Patents

Literature

33results about How to "Retain corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient nano-coating used for thermal barrier coating anti-corrosion function and preparation method thereof

InactiveCN103058654AOvercoming differences in thermal expansion coefficientsThe method is simple and easyTotal thicknessThermal barrier coating

The invention discloses a gradient nano-coating used for a thermal barrier coating anti-corrosion function and a preparation method thereof. A substrate is steeped and lifted in pure sol and mixed sol of yttria stabilization zirconia (YSZ) and Al 2O3. A gradient coating structure with proportion of the YSZ and the Al2O3 changed from inside to outside is obtained in a prepared mode. The gradient nano-coating is composed of particles with the particle diameter of 10 to 100nm. The total thickness of the coating is 0.5 to 5 micrometers. According to the novel gradient coating structure, the facts that anti-corrosion property of the Al2O3 is kept and meanwhile a phenomenon of coating exfoliation due to difference of thermal expansion coefficients between the YSZ and the Al2O3 materials is overcome are hopeful to be achieved, the gradient nano-coating structure is prepared through a mixed sol steeping and lifting method, and then high temperature roasting is conducted. A composition weight ratio of the YSZ to the Al2O3 in the mixed sol changes between 9 to 1 and 1 to 9. The particles contained by the YSZ sol are in a monoclinic crystal shape. Temperature of the high temperature roasting is 500 to 800 DEG C. The preparation method is simple and convenient to achieve, and practical. The coating prepared is even in structure.

Owner:SHANGHAI UNIV

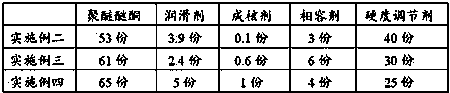

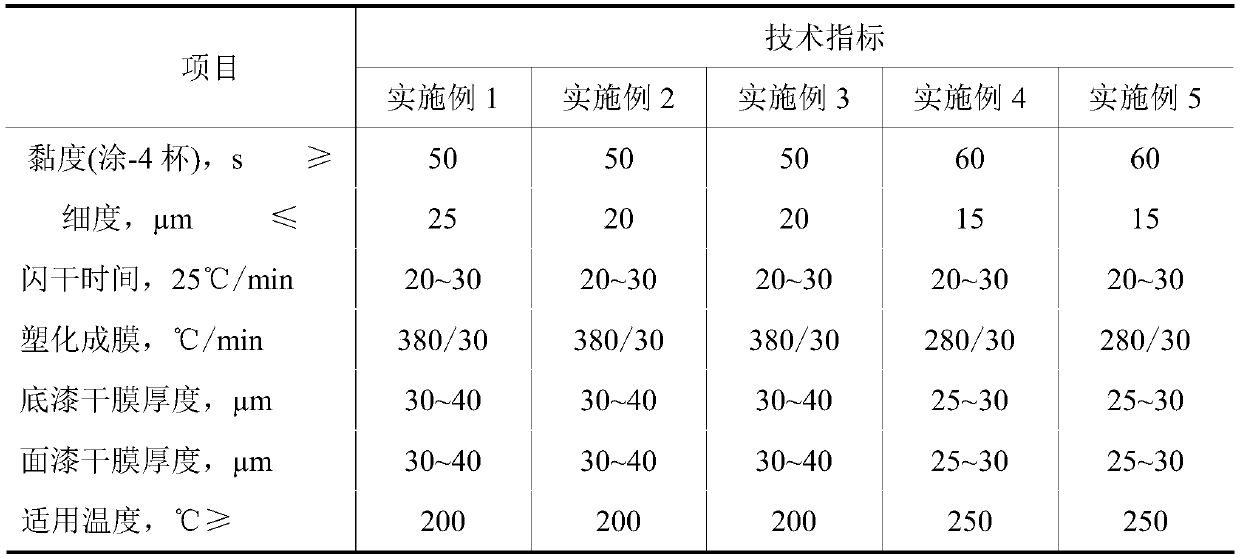

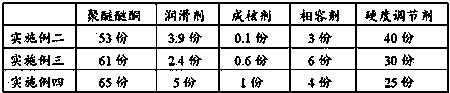

Polyether-ether-ketone cable material and preparation method thereof

ActiveCN103450631AImprove performanceReduce hardnessPlastic/resin/waxes insulatorsNuclear powerHardness

The invention provides a polyether-ether-ketone cable material. The polyether-ether-ketone cable material is characterized in that a raw material formula comprises the following materials in parts by weight: 50-70 parts of polyether-ether-ketone, 1-5 parts of a lubricating agent, 0.1-1 part of a nucleating agent, 3-8 parts of a compatilizer and 25-40 parts of a hardness conditioning agent. A preparation method of the polyether-ether-ketone cable material is characterized by comprising the following steps of weighting the materials according to the mass part of the materials in the raw material formula, mixing and stirring all the materials for 15-30 minutes in a high-speed mixing machine, then discharging, pelleting through a double-screw extruder at the process temperature of 220-380 DEG C, and packaging. The polyether-ether-ketone cable material provided by the invention has the advantages that the machining property of the polyether-ether-ketone product is improved, the extrusion molding is facilitated, the hardness of the material is reduced, the polyether-ether-ketone is suitable for being applied to cable industries, the excellent property of polyether-ether-ketone material can also be retained, and the polyether-ether-ketone cable material is flame-retardant, resists high temperature, low temperature, corrosion, oil and abrasion and can be widely applied to automobile cables, locomotive cables, nuclear power and the like with strict operating requirements.

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

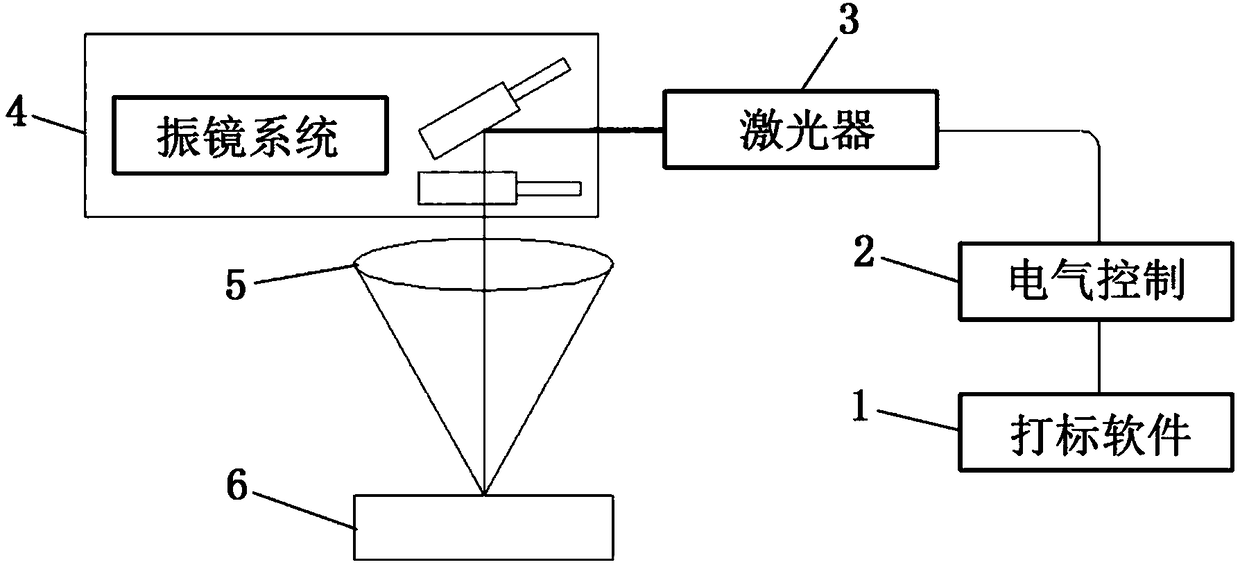

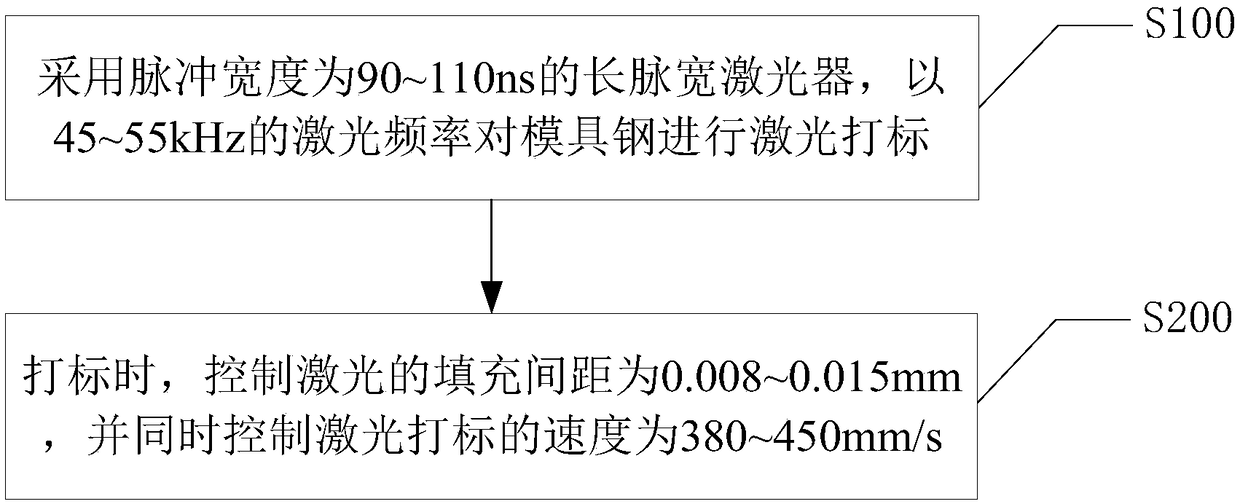

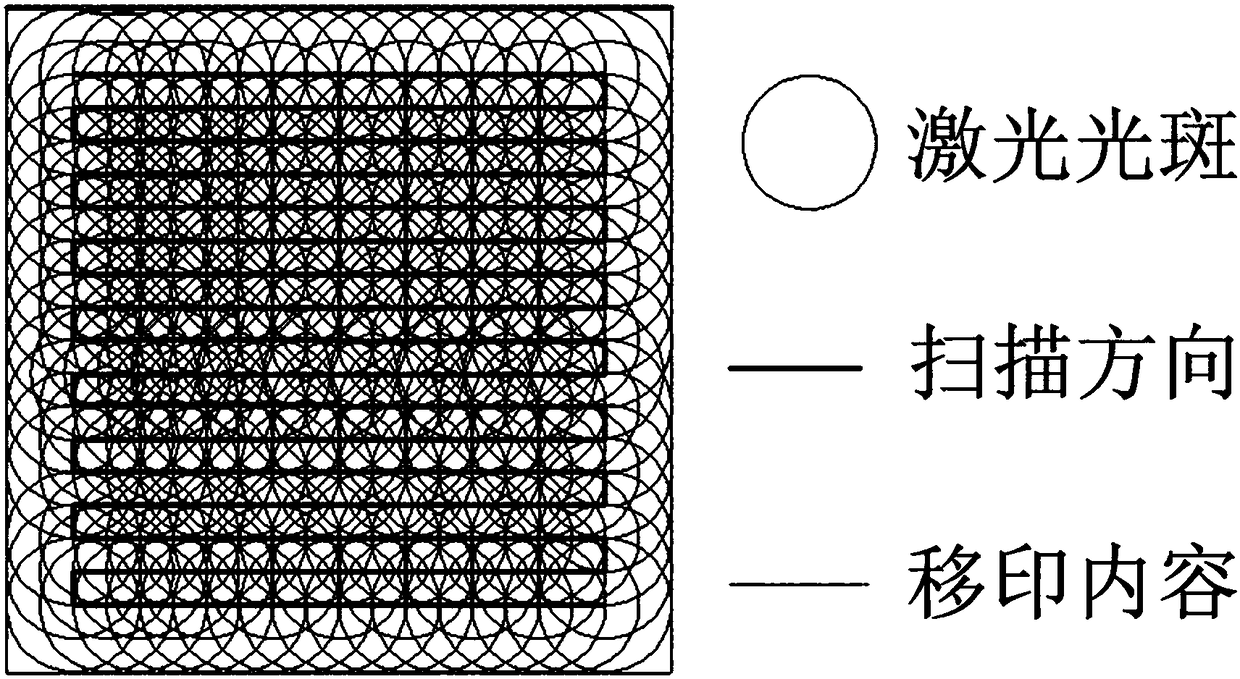

Laser marking method for die steel

ActiveCN108326435ARetain corrosion resistanceRetain wear-resistantWelding/soldering/cutting articlesLaser beam welding apparatusVaporizationOptoelectronics

The invention discloses a laser marking method of die steel. The method comprises the steps that a long pulse width laser with the pulse width of 90-110 ns is adopted, and laser marking is carried outon the die steel at the laser frequency of 45-55 kHz; and during marking, a filling distance of the laser is controlled to be 0.008-0.015 mm, and meanwhile, the laser marking speed is controlled to be 380-450 mm / s. According to the laser marking method, the laser with a long pulse width and a high frequency is adopted, marking machining is carried out on the die steel under the preferable fillingdensity and the low marking speed so that the instantaneous peak power can be guaranteed not to exist while enough heat can be guaranteed, and then the effect that steel on the surface of the die steel is removed through heating and vaporization and the bottom material is not damaged is achieved; and the shape of the part subjected to the steel removing and machining is consistent with the shapeof the unmachined part, the boundary is clear and straight, the surface is smooth, the hand feeling is free of depth and dirt resistance, the advantages of corrosion resistance and wear resistance ofthe die steel are perfectly reserved, and the machined die steel can be stored for a long time.

Owner:HANS LASER TECH IND GRP CO LTD

Ternary polymerization polytetrafluoroethylene resin, and preparation method and concentrated dispersion liquid thereof

ActiveCN102887972ARetain high and low temperature resistanceRetain corrosion resistanceVinyl etherTetrafluoroethylene

The invention relates to a ternary polymerization polytetrafluoroethylene resin which is formed by copolymerizing tetrafluoroethylene, fluorine-containing olefin and perfluor (alkyl vinyl ether) and also relates to a preparation method and concentrated dispersion liquid of the ternary polymerization polytetrafluoroethylene resin. On the basis that the original characteristics of the polytetrafluoroethylene resin are kept, the provided ternary polymerization polytetrafluoroethylene resin can be processed to form products with various specifications and shapes through melting, so that the application range of the polytetrafluoroethylene resin is widened; the provided concentrated dispersion liquid of the polytetrafluoroethylene can fully cover the surface of a base material during film coating, and the light-transmitting performance and the glossiness of the coated film are improved; and by the provided preparation method, the production cost is reduced, environment pollution is reduced, the reaction conditions are mild, and high safety can be achieved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Epoxy resin coating and preparation method and application thereof

ActiveCN104263199AGood dispersionRetain corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentResin coating

The invention provides an epoxy resin coating and a preparation method and application thereof. The coating comprises a component A and a component B which are independently packaged, wherein the component A comprises the following materials in parts by weight: 36-40 parts of epoxy resin, 3.3-3.6 parts of packing such as micron-order Ti-Al alloy powder, 1.3-1.4 parts of pigment, 13.3-21 parts of solvent and assistants such as 0.6-1 part of degassing agent, 0.6-1 part of curing accelerator and 0.6-1 part of dispersing agent; and the component B comprises 36-40 parts of curing agents. The process of preparing the micron-order Ti-Al alloy powder comprises the following two steps: performing plasma rotation electrode atomization and performing ball-milling and refining. The coating is mainly applied to a metal workpiece anticorrosive coating. The coating disclosed by the invention can effectively improve the anticorrosive properties of metal workpieces and is low in cost, simple in production process, low in equipment requirement, high in quality, uniform in components and easy for industrialization.

