Assembly form and supporting method for in-soil assembled plastic pipes

A plastic pipe and assembled technology, which is applied in earthwork drilling, tunnel, tunnel lining, etc., can solve the problems of inconvenient transportation and construction of large-diameter pipes, achieve convenient transportation and construction, strong corrosion resistance, and reduce other related costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

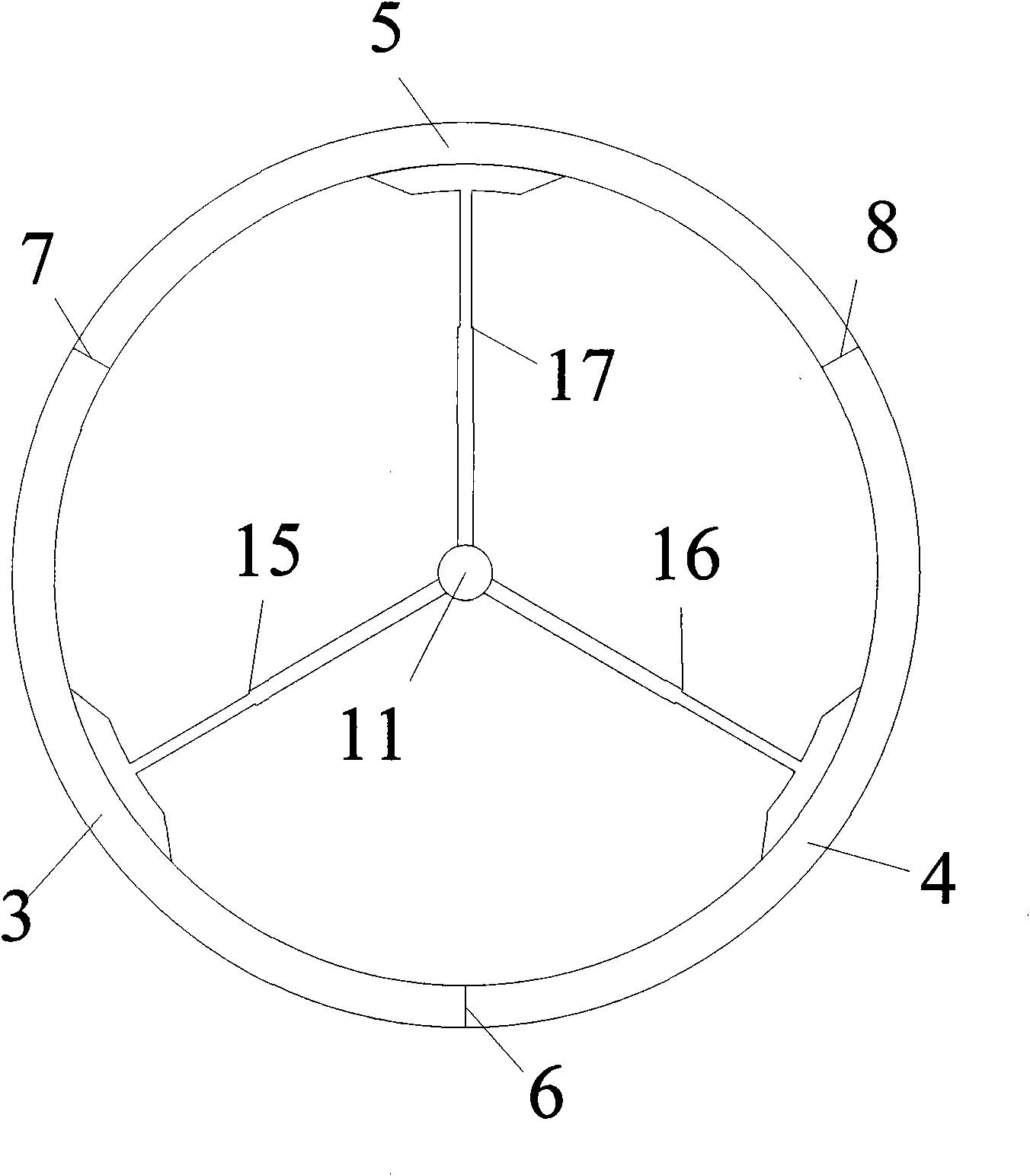

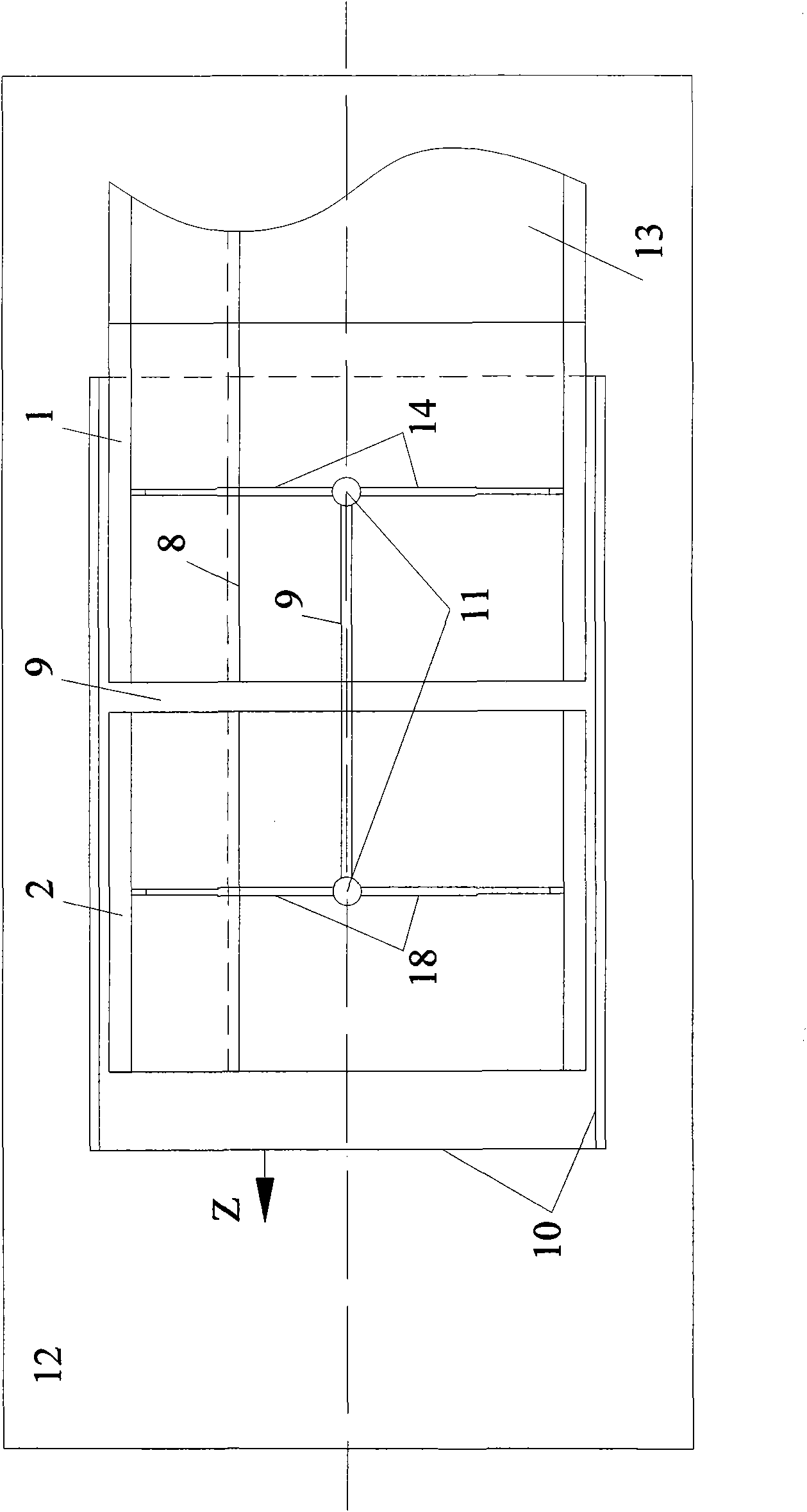

