Preparation method of two-dimensional homogenized corundum mullite high-temperature material

A high-temperature material, mullite technology, applied in the field of preparation of two-dimensional homogeneous corundum mullite high-temperature materials, can solve the problems of thermal shock resistance, creep resistance and high-temperature bending resistance, etc., to improve heat resistance The effect of improving the shock performance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A two-dimensional homogeneous corundum-mullite high-temperature material. The high-temperature material is composed of A component and B component mixed with a binder, wherein the ratio of A:B:binder is 2.5:7.5:0.02; wherein B component 90 parts by mass of corundum and 10 parts by mass of corundum seed crystals; component A consists of 75 parts by mass of mullite and 25 parts by mass of mullite precursor.

Embodiment 2

[0040] A two-dimensional homogeneous corundum-mullite high-temperature material. The high-temperature material is composed of A component and B component mixed with a binder, wherein the ratio of A:B:binder is 1.5:8.5:0.05; wherein B component 70 parts by mass of corundum, 30 parts by mass of corundum seed crystals, 80 parts by mass of mullite and 20 parts by mass of mullite precursor.

Embodiment 3

[0042] A two-dimensional homogeneous corundum-mullite high-temperature material. The high-temperature material is composed of A component and B component mixed with a binder, wherein the ratio of A:B:binder is 2.0:8.0:0.03; wherein B component 80 parts by mass of corundum, 20 parts by mass of corundum seed crystals, 90 parts by mass of mullite and 10 parts by mass of mullite precursor in component A.

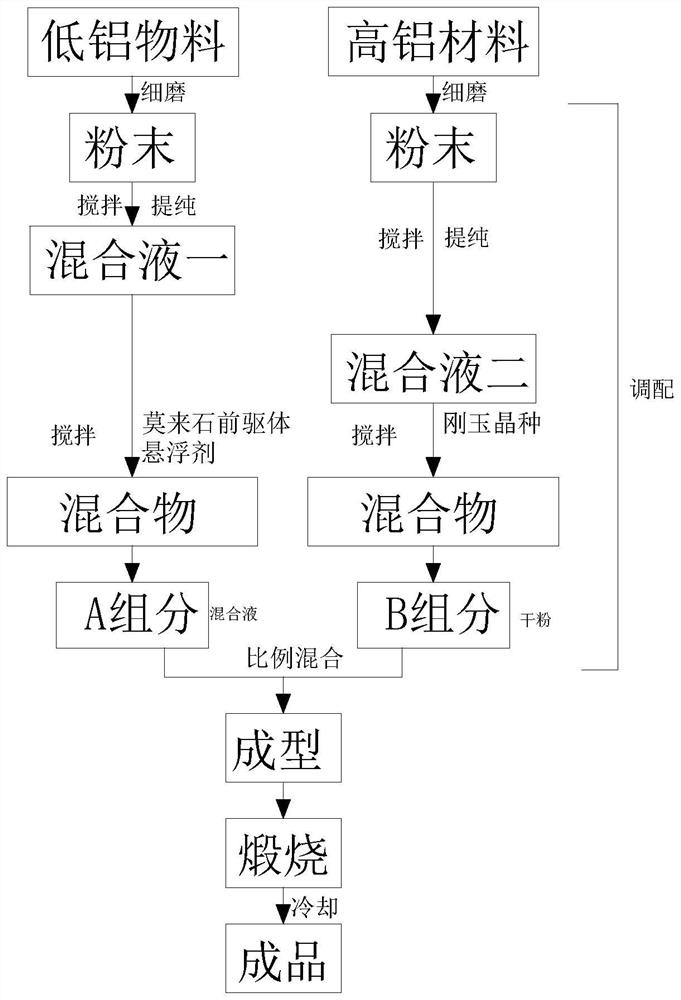

[0043] see figure 1 , a method for preparing a two-dimensional homogeneous corundum-mullite high-temperature material, comprising the following steps:

[0044] The first step: select the main material and auxiliary materials; the main material includes high-alumina materials, mainly to form corundum phase; the main material also includes low-alumina materials, mainly to form mullite phase; the first step The auxiliary materials include mullite precursors, corundum seeds, suspending agents and binders.

[0045] Step 2: prepare components A and B respectively; component A is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com