A kind of high flame-retardant composite material for new energy high-voltage line and preparation method thereof

A composite material, high flame retardant technology, used in plastic/resin/wax insulators, electrical components, circuits, etc., can solve the problems affecting other properties, oil resistance, softness can not be guaranteed, etc., to achieve excellent flame retardant performance , The effect of excellent extrusion process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

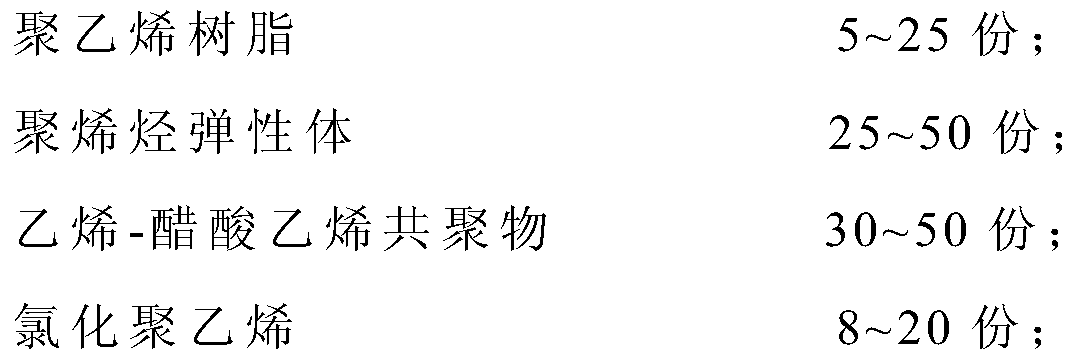

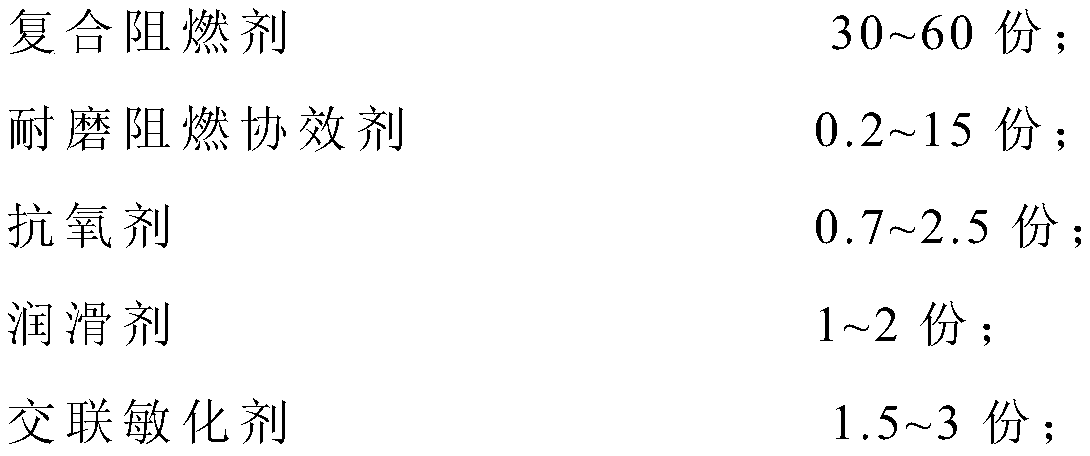

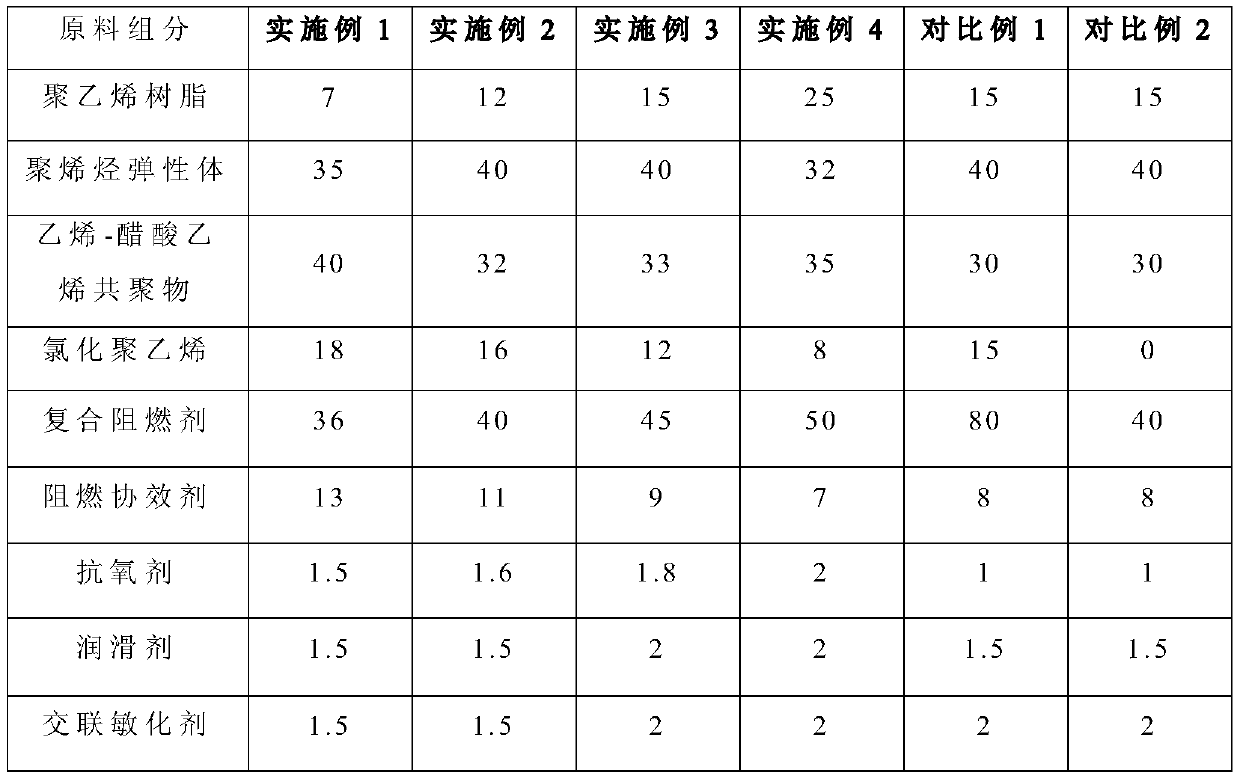

[0032] This example provides a high-flame-retardant composite material for new energy high-voltage lines. The raw materials and dosages used are shown in Table 1, where:

[0033] Polyethylene resin: bimodal high-density polyethylene (derived from Borealis, brand FB2230) with a melt index of 0.3g / 10min and high-density polyethylene with a melt index of 12g / 10min (derived from a petrochemical company, brand 2909 ) according to the mass ratio of 1:3 composition.

[0034] Polyolefin elastomer: It is composed of ethylene-octene copolymer with a hardness of 65A and an ethylene-octene copolymer with a hardness of 87A in a mass ratio of 1:1.

[0035] Ethylene-vinyl acetate copolymer: It is composed of EVA with 18% VA content and EVA with 40% VA content in a mass ratio of 1:2.

[0036] Chlorinated polyethylene: Chlorinated polyethylene with a chlorine content of 30%.

[0037] Composite flame retardant: composed of decabromodiphenylethane and antimony trioxide in a mass ratio of 3:1. ...

Embodiment 2

[0044] This example provides a high-flame-retardant composite material for new energy high-voltage lines. The raw materials and dosages used are shown in Table 1. The raw materials other than the following are the same as those in Example 1.

