Patents

Literature

102results about How to "Improve hardness performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

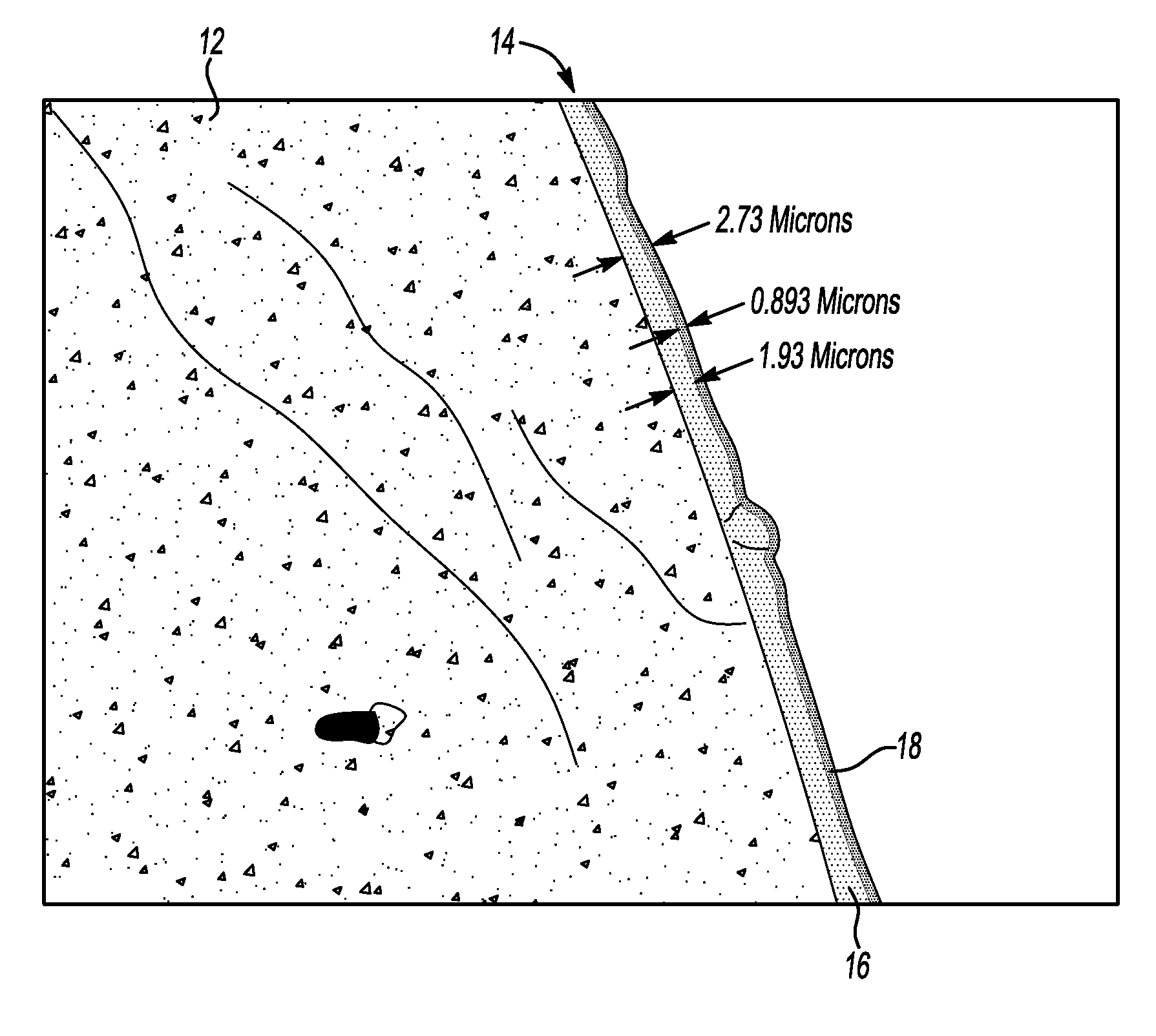

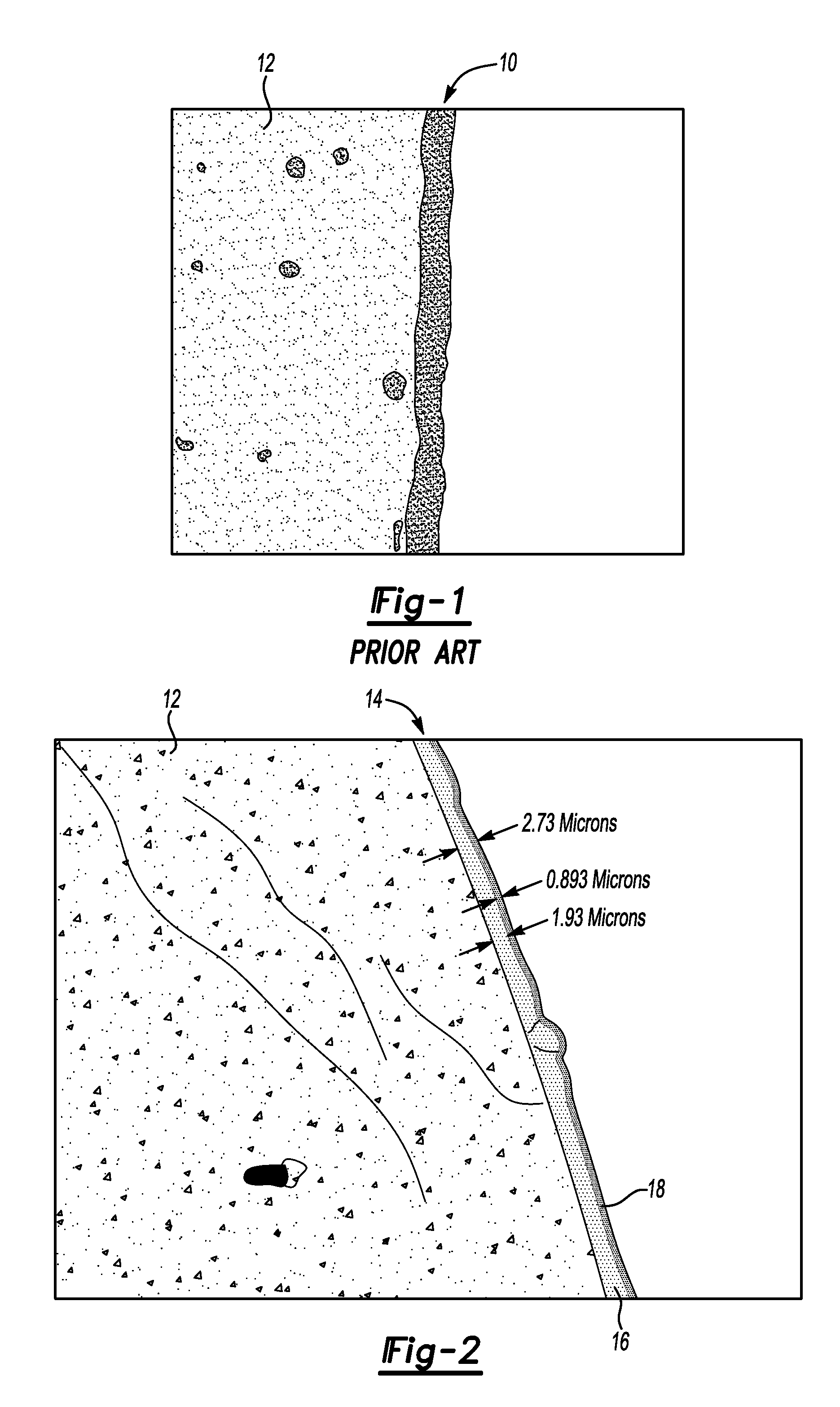

Friction- and wear-reducing coating

InactiveUS20100028641A1Improve tribological propertiesImprove performanceSynthetic resin layered productsVacuum evaporation coatingAlloyHardness

A coating includes a first layer of a ceramic alloy and a second layer disposed on the first layer and including carbon. The coating has a hardness of from 10 to 20 GPa and a coefficient of friction of less than or equal to 0.12. A method of coating a substrate includes cleaning the substrate, forming the first layer on the substrate, and depositing the second layer onto the first layer to thereby coat the substrate.

