Full-biodegradable antibacterial PLA/PBAT film and preparation method thereof

An all-biological, PLA technology, applied in the field of fully biodegradable antibacterial PLA/PBAT film and its preparation, can solve the problems of less research on the antibacterial performance of PLA/PBAT film, achieve good dimensional stability, avoid high temperature inactivation, and improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

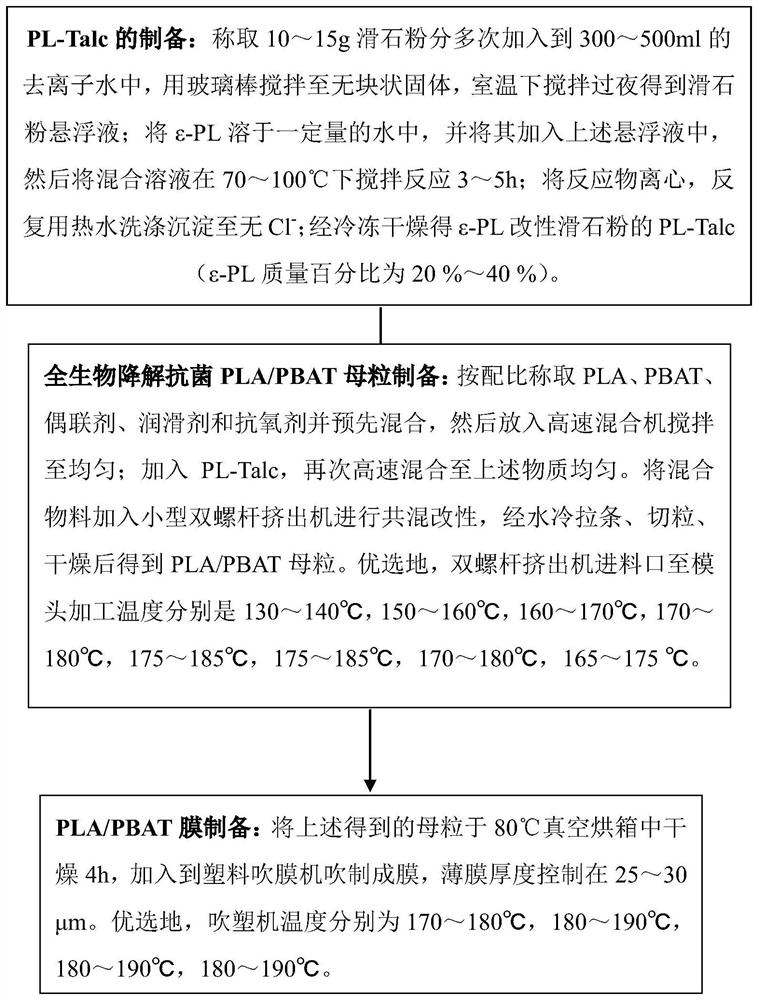

Method used

Image

Examples

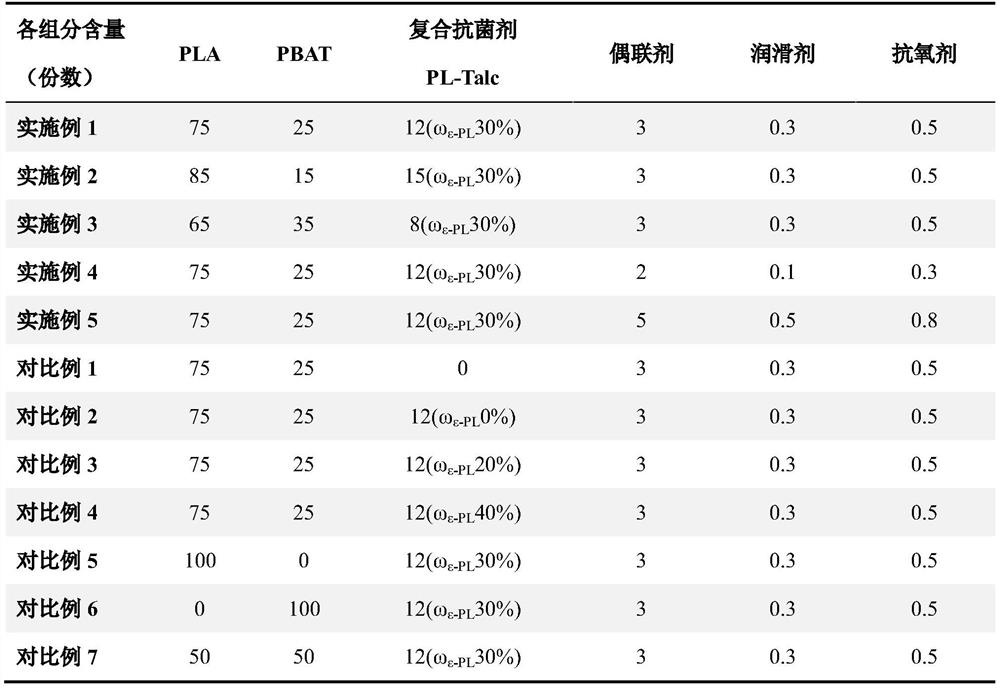

Embodiment 1

[0036] A fully biodegradable antibacterial PLA / PBAT film and its preparation method, including the following raw materials in parts by weight: PLA: 75 parts; PBAT: 25 parts; composite antibacterial agent: 12 parts; coupling agent: 3 parts; lubricant: 0.3 part; Antioxidant: 0.5 part;

[0037] The composite antibacterial agent is talc powder (Talc) modified by an organic antibacterial agent ε-polylysine hydrochloride (ε-PL). Wherein, the mass percentage of ε-PL is 30%.

[0038] The ε-PL is ε-polylysine hydrochloride produced by Zhejiang Xinyinxiang Bioengineering Co., Ltd.

[0039] The PLA is 4032D produced by Natureworks, USA.

[0040] The PBAT is C1200 produced by BASF, Germany.

[0041] The coupling agent is a mixture of tetrabutyl titanate and triethoxyvinylsilane in a weight ratio of 1:1.

[0042] Described lubricant is Malaysia EBS-SF lubricant.

[0043] The antioxidant is hindered phenolic antioxidant 1010 produced by BASF.

[0044] According to another aspect of th...

Embodiment 2

