High-compressive-strength rubber aggregate concrete and preparation method thereof

A rubber aggregate and compressive strength technology, applied in the field of building materials, can solve the problems that the tensile and compressive strength cannot be improved at the same time, the concrete work performance is poor, and the engineering universality is not high, so as to achieve good water retention performance, The effect of saving cement clinker, improving compressive strength and splitting tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

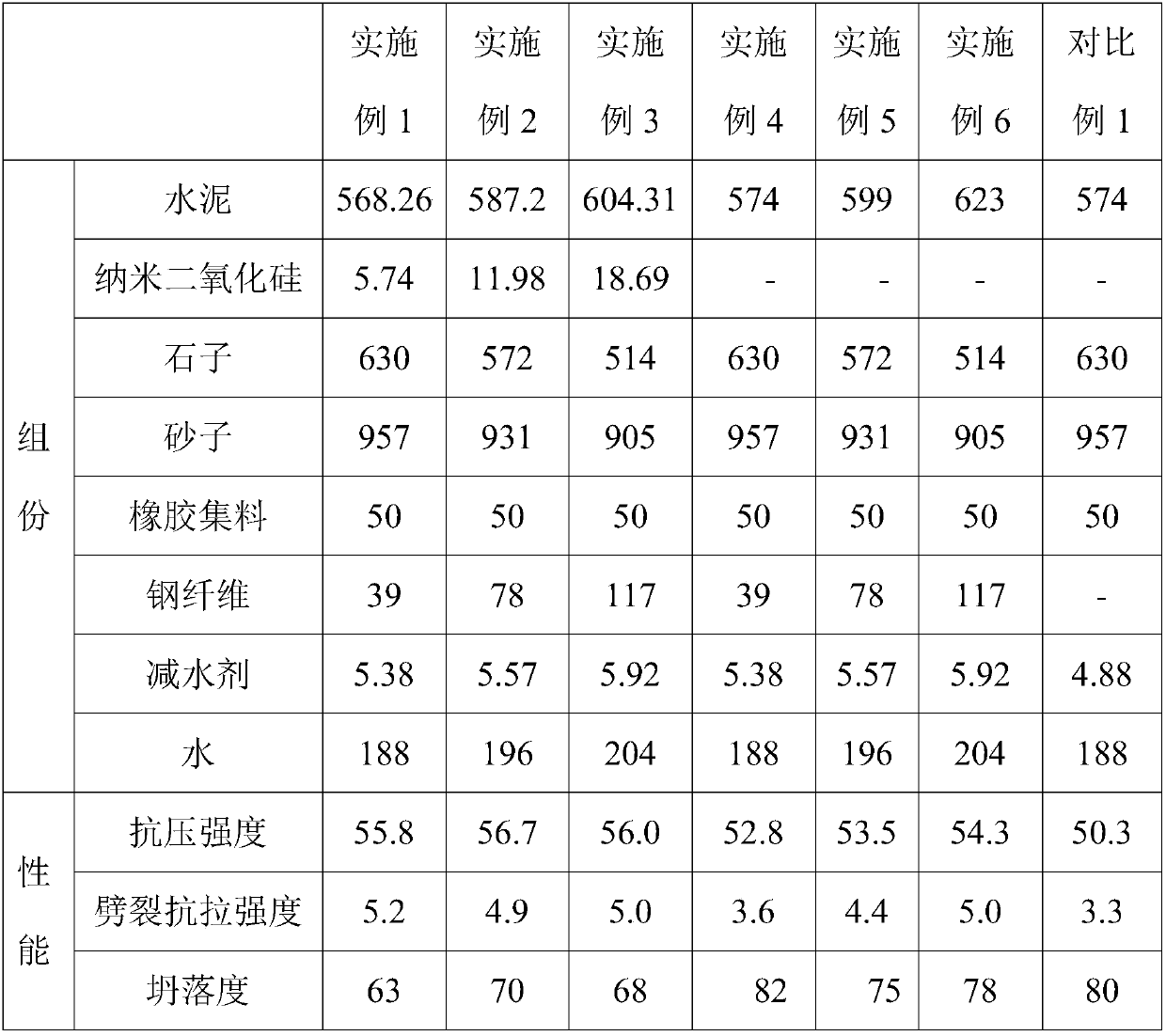

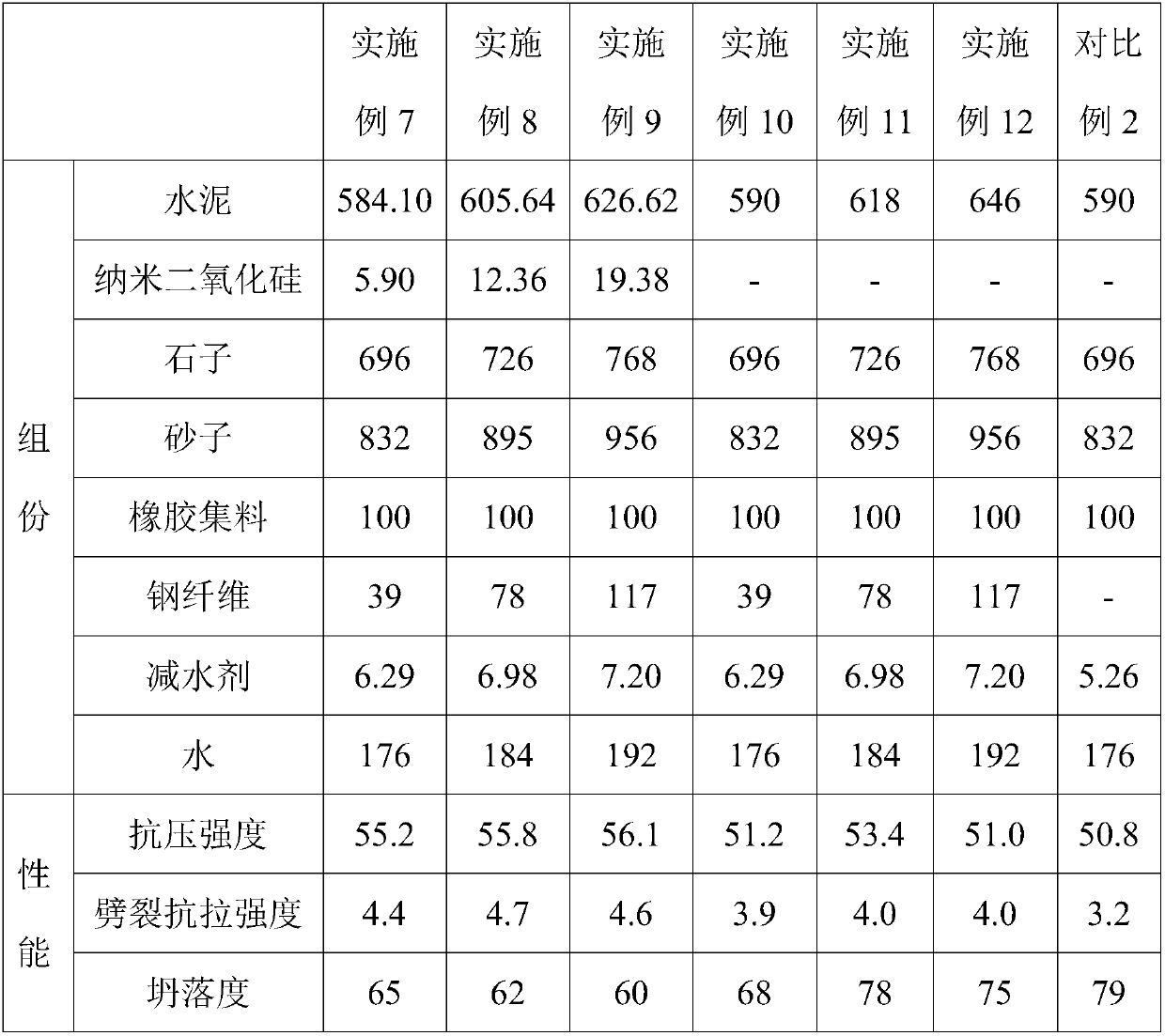

Examples

preparation example Construction

[0037] The method for preparing high compressive strength rubber aggregate concrete disclosed in the embodiment of the present invention includes the following steps:

[0038] a) Pour the sand and stones into the mixing pot, pre-stir it, add the steel fiber slowly and continuously, and stir until the steel fiber is evenly dispersed; before this step, the wetting step of the mixing pot can be added;

[0039] b) Add rubber aggregate and mix until uniform; the addition of rubber aggregate can be carried out at a uniform speed, which is convenient for uniform mixing;

[0040] c) Add nano-silica into the cement, stir evenly, then add it to the mixing pot and stir;

[0041] d) The water reducing agent is fully dissolved in the water, and then added to the mixing pot in batches and stirred until the mixture is evenly mixed.

[0042] In the embodiment of the present invention, the intensity detection is performed by the following method.

[0043] Sample preparation method:

[0044] The high compr...

Embodiment 1