Owner:EATON CORP

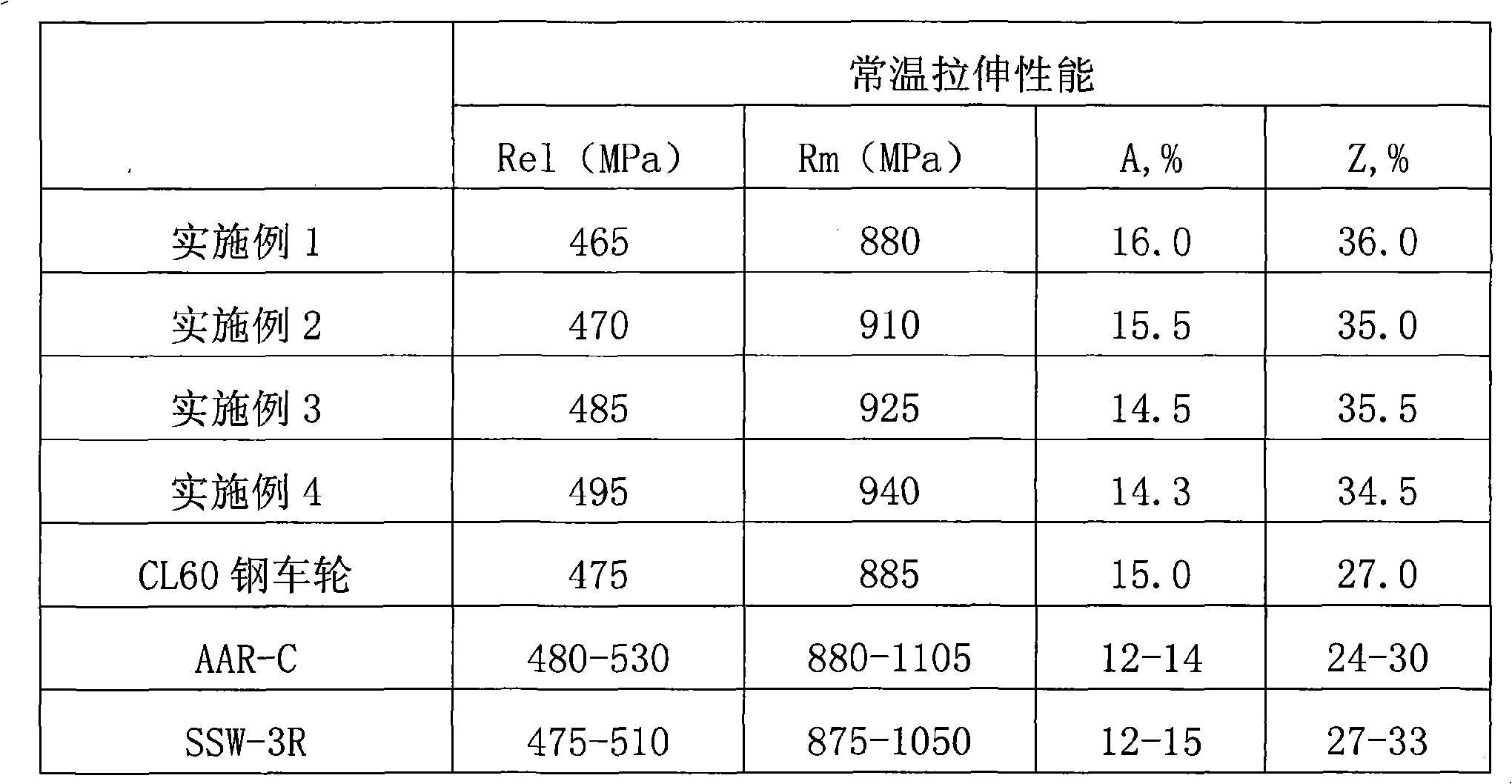

Wheel steel for heavy duty goods train and manufacture method thereof

InactiveCN101314833AThe probability of austenite transformation is reducedImprove heat damage resistanceSteelmakingIngot

The invention discloses a wheel steel used in a heavy-load railway freight car, which comprises the alloying elements by mass percentage (percent) as follows: C is 0.52 to 63 percent, Si is 0.50 to 0.10 percent, Mn is 0.80 to 1.20 percent, Cr is less than or equal to 0.70 percent, S is 0.005 to 0.020 percent, P is less than or equal to 0.030 percent, and the others are ferrum and impurity elements. A preparation method of the wheel steel comprises a converter steelmaking working procedure, an LF furnace refining working procedure, a VD vacuum treatment working procedure, a continuous round-billet casting working procedure, an ingot slicing rolling working procedure, a heat treatment working procedure, a machining working procedure, and a finished product detecting working procedure; the heat treatment working procedure comprises the steps that the heating treatment lasts for 2.0 to 2.5 hours under the temperature that ranges from 880 to 900 DEG C, the jet hardening satisfies 200 to 300S, and then the tempering treatment lasts for 3 to 4 hours under the temperature that ranges from 500 to 550 DEG C. A wheel, which is manufactured by using the wheel steel, increases the strength and the hardness performance obviously on the basis of preserving the original toughness and plasticity of the wheel.