[0045] Polyethylene resin: It is composed of bimodal high-density polyethylene with a melt index of 0.3g / 10min and high-density polyethylene with a melt index of 20g / 10min in a mass ratio of 1:2.

[0046] Polyolefin elastomer: composed of ethylene-octene copolymer with a hardness of 60A and an ethylene-octene copolymer with a hardness of 82A in a mass ratio of 5:3.

[0047] Ethylene-vinyl acetate copolymer: It is composed of EVA with 28% VA content and EVA with 40% VA content in a mass ratio of 1:2.5.

[0048] Chlorinated polyethylene: Chlorinated polyethylene with a chlorine content of 25%.

[0049] Composite flame retardant: composed of decabromodiphenylethane, antimony trioxide and magnesium hydroxide in a mass ratio of 3:1:1.

[00...

Embodiment 3

[0053] This example provides a high flame-retardant composite material for new energy high-voltage lines. The raw materials and dosages used are shown in Table 1. The raw materials other than the following are the same as those in Example 2.

[0054] Ethylene-vinyl acetate copolymer: It is composed of EVA with VA content of 28% and EVA with VA content of 50% in a mass ratio of 1:2.

[0055] Chlorinated polyethylene: Chlorinated polyethylene with a chlorine content of 35%.

[0056] Wear-resistant and flame-retardant synergist: It is composed of polytetrafluoroethylene powder, silicon dioxide, and talcum powder in a mass ratio of 0.2:2.5:6.

[0057] Antioxidant: It is composed of antioxidant 1035, antioxidant 1024, antioxidant 1010, and antioxidant DLTP in a mass ratio of 2:1:1:0.5.

[0058] The preparation process of the high flame-retardant composite material is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com