Patents

Literature

75results about How to "Good performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile terminal and method for adjusting CPU (Central Processing Unit) frequency thereof

ActiveCN103324270AReduce power consumptionExtend battery lifePower supply for data processingConservative strategyPower consumption

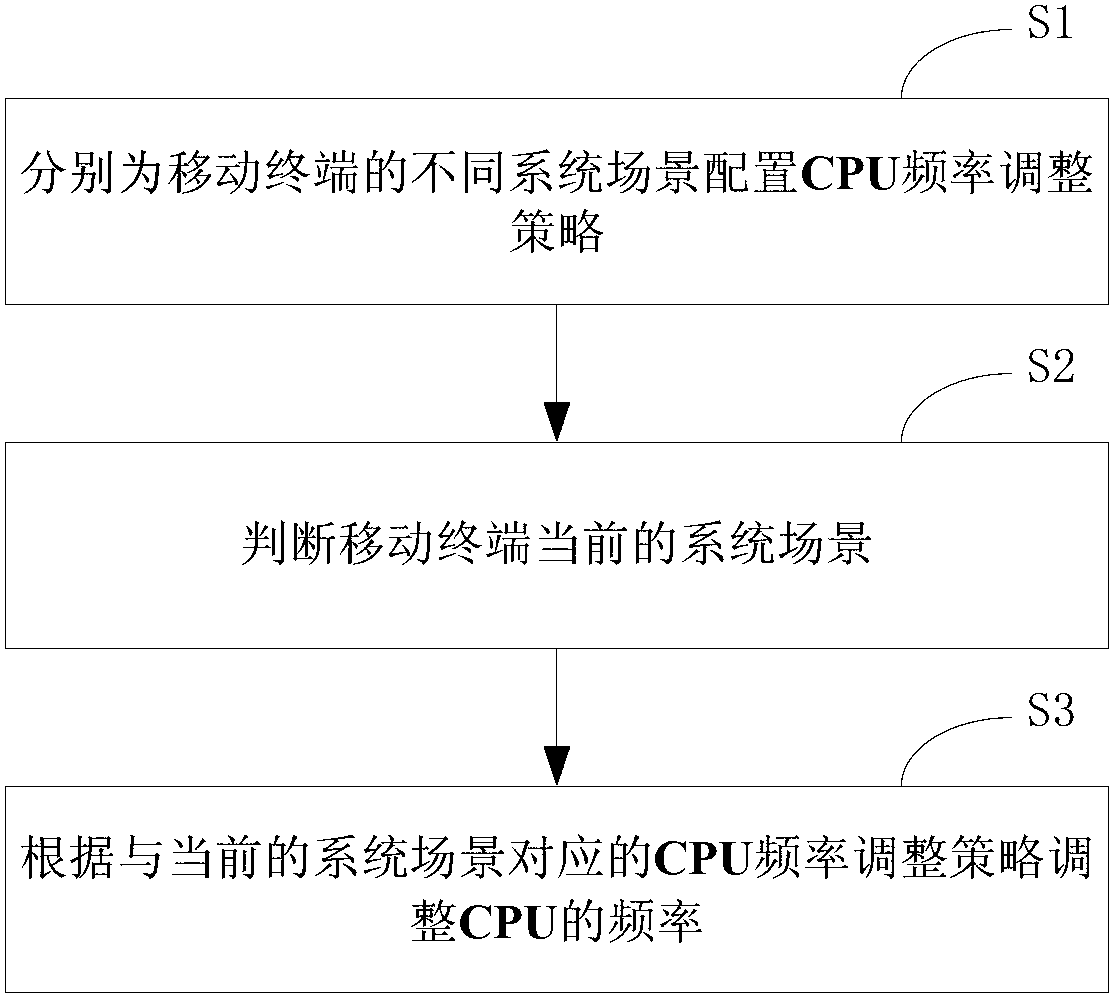

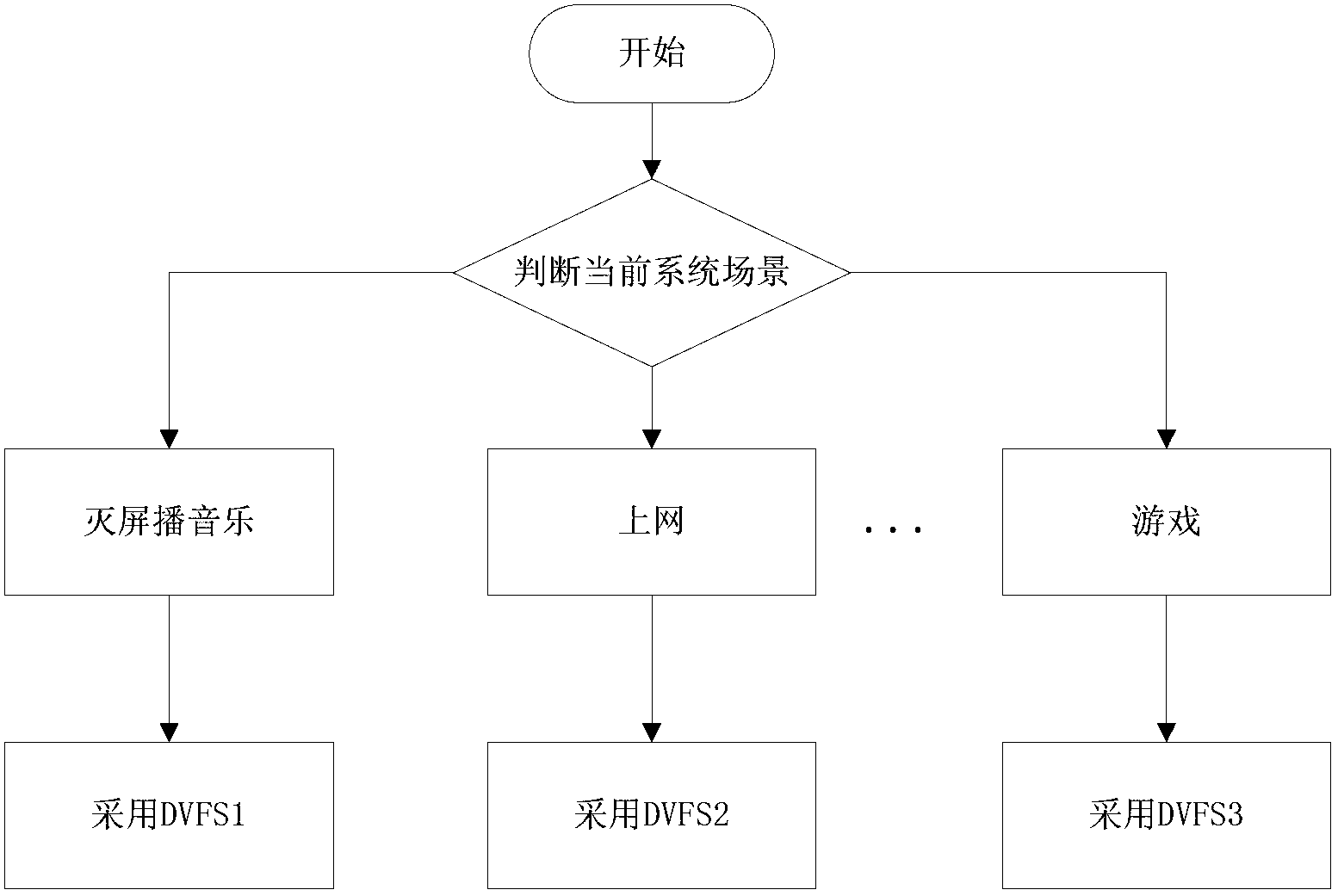

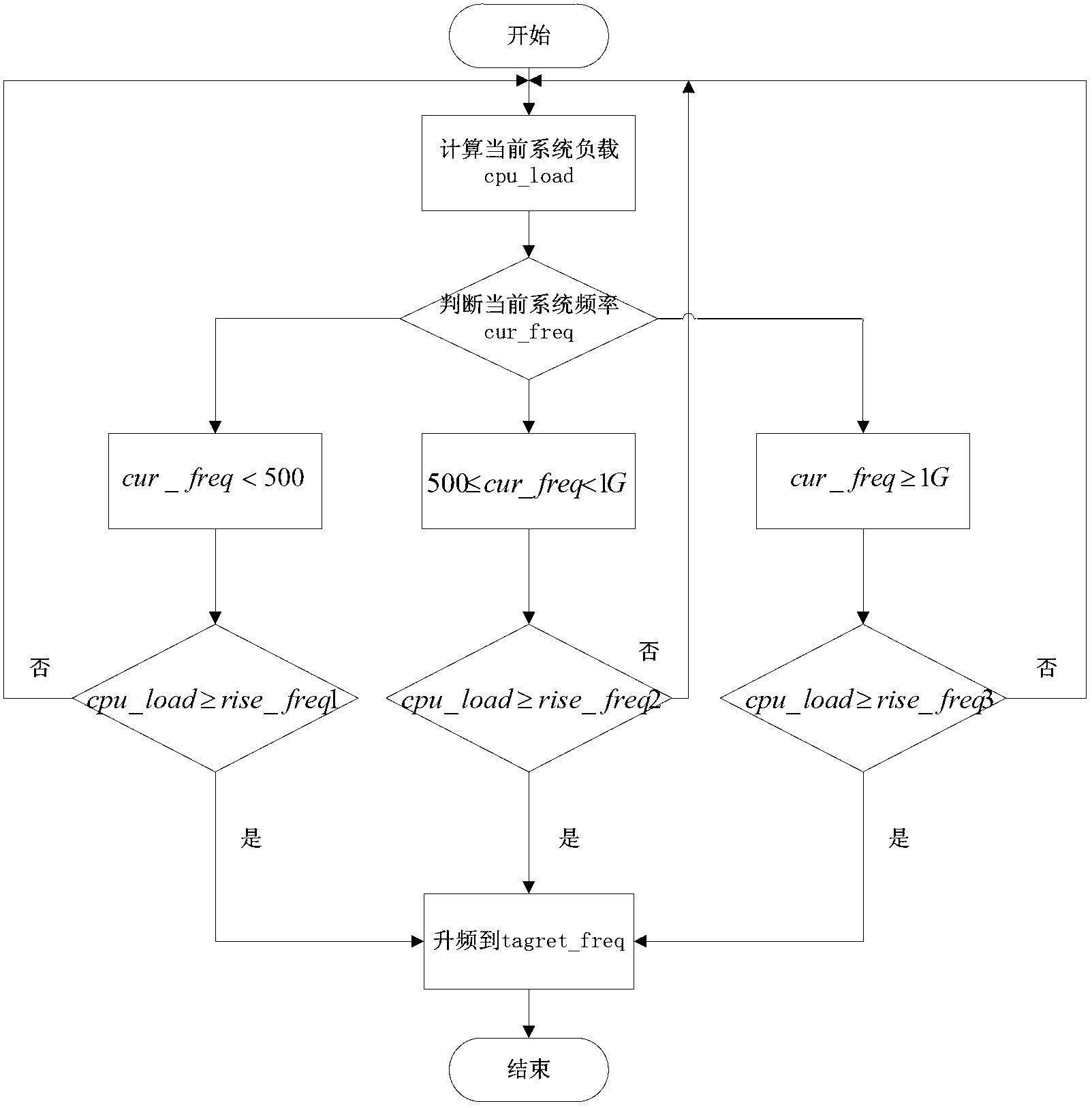

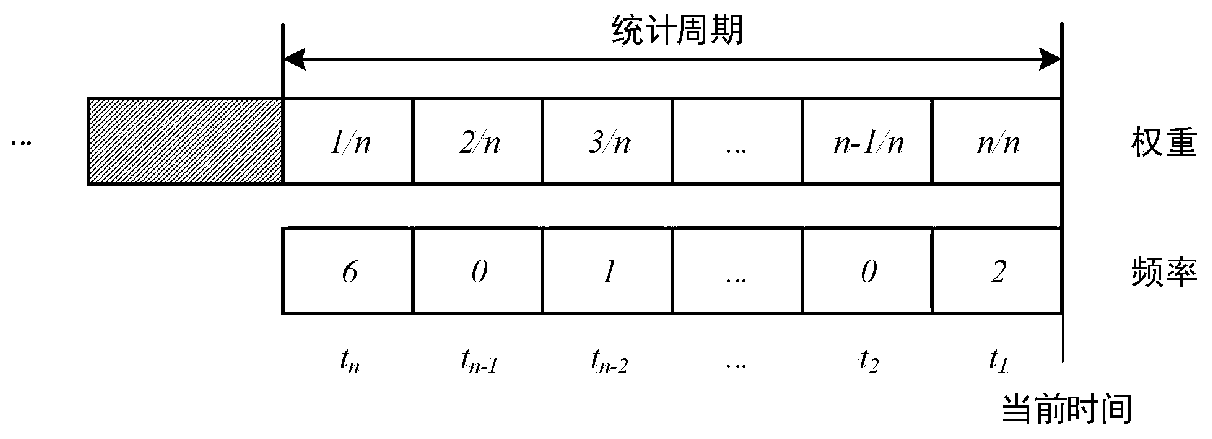

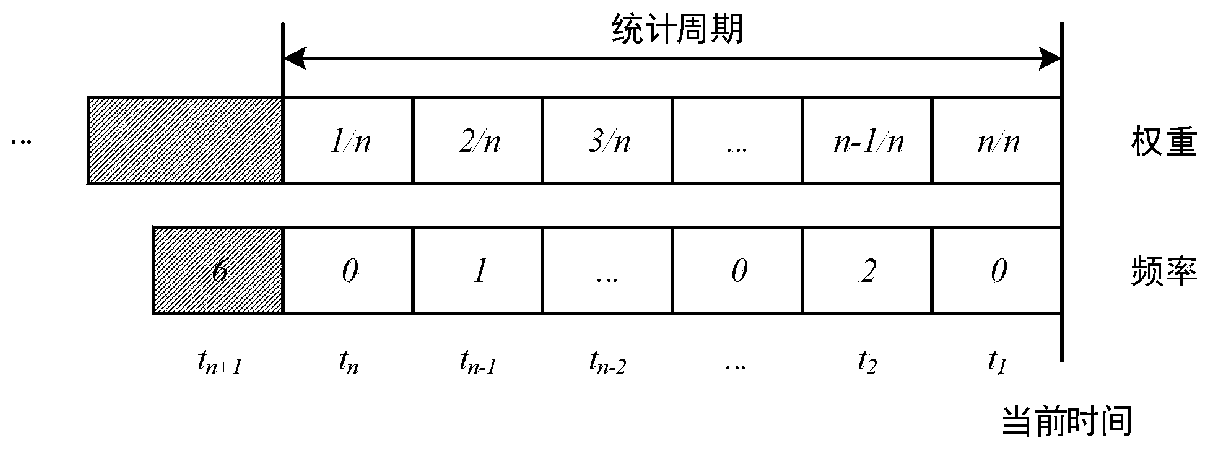

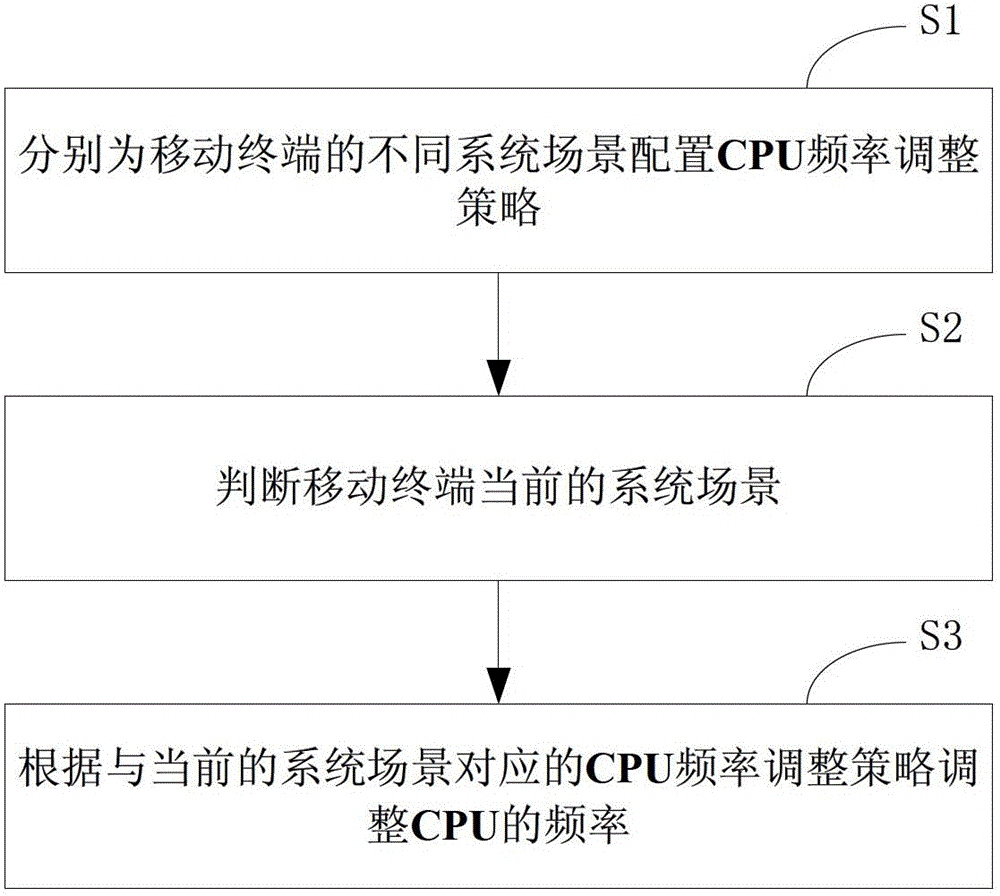

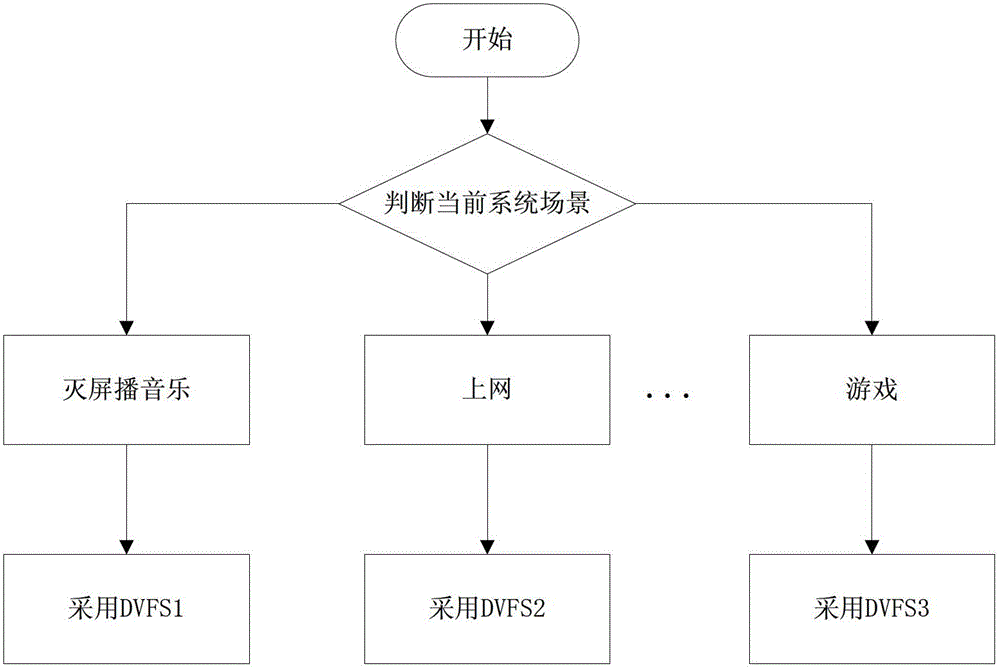

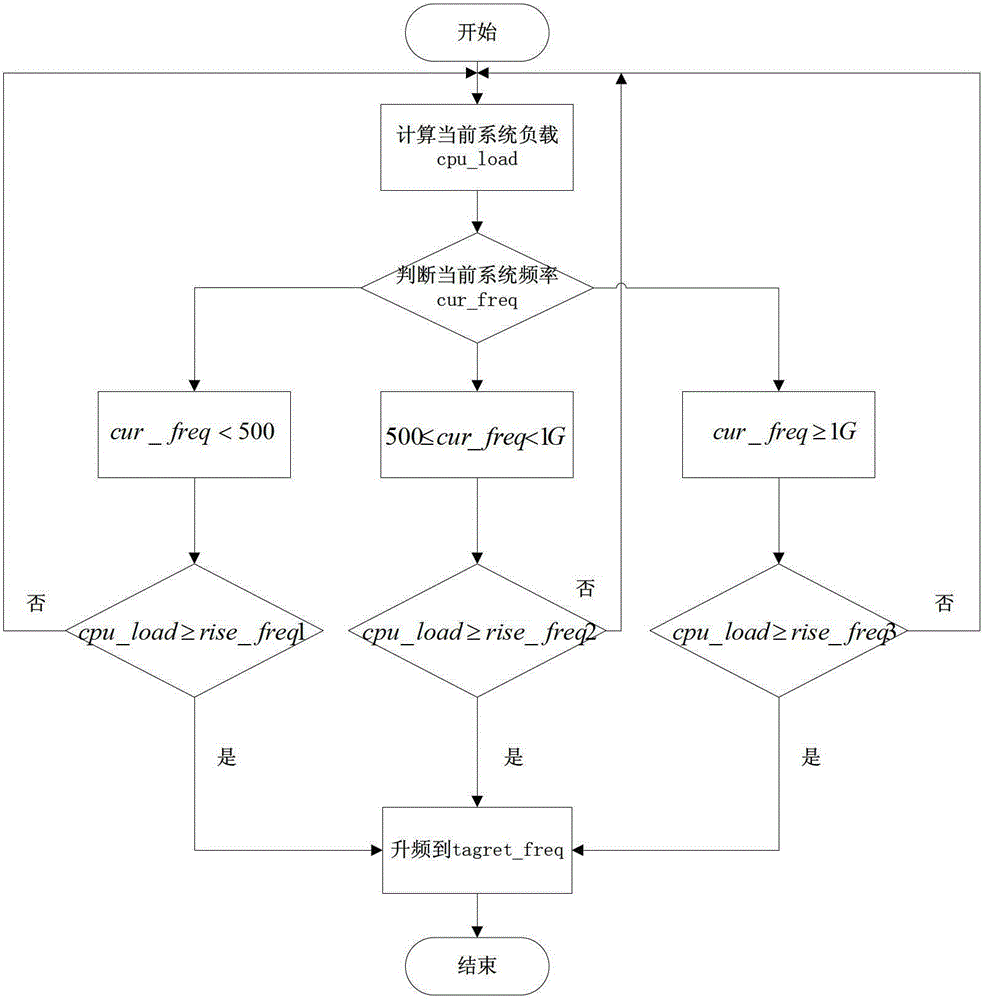

The invention discloses a mobile terminal and a method for adjusting the CPU frequency thereof. The mobile terminal comprises a strategy configuration unit, a system scene determination unit and a frequency adjustment unit. The method includes S1, configuring CPU frequency adjustment strategies for different system scenes of the mobile terminal respectively; S2, determining the current system scene of the mobile terminal; S3, adjusting the CPU frequency according to the CPU frequency adjustment strategy corresponding to the current system scene. The mobile terminal and the method for adjusting the CPU frequency thereof can be used for automatically switching the CPU frequency adjustment strategies for the different system scenes, so that system scenes of low power consumption can be applied with a conservative frequency adjustment strategy, and system scenes of high performance requirement and high power can be applied with an active frequency adjustment conservative strategy. Therefore, the power consumption is reduced and the battery life of the mobile terminal is prolonged.