Owner:CENT SOUTH UNIV

Thermally-conductive far-infrared synergistic non-stick coating and preparation method thereof

InactiveCN110467831ARetain high temperature resistancePreserve anti-agingFireproof paintsAnti-corrosive paintsCell membraneFar infrared

The invention provides a thermally-conductive far-infrared synergistic non-stick coating. The thermally-conductive far-infrared synergistic non-stick coating is a special coating using aqueous dispersion resin formed by mutual modification of a nanometer oxide gel and an organic fluororesin emulsion as a film forming matrix, and plasticized high-performance resin micropowder for modification, functional thermal-conductive exothermic synergistic filler, a tinting pigment and a coating additive as auxiliary components. After the coating of the invention is modified by graphene, the coating retains the original high temperature resistance, weather resistance and strong-corrosion resistance, and is endowed with the new functional characteristics of thermal stability, thermal balance, high hardness, high toughness, wear resistance, scratch resistance, wettability, no adhesion and the like; and nanometer negative ion powder releases far-infrared electromagnetic waves under the excitation ofheat (so thermal conductivity is good), and generates small-molecular-group water which permeates the cell membranes of cooked rice grains, so starch structures inside the cooked rice grains absorb water and become bulky and flexible, which improves the palatability of cooked rice.

Owner:广东健玺表面工程技术有限公司

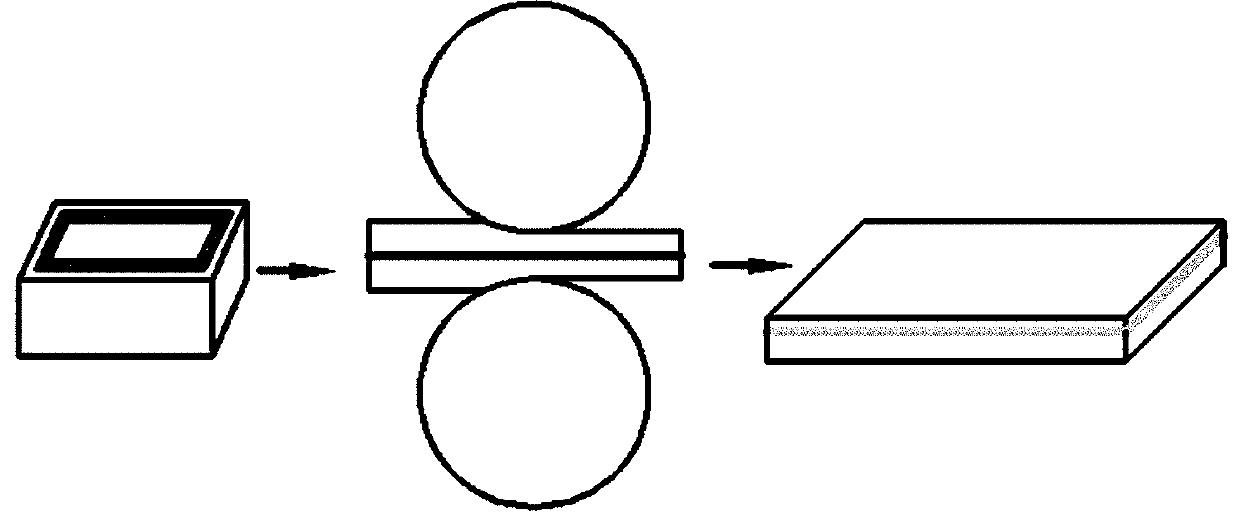

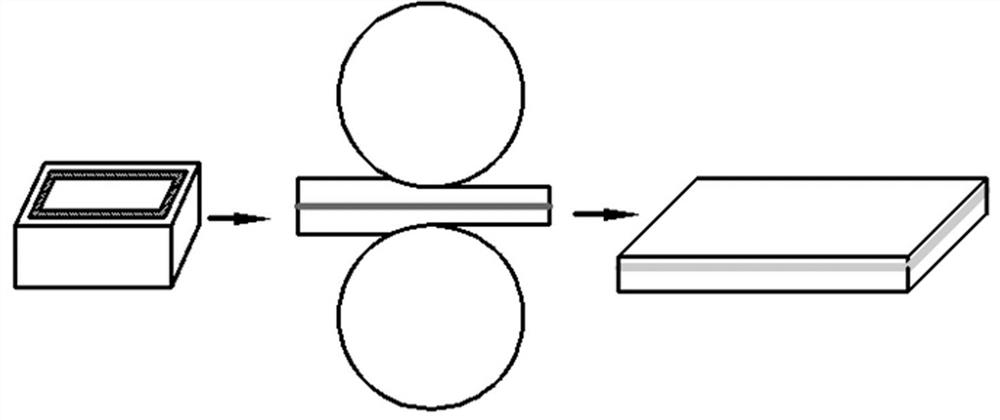

Method for preparing metal composite plate by using as-cast blanks

ActiveCN110788137AHigh bonding strengthShorten the production cycleTemperature control deviceWork heating devicesWater vaporSorbent

The invention provides a method for preparing a metal composite plate by using as-cast blanks. The metal composite plate comprises a multi-layer metal, base-layer carbon steel or alloy steel, a bonding agent and a mixed activated adsorbing agent, wherein the bonding surfaces of the multi-layer metal and the base-layer metal are subjected to rust removal, passivation and chemical cleaning, the bonding agent is added to the bonding surfaces of the base plate and the compound plate, the mixed adsorbing agent is added to the peripheries of the bonding surfaces, before rolling, heating is conductedtwo times under atmosphere protection, so that air, water vapor and the like on the bonding surfaces are removed or adsorbed by the mixed activated adsorbing agent, the bonding agent is melted to make the bonding surfaces sealed, and oxidation is avoided. The method for preparing the metal composite plate by using the as-cast blanks can effectively solve the problems that a conventional preparation method for the compound plate is long in assembling period, high in cost and the like, a vacuum extraction equipment is omitted, and the production cost is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

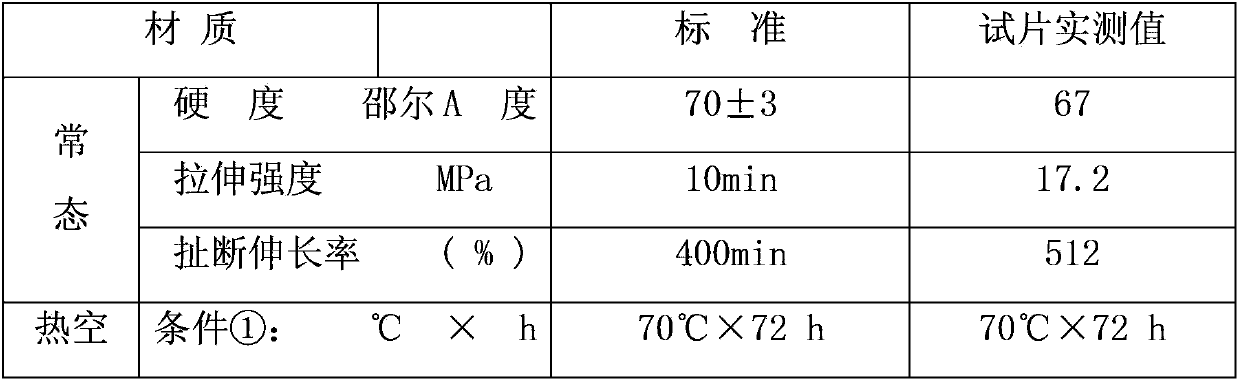

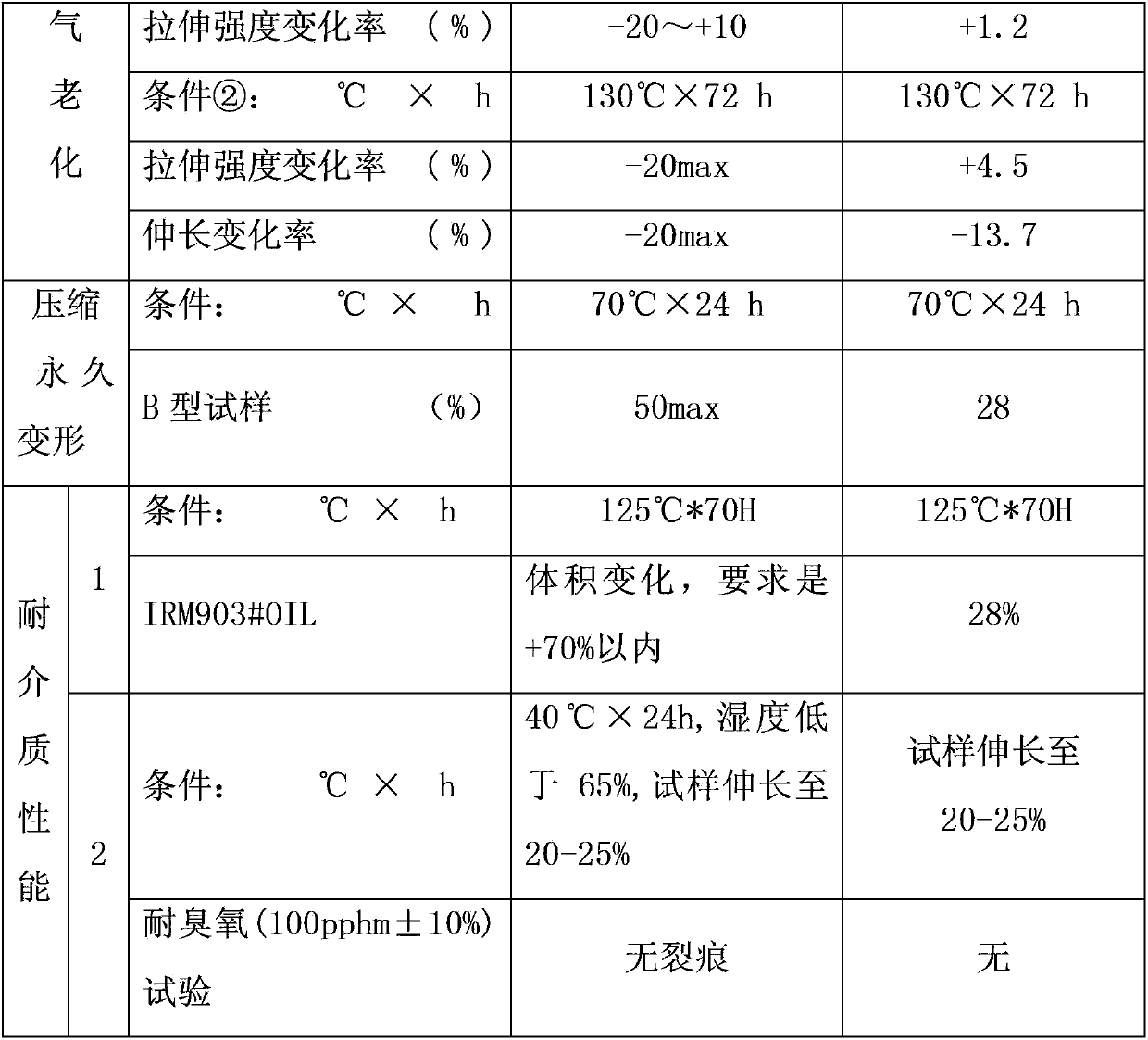

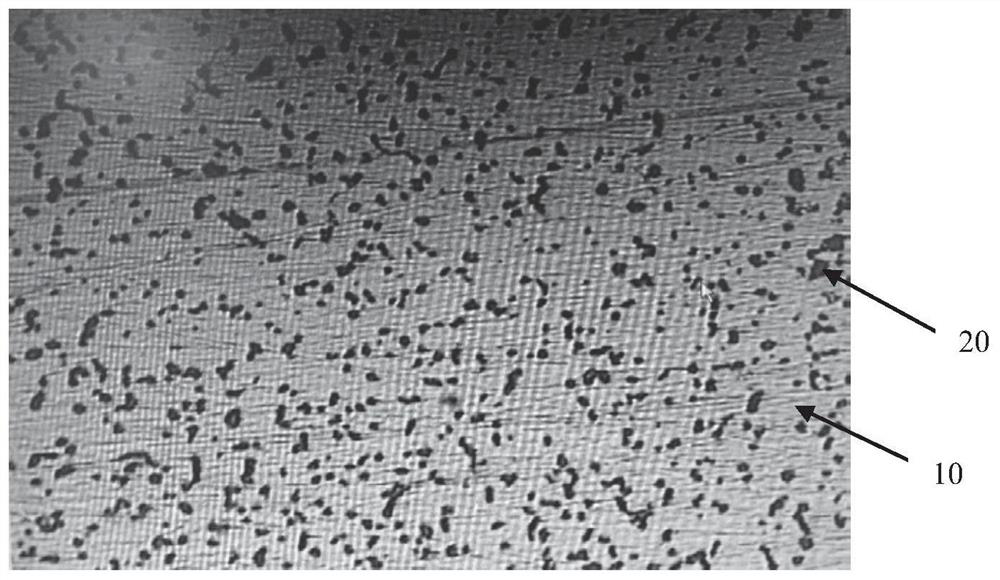

Anti-aging and permanent-compression-deformation-resistant rubber material

InactiveCN104072891ARetain corrosion resistanceGood oil resistanceRubber materialEthylene-propylene-diene-monomer

The invention discloses an anti-aging and permanent-compression-deformation-resistant rubber material. The rubber material comprises the following components in parts by weight: 30-50 parts of ethylene propylene diene monomer, 20-30 parts of modified ethylene propylene diene monomer, 0.8-1.5 parts of dicumyl peroxide, 1.5-2 parts of maleimide vulcanizing aids, 0.5-1.5 part of a vulcanizing agent BIBP, 2-4 parts of magnesium oxide, 2-5 parts of trioctyl trimellitate, 0.5-1.2 parts of paraffin, 20-30 parts of magnesium hydroxide, 5-8 parts of red phosphorus, 20-25 parts of superfine active clay, 15-20 parts of ultra-fine powder, 10- 20 parts of kaolin and 1-1.8 parts of an anti-aging agent RD, wherein the modified ethylene propylene diene monomer is acrylonitrile-grafted ethylene propylene diene monomer. The rubber material disclosed by the invention has the advantages of excellent anti-aging performance and good resistance to permanent compression deformation.