[0049] A fully biodegradable antibacterial PLA / PBAT film and its preparation method, including the following raw materials in parts by weight: PLA: 85 parts; PBAT: 15 parts; composite antibacterial agent: 15 parts; coupling agent: 3 parts; lubricant: 0.3 parts part; Antioxidant: 0.5 part;

[0050] The composite antibacterial agent is talc powder (Talc) modified by an organic antibacterial agent ε-polylysine hydrochloride (ε-PL). Wherein, the mass percentage of ε-PL is 30%.

[0051] The preparation method of this embodiment is roughly the same as that of Example 1, except that the consumption of PLA, PBAT and composite antibacterial agent is different from that of Example 1. In this embodiment, the weight part of PLA is 85 parts, the weight part of PBAT is 15 parts, and the weight part of composite antibacterial agent is 15 parts.

Embodiment 3

[0053] A fully biodegradable antibacterial PLA / PBAT film and its preparation method, including the following raw materials in parts by weight: PLA: 65 parts; PBAT: 35 parts; composite antibacterial agent: 8 parts; coupling agent: 3 parts; lubricant: 0.3 part; Antioxidant: 0.5 part;

[0054] The composite antibacterial agent is talc powder (Talc) modified by an organic antibacterial agent ε-polylysine hydrochloride (ε-PL). Wherein, the mass percentage of ε-PL is 30%.

[0055] The preparation method of this embodiment is roughly the same as that of Example 1, except that the consumption of PLA, PBAT and composite antibacterial agent is different from that of Example 1. In this embodiment, the weight part of PLA is 65 parts, the weight part of PBAT is 35 parts, and the weight part of composite antibacterial agent is 8 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com