AlCrSiN-based multilayer nanometer composite cutter coating layer and preparation method thereof

A nano-composite and cutting tool technology, which is applied in coating, metal material coating process, ion implantation plating, etc., to achieve the improvement of mechanical wear resistance and high temperature oxidation resistance, meet the demand for better performance, huge market potential and Use value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

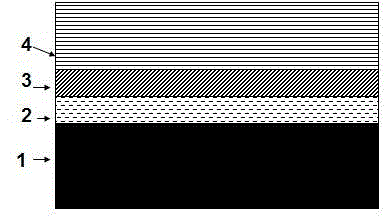

[0029] An AlCrSiN-based cutting tool coating, the coating comprising a bonding layer, a transition layer and a main wear-resistant layer; the bonding layer is attached to a WC-Co cemented carbide or high-speed steel cutting tool substrate, with a thickness of 0.1 to 1 micron The Ti metal layer; the transition layer AlTiN coating is prepared by high-power pulse magnetron sputtering technology, attached to the bonding layer, which is an AlTiN coating of 0.5-2 microns; the main wear-resistant layer of AlCrSiN adopts arc ion plating Technology preparation, attached to the transition layer, the thickness is 1~5 microns;

[0030] Among them, the coating formula of the transition layer and the main wear-resistant layer is as follows:

[0031] Aluminum titanium nitrogen layer: aluminum 29 at.%, titanium 20 at.%, nitrogen 51 at.%;

[0032] Aluminum chromium silicon nitrogen layer: aluminum 25 at.%, chromium 20 at.%, silicon 5 at.%, nitrogen 50 at.%;

[0033] For the chromium alum...

Embodiment 2

[0038] An AlCrSiN-based cutting tool coating, the coating comprising a bonding layer, a transition layer and a main wear-resistant layer; the bonding layer is attached to a WC-Co cemented carbide or high-speed steel cutting tool substrate, with a thickness of 0.1 to 1 micron The Ti metal layer; the transition layer AlTiN coating is prepared by high-power pulse magnetron sputtering technology, attached to the bonding layer, which is an AlTiN coating of 0.5-2 microns; the main wear-resistant layer of AlCrSiN adopts arc ion plating Technology preparation, attached to the transition layer, the thickness is 1~5 microns;

[0039] Among them, the coating formula of the transition layer and the main wear-resistant layer is as follows:

[0040] Aluminum titanium nitrogen layer: aluminum 35at.%, titanium 18at.%, nitrogen 47at.%;

[0041] Aluminum chromium silicon nitrogen layer: aluminum 30 at.%, chromium 20 at.%, silicon 5 at.%, nitrogen 45 at.%;

[0042] For the chromium aluminum si...

Embodiment 3

[0047] An AlCrSiN-based cutting tool coating, the coating comprising a bonding layer, a transition layer and a main wear-resistant layer; the bonding layer is attached to a WC-Co cemented carbide or high-speed steel cutting tool substrate, with a thickness of 0.1 to 1 micron The Ti metal layer; the transition layer AlTiN coating is prepared by high-power pulse magnetron sputtering technology, attached to the bonding layer, which is an AlTiN coating of 0.5-2 microns; the main wear-resistant layer of AlCrSiN adopts arc ion plating Technology preparation, attached to the transition layer, the thickness is 1~5 microns;

[0048] Among them, the coating formula of the transition layer and the main wear-resistant layer is as follows:

[0049] Aluminum titanium nitrogen layer: aluminum 30at.%, titanium 20at.%, nitrogen 50at.%;

[0050] Aluminum chromium silicon nitrogen layer: aluminum 28 at.%, chromium 22 at.%, silicon 2 at.%, nitrogen 48 at.%;

[0051] For the chromium aluminum si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com