Owner:DONGGUAN YULONG COMM TECH +1

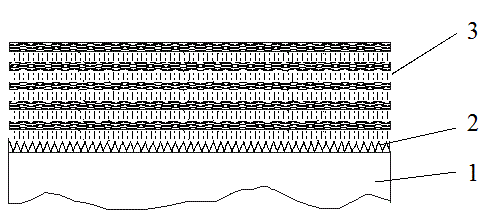

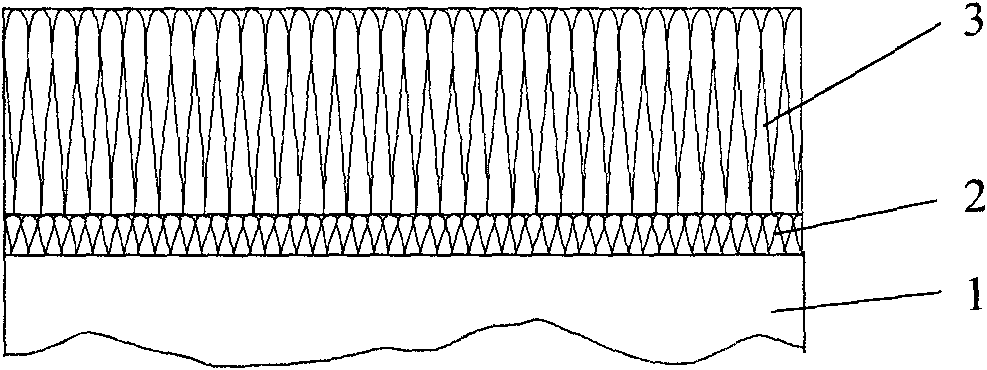

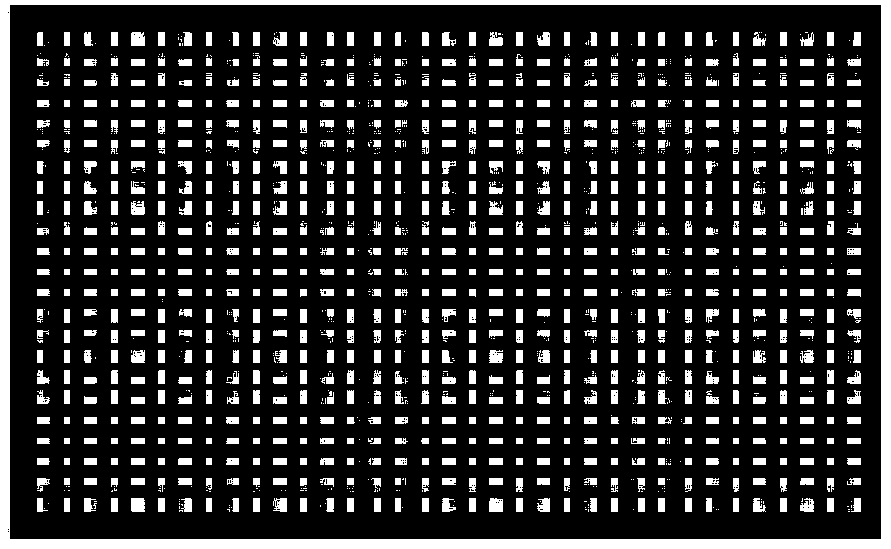

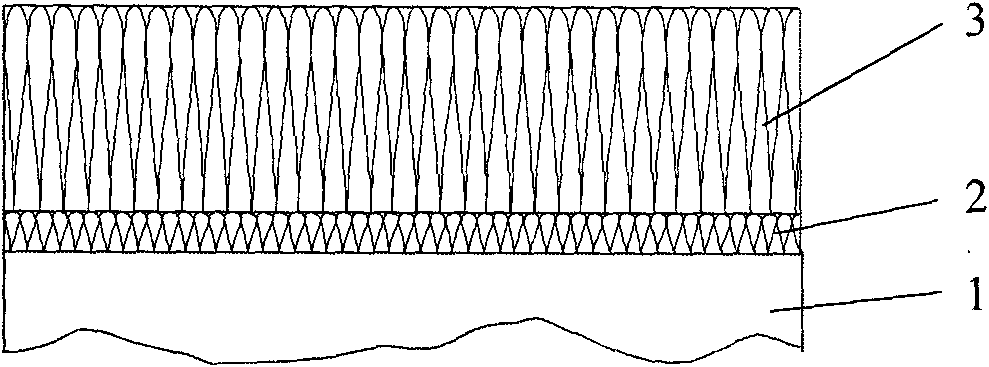

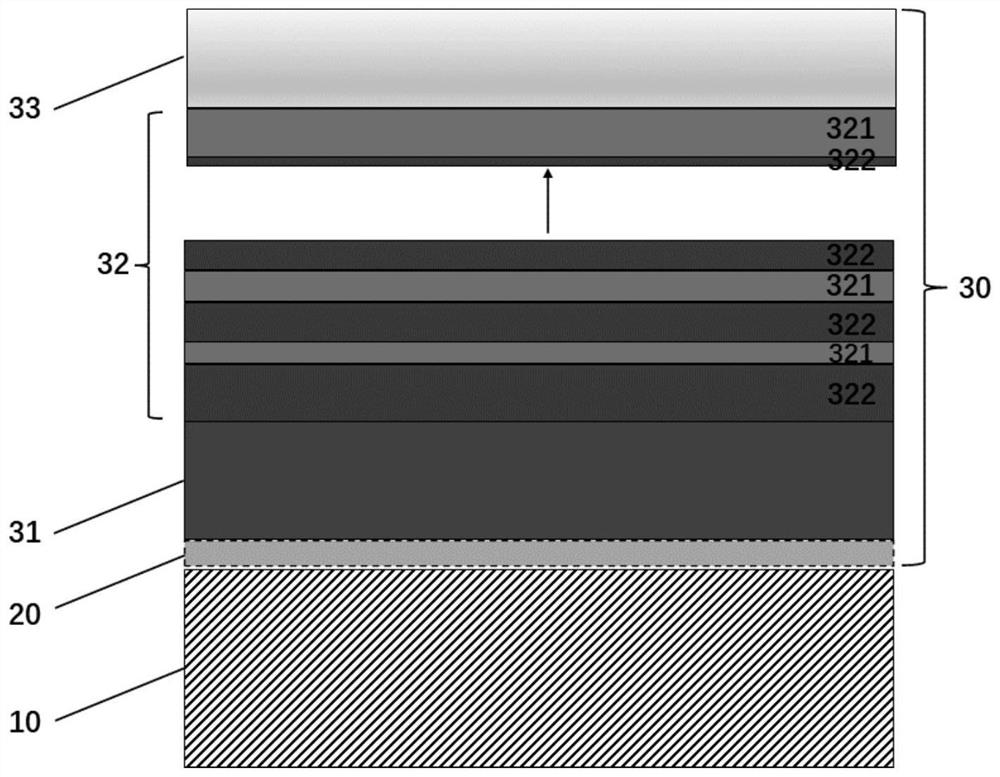

AlCrSiN-based multilayer nanometer composite cutter coating layer and preparation method thereof

InactiveCN104928638AExtend your lifeImprove mechanical propertiesVacuum evaporation coatingSputtering coatingWear resistantChromium

The invention relates to an AlCrSiN-based multilayer nanometer composite cutter coating layer and a preparation method thereof, and belongs to the technical field of preparation of cutter coating layers. A cutter basal body of the AlCrSiN-based multilayer nanometer composite cutter coating layer adopts a WC-Co hard allot or high-speed steel; the coating layer structure comprises a Ti metal bonding layer, an AlTiN transition layer and an AlCrSiN main wear resistant layer, wherein the AlTiN transition layer consists of 29-35 at.% of aluminum, 15-20 at.% of titanium, and 47-51 at.% of nitrogen; and the AlCrSiN main wear resistant layer consists of 25-30 at.% of aluminum, 20-25 at.% of chromium, 1-10 at.% of silicon, and 45-50 at.% of nitrogen. The transition layer AlTiN coating layer is prepared by a high-power pulse magnetron sputtering technology; and the AlCrSiN coating layer is prepared by an arc ion plating technology. The AlCrSiN-based multilayer nanometer composite cutter coating layer has the advantages of high hardness, low friction coefficient, low internal stress, high bonding strength and good high-temperature stability; a deposition coating cutter is suitable for cutting a high-hardness steel material under the condition of high speed; and the service life of the cutter can be largely prolonged.

Owner:GUANGDONG UNIV OF TECH

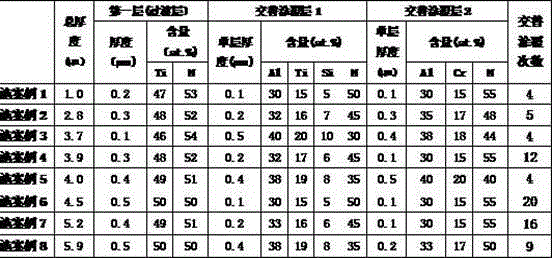

Multilayer nanometer composite cutting tool coating and preparation method thereof

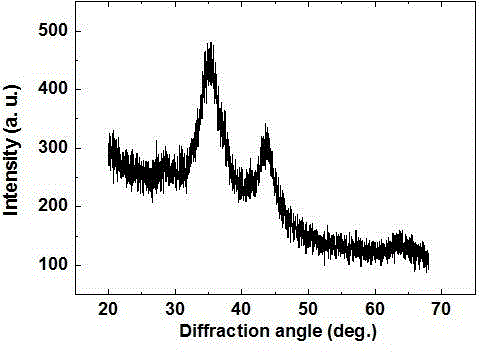

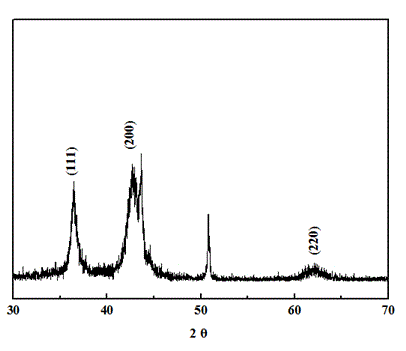

ActiveCN104131256AAdjust the microstructureTuning Microhardness PropertiesLayered productsVacuum evaporation coatingTitanium nitrideTotal thickness

The invention discloses a multilayer nanometer composite cutting tool coating and a preparation method thereof. The surface of a cutting tool substrate is coated with a titanium nitride transition layer by using physical vapor deposition technology and is then alternately and periodically coated by multiple layers of an aluminum-titanium-silicon nitride coating and an aluminum-chromium-nitrogen coating, wherein the thickness of the titanium nitride transition layer is 0.1 to 0.5 mu m, the thickness of each layer of the aluminum-titanium-silicon nitride coating and the aluminum-chromium-nitrogen coating is 0.1 to 0.5 mu m, and the substrate is coated by 4 to 20 layers, thereby forming the AlTiSiN / AlCrN nanometer composite cutting tool coating with a multilayer structure. According to the invention, the crystal size of the coating is in a range of 5 to 15 nm, the total thickness of the coating is 1 to 6 mu m, the microscopic hardness of the coating is 25 to 40 GPa, and high temperature stability reaches more than 1050 DEG C. A cutting tool prepared by using the coating has greatly improved resistance to mechanical wear and high temperature oxidation resistance and can meet demands of high speed processing for better performance of a cutting tool material.

Owner:GUANGDONG UNIV OF TECH

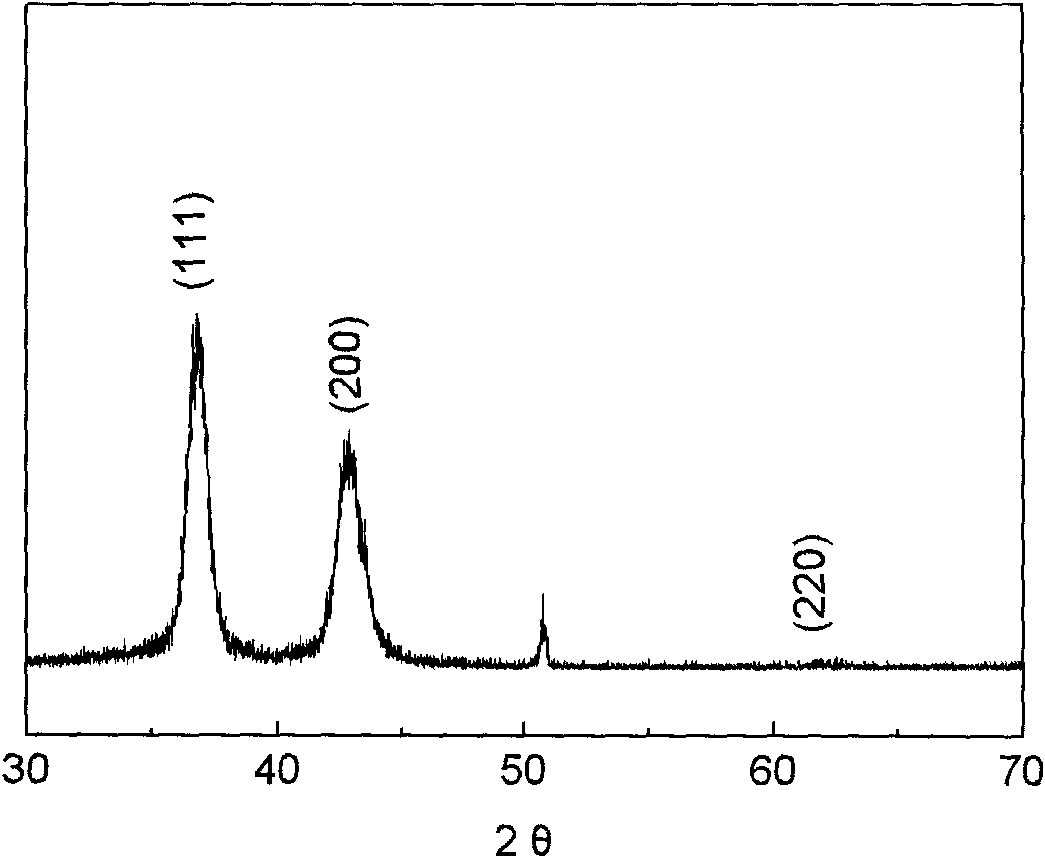

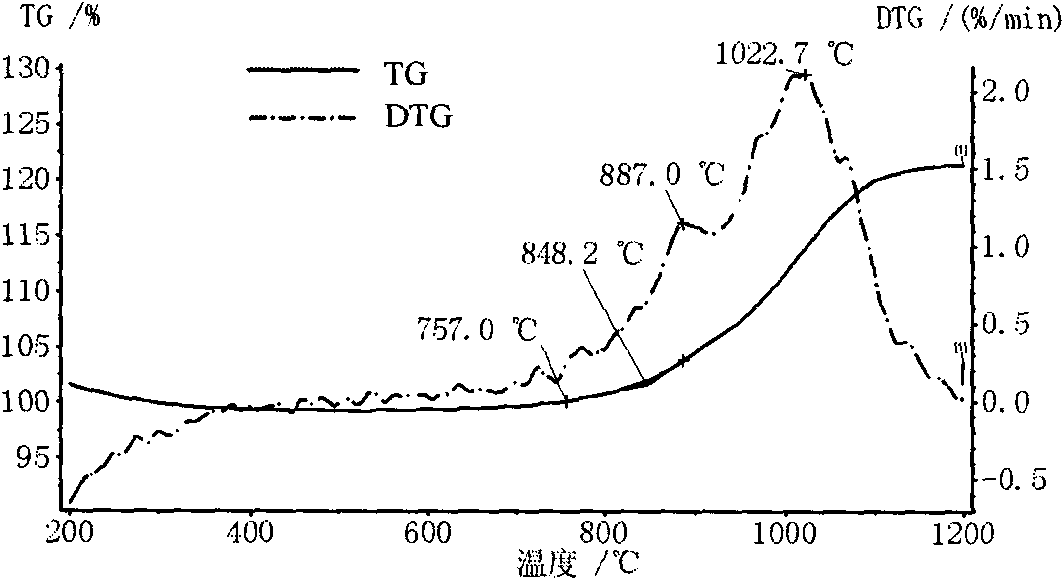

Nano composite titanium-chromium-aluminum-silicon nitride cutter coat and preparation method thereof

ActiveCN101831615AImproved resistance to mechanical wear and abrasive wearMeet the need for better performanceVacuum evaporation coatingSputtering coatingNanometreCrystallite

The invention discloses a nano composite titanium-chromium-aluminum-silicon nitride cutter coat and a preparation method thereof. The cutter matrix is WC / Co hard alloy, and the coat is a nano composite titanium-chromium-aluminum-silicon nitride coat containing a transition layer, wherein the coat contains titanium, chromium, aluminum, silicon and nitrogen elements; and the size of crystalline grains is 5 to 15 nanometers, the thickness of the coat is 1 to 4 microns, the micro hardness of the coat is 30GPa, and the high-temperature stability reaches over 1,022 DEG C. A nano composite titanium-chromium-aluminum-silicon nitride coat cutter is a nano composite structural coat cutter prepared in a mode of combining ion plating and sputter-plating, and is suitable for cutting and processing high-hardness steel materials at a high speed.

