Patents

Literature

51results about How to "Retain high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenylene sulfide/polyamide composite material and method for making same

The present invention discloses one kind of polyphenyl thioether / polyamide composite material and its preparation process. The polyphenyl thioether / polyamide composite material is prepared with polyphenyl thioether 23-69.3 wt%, polyamide 10-30 wt%, glass fiber 20-40 wt%, heat stabilizer 0.2-2 wt%, silane coupler 0.1-2 wt%, processing lubricant 0.2-2 wt% and crystallization promoter 0.1-1 wt%. The polyphenyl thioether / polyamide composite material has high shock toughness, simple preparation process and low cost.

Owner:ANHUI KEJU NEW MATERIALS

Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

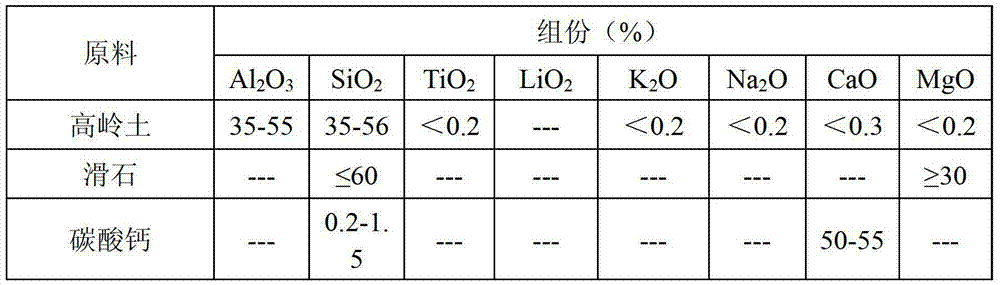

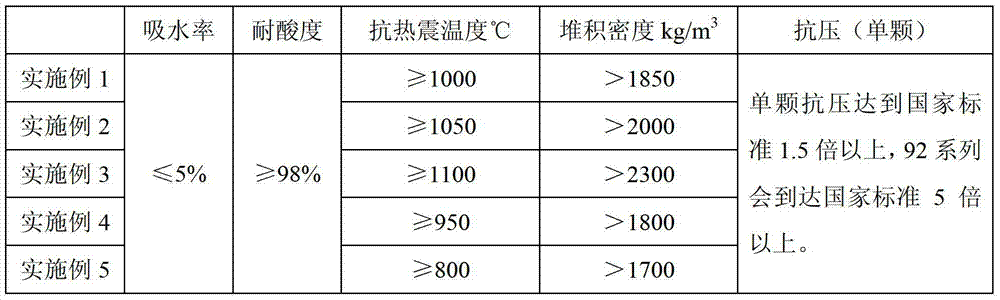

The invention discloses a method for preparing an inert porcelain ball by using an aluminum oxide dust-recovery powder and belongs to the technical field of new materials. A lot of aluminum oxide dust-recovery powder is used in the formulation of the method disclosed by the invention, the cost is obviously reduced, meanwhile a waste material is used and the environment is protected. According to the method disclosed by the invention, a composite sintering aid comprising calcium carbonate, talcum, and spodumene mineral powder is added into the formulation to facilitate the formation of magnesia-alumina spinel and mullite for enhancing in the product so as to improve the thermal shock resistance and strength of a product; a little kaolin is added into the formulation for improving the plasticity of a perform body, promoting molding conveniently and improving the strength of a green body; meanwhile in order to reduce the high energy consumption caused by wet ball milling, the powder for preparing the inert porcelain ball disclosed by the invention is subjected to continuous dry wet milling; the inert porcelain ball prepared by the method disclosed by the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance and the like, is excellent in comprehensive performance, and is completely suitable for requirements for a catalyst carrier and supporting performance in various industries.

Owner:JINGANG NEW MATERIALS

Full-biodegradable antibacterial PLA/PBAT film and preparation method thereof

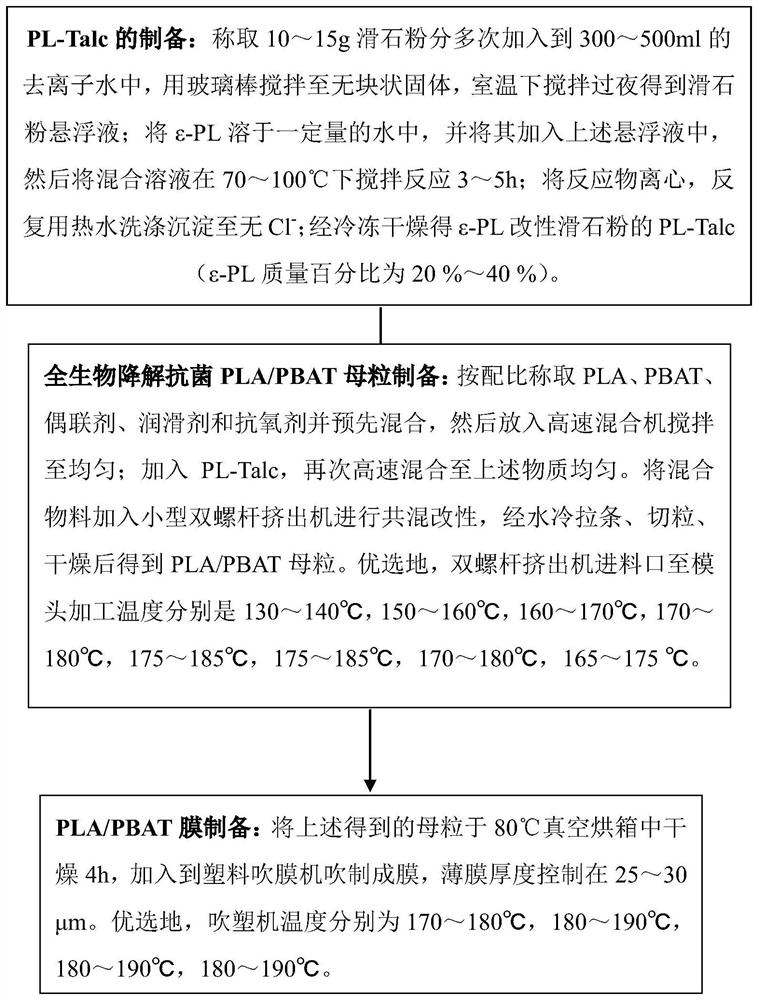

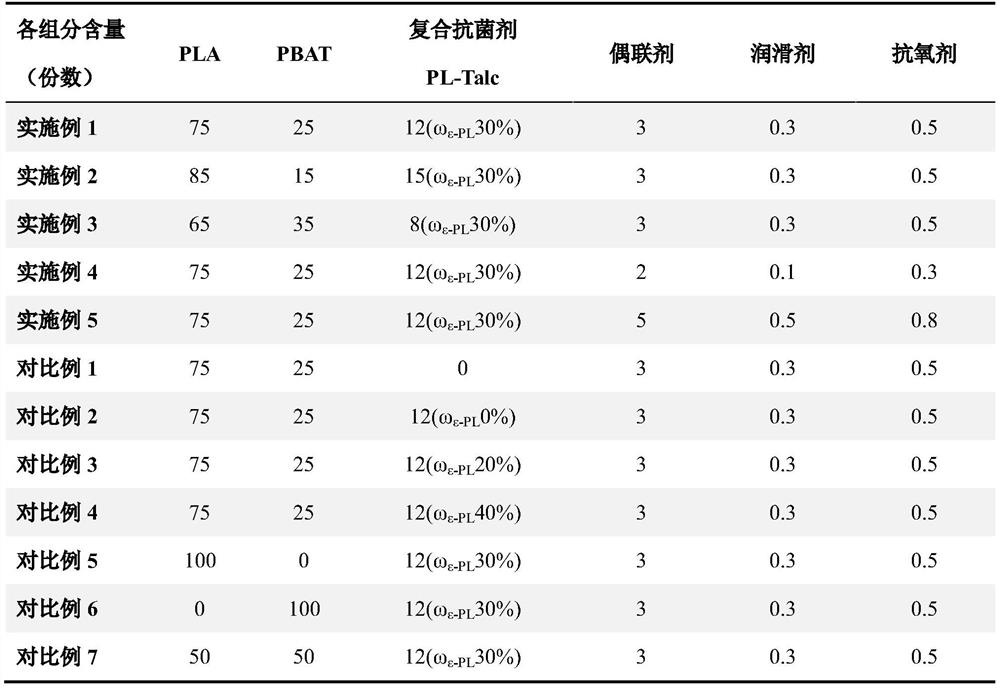

InactiveCN112679928AKeep securityRetain high temperature resistancePolymer scienceAntibacterial activity

The invention relates to the technical field of full-biodegradable films, in particular to a full-biodegradable antibacterial PLA / PBAT film and a preparation method thereof. The full-biodegradable antibacterial PLA / PBAT film is prepared from the following raw materials in parts by weight: 65 to 85 parts of PLA, 15 to 35 parts of PBAT, 8 to 15 parts of a composite antibacterial agent, 2 to 5 parts of a coupling agent, 0.1 to 0.5 part of a lubricating agent and 0.3 to 0.8 part of an antioxidant, wherein the composite antibacterial agent is prepared from epsilon-polylysine hydrochloride and talcum powder through a modification preparation method. According to the fully-biodegradable antibacterial PLA / PBAT film provided by the invention, two fully-biodegradable polymers PLA and PBAT are selected as matrixes, and inorganic filler talcum powder is adopted as a carrier to disperse an antibacterial active center epsilon-polylysine hydrochloride, so the PLA / PBAT film becomes a fully-biodegradable novel composite material with excellent mechanical properties and antibacterial properties.

Owner:东莞市三至新材料技术有限公司

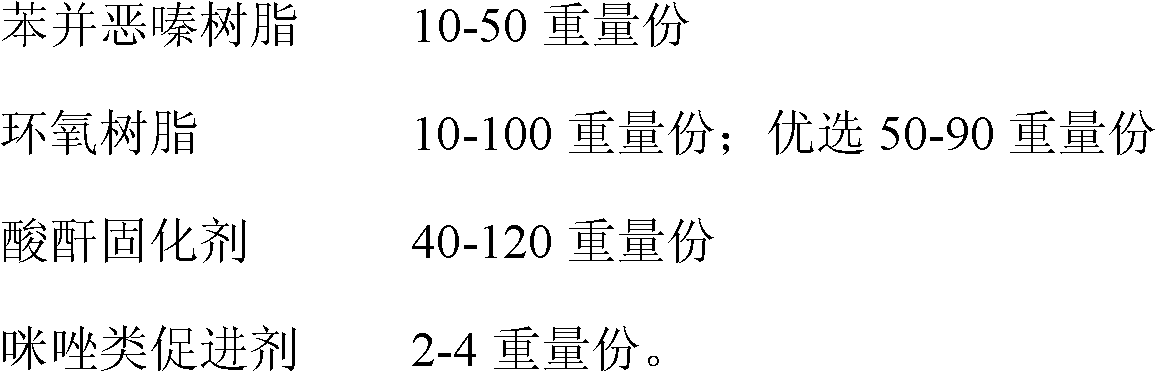

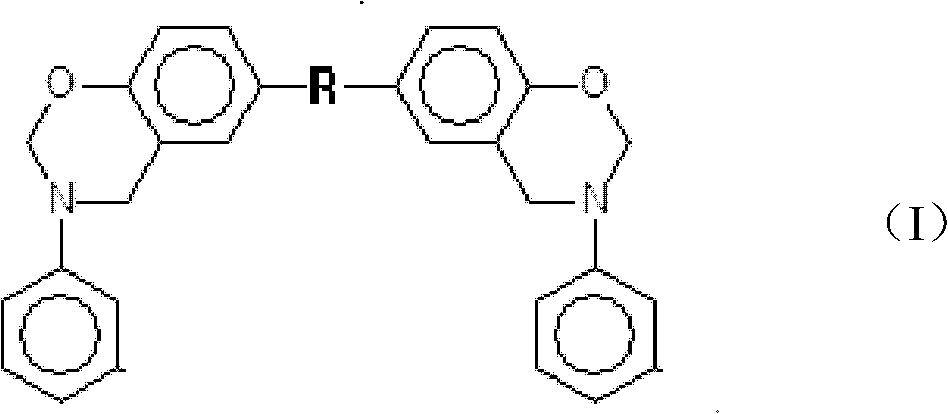

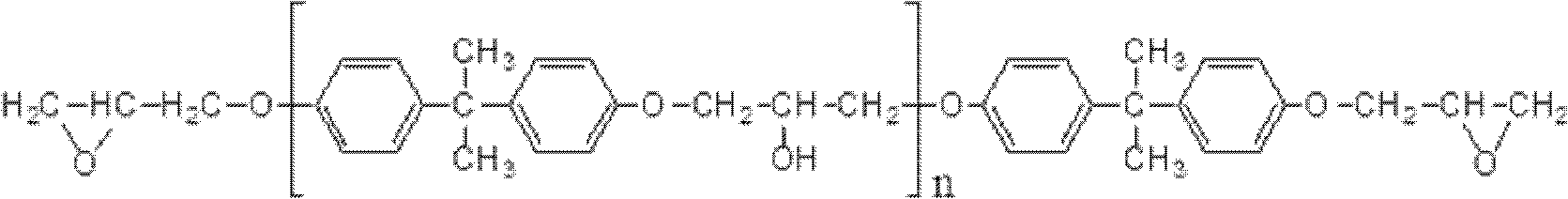

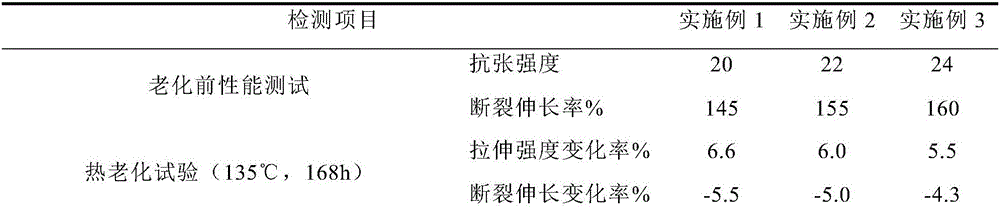

High-performance high-temperature-resistant modified epoxy resin

The invention provides a benzoxazine modified epoxy resin composition, which comprises the following components in parts by weight: 10-50 parts of benzoxazine resin, 10-100 parts of epoxy resin, 40-120 parts of anhydride curing agent and 2-4 parts of imidazole accelerator. The benzoxazine resin is taken as a modifier for modifying an epoxy resin crosslinked anhydride curing agent, so that the glass transition temperature and shock strength of a crosslinkging product of epoxy resin and the anhydride curing agent can be enhanced at the same time, and the technical problem that the glass transition temperature and shock strength cannot be enhanced at the same time is well solved. The obtained benzoxazine modified epoxy resin keeps high temperature resistance of benzoxazine and has high processability and mechanical property.

