Engine chain system tightener plunger displacement measurement device and measurement method

A technology of measuring device and tensioner, applied in the direction of measuring device, electric device, instrument, etc., can solve the problems of sensor installation and debugging, and achieve the effect of meeting high performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

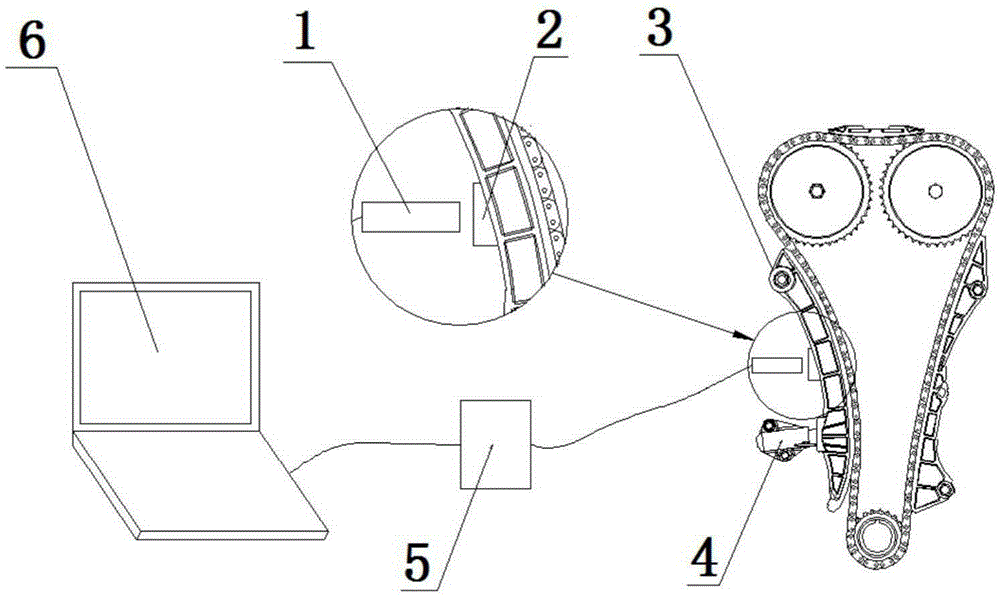

[0023] The measuring device is composed of metal conductor 2, displacement sensor 1, tension rail 3, data acquisition processor 5 and computer 6. Displacement sensor 1 is a non-contact eddy current displacement sensor, which is installed on the side cover of the engine. The conductor 2 is a cylindrical metal sheet, which is installed on the tension rail bracket of the chain system. The tension rail bracket supports the tension rail 3 and is connected with the tension rail 3. When the tension rail 3 swings, it drives the metal conductor 2 to move, and the tension rail 3 moves. When the tight rail 3 is not moving, the probe of the displacement sensor 1 is facing the metal conductor 2. When the tension rail 3 swings, the metal conductor 2 is driven to swing, so that the distance between the metal conductor 2 and the probe of the displacement sensor 1 changes, and the displacement sensor 1 can accurately measure the metal conductor 2. The dynamic relative displacement change betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com