Owner:GUANGDONG UNIV OF TECH

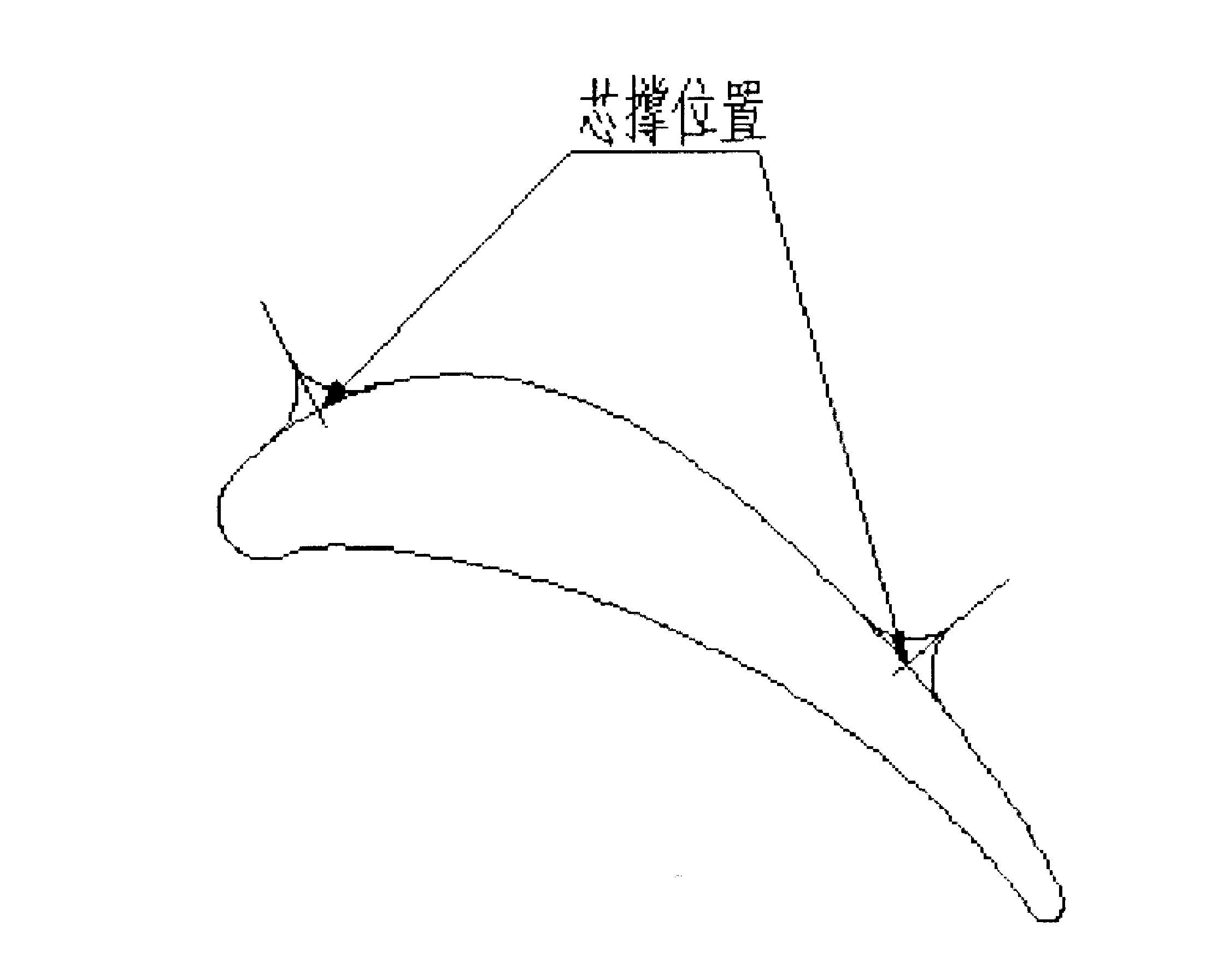

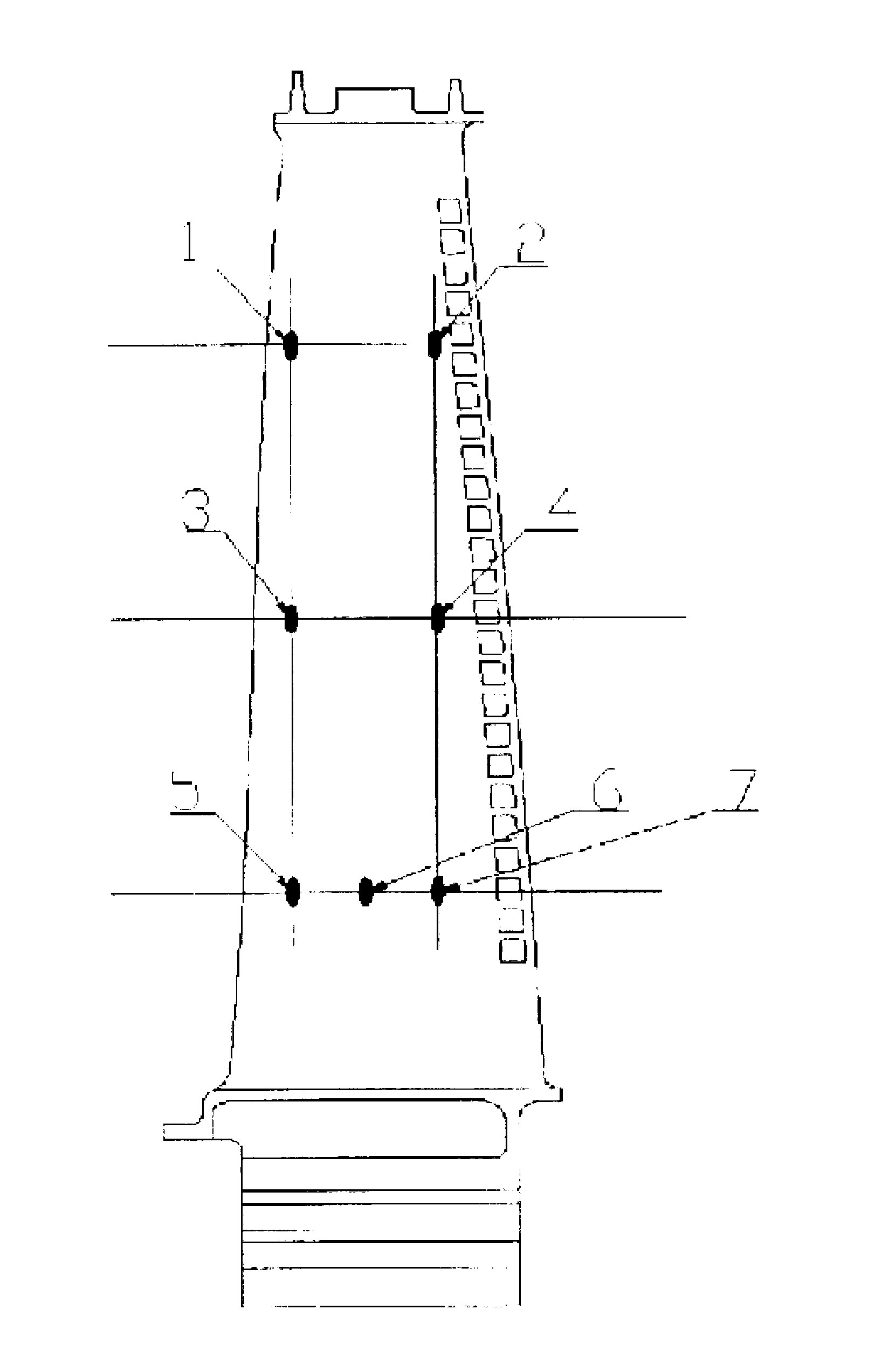

Method for enhancing strength of single crystal blade core by metal core support

InactiveCN103056313AIncrease impactGood performance requirementsFoundry mouldsFoundry coresWhite paraffinPlatinum

The invention provides a method for enhancing strength of a single crystal blade core by a metal core support. The method comprises the following steps: before a wax mold is combined, punching platinum-rhodium wires in wall thickness detecting point positions of a blade as a metal core support, wherein the height of the metal core support is 3-10 mm and a needle applying direction is a normal direction perpendicular to the blade surface; gripping the platinum-rhodium wires by using tweezers; heating the platinum-rhodium wires for 5-15 seconds on an alcohol lamp; punching the platinum-rhodium wires in a direction perpendicular to the blade surface; after fetching a small amount of white paraffin wax by using a metal stick and heating the white paraffin wax on the alcohol lamp for 1-5 seconds, dripping a wax liquid to the blade along the metal core support to form wax bumps; and after the wax bumps are cooled, trimming the shapes of the wax bumps by using the metal stick until the wax bumps are in smooth connection with the blade surface. The method provided by the invention has the advantages as follows: the metal liquid impact resisting capacity of a ceramic core in a high temperature state is effectively enhanced, defects of biased castings and core exposure are greatly reduced and the losses of waste products are greatly reduced. And moreover, the method for enhancing the strength of the single crystal blade core, provided by the invention, must bring about considerable economic benefits with the development of a casting process and the improvement of the overall performance of an aircraft engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Full-field lens assembling method and device

ActiveCN108037594ASimple structureGood performance requirementsOptical elementsCamera lensWavefront sensor

The invention provides a full-field lens assembling method which comprises the following steps: measuring wavefront of a measured lens at different full-field positions; processing the information ofthe wavefront at different positions to obtain various aberrations; and integrating the obtained aberrations, and adjusting the assembling position of the measured lens according to the integrated result. The invention further provides a full-field lens assembling device for realizing the method. The assembling device comprises a light source, a reticle, a telescope system and a wavefront sensor,wherein the wavefront sensor is used for receiving wavefront formed by parallel beams exiting from the telescope system and measuring the actual wavefront information; and the wavefront comprises an on-axis wavefront and an off-axis wavefront, and is used for adjusting the measured lens by comprehensively considering the full-field wavefont condition. The assembly mode for wavefront measurement replaces the traditional MTF-based assembling manner, the assembling accuracy and efficiency are improved, and large-scale production of a high-performance lens is realized.

Owner:北京全欧光学检测仪器有限公司

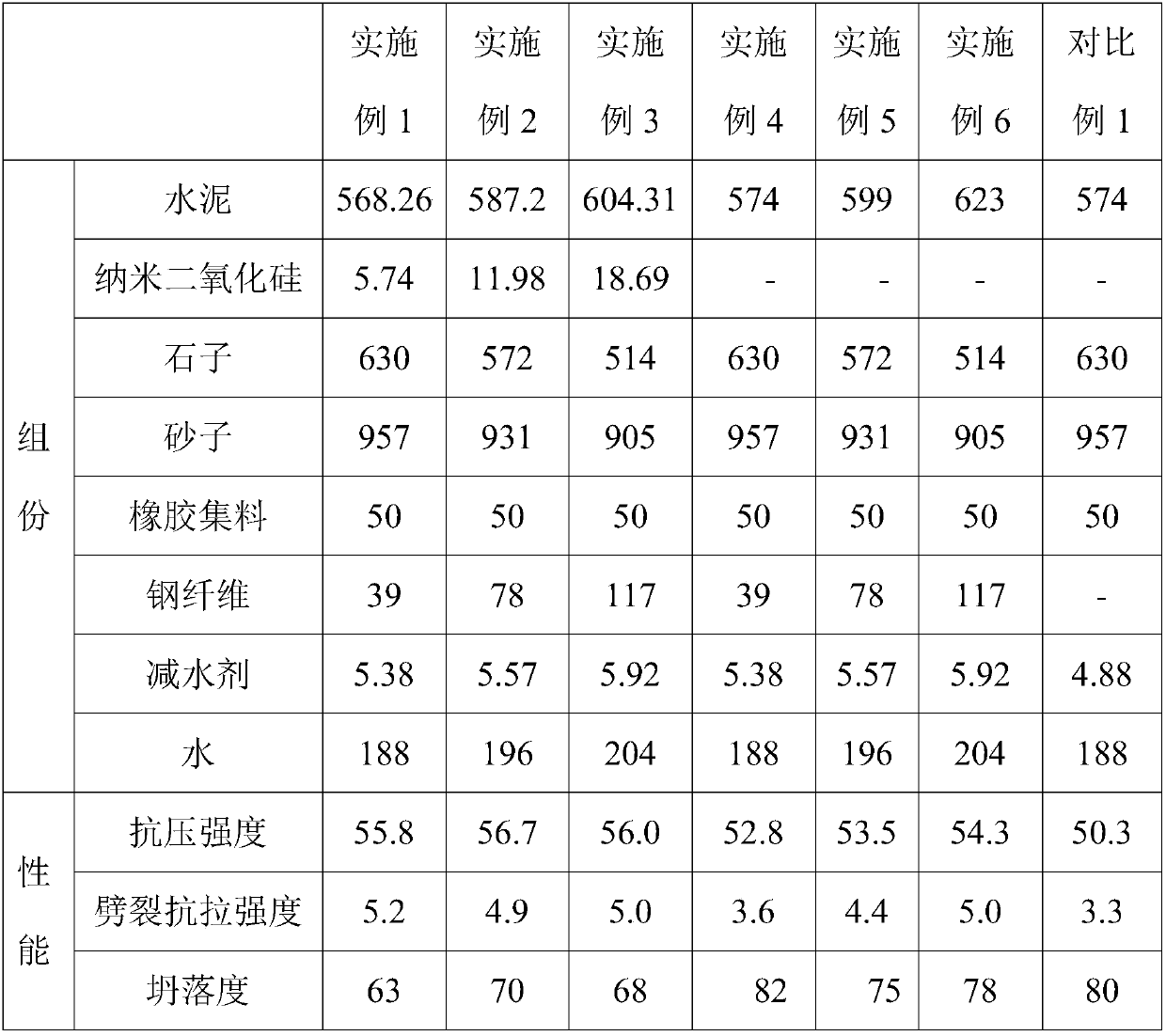

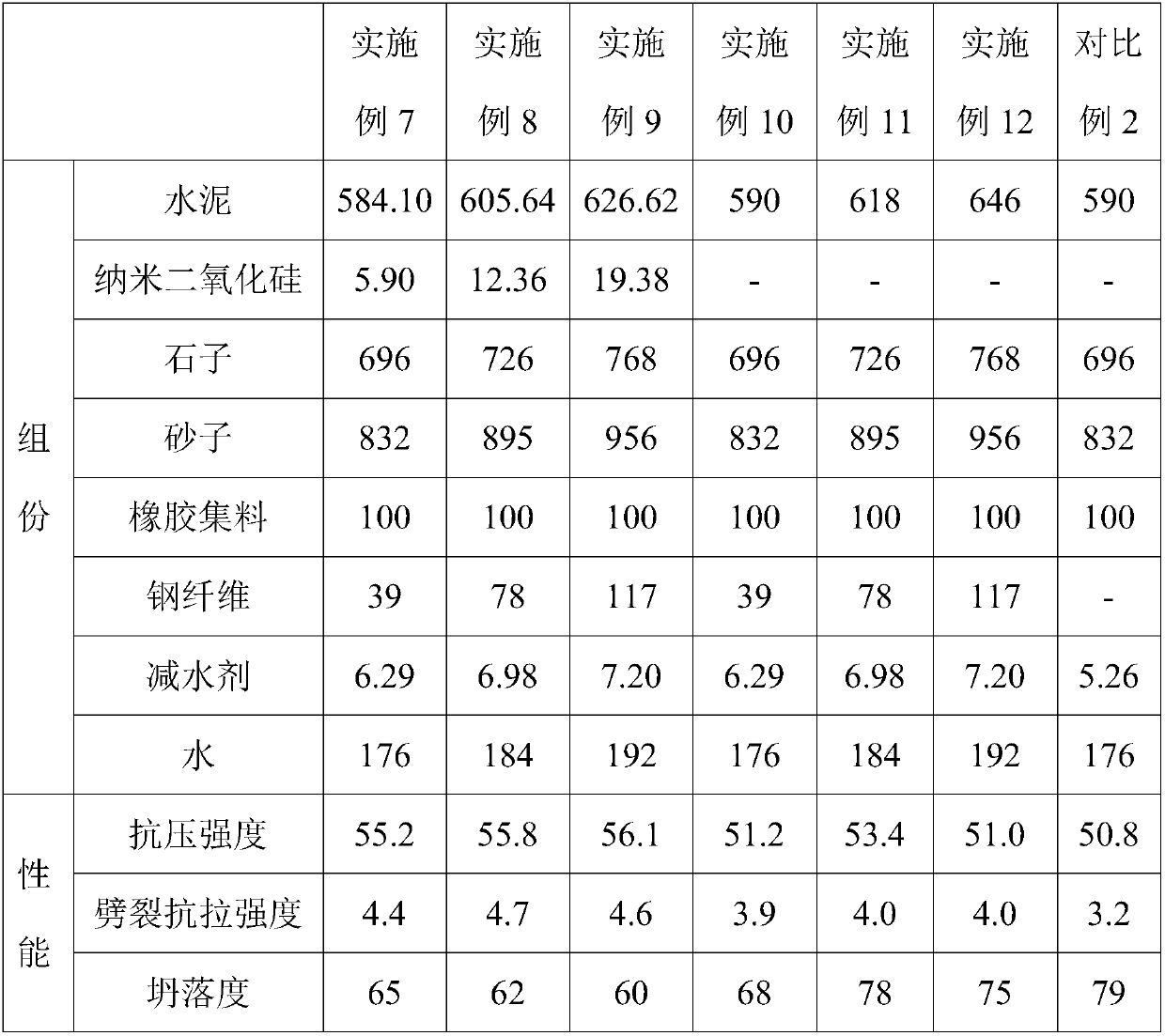

High-compressive-strength rubber aggregate concrete and preparation method thereof

The invention relates to high-compressive-strength rubber aggregate concrete, which is prepared from concrete base materials, rubber aggregates, steel fiber and water reducing agents, wherein the concrete base materials are prepared from nanometer silicon dioxide; the concrete base materials are prepared from gelling materials, stone and sand according to a mass ratio of (0.9 to 1.1):(0.6 to 0.9):(1.4 to 1.8); the gelling materials are prepared from cement and nanometer silicon dioxide; the volume mixing amount of the rubber aggregates is 50 to 100kg / m<3>; the volume mixing amount of the steelfiber is 70 to 120 kg / m<3>; the mass ratio of the water to the gelling materials is (0.28 to 0.33):1; the mass ratio of the water reducing agents to the gelling materials is (0.9 to 1.2):100. The compressive strength of the high-compressive-strength rubber aggregate concrete can reach C55 level; compared with that of traditional rubber aggregate concrete with the same water-binder ratio, the splitting tensile strength is improved by 50 percent or higher; the slump constant is 60mm or higher; the flowability and the water retaining capacity are good; the cement clinker is saved; the preparation process is simple and achieves an environment-friendly effect; the construction is easy.

Owner:ZHENGZHOU UNIV

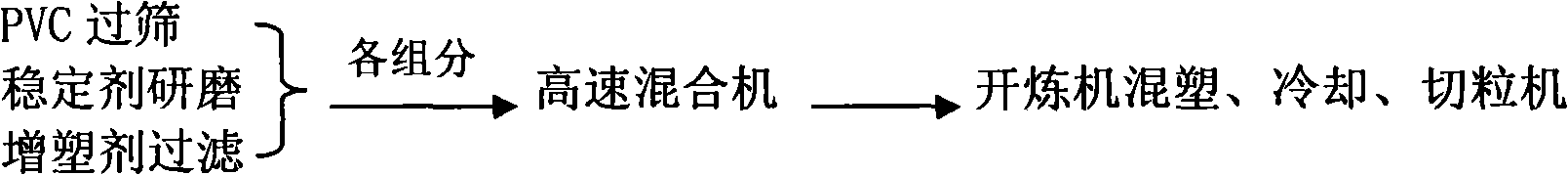

Polyvinyl chloride (PVC) insulating plastics with wide temperature and high electrical performance

ActiveCN101659775AGood performance requirementsImprove insulation performancePlastic/resin/waxes insulatorsElectricityPlasticizer

The invention relates to a polyvinyl chloride (PVC) insulating plastics with wide temperature and high electrical performance. The compositions and the weight percentage of each composition are as follows: 55-75% of PVS resin, 20-35% of plasticizer, 1.5-5% of stabilizer, 0.1-0.6% of antioxygen, 0.1-0.6% of lubricant, and 1-6% of functional fillers. The PVC insulating plastics has excellent electrical insulating property, good cold tolerance under low temperature, and is especially applied in outdoor exploration operation in cold regions with inclement condition. The cables produced by the plastic have no cracking phenomenon after being conducted winding test at the temperature of minus 40 DEG C for 24 hours under low-temperature environment. The plastics are not only applied in low temperature environment, but also used in the production and application of wires and cables with high electrical property requirement. The insulating plastics have low cost and good processing property, andare suitable for scale production, thereby meeting the requirement on high property of PVC insulating plastics in the market.

Owner:TIANJIN 609 CABLE COMPANY

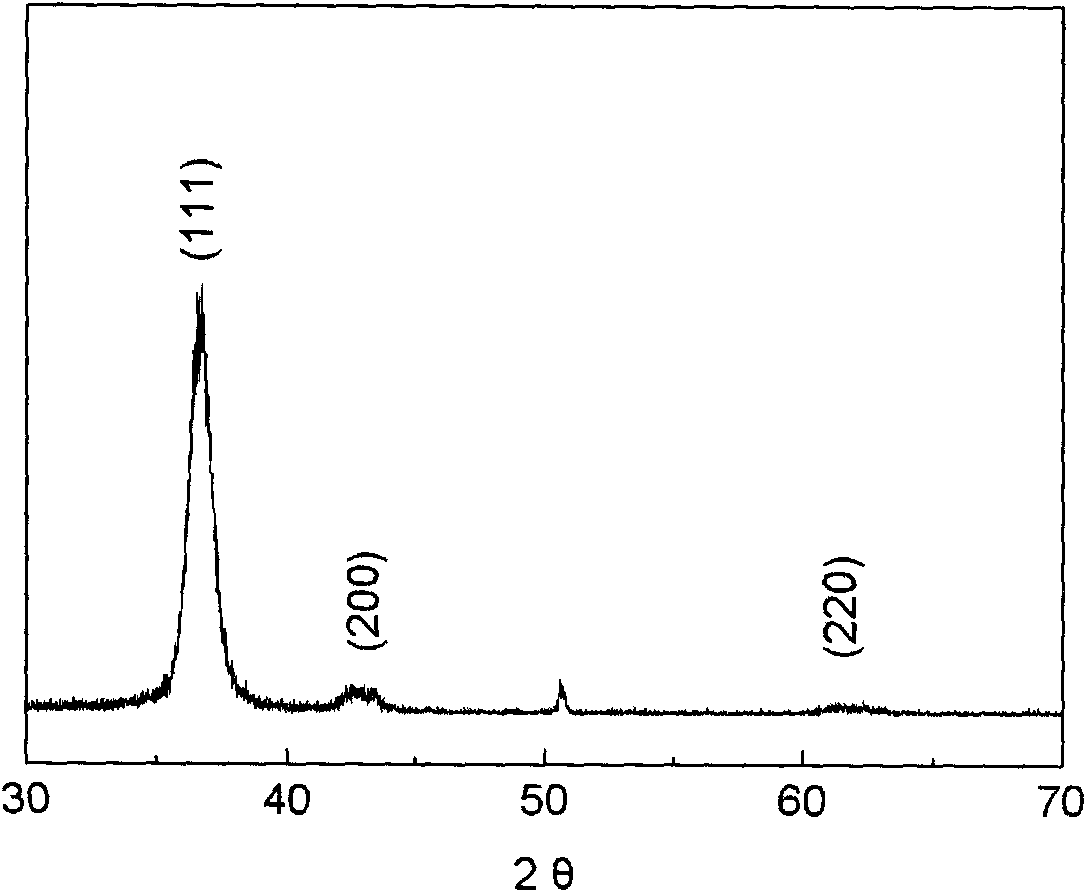

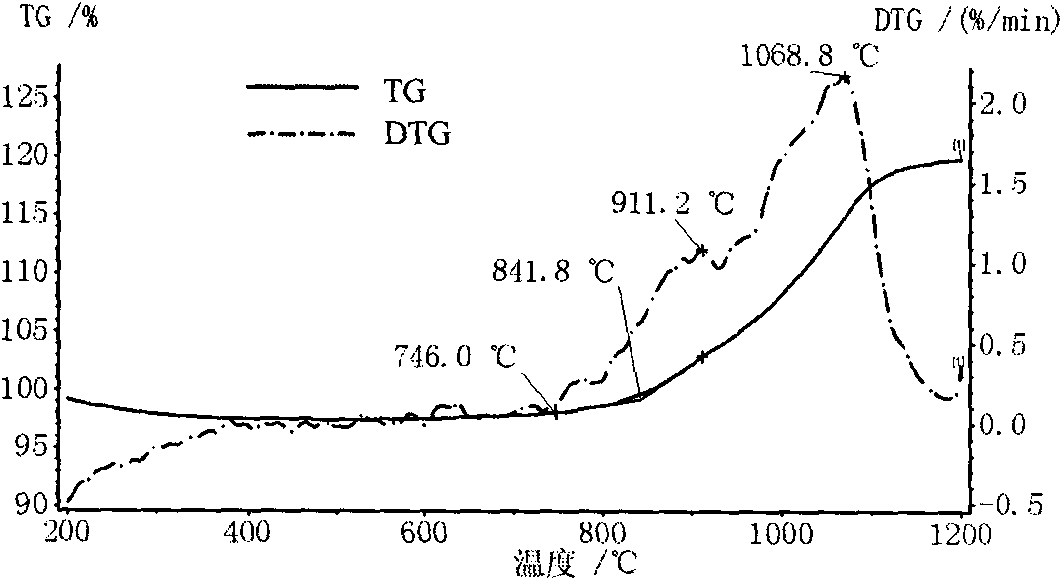

Nano composite titanium-chromium-silicon nitride cutter coat and preparation method thereof

ActiveCN101831616AAdaptability to processabilityAdapt to the conditionsVacuum evaporation coatingSputtering coatingNitrogenAlloy

The invention discloses a nano composite titanium-chromium-silicon nitride cutter coat and a preparation method thereof. The cutter matrix is WC / Co hard alloy, and the coat is a titanium-chromium-silicon nitride coat containing a transition layer, wherein the coat contains titanium, chromium, silicon and nitrogen elements; and the size of crystalline grains is 5 to 15 nanometers, the thickness of the coat is 1 to 4 microns, the micro hardness of the coat is 26GPa, and the high-temperature stability reaches over 1,068 DEG C. A nano composite titanium-chromium-silicon nitride coat cutter is a coat cutter prepared in a mode of combining ion plating and sputter-plating, and is suitable for cutting and processing high-hardness steel materials at a high speed.