Owner:SHANGHAI MASTECK ENVIRONMENTAL

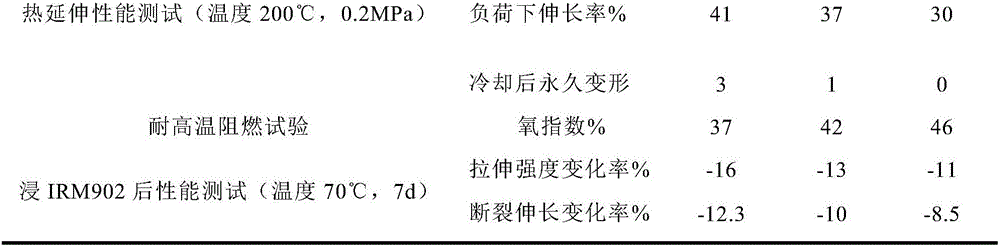

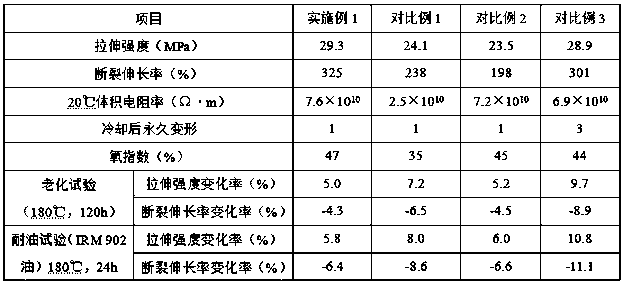

Oil-resistant and high-temperature-resistant mining cable sheath material and method for preparing same

InactiveCN106046464ARetain high temperature resistanceEasy to processInsulated cablesInsulated conductorsFiberTemperature resistance

The invention provides an oil-resistant and high-temperature-resistant mining cable sheath material and a method for preparing the same. The oil-resistant and high-temperature-resistant mining cable sheath material comprises, by weight, 30-40 parts of chloroprene rubber, 25-35 parts of fluorine-silicon rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 10-15 parts of fluoroether rubber, 6-8 parts of carbon nanometer fibers, 35-45 parts of carbon black, 10-15 parts of plasticizers TOTM, 8-12 parts of compound stabilizers, 2-4 parts of anti-aging agents 4010NA, 0.5-1.5 parts of anti-aging agents ODA, 0.8-1.2 parts of dicumyl peroxide, 6-10 parts of talc powder, 10-15 parts of compound flame retardants, 1-3 parts of accelerators TMTD, 10-20 parts of diatomaceous earth and 20-25 parts of modified kaolin. The oil-resistant and high-temperature-resistant mining cable sheath material and the method have the advantages that the chloroprene rubber, the chlorosulfonated polyethylene rubber, the fluorine-silicon rubber and the fluoroether rubber are compounded with one another, accordingly, the processing property and the mechanical property of the oil-resistant and high-temperature-resistant mining cable sheath material can be improved while the original properties of raw materials for the oil-resistant and high-temperature-resistant mining cable sheath material in a formula are guaranteed, the oil-resistant and high-temperature-resistant mining cable sheath material is excellent in physical and mechanical property, good in oil resistance, high-temperature resistance, abrasion resistance and insulating and flame-retardant property and long in service time, and the aging speeds can be obviously lowered.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

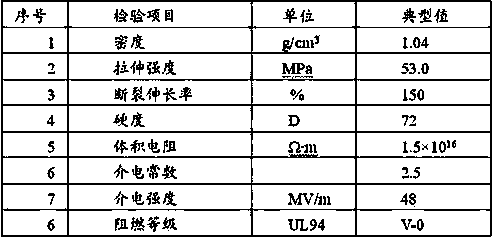

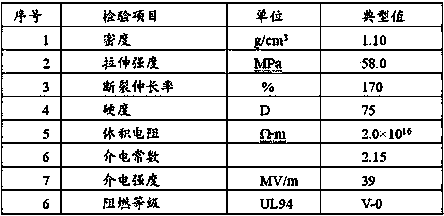

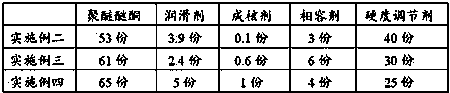

Polyether-ether-ketone cable material and preparation method thereof

ActiveCN103450631AImprove performanceReduce hardnessPlastic/resin/waxes insulatorsNuclear powerHardness

The invention provides a polyether-ether-ketone cable material. The polyether-ether-ketone cable material is characterized in that a raw material formula comprises the following materials in parts by weight: 50-70 parts of polyether-ether-ketone, 1-5 parts of a lubricating agent, 0.1-1 part of a nucleating agent, 3-8 parts of a compatilizer and 25-40 parts of a hardness conditioning agent. A preparation method of the polyether-ether-ketone cable material is characterized by comprising the following steps of weighting the materials according to the mass part of the materials in the raw material formula, mixing and stirring all the materials for 15-30 minutes in a high-speed mixing machine, then discharging, pelleting through a double-screw extruder at the process temperature of 220-380 DEG C, and packaging. The polyether-ether-ketone cable material provided by the invention has the advantages that the machining property of the polyether-ether-ketone product is improved, the extrusion molding is facilitated, the hardness of the material is reduced, the polyether-ether-ketone is suitable for being applied to cable industries, the excellent property of polyether-ether-ketone material can also be retained, and the polyether-ether-ketone cable material is flame-retardant, resists high temperature, low temperature, corrosion, oil and abrasion and can be widely applied to automobile cables, locomotive cables, nuclear power and the like with strict operating requirements.

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

High-temperature self-lubricating nano composite ceramic material with toughness and preparation method thereof

InactiveCN102094143ARetain high temperature resistanceRetain wear resistanceAdditivesBase-materialsHybrid typeHigh fracture

The invention discloses a high-temperature self-lubricating nano composite ceramic material with toughness and a preparation method thereof. The material consists of a matrix phase, a reinforcing phase and a lubricating phase; the structure of the material mainly consists of hybrid crystal boundary type, intra-crystal type and nano-nano type; the matrix phase is ZrO2-Y2O3 and accounts for 65 to 80 mass percent, and the grain diameter of the matrix phase is 50 to 100 nanometers; the reinforcing phase is Al2O3 and accounts for 5 to 10 mass percent, and the grain diameter of the reinforcing phase is 100 to 150 nanometers; and the lubricating phase is metal Mo and accounts for 10 to 30 mass percent, and the grain diameter of the lubricating phase is 200 to 300 nanometers. The hybrid structure of the material has very high fracture toughness; and due to a lubricating oxide film generated at high-temperature friction, the material has low friction coefficient and can be used as a structural material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

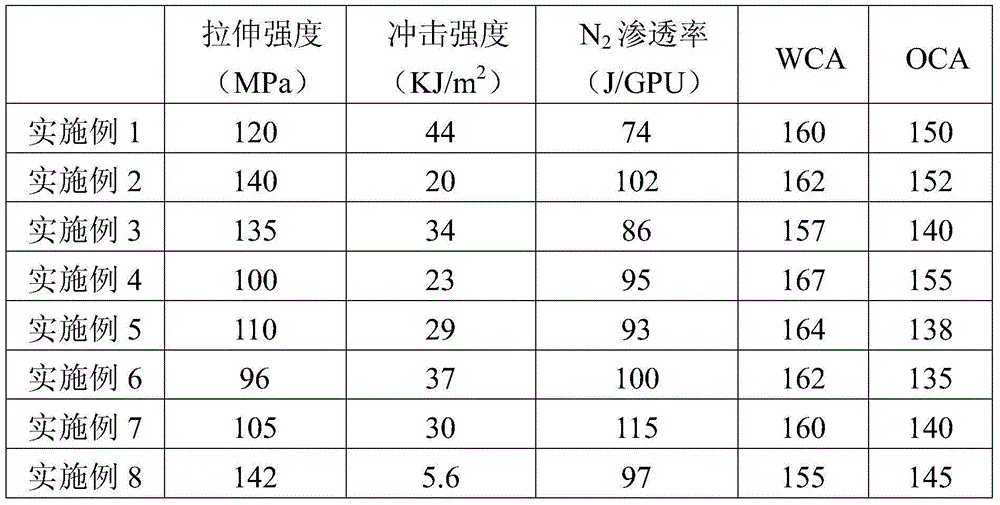

Self-cleaning aramid fiber film, preparation method thereof, and applications thereof in gas separation

ActiveCN103908903AAchieve decentralizationImprove the problem of using concentrated sulfuric acidSemi-permeable membranesDispersed particle separationEpoxyOrganic solvent

The invention belongs to the technical field of aramid fiber film preparation, and discloses self-cleaning aramid fiber film, a preparation method thereof, and applications thereof in gas separation. The method includes steps of: adding aramid fiber into a mixed solution of an organic solvent and a strong alkali, stirring to obtain a uniform solution, adding a pore-forming agent, stirring and degassing, casting on a substrate to form film, immersing the film together with the substrate into water, allowing the film to gel in water and be separated from the substrate so as to obtain gel film, drying the gel film to obtain aramid fiber film, dipping the prepared aramid fiber film into fluorine-containing epoxy resin dispersed by a solvent, taking the aramid fiber film out, and heating the aramid fiber film to obtain the self-cleaning aramid fiber film. A film casting liquid is prepared by dispersing the aramid fiber through the strong alkali, and then the aramid fiber film is prepared by a solution phase transfer method, thus maintaining the good molecular structure integrity of the aramid fiber, and preserving inherent performances of the aramid fiber, thus as high-temperature resistance, solvent tolerance and high strength. Then the fluorine-containing epoxy resin is grafted into the aramid fiber film to obtain the aramid fiber film with hydrophobicity or amphiphobicity, thus obtaining the self-cleaning aramid fiber film.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Spray type elastomer anti-corrosive protective material and its preparing method

InactiveCN1470582AHigh strengthRetain wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerPolyol

The present invention discloses a spray-coating type elastomer anticorrosive protective material formed from two components of A an B whose volume ratio is 1:1, in which the component A is the isocyanate prepolymer whose isocyanate (NCO) content is 12-23%, said isocyanate prepolymer is synthesized by using polyisocyanate and polyether polyol; and the component B is formed from 40-90% of high activity polyether and 10-60% of polyamine / alcohol chain extender. In the formula of component B the low-cost high-activity alcohol ether and trihydroxymethyl propane are substituted for high-cost amine chain extenders of end amino polyether and DETDA, etc. It can be used for paving seamless ground surface and wall surface of GMP pharmaceutical workshop and chemical workshop and internal and external layer anticorrosion protection of oil pipeline, marine platform and others.

Owner:AODEHUA SCI & TECH IND YANTAI

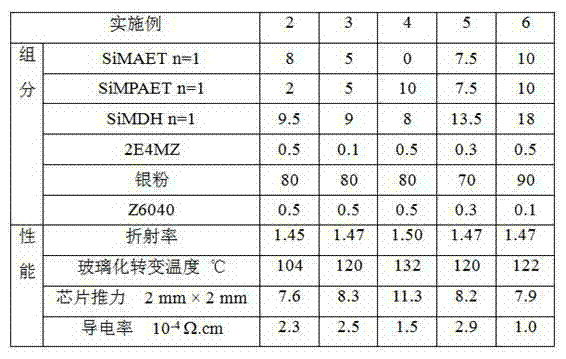

Epoxy functionalized organosilicon conductive adhesive for light emitting diode (LED)

ActiveCN102286259ARetain high temperature resistanceGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesSilane couplingAdhesive cement

The invention discloses an epoxy functionalized organosilicon conductive adhesive for an LED. The organosilicon conductive adhesive comprises 10 to 20 weight parts of organosilicon epoxy resin, 7 to 20 weight parts of organosilicon curing agent, 0.1 to 0.5 weight part of curing accelerator, 70 to 90 weight parts of silver powder conductive filler and 0.1 to 0.5 weight part of silane coupling agent serving as an interface reinforcing agent. The conductive adhesive can be stored at a low temperature for more than 6 months, and the viscosity is increased by 25 percent at room temperature for more than 48 hours. After the adhesive is cured, the thermal decomposition temperature (2 percent mass loss) is 300 DEG C, the small piece thrust at room temperature is 5Kgf / die(2*2mm), and the volume resistivity is less than or equal to 3.0*10<-4>W.cm; and the adhesive has high conductivity, heat resistance and ultraviolet (UV) resistance.

