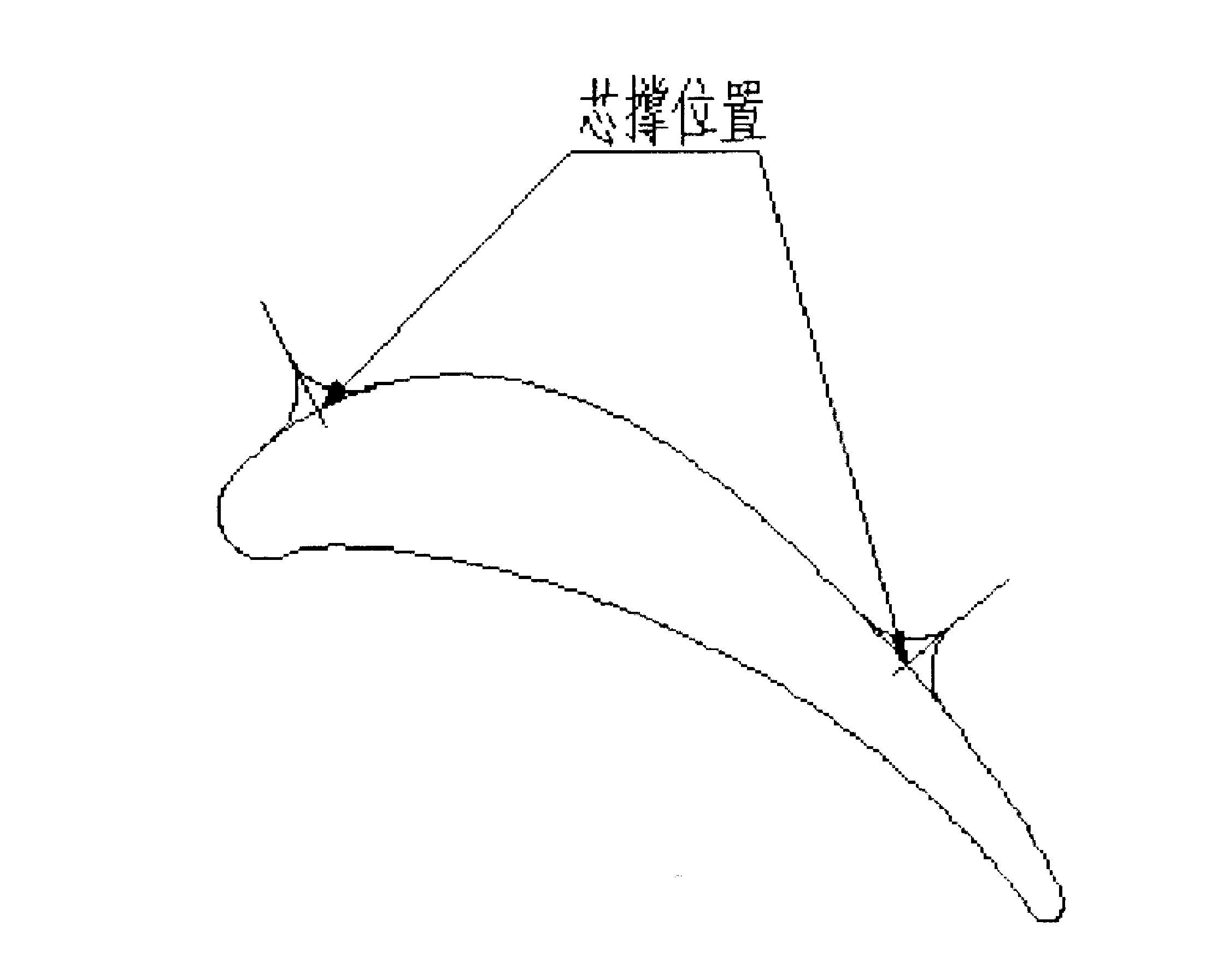

Method for enhancing strength of single crystal blade core by metal core support

A technology of single crystal blades and metal cores, applied in metal processing equipment, cores, mold boxes, etc., can solve problems such as difficult to meet the production needs of single crystal blades, complex and narrow inner cavity of single crystal blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