Owner:GUANGDONG UNIV OF TECH

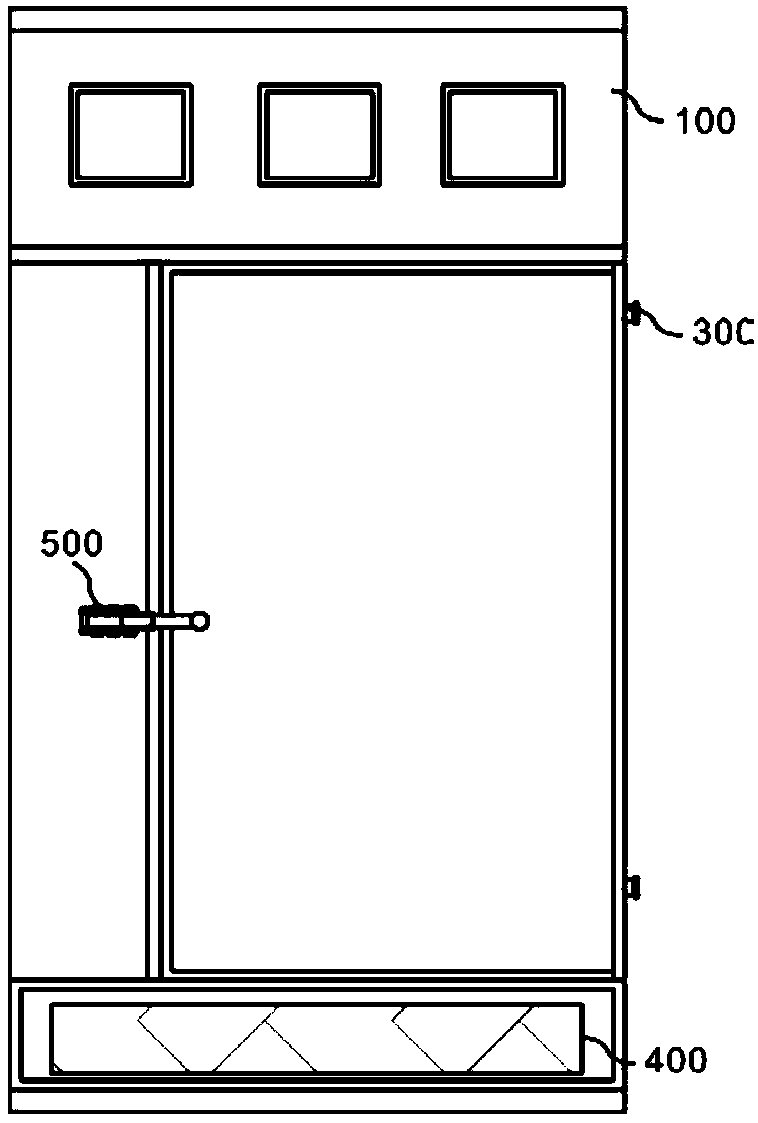

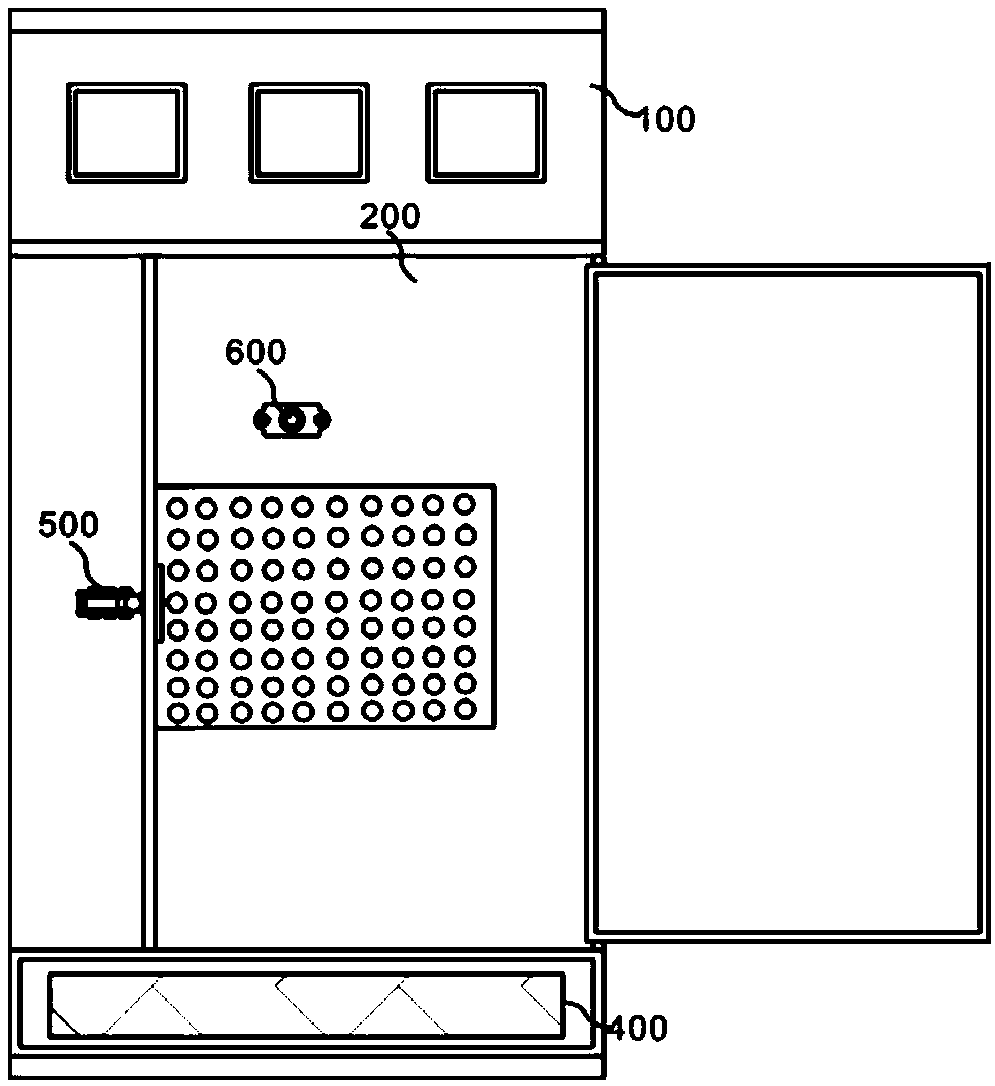

Intelligent switch cabinet with extremely high performance

InactiveCN107611795AHigh degree of intelligencePrevent accidental injuryBuilding locksSubstation/switching arrangement cooling/ventilationCombined useEngineering

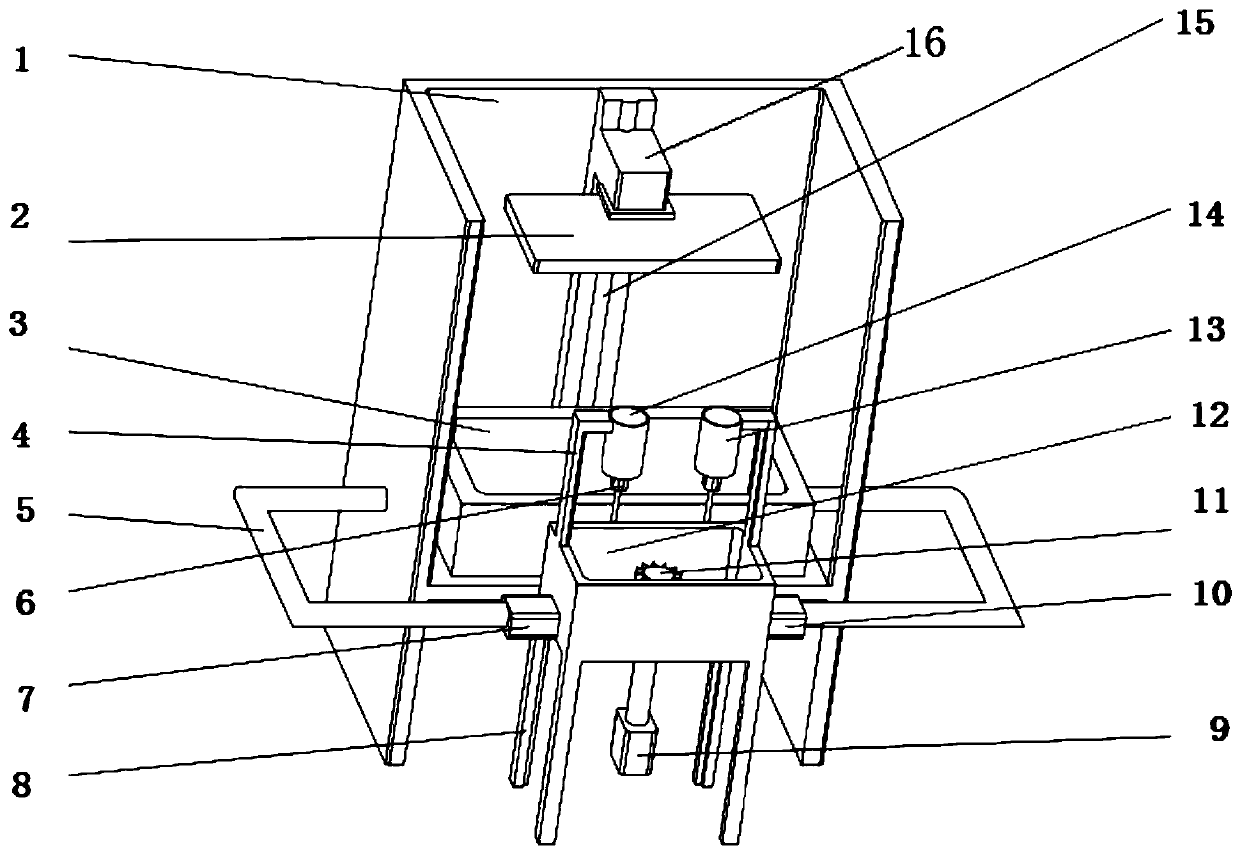

The invention discloses an intelligent switch cabinet with extremely high performance. The intelligent switch cabinet comprises a bearing assembly, a spacing assembly, a heat dissipation assembly, a capturing assembly and a self-locking assembly, wherein a first containing space and a second containing space are formed in the bearing assembly, and the first containing space is formed in one sideof the second containing space; the spaacing assembly is arranged at the boundary of the first containing space and the second containing space; the heat dissipation assembly is arranged in the secondcontaining space formed in the bearing assembly; the capturing assembly is arranged at the bottom in the first containing space of the bearing assembly; the self-locking assembly is arranged on the bearing assembly. The heat dissipation assembly arranged in a cabinet body can cool the swtich cabinet through air cooling or liquid cooling, and the heat dissipation effect is obvious; meanwhile, theheat dissipation assembly can be combined with an induction piece in use, heat dissipation can be carried out according to the temperature in the switch cabinet, the intelligent degree of the switch cabinet is further improved, and resources are also saved.

Owner:BAOHENG NEW ELECTRIC GRP

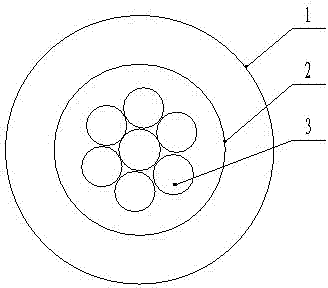

Heat-resisting anti-flaming insulated cable

InactiveCN103489521AImprove flame retardant performanceImprove heat resistanceInsulated cablesInsulated conductorsElectrical conductorHeat resistance

The invention discloses a heat-resisting anti-flaming insulated cable which comprises an insulating layer, a shielding layer and a conductor. The insulating layer is made of anti-flaming polyvinyl chloride insulating materials and comprises, by weight, 40-50% of polyvinyl chloride, 10-20% of plasticizer, 35-45% of fire retardant, 0.5-1.5% of antioxygen and 0.4-1% of stabilizer. The shielding layer is made of crosslinked polyethylene, and the conductor is made of oxygen-free copper with the copper content lager than 99.95%. In this way, the heat-resisting anti-flaming insulated cable has good fire resistance and heat resistance, and meets the demand of markets for high performance of insulated cables.

