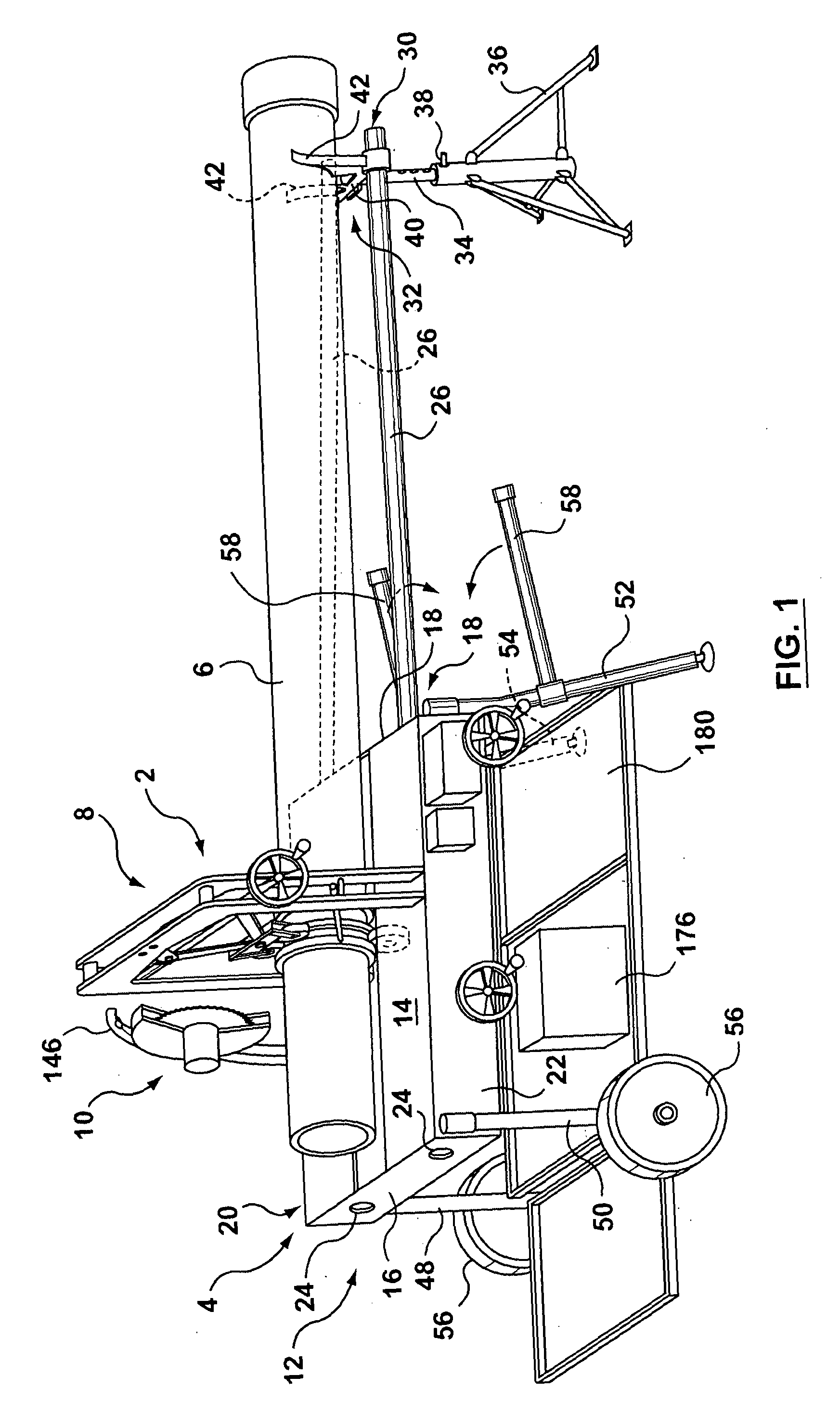

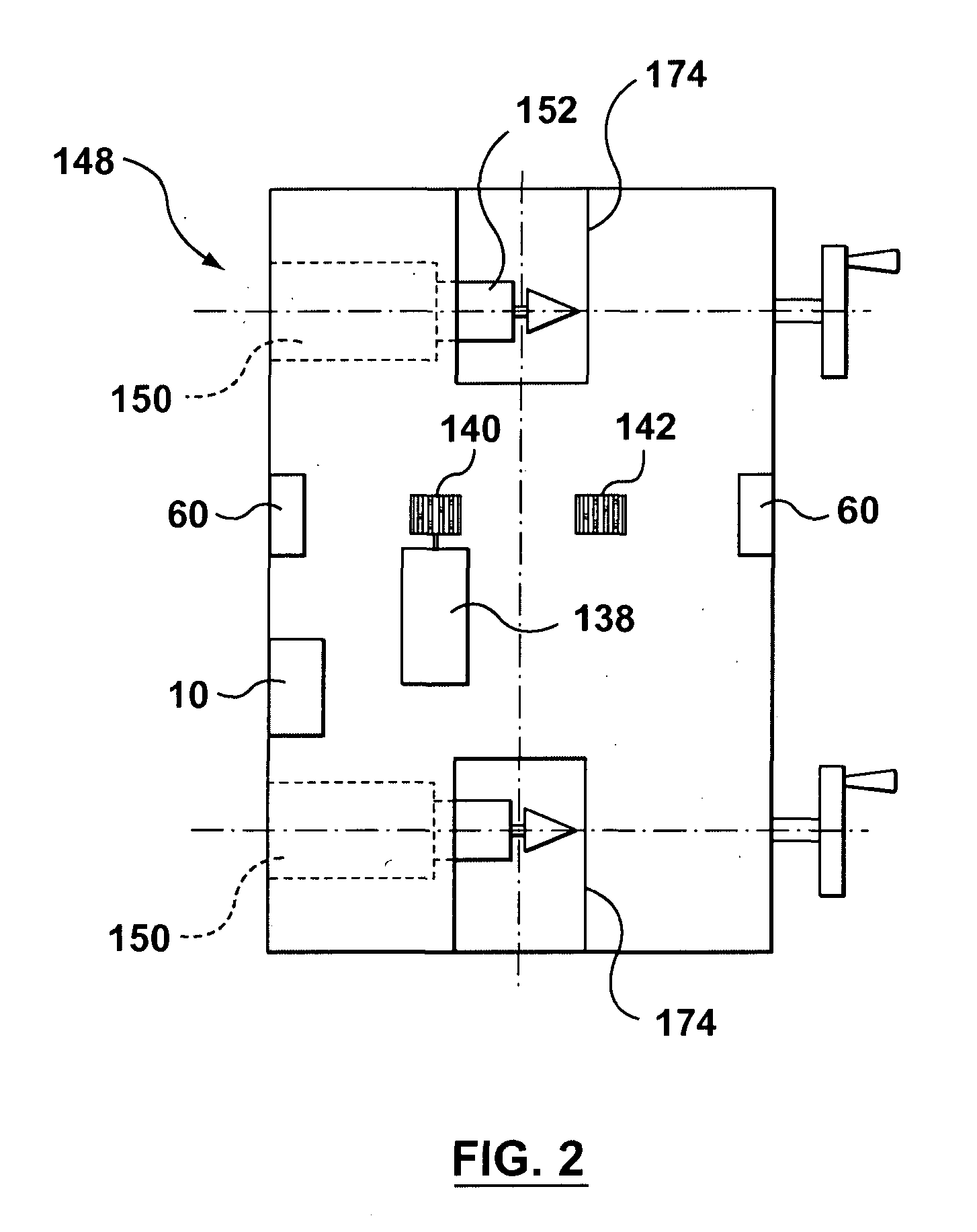

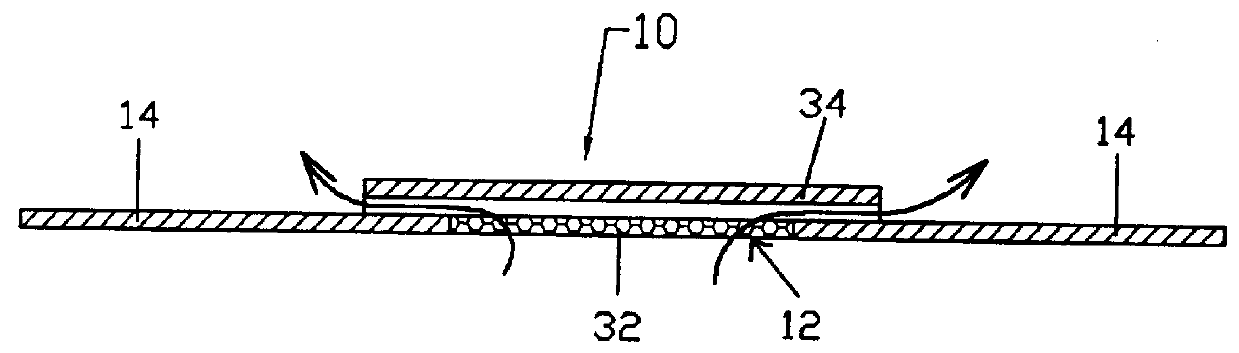

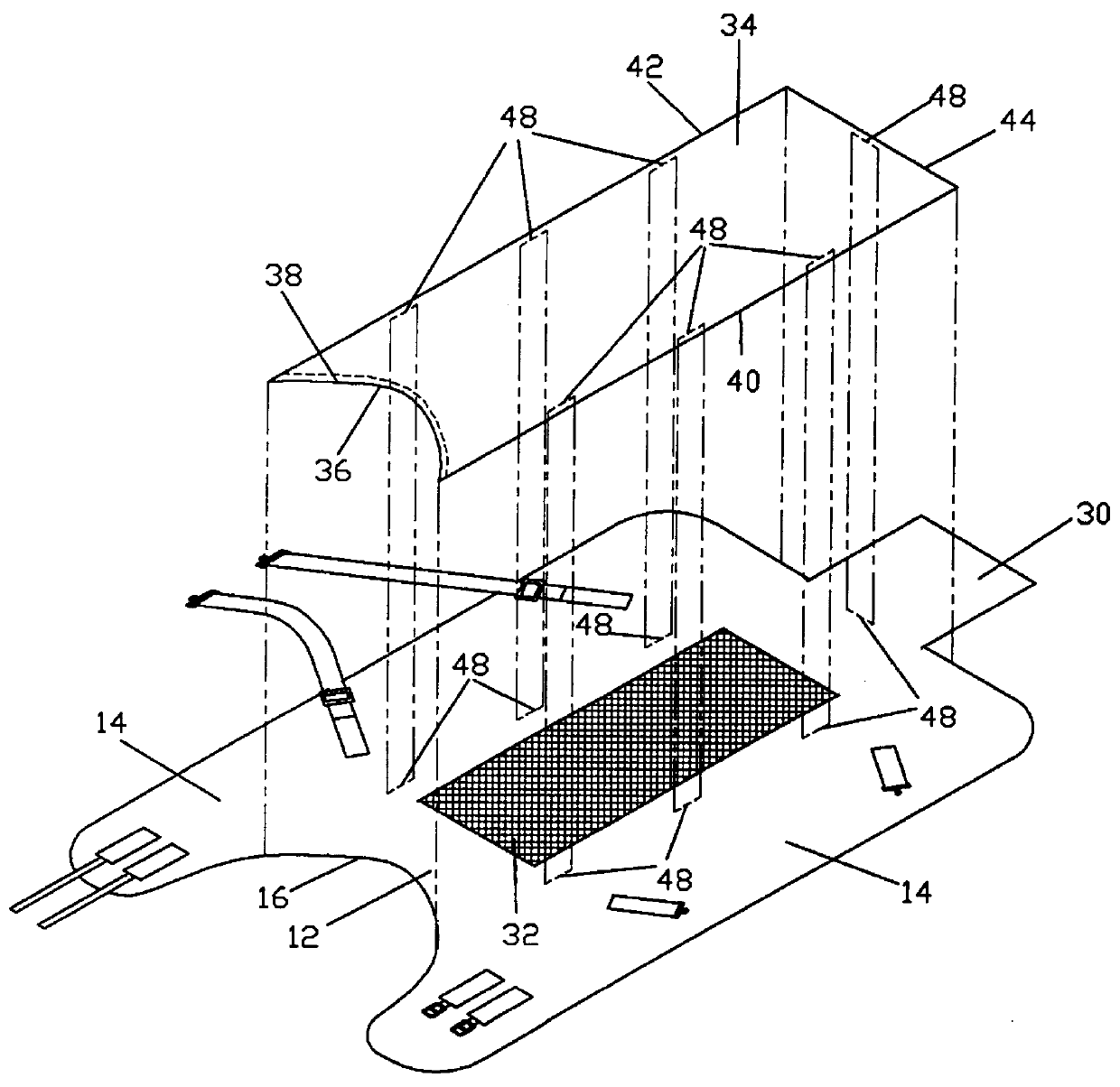

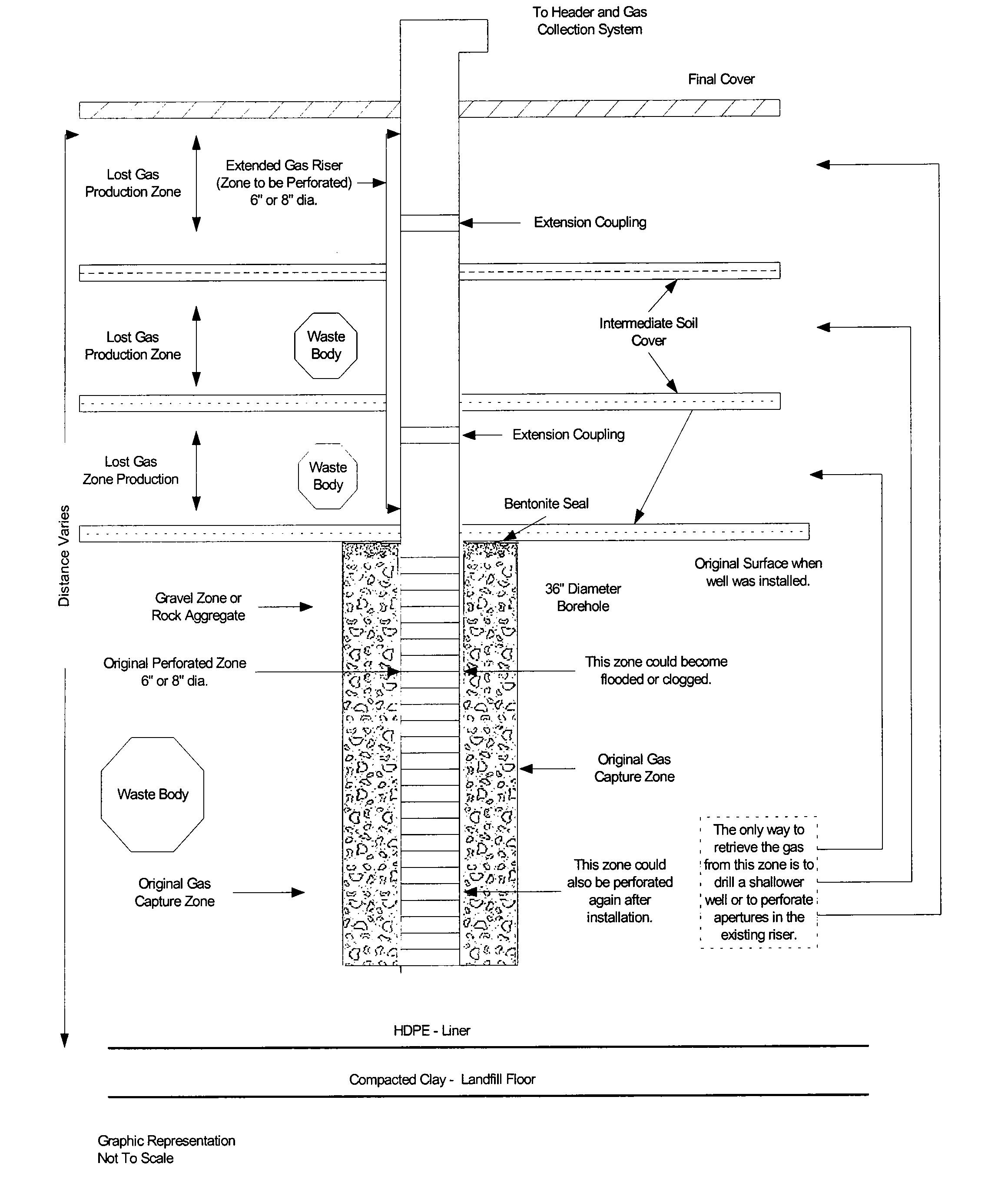

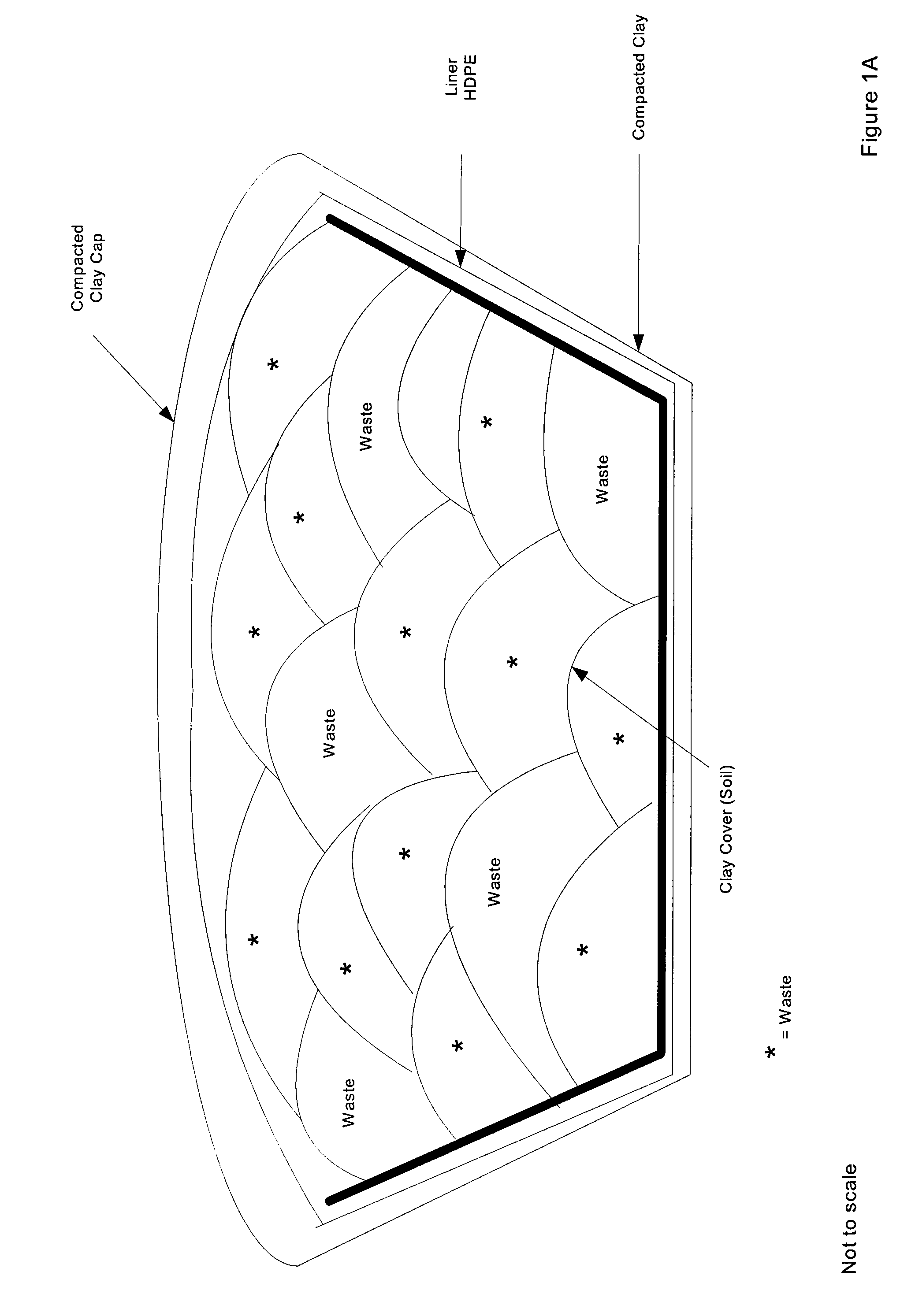

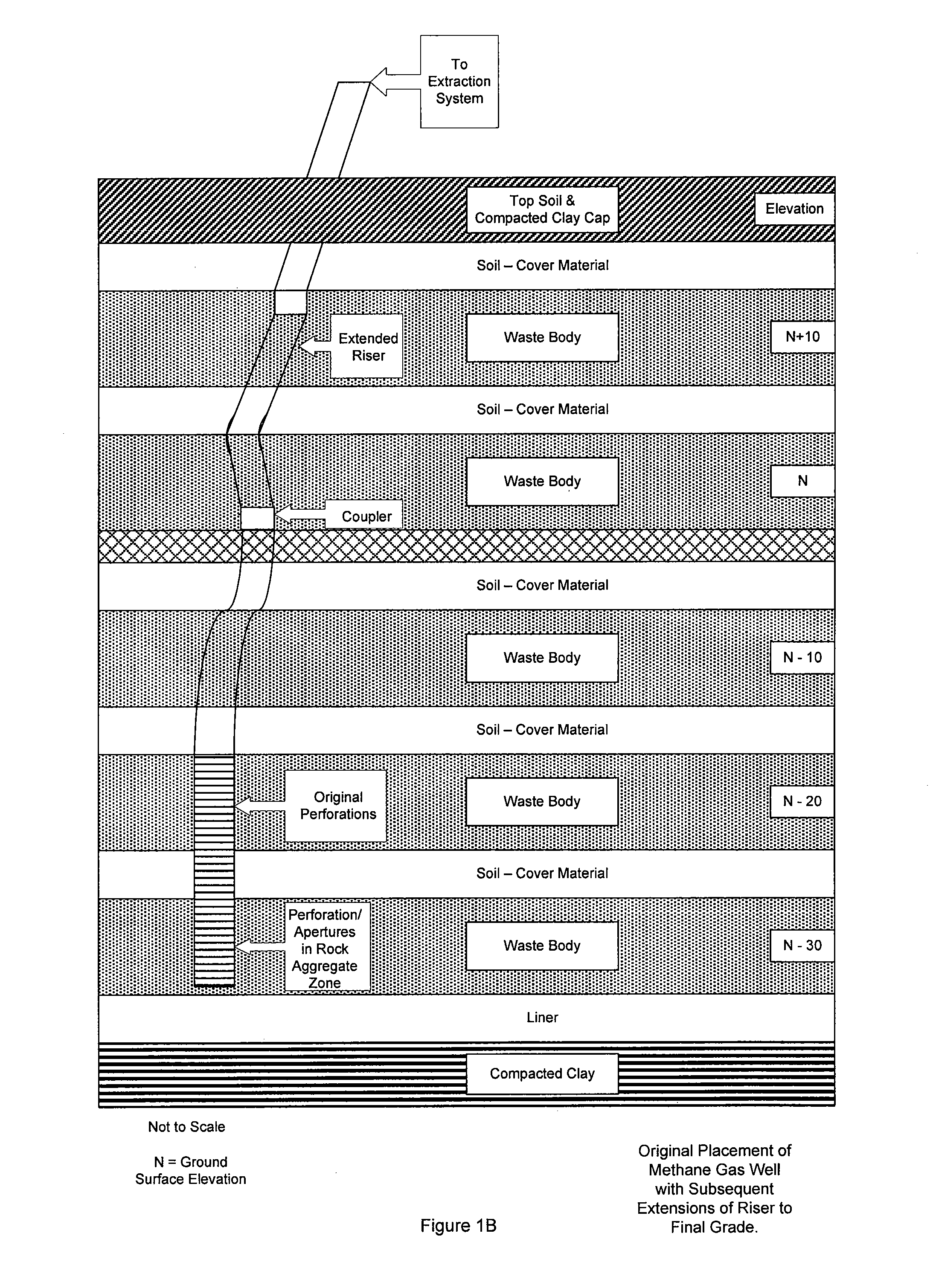

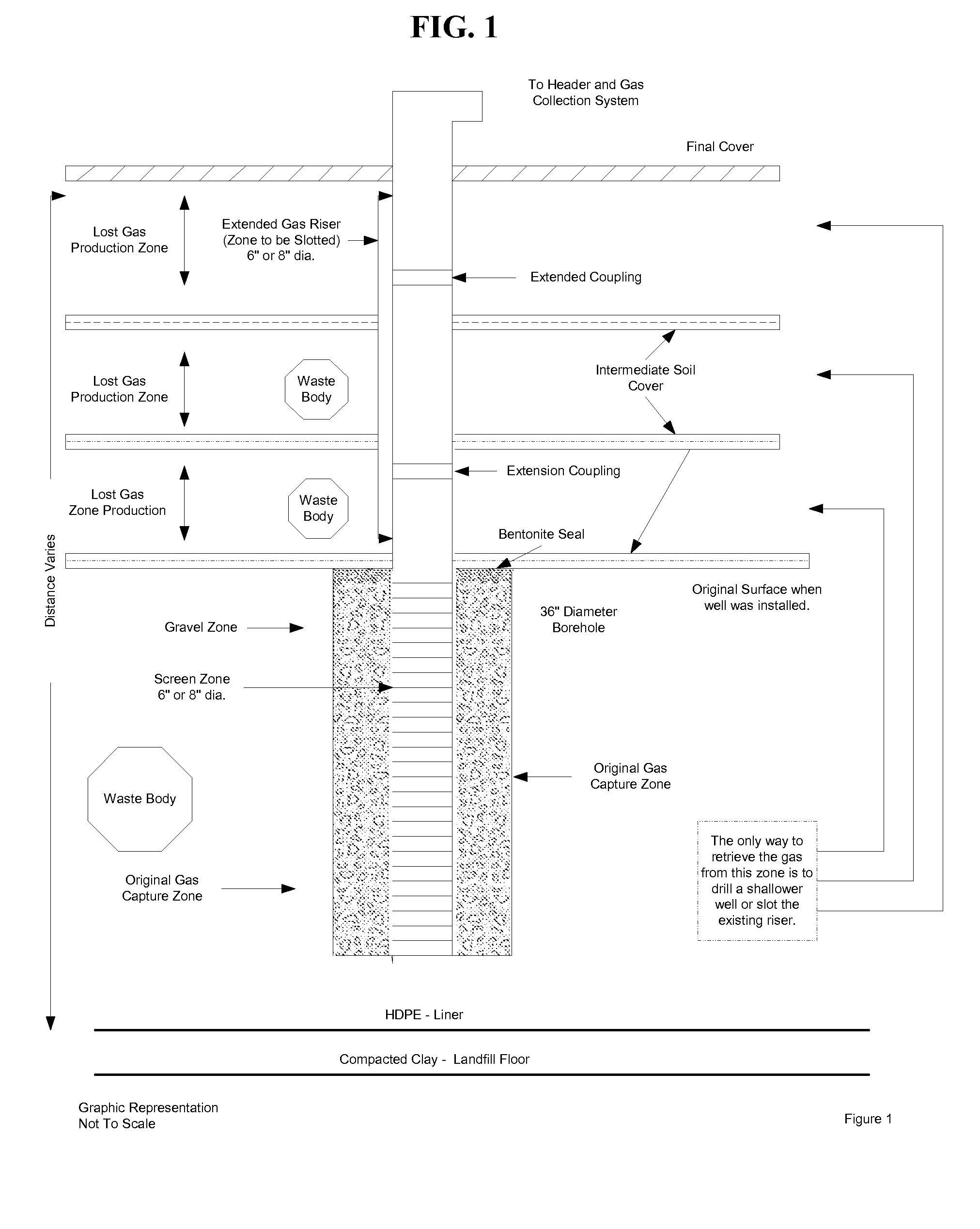

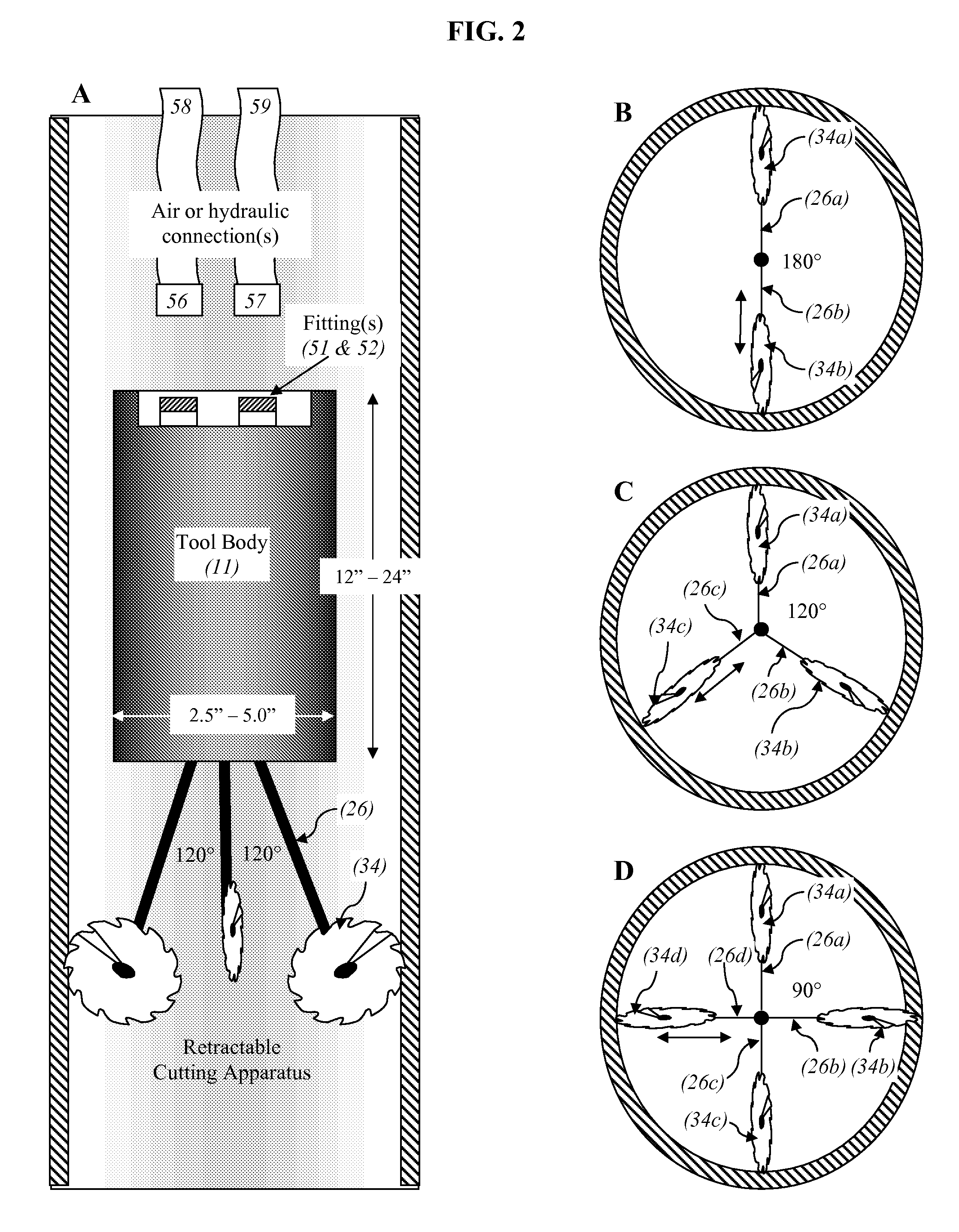

Tool and method for extracting landfill gas

An apparatus and method to internally provide apertures inside PVC, HDPE, or plastic pipe-riser (blank casing) in existing methane gas recovery wells (extraction wells) that have been installed at Municipal Solid Waste Facilities are described. Apertures in methane well risers allow methane gas, LFG derived from the decomposition of waste, to enter the existing riser and extraction system. This process saves time and cost associated with drilling additional wells to retrieve methane gas from subsequent layers of the waste body. The process assists in maintaining regulatory compliance by capturing LFG and preventing it from being emitted into the atmosphere.

