Polyether-ether-ketone cable material and preparation method thereof

A technology of polyether ether ketone and cable materials, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of difficult wire and cable manufacturing, unsuitable processing characteristics, high fracture toughness, etc., and achieve long storage period and improved Processing characteristics and effects of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A polyether ether ketone cable material and its preparation method

[0028] Weighing by mass:

[0029] Polyetheretherketone (brand: 450G, manufacturer: Victrex, UK) 65 parts;

[0030] Silicone (brand: GENIOPLAST ? PELLET S, manufacturer: Wacker) 4 parts;

[0031] 0.5 part of nano-montmorillonite;

[0032] 4.5 parts of maleic anhydride grafted SEBS;

[0033] SEBS 26 copies;

[0034] After weighing, mix all the materials evenly in a closed high-speed mixer, release them after 20 minutes, granulate them through a twin-screw extruder at a process temperature of 220-380°C, and pack them to form finished polyetheretherketone cable materials.

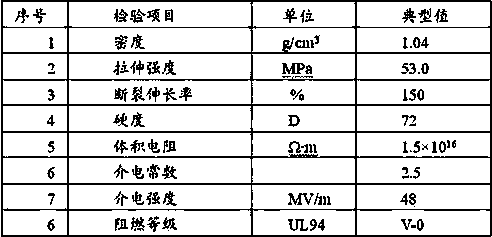

[0035] The typical values of the finished polyetheretherketone cable material obtained in Example 1 are as follows:

[0036]

Embodiment 2 4

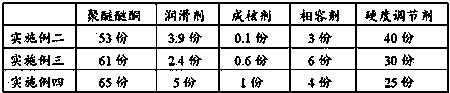

[0037] Embodiments 2-4: A polyetheretherketone cable material and its preparation method

[0038] The formula of embodiment is as follows:

[0039]

Embodiment 2

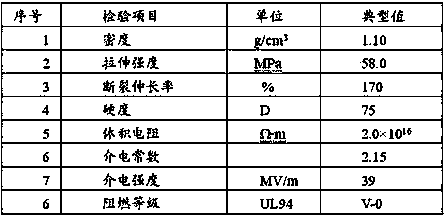

[0041] The typical values of the finished polyetheretherketone cable materials obtained in Example 2 are as follows:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com