Owner:KUNSHAN FENFA INSULATING MATERIALS

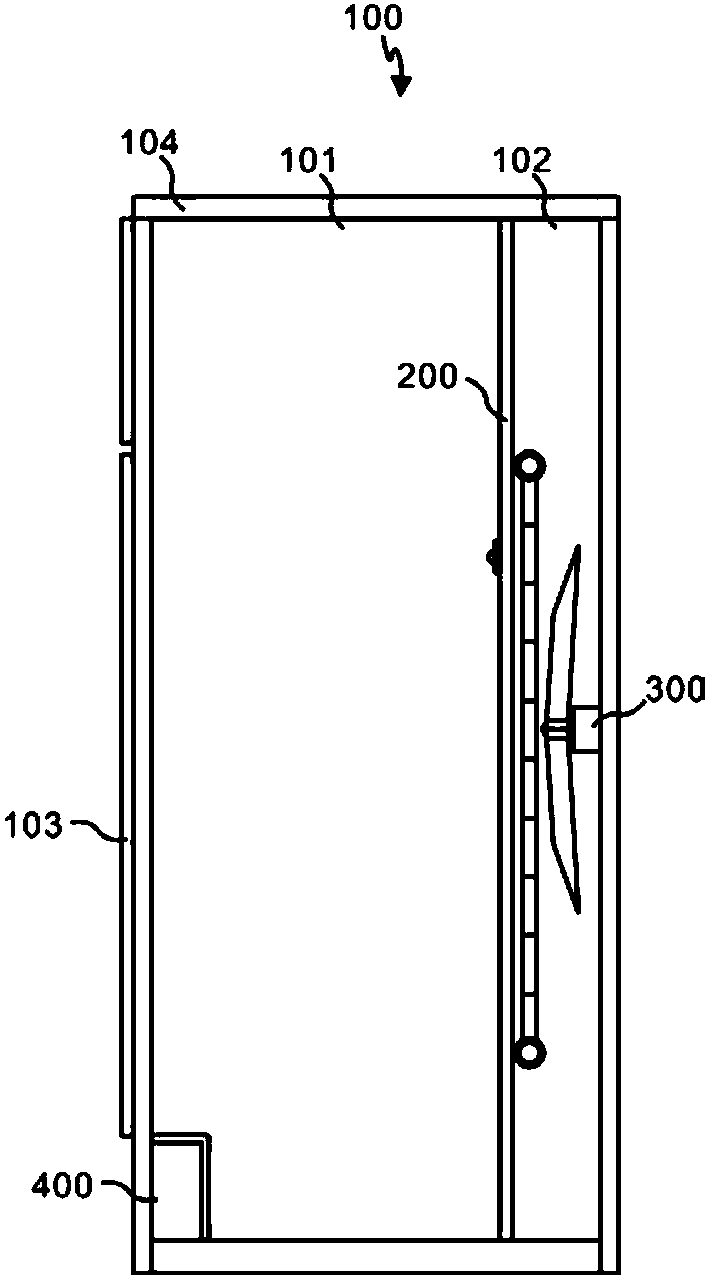

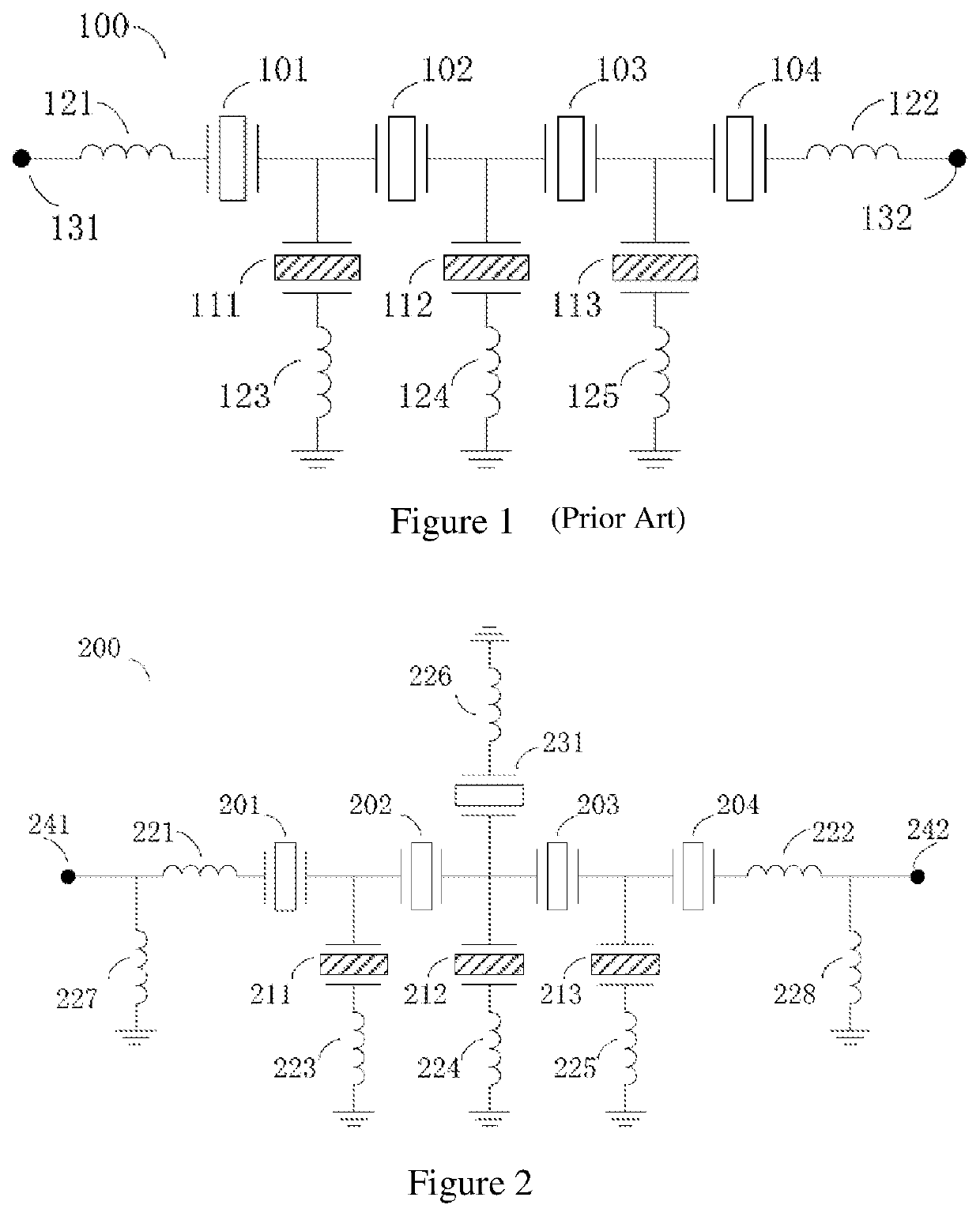

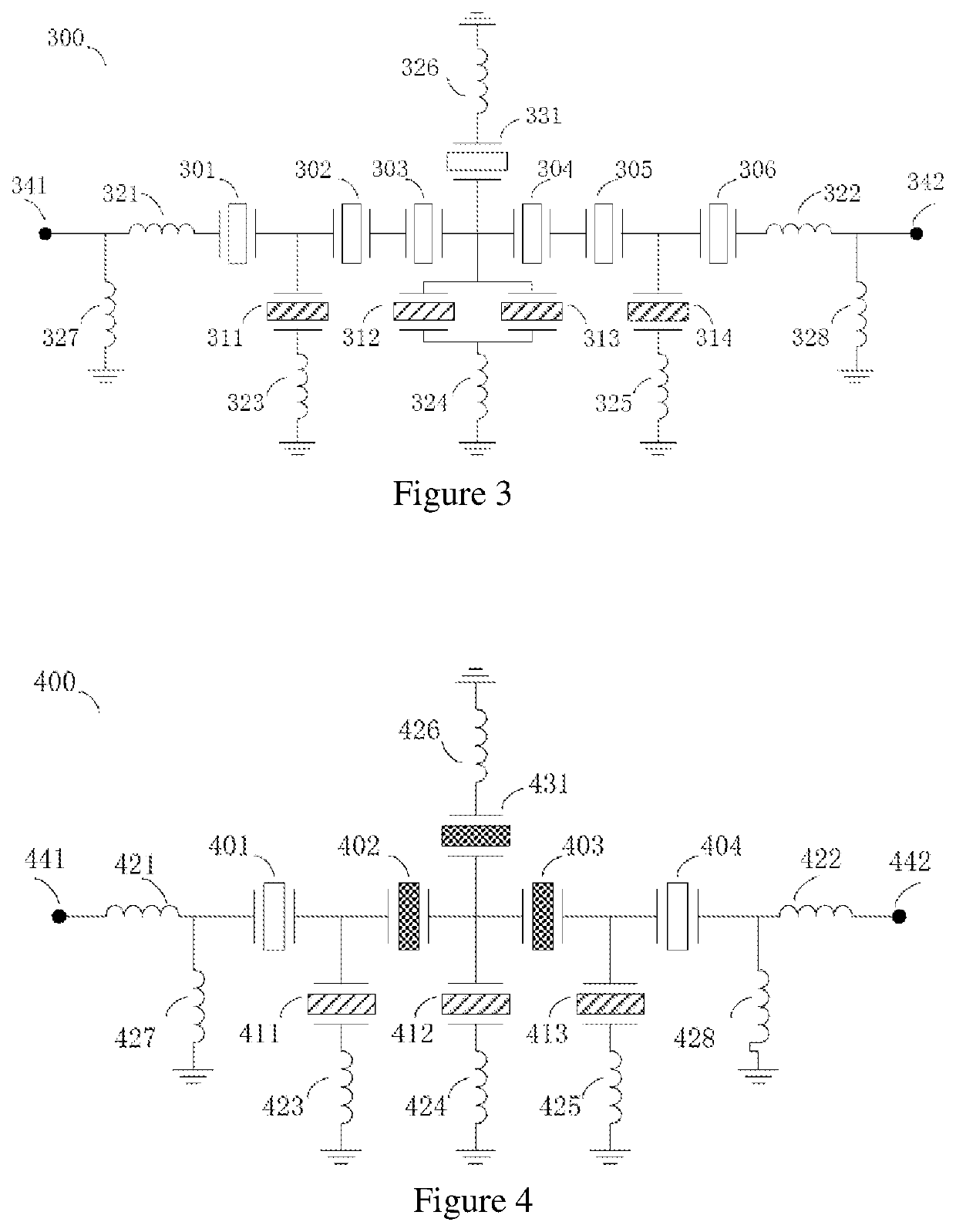

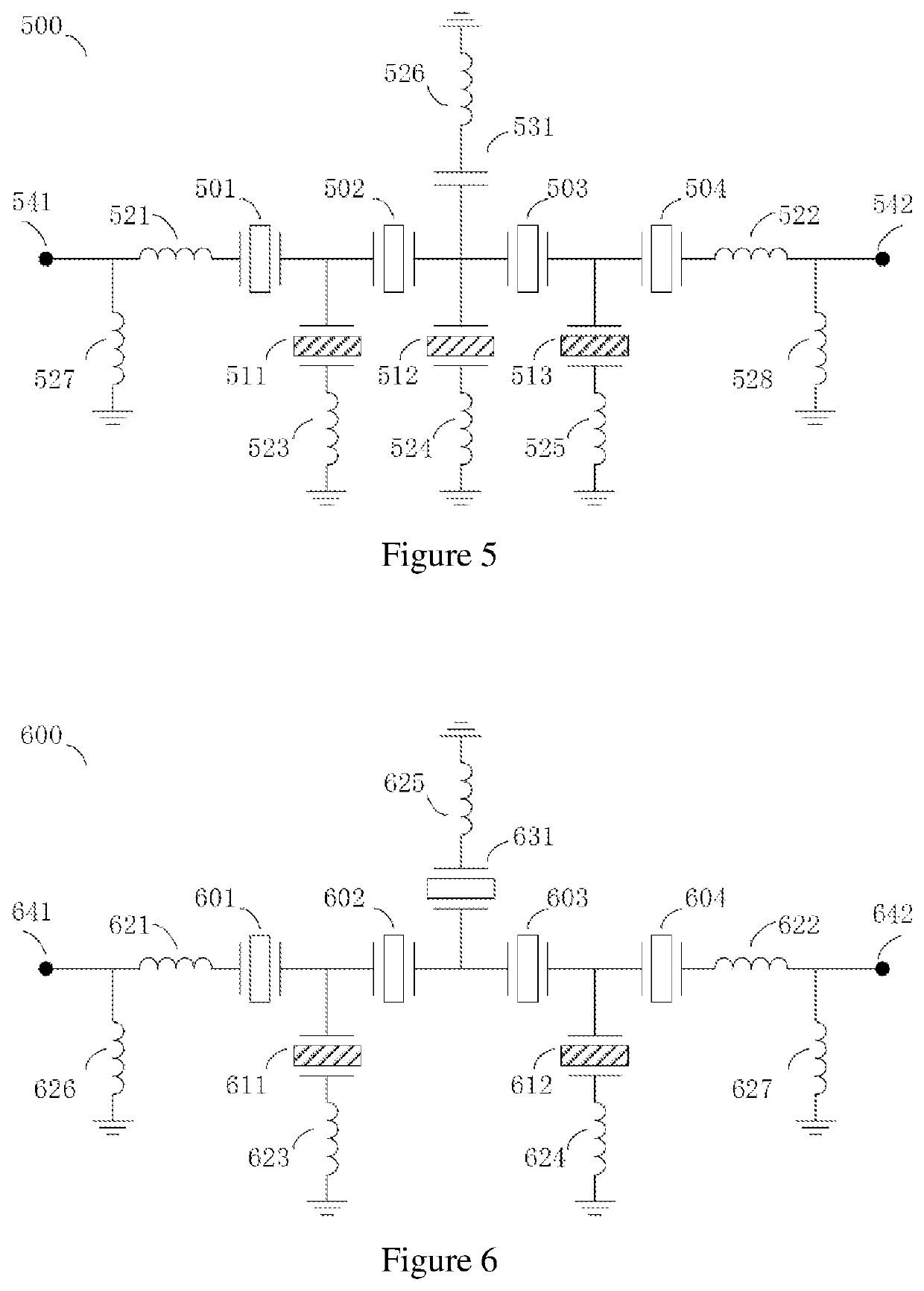

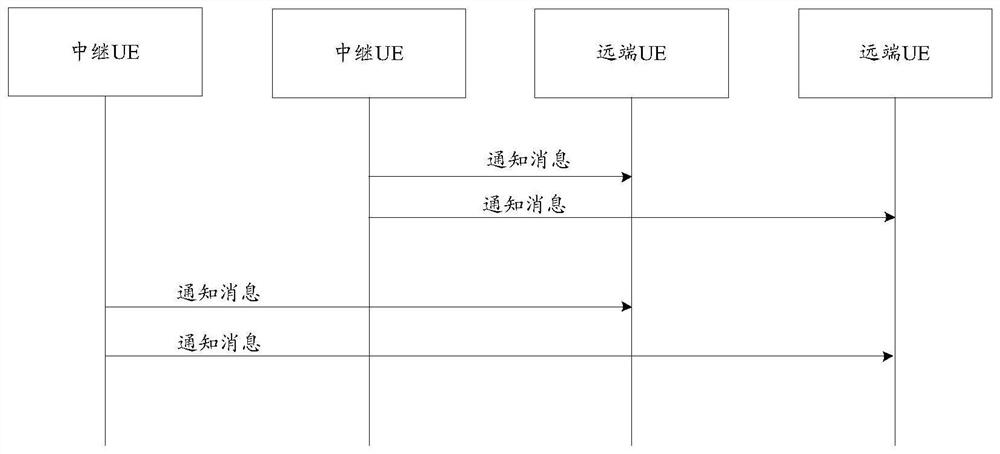

Wideband piezoelectric filter with ladder-structure

ActiveUS20190341910A1Good out-of-band suppressionGood performance requirementsImpedence networksOut of band rejectionInductor

A wideband piezoelectric filter with a ladder-type is provided, which is composed of a plurality of first resonators connected in series, a plurality of second resonators connected in parallel, an impedance matching device disposed near the input terminal or the output terminal of the filter, and at least one special parallel ground path led out from serial nodes. The special parallel ground path at least comprises one inductor having a larger inductance value, and a resonator having the same resonant frequency as a serial branch or a capacitor, wherein the larger inductor is connected to the resonator or capacitor in series in the parallel path. The ladder filter according to the invention can have a bandwidth which is more than twice that of the conventional ladder filter, and also has excellent out-of-band rejection characteristics.

Owner:ROFS MICROSYST TIANJIN CO LTD

Nano composite titanium silicon nitride tool coating and preparation method thereof

InactiveCN101851738AImprove mechanical propertiesImprove high temperature stabilityVacuum evaporation coatingSputtering coatingWear resistantMechanical wear

The invention discloses a nano composite titanium silicon nitride tool coating. The coating formulation is as follows: 30-68at.% of titanium, 2-20at.% of Si and 30-50at.% of nitrogen. The titanium silicon nitride coating prepared by the formulation comprises the components the sum of which is 100%. The tool manufactured by the invention has significantly improved mechanical wear resistant performance and abrasion wear resistant performance, can meet the requirement on better performance of alloy tools of modern industry, and has huge market potential and practical use value.

Owner:DONGGUAN HANJING NANO MATERIAL

Preparation method of prefabricated framework type integrally-formed composite square cabin

The invention provides a preparation method of a prefabricated framework type integrally-formed composite square cabin. The preparation method includes the following steps that a square cabin framework system is prepared from prefabricated carbon fiber parts, prepreg is adopted as a square cabin skin material, rigid foams are adopted as a filling material, and under the assistance of a combined die, in a vacuum bag pressing manner, the composite square cabin is prepared at a certain temperature through integral forming. The continuity of inner skin and outer skin of the square cabin is good, the defects that a traditional metal framework type square cabin structure and a large plate type square cabin structure are complex in procedure, and the mechanical performance of combined joints is weak are overcome, and the square cabin is better in sealing performance and durability and lighter; and meanwhile, through the rigid foam and other functionalization, the square cabin can be embodiedwith the beneficial effects of being invisible, having shielding electromagnetism, being resistant to impact and the like, and the high-performance requirements in the fields such as military and civilian dual-use commanding systems, communication, medical treatment and logistical support are better met.

Owner:LIANYUNGANG YINGYOU HEDA MOLD MFG

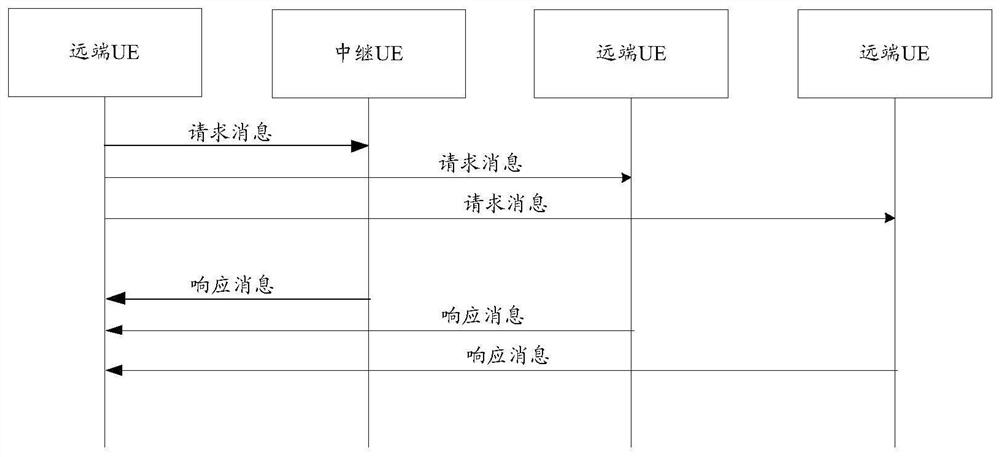

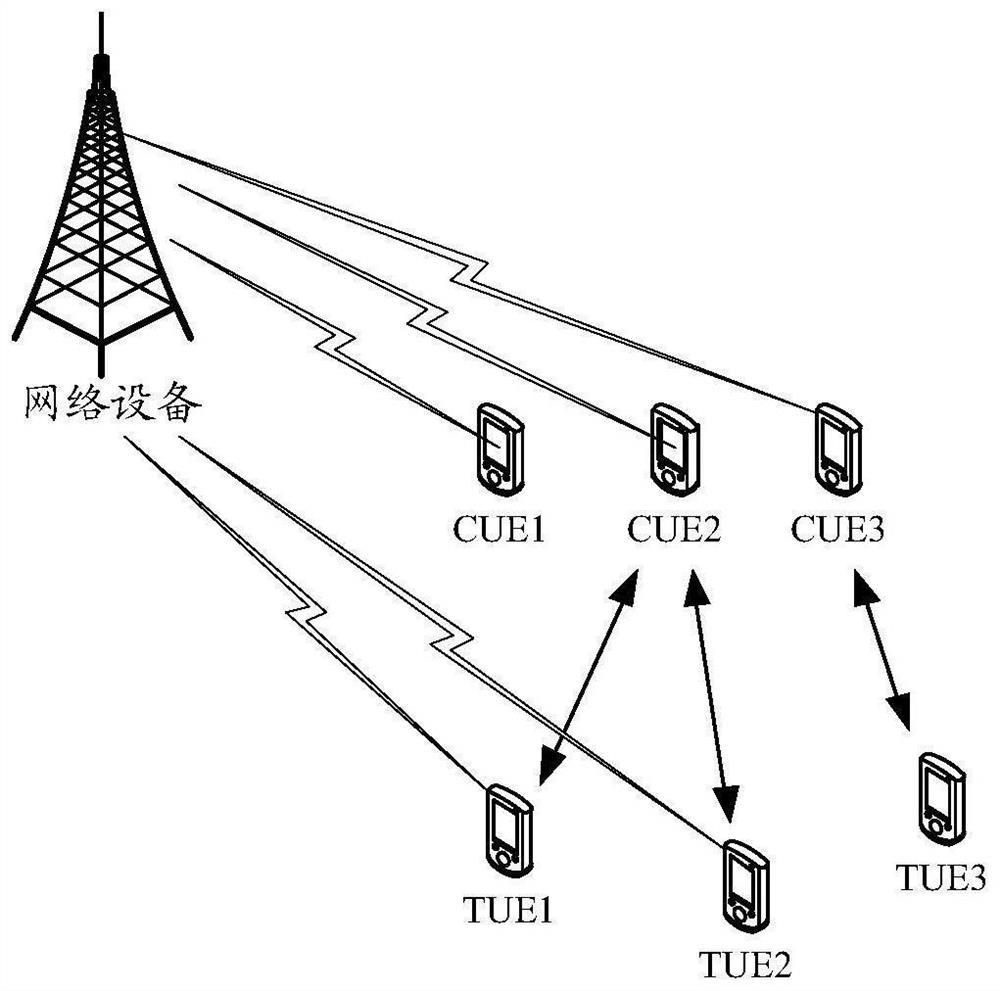

Relay communication method and device

PendingCN113133047AImprove transmission efficiencyImprove transmission reliabilityNetwork traffic/resource managementAssess restrictionCommunications systemSignal quality

The embodiment of the invention discloses a relay communication method and device, relates to the technical field of communication, and aims to solve the problem that the performance of a communication system cannot be met due to the fact that relay UE selected by remote UE forwards data in existing relay communication. The method comprises the steps: a network device obtaining a measurement report including signal quality of a sidelink (SL) between a first user equipment and at least one second user equipment and a wireless network identifier of the at least one second user equipment, the network device determining, according to the measurement report and auxiliary selection information associated with each second user equipment, target relay user equipment of the first user equipment is selected from the at least one second user equipment.

Owner:HUAWEI TECH CO LTD

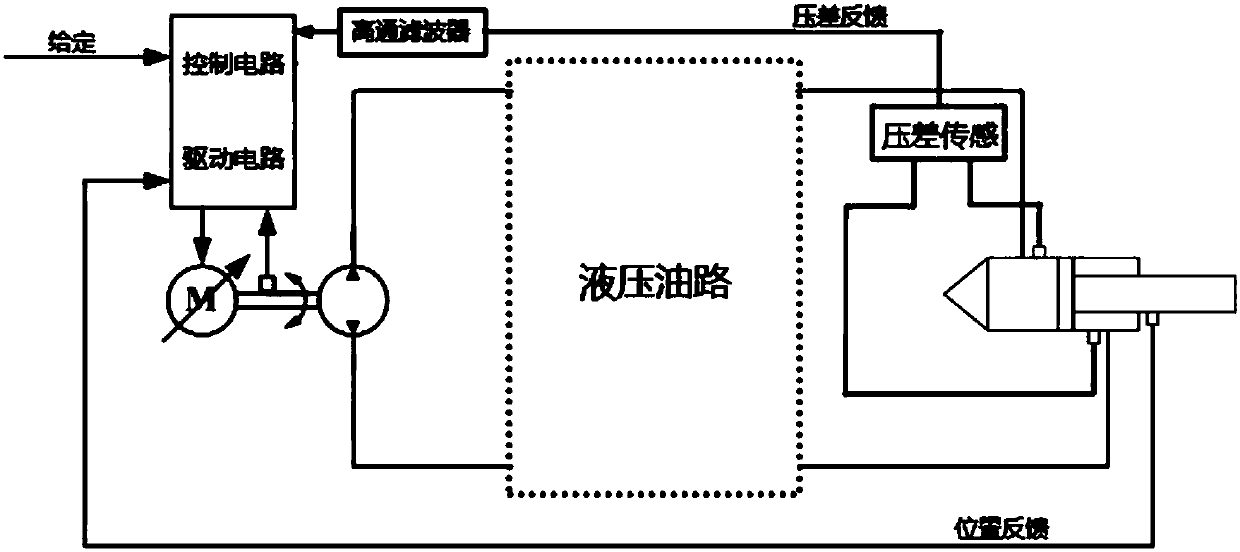

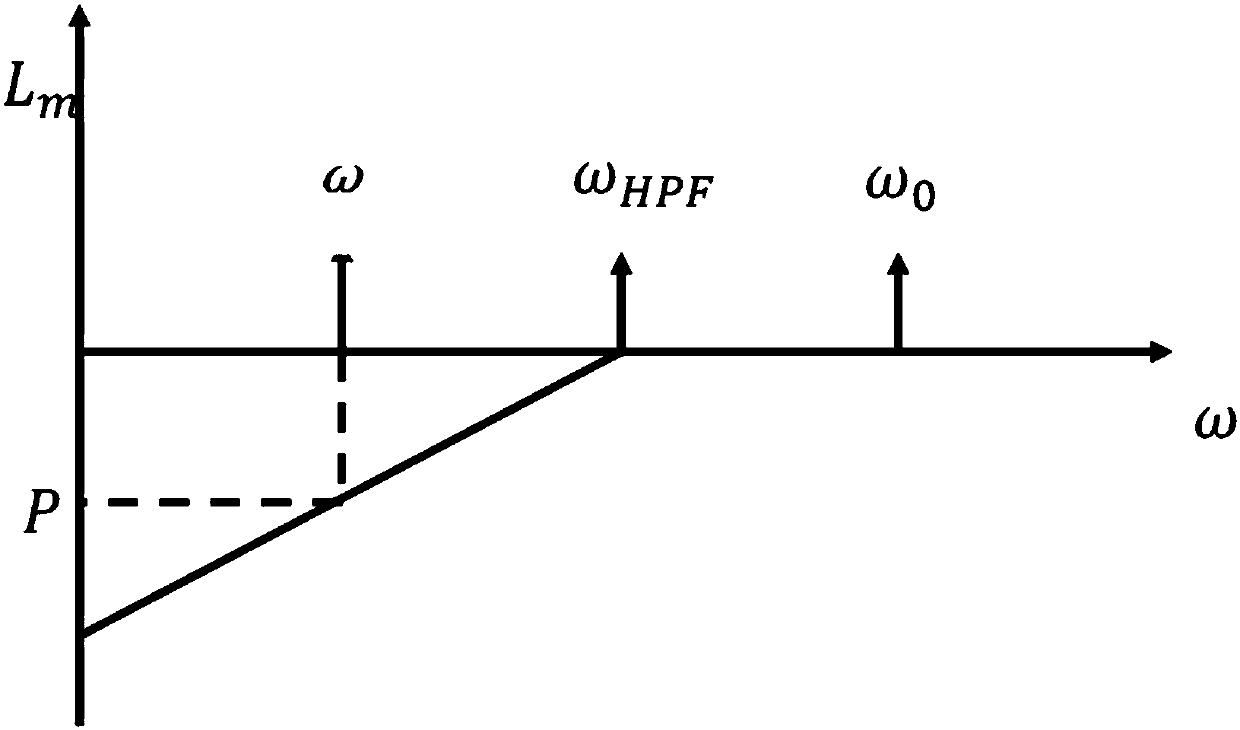

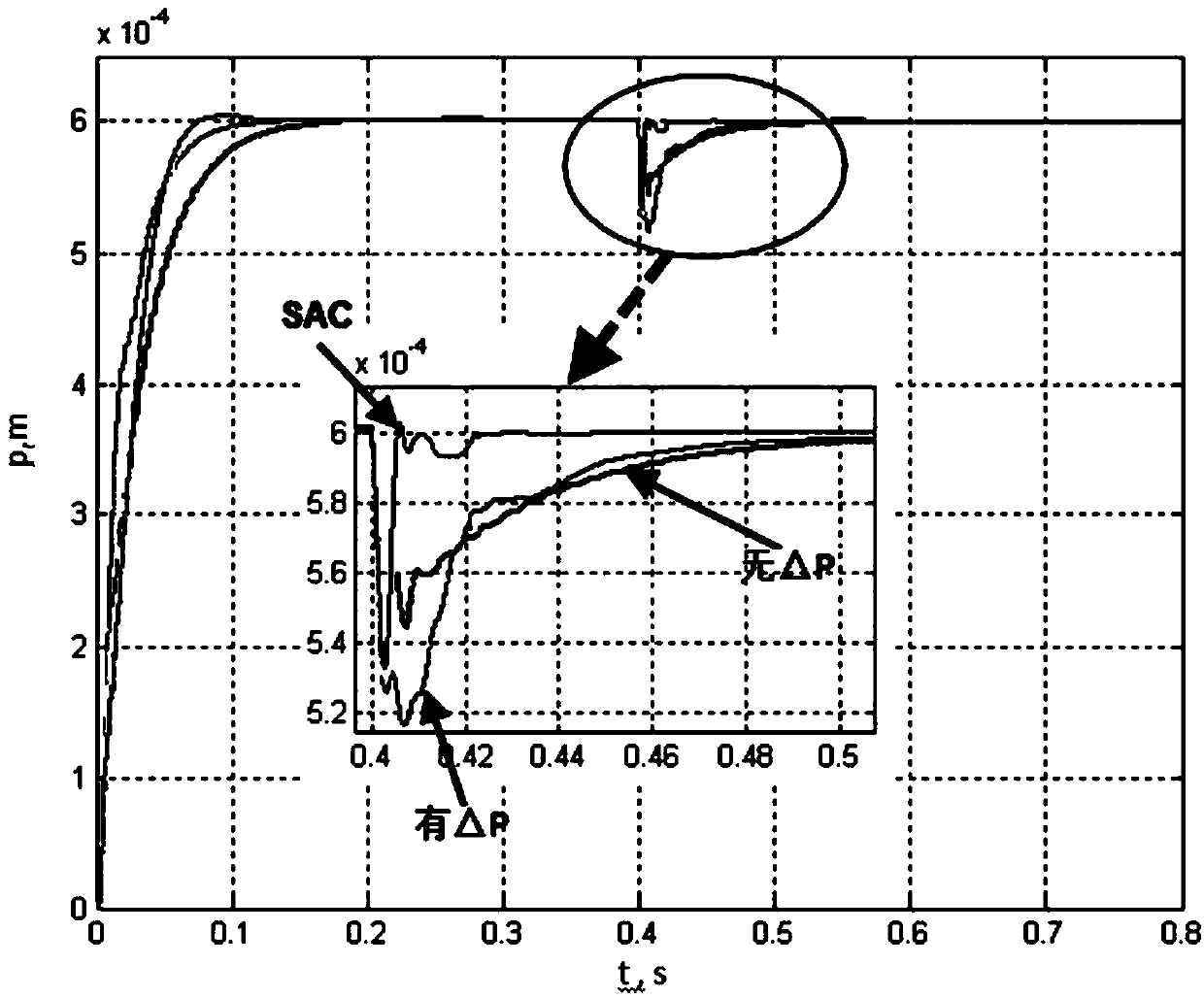

Electro-hydrostatic actuation system double-closed-loop model reference adaptive control method

ActiveCN107315350AGood performance requirementsImprove anti-interference abilityAdaptive controlInner loopSelf adaptive

The invention discloses an electro-hydrostatic actuation system double-closed-loop model reference adaptive control method which includes the following steps: an actuator pressure difference inner loop control system is constructed, and the damping of an electro-hydrostatic actuator is increased; a feedback channel high-pass filter is added to the actuator pressure difference inner loop control system to eliminate the reduction in stiffness of the electro-hydrostatic actuator caused by damping increase; a model reference adaptive control method is adopted to improve the adaptability to the inherent uncertainty of the actuation system; and a signal-based control output compensator is used to make compensation for the equivalent output control of an adaptive regulator to get the equivalent output of the adaptive regulator after compensation, and the response precision and sensitivity of the system under small signal task instructions are improved. Through the method, the dynamic performance of the system can be adjusted flexibly according to the actual working condition, the speed of response under large signal task instructions is increased, and the sensitivity and accuracy of the system under small signal task instructions are improved significantly.

