Antistatic and anti-bacteria PC/PBT (poly carbonate/polybutylene terephthalate) alloy and preparation method thereof

An anti-static and alloy technology, applied in the field of modified PC/PBT alloy and its preparation, can solve the problems of no bacteriostatic effect, not given, etc., to improve anti-static properties, low cost, high temperature resistance and wear resistance The effect of feature retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

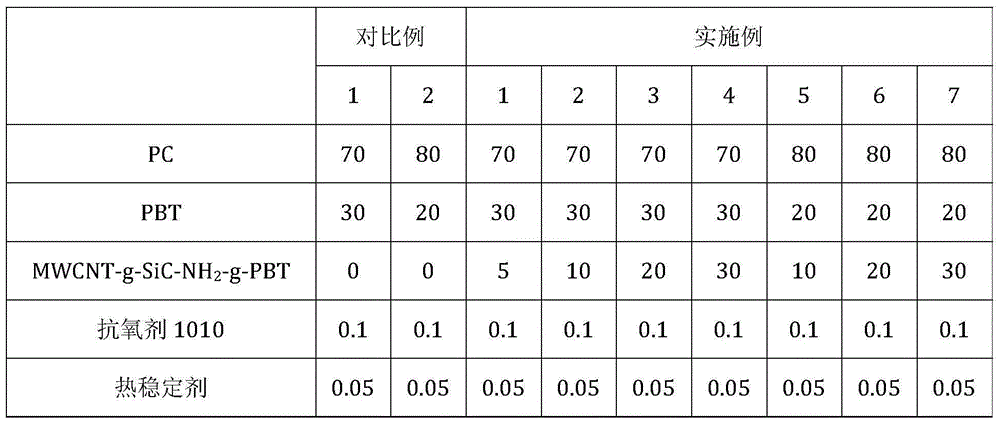

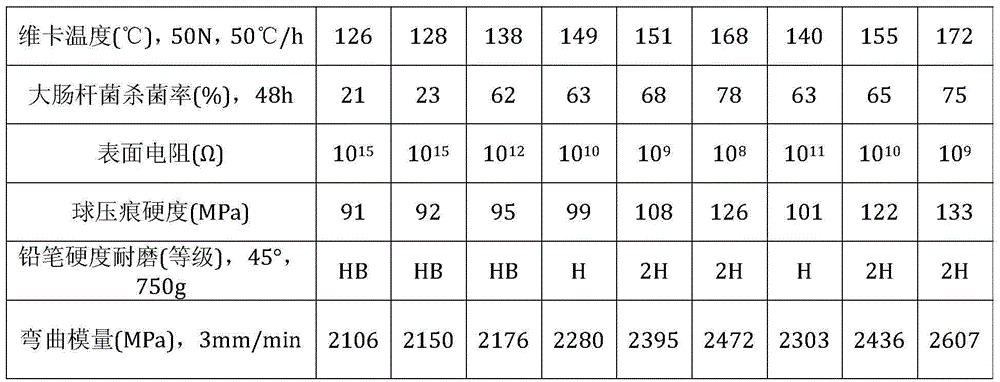

Examples

Embodiment 1

[0020] Used in the following examples: ethanol is 95% ethanol of Sinopharm Group Shanghai Experimental Reagent Co., Ltd.; MWCNT is M1205 of Zhongke Times Nano, with an average diameter of 20-30nm; SiC is 98% powdered silicon carbide of Saint-Gobain Advanced Ceramics Co., Ltd. The particle size is less than 5 μm; the ammonia water is the concentrated ammonia water with a specific gravity of 99.7% of Sinopharm Group Shanghai Chemical Reagent Co., Ltd.; the PBT is PBT from Changchun, Taiwan, and the intrinsic viscosity is 0.8‐1.3dl / g; Carbonate PClexan141R, the molecular weight is 25000-28000g / mol; the ultrasonic equipment adopts 40kHz American SONICS ultrasonic equipment; the internal mixer adopts the Rheocord90 type of German HAAKE company; the high-speed mixer adopts Zhangjiagang Matsumoto SHR type; the twin-screw extruder is produced by German Berstorff company ZE‐25 twin-screw extruder.

[0021] This embodiment includes the following steps:

[0022] 1) MWCNT‐g‐SiC‐NH 2 Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com