[0048] The high compressive strength rubber aggregate concrete disclosed in the first embodiment includes concrete base material, rubber aggregate, steel fiber, water reducing agent, and water, wherein the concrete base material includes cementitious materials, stones, sand, and cementitious materials include cement And nano silica, the mass content of cement is 99%, the mass content of nano silica is 1%, the cement is PO 42.5 ordinary Portland cement, the average particle size of nano silica is 40nm, the specific surface area is 175m 2 / g. The masses of cement, nano silica, stones, sand, rubber aggregate, steel fiber and water are 568.26kg, 5.74kg, 630kg, 957kg, 50kg, 39kg and 188kg respectively. The naphthalene-based powdered water reducing agent is 5.38kg, The water reduction rate is 26%, the average diameter of the steel fiber is 0.4mm, the length is 30-40mm, and the particle diameter of the rubber aggregate is 1-2mm.

[0049] The preparation method of the high compressive st...

Embodiment 2

[0056] The high compressive strength rubber aggregate concrete disclosed in the second embodiment includes concrete base material, rubber aggregate, steel fiber, water reducing agent and water, wherein the concrete base material includes cementitious materials, stones, sand, and cementitious materials include cement The mass content of nano-silica cement is 98%, the mass content of nano-silica is 2%, the cement is PO 42.5 ordinary Portland cement, the average particle size of nano-silica is 40nm and the specific surface area is 175m 2 / g. The masses of cement, nano-silica, stones, sand, rubber aggregate, steel fiber and water are 587.02kg, 11.98kg, 572kg, 931kg, 50kg, 78kg and 196kg respectively. The naphthalene-based powdered water reducing agent is 5.57kg. The water reduction rate is 26%, the average diameter of the steel fiber is 0.4mm, the length is 30-40mm, and the particle diameter of the rubber aggregate is 1-2mm.

[0057] For the high compressive strength rubber aggregate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com