Owner:PROSPECTOR DRILLING & TOOL

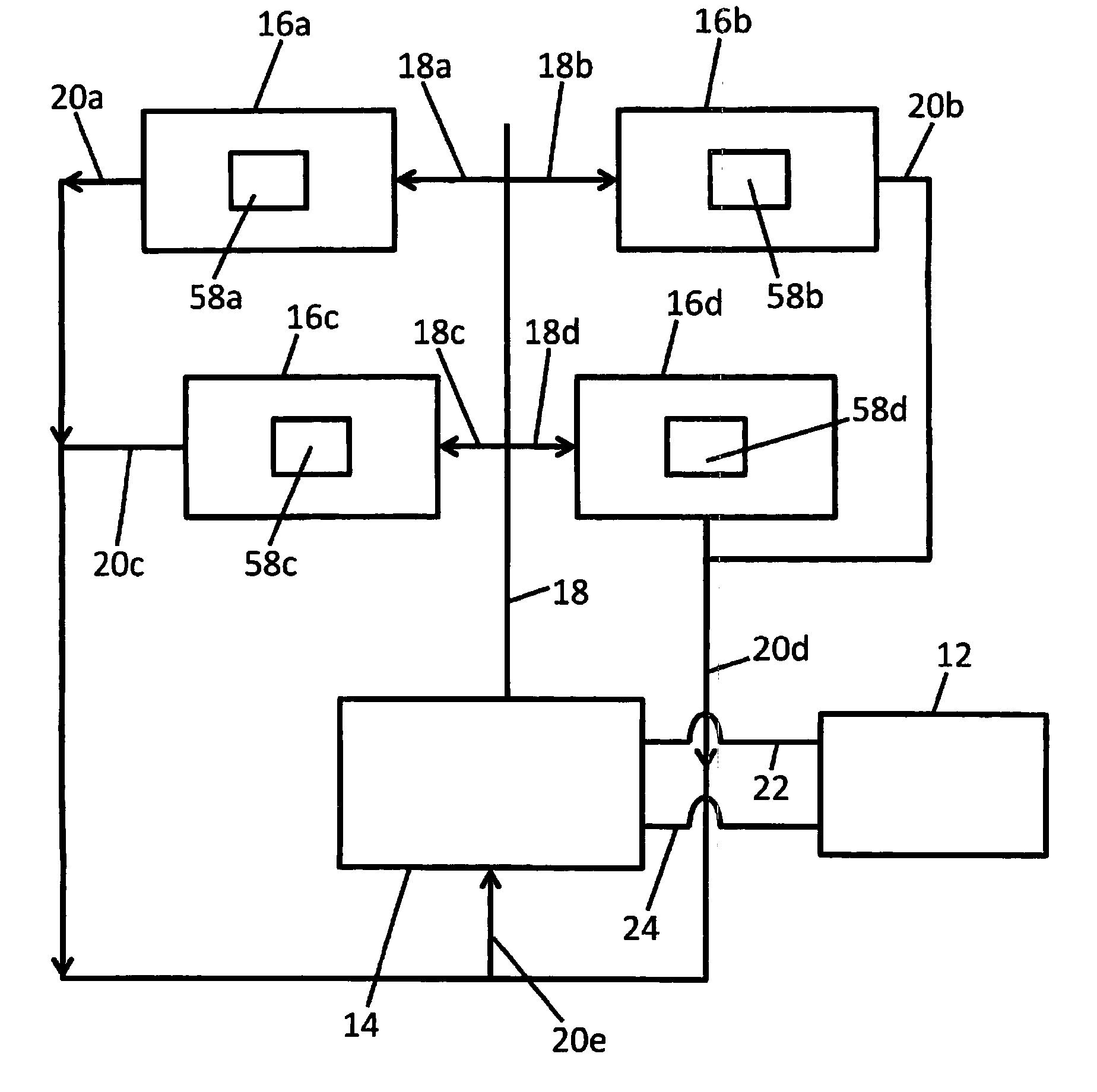

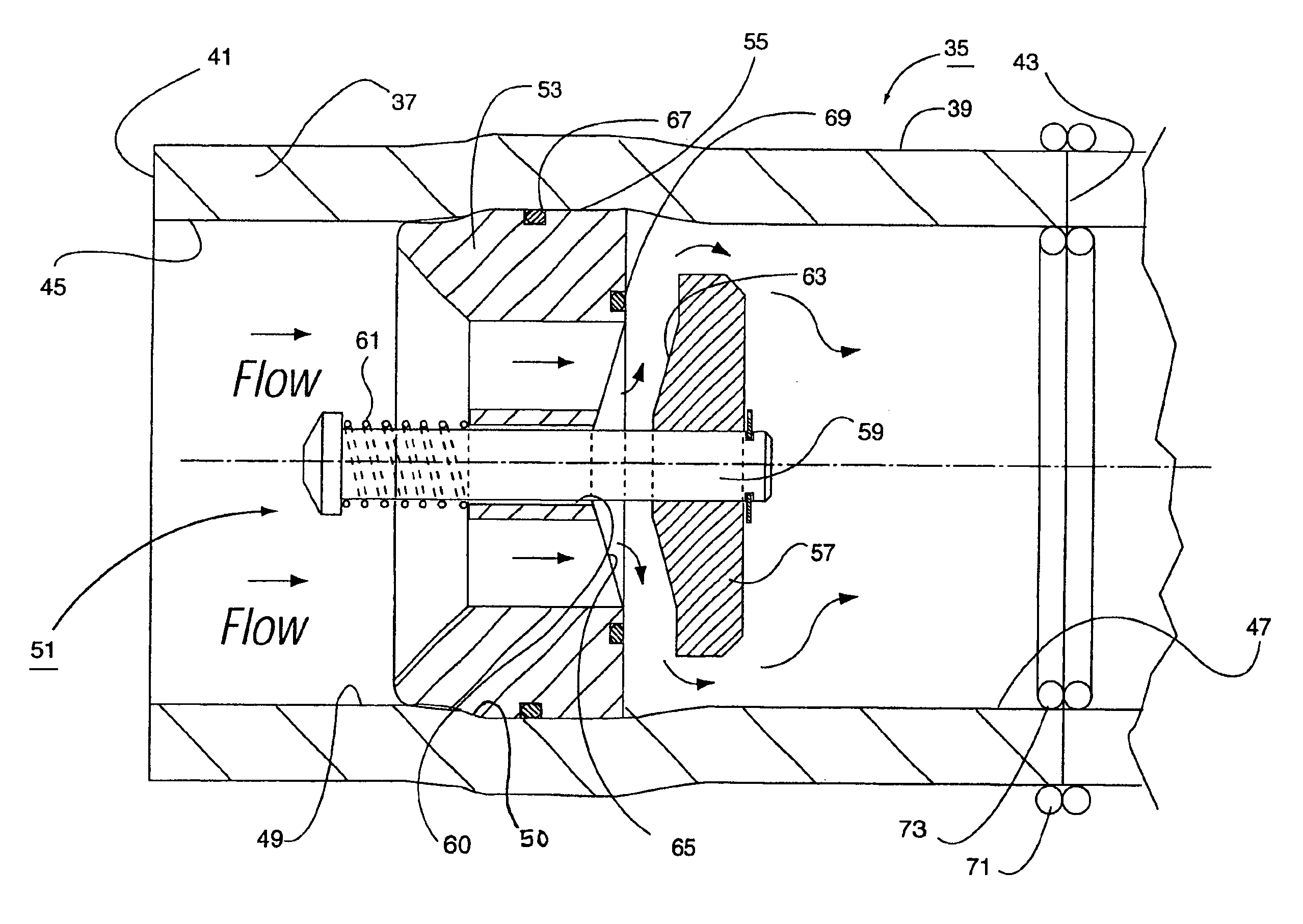

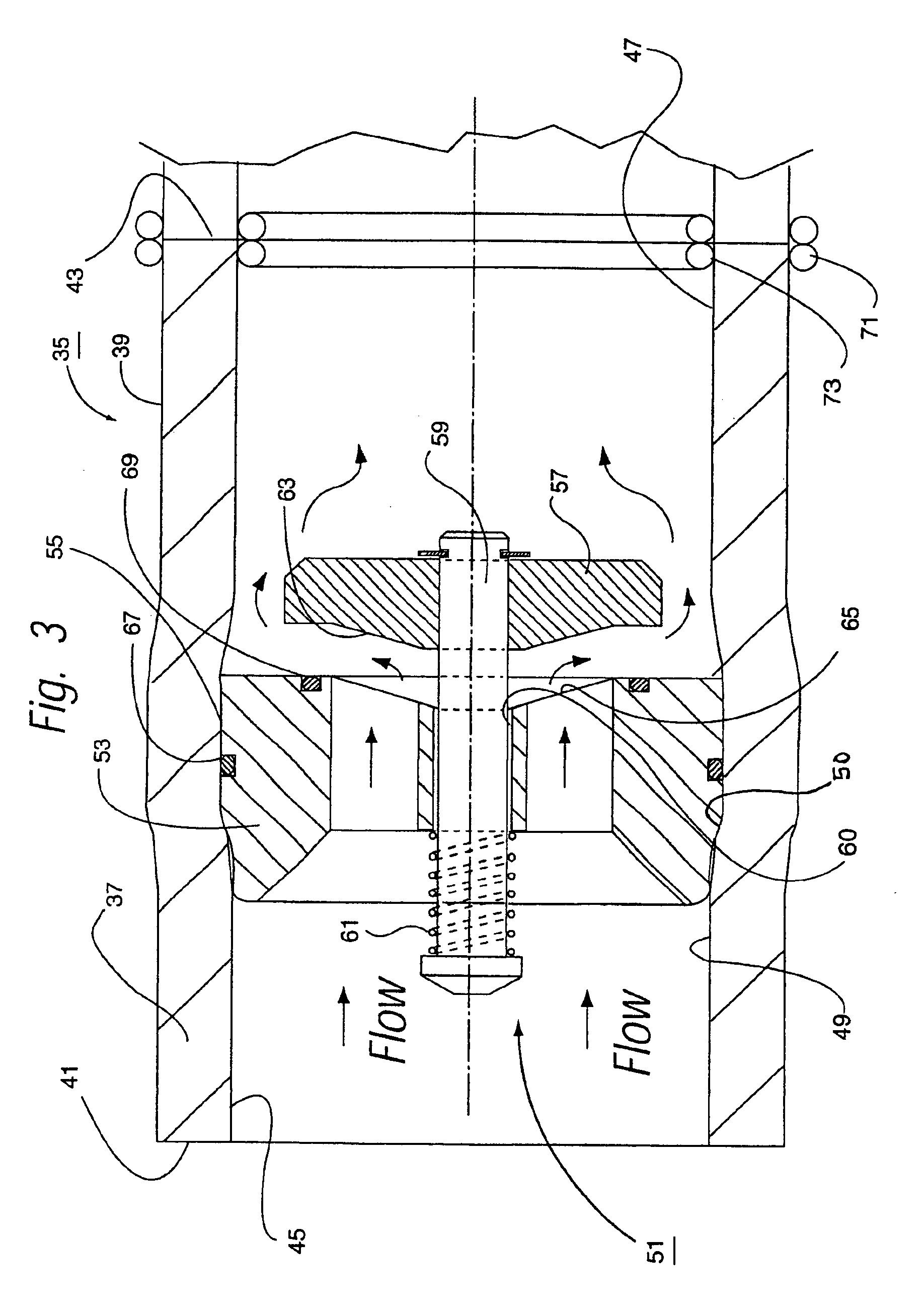

Heating, ventilation, and air conditioning system

A high-efficiency HVAC system and method of operation, for use in a house or building, having a plurality of components, including flexible, plastic duct tubing forming supply pipes that connect an air handler and a plurality of zones to deliver supply air to the zones and return pipes that connect the air handler and the zones to re-circulate return air; the air handler having a fan assembly powered by a variable blower motor to blow supply air to the zones; a heat pump having a variable compressor powered by a variable compressor motor to direct a working fluid to and from the air handler and a variable fan motor that rotates a fan blade within the heat pump; and a circuit control system for adjusting the variable compressor motor and the variable fan motor in the heat pump and the variable blower motor in the air handler.

Owner:SCHLESINGER STEPHEN

Glass fiber reinforced plastic pipeline and its production process

InactiveCN1892086AImprove performanceRetain corrosion resistanceRigid pipesTubular articlesFiberGlass fiber

The invention is a glass fiber reinforced plastic pipeline, comprising outer layer and inner layer, characterized in that a filling layer is arranged between the inner and outer layers. And its producing process flow comprises: 1. the producing mould adopts inner mould and outer mould; 2. a group of glass fibers is dipped in unsaturated polyester resin and then coiled on the outer surface of the inner mould and besides, the other group of glass fibers is dipped in unsaturated polyester resin and coiled on the inner surface of the outer mould; 3. injecting the mixture of fillings and unsaturated polyester resin in the annular die formed between the two glass fiber surface layers; 4. the producing mould is heated by electrifying to cure the resin; 5. drawing out the formed pipeline by a tractor and cutting the pipeline for the needed size. And the products are strongly designable and have good synthetic performance. Besides, in the producing course, no styrene volatilizes, according with environmental protection requirements.

Owner:上海意耐玻璃钢有限公司

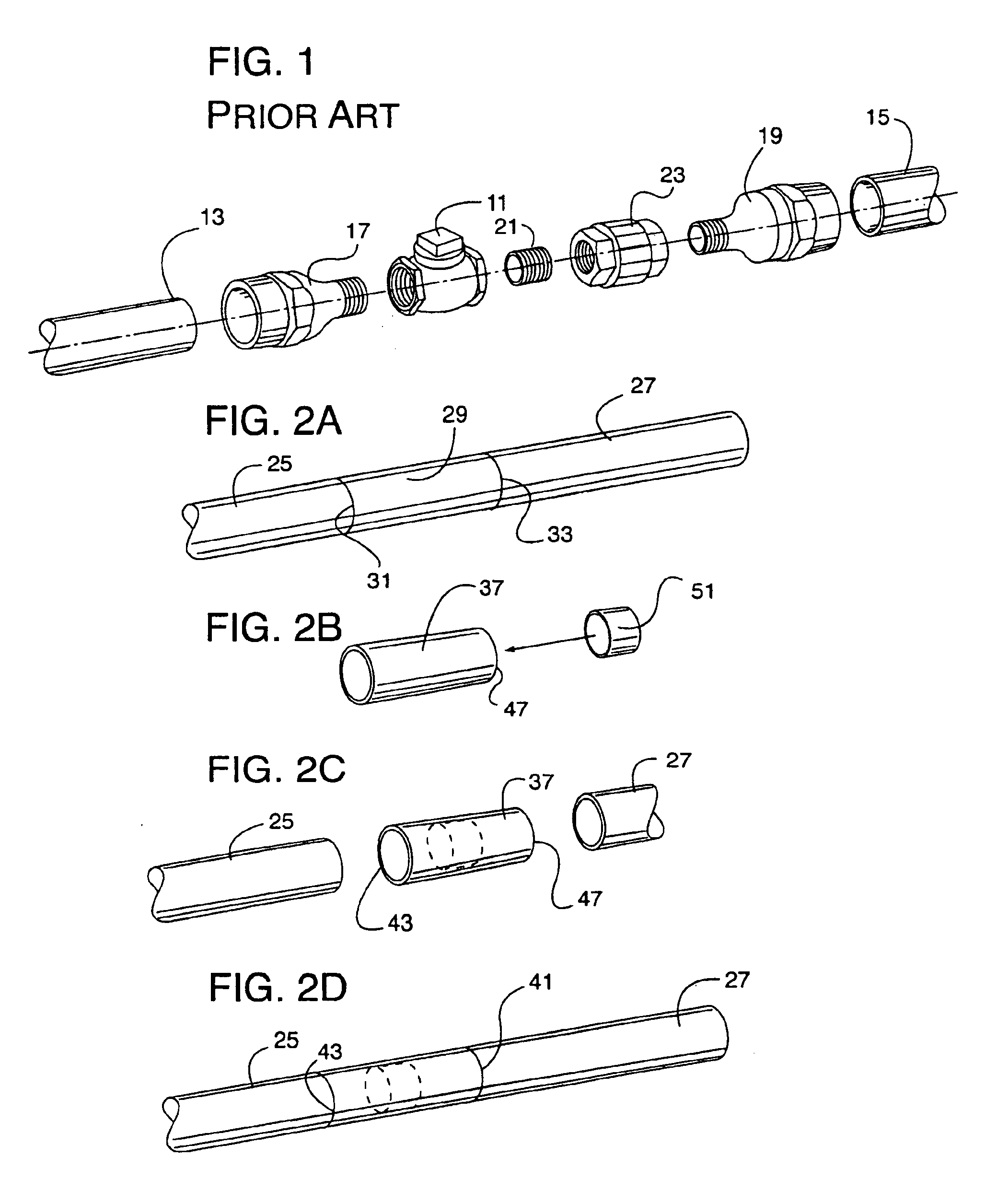

Method and apparatus for preventing overinsertion in plastic pipe systems

InactiveUS20080001401A1Simple designEasy to operateSleeve/socket jointsCouplingsPlastic pipeworkEngineering

A method is shown for joining and sealing a female plastic pipe end having a belled end opening to a mating male plastic pipe end having an interior surface and an exterior surface. A sealing element is installed within a groove formed in the belled end of the female pipe section. The male pipe end is then inserted into the end opening of the female pipe end so that the elastomeric sealing gasket makes sealing contact with the exterior surface of the male pipe. A control mechanism controls the distance the male pipe travels longitudinally within the end opening of the female plastic pipe to prevent overinsertion of the male pipe within the female pipe opening.

Owner:S & B TECHN PRODS

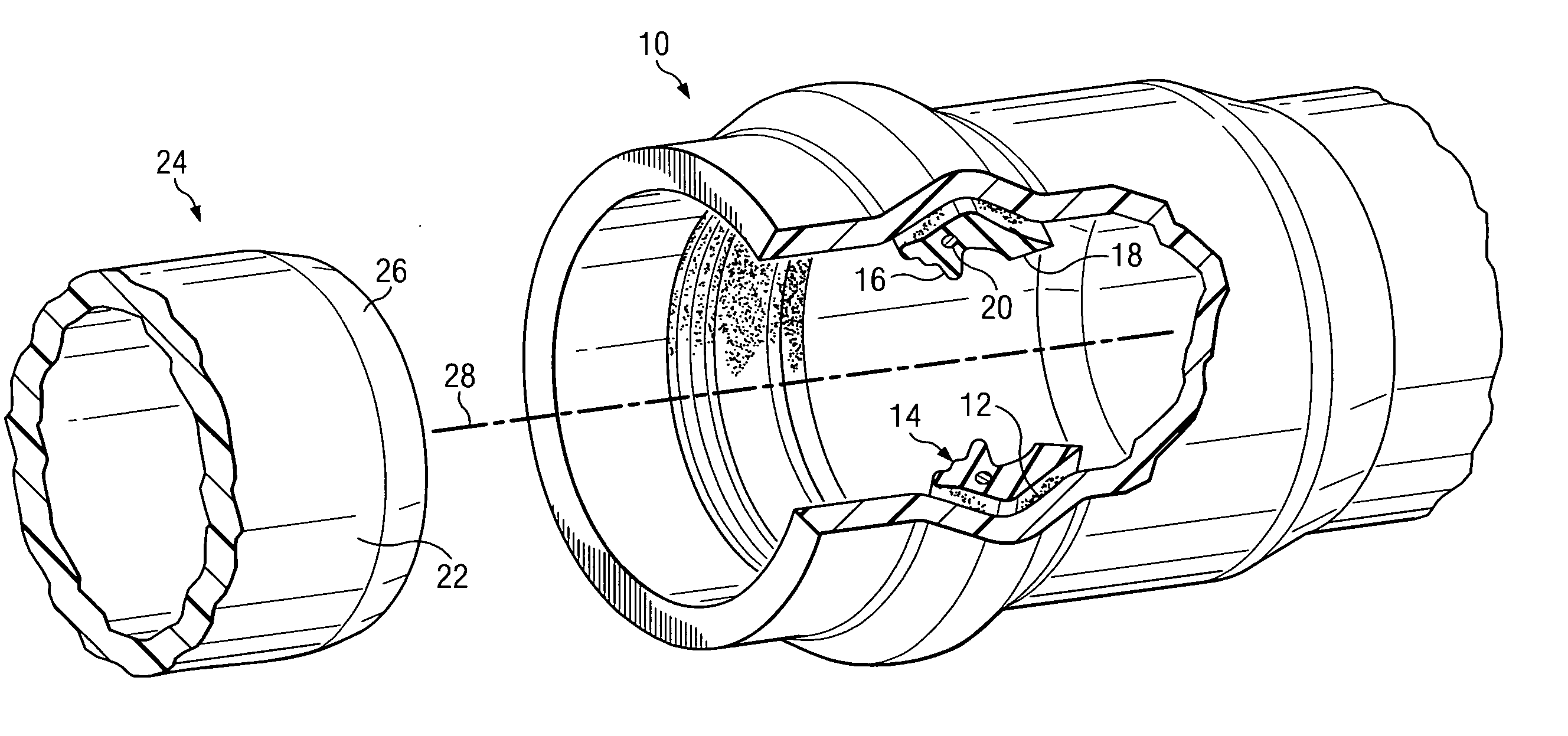

Plastic pipe coupling system

InactiveUS6676166B1Simply and easily assembled togetherStable and reliable locking engagementEngine sealsJoints with sealing surfacesInterference fitPlastic pipework

A plastic pipe coupling system including a female coupling and a support ring. A circumferential groove is molded or cut into the outer diameter of a plastic pipe. The female coupling includes a reduced diameter portion with a coupling rib at the free end. The ends of the pipe, coupling, and support ring are beveled in order that the ends pressed together engage and by the slight resiliency of the plastic construction permit the slight expansion and contraction of the ends to provide a locking interfit of the respective groove and rib at the two ends. There is an interference fit between the support ring and the coupling so that a radial preload is induced when the support ring is assembled onto the coupling. The inner surface of the sleeve or the outer surface of the coupling is tapered for ease of installation of the support ring over the coupling and to provide radial support to keep the coupling in the groove. Installation of the support ring over the female coupling results in a mechanically strong joint under axial and bending loads. Additionally, the joint is water tight under pressure without the use of a rubber gasket or solvent.

Owner:WRAITH MATTHEW WILLIAM +2

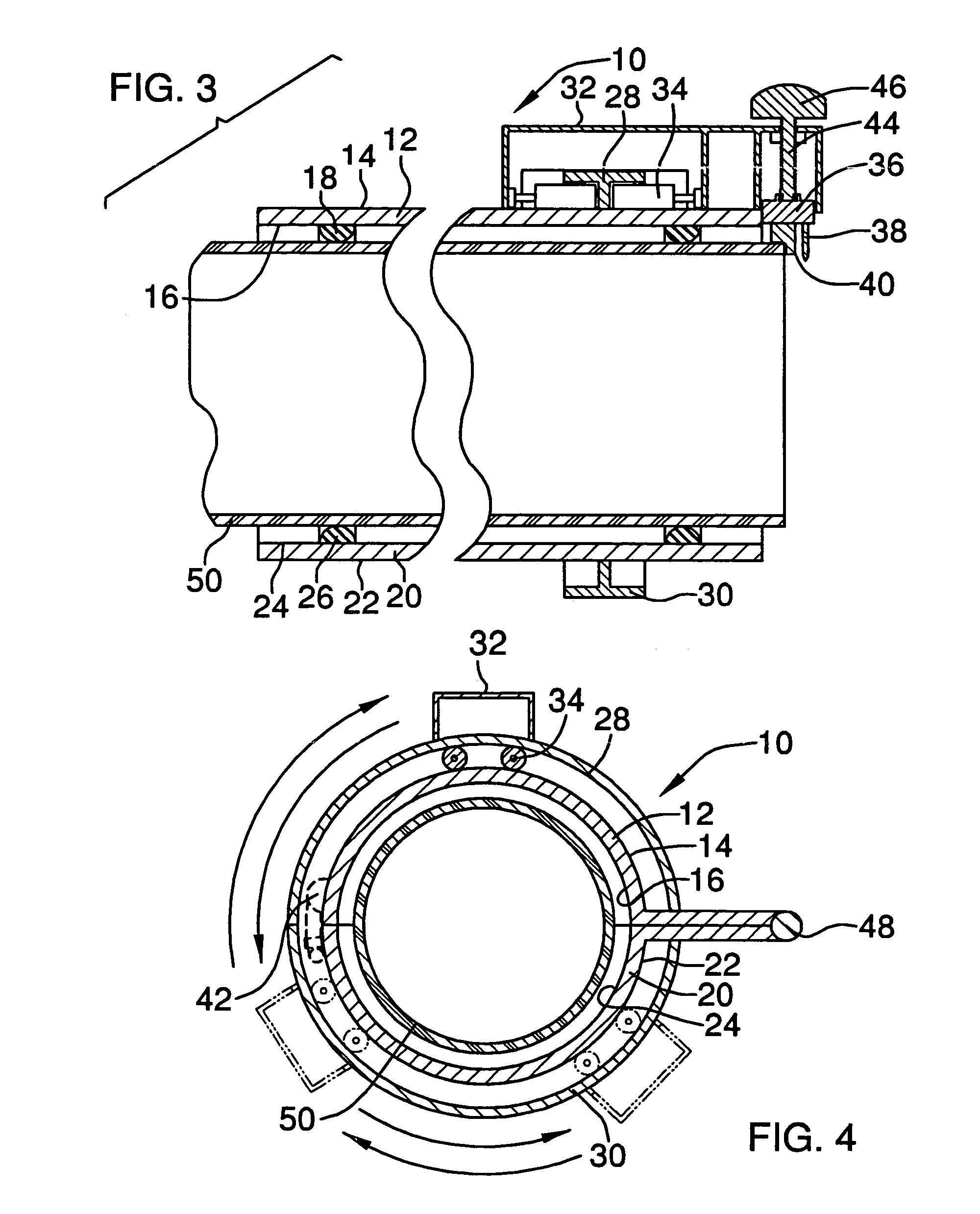

Back flow prevention device for pipelines conveying fluids

InactiveUS6929023B2Conveniently installedEasy to installCheck valvesEqualizing valvesPlastic materialsPlastic pipework

A back flow prevention device is shown for use in a plastic pipeline for conveying water, sewage, hydrocarbons or other fluids. A valve body features a flow control mechanism which is formed entirely or primarily of plastic materials. The valve body and its opposing ends are formed of a plastic material which is compatible with the plastic material of the existing pipeline, whereby the valve body can be installed in the pipeline in co-axially fashion by directly joining the opposing ends of the body to the opposing mating pipe ends at a selected location within the pipeline.

