Anti-aging and permanent-compression-deformation-resistant rubber material

A permanent compression deformation, rubber material technology, applied in the field of rubber materials, can solve the problem of difficult to meet the requirements of resistance to permanent compression deformation and aging resistance, to improve the cross-linking efficiency and vulcanization speed, excellent oxidation resistance, improve compatibility sexual effect

Inactive Publication Date: 2014-10-01

安徽宁国尚鼎橡塑制品有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the above properties of EPDM rubber, it is widely used in various aspects, but the existing EPDM rubber is still difficult to meet the requirements of permanent compression deformation resistance and aging resistance, and it is necessary to add various auxiliary ingredients or through modification. Improve its mechanical and chemical properties to meet the above requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

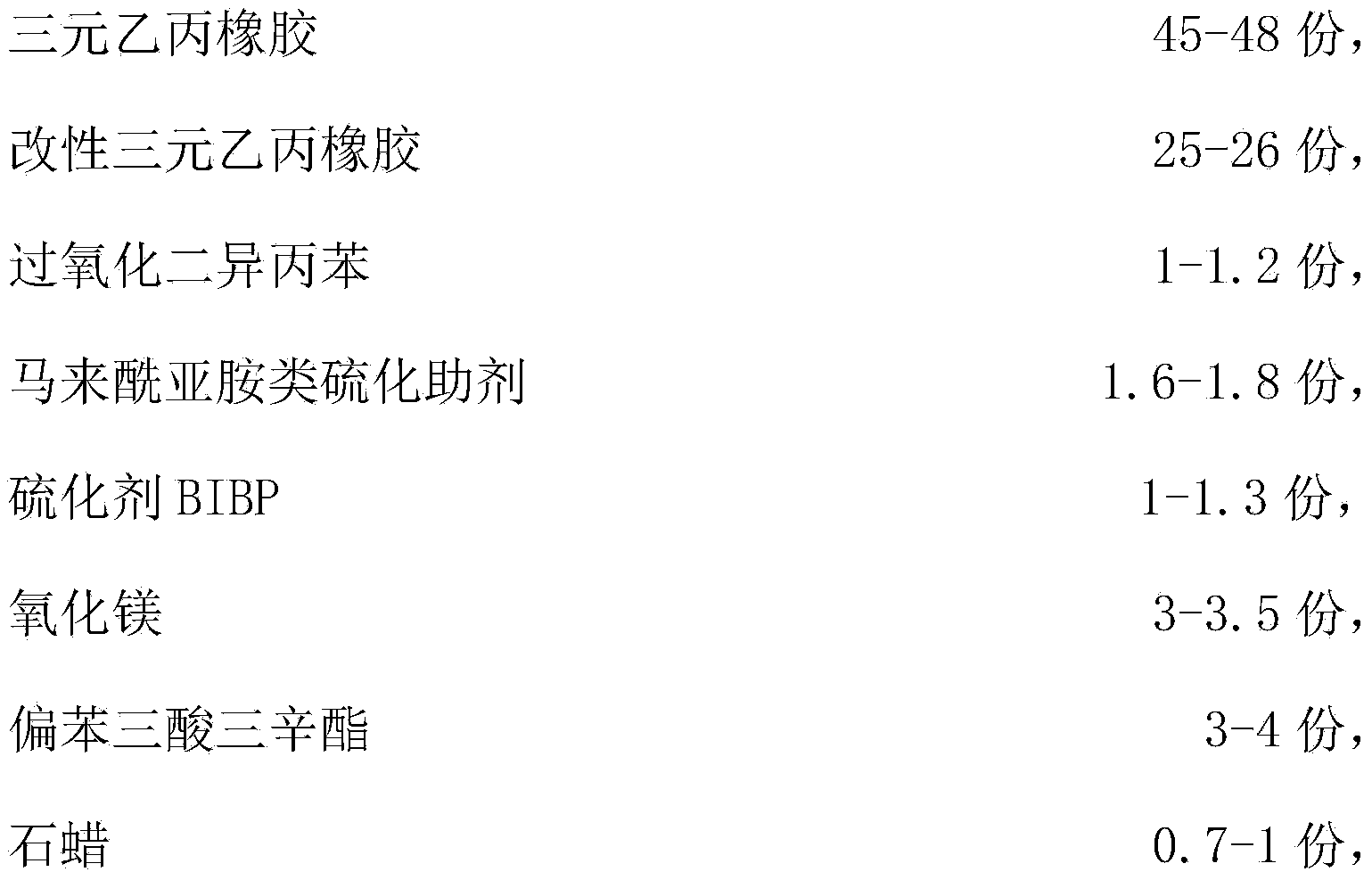

[0020] In embodiment 1, ethylene content is 55wt% in the EPDM rubber, and Mooney viscosity ML (1+4) 100 ℃ is 85; In embodiment 2, the particle diameter of superfine activated clay is 50-90nm; Implementation In Example 3, the maleimide vulcanization aid is N, N'-m-phenylene maleimide; in Example 4, the ethylene content in EPDM rubber is 63wt%, Mooney viscosity ML (1+4) 93 at 100°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