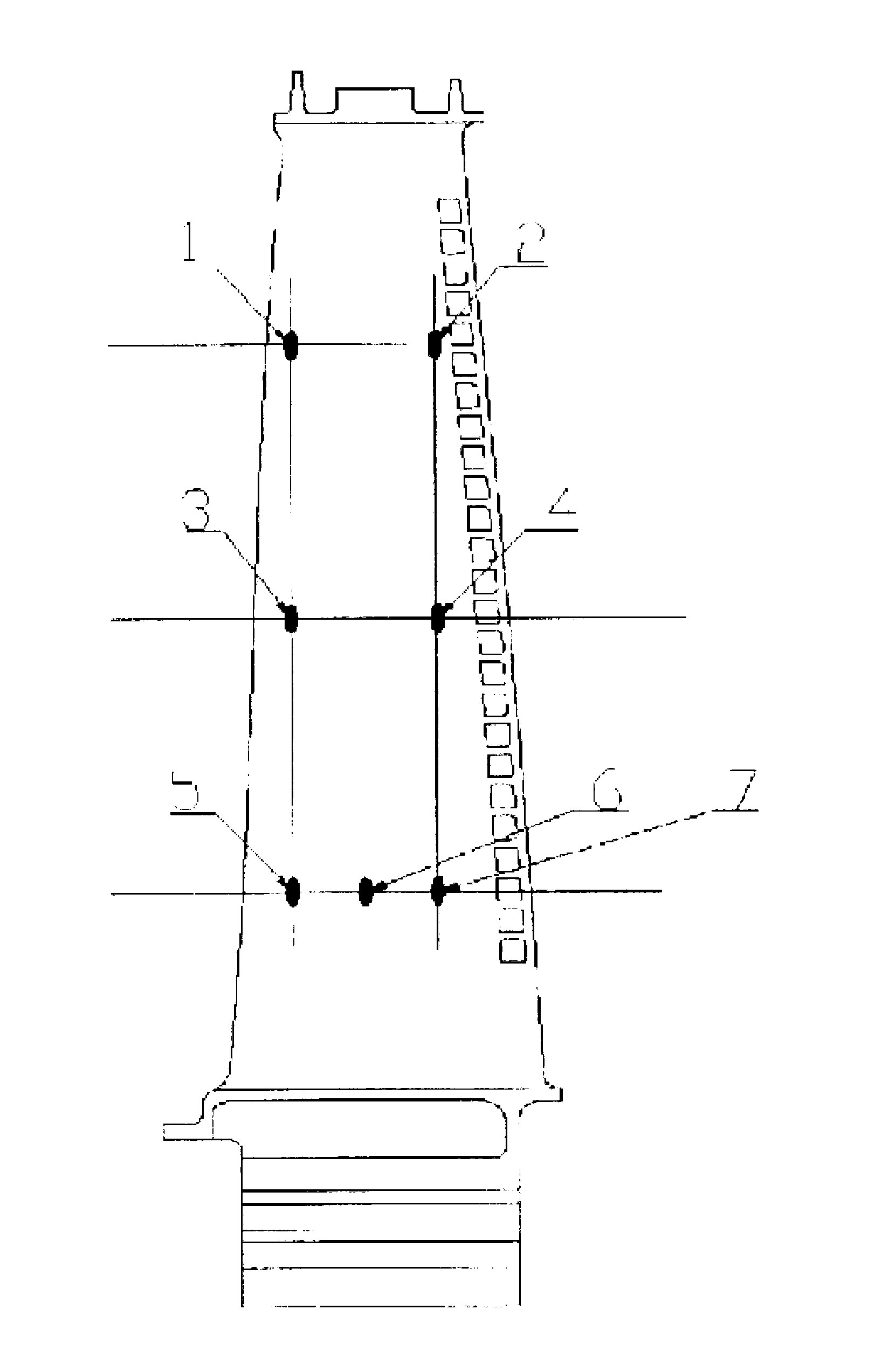

[0015] 0.3mm platinum rhodium wire is used as the metal core support as the raw material. Cut 5mm long and 0.3mm platinum-rhodium wire, hold it with tweezers, heat it on the alcohol lamp for 5 seconds, insert it perpendicular to the shape of the blade, and then use a metal stick to take a little white paraffin and heat it on the alcohol lamp for 2 seconds Finally, drip the wax liquid along the metal core support to form a wax bag. After the wax bag cools down, use a metal stick to trim the shape of the wax bag to achieve a smooth transfer with the blade surface.

Embodiment 2

[0017] 0.5mm platinum rhodium wire is used as the metal core support as the raw material. Cut a 5mm long and 0.5mm diameter platinum-rhodium wire, hold it with tweezers, heat it on an alcohol lamp for 10 seconds, pierce it perpendicular to the shape of the blade, and then use a metal prick to take a little white paraffin and heat it for 4 seconds in the alcohol lamp , drip the wax solution along the gold flex core support to form a wax bag, and after the wax bag cools down, use a metal stick to trim the shape of the wax bag to achieve a smooth transfer to the blade surface.

Embodiment 3

[0019] 0.5mm platinum rhodium wire is used as the metal core support as the raw material. Cut a platinum-rhodium pole with a length of 7 mm and a diameter of 0.5 mm, hold it with tweezers, heat it on an alcohol lamp for 15 seconds, insert it perpendicular to the blade surface, and then use a metal stick to take a little white paraffin and heat it on an alcohol lamp for 3 seconds Finally, drip the wax liquid along the metal core support to form a wax bag. After the wax bag cools down, use a metal stick to trim the shape of the wax bag to achieve a smooth transfer with the blade surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com