Owner:MAANSHAN IRON & STEEL CO LTD +1

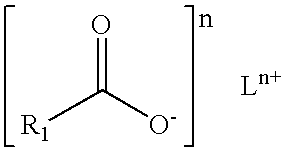

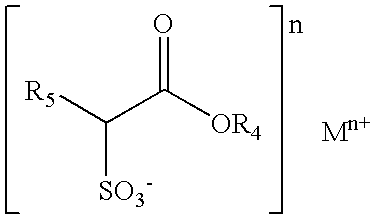

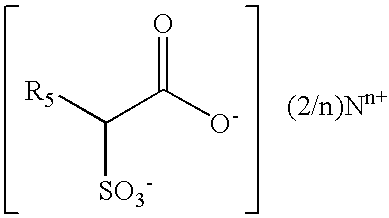

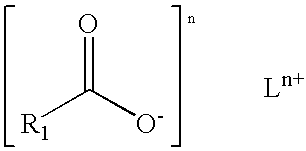

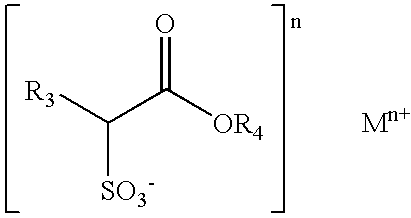

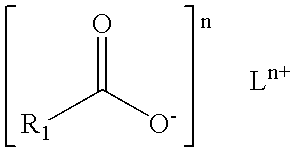

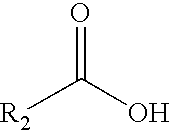

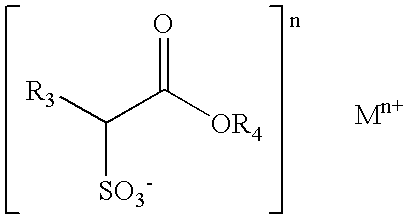

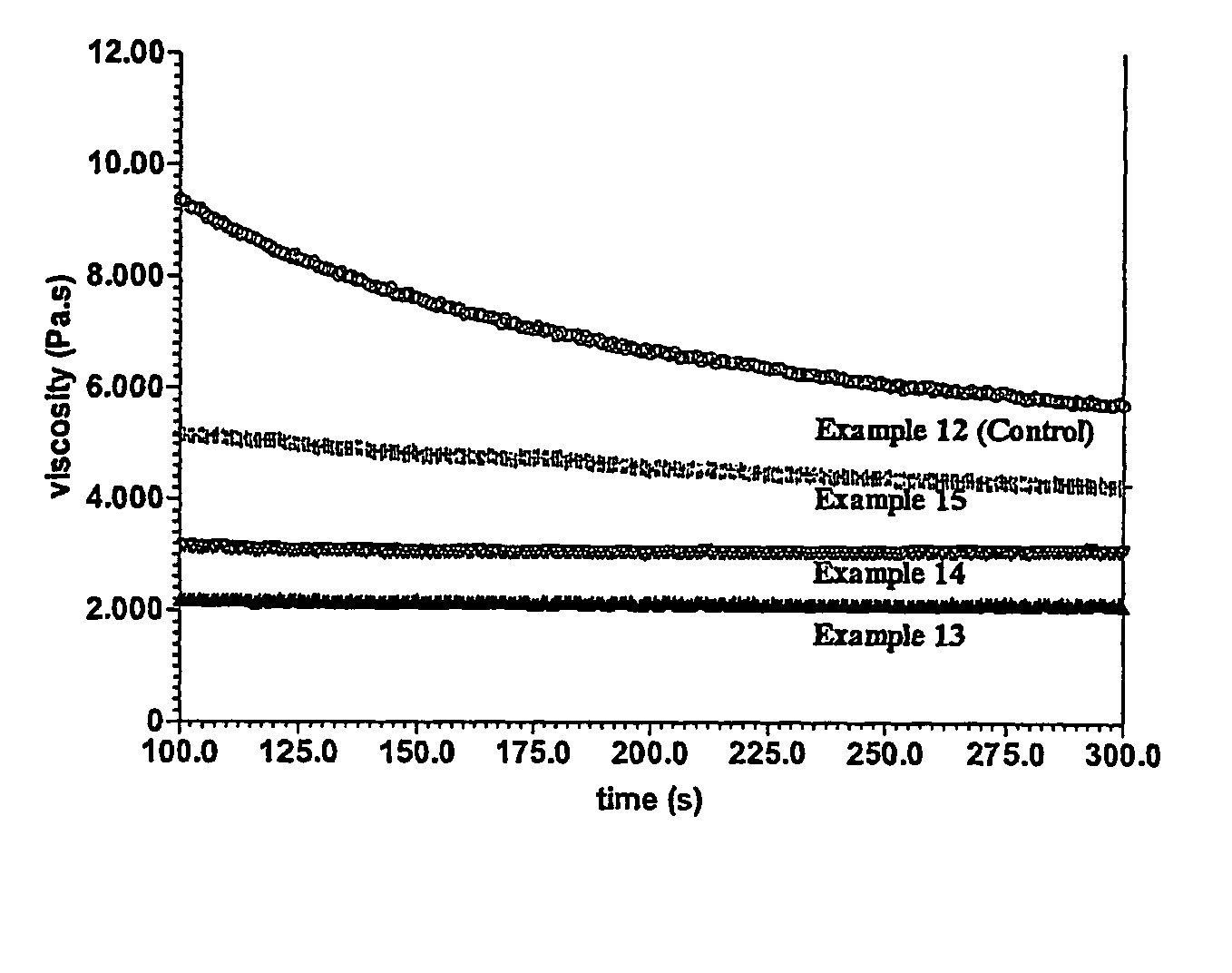

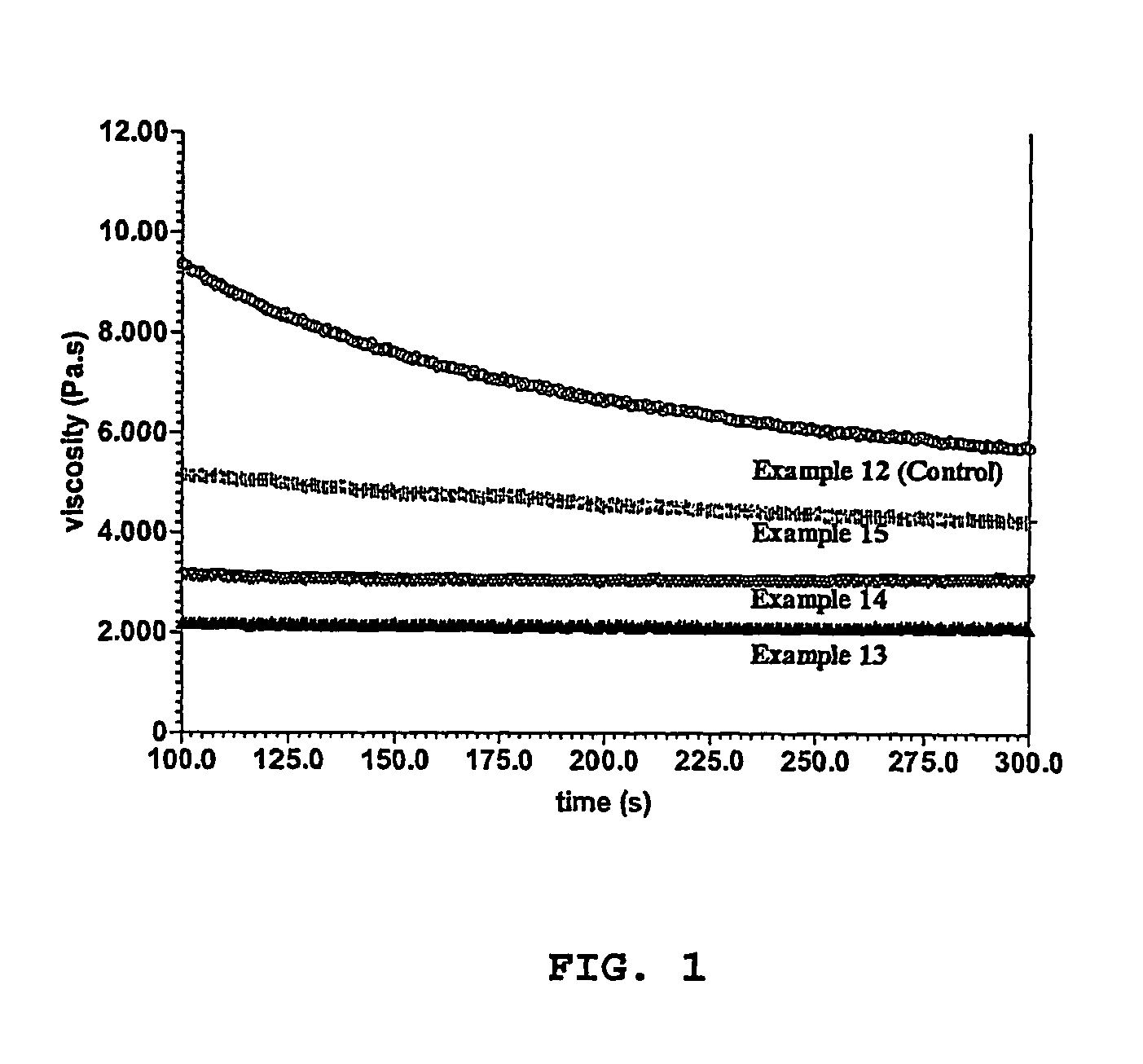

Soap bar compositions comprising alpha sulfonated alkyl ester or sulfonated fatty acid and synthetic surfactant and processes for producing same

InactiveUS20050153853A1PerformanceProcessingInorganic/elemental detergent compounding agentsCosmetic preparationsHardnessSynthetic surfactant

A composition suitable for use in personal cleaning or detergent soap bars, which includes a sulfonated fatty acid or alpha sulfonated alkyl ester and a secondary synthetic surfactant, and methods for producing such a composition. The composition and methods exhibit efficient processing and allow for formation of cleansing or detergent bars with improved hardness, improved resistance to marring and improved processability, lowered wear-rate and decreased mush formation during consumer use.

Owner:STEPAN COMPANY

Optical device

ActiveUS20120262639A1Increased durabilityStable light division propertyLiquid crystal compositionsPolarising elementsOpticsPhysics