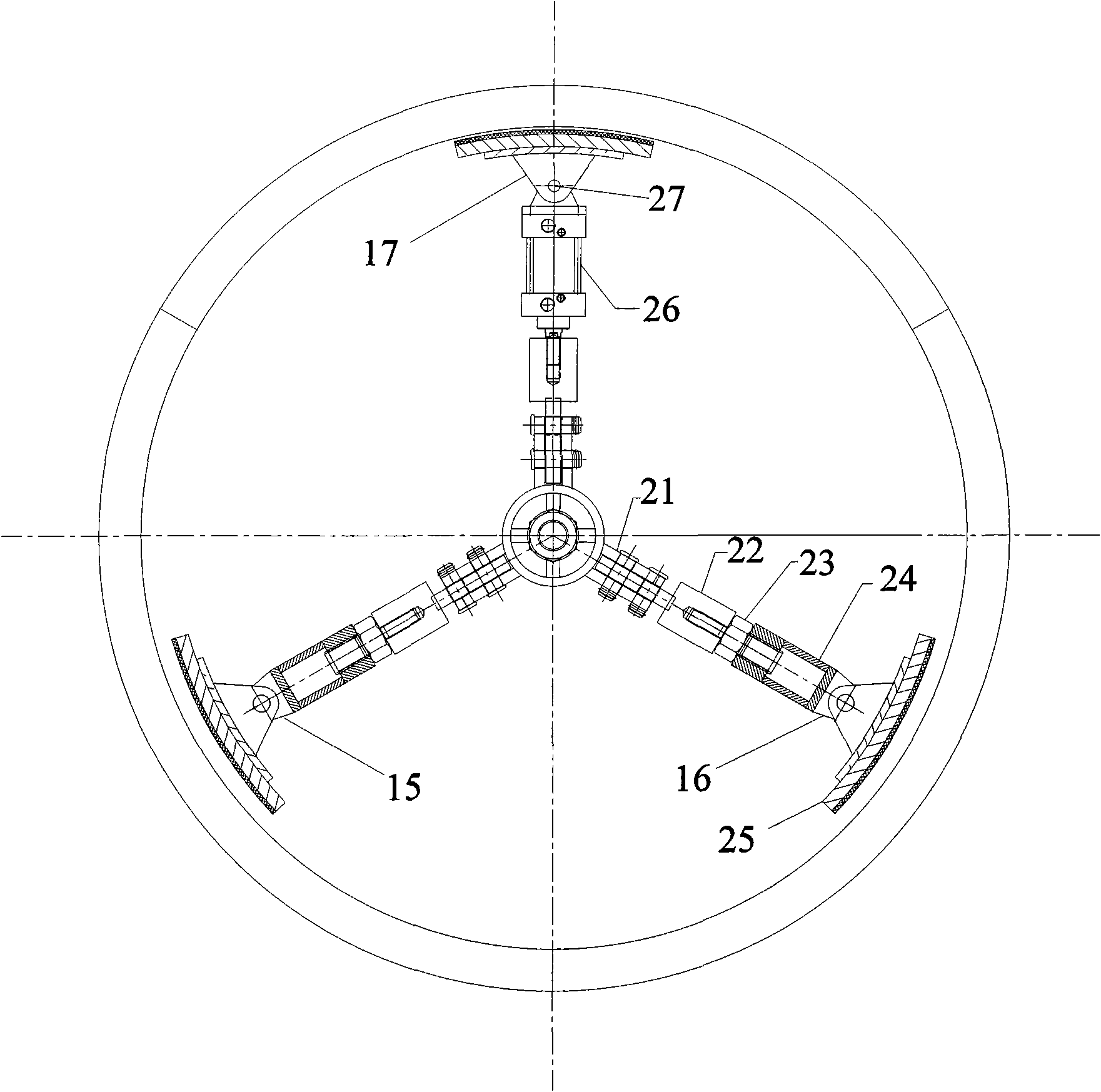

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] In this embodiment, the pipe is divided into 3 pieces and assembled through the joints as an example, and its assembly form and supporting method are described:

[0033] 1) First cut the large-diameter integral plastic pipe longitudinally on the ground into a pipe segment with a length of L; III segment. The value range of the length L of each pipe section is: 300mm≤L≤2000mm;

[0034] 2) After the self-propelled tunneling machine in the soil completes a cycle of tunneling in front, the three pieces of segments belonging to the first segment 1 that have been cut are sequentially transported to the sleeve at the tail of the tunneling machine;

[0035] 3) Use the supporter to re-support the N pieces of segments in the sleeve at the tail of the self-propelled roadheader to form pipe joints;

[0036] 4) Connect the longitudinal splicing seams between the segments respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com