Owner:上海本诺电子材料有限公司

Composite anode material for lithium battery, and preparation method of composite anode material

ActiveCN109786679AImprove resistance to electrolyte corrosionImprove cycle performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

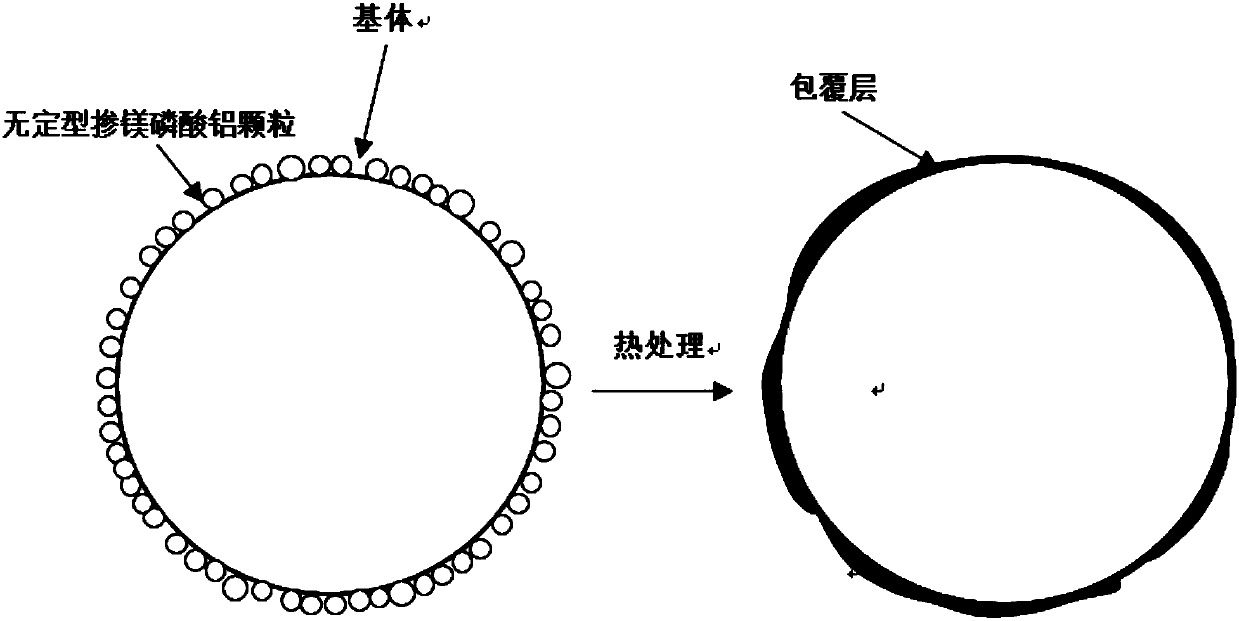

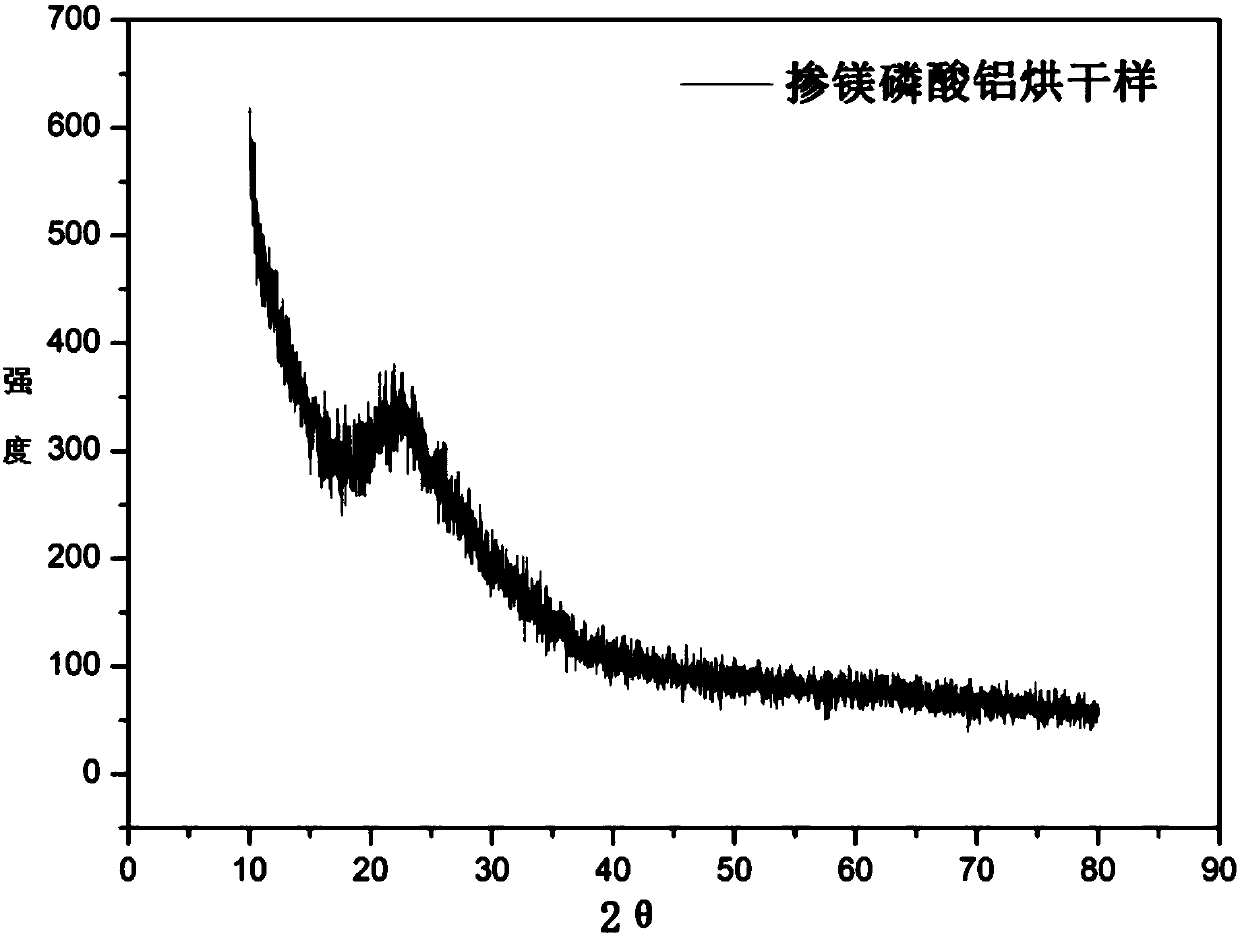

The invention discloses a composite anode material for a lithium battery, which is characterized in that the surface of a lithium cobalt oxide material substrate is coated with a magnesium-doped aluminum phosphate layer. A preparation method of the composite anode material comprises the following steps: dissolving a soluble aluminum salt and a soluble magnesium salt in a solvent to obtain a solution A; dissolving a soluble phosphate in the solvent to obtain a solution B; injecting the solution B into the solution A under stirring conditions, controlling the pH value in a system during reactionto range from 4 to 6, and carrying out filtering, washing and drying on an obtained product to obtain amorphous magnesium-doped aluminum phosphate particles; and uniformly mixing the amorphous magnesium-doped aluminum phosphate particles with a lithium cobalt oxide material, and carrying out sintering to obtain the composite anode material. The composite anode material and the preparation methodof the composite anode material have the advantages that the lithium cobalt oxide material substrate is coated with the magnesium-doped aluminum phosphate layer for modification, so that the crystallinity of the coating layer can be improved through doping of the magnesium element, higher electrolyte erosion resistance of the composite anode material can be achieved, an electrolyte can be isolatedfrom active substances for a longer time, and the cycling performance and the safety performance of the lithium battery can be further improved.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

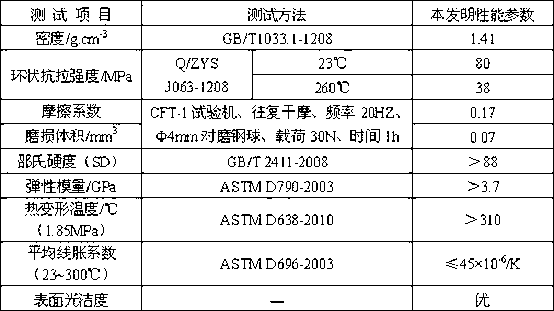

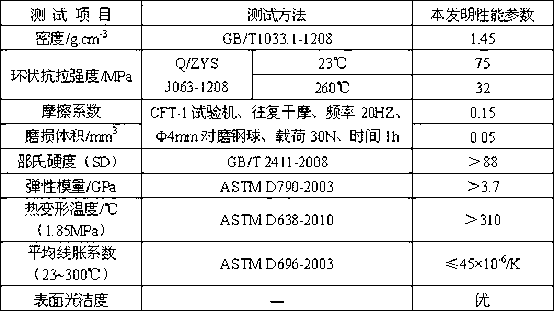

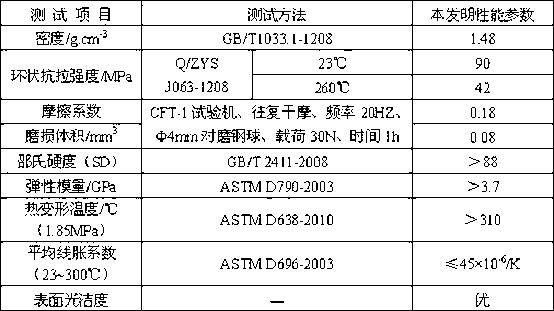

Manufacturing method of ketone-anhydride type polyimide composite retainer tube blank

The invention discloses a manufacturing method of a ketone-anhydride type polyimide composite retainer tube blank. The retainer tube blank material is prepared from the following three components in percentage by weight: 75-85% of ketone-anhydride type polyimide molding powder, 8-15% of carbon fiber and 5-12% of polytetrafluoroethylene. The preparation method comprises the process steps of drying, proportioning, annealing and the like. The ketone-anhydride type polyimide composite retainer tube blank prepared by the method has the characteristics of light weight, high tensile strength, high-temperature resistance and excellent tribological properties; the ketone-anhydride type polyimide composite retainer tube blank contains ketone-anhydride type polyimide, carbon fiber and polytetrafluoroethylene, and the retainer material keeps the advantages of high-temperature resistance, high tensile strength and high high-temperature strength conservation rate of the ketone-anhydride type polyimide, and also improves the tribological properties of the polyimide at the same time.