Owner:POLYCHECK CORP

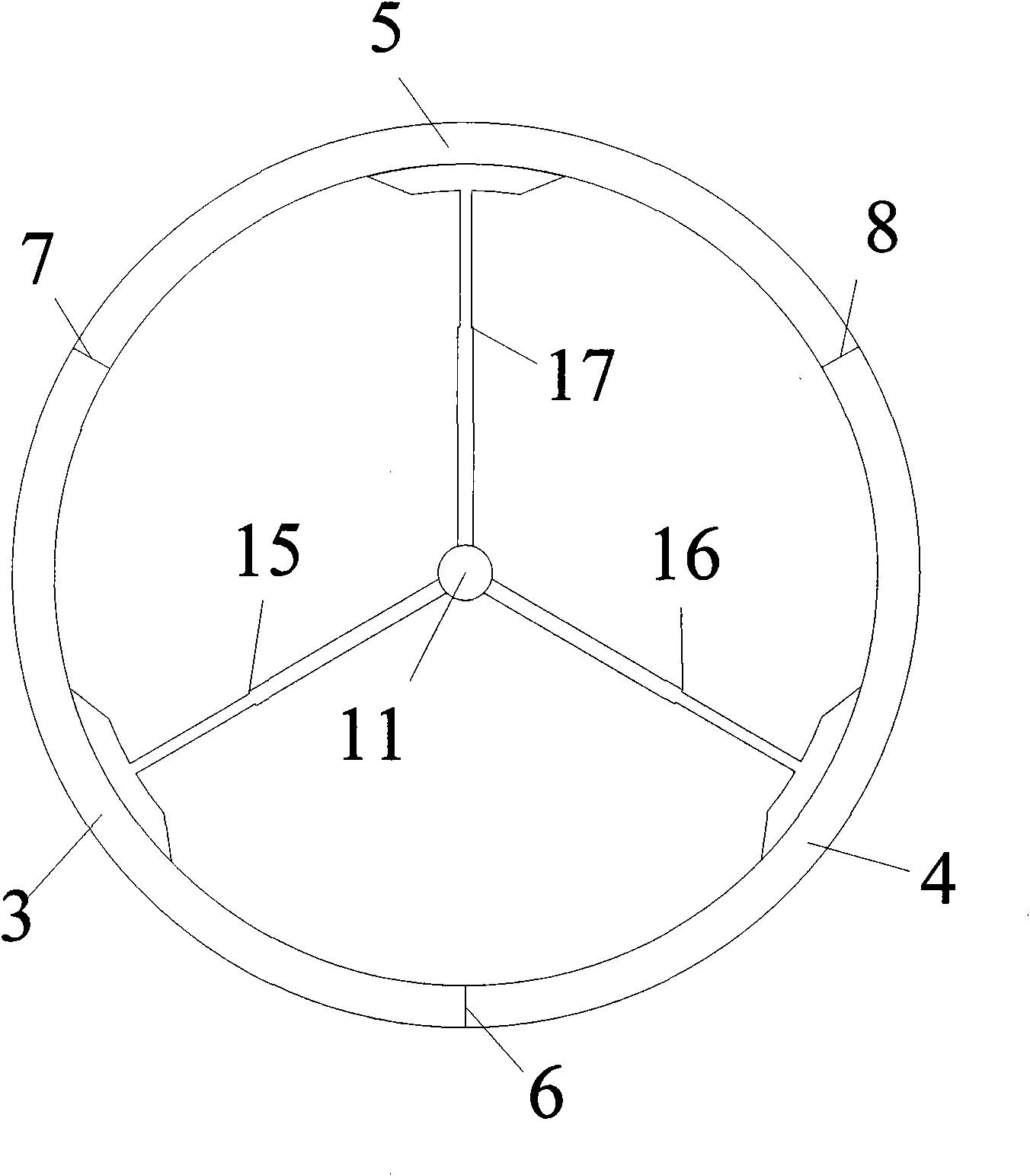

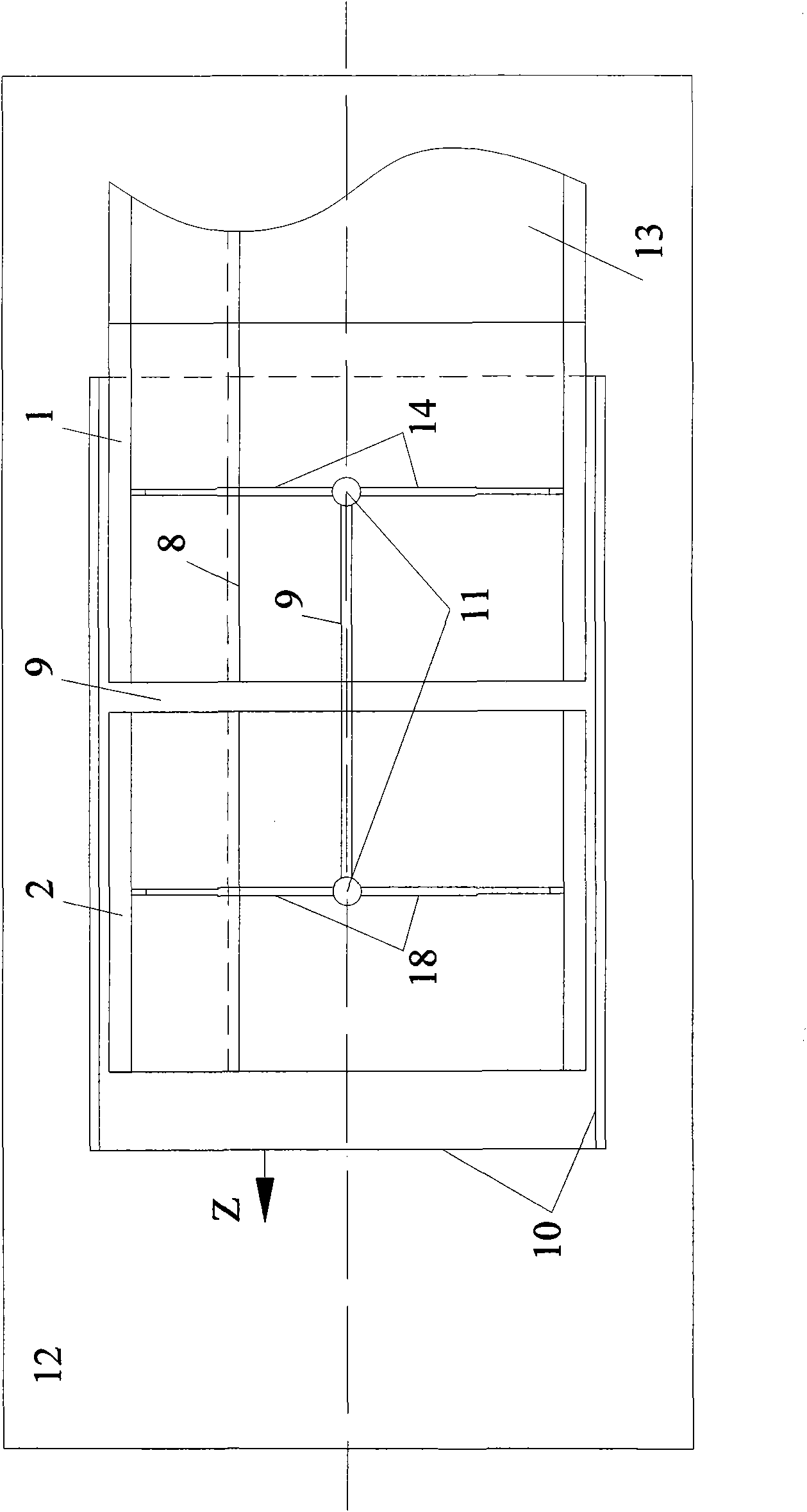

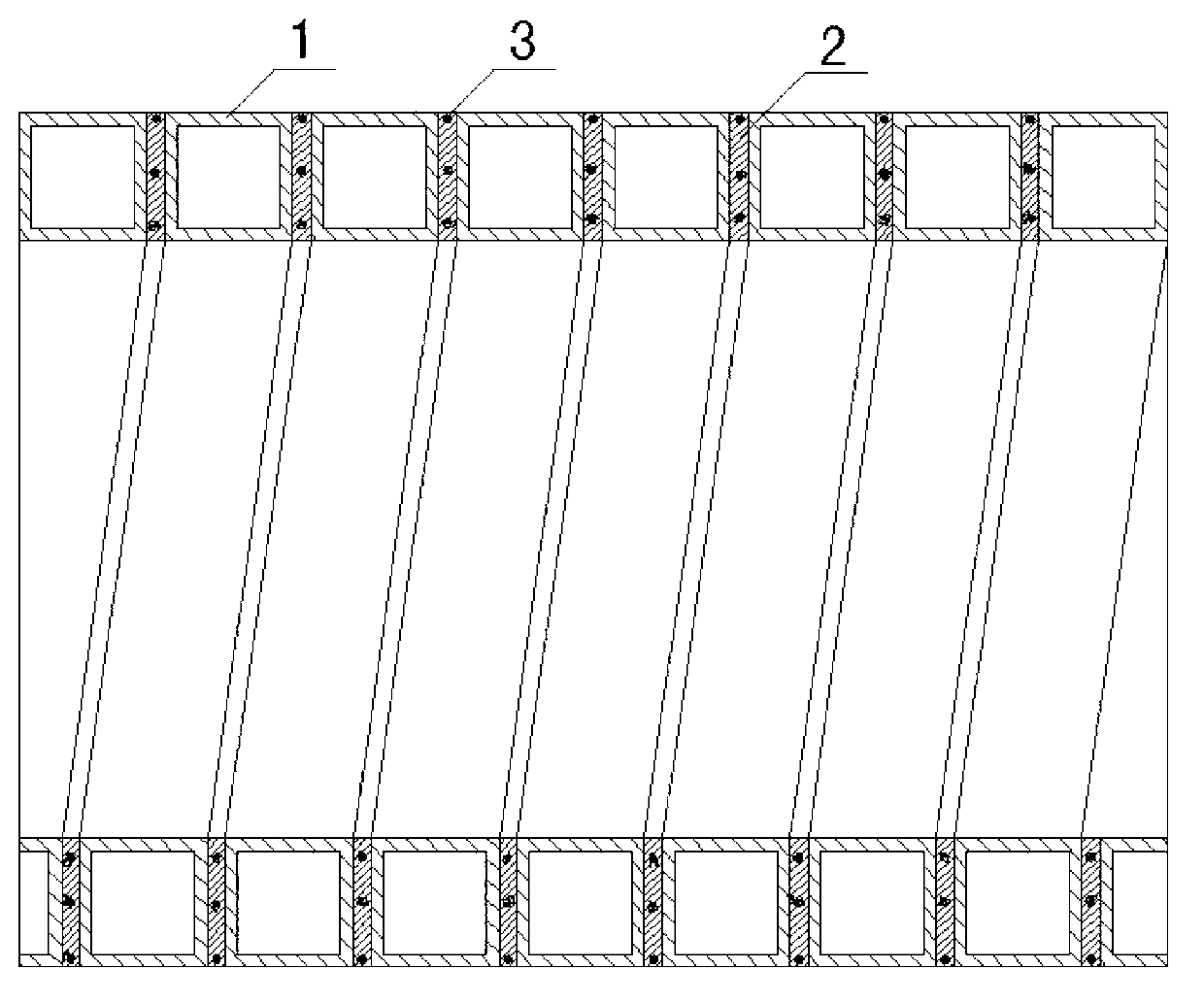

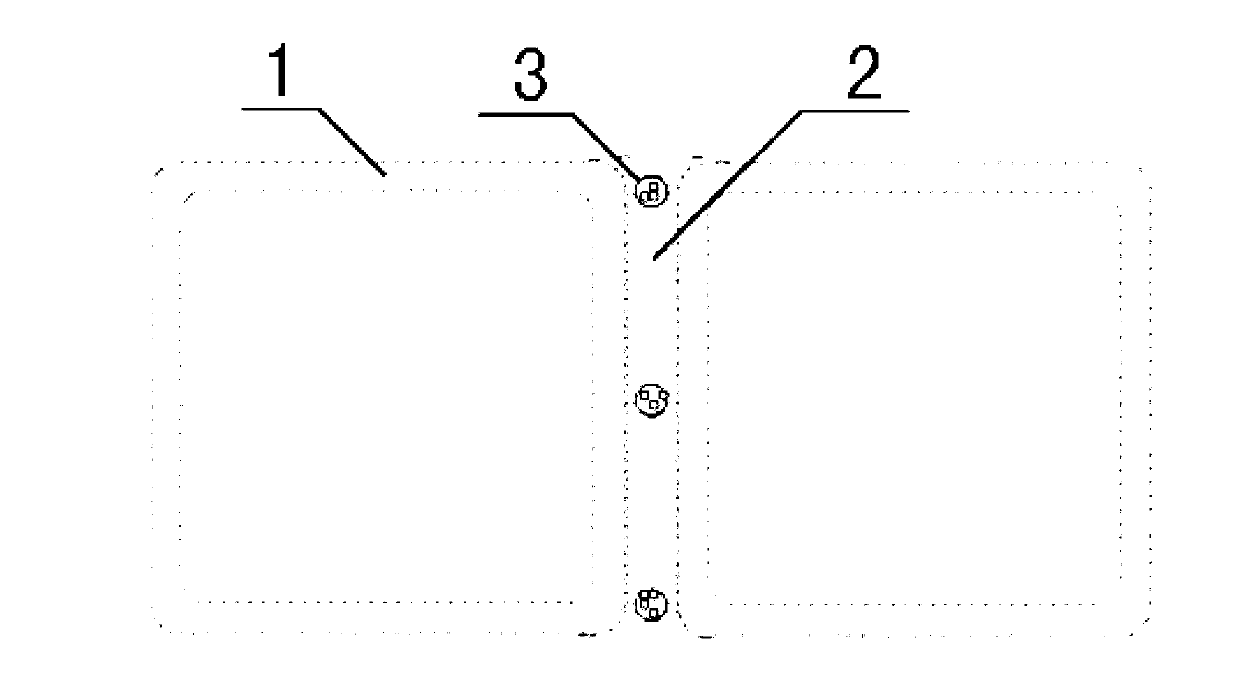

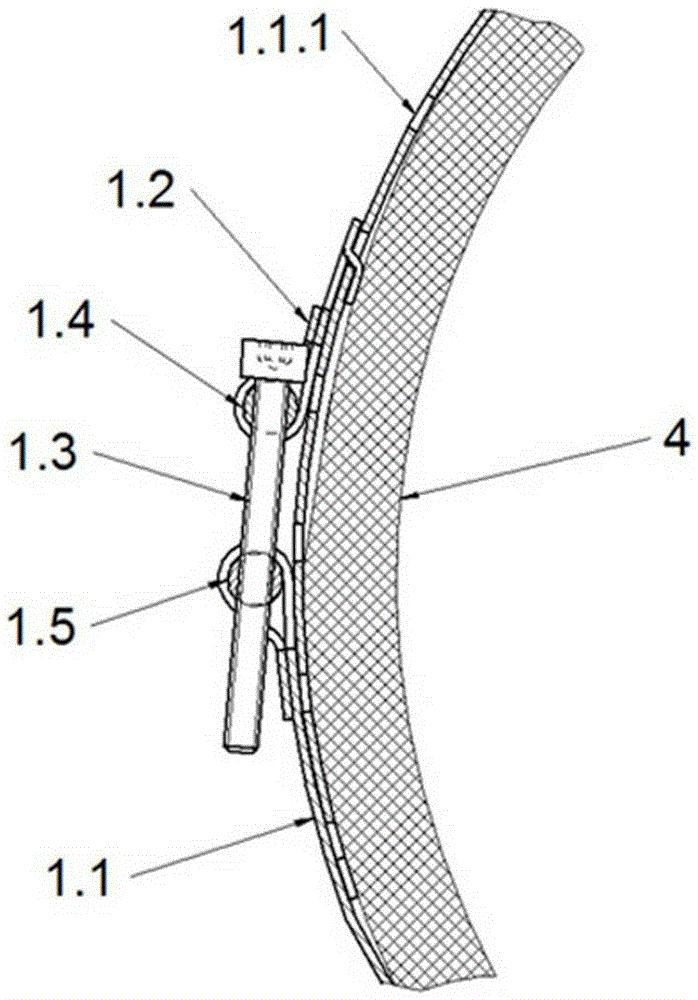

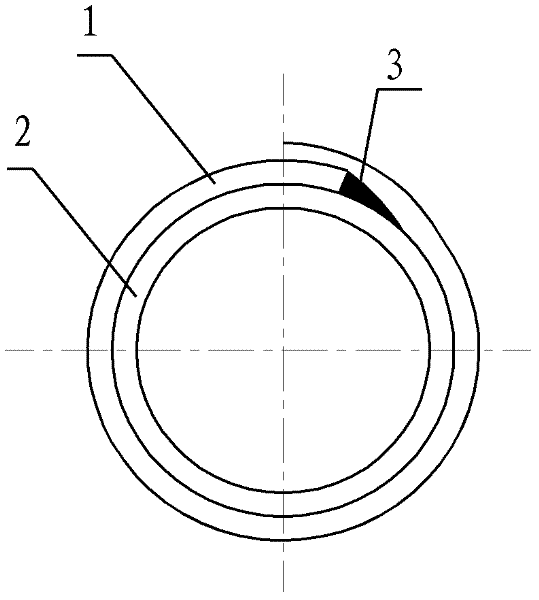

Assembly form and supporting method for in-soil assembled plastic pipes

InactiveCN101592033AShorten the construction periodReduce adverse effectsUnderground chambersTunnel liningPlastic pipeworkSelf driven

The invention discloses an assembly form and a supporting method for in-soil assembled plastic pipes, provides complete technology for supporting after a heading machine moves forward of novel tunnel or channel excavation technology, and belongs to the field of trenchless underground pipe supporting technology. The assembly form and the supporting method comprise the following steps: cutting an integral pipe into a plurality of pipe pieces from a cross section, sequentially carrying the pipe pieces into a sleeve at the rear part of a self-drive heading machine in soil, and assembling the pipe pieces by using foot stand supports; repeating the previous step to complete the assembly of the pipe pieces of a next pipe in a mode of straight joint or break joint and connecting a circumferential joint of the two pipes; and after the self-drive heading machine drives the sleeve to move a certain distance, assembling the follow-up pipes and sequentially forming a supporting channel behind the self-drive heading machine and the rear complete sleeve with the advance of the self-drive heading machine and the rear complete sleeve. The method can realize an emergent turning function which is strongly demanded at present together with the self-drive heading technology and has the advantages of safety, convenience, high efficiency and the like.