Owner:安徽宁国尚鼎橡塑制品有限公司

Epoxy orange peel antiskid floor paint and preparation method thereof

InactiveCN111019475AStable thixotropyHigh activityAnti-corrosive paintsEpoxy resin coatingsComposite materialAntifoam agent

The invention discloses an epoxy orange peel antiskid floor paint and a preparation method thereof, and belongs to the technical field of paints. The floor paint comprises, by weight, 30-50 parts of epoxy resin, 20-40 parts of dolomite powder, 5-10 parts of talcum powder, 1-3 parts of white carbon black, 0.3-1 part of a dispersant, 0.5-2 parts of an antifoaming agent, 0.5-1 part of a rheological modifier, and 10-20 parts of a curing agent. The epoxy orange peel antiskid floor paint not only retains the characteristics of toughness, wear resistance, corrosion resistance and the like of common epoxy floor paints, but also has antiskid and beautiful decorative effects, and has very good constructability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

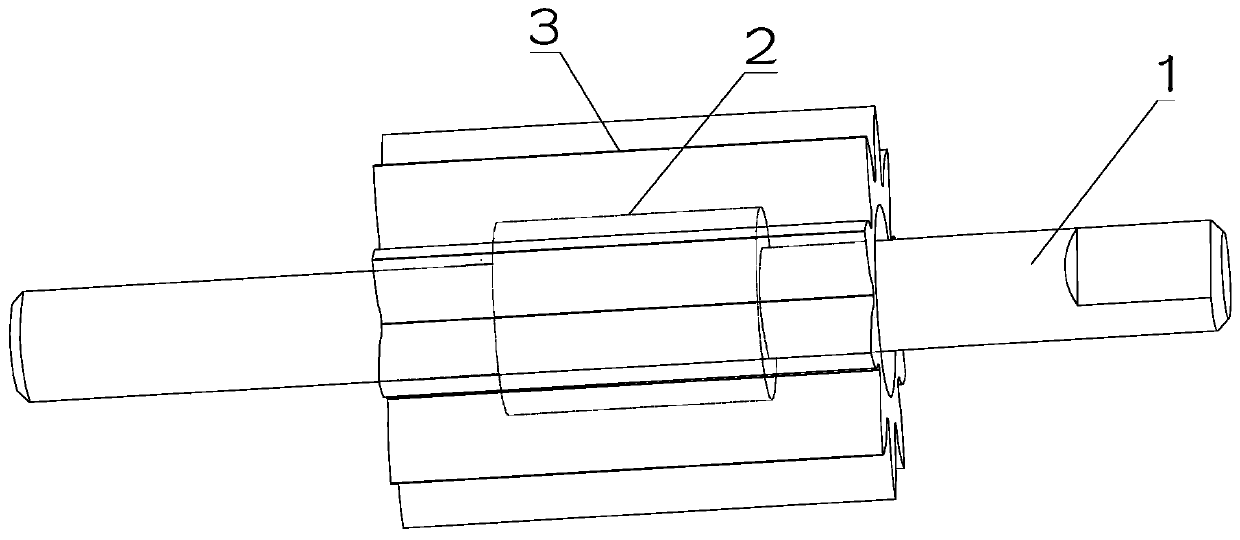

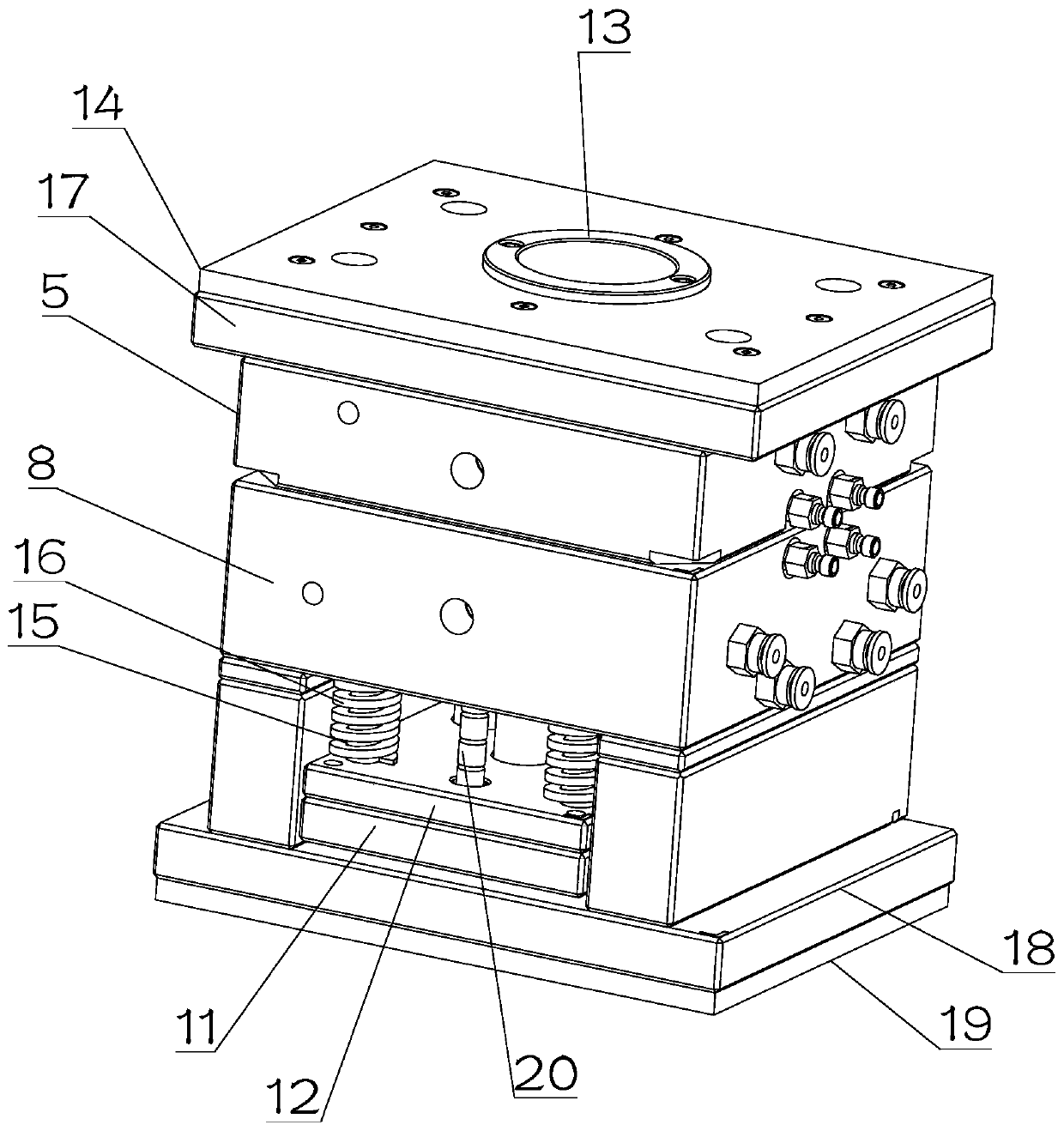

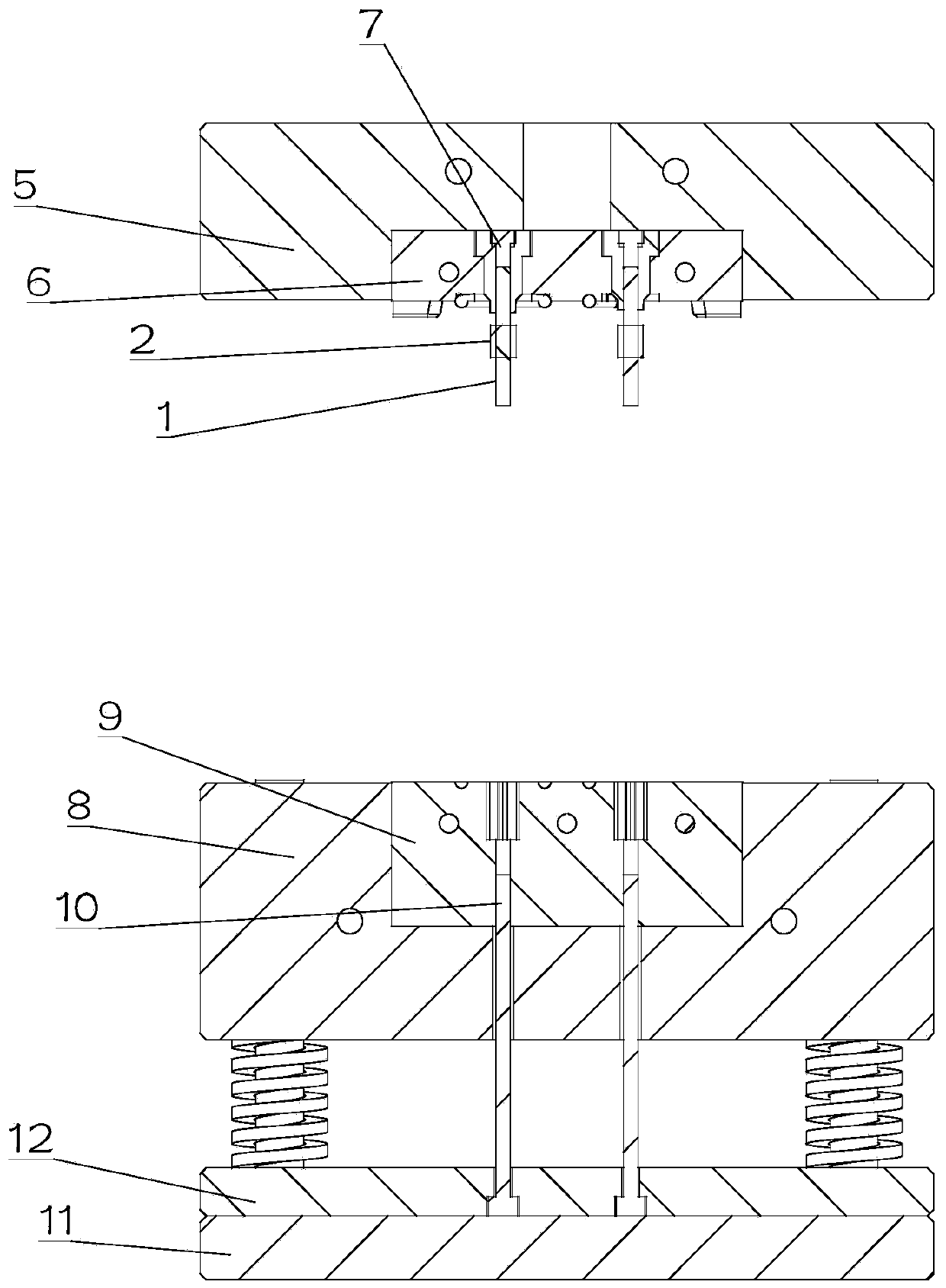

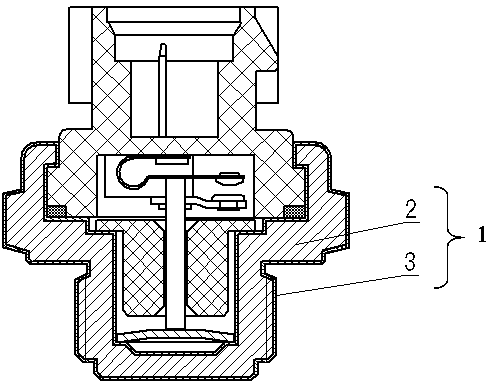

Encapsulated injected gear, injection process and mold

InactiveCN111577863AGuaranteed coaxialityHigh strengthShaftsPortable liftingGear wheelStructural engineering

The invention belongs to the technical field of high-performance material small gears, and provides an encapsulated injected gear. The encapsulated injected gear comprises a gear shaft, a gear inner core arranged on the gear shaft, and a gear body encapsulated and injected on the gear inner core. According to the encapsulated injected gear, a metal inner core is used for replacing an original injection molding material, and firstly, the coaxiality of the shaft and the gear can be guaranteed well, the thickness of the injection molding material is reduced to a large degree, and the problem of contraction and deformation generated in the conventional injection molding process is solved; and secondly, the metal is higher in strength and economical in cost, and compared with expensive high-performance injection molding materials, it is a good choice to replace the gear inner core with the metal.