Owner:LG CHEM LTD

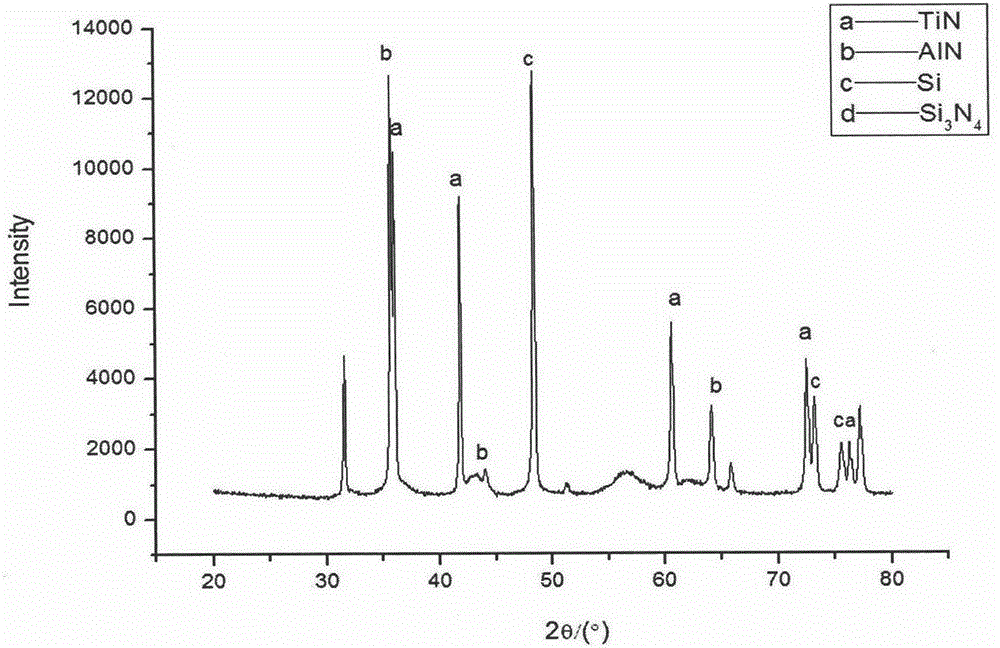

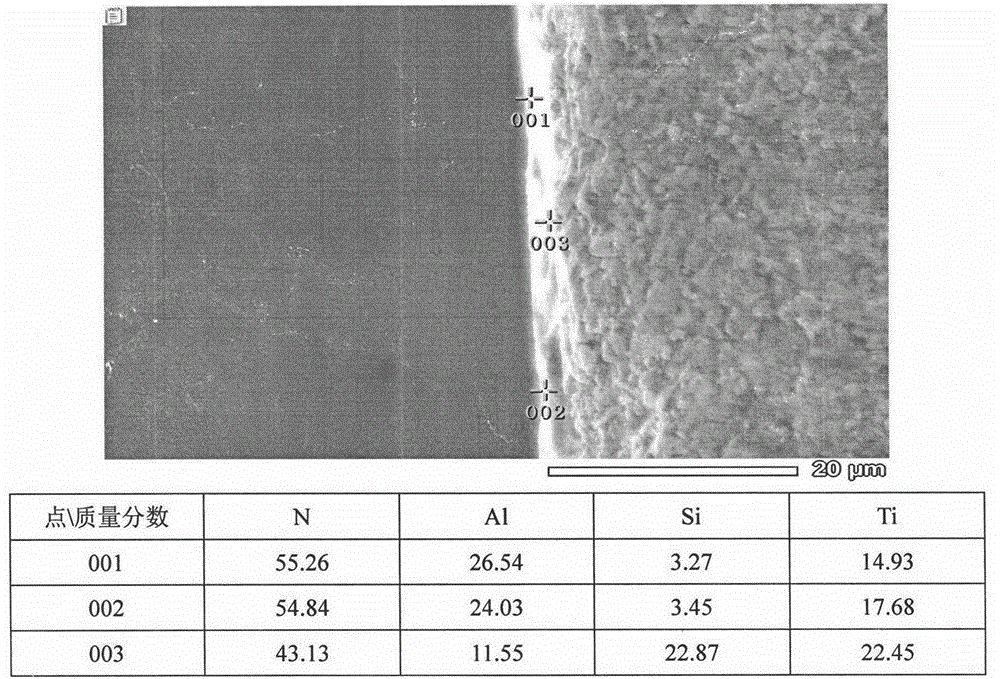

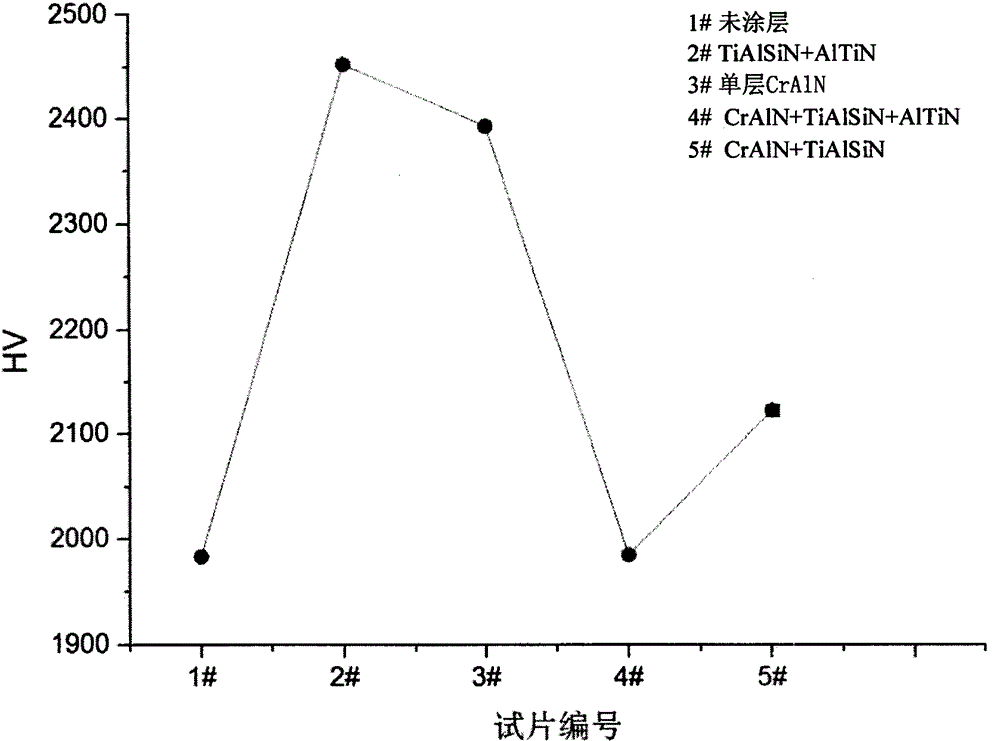

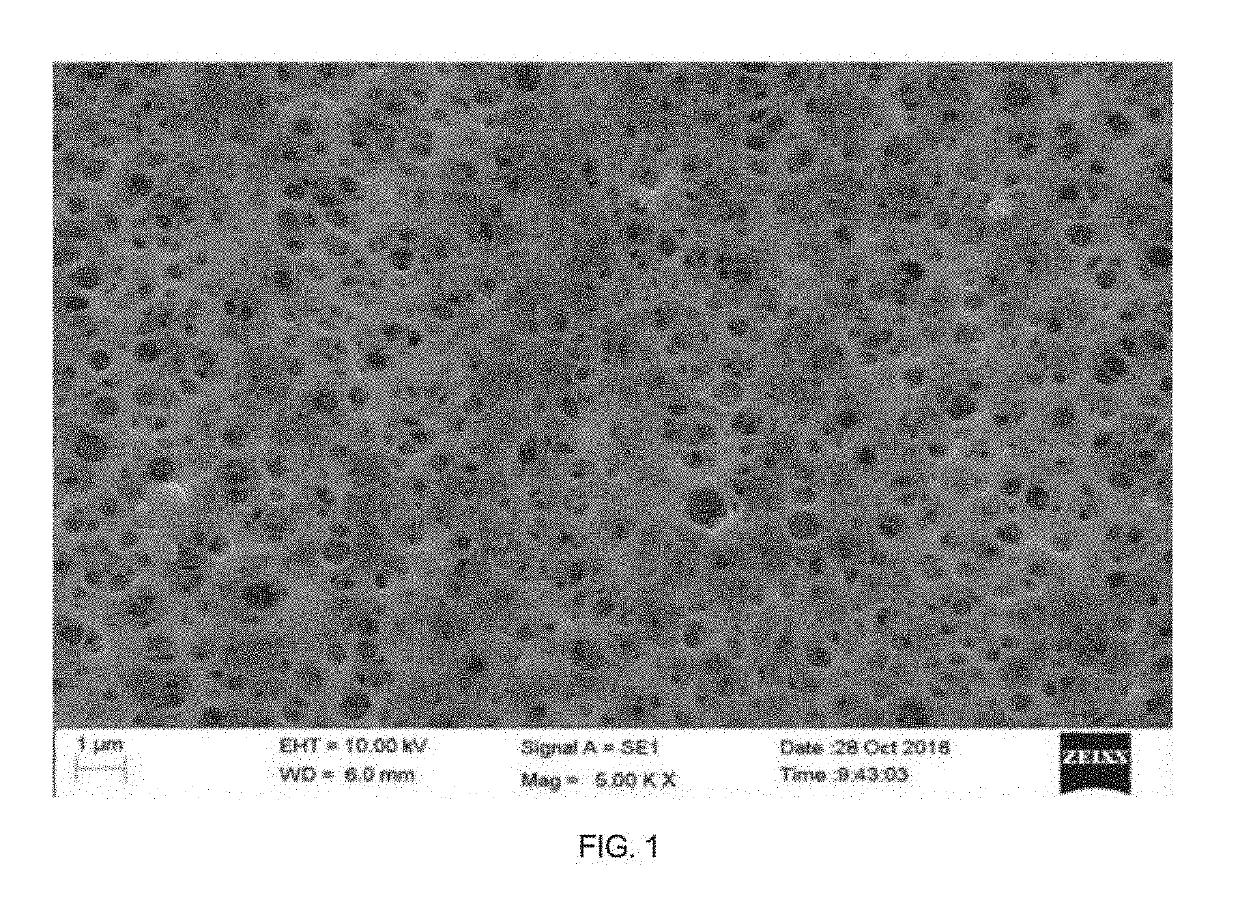

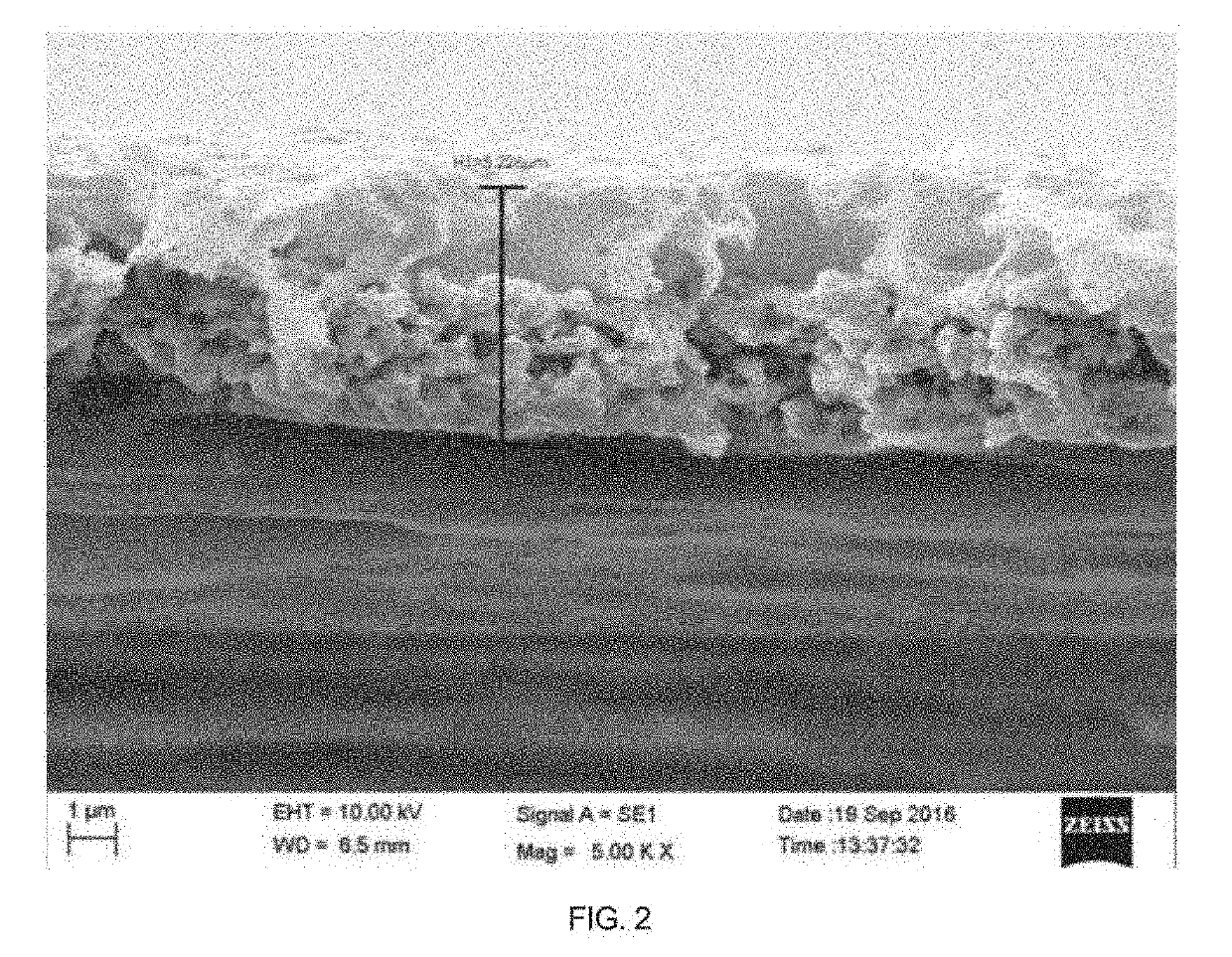

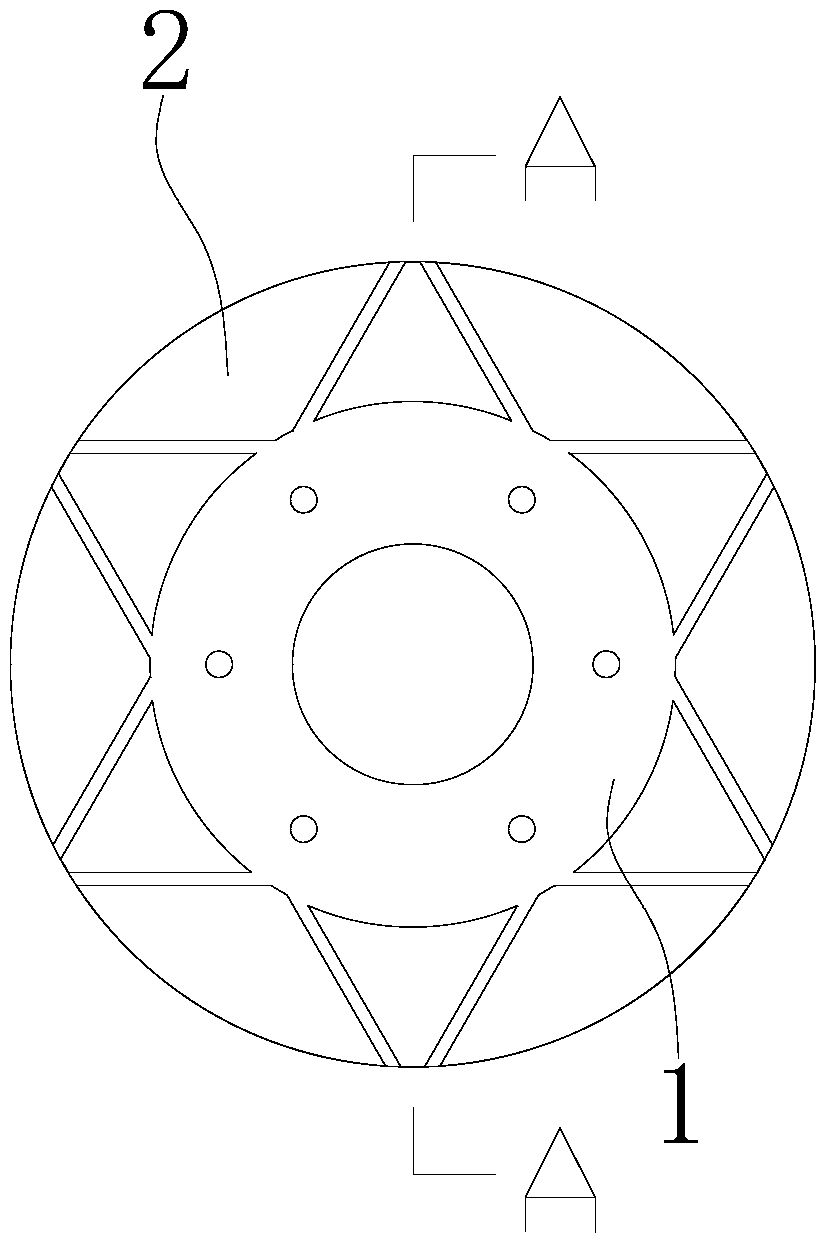

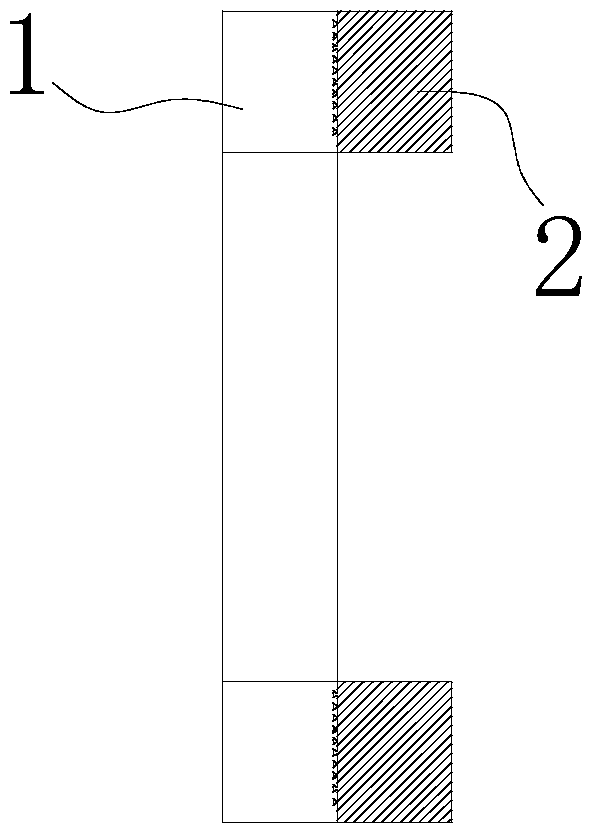

TiAlSiN-AlTiN composite coating and preparation process thereof

InactiveCN106480417AImprove hardness performanceExtended service lifeVacuum evaporation coatingSputtering coatingComposite filmPulse power supply

The invention relates to a TiAlSiN-AlTiN composite coating and a preparation process thereof. According to the TiAlSiN-AlTiN composite coating, a substrate is pre-treated, the pre-treated substrate is placed into electric arc and magnetron sputtering composite film plating equipment, a circular arc Ti target is adopted as a Ti source, the sputtering rate of the circular Ti target is controlled through a circular arc power supply current, a circular arc AlTi target is adopted as an AlTiN coating corresponding element source, the atom ratio of Al to Ti (Al / Ti) is 67 / 33, an AlTiSi target is adopted as a TiAlSiN coating corresponding element source, and the atom ratio of Al to Ti to Si (Al / Ti / Si) is 60 / 30 / 10; 12 pairs of the circular arc sources are spirally arranged on the periphery of the wall of a vacuum cavity, and by adjusting the power of a medium frequency pulse power supply to control the sputtering rate of the target, based on different coatings, the background vacuum is 5*-<3>pa before the coating, and the rotating is the 3-dimensional rotating at a speed of 2 r / min; high-purity Ar is adopted as a main ionization gas so as to ensure an effective glow discharge process; high-purity N2 is adopted as a reaction gas and is ionized, and the ionized N2 is combined with Ti, Si and Al so as to deposit on the substrate surface and form the TiAlSiN-AlTiN composite coating; and the prepared TiAlSiN-AlTiN coating has the thickness of about 3.5 [mu]m, the microhardness of 24.5 GPa, and high hardness.