Owner:LUOYANG BEARING RES INST CO LTD

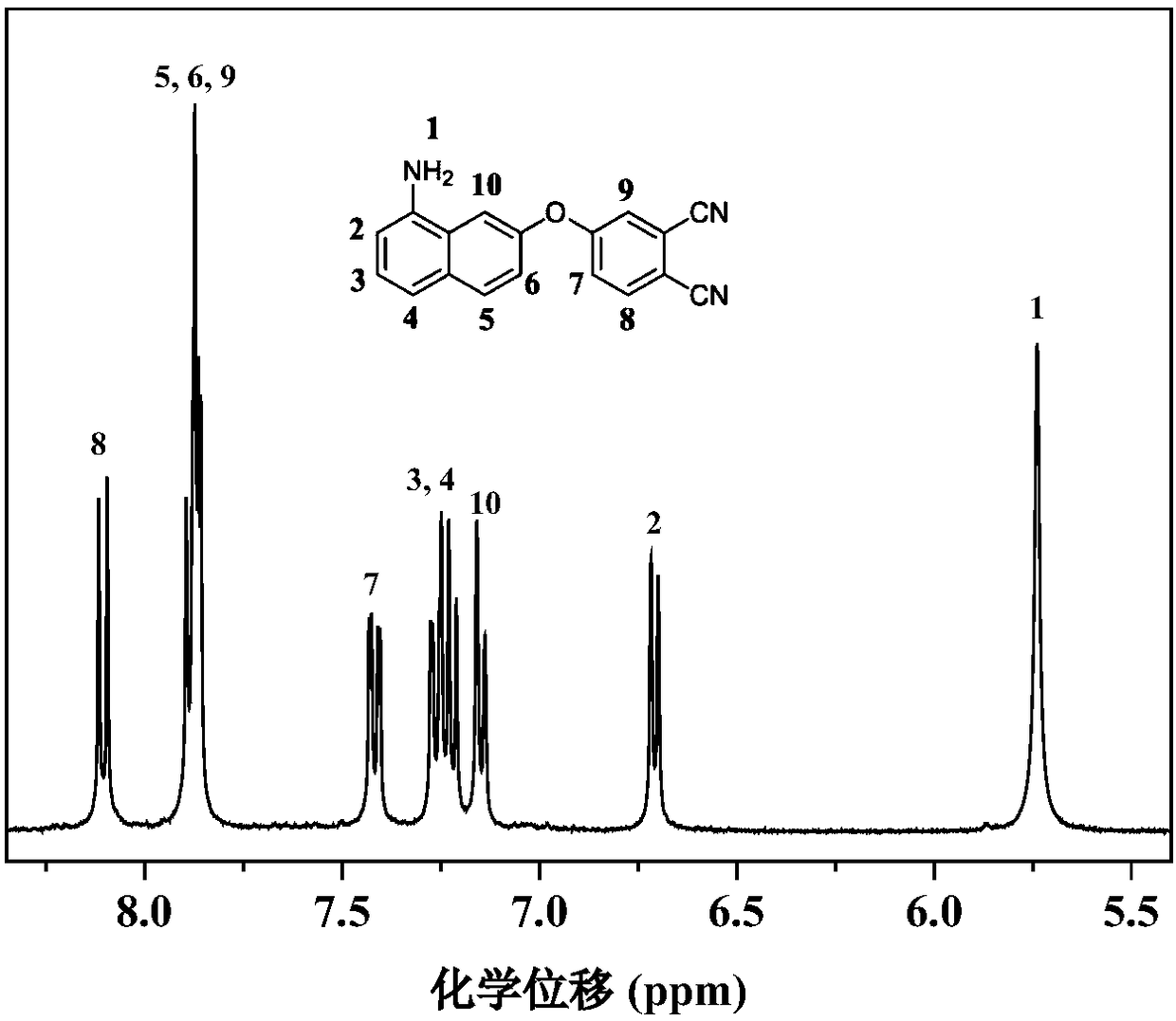

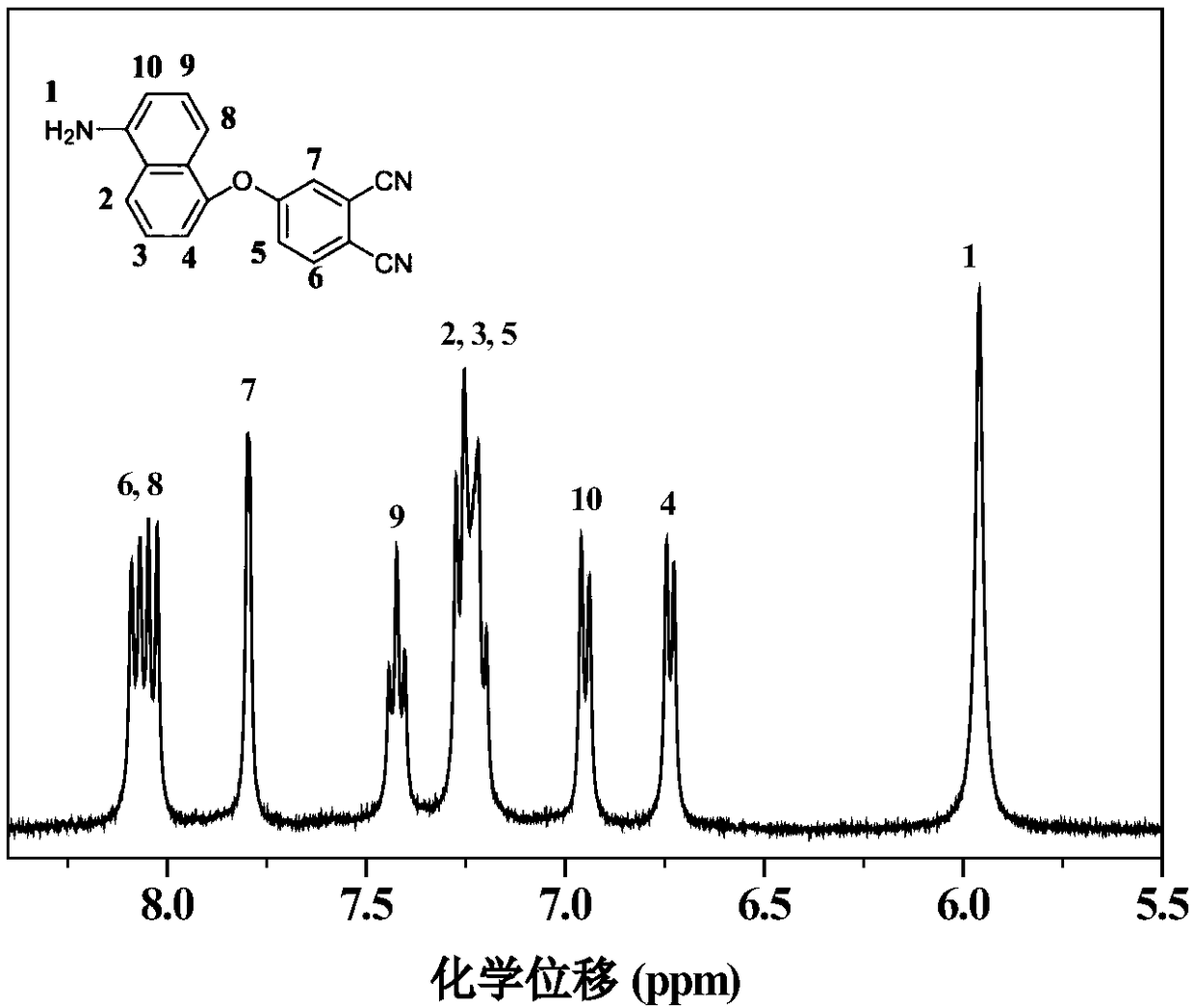

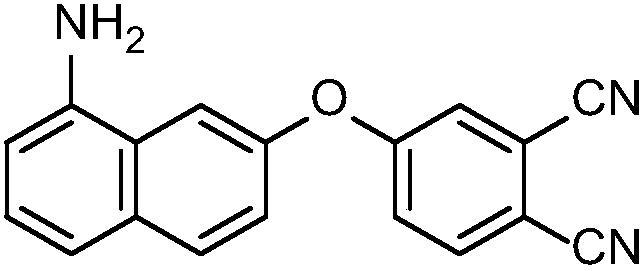

Method for preparing naphthyl autocatalytic poly-cyanophenyl resin

The invention discloses a method for preparing naphthyl autocatalytic poly-cyanophenyl resin. The method comprises the following steps of (1) adding aminonaphthol, an alkaline catalyst and an organicsolvent in a reactor, performing stirring for 1-2h at the temperature of 60-70 DEG C under the protection of inert atmosphere, then adding 4-nitrophthalonitrile, and performing continuous reaction for6-7h to obtain an autocatalytic cyanophenyl monomer; and (2) putting the autocatalytic cyanophenyl monomer in the reactor, performing melting reaction to obtain a prepolymer, then grinding the prepolymer into powder, transferring the powder into a muffle furnace, rising the temperature from 200-230 DEG C to 280-310 DEG C step by step within 7-9h, and finally obtaining the poly-cyanophenyl resin.By adopting the method provided by the invention, the reaction activity is improved while the melting point of the monomer is lowered, so that the post solidification temperature of the naphthyl autocatalytic poly-cyanophenyl resin is lowered by about 100 DEG C compared with the traditional autocatalytic monomer, the solidification time is reduced by about 8h, and the naphthyl autocatalytic poly-cyanophenyl resin still keeps the characteristics of high temperature resistance and high carbon residue rate.

Owner:HEBEI UNIV OF TECH

Metal rope belt for cable sling and manufacturing process

InactiveCN104131481ARetain high temperature resistanceGood flexibilityTextile cablesStructural engineeringMetal fibers

The invention discloses a metal rope belt for a cable sling. The metal rope belt is formed by multiple metal fiber filament bundles of 2-3o micrometers in filament diameter through plying and twisting or weaving or formed by metal fiber filament bundles and nonmetal fiber filament bundles of 2-30 micrometers in filament diameter through plying and twisting or weaving, and weight percentage of the metal fiber filament bundles is 10-100%. The invention further discloses a manufacturing process of the metal rope belt for the cable sling. Flexibility of a rope can be improved, and bending performance and folding resistance are improved.

Owner:LONGYAN QIANGLONG METAL FIBER

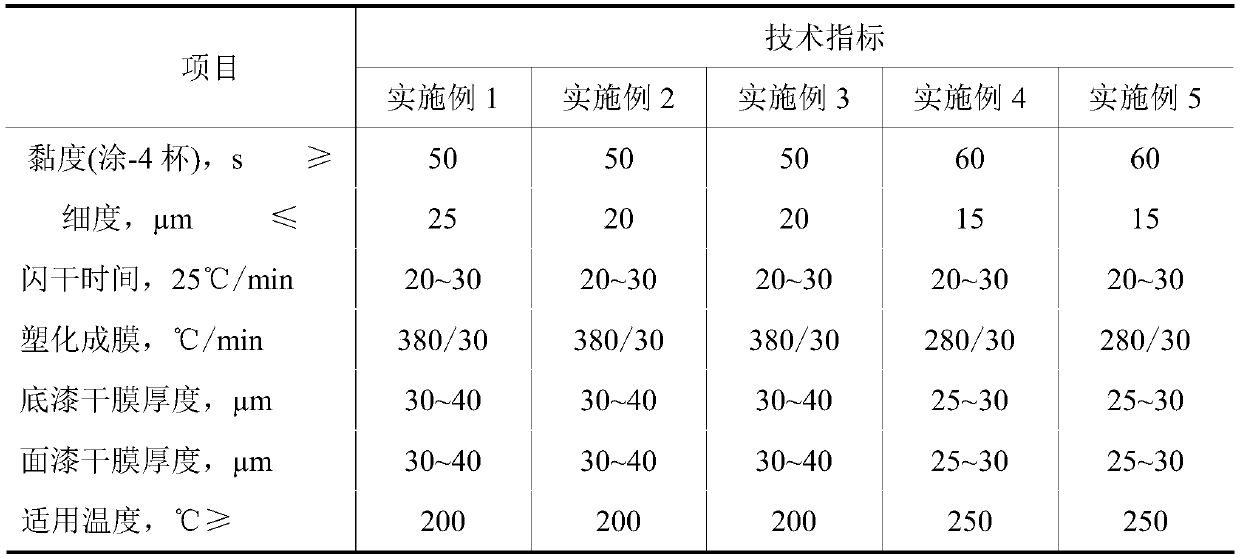

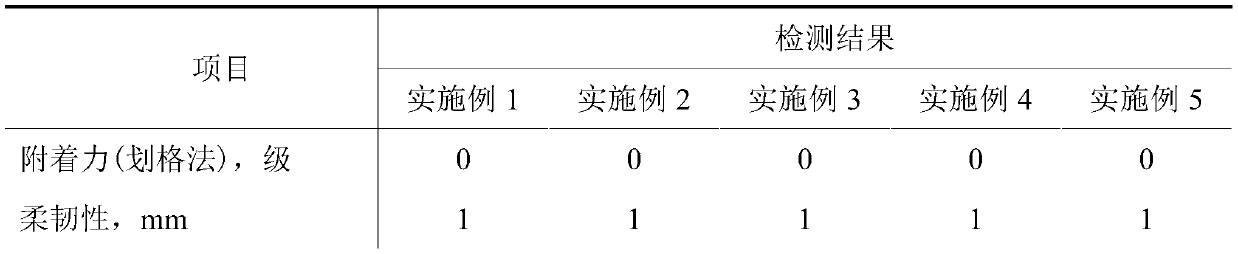

Thermally-conductive far-infrared synergistic non-stick coating and preparation method thereof

InactiveCN110467831ARetain high temperature resistancePreserve anti-agingFireproof paintsAnti-corrosive paintsCell membraneFar infrared

The invention provides a thermally-conductive far-infrared synergistic non-stick coating. The thermally-conductive far-infrared synergistic non-stick coating is a special coating using aqueous dispersion resin formed by mutual modification of a nanometer oxide gel and an organic fluororesin emulsion as a film forming matrix, and plasticized high-performance resin micropowder for modification, functional thermal-conductive exothermic synergistic filler, a tinting pigment and a coating additive as auxiliary components. After the coating of the invention is modified by graphene, the coating retains the original high temperature resistance, weather resistance and strong-corrosion resistance, and is endowed with the new functional characteristics of thermal stability, thermal balance, high hardness, high toughness, wear resistance, scratch resistance, wettability, no adhesion and the like; and nanometer negative ion powder releases far-infrared electromagnetic waves under the excitation ofheat (so thermal conductivity is good), and generates small-molecular-group water which permeates the cell membranes of cooked rice grains, so starch structures inside the cooked rice grains absorb water and become bulky and flexible, which improves the palatability of cooked rice.

Owner:广东健玺表面工程技术有限公司

Method for preparing metal composite plate by using as-cast blanks

ActiveCN110788137AHigh bonding strengthShorten the production cycleTemperature control deviceWork heating devicesWater vaporSorbent

The invention provides a method for preparing a metal composite plate by using as-cast blanks. The metal composite plate comprises a multi-layer metal, base-layer carbon steel or alloy steel, a bonding agent and a mixed activated adsorbing agent, wherein the bonding surfaces of the multi-layer metal and the base-layer metal are subjected to rust removal, passivation and chemical cleaning, the bonding agent is added to the bonding surfaces of the base plate and the compound plate, the mixed adsorbing agent is added to the peripheries of the bonding surfaces, before rolling, heating is conductedtwo times under atmosphere protection, so that air, water vapor and the like on the bonding surfaces are removed or adsorbed by the mixed activated adsorbing agent, the bonding agent is melted to make the bonding surfaces sealed, and oxidation is avoided. The method for preparing the metal composite plate by using the as-cast blanks can effectively solve the problems that a conventional preparation method for the compound plate is long in assembling period, high in cost and the like, a vacuum extraction equipment is omitted, and the production cost is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

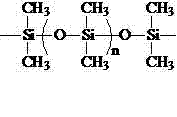

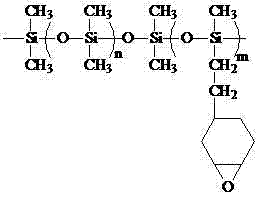

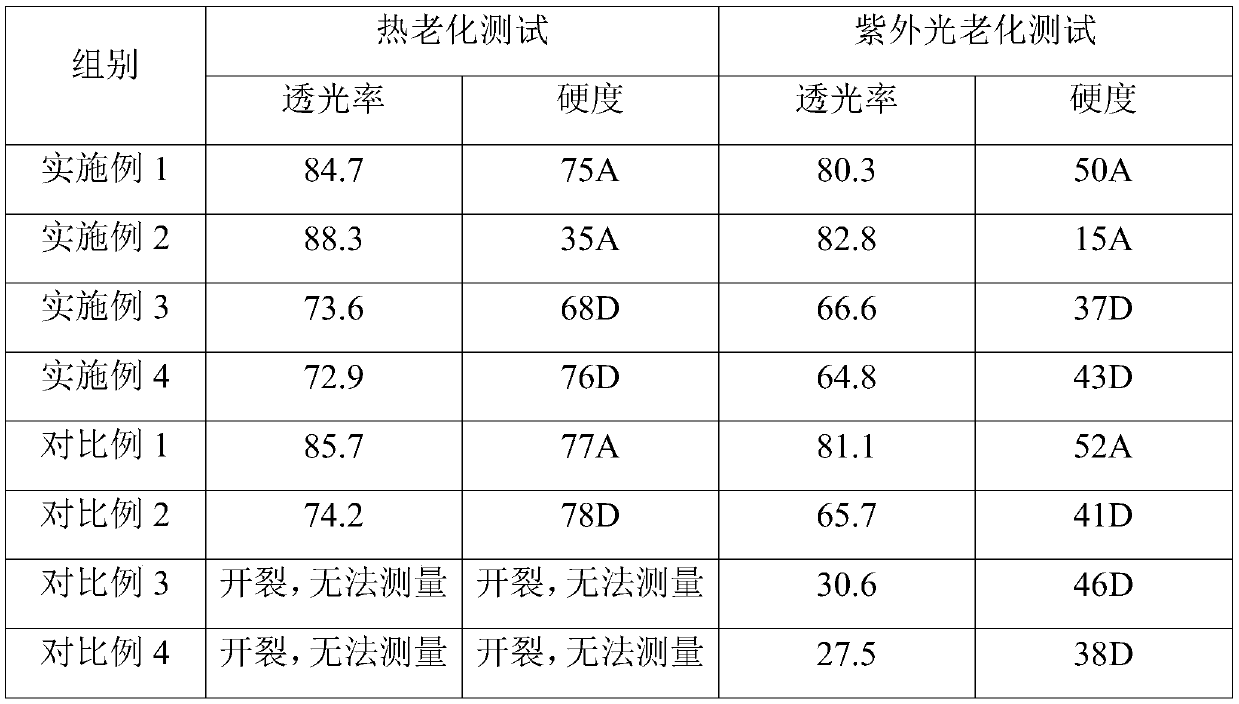

UV curing non-modified organic silicon material for LED packaging and preparation method thereof

InactiveCN110951263ARetain high temperature resistanceIncrease productivitySemiconductor devicesPtru catalystUV curing

The invention belongs to the technical field of LED packaging and particularly relates to a UV curing non-modified organic silicon material for LED packaging and a preparation method thereof. The UV curing non-modified organic silicon material for LED packaging is prepared from the following components in parts by weight: 70 to 95 parts of vinyl polysiloxane, 1 to 10 parts of hydrogen-containing polysiloxane, 0.001 to 0.1 part of a catalyst, 0.0001 to 0.1 part of an inhibitor and 0.1 to 4 parts of an auxiliary agent. According to the organic silicon material disclosed by the invention, the hydrosilylation reaction is catalyzed by s platinum catalyst with a special structure under the irradiation of UV light, so that UV curing is realized on the premise of not carrying out organic group modification, and the organic silicon material is high in curing speed, high in light transmittance and good in aging resistance.