Owner:上海芮朔精密模塑科技有限公司

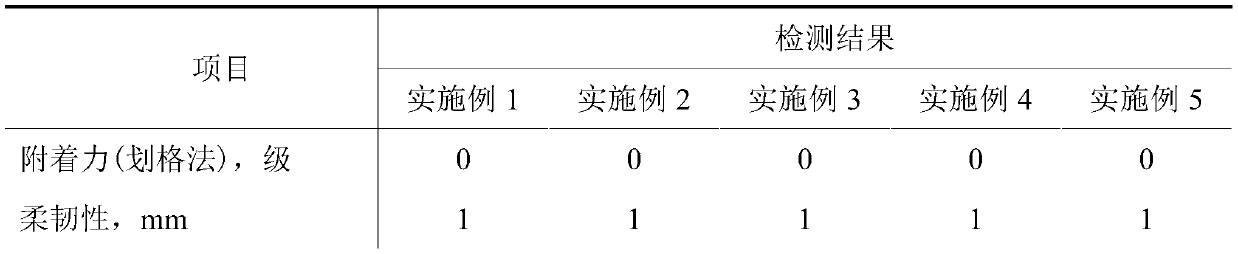

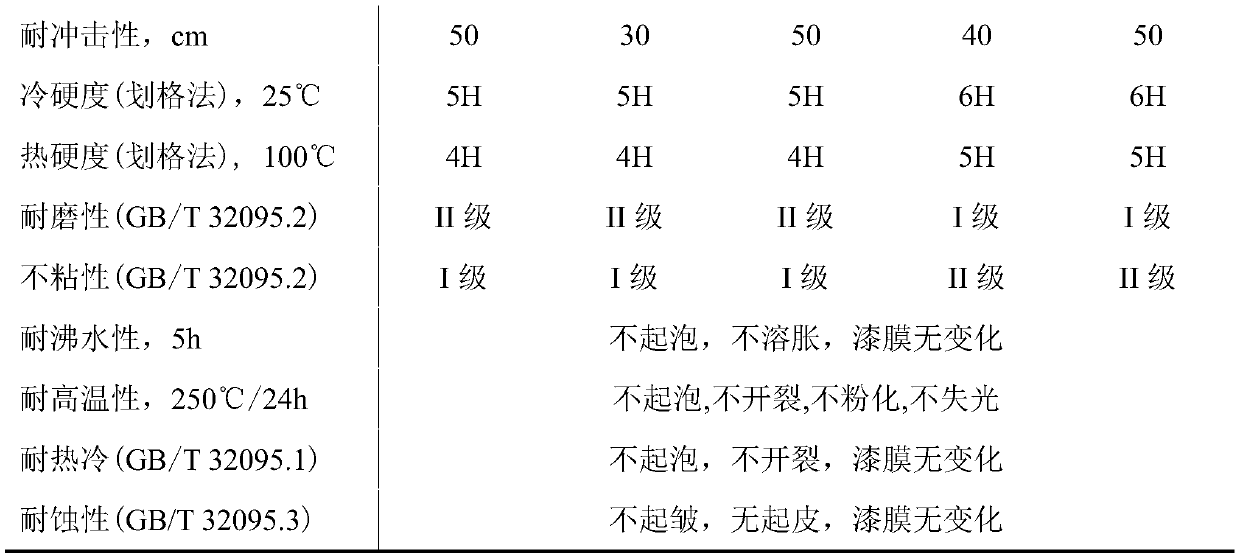

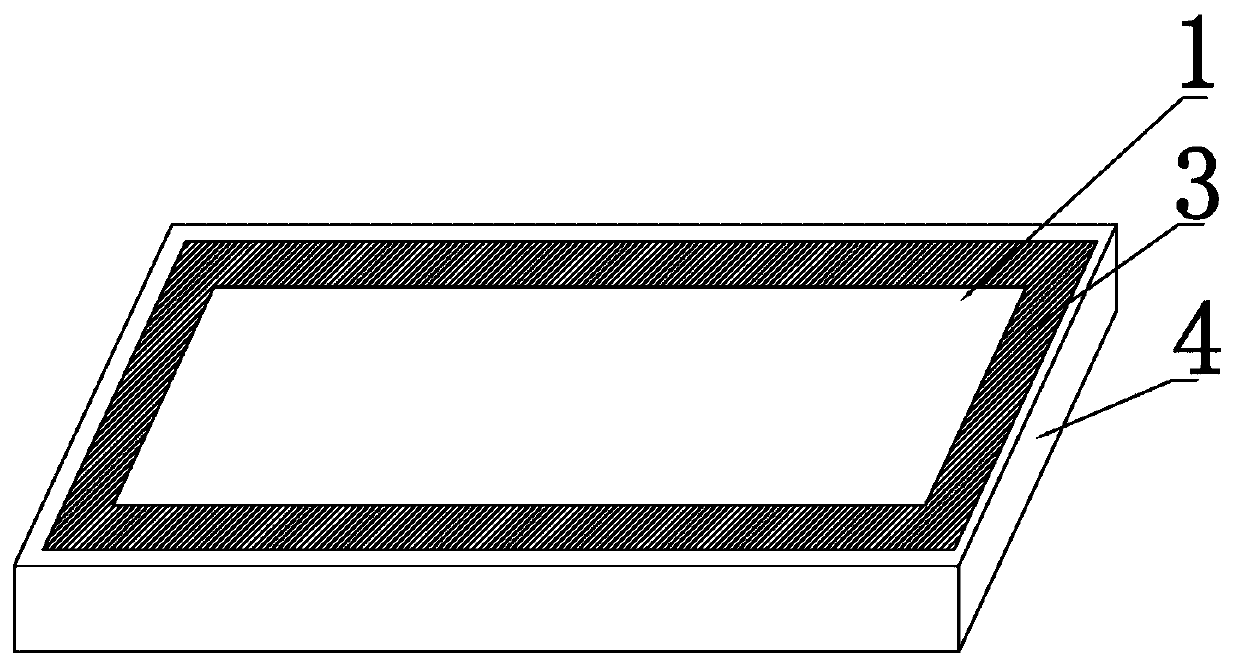

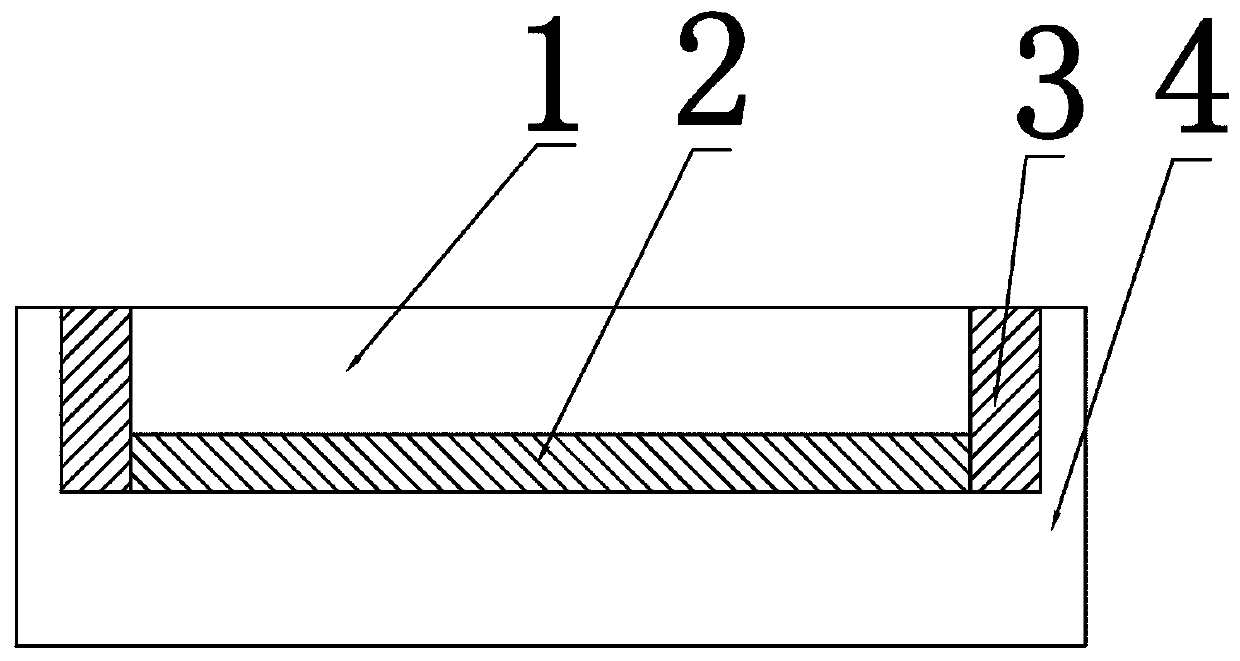

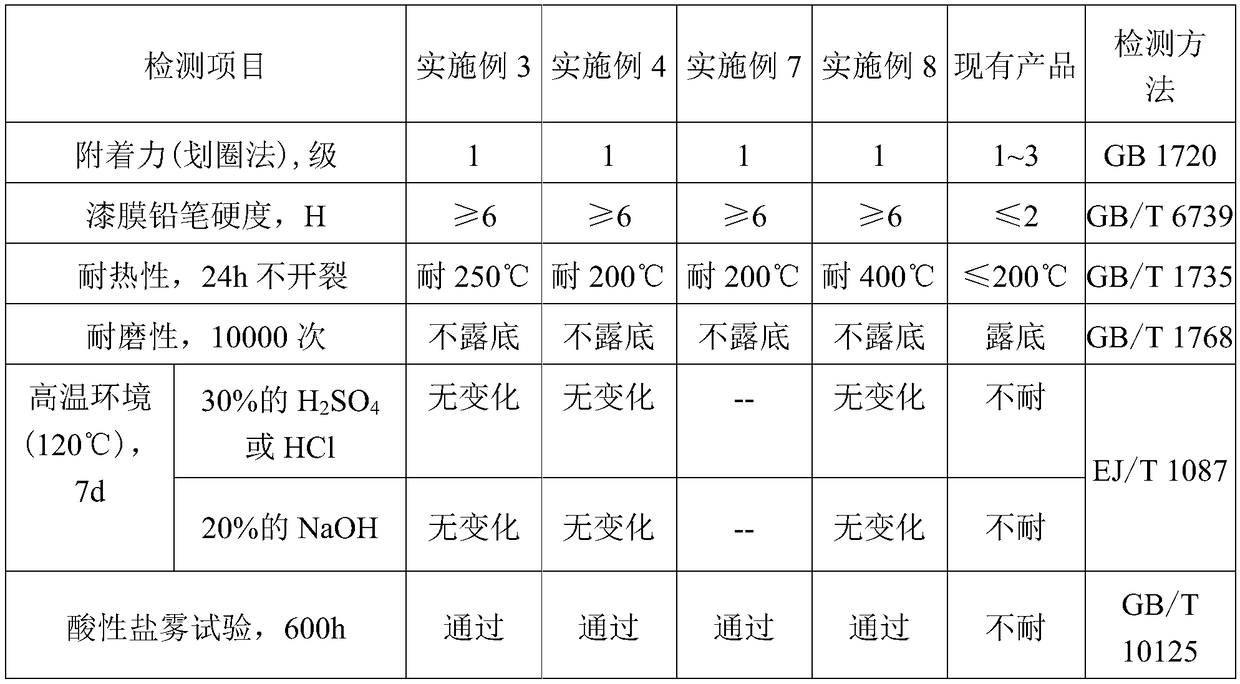

Nanometer hybridized ceramic resin coating as well as preparation method and application of nanometer hybridized ceramic resin coating

InactiveCN109370397ARetain high temperature resistanceRetain corrosion resistanceFireproof paintsAnti-corrosive paintsChemical industryNano hybrid

The invention discloses a nanometer hybridized ceramic resin coating as well as a preparation method and an application of the nanometer hybridized ceramic resin coating and belongs to the technical field of chemical industry of coatings. By adopting the coating disclosed by the invention, not only are the original high temperature resistance, corrosion resistance, weather resistance and ageing resistance retained, but also the brittleness problem of the coating is solved, and the nanometer hybridized ceramic resin coating has the characteristics such as high hardness, high toughness, wear resistance, scratch resistance, no infiltration, inadhesion and no scale formation. Different coating varieties can be prepared by selecting film forming matrix materials with different structures according to different working environments and construction conditions, and proved by a contrast test, an endurance test and overall performance detection, the nanometer hybridized ceramic resin coating disclosed by the invention far exceeds like products on the current market.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

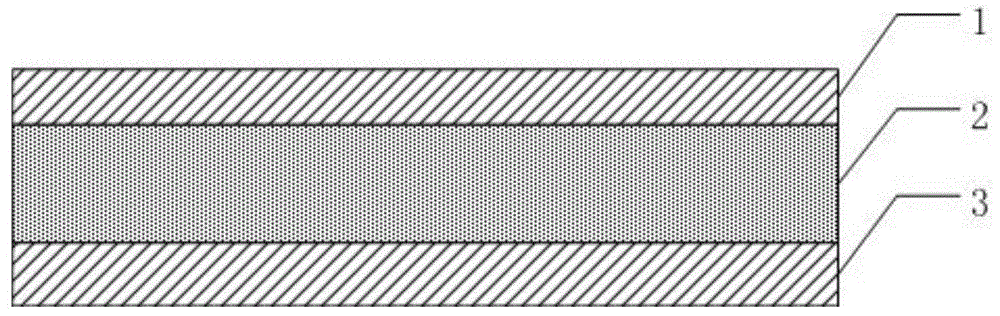

Nano-zinc oxide modified composite plate and preparation process thereof

InactiveCN104626698AImprove the finishGood thermal stabilitySynthetic resin layered productsNano zinc oxideHeat stability

The embodiment of the invention discloses a nano-zinc oxide modified composite plate and a preparation process of the nano-zinc oxide modified composite plate. The tensile strength and the impact strength of polyvinyl chloride sheets in practical application can be effectively improved, the surface smoothness of the sheets is improved, and the heat stability and anti-aging performance of the sheets can be increased. In the embodiment of the invention, the nano-zinc oxide modified composite plate is formed by compounding three layers including a PMMA layer, a nano-zinc oxide modified layer and a PMMA layer from top to bottom respectively, wherein a nano-zinc oxide modified layer contains nano-zinc oxide and polyvinyl chloride. The nano-zinc oxide modified composite plate is high in tensile strength, high in impact strength, high in smooth finish, high in heat stability and high in aging resistance.

Owner:广州市威士丹利智能科技有限公司

Modified polytetrafluoroethylene turning large plate and processing method

ActiveCN102585404BRetain weather resistanceRetain corrosion resistanceFlat articlesHigh pressureExhaust pipe

The invention discloses a modified polytetrafluoroethylene turning large plate which is characterized in that by comprising the components as follows: 10 to 15 percent of crystal whiskers, 10 to 15 percent of graphite and the rest percent of polytetrafluoroethylene. The invention simultaneously discloses a processing method of the large plate, which comprises the steps of crystal whisker surface modification treatment, material mixing, pressing, sintering, rotary cutting, post-treatment of the product, and the like. The large plate disclosed by the invention has not only the advantages of weather resistance, corrosion resistance, and the like of a polytetrafluoroethylene material, but also high creep resistance and wear resistance, so as to enhance the mechanical strength of the large plate. Therefore, the application range of the large plate in the field of chemical equipment such as liquid delivery pipes, gas exhaust pipes, steam pipes, and high pressure oil pipes of rolling mills is widened, and the service life of the large plate is prolonged.