Owner:刘涛 +2

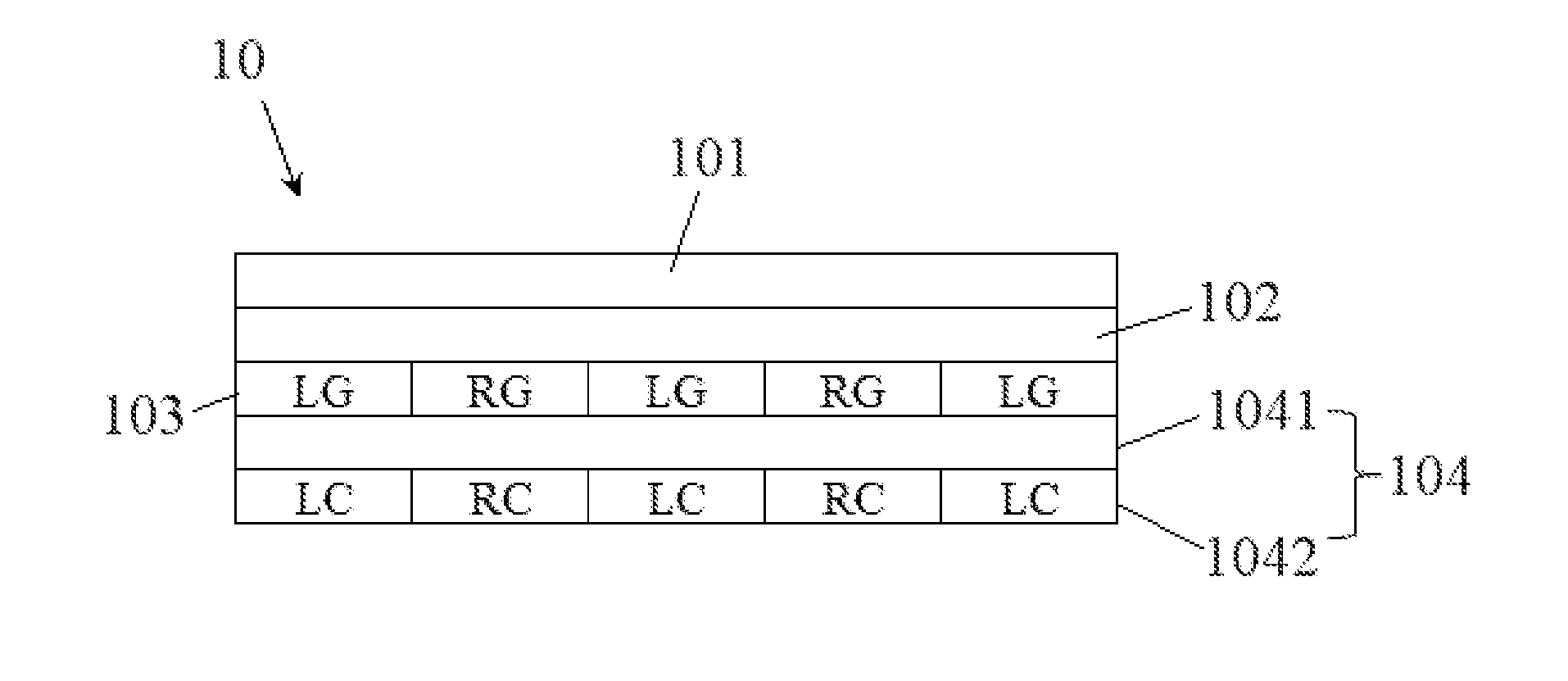

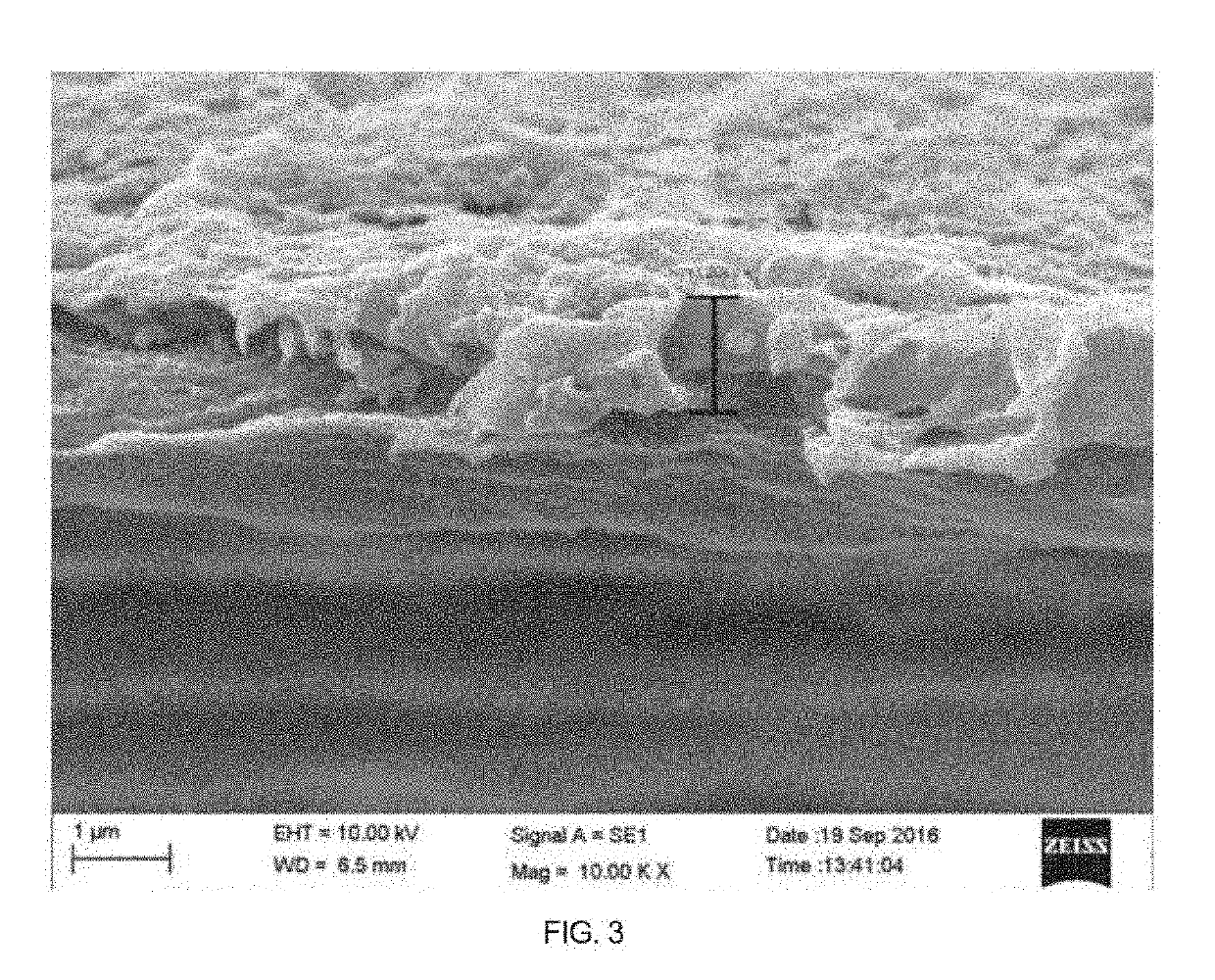

Ceramic-and-Polymer-Compositely-Coated Lithium Ion Separator and Preparation Method Therefor

PendingUS20190245182A1Improve resistance performanceImprove hardness performanceCell component detailsSecondary cells servicing/maintenanceDislocationBonding strength

Disclosed are a ceramic and polymer compositely coated lithium ion separator and a preparation method therefor. The ceramic and polymer compositely coated lithium ion separator comprises a polyolefin porous membrane, a ceramic coating coated onto one or both sides of a membrane surface, and a polymer coating coated onto a ceramic surface or the membrane surface. The composite separator prepared in the present disclosure significantly enhances heat resistance of the separator and bonding strength thereof with positive and negative pole pieces, improves the wettability of an electrolyte, can effectively prevent an internal short circuit due to layer dislocation between the separator and the electrodes, and also improves hardness and safety performance of the battery. Further disclosed is a method for preparing the ceramic and polymer compositely coated lithium ion separator, which method enables the preparation of a separator having even coating thickness of the ceramic coating and the polymer coating and good uniformity, and is favorable for continuous and large-scale production.

Owner:SHENZHEN SENIOR TECH MATERIAL

Soap bar compositions comprising alpha sulfonated alkyl ester or sulfonated fatty acid and synthetic surfactant and process for producing the same

InactiveUS20070004611A1Easy to processGood foaming effectInorganic/elemental detergent compounding agentsAnionic surface-active compoundsHardnessSynthetic surfactant

A composition suitable for use in personal cleaning or detergent soap bars, which includes a primary surfactant comprising a sulfonated fatty acid, an alpha sulfonated alkyl ester, or a mixture thereof, and a secondary synthetic surfactant, and methods for producing such a composition. The composition and methods exhibit efficient processing and allow for formation of cleansing or detergent bars with improved hardness, improved resistance to marring, improved processability, lower wear-rate and decreased mush formation during consumer use.

Owner:OSPINAL CARLOS E +2

Soap Bar Compositions Comprising Alpha Sulfonated Alkyl Ester or Sulfonated Fatty Acid and Synthetic Surfactant and Process for Producing the Same

InactiveUS20080058236A1PerformanceProcessingInorganic/elemental detergent compounding agentsCosmetic preparationsHardnessSynthetic surfactant

A composition suitable for use in personal cleaning or detergent soap bars, which includes a primary surfactant comprising a sulfonated fatty acid, an alpha sulfonated alkyl ester, or a mixture thereof, and a secondary synthetic surfactant, and methods for producing such a composition. The composition and methods exhibit efficient processing and allow for formation of cleansing or detergent bars with improved hardness, improved resistance to marring, improved processability, lower wear-rate and decreased mush formation during consumer use.

