Preparation method of flexible transparent conductive electrode with low surface roughness

A transparent conductive electrode, roughness technology, applied in the equipment for manufacturing conductive/semiconducting layer, conductive layer on insulating carrier, cable/conductor manufacturing, etc. Problems such as poor adhesion to the substrate, low surface resistivity, light transmittance, etc., to achieve the effects of green and pollution-free raw materials, high transmittance, and reduced surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

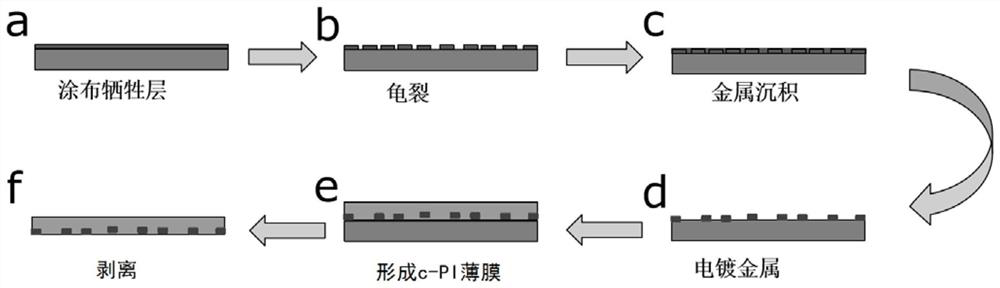

[0061] Flexible transparent conductive electrodes with low surface roughness are fabricated by the following method:

[0062] S0: Clean the substrate: ultrasonically clean the substrate in isopropanol, absolute ethanol, and deionized water for 15 minutes, and then dry the substrate with an air gun; place it in a plasma cleaning machine for hydrophilic treatment, For hydrophilic treatment, the plasma cleaning machine cleans for 100s, and the power of the plasma cleaning machine is 220w;

[0063] S1: Coating the cracking material CA600 nail polish on the substrate to make a sacrificial layer, and the sacrificial layer gradually cracks under natural conditions to form a crack template;

[0064] S2: Place the substrate covered with the cracked template in a magnetron sputtering device to deposit metallic silver. After the deposition is completed, place it in absolute ethanol, ultrasonically clean it for 30s, and then wash it with deionized water to remove the cracked template. Ge...

Embodiment 2

[0071] Flexible transparent conductive electrodes with low surface roughness are fabricated by the following method:

[0072] S0: Clean the substrate: ultrasonically clean the substrate in isopropanol, absolute ethanol, and deionized water for 15 minutes, and then dry the substrate with an air gun; place it in a plasma cleaning machine for hydrophilic treatment, For hydrophilic treatment, the plasma cleaning machine cleans for 100s, and the power of the plasma cleaning machine is 220W;

[0073] S1: Coating the cracking material cellulose on the substrate to make a sacrificial layer, and gradually cracking the sacrificial layer under the heating conditions of 70°C and holding time for 10 minutes to form a cracking template;

[0074] S2: Place the substrate covered with the cracked template in a magnetron sputtering device to deposit metallic silver. After the deposition is completed, place it in absolute ethanol, ultrasonically clean it for 30s, and then wash it with deionized ...

Embodiment 3

[0081] Flexible transparent conductive electrodes with low surface roughness are fabricated by the following method:

[0082] S0: Clean the substrate: ultrasonically clean the substrate in isopropanol, absolute ethanol, and deionized water for 15 minutes, and then dry the substrate with an air gun; place it in a plasma cleaning machine for hydrophilic treatment, For hydrophilic treatment, the plasma cleaning machine cleans for 100s, and the power of the plasma cleaning machine is 220W;

[0083] S1: coating the cracking material egg white sol on the substrate to make a sacrificial layer, and gradually cracking the sacrificial layer under the heating conditions of 70°C and holding time for 10 minutes to form a crack template;

[0084] S2: Place the substrate covered with the cracked template in a magnetron sputtering device to deposit metallic silver. After the deposition is completed, place it in absolute ethanol, ultrasonically clean it for 30s, and then wash it with deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com