Owner:CHINA UNIV OF MINING & TECH

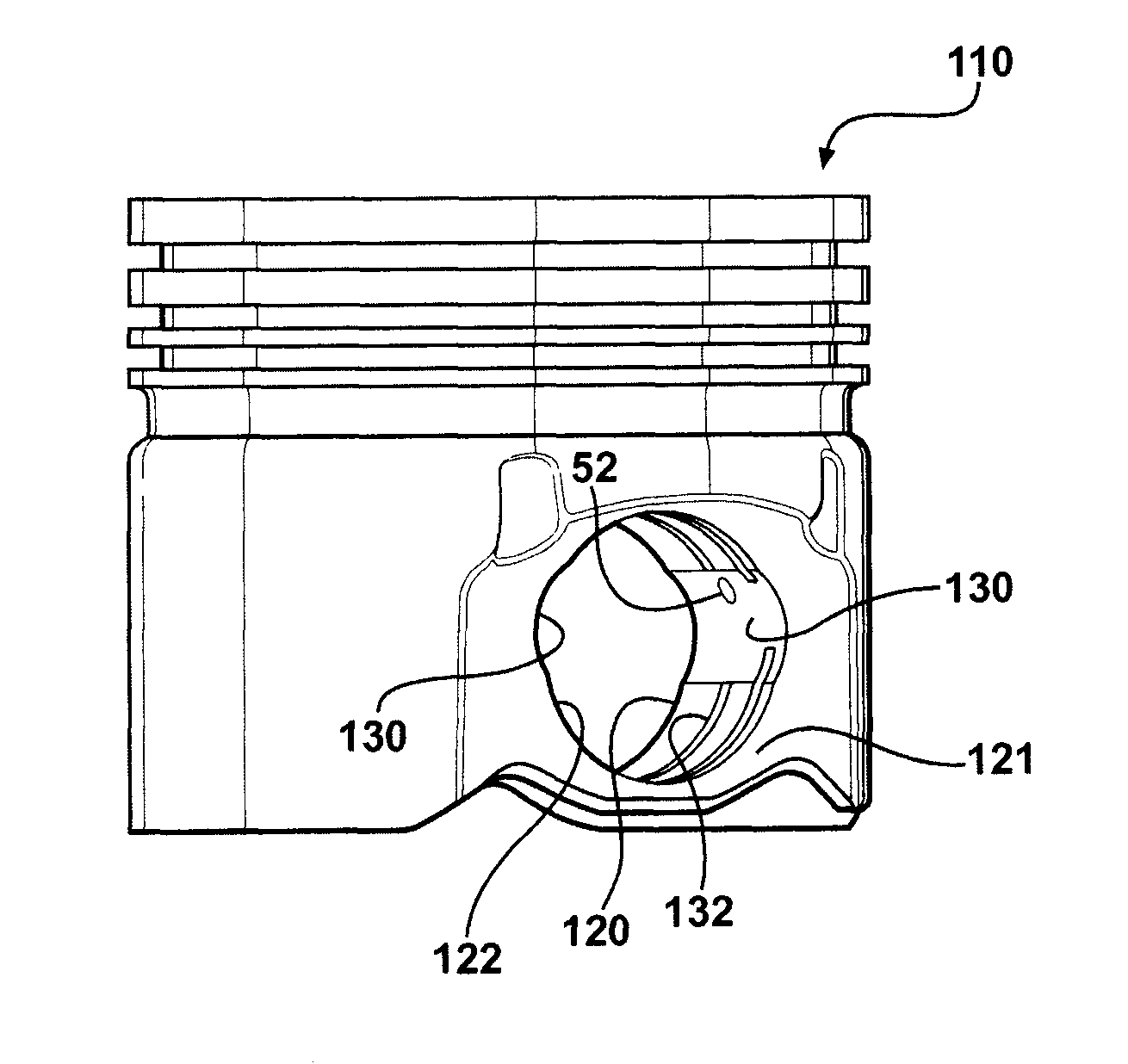

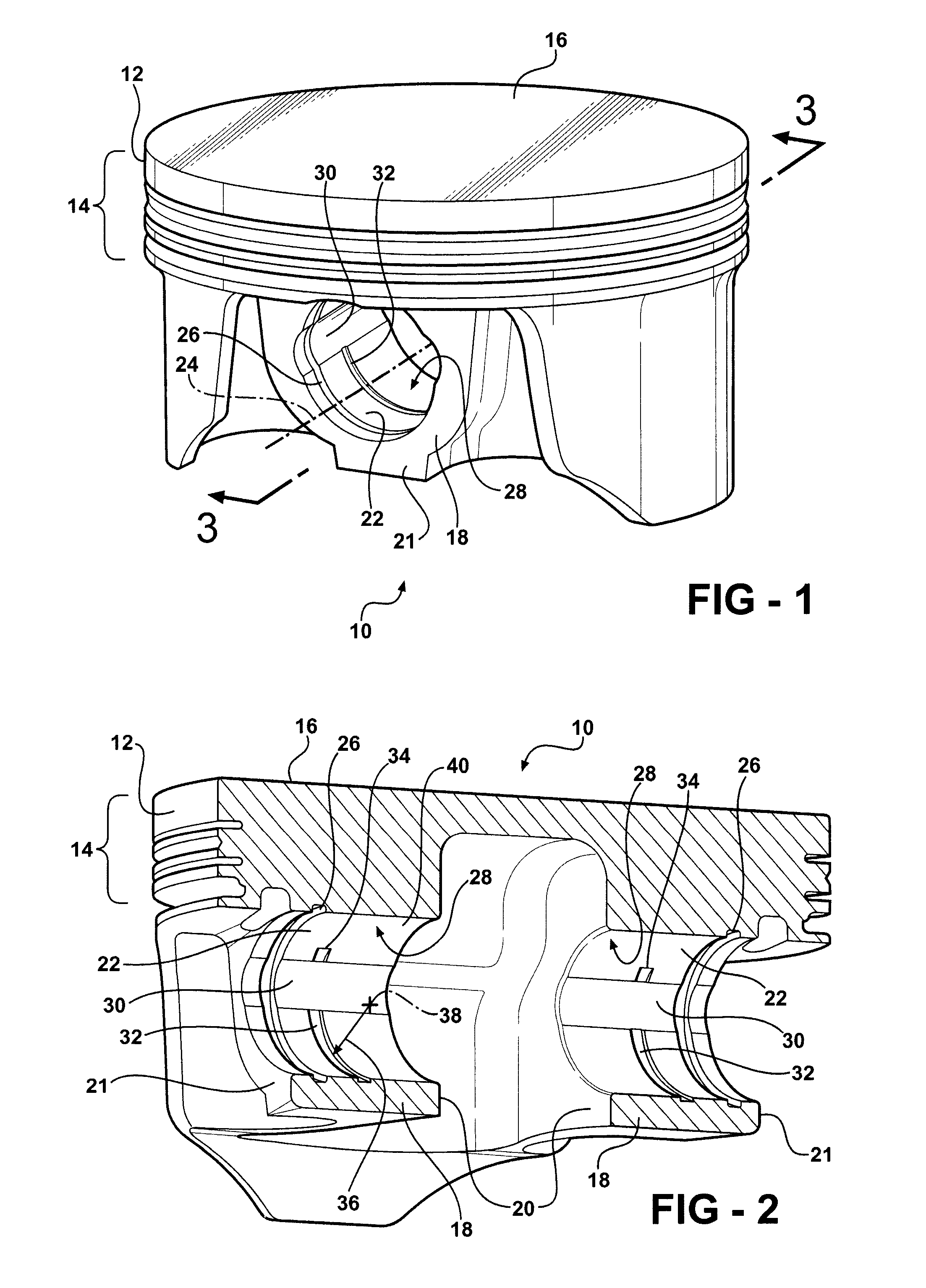

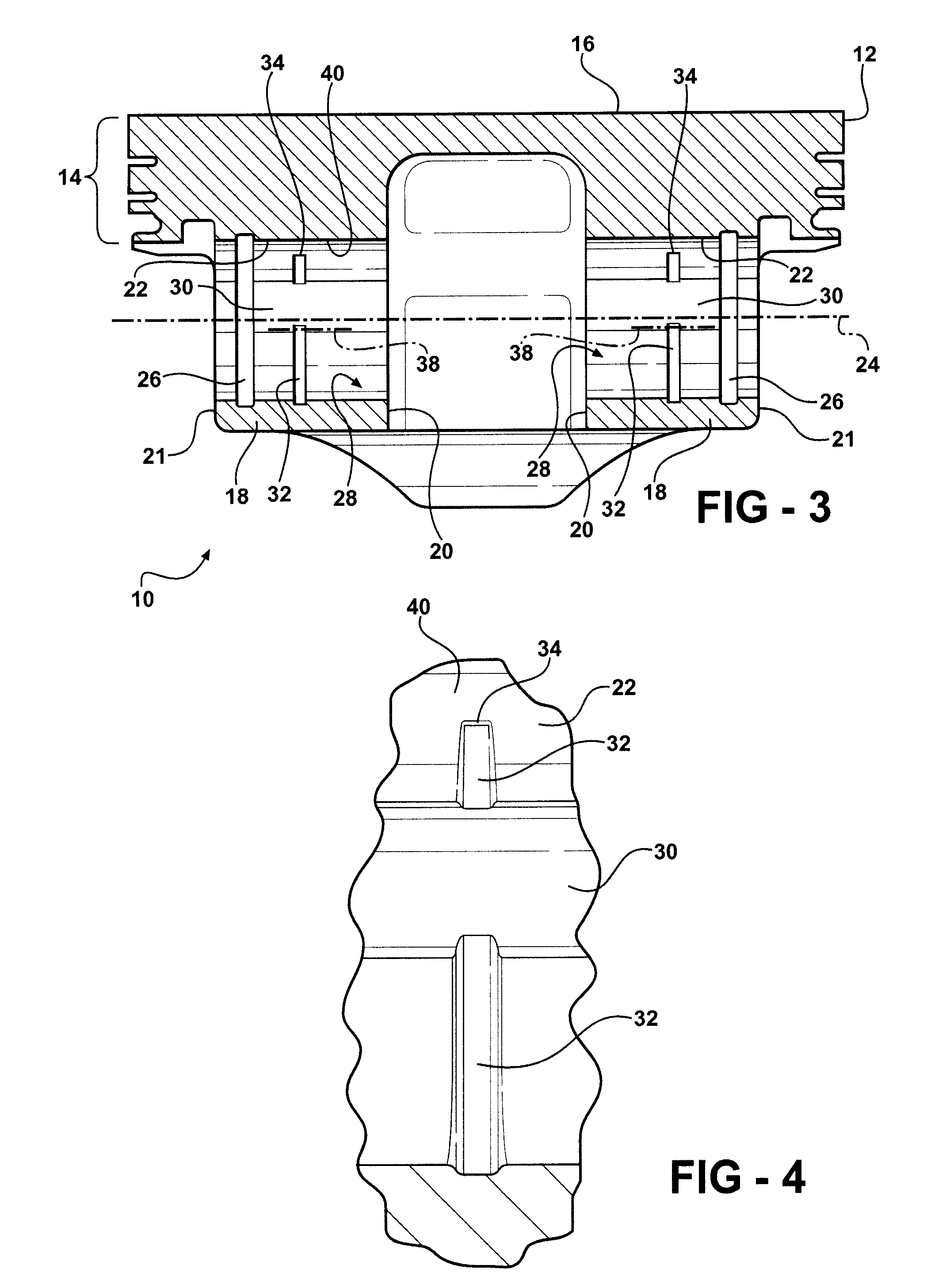

Piston with pin bore lubrication features

ActiveUS7845269B2Maximize capacityReduce manufacturing costPlungersLubricant conduit arrangementsEngineeringBearing surface

A piston has a piston body with a pair of pin bosses having pin bores aligned along a central axis. The pin bores have bearing surfaces, wherein at least one recess extends axially across at least one of the bearing surfaces. A groove extends partially about the bearing surface circumference and is arranged in fluid communication with the recess. The recess and groove provide a lubrication feature to the pin bore, while the bearing surface has an uninterrupted portion for enhanced load carrying capacity.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Method for integrally forming low-cost composite material large cabin

The invention discloses a method for integrally forming a low-cost composite material large cabin, and belongs to the field of composite material large cabins. The method comprises the steps of manufacturing a large metal die, sealing the die, forming the outer skin, vacuumizing and curing, forming a cap-shaped reinforcing rib, vacuumizing and curing again, forming the inner skin, vacuumizing andcuring for the third time, demolding and finishing. The method overcomes the defects that a mode of splicing into a whole after sectional forming or a traditional metal framework type square cabin structure is complex in process and weak in mechanical property at the splicing positions, and an integrally formed cabin body is better in air tightness and durability and lighter in weight; and meanwhile, by using a rigid polyurethane foam as a filling material, the integrally formed cabin body is better in thermal insulation performance and higher in functionality, so that the higher performance requirements of a military and civil dual-use large cabin are better met.

Owner:长春长光宇航复合材料有限公司

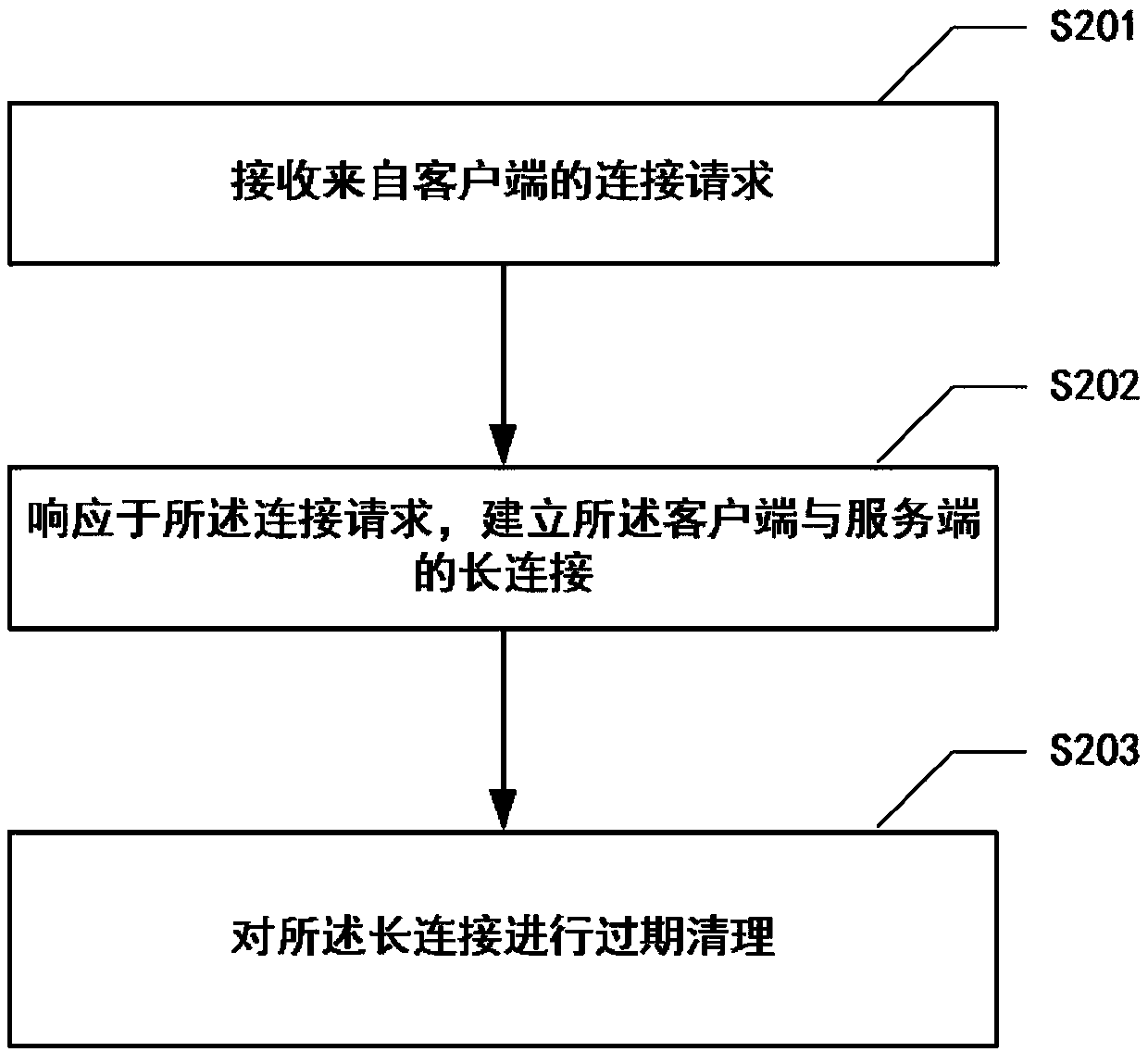

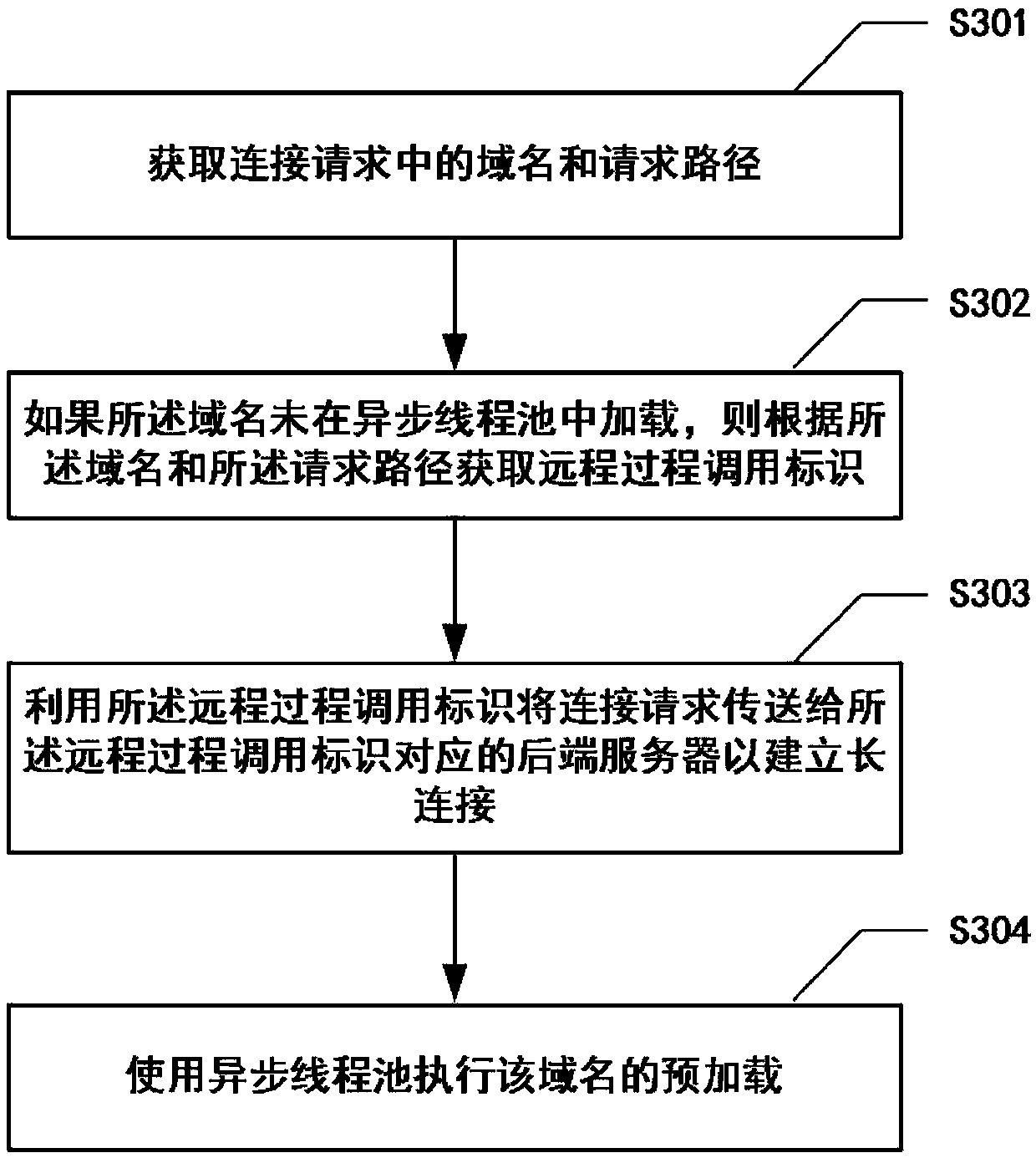

Communication method and device, gateway, calculation equipment and medium

PendingCN110855726ASolve problems that cannot meet performance needsImprove performanceTransmissionTelecommunicationsEngineering

The invention provides a communication method applied to a gateway. The method comprises the following steps: receiving a connection request from a client; in response to the connection request, establishing a long connection between the client and a server; and performing expired cleaning on the long connection. The invention also provides a communication device, a gateway, an internet, a calculation device and a computer readable medium.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

High-performance and low-cost high strength titanium alloy

The invention discloses a high-performance and low-cost high strength titanium alloy. The titanium alloy is prepared from the following components in percentage by mass: 5.1 to 6.25 percent of Al, 2.5to 2.8 percent of V, 0.4 to 0.5 percent of Mo, 0.8 to 1.0 percent of Zr, less than or equal to 0.5 percent of Fe, less than or equal to 0.35 percent of O and the balance of Ti and other inevitable impurities. The titanium alloy is prepared by mixing and smelting a recovered TC4 alloy and a recovered TA15 alloy. The titanium alloy disclosed by the invention is prepared by directly mixing the recovered TC4 alloy and the recovered TA15 alloy proportionally and smelting. Through reasonable matched use of the two recovered materials, the raw material cost is lowered on the premise of ensuring thatthe titanium alloy has excellent mechanical property, so that the preparation cost of the titanium alloy is reduced greatly, and the demand for high performance of titanium alloy structural parts invarious industrial fields is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

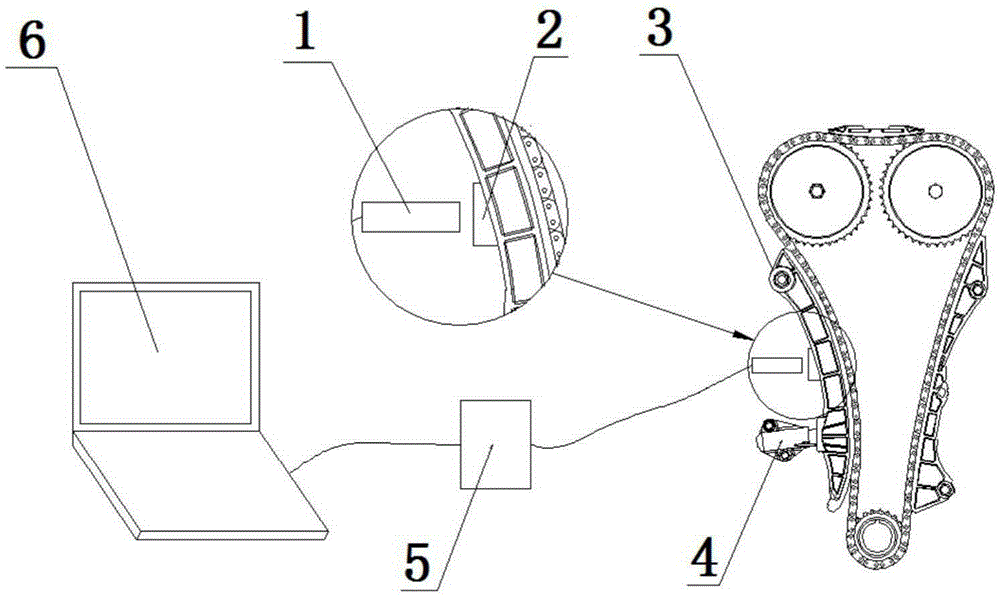

Engine chain system tightener plunger displacement measurement device and measurement method

InactiveCN106802124AGood performance requirementsHelps to check working performanceUsing electrical meansElectricityElectrical conductor

The invention provides an engine chain system tightener plunger displacement measurement device and a measurement method. The measurement device comprises a data acquisition processor, a computer, a tightening rail, a tightening rail support for supporting the tightening rail, a metal conductor arranged on the tightening rail support, and a displacement sensor fixed on the side cover of the engine, wherein the tightener plunger ejects against the tightening rail; and the data acquisition processor is respectively electrically connected with the displacement sensor and the computer. The tightener plunger displacement fluctuation condition of the engine timing chain in different working conditions can be detected in real time, the working condition of the measured chain system is further known, the working performance of the engine tightener is checked, and guarantee is provided for meeting high-performance requirements of the engine.

