Design method of high-performance imaging system

A technology of imaging system and design method, applied in the field of visual imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

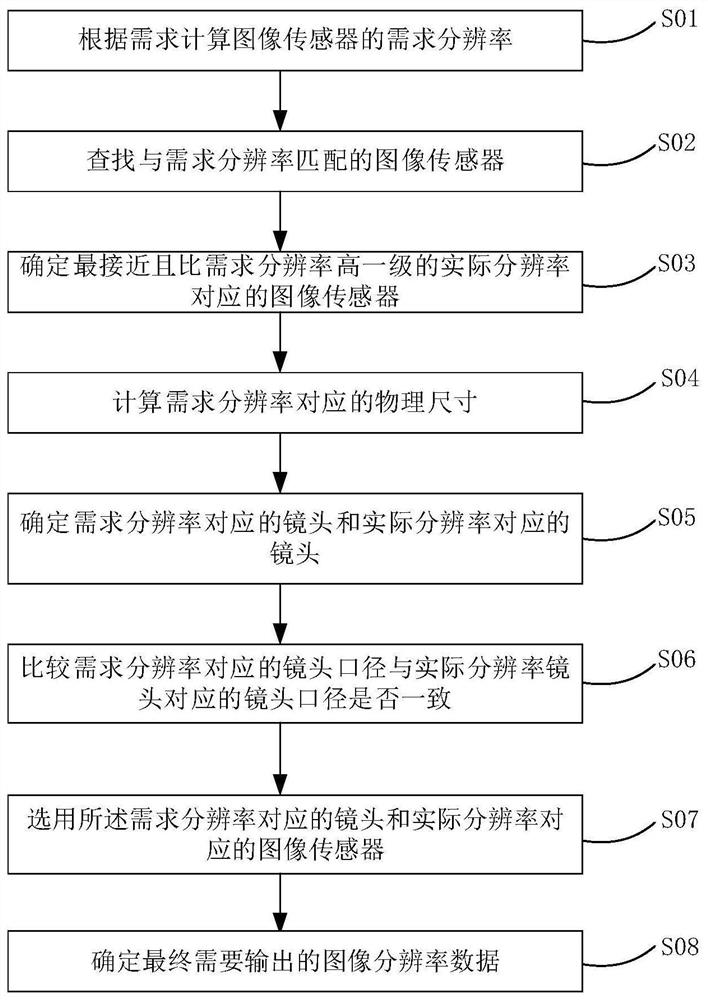

[0044] Such as figure 2 As shown, the design method of a high-performance imaging system provided by the application includes the following steps:

[0045] S01: Calculate the required resolution of the required image sensor according to the application requirements;

[0046] In this embodiment, the application requirements include: the required detection accuracy of the image sensor and the field of view of the camera.

[0047] Specifically: the application requirements include the application requirements of line array cameras and the application requirements of area array cameras;

[0048] Then, for the line array camera, the application requirements of the line array camera include: the detection accuracy of the required image sensor corresponding to the line array camera and the horizontal field of view width of the line array camera, the field of view of the line array camera is represented by the image of the line array camera The long side of the sensor shall prevail...

Embodiment 2

[0083] Different from Embodiment 1, Embodiment 2 includes the following steps:

[0084] S01: Calculate the required resolution of the required image sensor according to the application requirements;

[0085] S02: Find an image sensor that matches the required resolution;

[0086] S03: If there is an image sensor matching the required resolution, select an image sensor matching the required resolution;

[0087] S04: Obtain the physical size corresponding to the required resolution;

[0088] S05: Determine the lens corresponding to the required resolution according to the physical size corresponding to the required resolution.

Embodiment 3

[0090] Different from Embodiment 1 and Embodiment 2, Embodiment 3 includes the following steps:

[0091] S01: Calculate the required resolution of the required image sensor according to the application requirements;

[0092] S02: Find an image sensor that matches the required resolution;

[0093] S03: If there is no image sensor matching the required resolution, determine the image sensor corresponding to the actual resolution that is closest and one level higher than the required resolution;

[0094] S04: Calculate the physical size corresponding to the required resolution according to the required resolution, the actual resolution, and the physical size corresponding to the actual resolution;

[0095] S05: Determine the lens corresponding to the required resolution and the lens corresponding to the actual resolution according to the physical size corresponding to the required resolution and the physical size corresponding to the actual resolution;

[0096] S06: Compare whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com