Hard coating cutting tool with gradient composite structure and preparation method of hard coating cutting tool

A composite structure, hard coating technology, applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of high stress of the base coating, poor heat resistance, weak bonding strength of the film base, etc. , to achieve the effect of expanding the application range, improving wear resistance and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

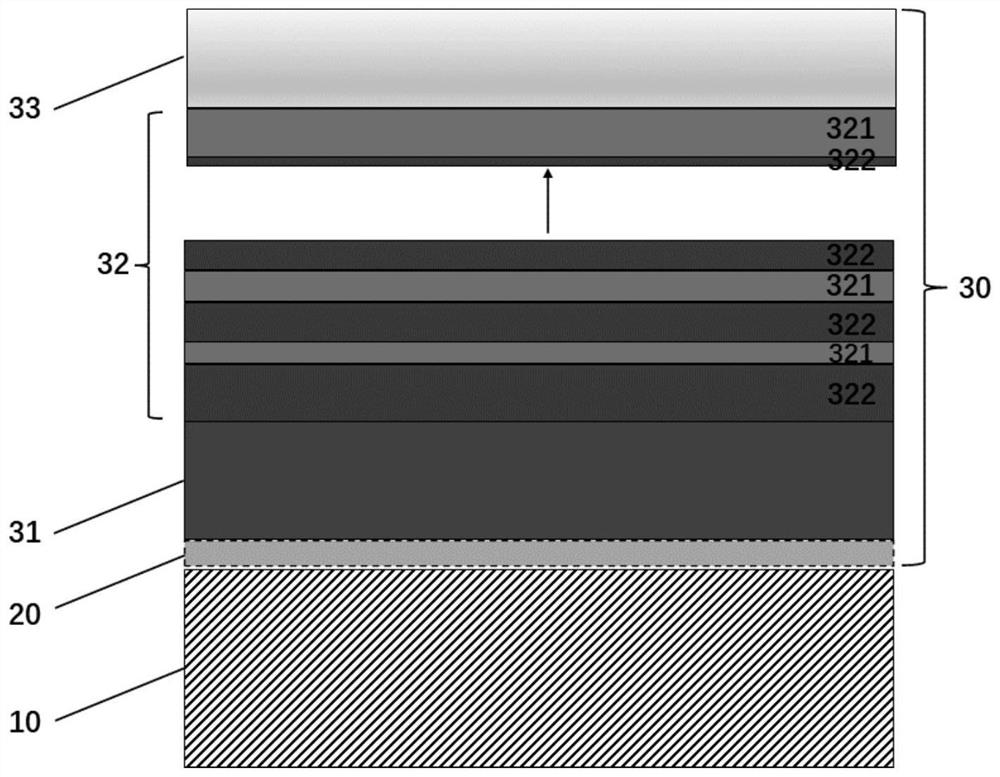

[0053] A kind of hard coating tool containing gradient composite structure of the present invention, such as figure 1 As shown, it includes a tool base 10 and a hard coating 30 deposited on the tool base 10. The hard coating 30 includes a multi-layer coating 32 of a gradient composite structure (also referred to as a gradient layer 32) and provided on the gradient composite structure. The functional layer 33 on the surface of the multi-layer coating 32, the functional layer 33 is TiB 2 layer, gradient composite structure multilayer coating 32 comprising alternately deposited Ti 1-x Al x N layer 322 and TiBN layer 321, Ti 1-x Al x In the N layer 322, x is 0.6, that is, Ti 0.40 Al 0.60 N layer, Ti 1-x Al x The thickness of the N layer 322 decreases as the distance from the tool base 10 increases, and the thickness of the TiBN layer 321 increases as the distance from the tool base 10 increases. The first layer of the gradient composite structure multilayer coating 32 is Ti...

Embodiment 2

[0084] A kind of hard coating tool containing gradient composite structure of the present invention, such as figure 1 As shown, it includes a tool base 10 and a hard coating 30 deposited on the tool base 10. The hard coating 30 includes a gradient composite structure multilayer coating 32 and a functional layer provided on the surface of the gradient composite structure multilayer coating 32 33, the functional layer 33 is TiB 2 layer, gradient composite structure multilayer coating 32 comprising alternately deposited Ti 1-x Al x N layer 322 and TiBN layer 321, Ti 1-x Al x In the N layer 322, x is 0.6, that is, Ti 0.40 Al 0.60 N layer, Ti 1-x Al x The thickness of the N layer 322 decreases as the distance from the tool base 10 increases, and the thickness of the TiBN layer 321 increases as the distance from the tool base 10 increases. The first layer of the gradient composite structure multilayer coating 32 is Ti 0.40 Al 0.60 N layers, the last layer is TiBN layer 321,...

Embodiment 3

[0112] A kind of hard coating tool containing gradient composite structure of the present invention, such as figure 1 As shown, it includes a tool base 10 and a hard coating 30 deposited on the tool base 10. The hard coating 30 includes a gradient composite structure multilayer coating 32 and a functional layer provided on the surface of the gradient composite structure multilayer coating 32 33, the functional layer 33 is TiB 2 layer, gradient composite structure multilayer coating 32 comprising alternately deposited Ti 1-x Al x N layer 322 and TiBN layer 321, Ti 1-x Al x In the N layer 322, x is 0.5, that is, Ti 0.50 Al 0.50 N layer, Ti 0.50 Al 0.50 The number of N / TiBN modulation cycles is 5, the first cycle: Ti 0.50 Al 0.50 The thickness of the N layer is 350 nm, the thickness of the TiBN layer 321 is 30 nm, and the second period: Ti 0.50 Al 0.50 The thickness of the N layer is 260 nm, the thickness of the TiBN layer 321 is 60 nm, and the third period: Ti 0.50 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com