Owner:QINGDAO CHOHO IND CO LTD

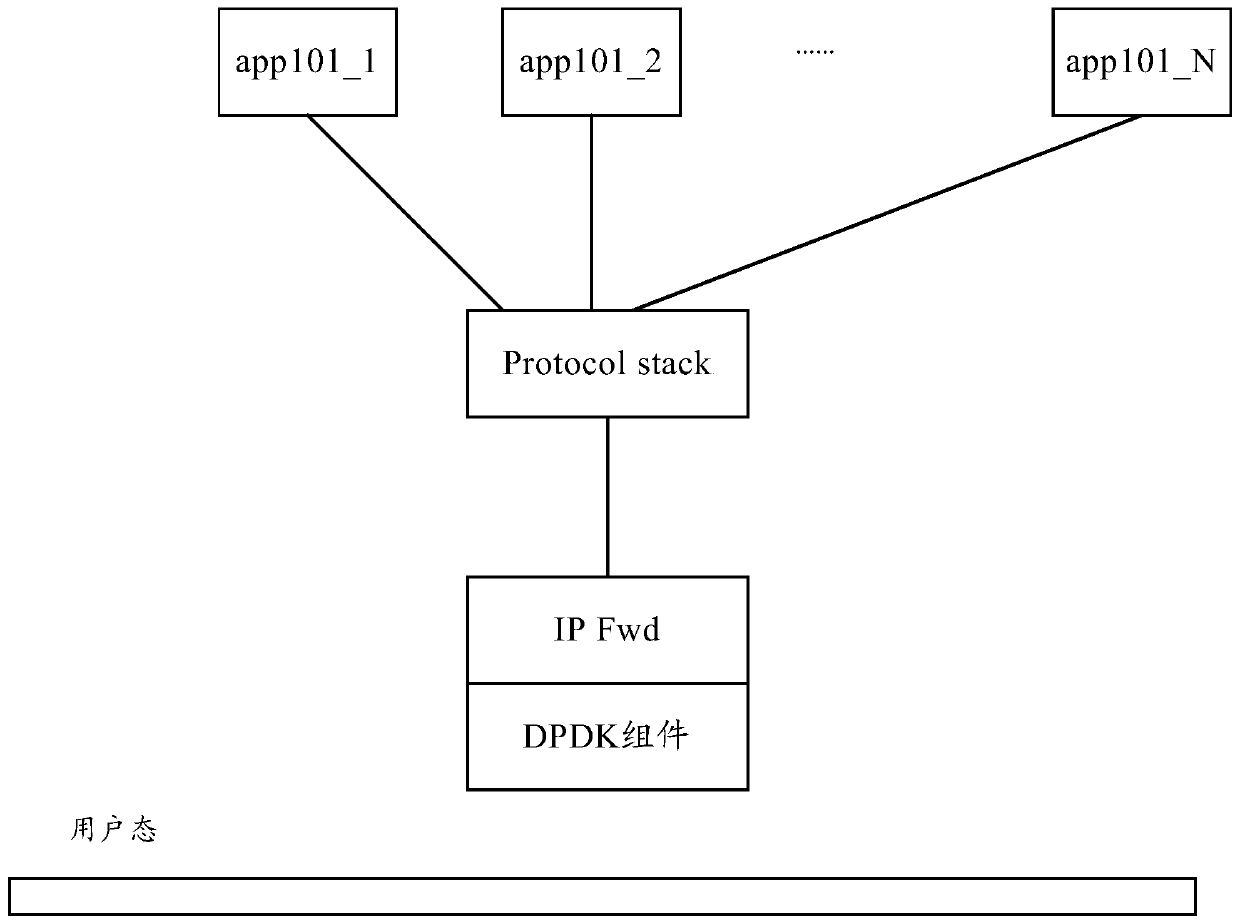

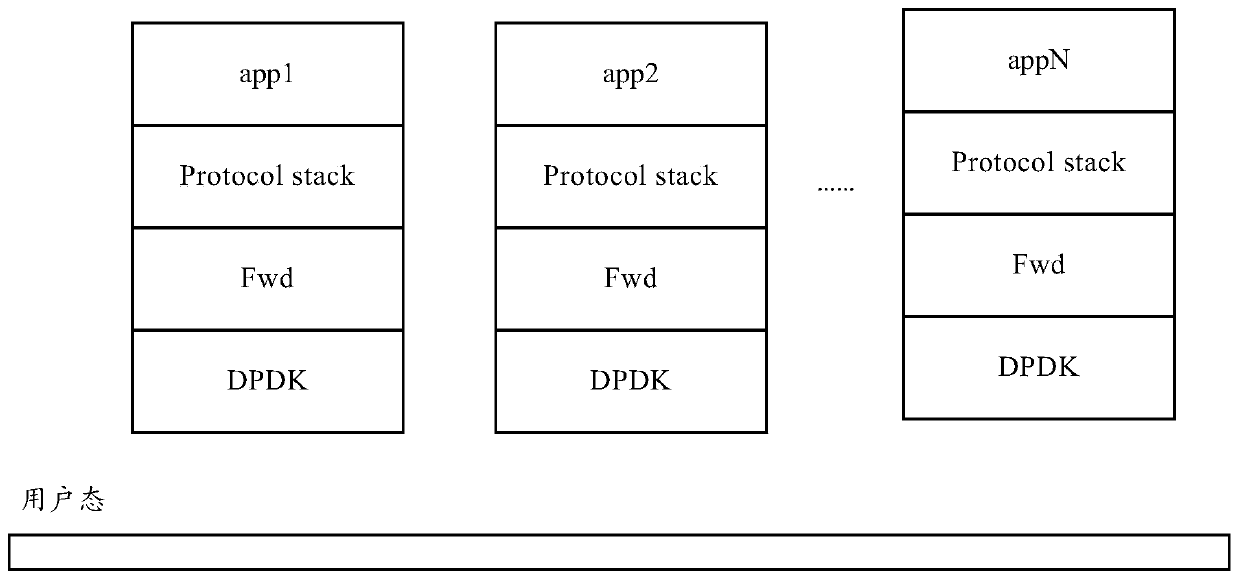

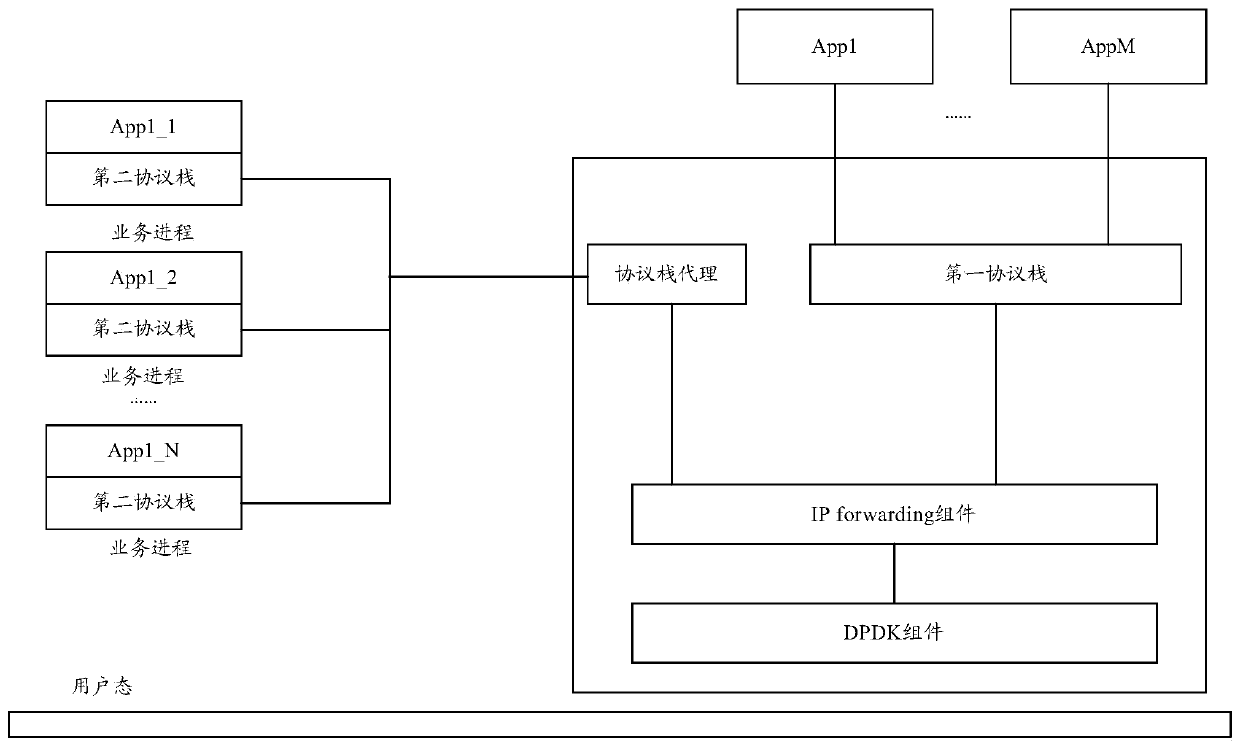

Network operating system and message forwarding method

The invention provides a network operating system and a message forwarding method. In the application, the network operating system fuses the sharing model and the exclusive model to realize coexistence of the protocol stack (called the sharing protocol stack and the first protocol stack) in the sharing model and the protocol stack (called the exclusive protocol stack and the second protocol stack) in the exclusive model. Due to coexistence of the shared protocol stack and the exclusive protocol stack, a network operating system can support various services and can meet the requirement for high performance.

Owner:NEW H3C TECH CO LTD

Hard coating cutting tool with gradient composite structure and preparation method of hard coating cutting tool

PendingCN114592166AImprove wear resistanceOvercome stressVacuum evaporation coatingSputtering coatingInterface layerUltimate tensile strength

The invention discloses a hard coating cutter containing a gradient composite structure and a preparation method thereof.The cutter comprises a cutter base body and a hard coating, the hard coating comprises a gradient composite structure multi-layer coating and a functional layer TiB2 arranged on the surface of the multi-layer coating, the multi-layer coating comprises Ti1-xAlxN layers and TiBN layers, and the Ti1-xAlxN layers and the TiBN layers are alternately deposited; the thickness of the Ti < 1-x > Al < x > N layer is reduced along with increasing of the distance relative to the cutter base body, and the thickness of the TiBN layer is increased along with increasing of the distance relative to the cutter base body. The preparation method comprises the steps that the interface layer and the supporting layer are deposited on the pretreated cutter base body, then the Ti < 1-x > Al < x > N layers and the TiBN layers are alternately deposited, and then the functional layer is deposited. The hard coating cutter has the advantages of low stress, high strength and toughness, high film-substrate bonding strength, excellent wear resistance, high heat resistance and the like, the application range of the TiB2-based coating can be expanded, and the preparation method is simple in process and low in production cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