Owner:JIANGSU XIANGJIAN NEW MATERIAL TECH CO LTD

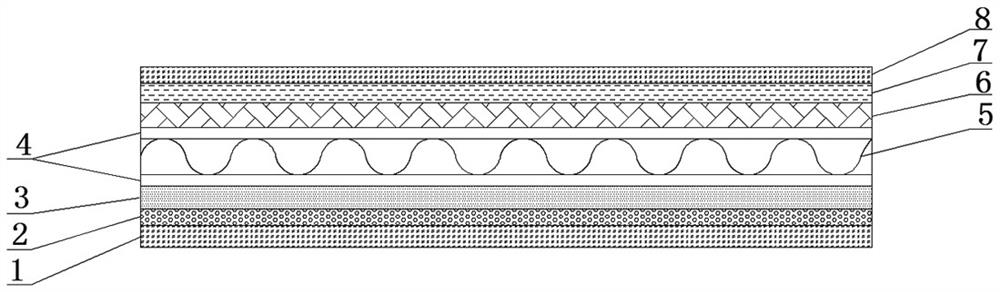

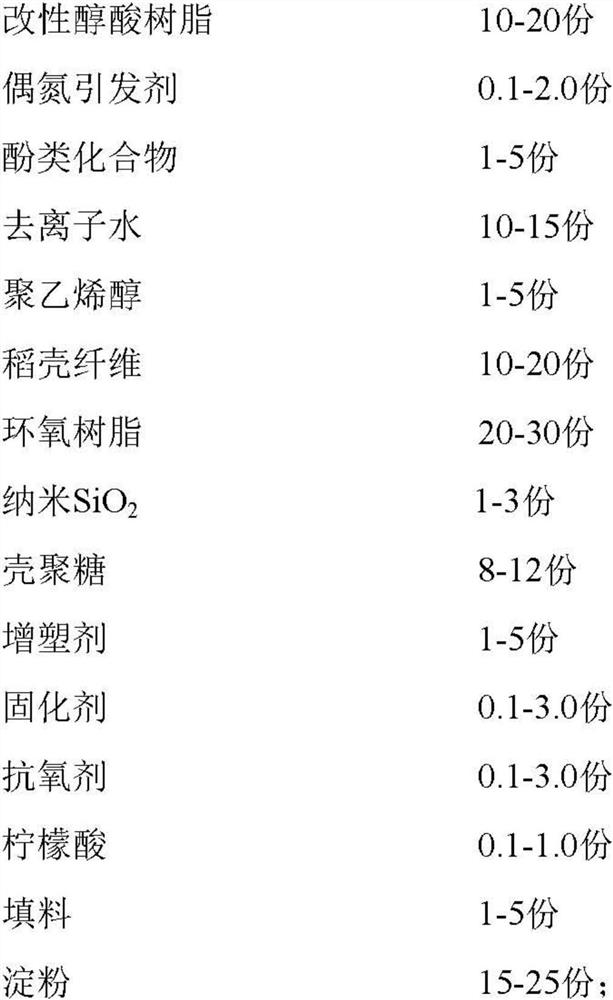

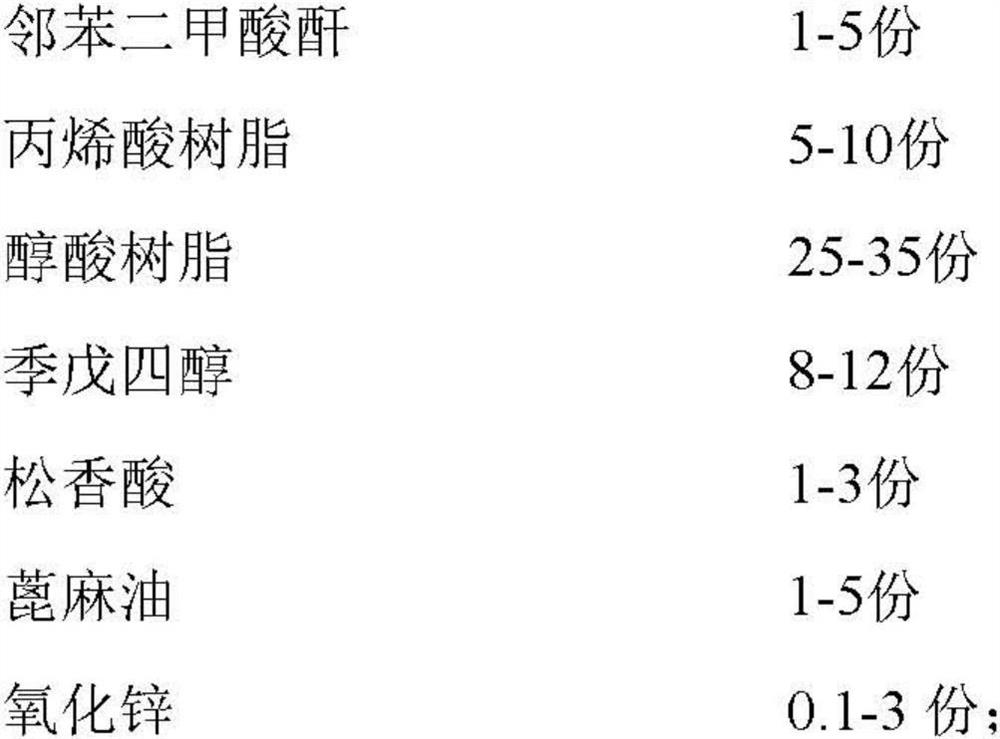

Composite corrugated paper and preparation method thereof

PendingCN112523005AHigh strengthImprove impact resistanceMechanical working/deformationWrappersFiberPolymer science

The invention relates to the technical field of corrugated paper, in particular to composite corrugated paper and a preparation method thereof. The composite corrugated paper comprises first surface paper, an antibacterial layer, a reinforcing layer, corrugated core paper, a fiber layer, a waterproof layer and second surface paper which are sequentially attached, and the upper surface of the reinforcing layer and the lower surface of the fiber layer are each coated with a composite adhesive layer. A composite adhesive is prepared from the following raw materials in parts by weight: 10-20 partsof modified alkyd resin, 0.1-2.0 parts of azo initiator, 1-5 parts of phenolic compound, 10-15 parts of deionized water, 1-5 parts of polyvinyl alcohol, 10-20 parts of rice hull fiber, 20-30 parts ofepoxy resin, 1-3 parts of nano SiO2, 8-12 parts of chitosan, 1-5 parts of plasticizer, 0.1-3.0 parts of curing agent, 0.1-3.0 parts of antioxidant, 0.1-1.0 part of citric acid, 1-5 parts of a fillerand 15-25 part of starch. The composite corrugated paper provided by the invention has good strength and mildew-proof and antibacterial effects, and is long in service life.

Owner:东莞顺裕纸业有限公司

Ternary polymerization polytetrafluoroethylene resin, and preparation method and concentrated dispersion liquid thereof

ActiveCN102887972BRetain high and low temperature resistanceRetain corrosion resistanceVinyl etherTetrafluoroethylene

The invention relates to a ternary polymerization polytetrafluoroethylene resin which is formed by copolymerizing tetrafluoroethylene, fluorine-containing olefin and perfluor (alkyl vinyl ether) and also relates to a preparation method and concentrated dispersion liquid of the ternary polymerization polytetrafluoroethylene resin. On the basis that the original characteristics of the polytetrafluoroethylene resin are kept, the provided ternary polymerization polytetrafluoroethylene resin can be processed to form products with various specifications and shapes through melting, so that the application range of the polytetrafluoroethylene resin is widened; the provided concentrated dispersion liquid of the polytetrafluoroethylene can fully cover the surface of a base material during film coating, and the light-transmitting performance and the glossiness of the coated film are improved; and by the provided preparation method, the production cost is reduced, environment pollution is reduced, the reaction conditions are mild, and high safety can be achieved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Wooden door machining method for improving thermal insulation performance

InactiveCN111267203AEasy to break intoFully retains corrosion resistanceFireproof doorsCeramic shaping apparatusYarnSpinning

The invention belongs to the field of furniture manufacturing, and particularly discloses a wooden door machining method for improving thermal insulation performance. The wooden door machining methodcomprises the following steps of grinding bentonite into powder, performing calcining at a high temperature, grinding together with diatomite to obtain mixed clay, and mixing with aluminum phosphate emulsion and water in proportion to obtain viscose; shearing aluminum silicate ceramic fibers and glass fibers to obtain mixed fiber powder, and then mixing with expanded graphite to obtain a mixed rawmaterial; and processing the viscose and the mixed raw material to obtain a molten feed liquid, performing spinning to obtain composite fiber yarns, preparing a composite thermal insulation board, and compounding the composite thermal insulation board with an external composite board to obtain the required wooden door. According to the wooden door machining method, the bentonite is calcined at the high temperature and mixed with the diatomite, thereby facilitating the intrusion of expanded graphite powder into micropores. The aluminum silicate ceramic fibers and the glass fibers are taken asthe raw materials, so that a good heat preservation effect is achieved. Meanwhile, the raw material is compounded with the aluminum phosphate emulsion, so that the bonding capability of each componentis optimized; a good environmental protection effect is achieved; the thermal insulation effect of each component can be brought into full play; and the thermal insulation performance of a door bodyis improved effectively.

Owner:重庆市豪迈家具有限公司

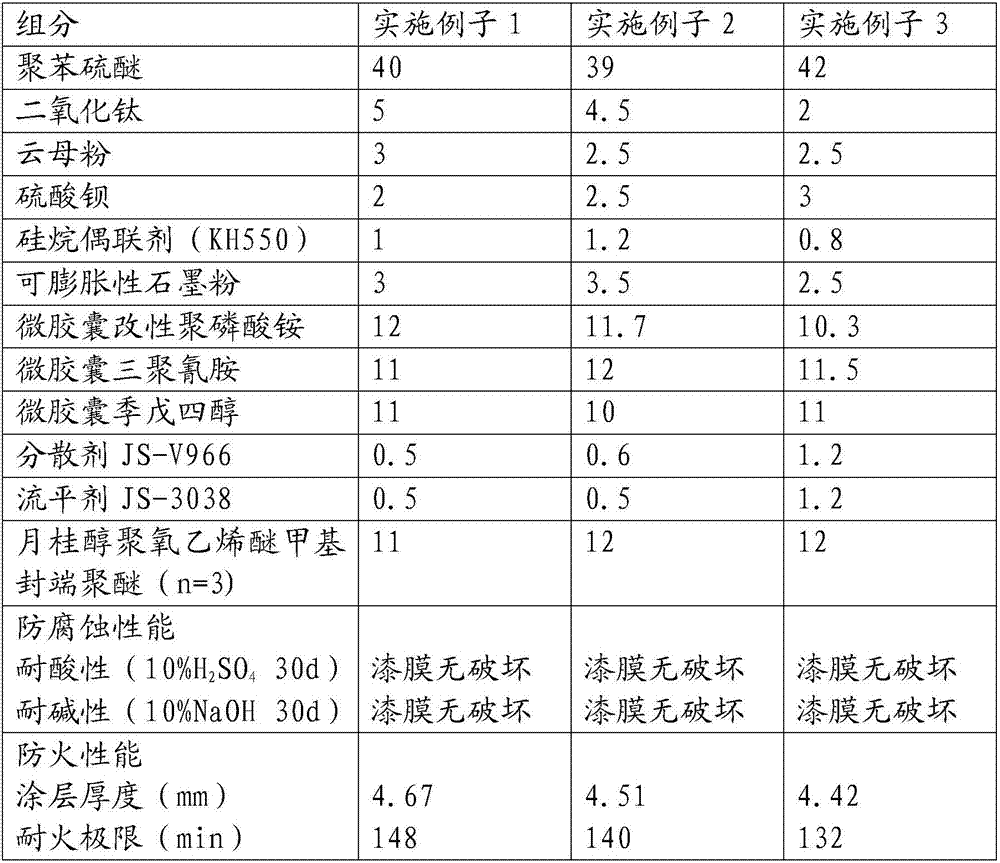

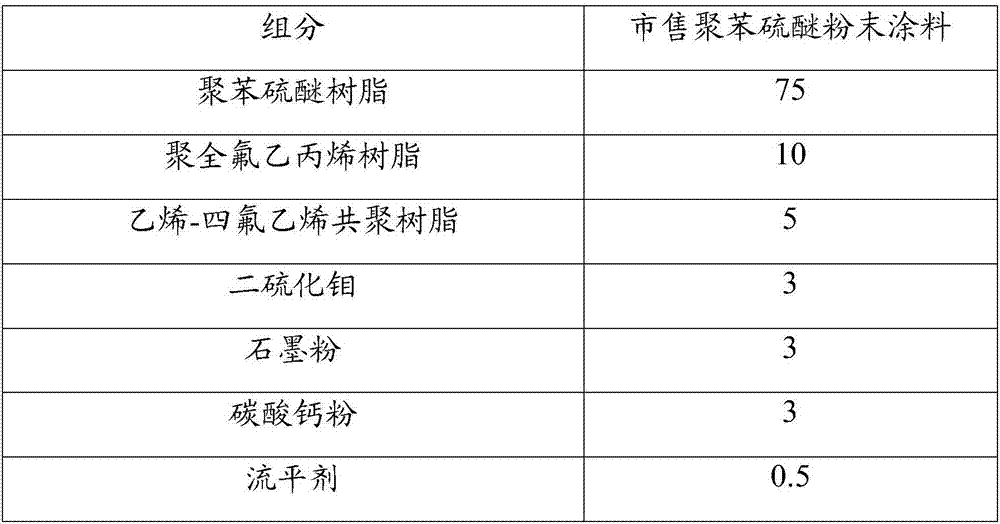

A polyphenylene sulfide powder coating with both anti-corrosion and fire-proof functions

ActiveCN105713510BImprove fire performanceGuaranteed physical propertiesFireproof paintsAnti-corrosive paintsChemical reactionSulfide

The invention belongs to the technical field of preparation of powder coatings and particularly discloses a polyphenylene sulfide powder coating having both anti-corrosion and fire-proof functions. The coating is prepared from 15%-55% of polyphenylene sulfide, 0-10% of titanium dioxide, 0-5% of mica powder, 0-3% of barium sulfate, 0.5%-1.5% of a silane coupling agent, 2.5%-5% of expandable graphite powder, 6%-10% of microcapsule modified ammonium polyphosphate, 6%-10% of microcapsule melamine, 6%-10% of microcapsule pentaerythritol, 0.5%-1.5% of a dispersing agent, 0.5%-1.5% of a leveling agent and 3%-7.5% of fatty alcohol polyoxyethylene methyl terminated polyether. The polyphenylene sulfide powder coating is applicable to fire-proof and anti-corrosion protection of steel structure buildings, large chemical reaction kettles, chemical corrosive raw material delivery pipelines and valves and has excellent anti-corrosion performance and good fire-proof performance.