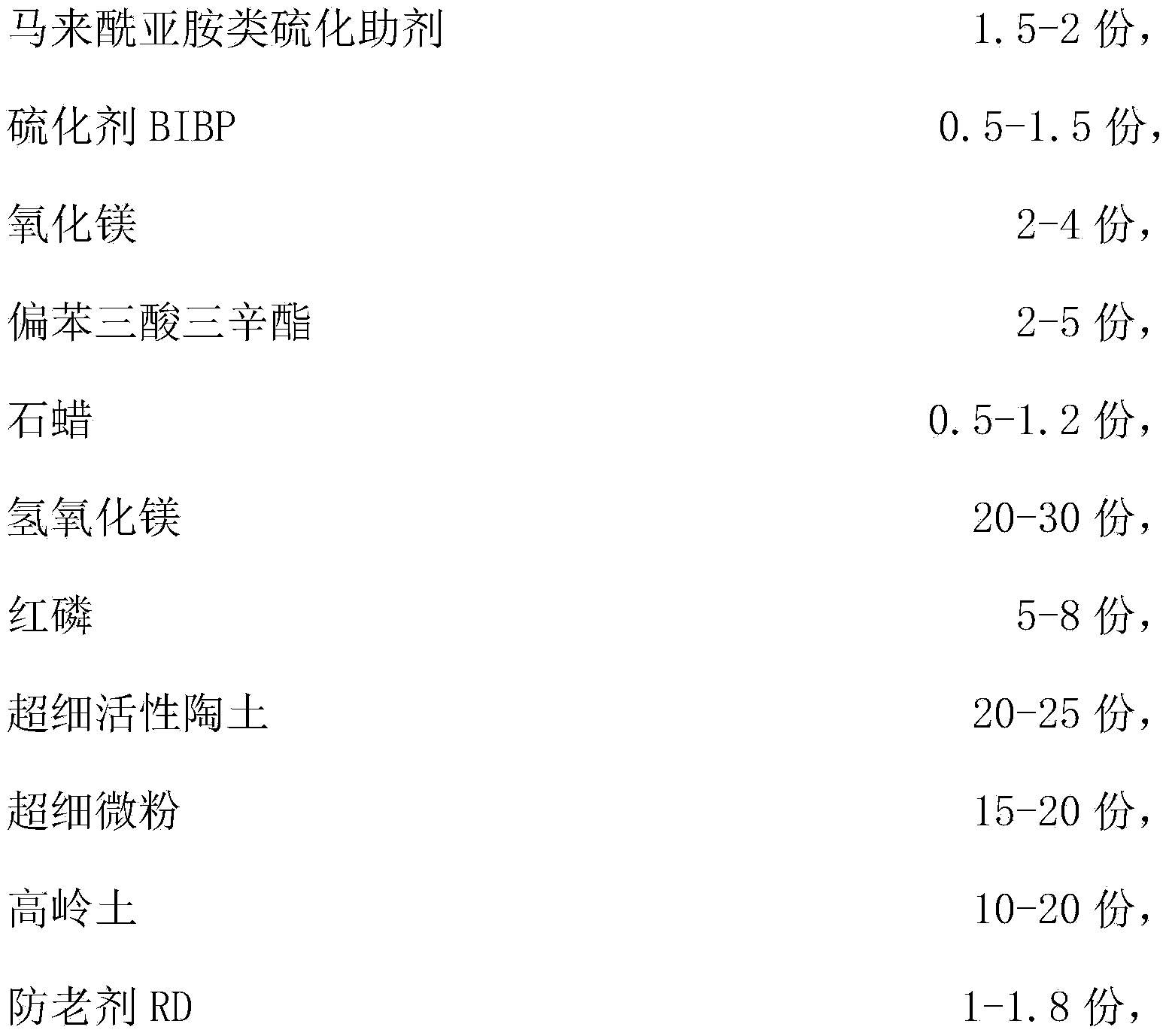

The invention discloses an anti-aging and permanent-compression-deformation-resistant rubber material. The rubber material comprises the following components in parts by weight: 30-50 parts of ethylene propylene diene monomer, 20-30 parts of modified ethylene propylene diene monomer, 0.8-1.5 parts of dicumyl peroxide, 1.5-2 parts of maleimide vulcanizing aids, 0.5-1.5 part of a vulcanizing agent BIBP, 2-4 parts of magnesium oxide, 2-5 parts of trioctyl trimellitate, 0.5-1.2 parts of paraffin, 20-30 parts of magnesium hydroxide, 5-8 parts of red phosphorus, 20-25 parts of superfine active clay, 15-20 parts of ultra-fine powder, 10- 20 parts of kaolin and 1-1.8 parts of an anti-aging agent RD, wherein the modified ethylene propylene diene monomer is acrylonitrile-grafted ethylene propylene diene monomer. The rubber material disclosed by the invention has the advantages of excellent anti-aging performance and good resistance to permanent compression deformation.

Description

technical field [0001] The invention relates to the technical field of rubber materials, in particular to an aging-resistant and permanent compression-deformation-resistant rubber material. Background technique [0002] EPDM rubber is a terpolymer of ethylene, propylene and non-conjugated diene. Diene has a special structure. Only one of the two bonds can be copolymerized. The unsaturated double bond is mainly used as a cross-link. An unsaturated one will not become the main chain of the polymer, but only the side chain, so that the main polymer chain of EPDM rubber is completely saturated and can resist heat, light, oxygen, especially ozone. EPDM rubber is non-polar in nature, resistant to polar solutions and chemicals, has low water absorption, and has good insulating properties. EPDM has the lowest specific gravity of all rubbers and can absorb large amounts of fillers and oils with little effect on properties, making it possible to make inexpensive rubber compounds. Du...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/16C08L51/06C08K13/02C08K5/14C08K3/22C08K5/12C08K3/02C08K3/34

CPCC08L23/16C08K2201/014C08L2201/08C08L2205/03C08L51/06C08L91/06C08K13/02C08K5/14C08K2003/222C08K5/12C08K2003/2224C08K2003/026C08K3/346

Inventor 杨存俊

Owner 安徽宁国尚鼎橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com