Owner:BEIJING UNIV OF TECH

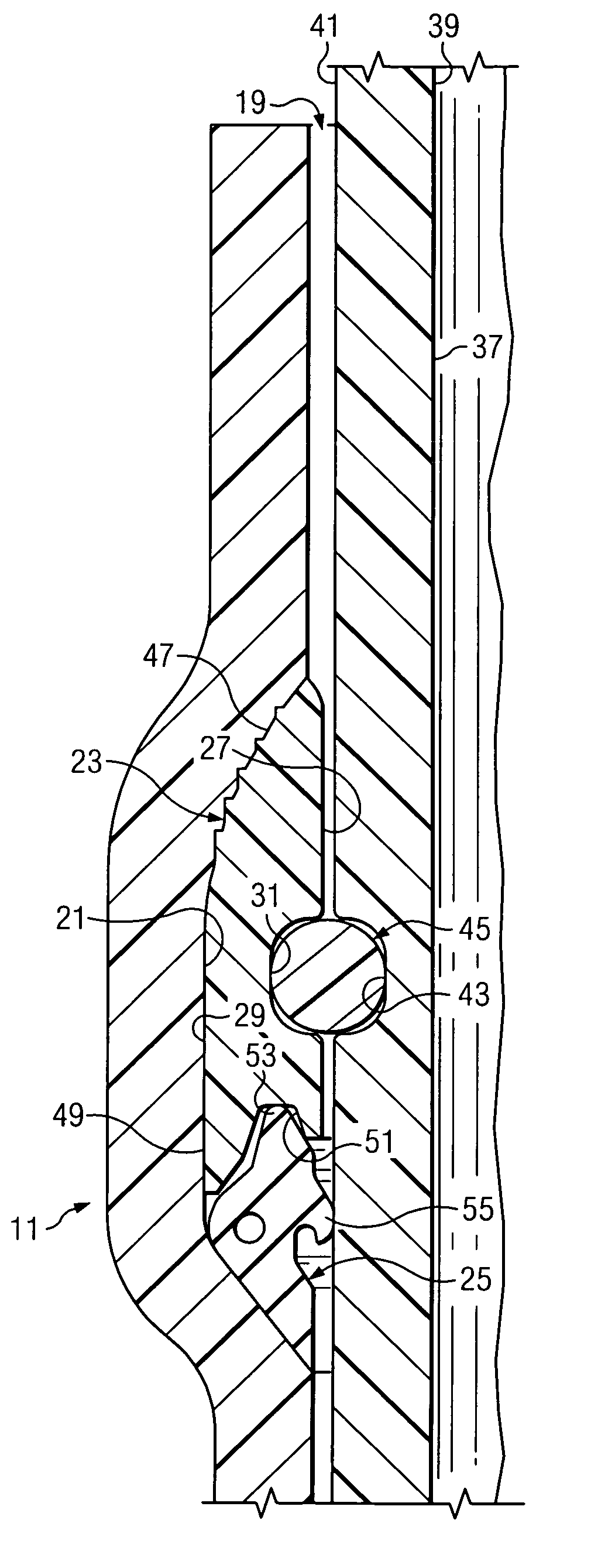

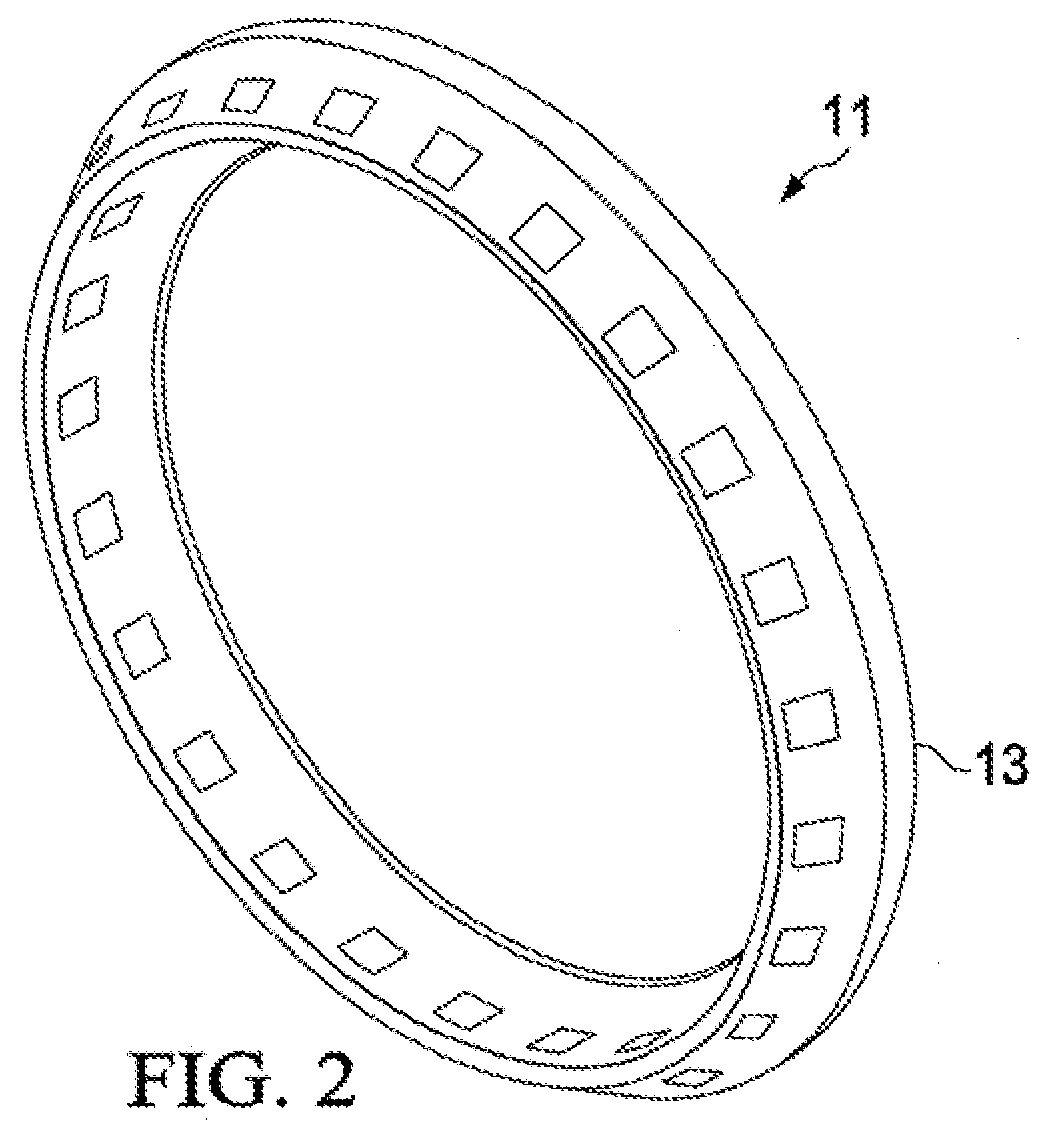

Restrained pipe joining system for plastic pipe

ActiveUS20090152863A1Dimensional precision can be increasedConveniently formedSleeve/socket jointsFluid pressure sealed jointsSpacing toothPlastic pipework

A restrained pipe joining system is shown comprising male and female ends each having aligned circumferential grooves which form a canal for passage of a locking key strap. During manufacture, the female belled end is sequentially formed over a Rieber style gasket and then over a ring shaped casing member having an inner circumferential groove formed on its inner circumferential surface. Preferably, the ring shaped casing has circumferentially spaced teeth that act as a pipe stop in cooperation with an outer circumferential groove on the male spigot to index the pipes to be coupled.

Owner:S & B TECHN PRODS

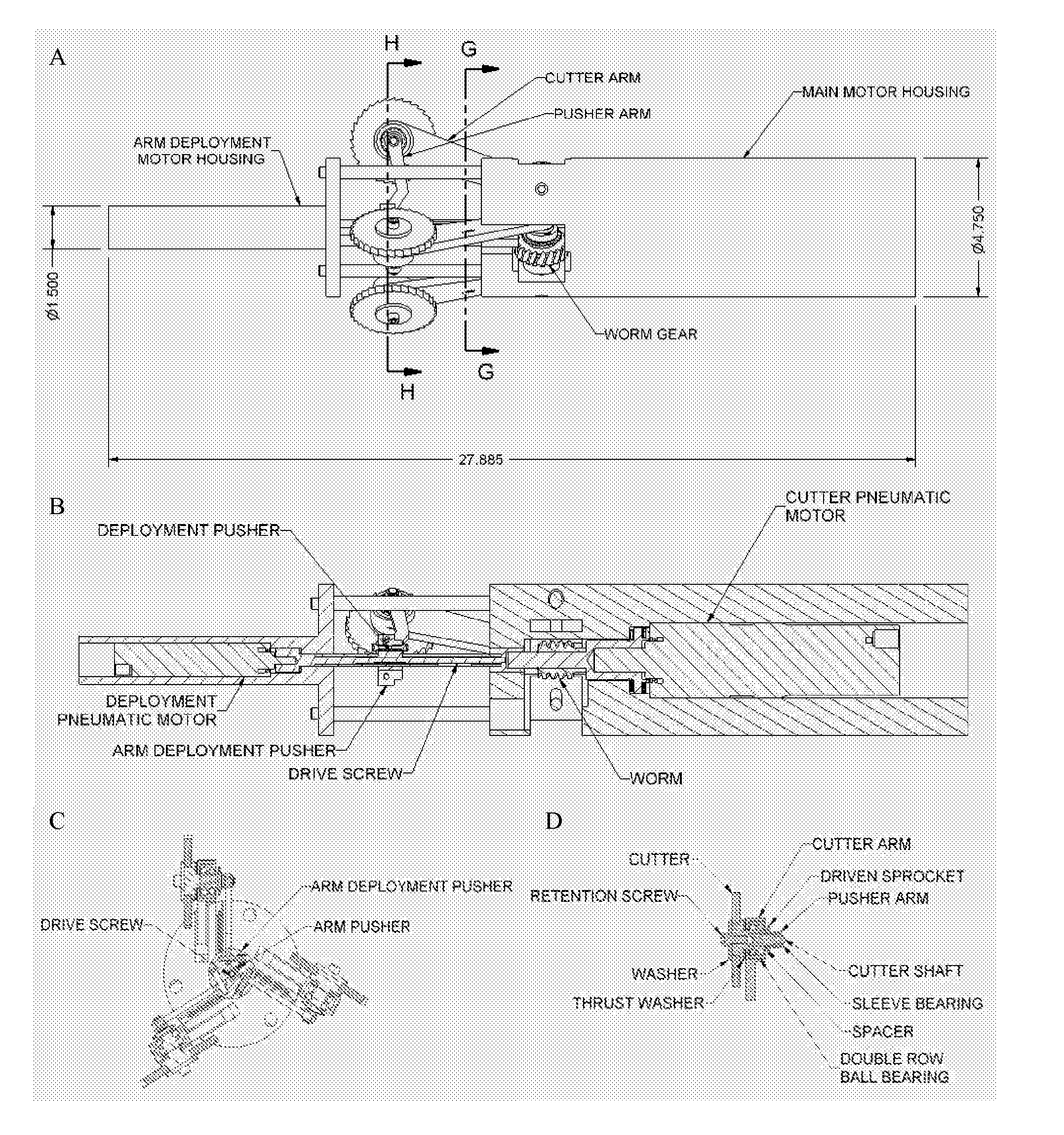

Internal pipe slot tool

An apparatus and method to internally cut vertical slots inside PVC, HDPE, or plastic pipe-riser (blank casing) in existing methane gas recovery wells (extraction wells) that have been installed at Municipal Solid Waste Facilities are described. Vertical slots cut in methane well risers allow methane gas, LFG derived from the decomposition of waste, to enter the existing riser and extraction system. This process saves time and cost associated with drilling additional wells to retrieve methane gas from subsequent layers of the waste body. The process assists in maintaining regulatory compliance by capturing LFG and preventing it from being emitted into the atmosphere.

Owner:PROSPECTOR DRILLING & TOOL

Process for manufacturing septic tank by using glass fibre reinforced plastic

InactiveCN102371685ASatisfy tightnessFulfil requirementsBiological sludge treatmentGlass fiberWater leakage

The invention discloses a process for manufacturing a septic tank by using glass fibre reinforced plastic, relating to a method for manufacturing a composite formed septic tank, belonging to the technical field of glass fibre reinforced plastic pipeline manufacturing. The invention aims to provide a composite formed glass fibre reinforced plastic pipeline, which is low in production cost, free from water leakage, long in service life, light in weight and low in liquid conveying resistance, and a production process thereof. The process has the benefits that: glass fibre taking resin as a basic body is wound on a bushing with a manufactured core mould one by one in three different manners according to process requirements; the glass fibre has corrosion resistance, aging resistance and insulating property; a pipe wall structure is rational and advanced; the action of materials is sufficiently played; the stiffness of a product is increased; the stability and the reliability of the production are ensured; the appearance quality is good; the production cost is reduced; the production process is simplified; the production difficulty is reduced; the production benefit is increased; by using the composite forming process in the invention, the designability of the product is strong; and the comprehensive property of the product is good.

Owner:民勤县威瑞环保有限责任公司

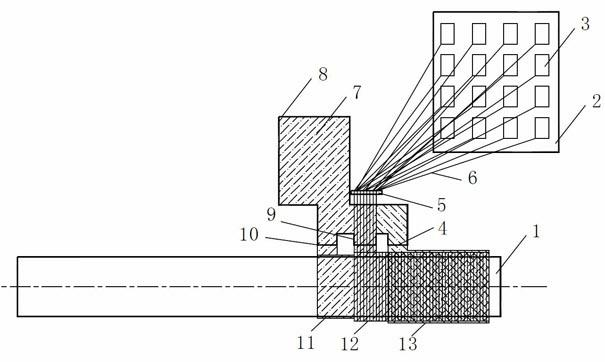

Glass fiber reinforced polyethylene hollow-wall winding pipe and manufacturing method thereof

A glass fiber reinforced polyethylene hollow-wall winding pipe is formed by spirally winding rectangular hollow polyethylene plastic pipes, welding the plastic pipes through a hot melt adhesive and synchronously winding at least one PP (Propene Polymer) / PE (Polyethylene) coated composite long glass fiber bundle, and the PP / PE coated composite long glass fiber bundle and the hot melt adhesive are bonded between two adjacent rectangular hollow polyethylene plastic pipes. Compared with pipes in the same specification and type as the pipe produced in the invention, the weight per meter is reduced by 20-30 percent, so that the manufacturing cost is greatly reduced. The production method provided by the invention enables glass fibers to be better embedded in the polyethylene pipe, is more suitable for producing large-caliber high-ring-stiffness plastic ducts (DN is 1500 and more and SN can be more than 16KN / m<2>), can produce pipes which have the specification of higher ring stiffness and are suitable for being used in environments such as runways, train tracks and the like, demanding more on the pipes, and enriches the production method for high-ring-stiffness plastic pipes.

Owner:SHANGHAI QINGYUAN PIPE TECH

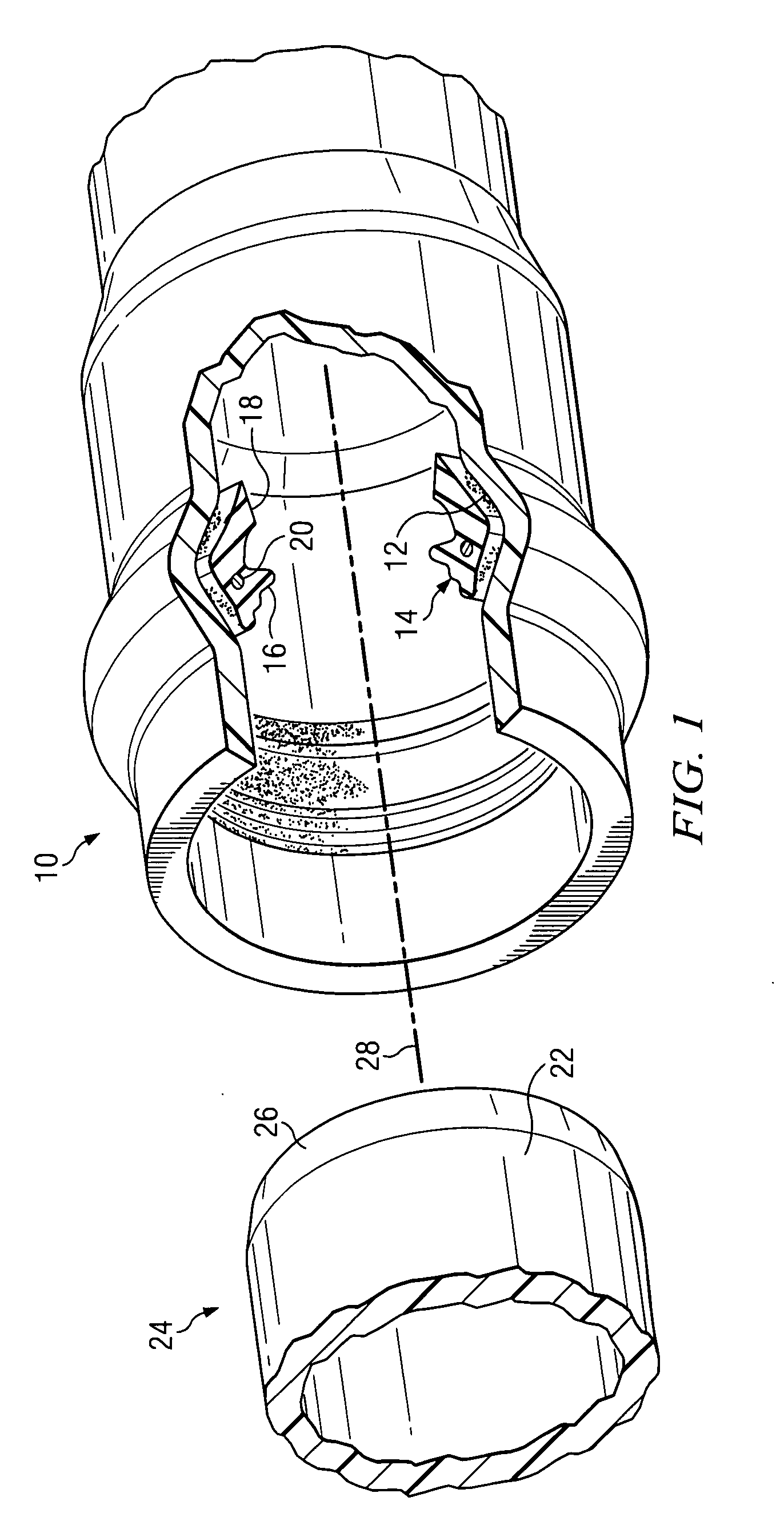

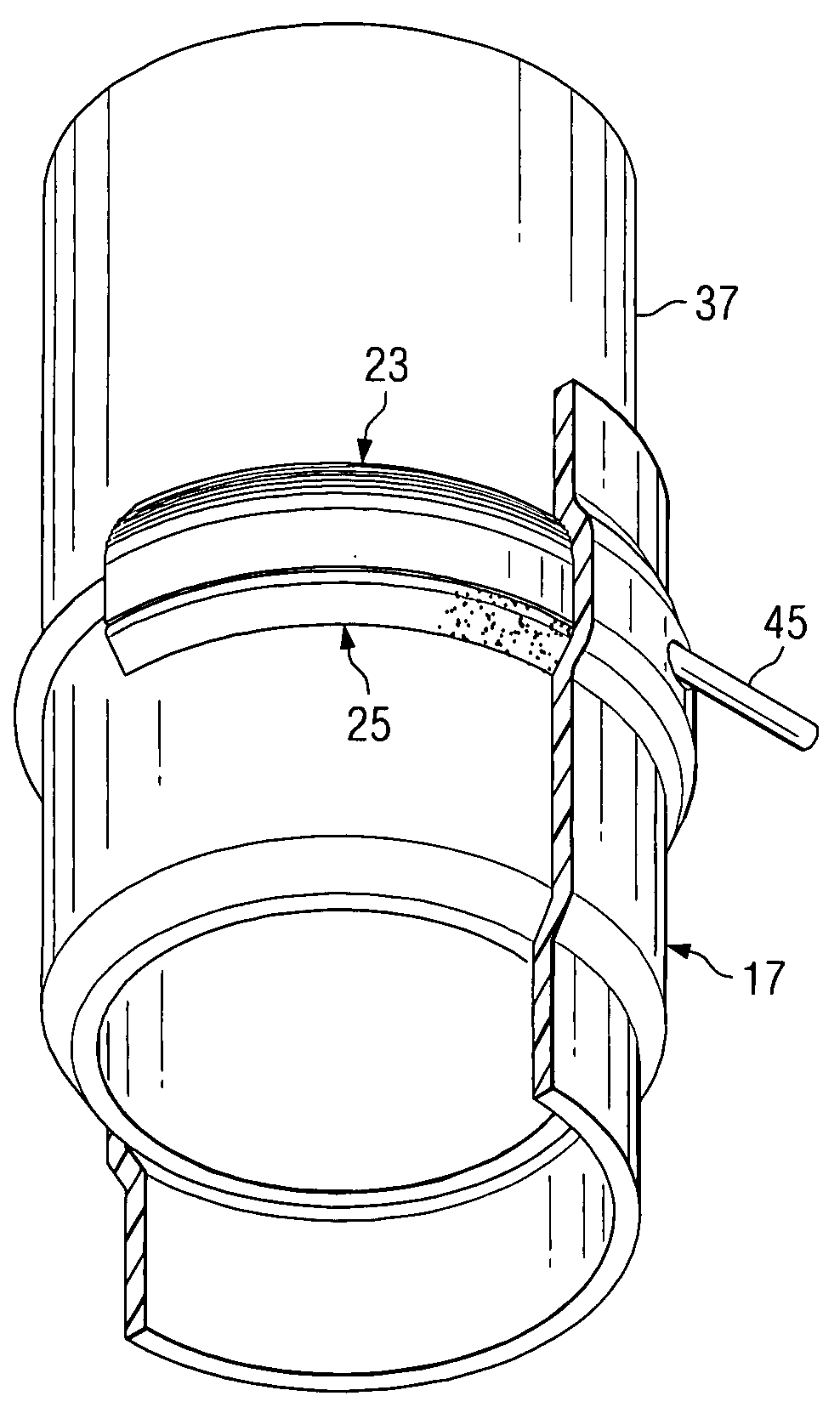

Restrained pipe joining system for plastic pipe

ActiveUS7845686B2Conveniently formedSleeve/socket jointsFluid pressure sealed jointsSpacing toothPlastic pipework

A restrained pipe joining system is shown comprising male and female ends each having aligned circumferential grooves which form a canal for passage of a locking key strap. During manufacture, the female belled end is sequentially formed over a Rieber style gasket and then over a ring shaped casing member having an inner circumferential groove formed on its inner circumferential surface. Preferably, the ring shaped casing has circumferentially spaced teeth that act as a pipe stop in cooperation with an outer circumferential groove on the male spigot to index the pipes to be coupled.