Owner:唐楷

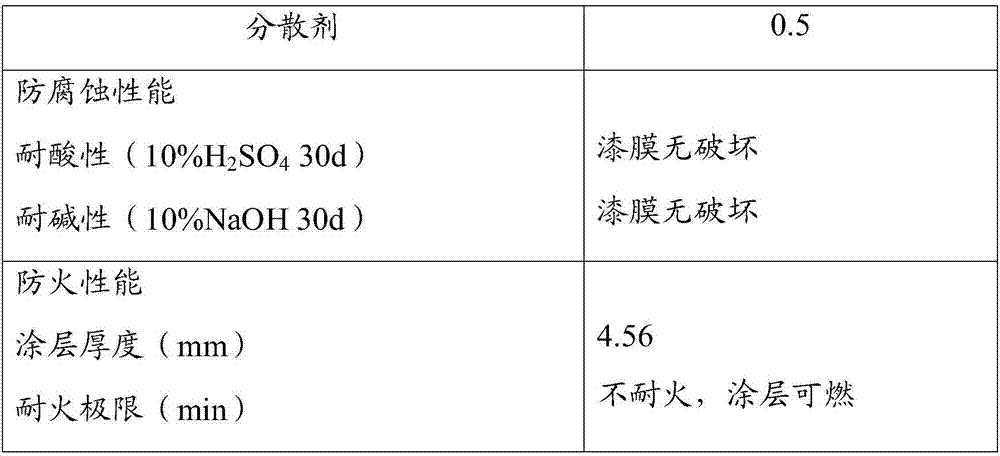

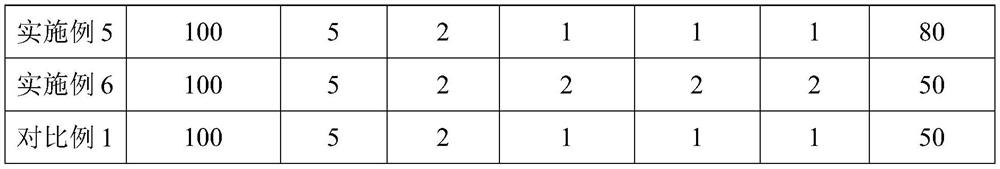

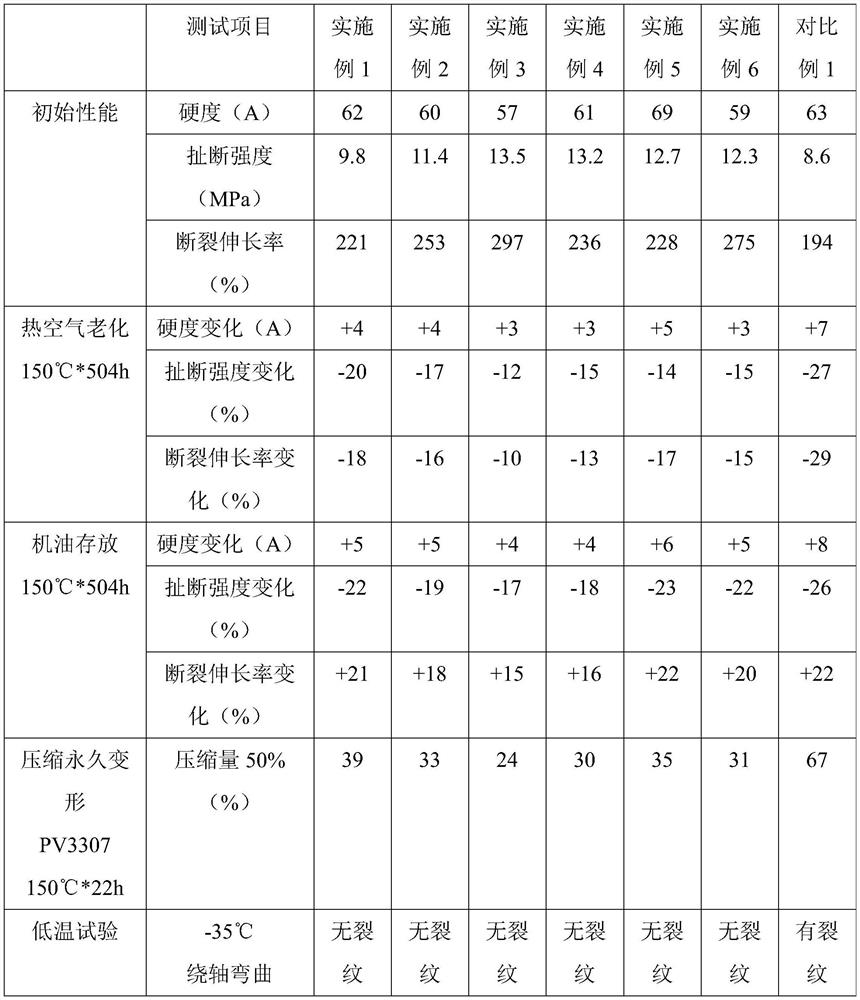

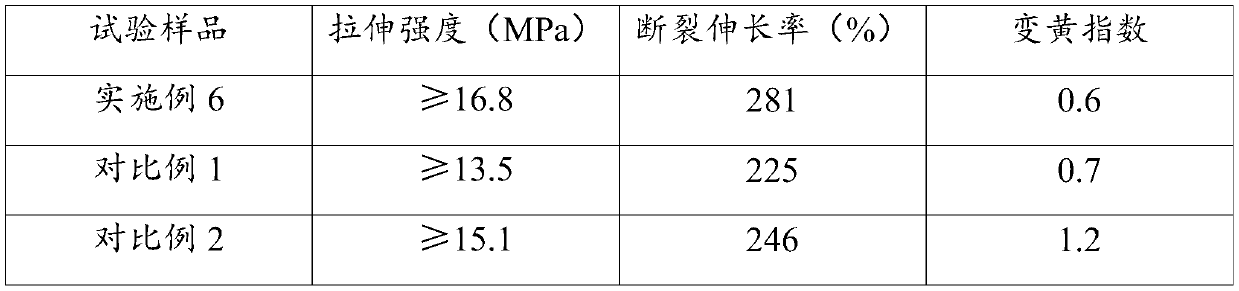

A sliding cross-linked network acrylate rubber seal and its preparation method

The invention relates to a high-performance acrylate rubber seal and a preparation method thereof, belonging to the technical field of sealing. The sliding cross-linked network acrylate rubber seal is composed of the following raw materials: acrylate rubber, polyrotaxane, vulcanizing agent, anti-aging agent, anti-scorch agent, lubricant, reinforcing agent. The present invention introduces supramolecular polyrotaxane into acrylate rubber, and forms a sliding cross-linked network structure through the co-vulcanization of the two, which not only retains the advantages of high temperature resistance, oil resistance, weather resistance and corrosion resistance of acrylate rubber, but also has excellent compression Resilience and stretch properties.

Owner:HUANGSHAN SHANGYI RUBBER & PLASTIC PRODS

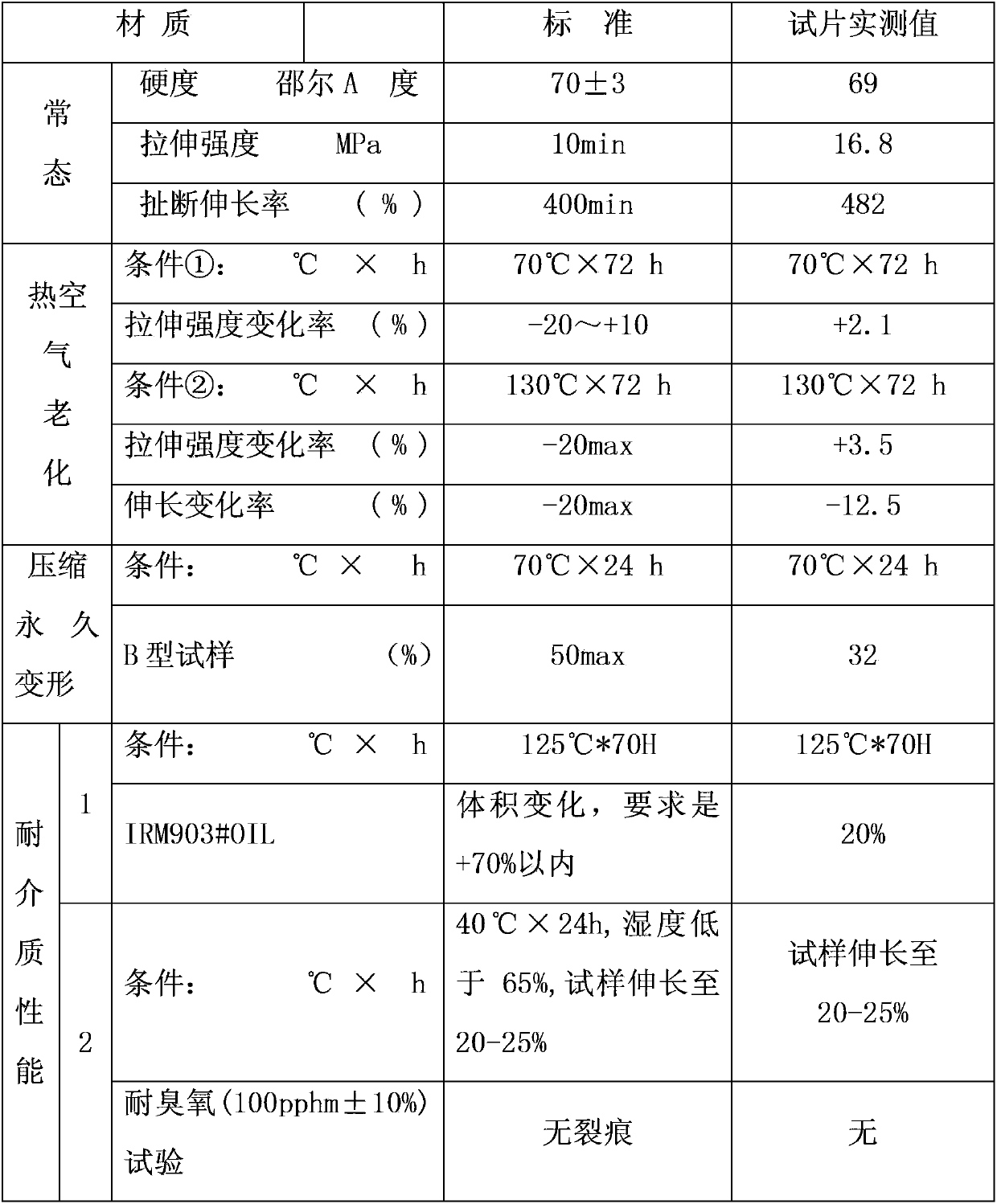

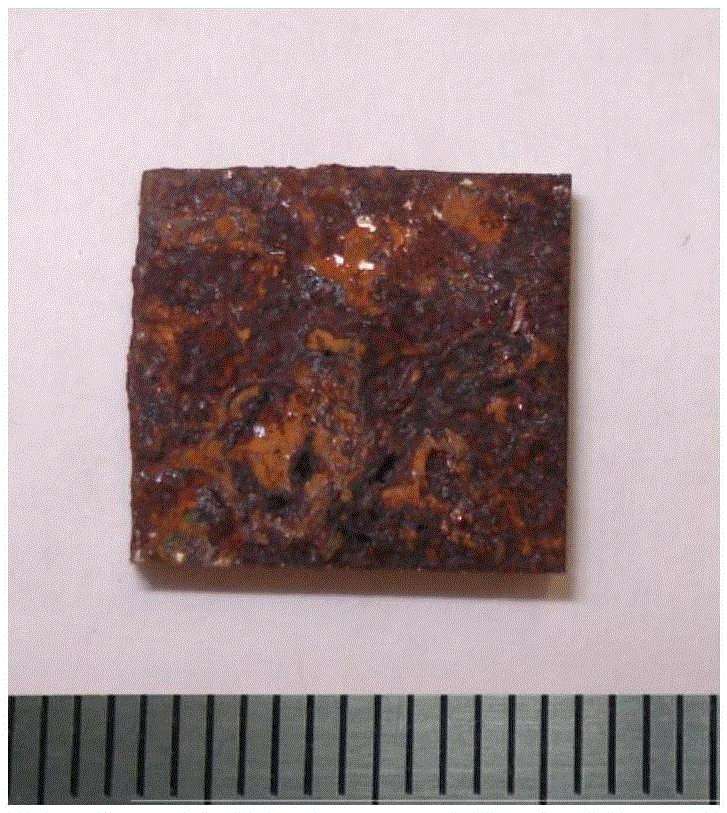

Preparation method of copper-steel composite material with authigenic copper-rich layer on steel surface

InactiveCN103952658AHigh strengthImprove toughnessSolid state diffusion coatingCopperUltimate tensile strength

The invention discloses a preparation method of a copper-steel composite material with an authigenic copper-rich layer on a steel surface. The problem about the bonding between the interfaces of a former externally added coating layer and a matrix is solved by means of spontaneously generating a copper-rich coating layer on the surface of a steel matrix. The preparation method comprises the following steps: corroding the surface of copper-containing steel, removing corrosion products, and treating the surface of the copper-steel composite material. According to the method, the copper-steel composite material with the copper-rich outer layer can be obtained without the means of externally adding a coating layer; as the coating layer is spontaneously generated by the matrix, the prepared copper-steel composite material does not have the problem about the bonding between the composite interfaces and the coating layer does not usually peel off; the prepared copper-steel composite material keeps not only the excellent properties such as high strength and good toughness of steel, but also the characteristics such as corrosion resistance and conductivity of copper; besides, the appearance of the composite material is attractive.

Owner:UNIV OF SCI & TECH LIAONING

Blending type rubber compound and preparation method thereof

ActiveCN102816390BRetain corrosion resistanceImprove mechanical propertiesRubber materialPolymer science

The invention belongs to the technical field of rubber materials and preparation of the rubber materials, and particularly relates to a blending type rubber compound and a preparation method thereof. The rubber compound comprises, by weight, 75-85 parts of ethylene-propylene-diene monomer (EPDM), 15-25 parts of rubber type chlorinated polyethylene (CPE), 2-3 parts of dicumyl peroxide (DCP), 0.8-1.5 parts of triallyl isocyanurate (TAIC), 25-35 parts of talcum powder, 25-35 parts of N660, 4-6 parts of TP759, 1-1.5 parts of SA and 3-6 parts of ZnO. The rubber type CPE and the EPDM are mixed in a certain proportion and other assistants are added simultaneously to obtain the blending type rubber compound through corresponding preparation processes, so that chlorine elements are added on the molecular weight of the EPDM, and the modified ethylene propylene rubber (EPR) not only reserves corrosion resistance of the EPR, but also is provided with good physical and mechanical properties and processability. The problems of the poor oil resistance and high cost of the existing EPR can be solved.