Owner:OSPINAL CARLOS E +2

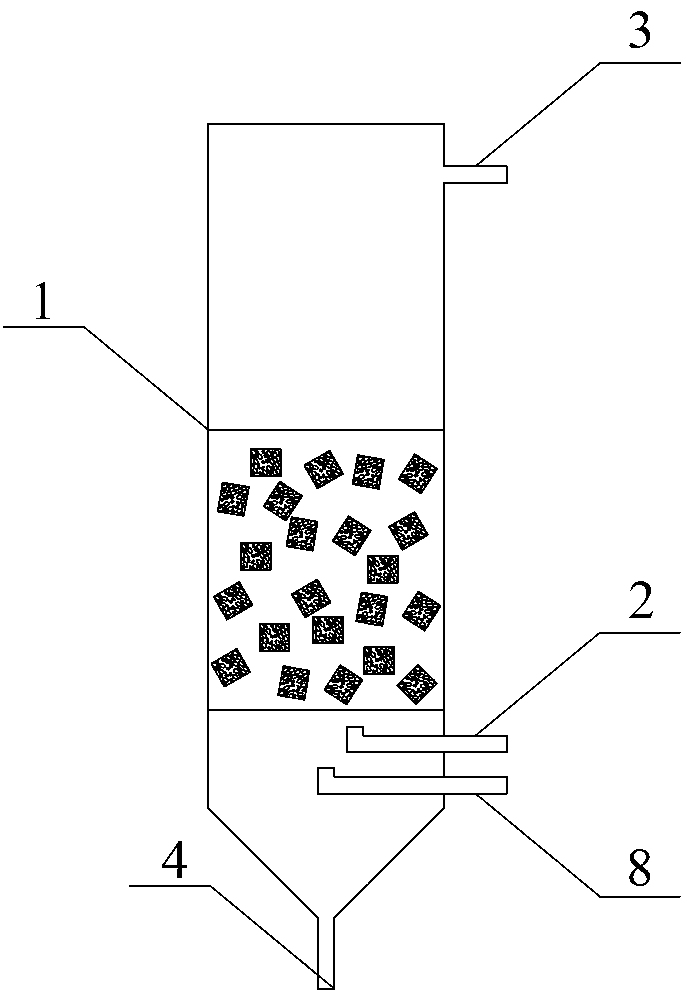

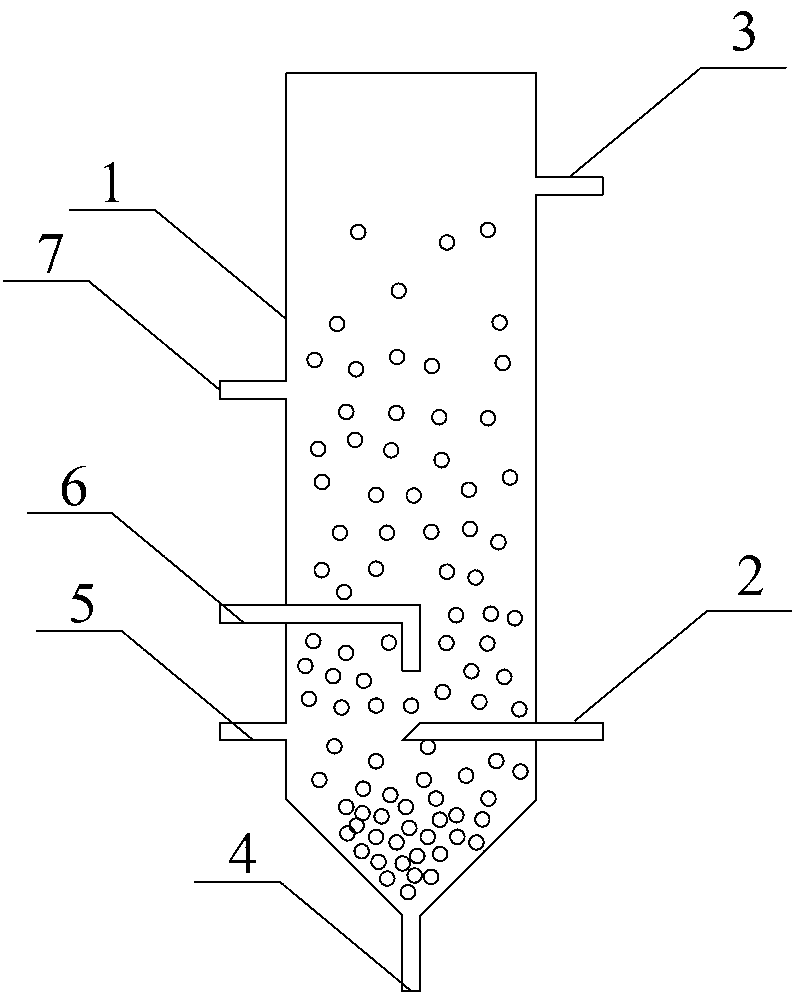

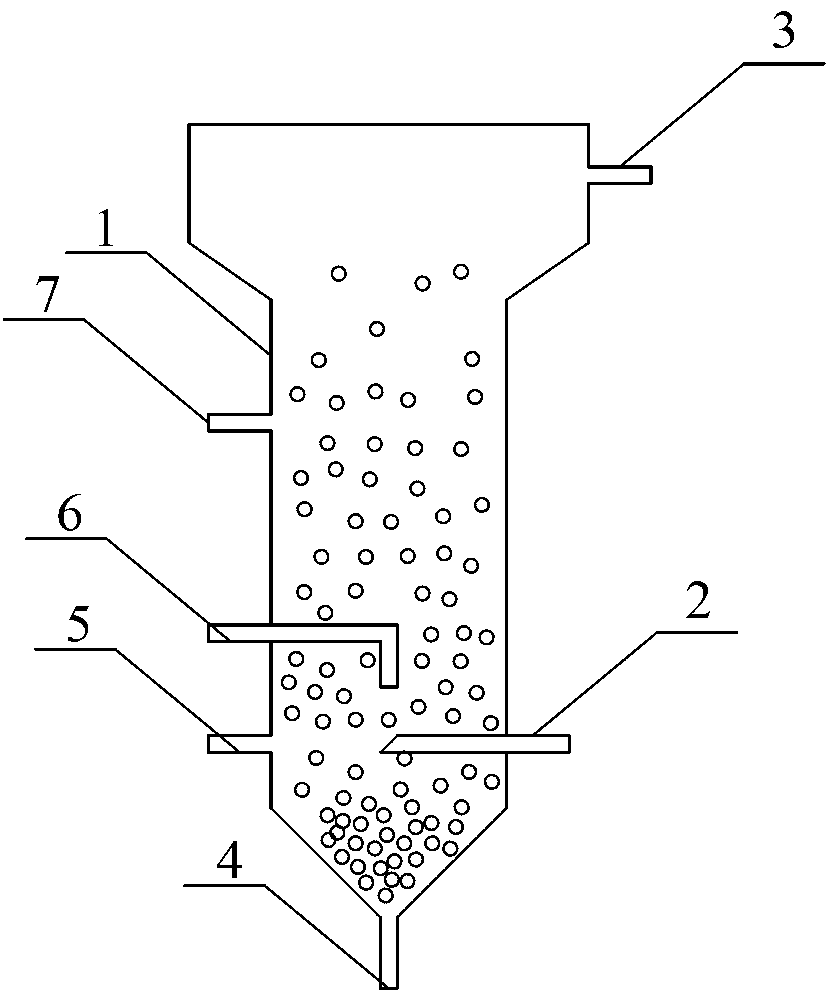

Industrial wastewater treatment device and treatment method

ActiveCN103011426AImprove hardness performanceSimple structureScale removal and water softeningFlocculationIndustrial effluent

The invention relates to an industrial wastewater treatment device and a treatment method. The device comprises a reactor body, a water inlet pipe, a water outlet pipe, a blow-off pipe and the like, wherein the reactor body is filled with a filler. According to the device and the method, inorganic ions in the industrial wastewater are crystallized and precipitated, and grow on the surface of the filler to form heterogeneous crystallization, so that the inorganic ions in the industrial wastewater are removed effectively; and the treated qualified waste water is discharged out of the reactor from the water outlet pipe. Water treatment can be conducted continuously through a method such as filler supplementing or filler regeneration. Compared with a conventional treatment method, the device does not need flocculation, precipitation or other units; no sludge is produced; and the device has the advantages that treatment speed and removing efficiency are high, secondary pollution cannot be caused easily, so as to have a broad prospect in actual industrial application.

Owner:BEIJING NOVEL ENVIRONMENTAL PROTECTION

Method for obtaining micro-nano SiO2 particle containing coating on surface of aluminium and aluminium alloy

ActiveCN102899644ASolve the hardnessSolve wear resistanceLiquid/solution decomposition chemical coatingMicro nanoChemical plating

A method for obtaining a micro-nano SiO2 particle containing coating on a surface of aluminium and aluminium alloy. Samples are firstly subjected to alcohol immersing, chemical removing for oil and alkali, acid erosion, water washing and zinc dipping, and finally pre-treated by acetone and alcohol ultrasonic cleaning; SiO2 nanometer particles are placed in a non-ionic surface active agent OP-21 to immerse; and then the samples are subjected to composite chemical plating and washed by cold water to obtain the finished product. The method is reasonable in technology and easy to operate, can produce the coating just by using equipment of traditional nickel-phosphorous chemical plating technology, and has relatively good economic benefit and popularization prospect. The obtained coating is compact and firm, and has advantages of good combinability, uniform surface, high hardness, wear resistance, heat resistance and high comprehensive properties; and hardness and wear resistance of the obtained coating are all higher than that of single nickel-phosphorus coatings. The active agent is nontoxic, environmentally-friendly, highly-efficient, simple in formula, easy to operate and low in cost.