Owner:S & B TECHN PRODS

Plastic pipe cutting device

InactiveUS7089668B1Easy and efficient to manufactureLower sales priceTube shearing machinesTurning machinesRaspPlastic pipework

A plastic pipe cutting device for both cutting and filing a plastic pipe has a semi-circular top sleeve and bottom sleeve. A top guide track is connected to the top sleeve and a bottom guide track is connected to the bottom sleeve. The top guide track and the bottom guide track are continuous upon closing the device. A guide roller is rotatably connected to the roller housing and is capable of rolling upon the top and bottom guide track. A blade is connected to the roller housing for cutting a plastic pipe. A rasp is connected to the roller housing for filing the end of a plastic pipe.

Owner:WHITEHEAD STEVEN

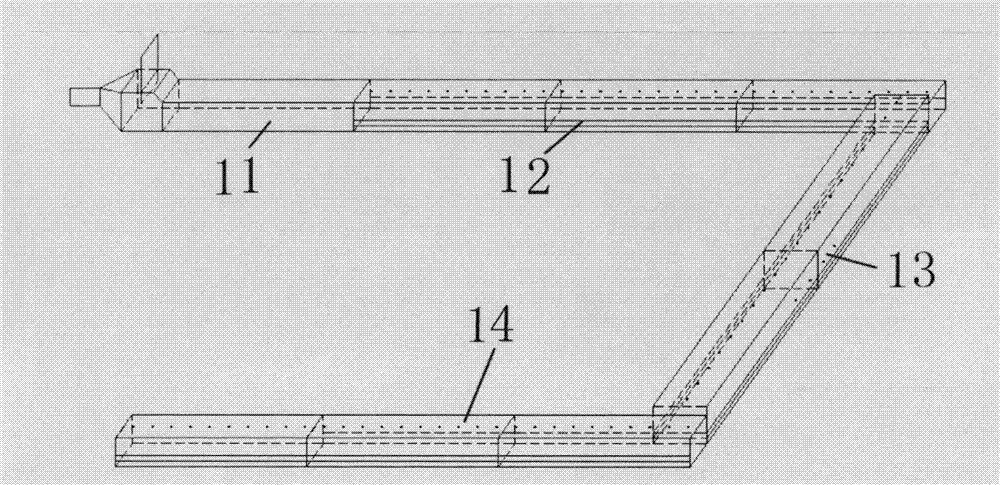

Adjustable working face dust simulation experiment device

InactiveCN103089287AEasy to adjustSave money on experimentsTunnel/mines ventillationPlastic pipeworkEngineering

The invention discloses an adjustable working face dust simulation experiment device. The adjustable working face dust simulation experiment device comprises an air source area, an air inlet way, a working face and an air return way which are sequentially connected with one another, wherein the air inlet way, the working face and the air return way are splicing square plastic pipelines, the air source area comprises a small fan, a baffle board and an air source pipeline, the small fan is in seal connection with a wild opening of the air source area, the baffle board which can be vertically adjusted is arranged in the middle above the wide-opening pipeline to control air forces, and a plurality of small equidistant circular holes are arranged at the tops of pipelines of the working face, the air inlet way and the air return way.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

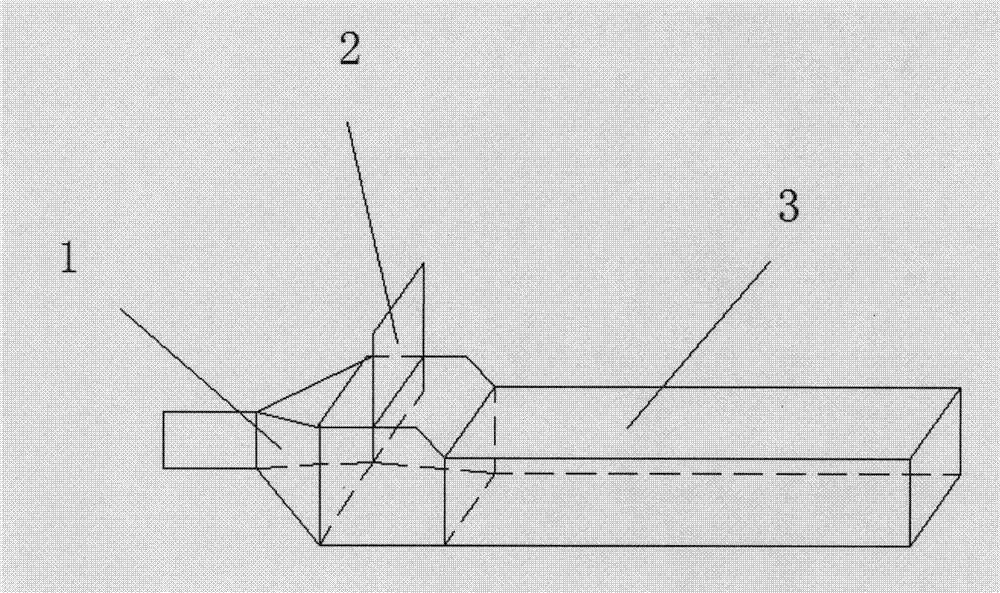

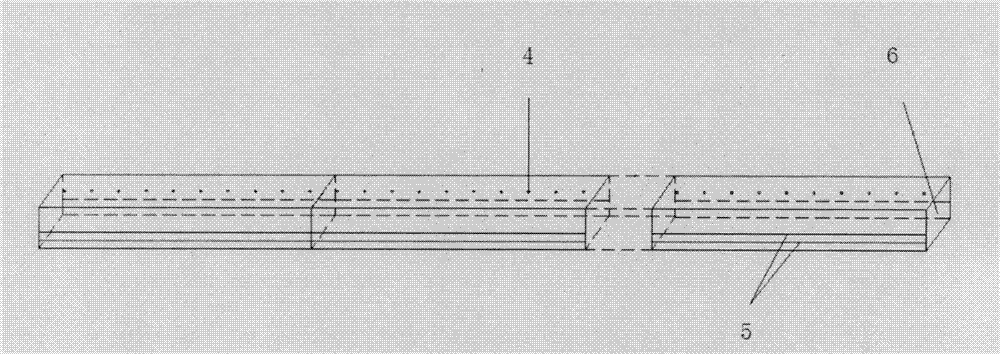

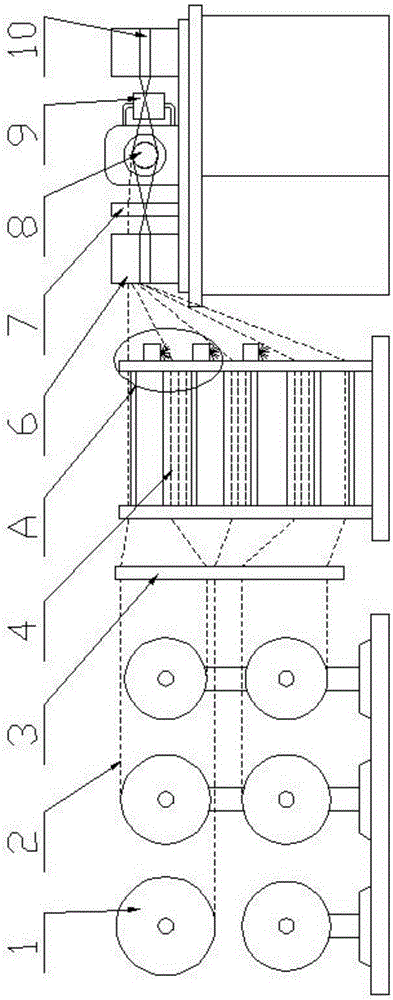

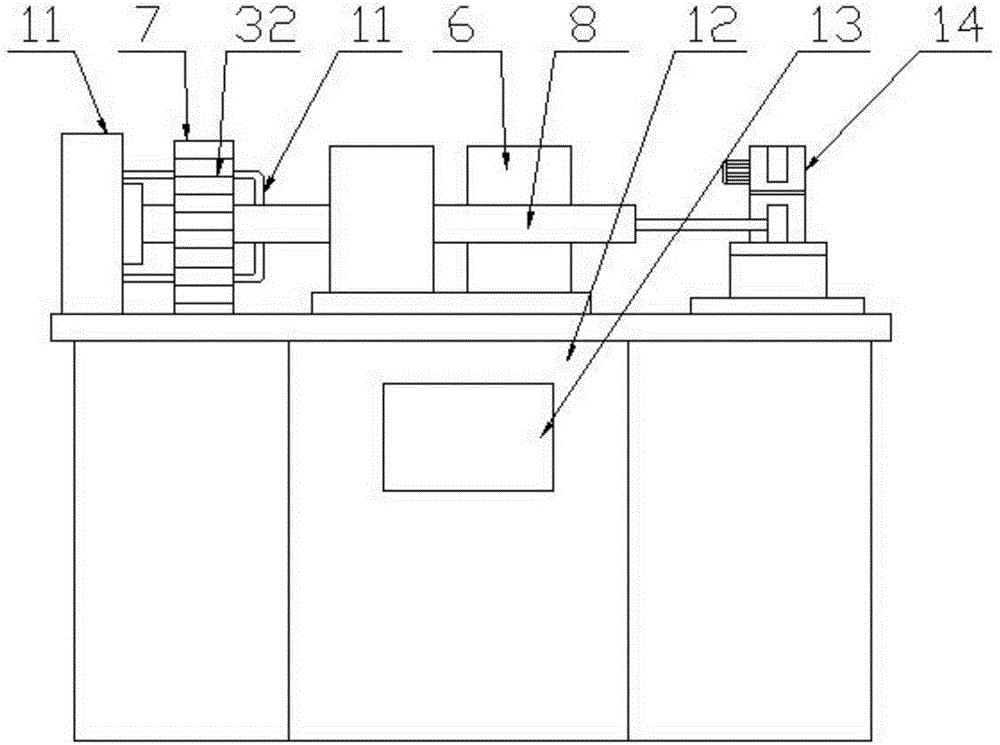

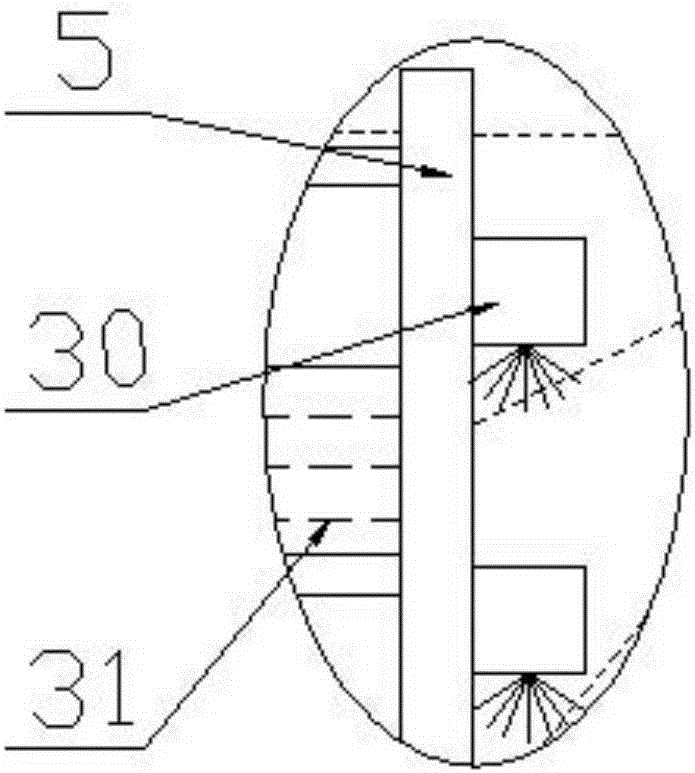

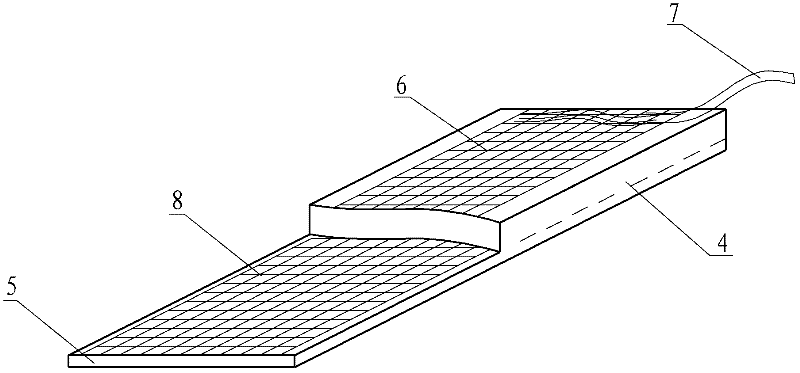

Continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines

ActiveCN105216340AEfficient productionContinuous compaction productivityTubular articlesProduction linePlastic pipework

The invention provides a continuous densification and efficient production line and technology of fiber-reinforced thermosetting plastic pipelines, and belongs to the field of fiber-reinforced thermosetting plastic pipeline manufacturing. After being innovatively improved, a paper tube machine production line is applied to the production field of the fiber-reinforced thermosetting plastic pipelines, the improved paper tube machine production line is sequentially provided with strip frames, a coating device, a curing agent applying device, hollow partition plates and a spiral paper tube machine refit device in the paper tube moving direction. Cylindrical dies transversely arranged above a rack are improved on the basis of an existing spiral paper tube machine, pressure perpendicular to the die direction and thrusting force parallel to the die direction are exerted on film strips wrapping the dies and impregnated and pre-cured fiber strips through a conveying belt, layer-by-layer densification and continuous efficient production are achieved, and the production efficiency is greatly improved. The produced pipelines have the beneficial effects of resisting pressure, being good in impact resistance and rigidity, resisting to corrosion and the like.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

Removable duct liner

InactiveUS20060070521A1Lighting and heating apparatusIsotope separationPlastic pipeworkPorous polymer membrane

The invention relates to liners for air ducts. Specifically, the invention is an article comprising a porous polymeric membrane layer and, optionally, a support layer, in which the article is a duct liner adapted to be removably positioned within a porous air duct. The liner may also be used in conventional metal and plastic ducts to reduce cleaning frequency. In another aspect, the invention is a porous air duct comprising: a liner comprising a porous polymeric membrane and, optionally, a support layer; and an openwork conduit, said liner disposed within the openwork conduit.