Owner:山东钧策科技服务有限公司

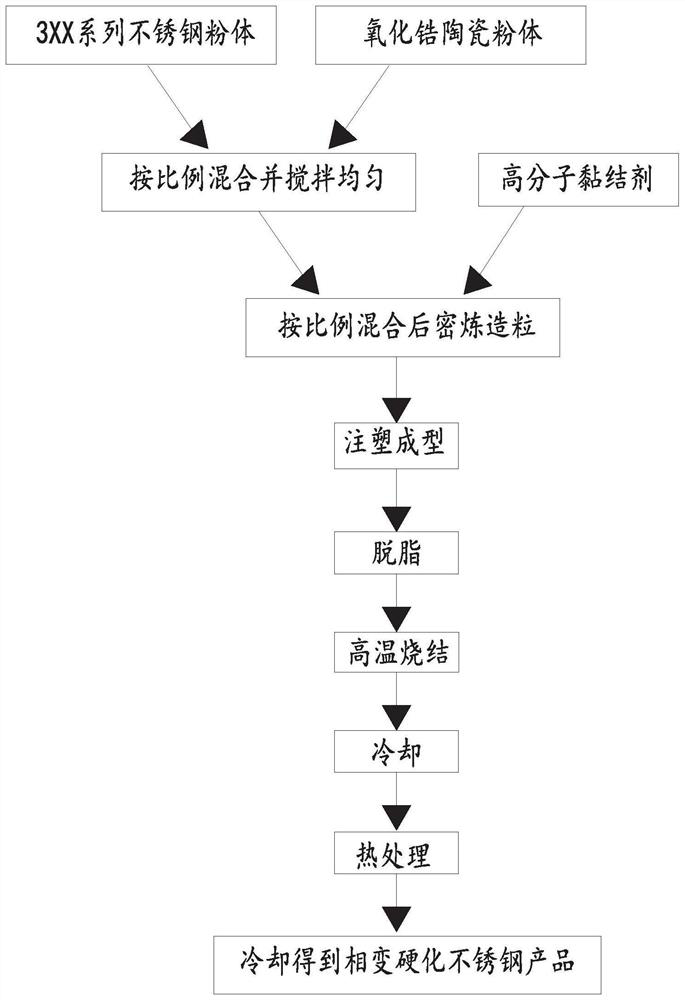

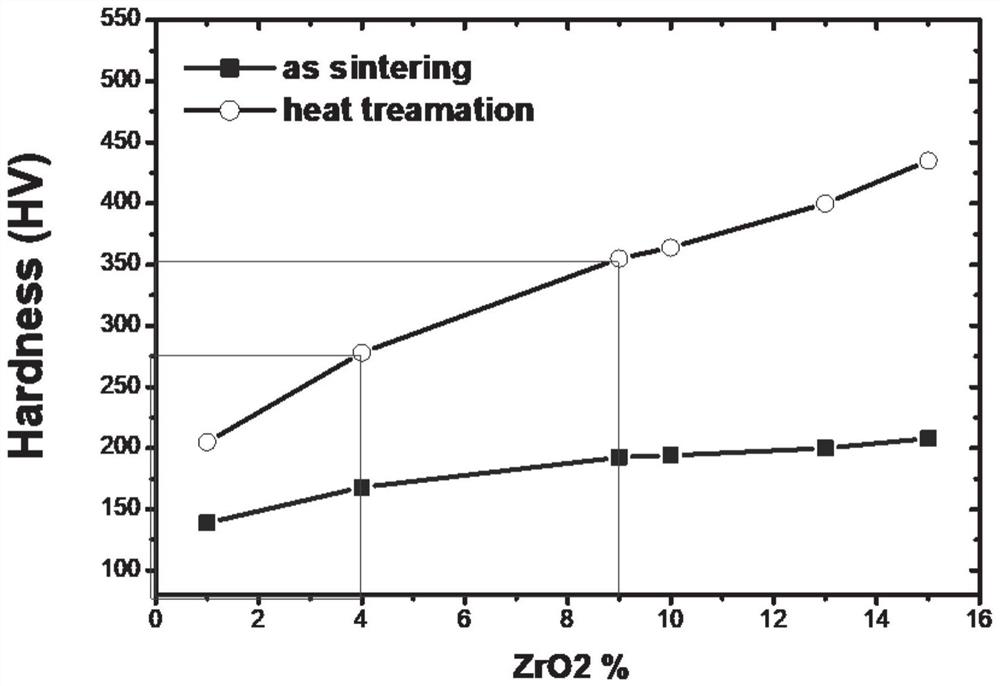

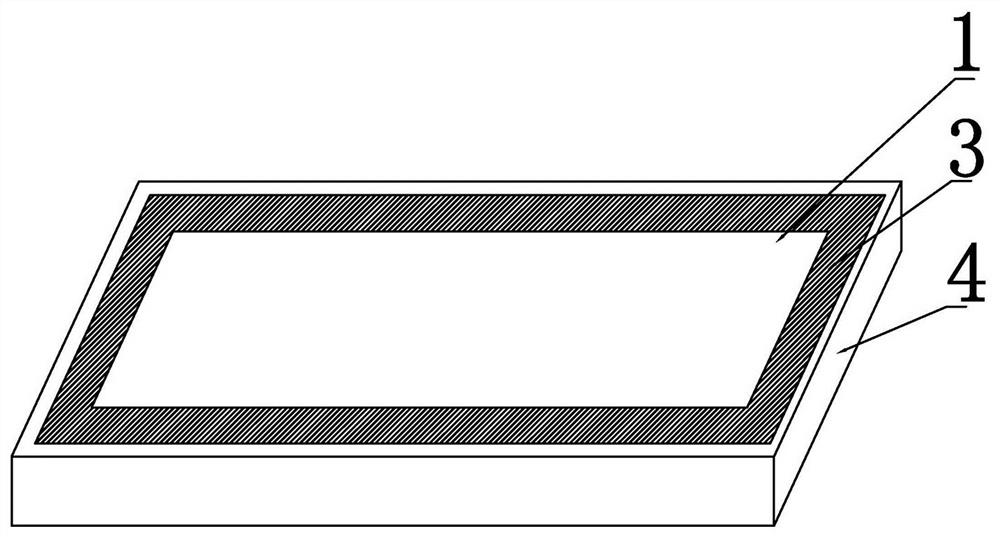

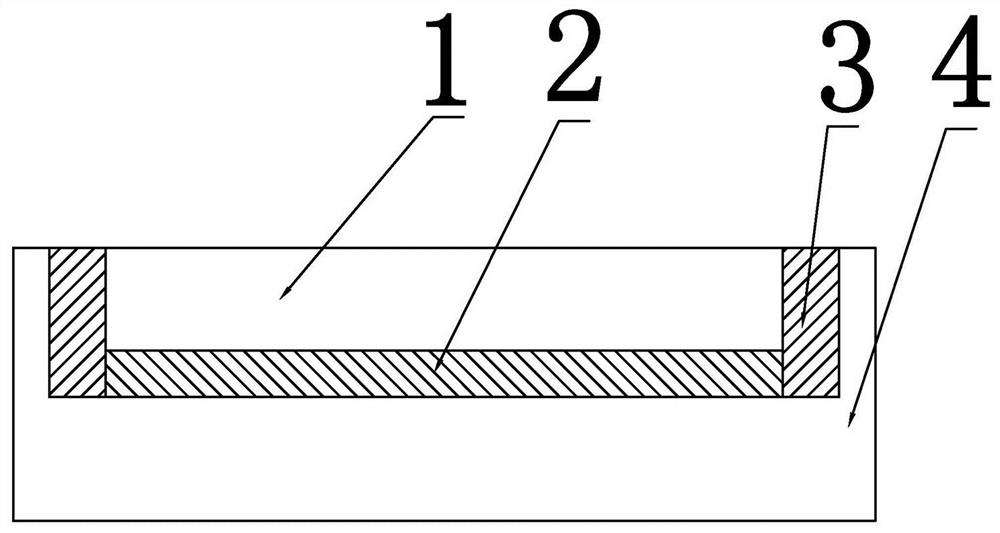

Phase change hardening stainless steel product and manufacturing method of phase change hardening stainless steel product

The invention provides a phase change hardening stainless steel product. The phase change hardening stainless steel product comprises a 3XX series stainless steel base material and zirconia ceramic powder evenly distributed in the base material. The d90 particle size of the ceramic powder is made to be smaller than 5 micrometers so that the proportion of the ceramic powder can be 0.03 wt%-30 wt%, adjacent crystals of the base material are in a mutual extrusion state, pre-stress is formed in the base material, hardness is improved, the stainless steel product not only can retain the characteristics of corrosion resistance, no magnetism and good ductility of 3xx series stainless steel, but also can have the characteristic of high hardness greater than or equal to HV200, has the advantages of the 3xx series stainless steel and 17-4PH stainless steel, and can be used in an extreme environment. The manufacturing method of the phase change hardening stainless steel product is simple in process, high in yield and easy to implement, stainless steel products of various complex shapes can be conveniently and rapidly manufactured, the application range is wide, and the manufactured phase change hardening stainless steel product has the characteristics of being good in corrosion resistance, good in ductility, free of magnetism, high in hardness and high in abrasion resistance, and can be used in an extreme environment.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

A method for preparing metal composite panels from as-cast billets

ActiveCN110788137BHigh bonding strengthShorten the production cycleTemperature control deviceWork heating devicesSorbentComposite plate

The disclosure of the present invention provides a method for preparing a metal composite panel by using a cast blank. The metal composite panel includes cladding metal, base carbon steel or alloy steel, a binder and a mixed active adsorbent, and the cladding metal and The base metal is subjected to derusting treatment, passivation treatment, and chemical cleaning on the joint surface. Add adhesive to the joint surface of the substrate and double board, add mixed active adsorbent around the joint surface, and heat the joint surface twice before rolling to make the joint surface Air, water vapor, etc. are excluded or absorbed by the mixed active adsorbent, and the binder melts to seal the joint surface and avoid oxidation. What the present invention obtains is a method for compounding metal composite plates by using as-cast blanks, which can effectively solve the problems of long billet assembly cycle and high cost in conventional composite plate preparation methods, save vacuuming equipment, and reduce production costs.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

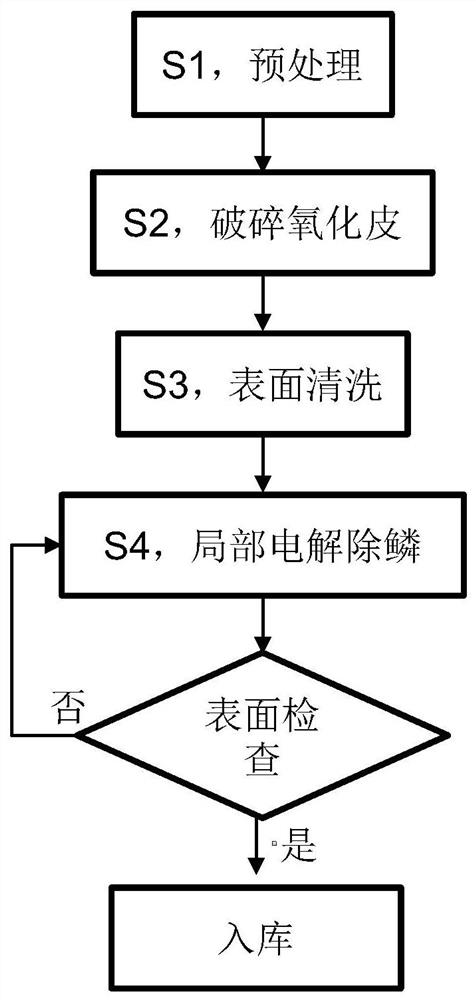

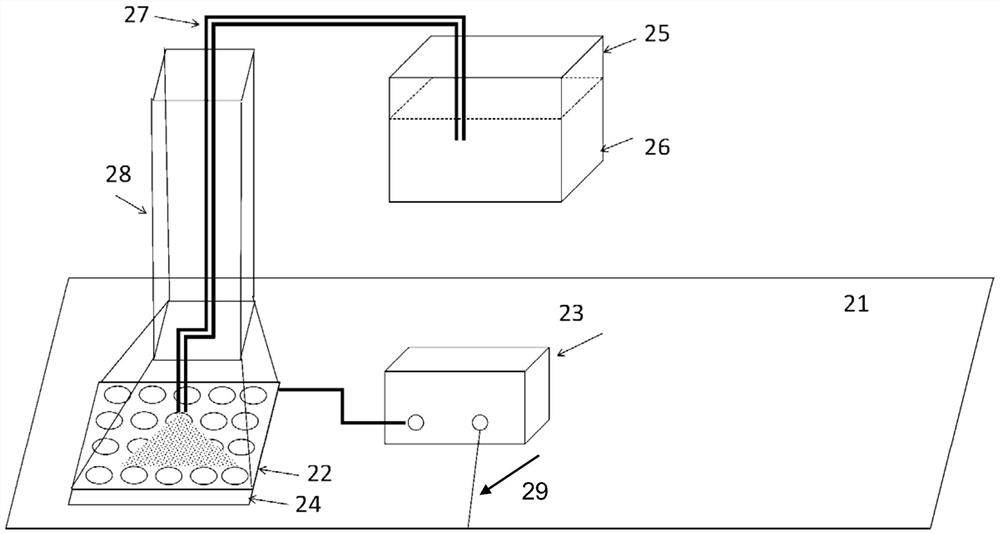

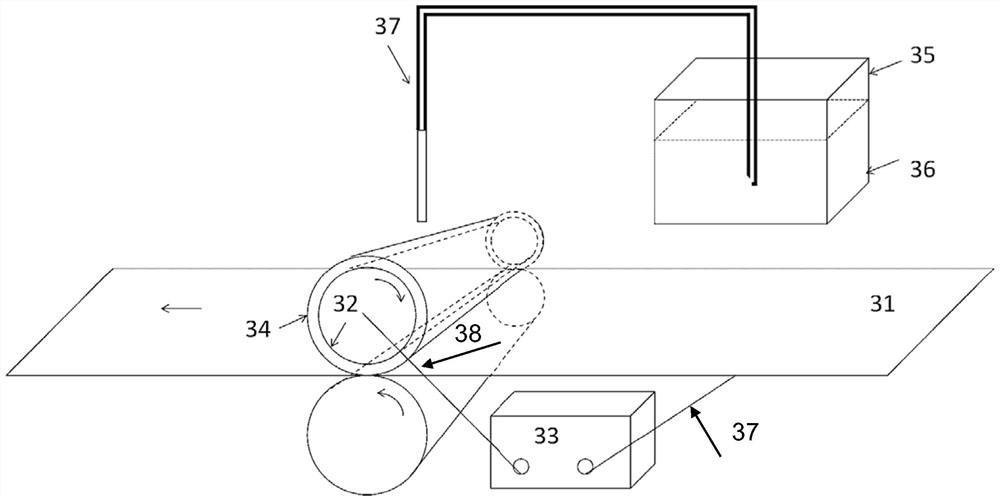

Anti-corrosion alloy and descaling method for derivatives of anti-corrosion alloy

The invention discloses an anti-corrosion alloy and a descaling method for derivatives of the anti-corrosion alloy. The method comprises the following steps of S1, pretreatment: removing impurities on the surfaces of the corrosion-resistant alloy and the derivatives thereof; S2, oxide skin crushing: crushing oxide skin on the surfaces of the corrosion-resistant alloy and the derivatives of the corrosion-resistant alloy in a physical mode; S3, surface cleaning: removing the impurities on the surfaces of the corrosion-resistant alloy and the derivatives of the corrosion-resistant alloy treated in the step S2; and S4, local electrolysis descaling: conducting electrolysis descaling on the surfaces, needing descaling, of the corrosion-resistant alloy and the derivatives of the corrosion-resistant alloy by adopting a local electrolysis device. According to the descaling method for the corrosion-resistant alloy and the derivatives thereof, on the premise that the performance of the corrosion-resistant alloy and the derivatives thereof is not affected, oxide skin on the surfaces of the corrosion-resistant alloy and the derivatives thereof and a chromium-poor layer below the oxide skin can be rapidly and efficiently cleaned, so that the surface quality of the corrosion-resistant alloy and the derivatives thereof is better, and the consumption cost in the cleaning process is lower.

Owner:BAOSHAN IRON & STEEL CO LTD

Installation body for automobile temperature switch

The invention relates to an automobile temperature switch, and particularly provides an installation body for the automobile temperature switch. The installation body comprises an aluminum alloy substrate and a copper plating. According to the installation body, the aluminum alloy substrate is adopted, and the copper plating is plated on the surface of the aluminum alloy substrate. The installation body for the automobile temperature switch can lower cost and save resources effectively, and can reduce the weight of the automobile temperature switch, thereby reducing the weight of an automobile.

Owner:曲阜天博汽车零部件制造有限公司

Polyether-ether-ketone cable material and preparation method thereof

ActiveCN103450631BImprove performanceReduce hardnessPlastic/resin/waxes insulatorsPoly ether ether ketoneHardness

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

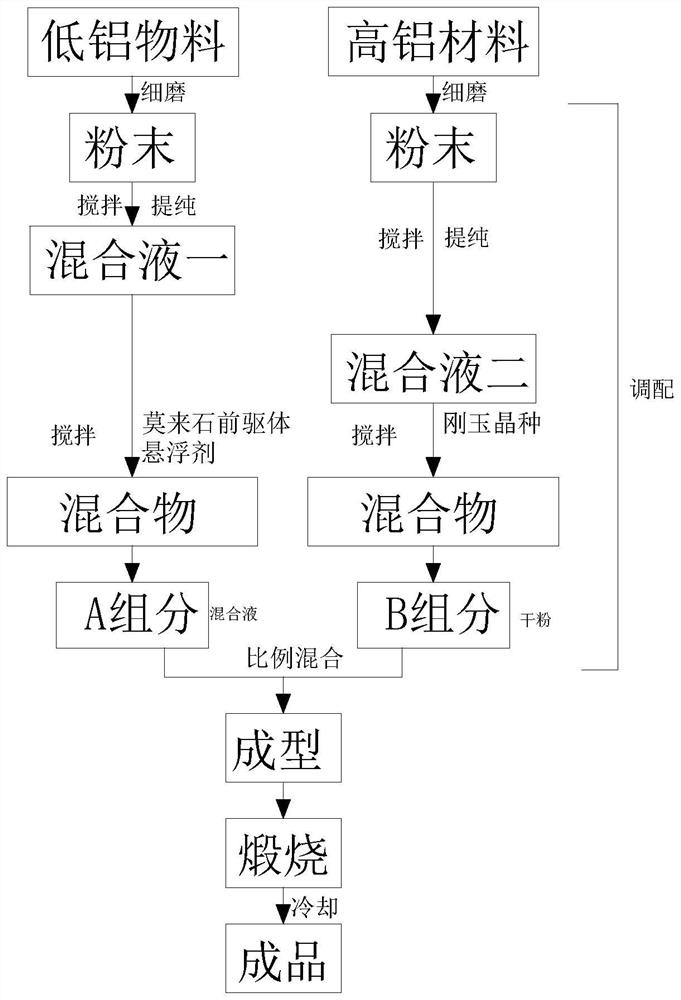

Preparation method of two-dimensional homogenized corundum mullite high-temperature material

PendingCN114409385ARetain corrosion resistanceImprove thermal shock resistancePhysical chemistryMullite

The invention relates to the technical field of high-temperature materials, and discloses a preparation method of a two-dimensional homogenized corundum mullite high-temperature material, which comprises the following steps: 1, selecting a main material and an auxiliary material: 2, respectively preparing a component A and a component B; 3, blending A and B according to the proportion and fully mixing; step 4, molding the mixed mixture; (5) calcining the formed mixture; and 6, cooling to obtain a finished product. A fine-ground high-aluminum material mainly forming a corundum phase serves as a substrate of a two-dimensional homogenized material, a fine-ground low-aluminum material mainly forming a mullite phase is added, and the two-dimensional homogenized material with the corundum phase serving as a surface and the mullite phase serving as a point structure is formed through mechanical uniform mixing, forming and sintering. The structure is similar to a long-range ordered and short-range disordered quasi-crystal structure of glass.