Owner:深圳市晨日科技股份有限公司

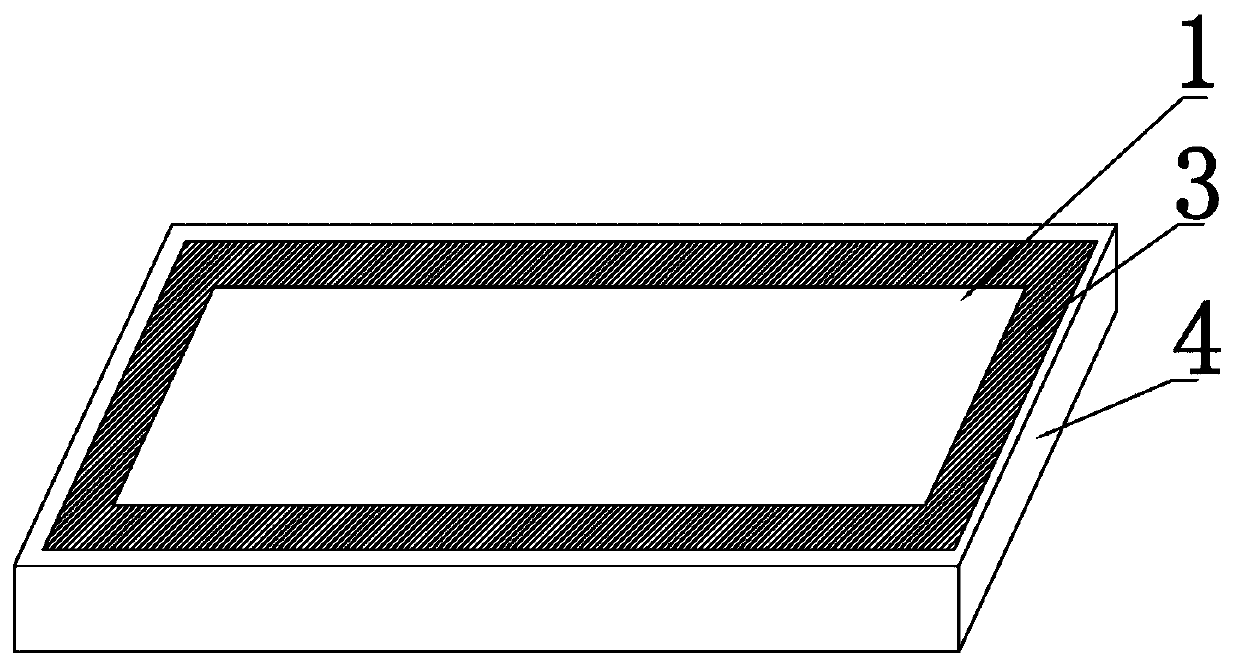

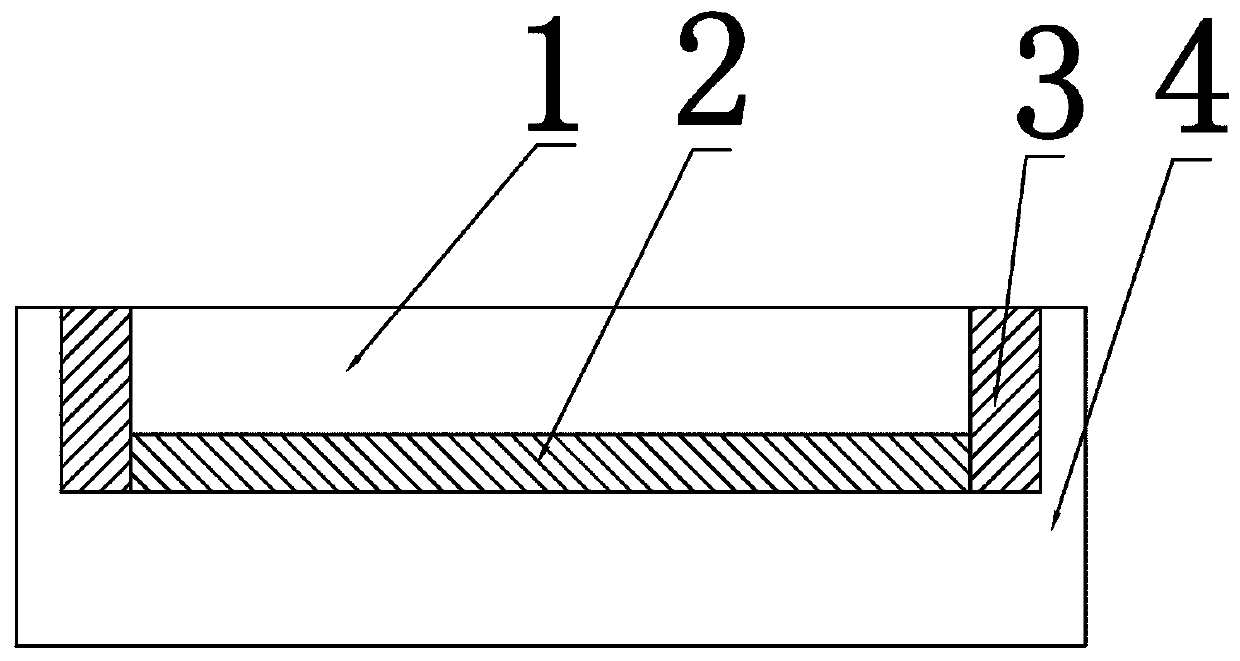

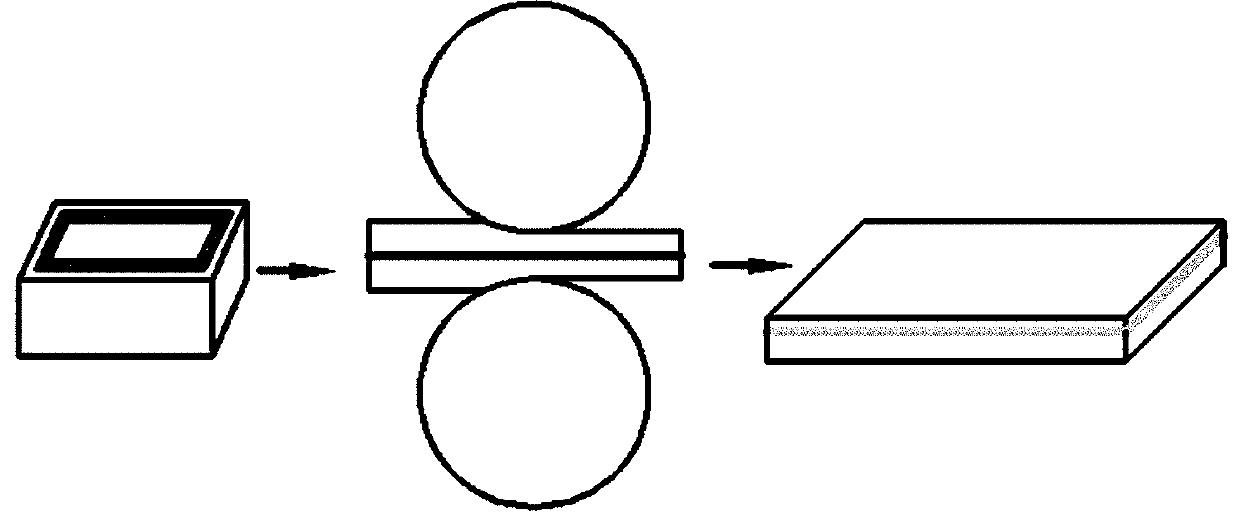

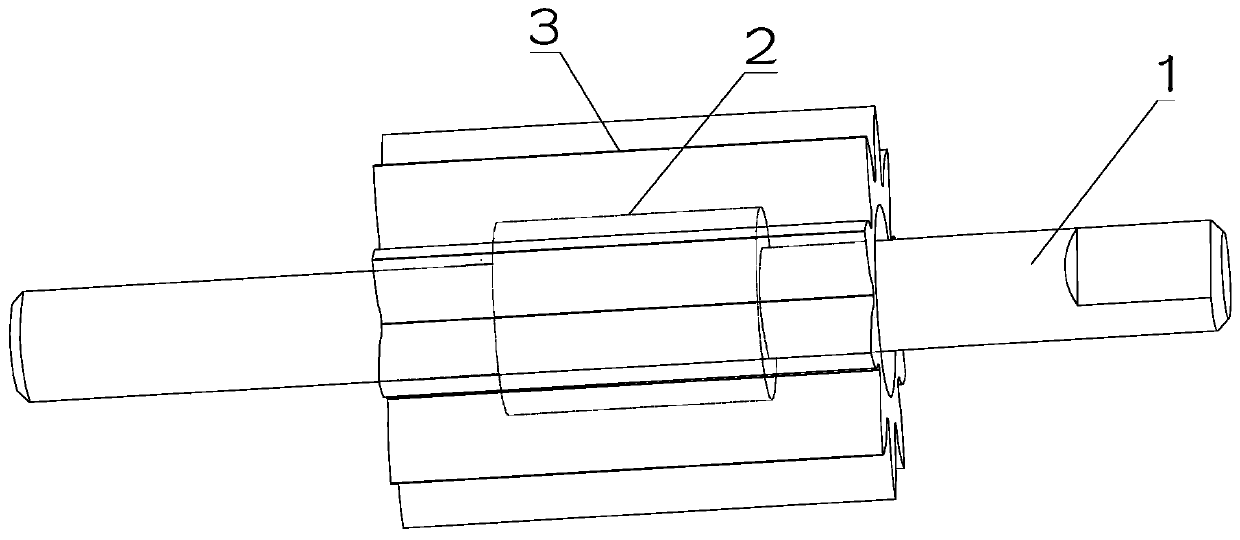

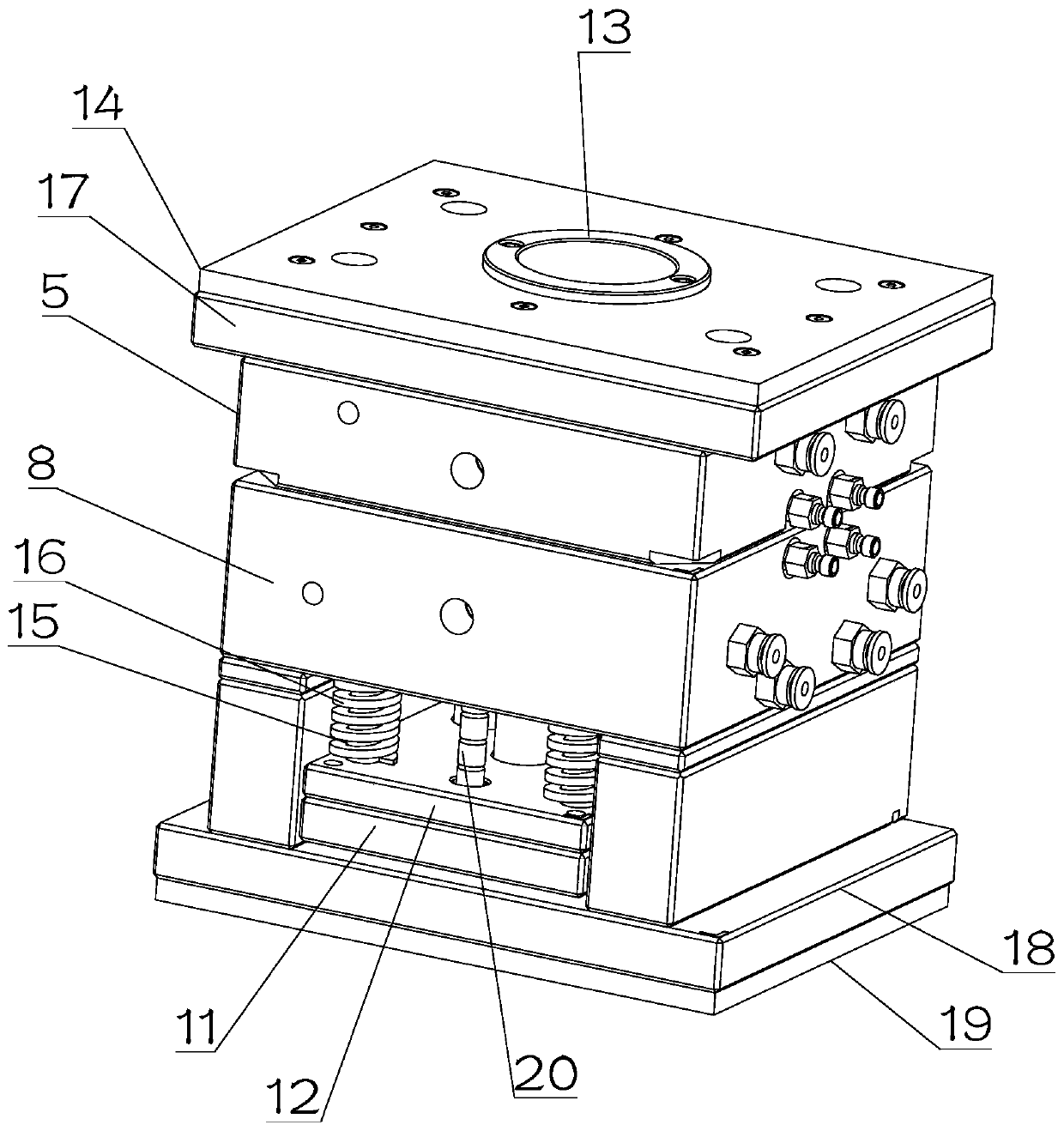

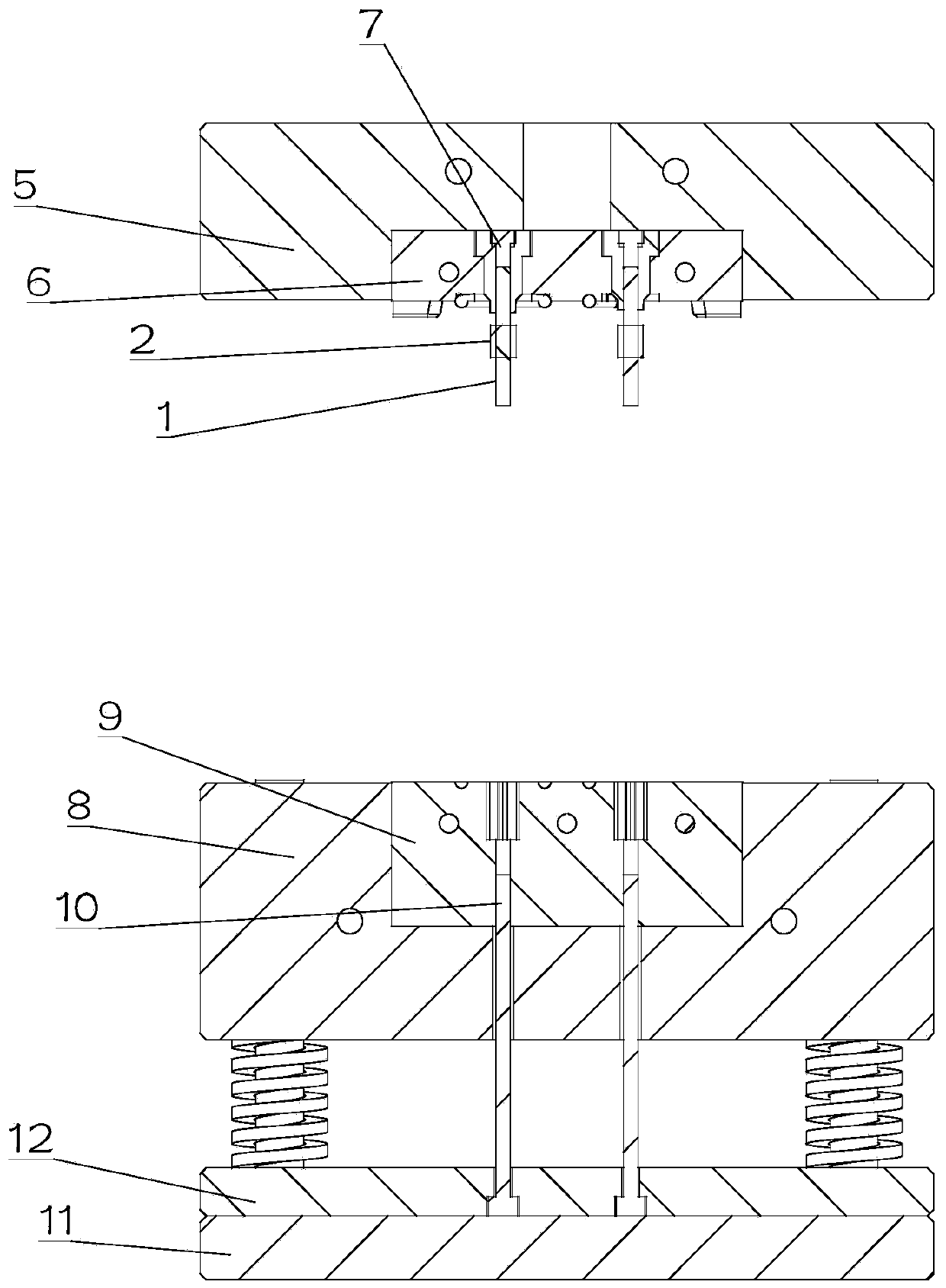

Encapsulated injected gear, injection process and mold

InactiveCN111577863AGuaranteed coaxialityHigh strengthShaftsPortable liftingGear wheelStructural engineering

The invention belongs to the technical field of high-performance material small gears, and provides an encapsulated injected gear. The encapsulated injected gear comprises a gear shaft, a gear inner core arranged on the gear shaft, and a gear body encapsulated and injected on the gear inner core. According to the encapsulated injected gear, a metal inner core is used for replacing an original injection molding material, and firstly, the coaxiality of the shaft and the gear can be guaranteed well, the thickness of the injection molding material is reduced to a large degree, and the problem of contraction and deformation generated in the conventional injection molding process is solved; and secondly, the metal is higher in strength and economical in cost, and compared with expensive high-performance injection molding materials, it is a good choice to replace the gear inner core with the metal.

Owner:上海芮朔精密模塑科技有限公司

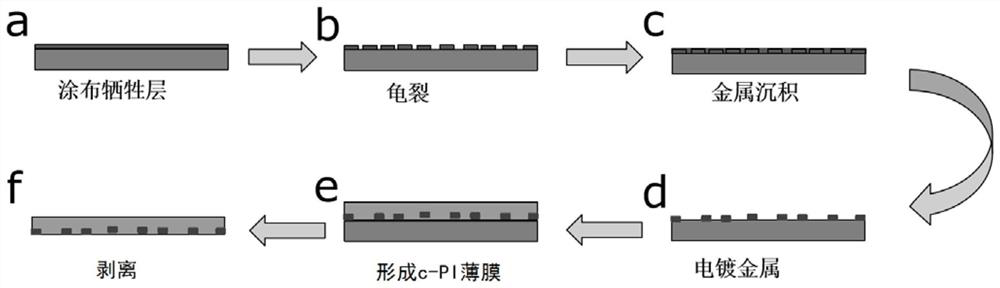

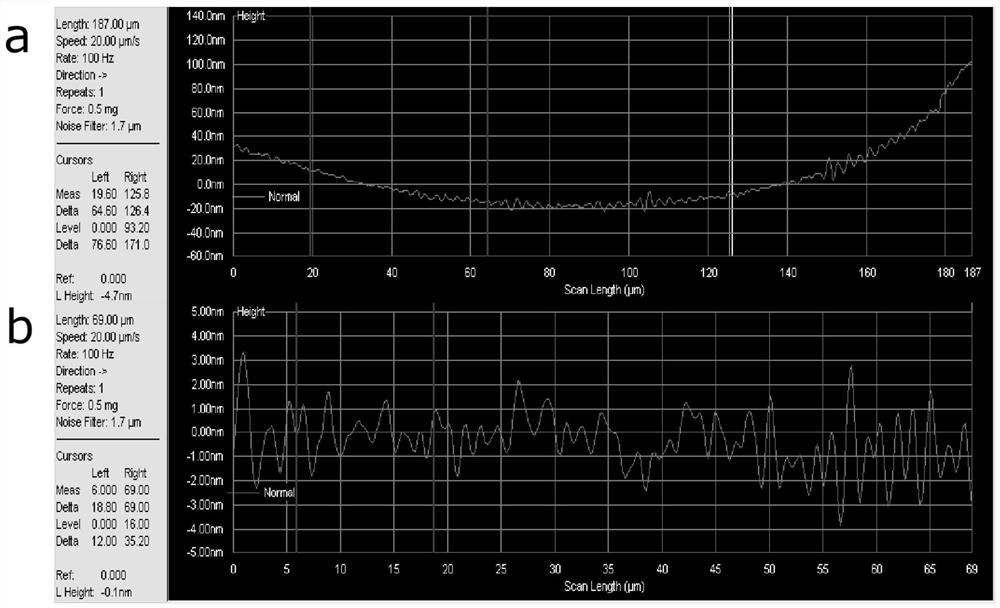

Preparation method of flexible transparent conductive electrode with low surface roughness

InactiveCN112768116AReduce surface roughnessGood performance requirementsConductive layers on insulating-supportsSolid-state devicesMetal coatingPerovskite solar cell

The invention discloses a preparation method of a flexible transparent conductive electrode with low surface roughness. The preparation method comprises the steps of depositing a metal network electrode on a substrate by adopting a cracking template method, forming a metal coating on the deposited metal network electrode through electroplating, performing plasma treatment, and infiltrating by using a c-PI