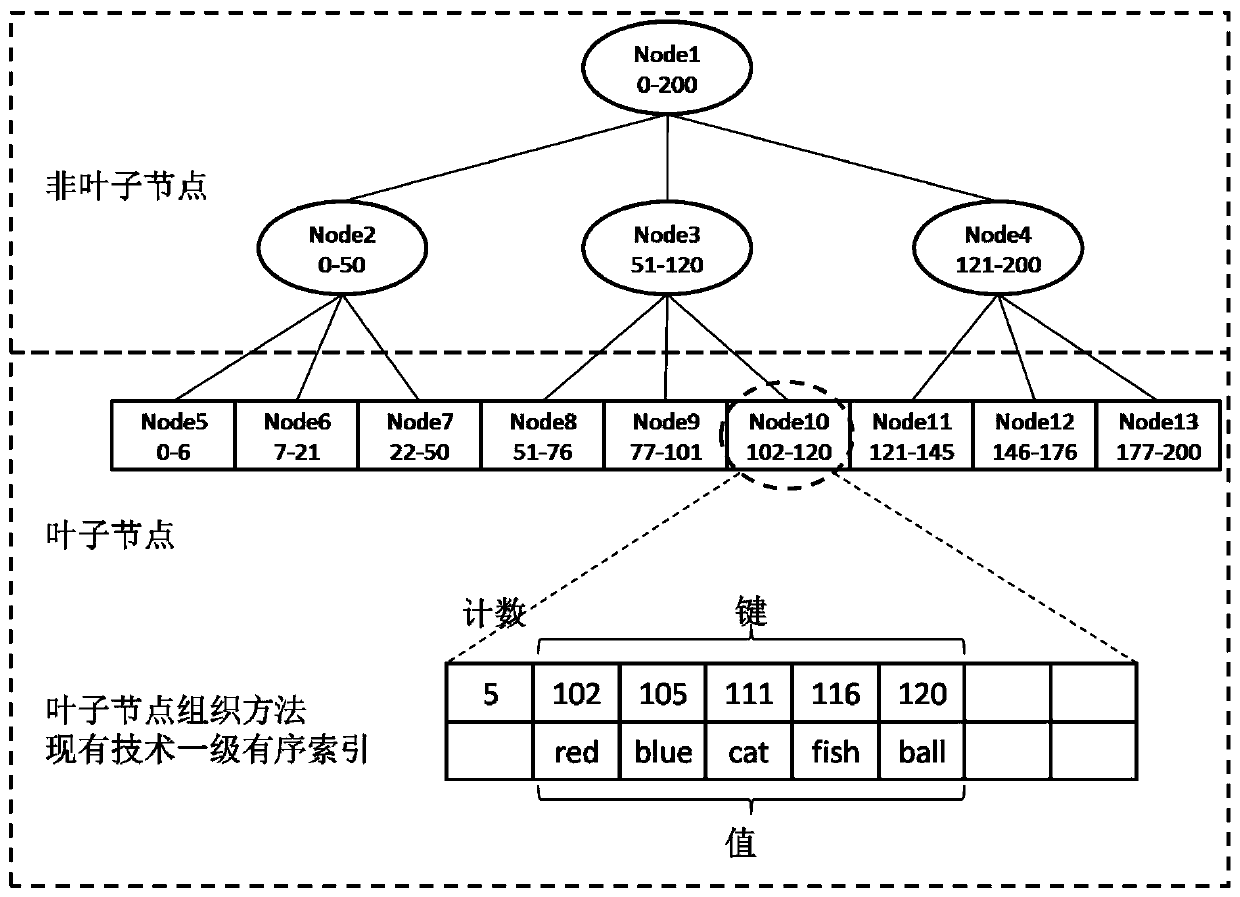

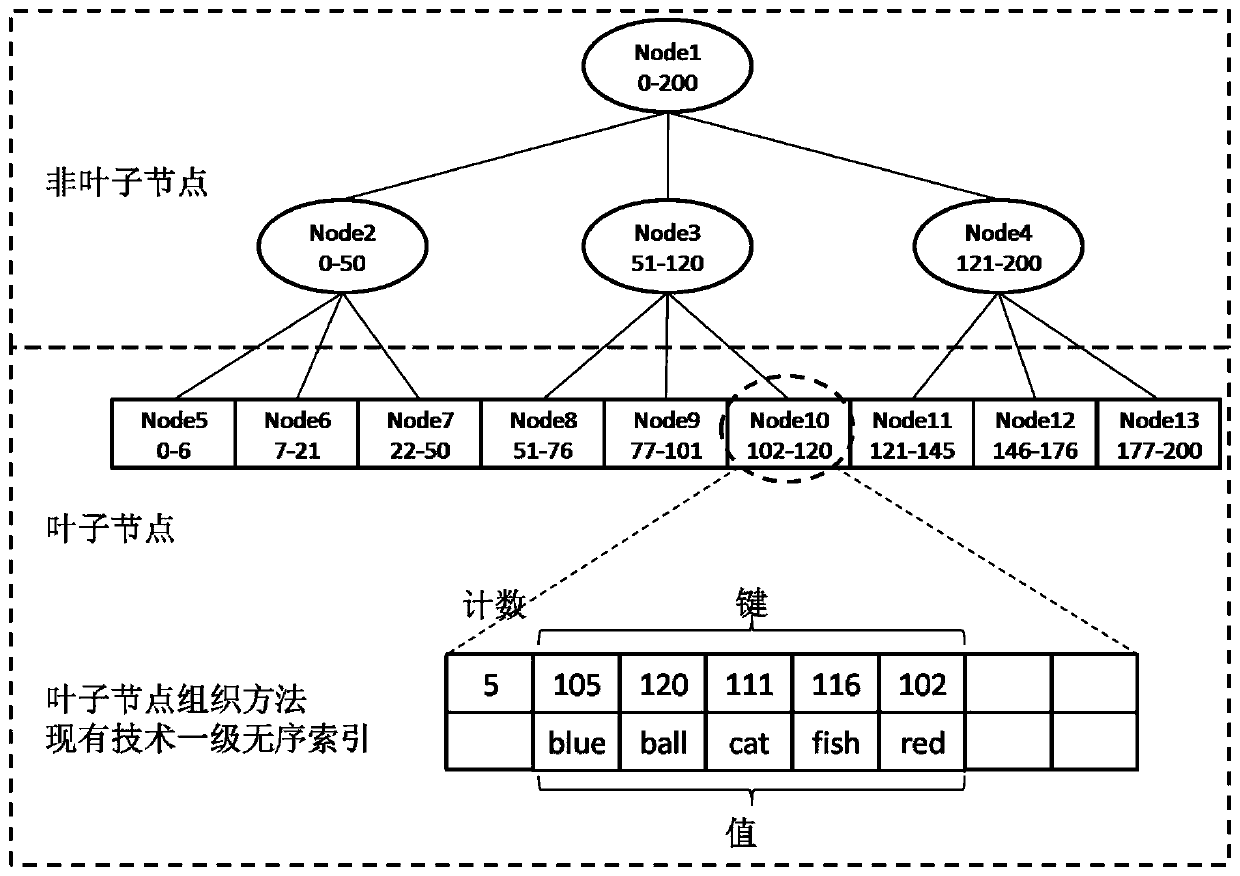

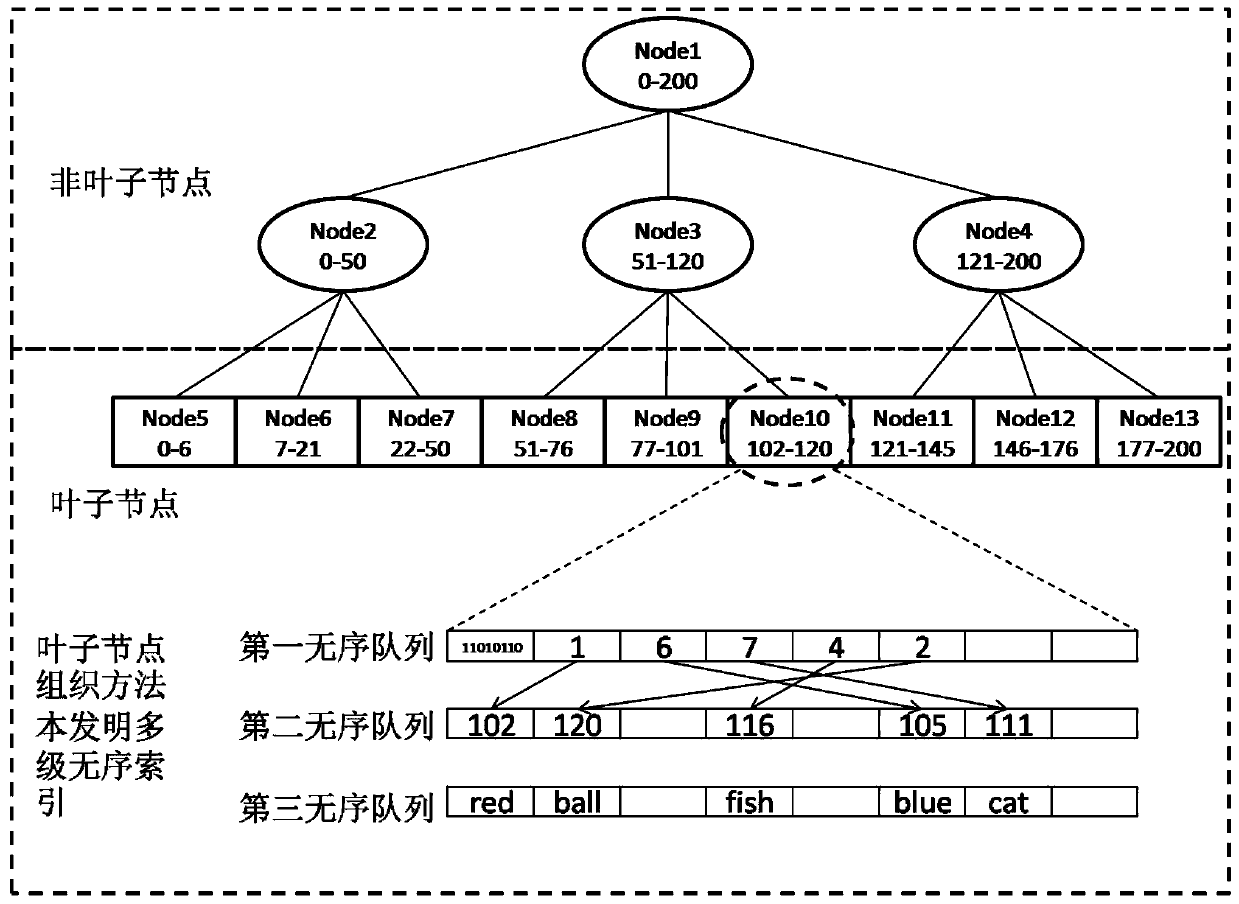

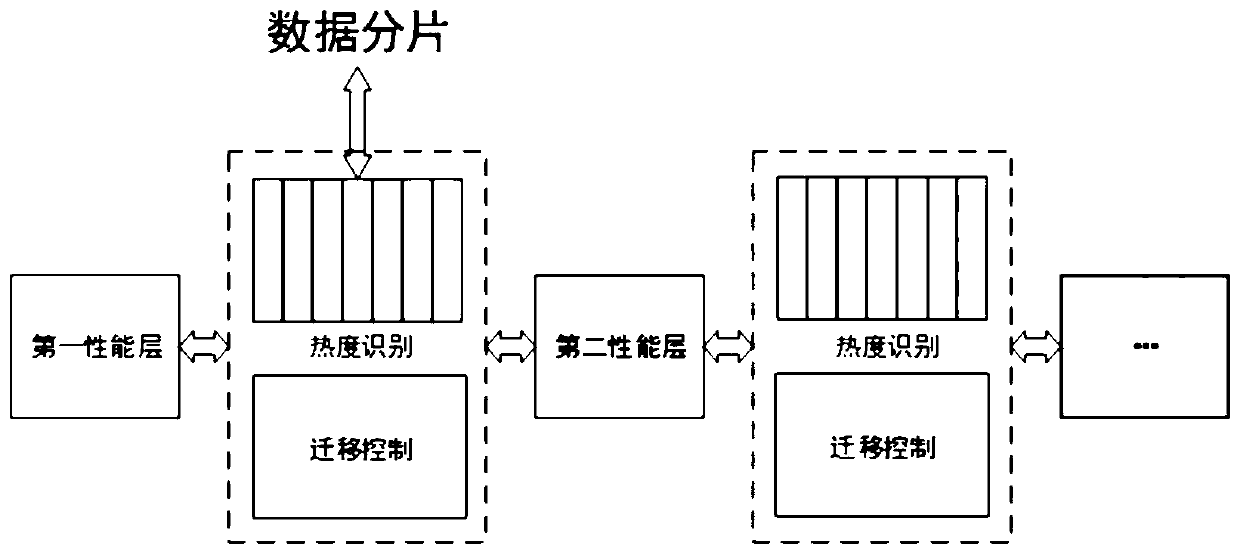

A multi-level disordered indexing method and system

ActiveCN109933584AQuick indexIndex multi-level unorderedDatabase indexingSequential methodTheoretical computer science

The invention discloses a rapid multi-level disordered indexing method and a rapid multi-level disordered indexing system. In a key value system constructed based on a storage device, all keys are organized into a B + tree, the keys are quickly indexed by adopting a sequential method or an improved dichotomy, and specific keys and value addresses thereof in leaf nodes are searched, so that orderedindexing is realized through multi-level disordered leaf nodes. The system comprises a first storage device and a second storage device, which are used for storing the non-leaf nodes and the leaf nodes of B + trees respectively; The same or different storage devices can be adopted respectively; Or mutually isolated storage areas are divided in the same storage device. According to the invention,through multistage disordered indexing, ordered indexing is ingeniously realized, so that the method has the advantages of ordered indexing and disordered indexing, and meanwhile, the requirements andeffects of reading, writing and deleting operations on high performance are met.

Owner:PEKING UNIV +1

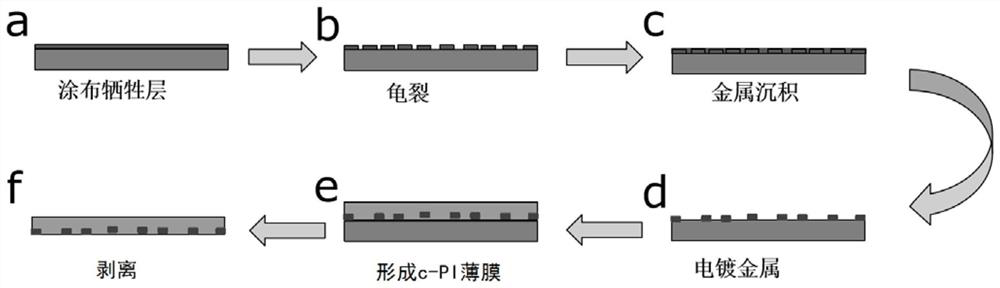

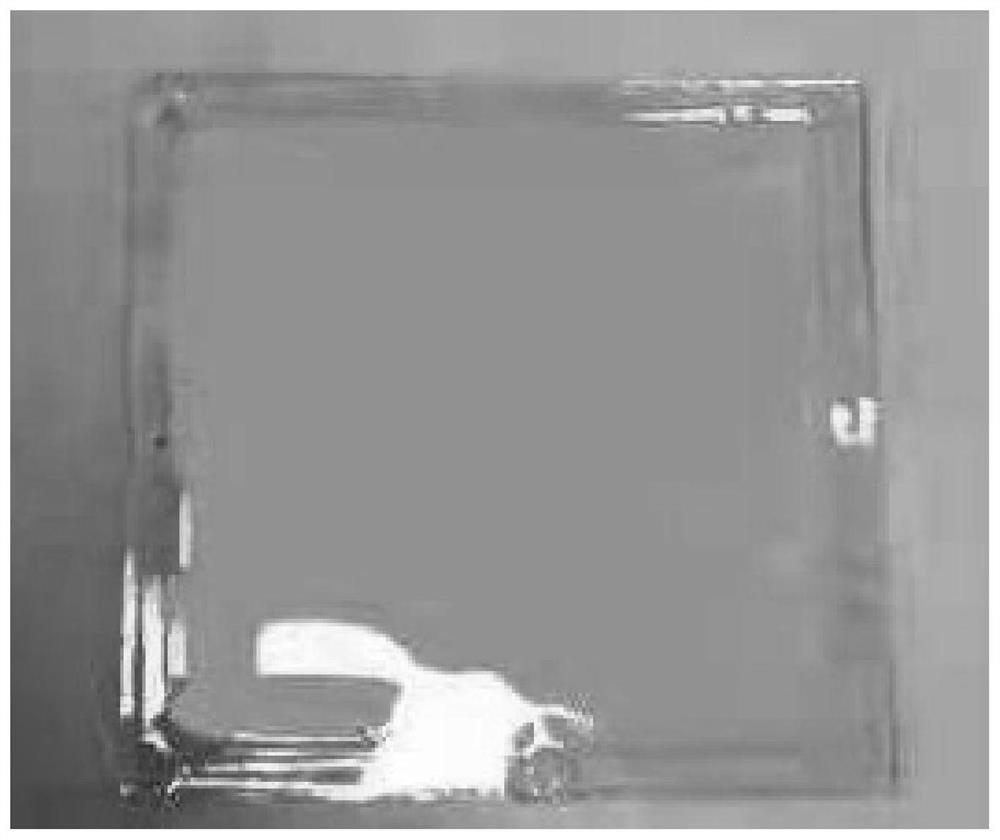

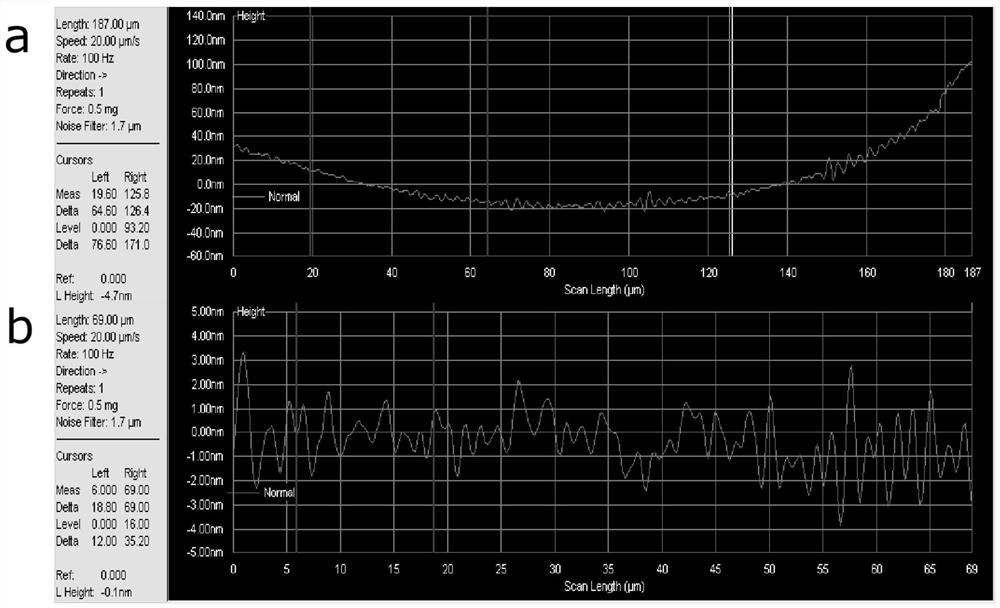

Preparation method of flexible transparent conductive electrode with low surface roughness

InactiveCN112768116AReduce surface roughnessGood performance requirementsConductive layers on insulating-supportsSolid-state devicesMetal coatingPerovskite solar cell

The invention discloses a preparation method of a flexible transparent conductive electrode with low surface roughness. The preparation method comprises the steps of depositing a metal network electrode on a substrate by adopting a cracking template method, forming a metal coating on the deposited metal network electrode through electroplating, performing plasma treatment, and infiltrating by using a c-PI precursor solution; and after c-PI is subjected to heating and heat preservation to form a film, stripping the c-PI film from the substrate in a hot bath to complete lossless transfer, so as to obtain the flexible transparent conductive electrode with low surface roughness. The flexible transparent conductive electrode prepared through the method has the performance of high transmittance, the surface roughness is within 10 nm, and the requirements of thin film photoelectric devices such as perovskite solar cells are completely met.

Owner:SOUTH CHINA NORMAL UNIVERSITY

High-performance dry-pressed permanent magnet ferrite rotor and manufacture method thereof

The invention discloses a high-performance dry-pressed permanent magnet ferrite rotor and a manufacture method thereof; the high-performance dry-pressed permanent magnet ferrite rotor is made from, by weight, 94.8-97.4% of ferrite magnet powder, and the balance of auxiliaries, including camphor powder, boric acid, calcium stearate, and silicon dioxide. The components of the high-performance dry-pressed permanent magnet ferrite rotor are selected and matched appropriately, the manufactured high-performance dry-pressed permanent magnet ferrite rotor has excellent properties, the manufacture method is easy to perform, the production cost is lowered, the use of secondary orientation gives rise to reduced repelling and friction between magnetic poles during magnet powder forming and improved orientation degree of magnet powder, and the performance indexes of the permanent magnet ferrite rotor are effectively increased.

Owner:HANYU GRP CO LTD

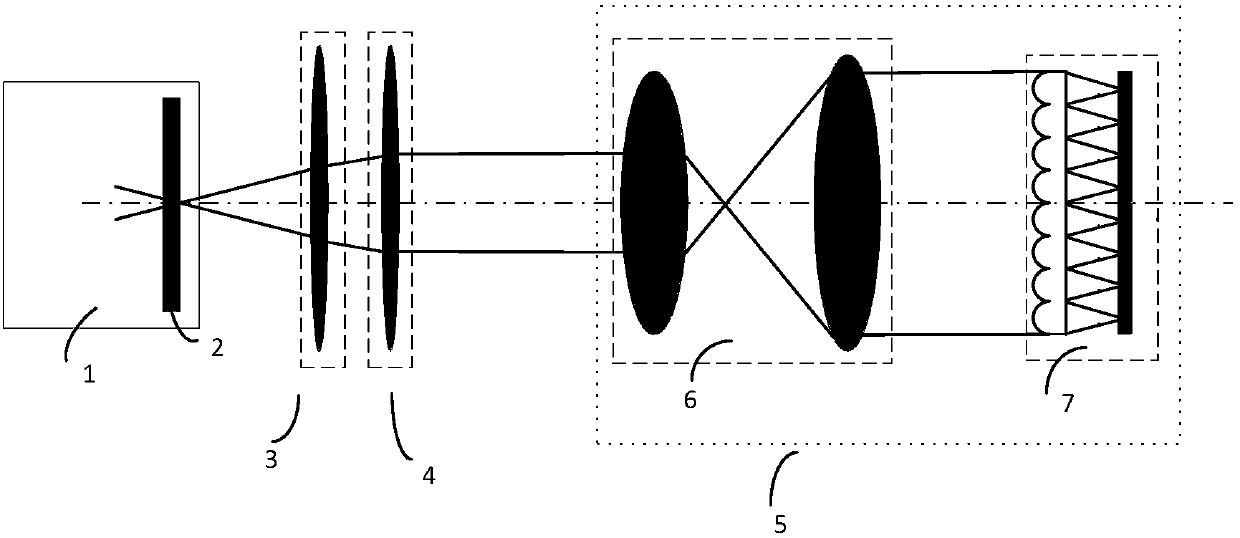

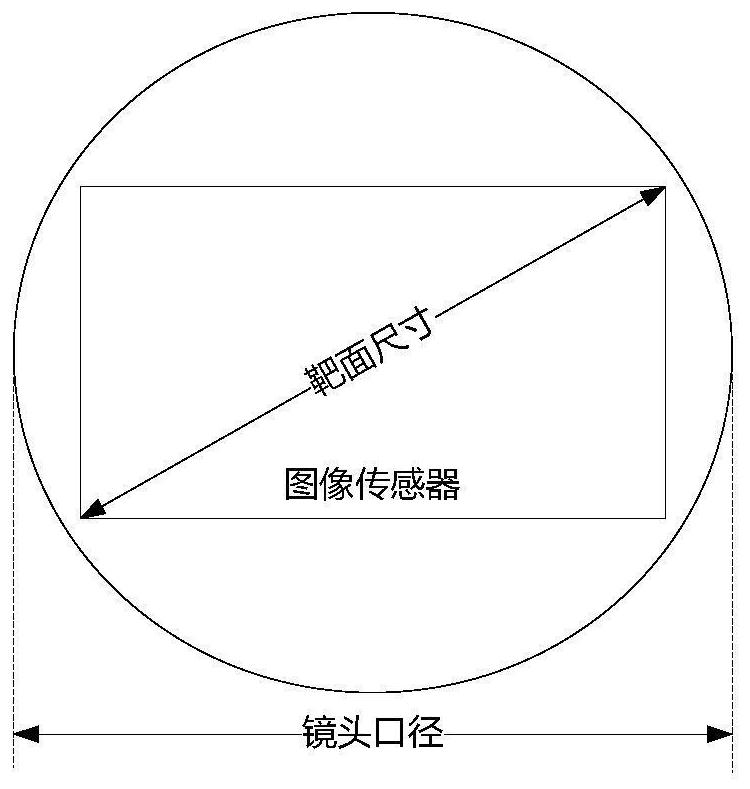

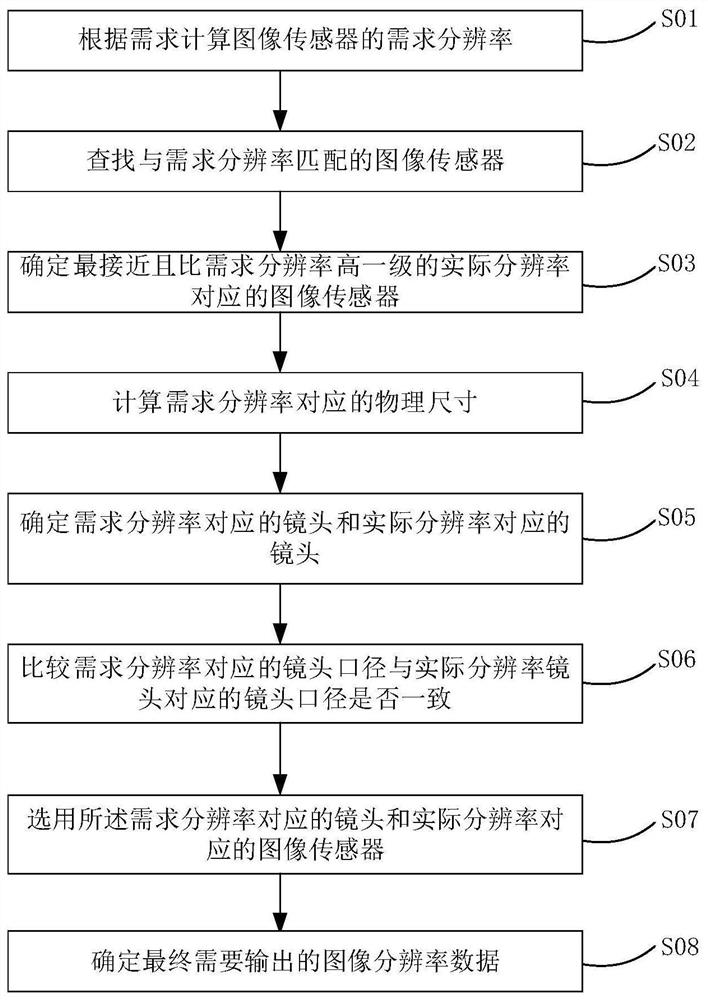

Design method of high-performance imaging system

ActiveCN113099092AGood performance requirementsLow costTelevision system detailsColor television detailsImage sensorImage resolution

The invention relates to a design method of a high-performance imaging system. The design method comprises the following steps: calculating a required resolution required to be met by an image sensor according to application requirements; searching an image sensor matched with the required resolution; if not, determining the image sensor corresponding to the actual resolution which is closest to the required resolution and is one level higher than the required resolution; calculating the physical size corresponding to the required resolution according to the required resolution, the actual resolution and the physical size corresponding to the actual resolution; determining a lens corresponding to the required resolution and a lens corresponding to the actual resolution according to the physical size corresponding to the required resolution and the physical size corresponding to the actual resolution; comparing whether the lens apertures are consistent or not; and if the lens aperture corresponding to the actual resolution is greater than the lens aperture corresponding to the required resolution, selecting a lens corresponding to the required resolution and an image sensor corresponding to the actual resolution. According to the invention, high-performance requirement of the imaging system can be met, and the processing amount of the imaging system can be effectively reduced.

Owner:BEIJING LUSTER LIGHTTECH

Attenuation type hierarchical storage system and method based on distributed storage system

InactiveCN110162273AMeet the needs of large capacityQuick interactionInput/output to record carriersUltrasound attenuationLow speed

The invention relates to an attenuation type hierarchical storage system and method based on a distributed storage system, and relates to the technical field of distributed storage. According to the invention, the timeliness of data in the information system is utilized to identify data flowing into the system with different heat degrees, a large number of cold data which are not accessed any moreare migrated out of precious high-speed storage media, and then low-speed storage media which are low in price and large in capacity are used for storage, so that rapid interaction between the hot data which are frequently accessed and a user is achieved through the high-speed storage media. With data migration, a large amount of cold data of the high-speed performance layer moves to the low-speed capacity layer; and a small amount of hot data in the low-speed capacity layer moves to the high-speed performance layer, so that the high-performance requirement on the access rate in a large-scalestorage system is met, the high-capacity requirement of mass data on a storage medium is also met, and meanwhile, the total ownership cost of the system is effectively reduced.

Owner:BEIJING INST OF COMP TECH & APPL

Photo-curing gradient material forming device and method

ActiveCN111037920AAchieving Density AdjustmentAchieve preparationManufacturing platforms/substratesManufacturing enclosuresMechanical engineeringMixing tank

The invention discloses a photo-curing gradient material forming device and method. The method is characterized in that a photo-curing groove is formed at a lower end of a forming platform, the forming platform is arranged at an upper end of the photo-curing groove through a vertical driving device, a photo-curing forming lamp panel is arranged at a lower end of the photo-curing groove, and a photo-curing forming material needed by printing is placed in the photo-curing groove; a mixing tank is connected with a feeding mechanism, density adjustment of the photo-curing forming material is realized, the mixing tank communicated with the photo-curing tank through a circulating pipeline is used for achieving flowing of a photo-curing forming material in the photo-curing tank, preparation of agradient material is achieved. The device is simple in structure, the preparation process of a traditional gradient material is simplified, manufacturing cost is reduced, conditions needed by formingof the gradient material are reduced, operation is easy, the device can realize preparation of density gradient materials with different performance requirements, only different fillers need to be added into the filler tank, and different fillers are added to improve performance requirements of different parts.

Owner:CHANGAN UNIV

A mobile terminal and method for adjusting its cpu frequency

ActiveCN103324270BExtend battery lifeReduce power consumptionPower supply for data processingConservative strategyComputer science

Owner:DONGGUAN YULONG COMM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com