Owner:义马瑞辉新材料有限公司

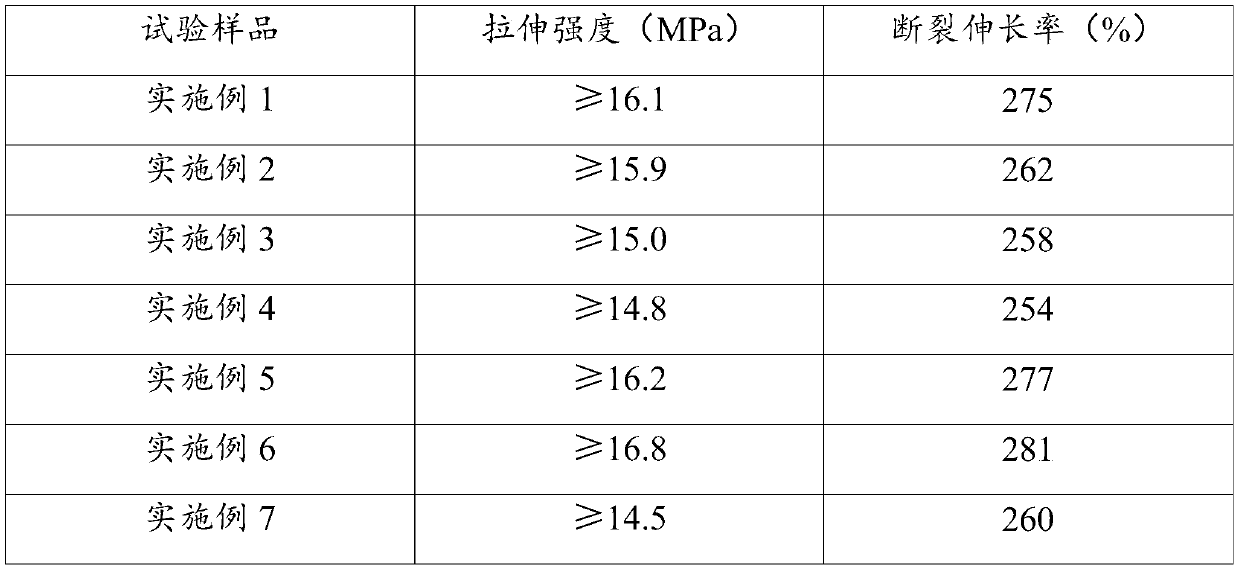

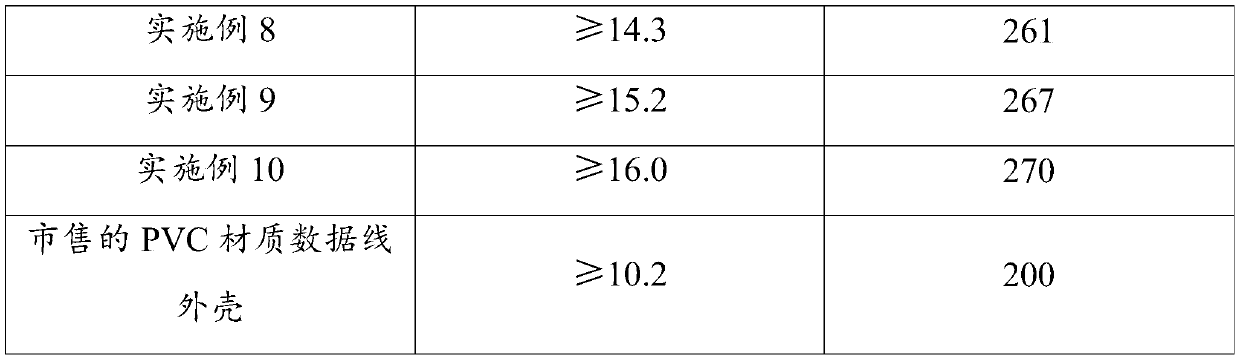

Data cable housing and preparation method thereof and data cable

InactiveCN110105699AImprove securityRetain corrosion resistanceCouplings bases/casesCross-linkPolyester

The invention is applied to the technical field of materials, and provides a data cable housing and a preparation method thereof and a data cable. The data cable housing is prepared from, by weight, 80-100 parts of a modified ethylene propylene diene monomer, 15-20 parts of microencapsulated red phosphorus, 3-7 parts of benzalkonium chloride, 13-18 parts of polyester adhesive powder and 4-6 partsof an assistant; the modified ethylene propylene diene monomer is prepared through the following steps that 35-40 parts of an ethylene propylene diene monomer, 10-25 parts of methylbenzene, 3.5-4.2 parts of an initiator, 17.5-20 parts of acrylonitrile, 5-9 parts of kaolin and 0.8-1.2 parts of a cross-linking agent by weight are weighed according to the formula; the ethylene propylene diene monomerand the methylbenzene are put in a reaction vessel, stirring and mixing are carried out for 5-15 hours, and a first mixture is obtained; after heating is carried out to 75-85 DEG C, the initiator andthe acrylonitrile are added, a stirring reaction is carried out for 2.5-4 hours, and a second mixture is obtained; heating is carried out to 140-155 DEG C, the kaolin and the cross-linking agent areadded, a stirring reaction is carried out for 1-2 hours, and the modified ethylene propylene diene monomer is obtained. The data cable housing has good insulativity, elasticity, toughness, ageing resistance and yellowing resistance and high safety.

Owner:深圳思锐科电子有限公司

High chromium rust free, wear resistance cored welding wire

InactiveCN100343008CWith wear resistanceRetain corrosion resistanceWelding/cutting media/materialsSoldering mediaNiobiumHigh carbon

The antiwear stainless cored high chromium wire has coat of low carbon steel and powder core comprising high carbon ferrochromium 36-42 wt%, micro carbon ferrochromium 26-32 wt%, metal Cr powder 15-17 wt%, ferromolybdenum 2-4 wt%, ferrovanadium 3-5 wt%, tungsten carbide 4-6 wt%, ferroboron 5-8 wt%, nickel powder 2-4 wt%, niobium powder 2-5 wt% and RE silicon 2-3 wt%, and with one welding wire filling amount of 0.49-0.52. The present invention results in raised comprehensive welding performance and raised welding quality, high anticossive performance, high anticracking performance and average fused-on metal hardness of HRC54, and may be applied widely in build-up welding field requiring high antiwear, anticorrosive and anticracking performance.

Owner:XIANGTAN UNIV

Preparation method of copper-steel composite material with self-generated copper-rich layer on steel surface

The invention discloses a preparation method of a copper-steel composite material with an authigenic copper-rich layer on a steel surface. The problem about the bonding between the interfaces of a former externally added coating layer and a matrix is solved by means of spontaneously generating a copper-rich coating layer on the surface of a steel matrix. The preparation method comprises the following steps: corroding the surface of copper-containing steel, removing corrosion products, and treating the surface of the copper-steel composite material. According to the method, the copper-steel composite material with the copper-rich outer layer can be obtained without the means of externally adding a coating layer; as the coating layer is spontaneously generated by the matrix, the prepared copper-steel composite material does not have the problem about the bonding between the composite interfaces and the coating layer does not usually peel off; the prepared copper-steel composite material keeps not only the excellent properties such as high strength and good toughness of steel, but also the characteristics such as corrosion resistance and conductivity of copper; besides, the appearance of the composite material is attractive.

Owner:UNIV OF SCI & TECH LIAONING

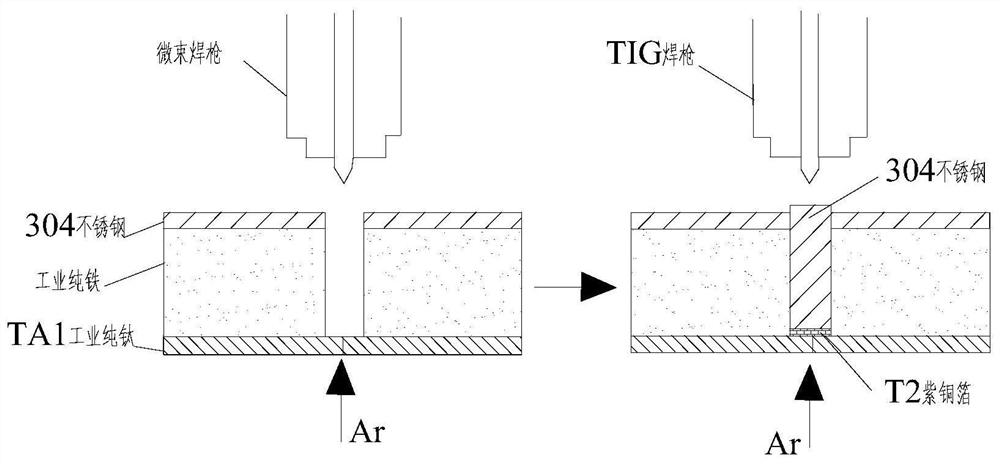

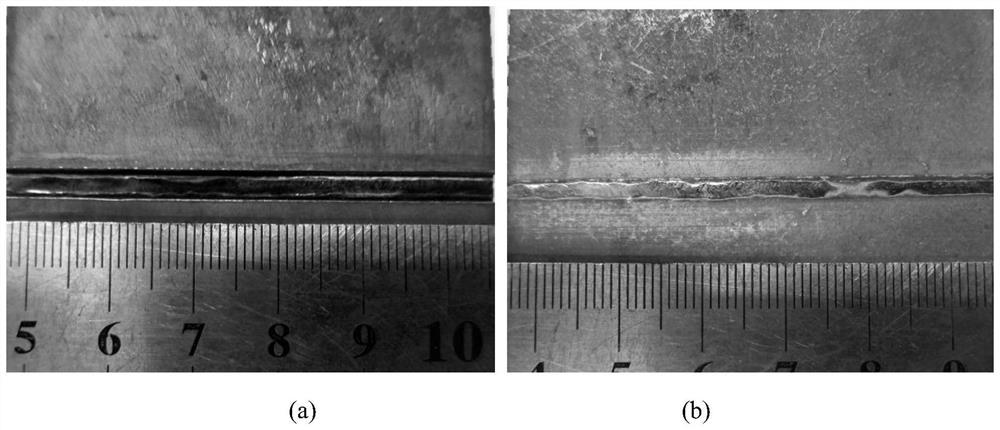

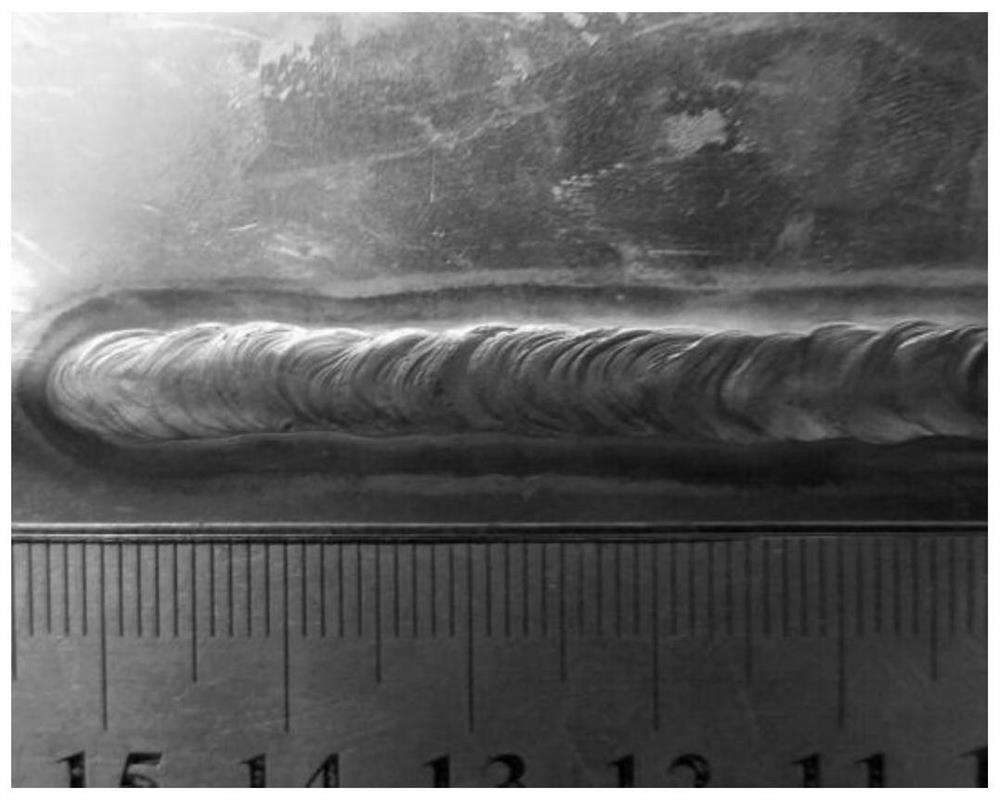

A kind of titanium-iron-stainless steel three-layer composite plate butt welding process method

ActiveCN110682020BWell formedAchieve weldingArc welding apparatusPlasma welding apparatusButt weldingThin slab

The invention discloses a butt welding process method of a titanium-iron-stainless steel three-layer composite plate, which belongs to the field of layered dissimilar metal composite plate welding. The method first processes the base material of the titanium-iron-stainless steel three-layer composite plate to prepare the base material with a welding groove; prepares the weld filler metal according to the welding groove form of the welded joint; prepares the base material with the welding groove The material is placed in the welding fixture, the titanium cladding is subjected to the first pass of bottom welding, and then the weld filler metal is placed, and the second pass of upper metal welding is performed to obtain the butt joint of the titanium-iron-stainless steel three-layer composite plate . This method is especially suitable for composite thin plates. At the same time, it solves the problem of brittle intermetallic compounds when welding titanium-iron dissimilar metals, and also retains its original corrosion resistance when welding iron-stainless steel dissimilar steels. The produced by this method The yield is high, the production cost is low, the welding efficiency is high, the strength of the welded joint is high, and the tensile strength of the welded joint reaches more than 75% of the tensile strength of the base metal.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com