precursor solution; and after c-PI is subjected to heating and heat preservation to form a film, stripping the c-PI film from the substrate in a hot bath to complete lossless transfer, so as to obtain the flexible transparent conductive electrode with low surface roughness. The flexible transparent conductive electrode prepared through the method has the performance of high transmittance, the surface roughness is within 10 nm, and the requirements of thin film photoelectric devices such as perovskite solar cells are completely met.

Owner:SOUTH CHINA NORMAL UNIVERSITY

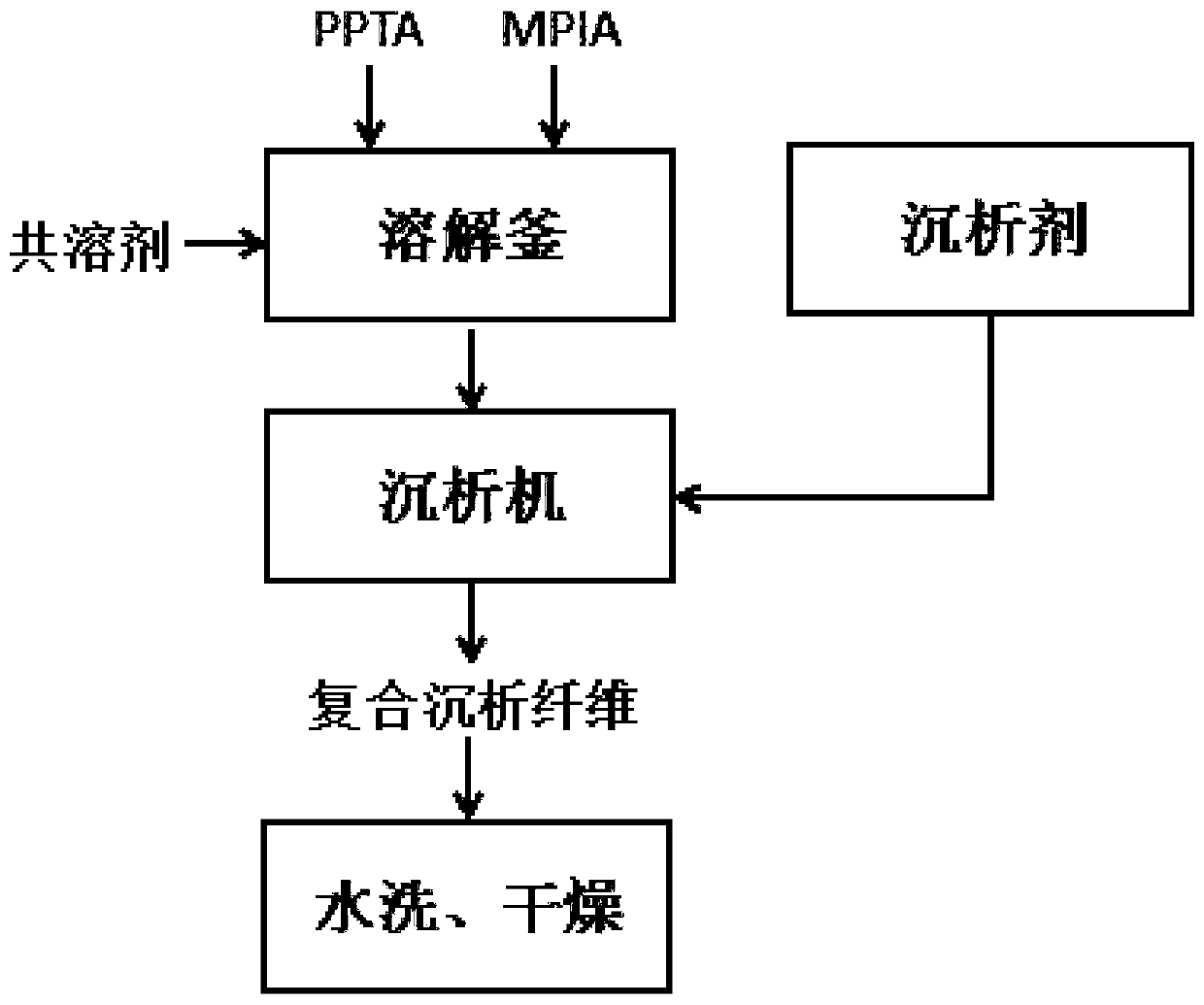

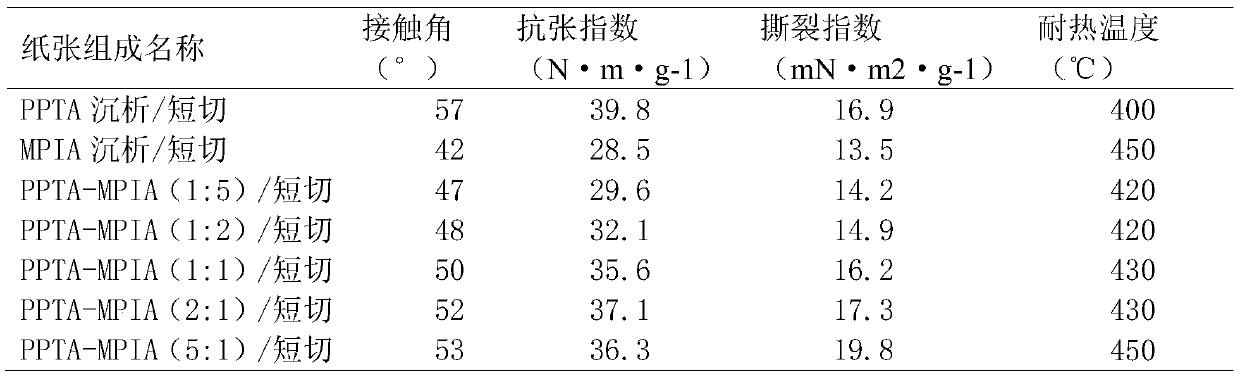

Preparation method of PPTA-MPIA in-situ composite fibrid

ActiveCN110184677ARetain high temperature resistanceWeak moisture retentionConjugated synthetic polymer artificial filamentsArtifical filament manufactureMoisture absorptionTemperature resistance

The invention discloses a preparation method of a PPTA-MPIA in-situ composite fibrid. The preparation method comprises the following steps: 1, dissolving PPTA and MPIA raw materials or raw stock in aco-solvent to obtain a PPTA-MPIA mixed solution; 2, feeding the PPTA-MPIA mixed solution into a precipitation machine containing a circulating coagulation bath for shearing, and executing washing withdistilled water for several times after shearing is finished to obtain the PPTA-MPIA in-situ composite fibrid; the cosolvent in the step 1 contains a solvent, a cosolvent and an end-capping reagent;the solvent is prepared from one or more of N-methyl pyrrolidone, concentrated sulfuric acid, N,N-dimethylacetamide; the cosolvent is an alkali metal chloride; the end-capping reagent is an alcohol end-capping reagent. The composite fibrid prepared by the preparation method not only can retain the excellent performances of high temperature resistance and weak moisture absorption of a para-aramid precipitation fiber, but also has the liquid phase dispersion performance and the composite reinforcing effect of a meta-aramid precipitation fiber, and has good mechanical performance and thermal stability.