Owner:WL GORE & ASSOC INC

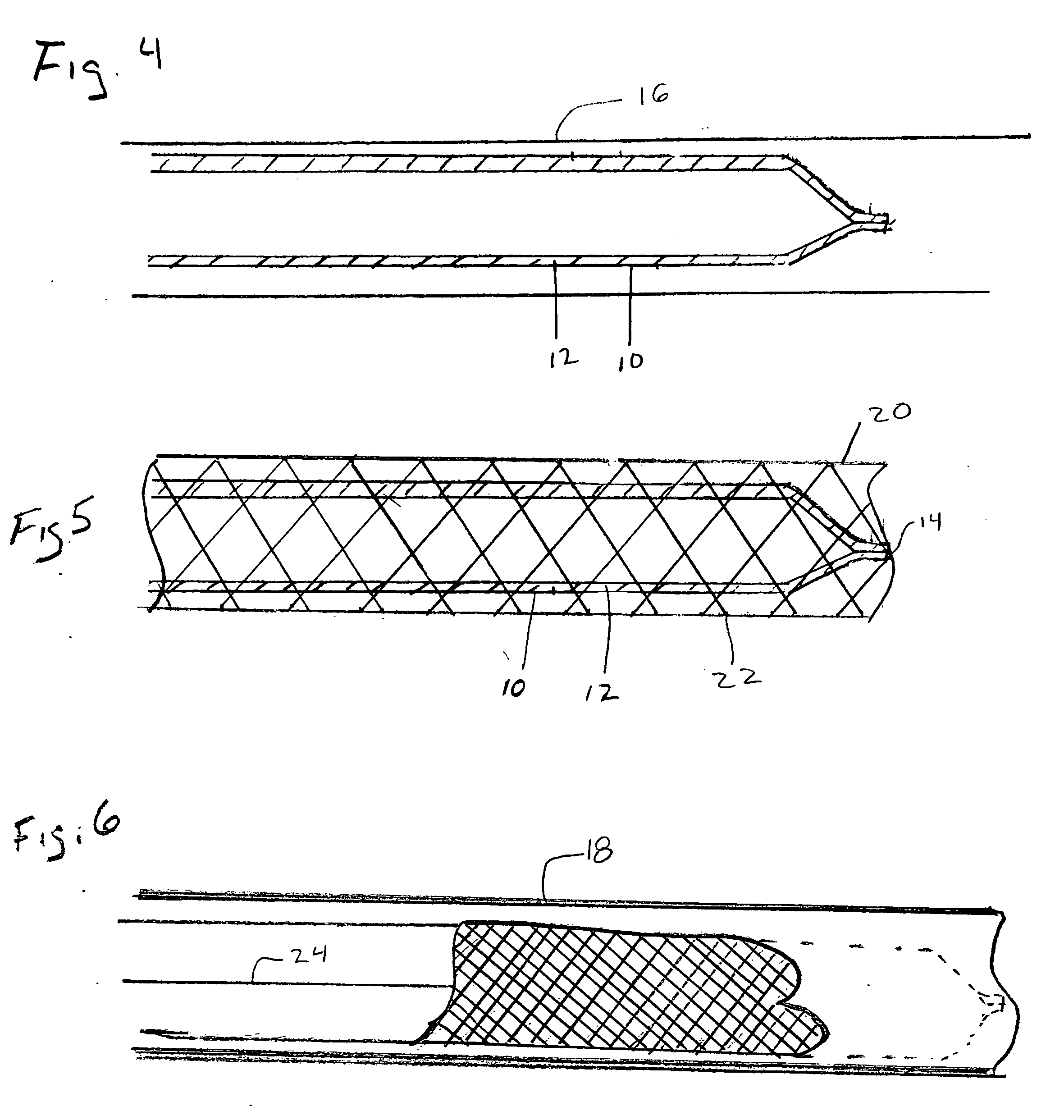

Plastic pipe machined by using bulk molding compounds

The invention relates to a plastic pipeline prepared by using bulk molding compounds. The plastic pipeline comprises the following materials in part by weight: 30-50 parts of unsaturated polyester, 0.3-0.5 part of cobalt naphthenate, 0.2-0.4 part of methyl ethyl ketone peroxide, 25-35 parts of reinforced fibers, 30-40 parts of calcium carbonate, 0.2-0.3 part of anti-static agent, 0.1-0.15 part of antioxidant and 0.2-0.3 part of pentabromo-phenol. According to the invention, the prepared unsaturated polyester fiber reinforced bulk molding compounds have the advantages of high toughness and high strength; the impact strength of the unsaturated polyester fiber reinforced bulk molding compounds is 150 kJ / m<2>, the bending strength of the unsaturated polyester fiber reinforced bulk molding compounds is 180 MPa, and the tensile strength of the unsaturated polyester fiber reinforced bulk molding compounds is 90 MPa. Through adoption of the prepared plastic pipeline, difficult problems in the prior art that the mechanical performance of the plastic material is lower and the prepared plastic pipeline, in particular a large-sized plastic pipeline, is hardly popularized and utilized in practice are solved. The plastic pipeline provided by the invention has the advantages of acid and alkali resistance, anti-corrosion property, low cost and good application prospect in the practice.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

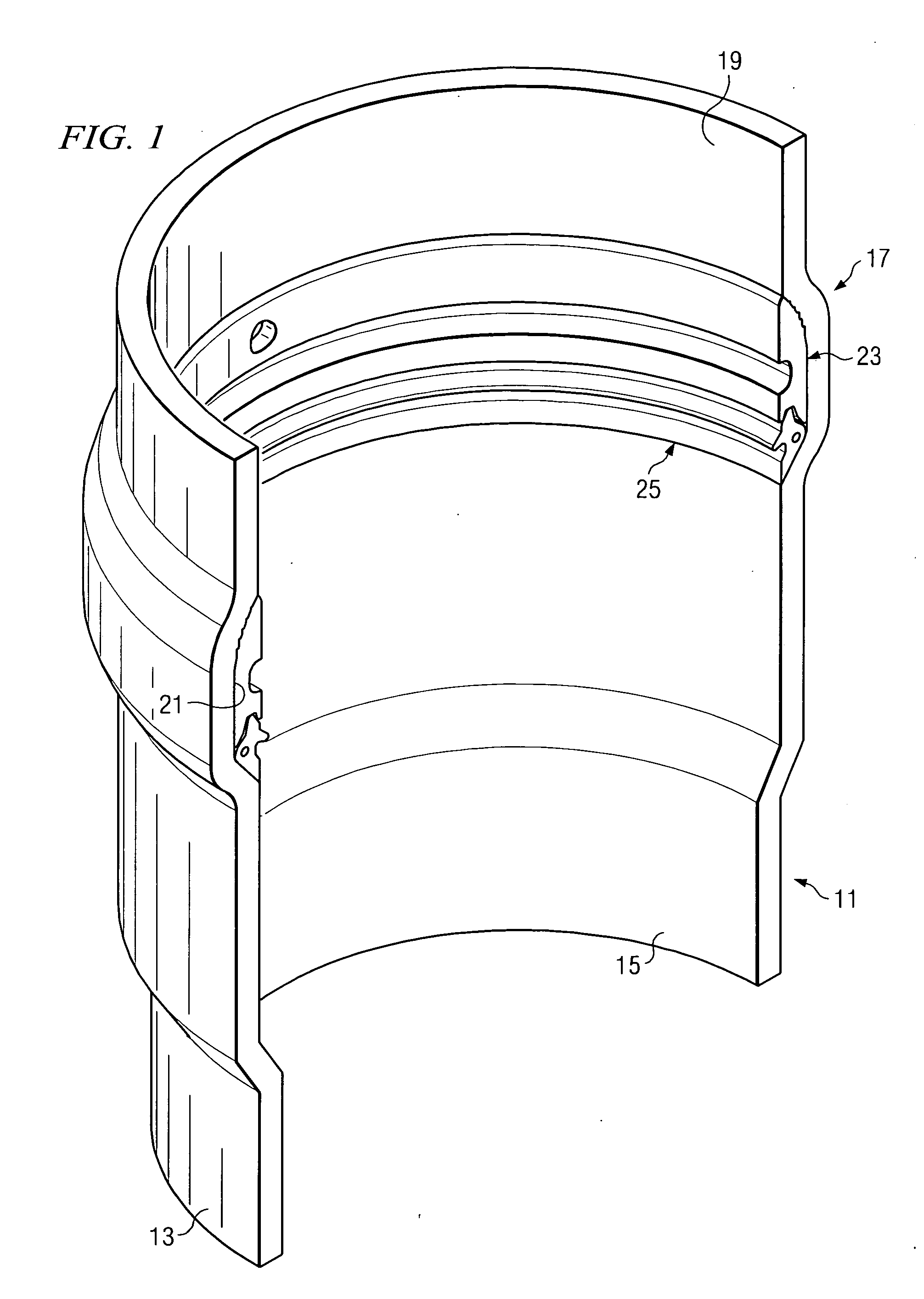

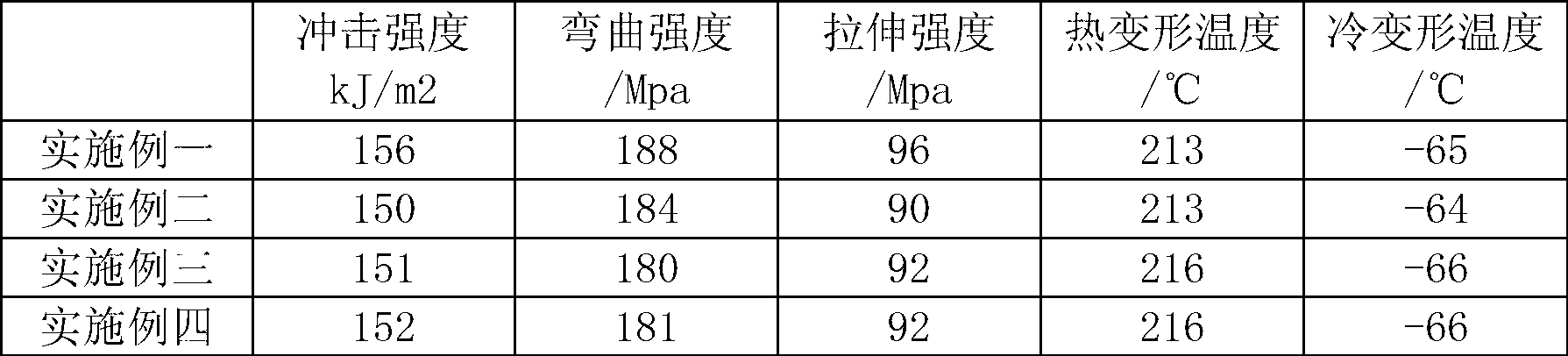

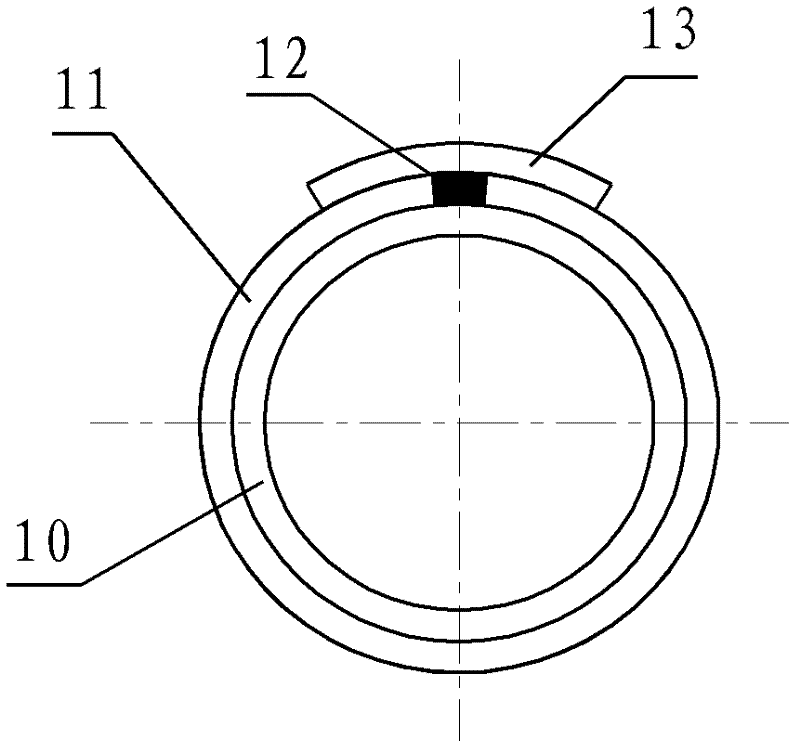

Sealing Gasket with Corrugated Insert for Sealing Restrained or Non-Restrained Plastic Pipelines

ActiveUS20180094754A1Create possibilityAvoid squeezingSleeve/socket jointsEngine sealsPlastic pipeworkEngineering

A pipe sealing gasket is shown which is designed to be received within a raceway provided within a socket end of a female bell plastic pipe end which is assembled with a mating male spigot pipe end to form a plastic pipe joint. The raceway in the female bell plastic pipe end is preformed during manufacture and the gasket is installed thereafter. The gasket has a rubber body portion which is reinforced by a hard corrugated ring-shaped insert. The hard corrugated ring-shaped insert acts to prevent extrusion of the gasket during a variety of pressure conditions as well as preventing displacement during field assembly.

Owner:S & B TECHN PRODS

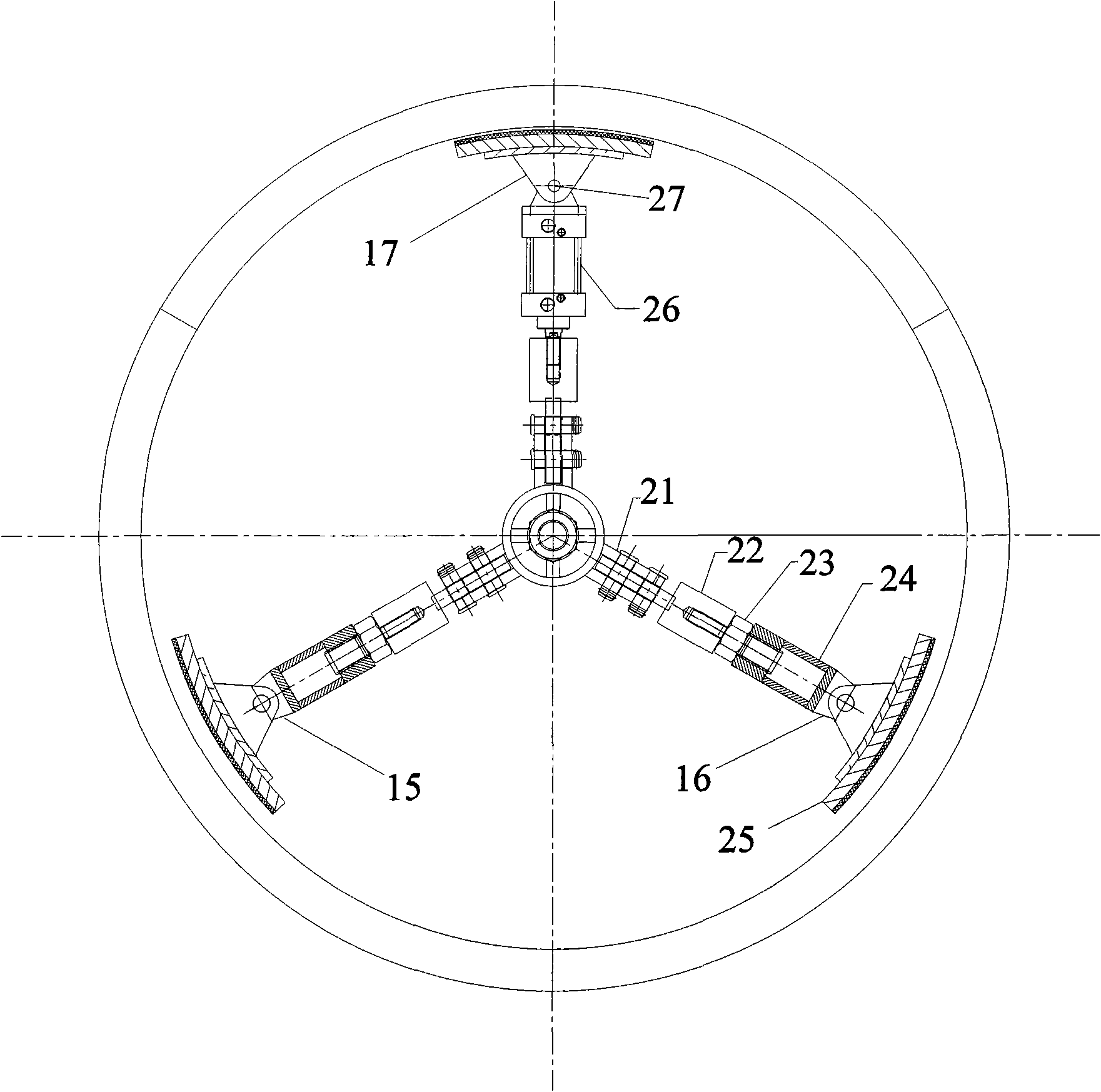

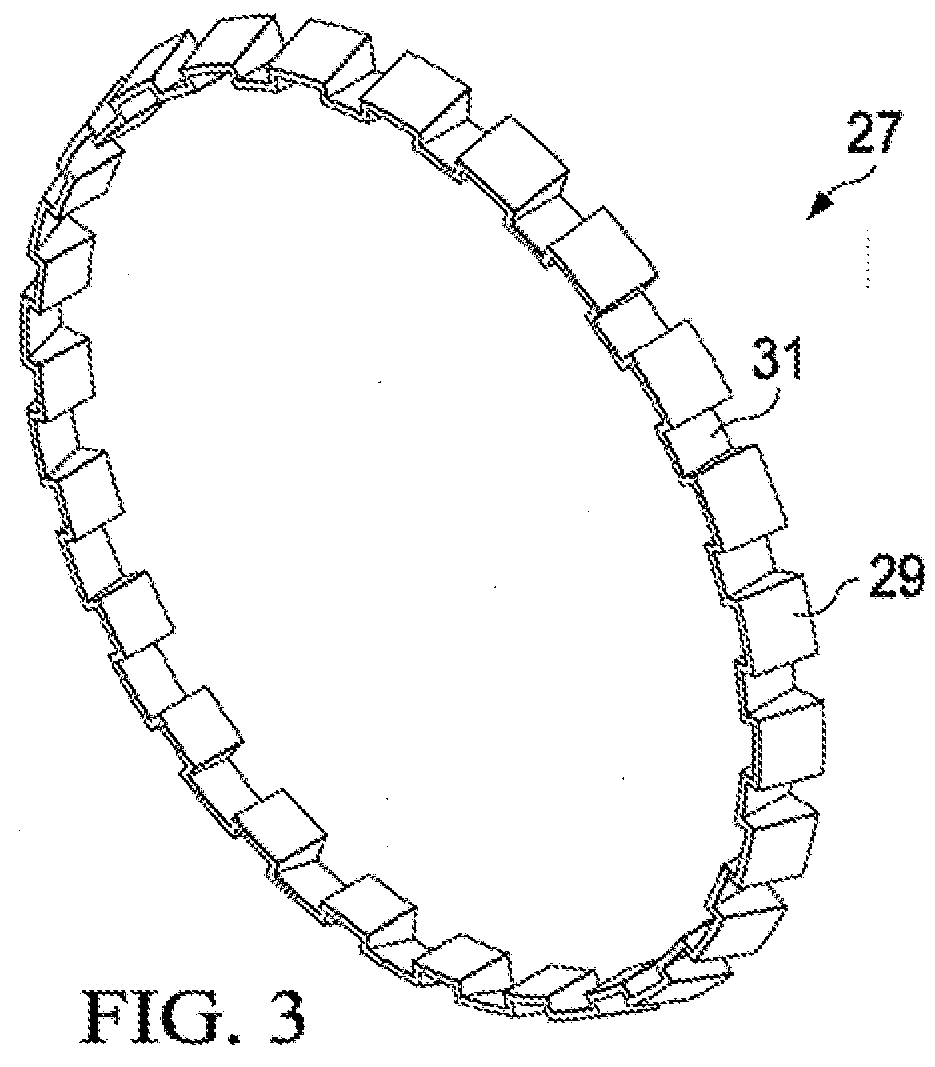

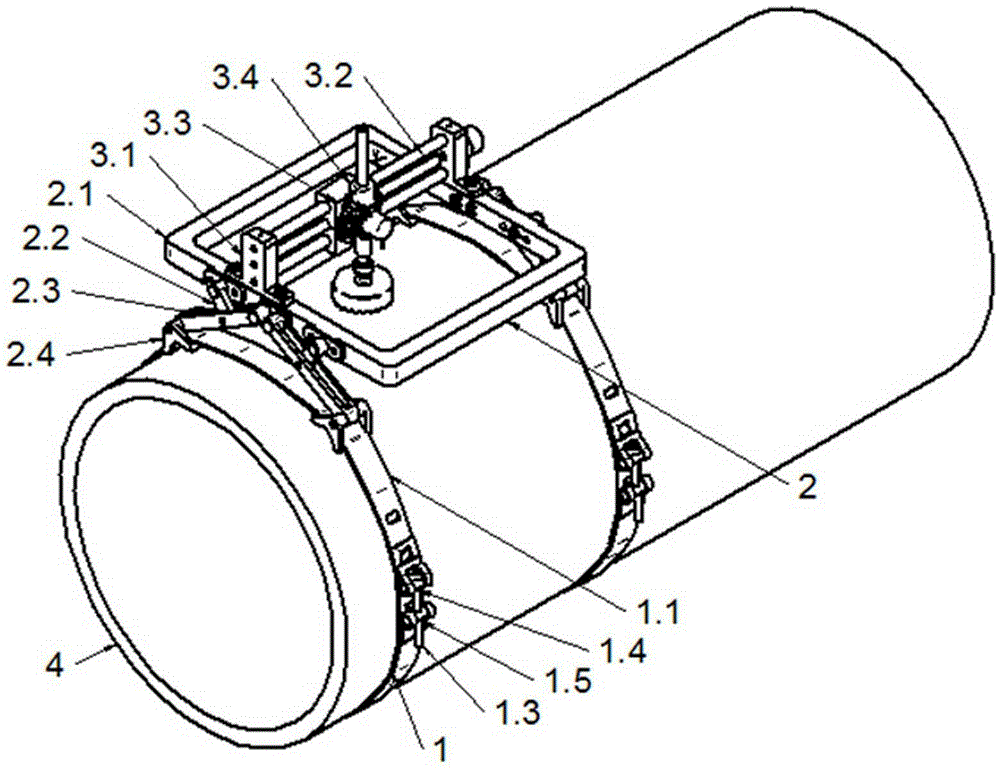

Large-caliber plastic pipeline trepanning equipment

InactiveCN105291185AFlexible angle adjustmentFlexible adjustment of hole sizeMetal working apparatusPlastic pipeworkStructural engineering

The invention provides large-caliber plastic pipeline trepanning equipment which comprises a pair of clamping devices, a supporting device and a trepanning device. The trepanning device is fixed to the supporting device. The clamping devices penetrate the supporting device and make the supporting device fixed to the outer wall of a pipeline. On the premise that no extra equipment is additionally arranged, the requirements of plastic pipelines of various specifications for trepanning construction can be met, the trepanning angle and the trepanning size of the equipment can be flexibly adjusted on the site, and adaptability is high; in the equipment trepanning operation process, rigidity is good, the trepanned shape of the pipeline is regular, the trepanning accuracy of the pipeline is high, and complex manual grinding operation is avoided; the contact faces between the clamping devices and the outer wall of the pipeline are large, so that damage caused by construction to the outer surface of the pipeline is small; and the overall trepanning operation is convenient and fast, labor intensity is relieved, and work efficiency is improved.