Owner:JIANGSU RUISHENG ADVANCED MATERIAL TECH CO LTD +2

Preparation method of self-cleaning fibers

ActiveCN109382089AHigh strengthAvoid separation processWater/sewage treatment by irradiationWater treatment compoundsAluminium silicateBismuth

The invention provides a preparation method of self-cleaning fibers, and belongs to the field of water purification materials. The preparation method of the self-cleaning fibers comprises the following process steps: mixing deionized water, sodium metavanadate and ethylenediamine tetraacetic acid disodium, regulating pH of a solution with hydrochloric acid, and then adding a mixed solution of deionized water, bismuth nitrate pentahydrate, neodymium nitrate and sodium bicarbonate to prepare an active precursor solution; carrying out hydrothermal reaction on the active precursor solution and aluminium silicate fibers, and drying and calcining to obtain the self-cleaning fibers. The self-cleaning fibers consist of aluminium silicate fibers of which the surfaces are coated with bismuth neodymium vanadate, resist high temperature, are flexible, are high in strength, can float in water, and can degrade organic pollutants in water under the condition of illumination.

Owner:嘉兴如运建筑科技有限公司

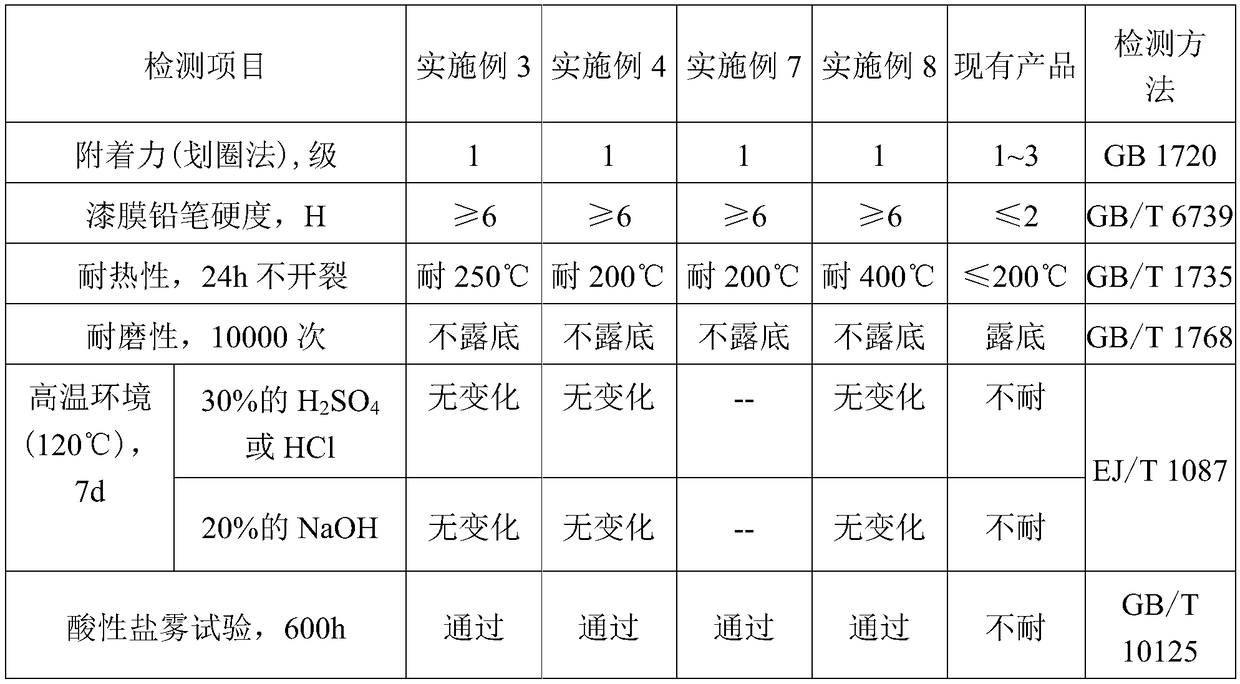

Nanometer hybridized ceramic resin coating as well as preparation method and application of nanometer hybridized ceramic resin coating

InactiveCN109370397ARetain high temperature resistanceRetain corrosion resistanceFireproof paintsAnti-corrosive paintsChemical industryNano hybrid

The invention discloses a nanometer hybridized ceramic resin coating as well as a preparation method and an application of the nanometer hybridized ceramic resin coating and belongs to the technical field of chemical industry of coatings. By adopting the coating disclosed by the invention, not only are the original high temperature resistance, corrosion resistance, weather resistance and ageing resistance retained, but also the brittleness problem of the coating is solved, and the nanometer hybridized ceramic resin coating has the characteristics such as high hardness, high toughness, wear resistance, scratch resistance, no infiltration, inadhesion and no scale formation. Different coating varieties can be prepared by selecting film forming matrix materials with different structures according to different working environments and construction conditions, and proved by a contrast test, an endurance test and overall performance detection, the nanometer hybridized ceramic resin coating disclosed by the invention far exceeds like products on the current market.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

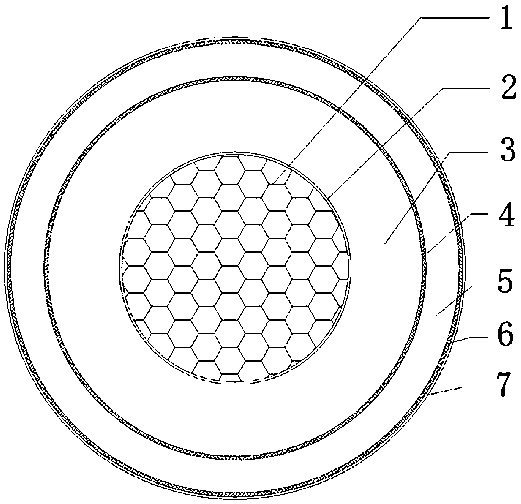

Oil-resistant and high-temperature-resistant ship cable

InactiveCN110964328AHigh strengthIncrease stiffnessRubber insulatorsInsulated cablesFiberBenzoyl peroxide

The invention relates to an oil-resistant and high-temperature-resistant ship cable, which sequentially comprises a conductor, a belting layer, an insulating layer, a fiber braided reinforcing layer,a sheath, a glass fiber braided layer and a coating layer from inside to outside, wherein the insulating layer and the sheath are respectively made of a silicon rubber, the insulating layer comprisesa fluorosilicon rubber, No.2 fumed silica, nano tin oxide, praseodymium oxide, methylphenyldiethoxysilane, hydroxyl fluorosilicone oil, mica powder, talcum powder, benzoyl peroxide, nano magnesium hydroxide, stearic acid and carbon black, and the sheath comprises a fluorosilicon rubber, a chlorosulfonated polyethylene rubber, a natural rubber, an epoxidized natural rubber, a filling reinforcing agent, dioctyl phthalate, triallyl trimellitate, hydroxyl silicone oil, hydrogen-containing silicone oil, a silane coupling agent, magnesium oxide and calcium hydroxide. The oil-resistant and high-temperature-resistant ship cable has advantages of excellent physical and mechanical properties, good oil resistance, good high-temperature resistance, good wear resistance, good insulation property and good flame retardance, can obviously reduce the aging speed, and can be applied to cables for ships.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Preparation method of TiO2@Mofs modified glass fiber film

InactiveCN109731553ARetains chemical resistanceRetain high temperature resistanceFatty/oily/floating substances removal devicesOther chemical processesGlass fiberEpichlorohydrin

The invention discloses a preparation method of TiO2@Mofs modified glass fiber film, comprising the steps of adding epichlorohydrin and strong sodium oxide solution into a beaker, subjecting glass fiber film to reaction in the solution at 20-25 DEG C for 10-12 h, and flushing many times with deionized water / ethanol to remove impurities on the surface of the film; dissolving TiO2@Mofs particles inmethanol solution, adding the film into the TiO2@Mofs solution, allowing to react at 70-90 DEG C for 20-24 h, flushing many times with deionized water / ethanol to remove impurities on the surface of the modified glass fiber film, and drying the modified glass fiber film in a blowing drying box at 40-50 DEG C for 12-24 h. The TiO2@Mofs modified glass fiber film retains the advantages of glass fiber,such a chemical corrosion tolerance and high temperature resistance and can effectively remove oil in oil-bearing wastewater.

Owner:江苏中丽新材料有限公司

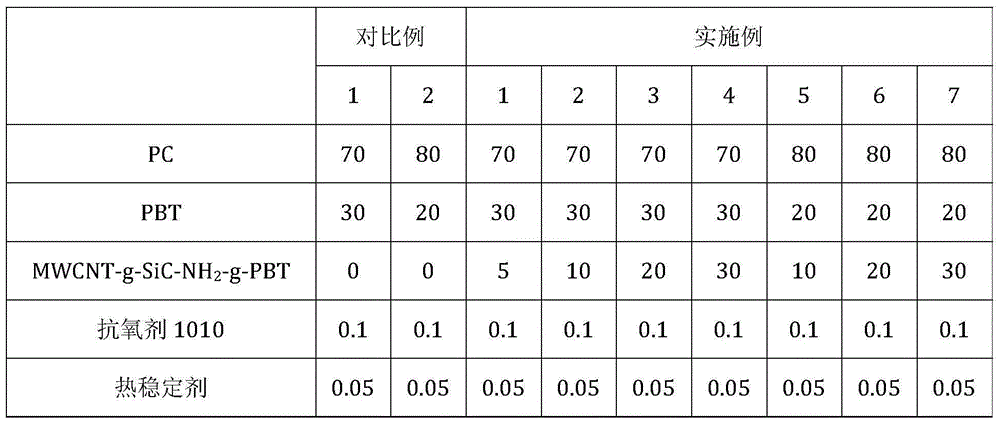

Antistatic and anti-bacteria PC/PBT (poly carbonate/polybutylene terephthalate) alloy and preparation method thereof

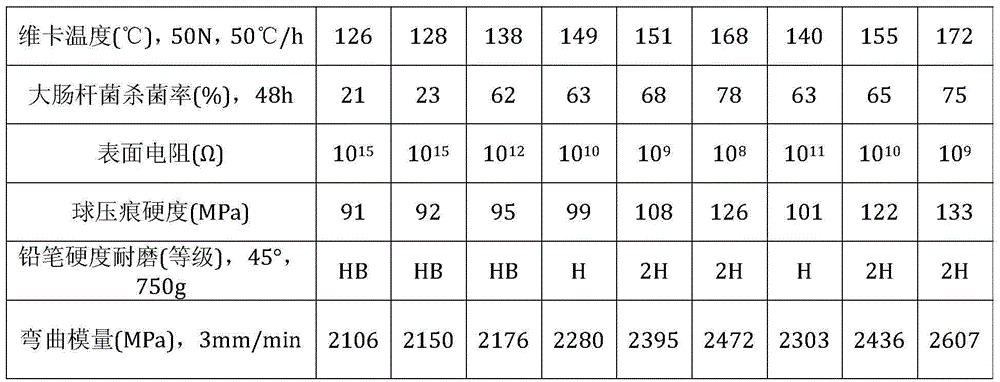

InactiveCN105086409AGood electrical conductivityImprove hardness performancePolymer scienceAutomobile safety

The invention provides antistatic and anti-bacteria PC / PBT (poly carbonate / polybutylene terephthalate) alloy and a preparation method thereof, and belongs to the field of polymer materials. The antistatic and anti-bacteria PC / PBT alloy is obtained by performing melt blending on PC (poly carbonate), PBT (polybutylene terephthalate) and MWCNT (multi-walled carbon nanotubes)-g-SiC-NH2-g-PBT master batches; and the MWCNT-g-SiC-NH2-g-PBT master batches are obtained by performing graft copolymerization on MWCNT-g-SiC-NH2, DBTO (dibutyl tin oxide) and the PBT. The prepared PC / PBT alloy has antistatic, anti-bacteria, high-temperature-resistant, high-hardness and wear-resistant characteristics, safety performance of an automobile can be improved effectively, by the preparation method, equipment such as an extruder can be protected, and the preparation method is easy and convenient to operate and suitable for industrialization.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