Owner:山东海丽管道科技有限公司

Reinforced electric hot melting belt and connecting structure and method thereof for connecting reinforced plastic electric hot melting belt with plastic pipeline

The invention relates to a screen mesh or metal hole plate-reinforced plastic electric hot melting belt used for connecting a plastic pipeline. The screen mesh or metal hole plate-reinforced plastic electric hot melting belt comprises a thermoplastic plastic plate belt, wherein a conductive metal net is pressed and embedded on a plate surface at one side of the plastic plate belt; two ends of the metal net in a length direction are provided with outgoing wire electrodes connected with the metal net; and at least one layer of reinforced screen mesh or metal hole plate is compounded in the plastic plate belt. A connecting structure for connecting the plastic pipeline with the electric hot melting belt comprises a coating electric hot melting belt, filling solders and a lapping electric hot melting belt, wherein the coating electric hot melting belt is coated and fusion-welded on the outer wall surfaces of two connected pipe end connecting areas in a manner of two-end butting or is adhered and fusion-welded on the inner wall surfaces of two connected pipe end connecting areas, and a gap suitable for welding is arranged at an abutting joint; the filling solders are used for welding and filling the gap of the abutting joint of the coating electric hot melting belt; and the lapping electric hot melting belt is used for fusion-welding a surface area of the abutting joint of the coating electric hot melting belt. A connecting method for connecting the plastic pipeline is comprised in the invention.

Owner:EZHOU XINGXIN BUILDING MATERIALS

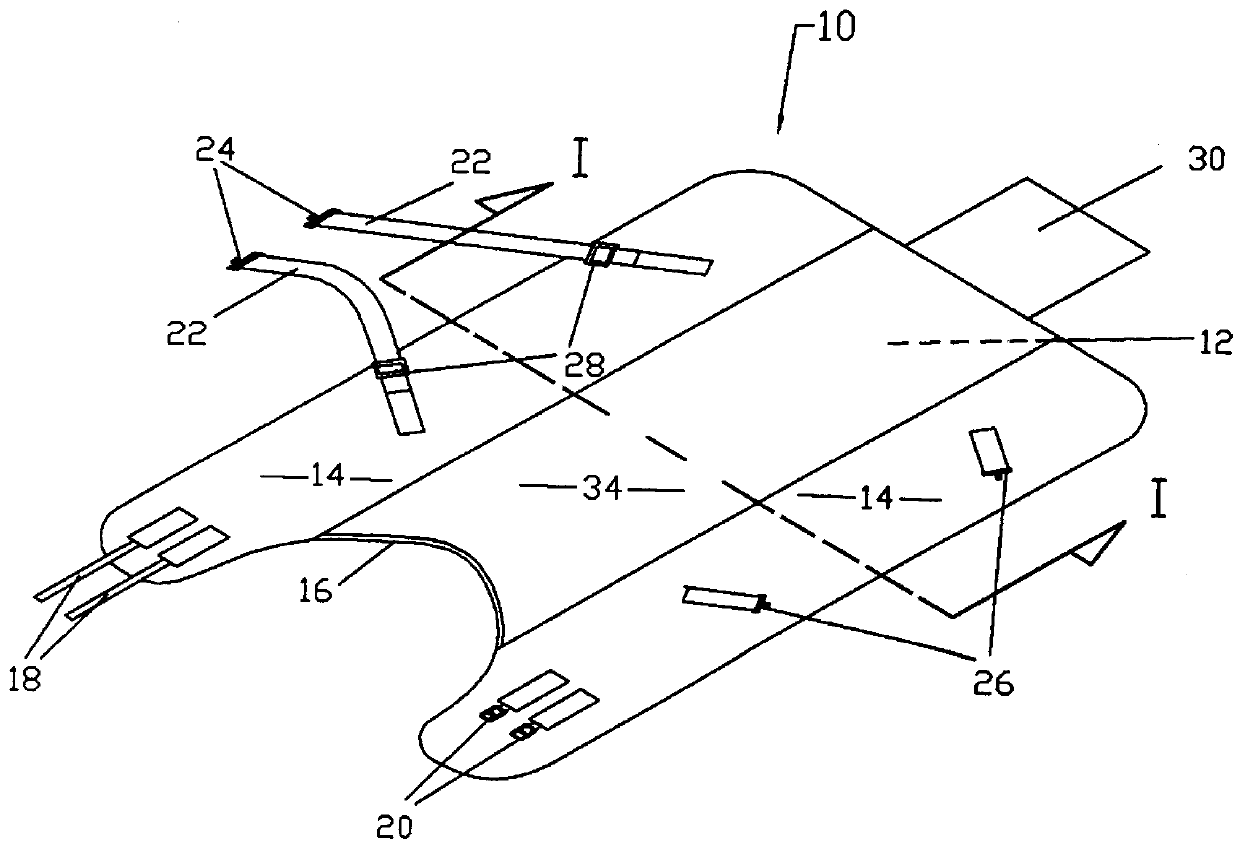

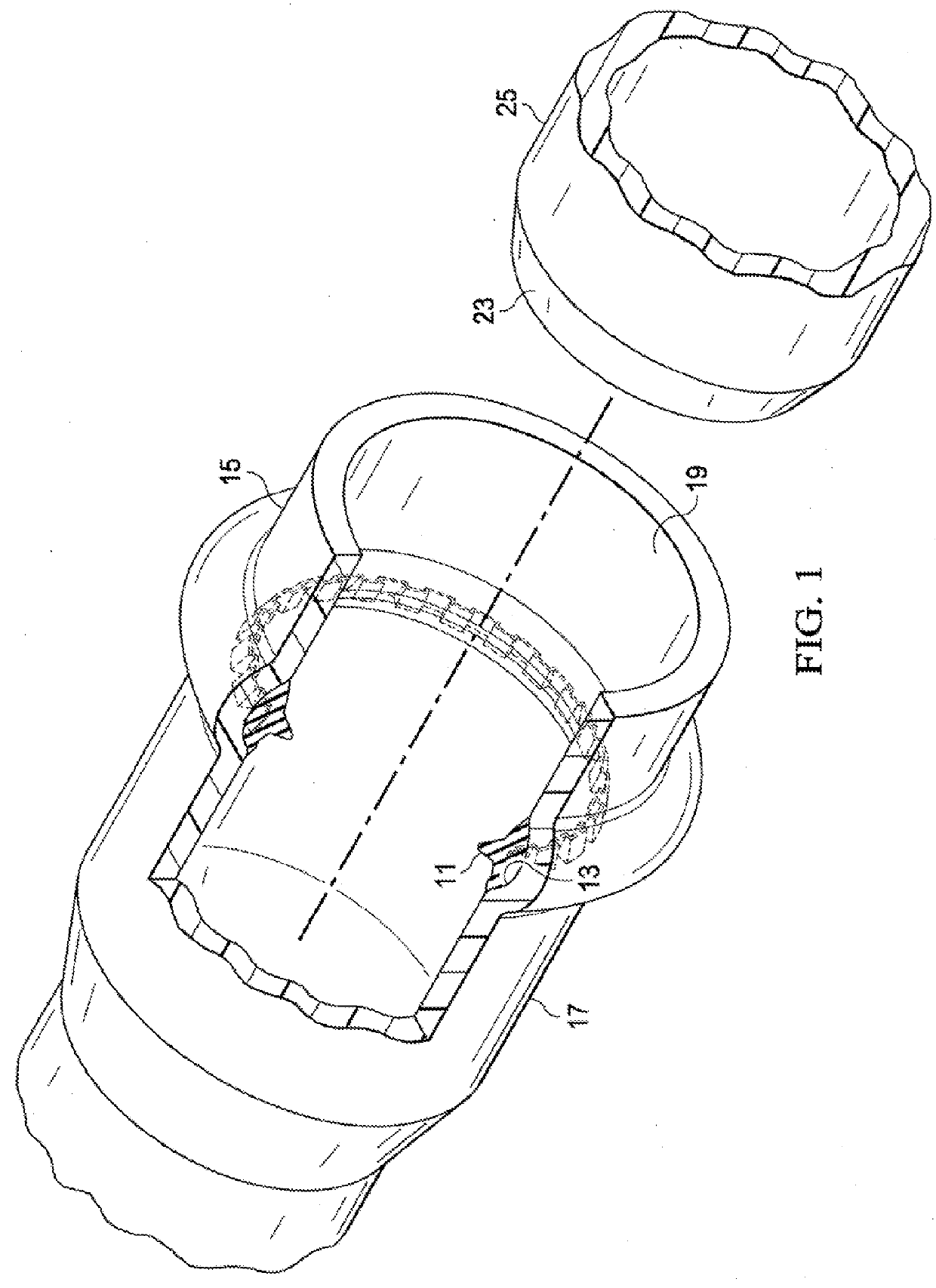

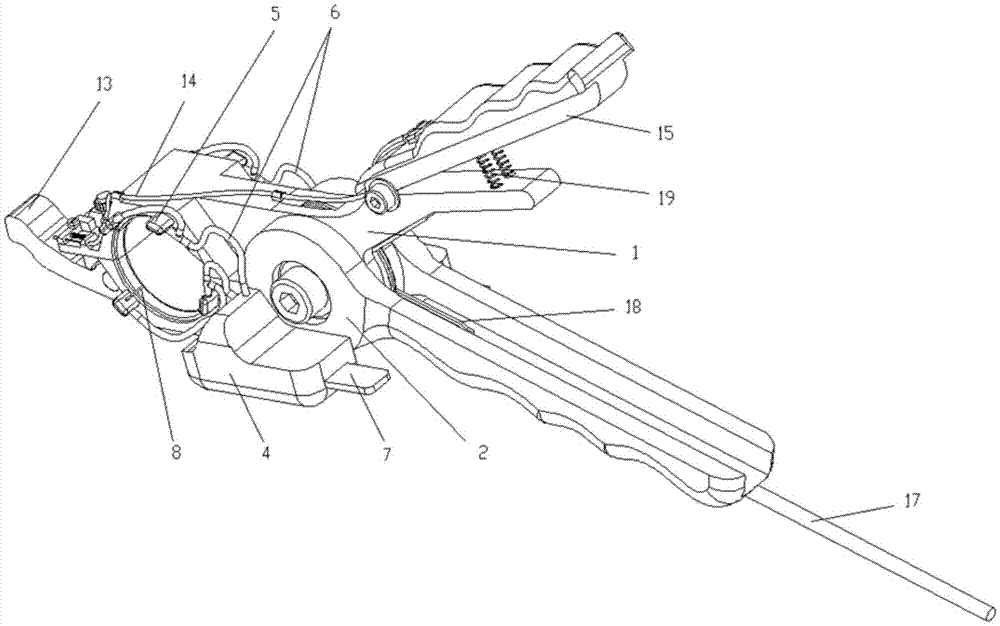

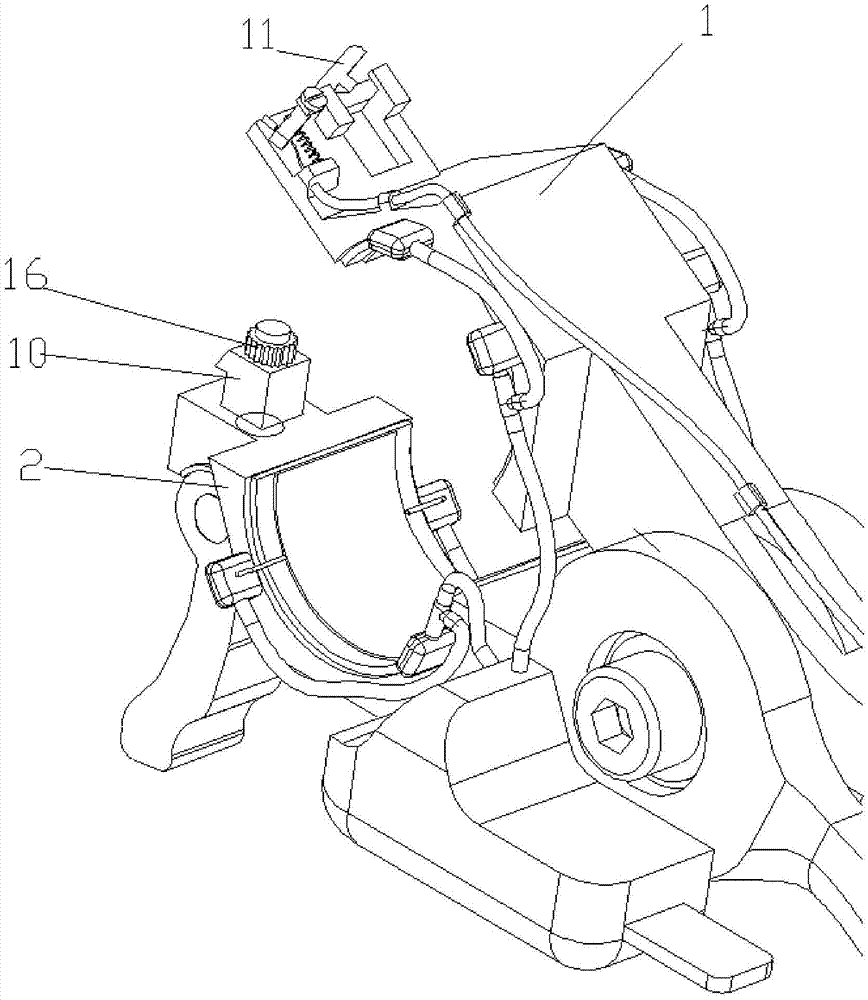

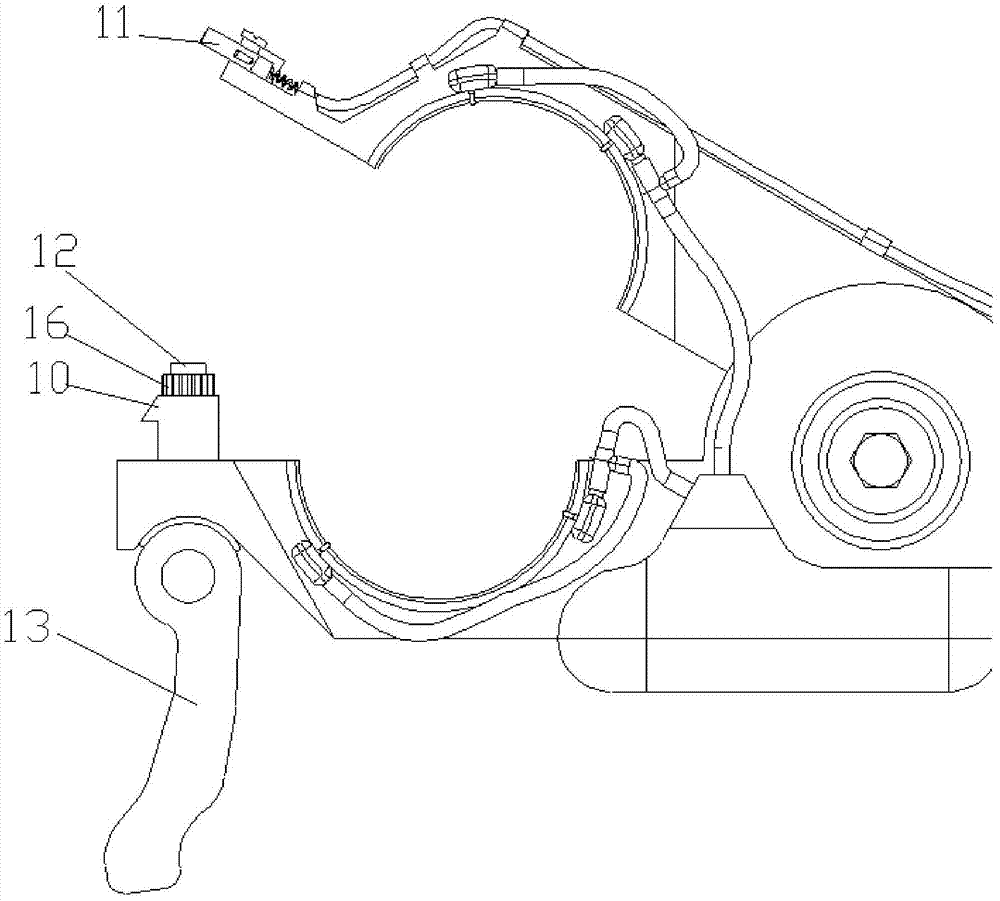

Handheld ultrasonic guided-wave structural damage detection device and detection method using same

ActiveCN105445375AQuick checkThe structure and technical means are simple and easy to implementAnalysing solids using sonic/ultrasonic/infrasonic wavesLocking mechanismAdhesive

The invention discloses a handheld ultrasonic guided-wave structural damage detection device and a detection method using same. The device comprises an upper clamping body for clamping a to-be-detected workpiece and a lower clamping body corresponding to the upper clamping body, wherein each of clamping parts of the upper clamping body and the lower clamping body comprises an upper clamping part body and a lower clamping part body which adopt symmetrical and semi-circular structures, and flexible piezoelectric patches are symmetrically attached to inner wall surfaces of the upper clamping part body and the lower clamping part body respectively; the device further comprises a coupling agent addition device and a locking mechanism, the coupling agent addition device is used for filling the space between the flexible piezoelectric patches and the to-be-detected workpiece with a coupling agent, and the locking mechanism is used for locking the upper clamping part bodies and the lower clamping part bodies. With the adoption of the device, the problem of low detection efficiency caused by the fact that PZT piezoelectric ceramic is required to be bonded by the aid of a two-component adhesive when a lot of existing cylindrical objects such as metal stranded wires and the like are detected with a stress wave detection method at present is solved, so that to-be-detected cylindrical pieces such as the metal stranded wires, plastic pipelines, round bars and the like can be detected quickly, and the detection efficiency can be substantially improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com