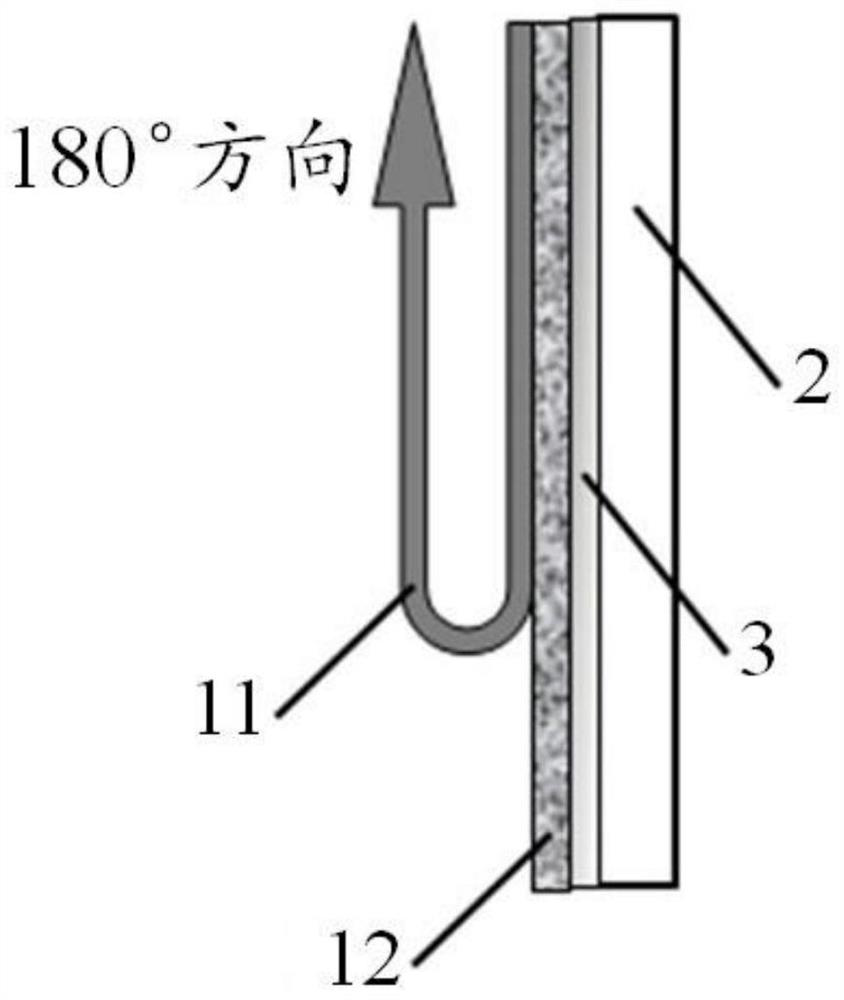

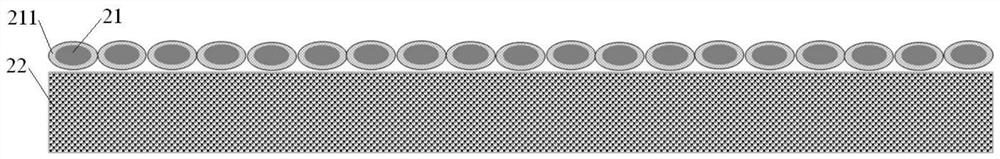

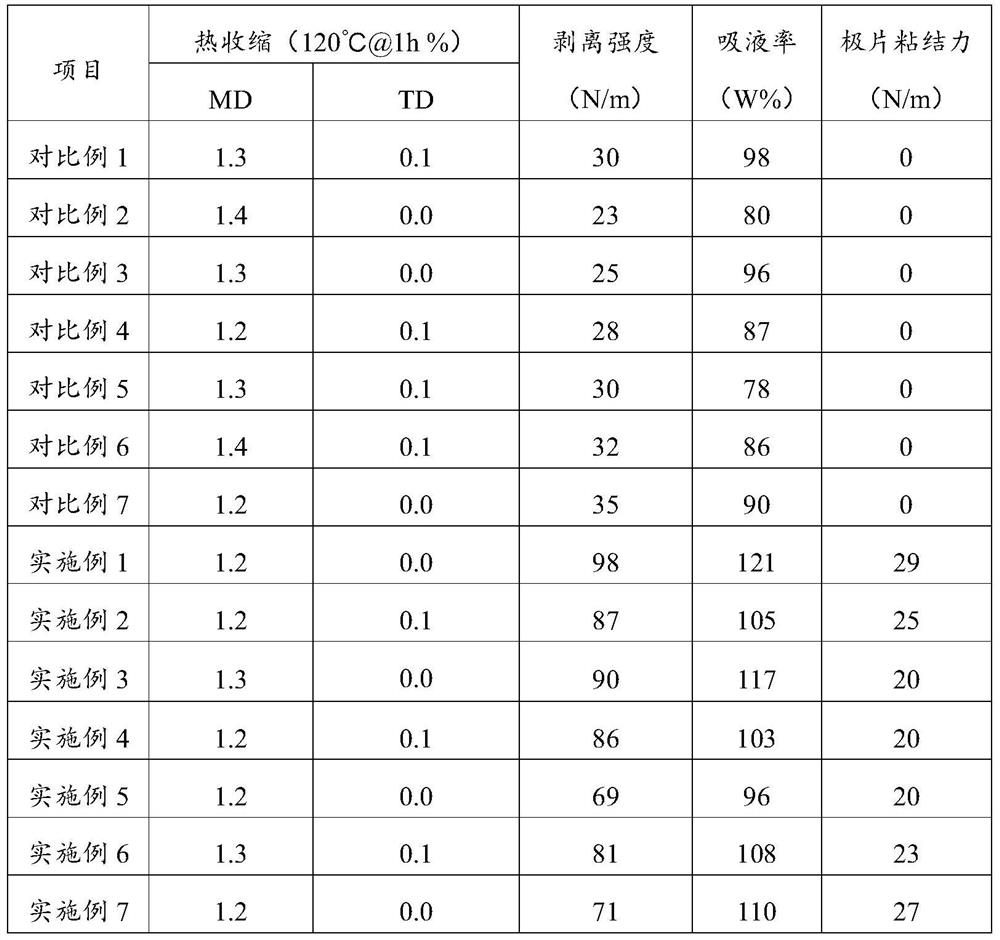

A kind of ceramic coating diaphragm and preparation method and application

ActiveCN108305972BRetain high temperature resistanceImprove uniformityCell component detailsCoatingsElectrolytic agentInorganic particle

The application discloses a ceramic coating diaphragm, a preparation method and an application. The ceramic coated separator of the present application includes a base film and a ceramic coating coated on at least one surface of the base film, wherein the ceramic coating is coated with inorganic particles grafted with polyethylene glycol on the surface. The ceramic coating diaphragm of the present application creatively uses inorganic particles grafted with polyethylene glycol on the surface to prepare a ceramic coating, which makes the interface bonding force between the inorganic particles and the base film better, and improves the overall peel strength of the ceramic coating diaphragm. While retaining the characteristics of ceramic coating such as high temperature resistance, it also solves the problem of inorganic particle shedding and powder falling. The inorganic particles grafted with polyethylene glycol on the surface have a better dispersion effect in water, so that the uniformity of the ceramic coating separator is better. The ceramic coating formed by the inorganic particles grafted with polyethylene glycol on the surface has a faster liquid absorption rate and a higher liquid absorption rate, and forms a gel after absorbing the electrolyte, so that the ceramic coating separator can be better attached to the electrode surface.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Asbestos-free seal fiberboard and manufacturing method thereof

The invention relates to an asbestos-free seal fiberboard and a manufacturing method thereof. The asbestos-free seal fiberboard is composed of 3800-4200 parts of rubber, 480-520 parts of zinc oxide, 1800-2200 parts of white carbon black, 180-220 parts of dibutyl ester, 40-60 parts of stearic acid, 50-70 parts of paraffin, 70-90 parts of sulfur, 980-1200 parts of defoaming agent, 1480-1520 parts of glass fiber, 1140-1160 parts of graphite powder, 100-120 parts of anti-aging agent and 320-360 parts of accelerator. The method comprises the following steps: mixing the zinc oxide, white carbon black, dibutyl ester, stearic acid, paraffin, sulfur, defoaming agent, glass fiber, graphite powder, anti-aging agent, accelerator, toner, waste powder, lime and carbon powder into the rubber according to the formula, pulping, adding the waste fiber to form the master batch, rolling into flakes, vulcanizing the flaky material, and molding the vulcanized rubber to obtain the finished product. The manufacturing method fully utilizes the wastes, and the finished product can maintain the characteristics of high temperature resistance and self lubrication.

Owner:舟山市金寿机械股份有限公司

Polyphenylene sulfide/polyamide composite material and method for making same

Owner:ANHUI KEJU NEW MATERIALS

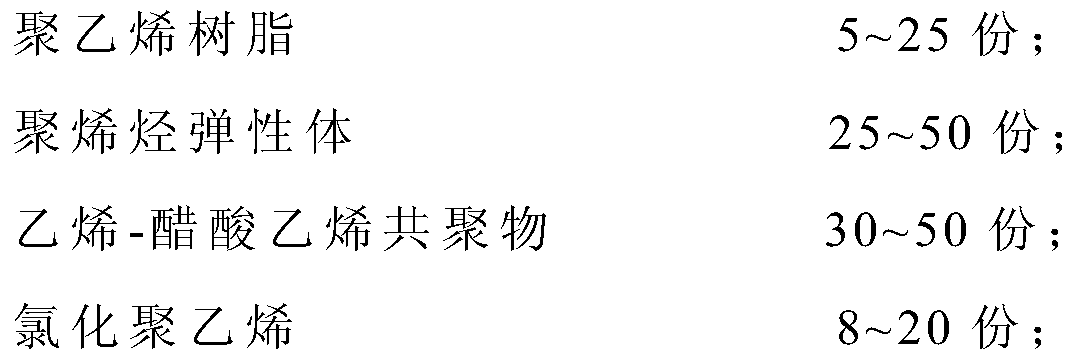

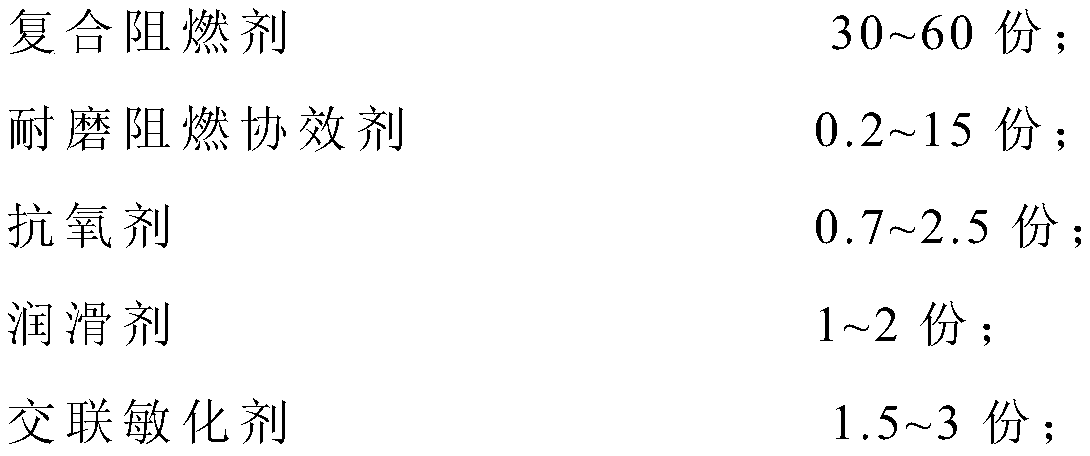

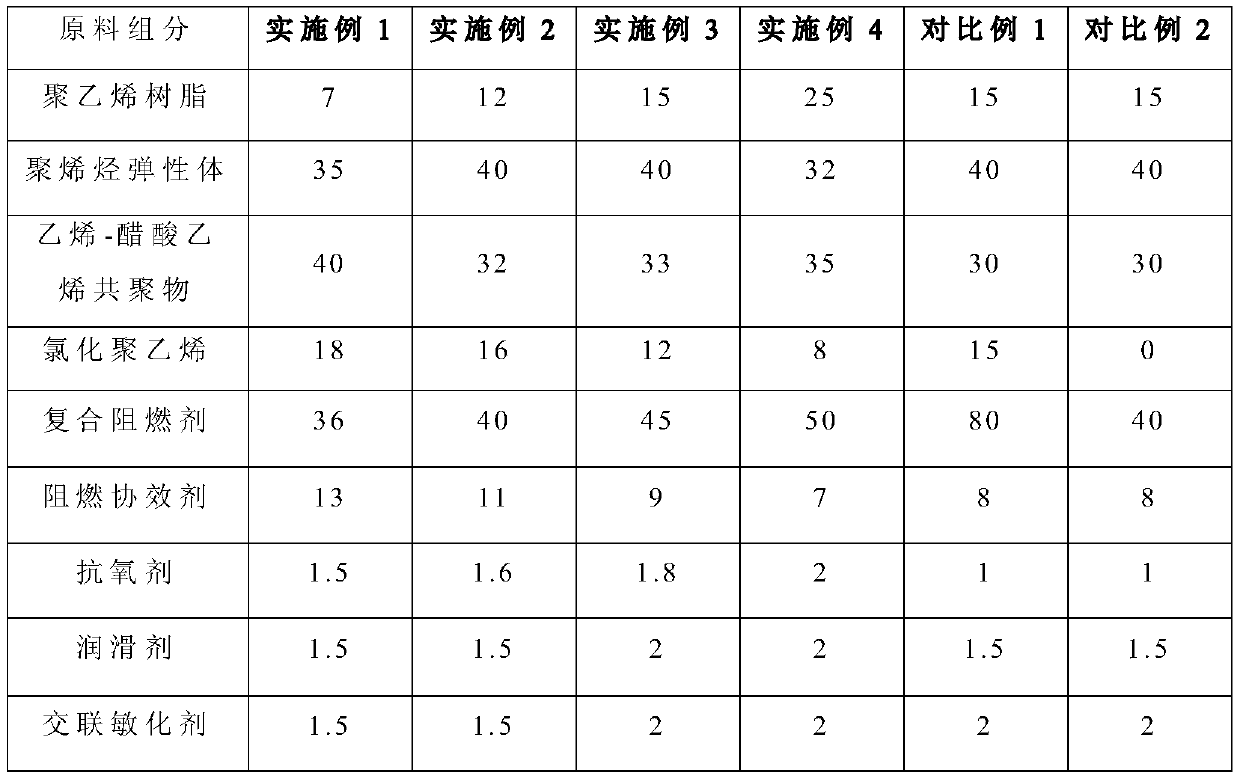

A kind of high flame-retardant composite material for new energy high-voltage line and preparation method thereof

ActiveCN107200917BImprove flame retardant performanceRetain softnessPlastic/resin/waxes insulatorsElastomerPolymer science

The present invention relates to a high flame retardancy composite material for a high voltage cable of a new energy automobile, the high flame retardancy composite material comprising the following raw materials in parts by weight: 5-25 parts of polyethylene resin; 25-50 parts of polyolefin elastomer; 30-50 parts of ethylene-vinyl acetate copolymer; 8-20 parts of chlorinated polyethylene; 30-60 parts of composite flame retardant; 0.2-15 parts of wear-resistant flame retardant synergist; 0.7-2.5 parts of antioxidant; 1-2 parts of lubricant; and 1.5-3 parts of cross-linking sensitising agent. The formulation of the present invention is improved, for example by using a mixture of bimodal polyethylene and high melt index high density polyethylene as a polyethylene resin and chlorinated polyethylene as a modifier, adding polyolefin elastomer and ethylene-vinyl acetate copolymer, and additionally adding a composite flame retardant, a flame retardant synergist, and an antioxidant, such that the composite material of the present invention has better flame retardancy properties and burns at a UL94 V0 grade whilst retaining the flexibility, high temperature resistance, oil resistance, and flame retardancy of high voltage cable material for use in a new energy automobile, and having excellent extrusion processing properties.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Furniture board and preparation method thereof

PendingCN111114051AEasy to prepareProcess stabilityLamination ancillary operationsSynthetic resin layered productsPolymer sciencePtru catalyst

The invention belongs to the field of furniture, and discloses a preparation method of a furniture board. The method comprises the following steps: adding nanometer silicon dioxide into ethylene glycol for dissolving; adding purified terephthalic acid, and carrying out an esterification reaction to obtain an esterified product; mixing diethylene glycol with dibasic acid, adding a titanium catalyst, and carrying out a polymerization reaction to obtain a prepolymer; adjusting temperature and pressure, and carrying out a hybrid reaction on the esterified product and the prepolymer to obtain a PETraw material with a melting point of 110-120 DEG C; carrying out melt extrusion on the PET raw material, and carrying out needling, hot bonding or spinning melting treatment to obtain a PET non-wovenfabric; pretreating the PET non-woven fabric with the melting point ranging from 110 DEG C to 120 DEG C and a PET non-woven fabric with a melting point ranging from 225 DEG C to 260 DEG C to obtain aPET non-woven fabric pre-material; and cutting, hot-pressing and cooling the pre-material to obtain the furniture board. The preparation method is simple and stable in process and suitable for large-scale industrial production.

Owner:广东顺德海一舸新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com