Owner:柳州一阳科技股份有限公司

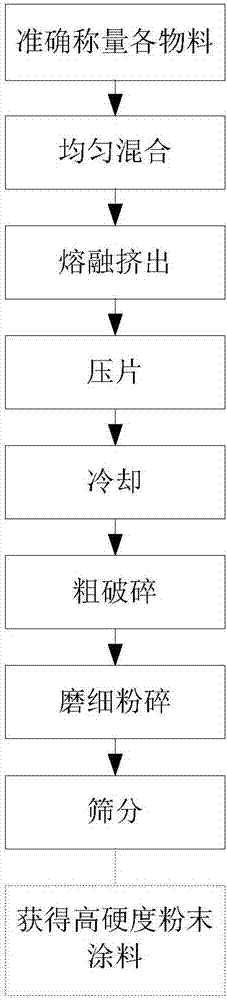

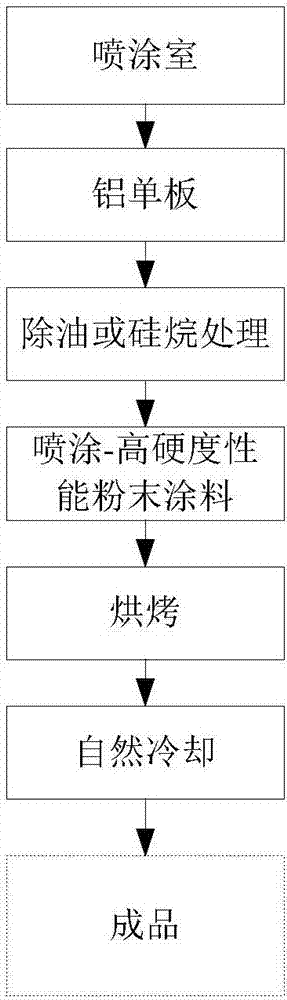

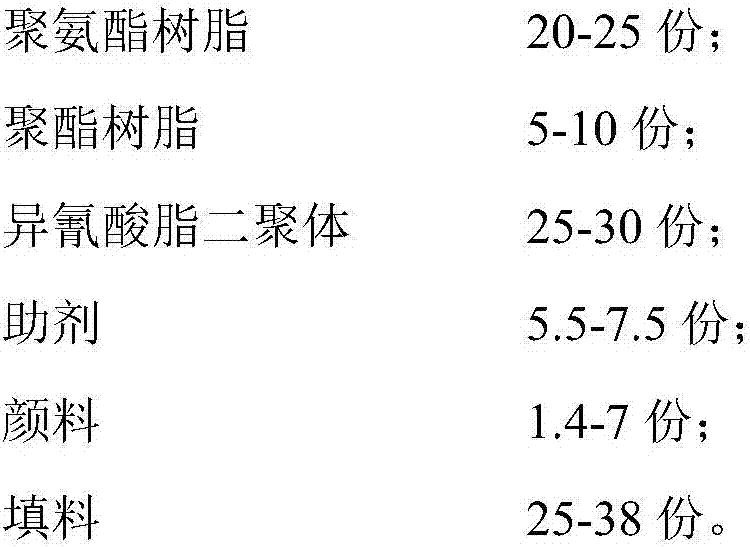

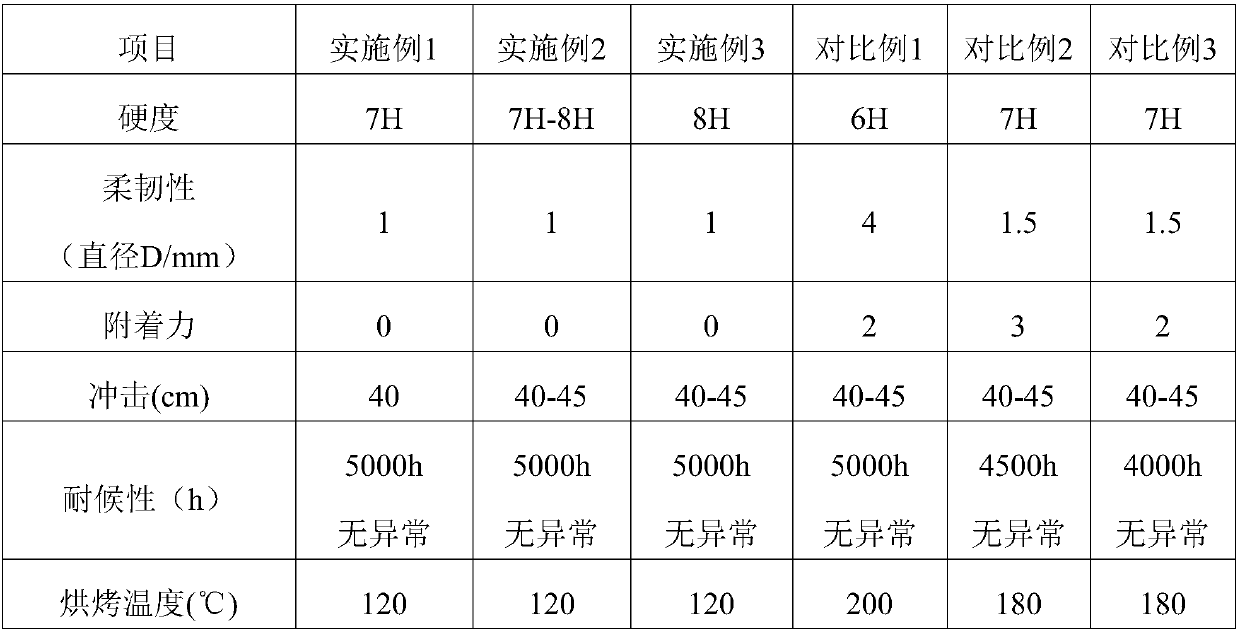

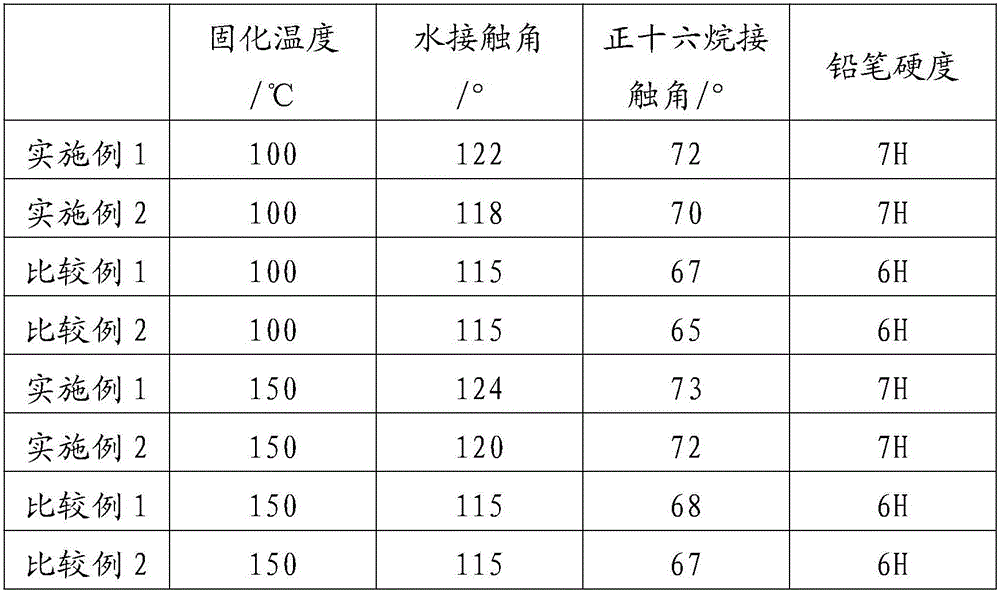

High-hardness powder coating as well as preparation method and application thereof

ActiveCN107254249AImprove hardness performanceImprove adhesionPolyurea/polyurethane coatingsPowdery paintsPolyester resinHardness

The invention discloses a high-hardness powder coating which comprises the following components in parts by weight: 20-25 parts of polyurethane resin, 5-10 parts of polyester resin, 25-30 parts of an isothiocyanate dipolymer, 5.5-7.5 parts of aids, 1.4-7 parts of pigment and 25-38 parts of a filler. The invention further discloses a preparation method of the high-hardness powder coating. The preparation method comprises the following steps: uniformly mixing 20-25 parts of the polyurethane resin, 5-10 parts of the polyester resin, 25-30 parts of the isothiocyanate dipolymer, 5.5-7.5 parts of the aids, 1.4-7 parts of the pigment and 25-38 parts of the filler, performing melting extrusion, tabletting, cooling, performing rough crushing and fine crushing in sequence, and screening, thereby obtaining the high-hardness powder coating. The high-hardness powder coating disclosed by the invention is excellent in hardness performance for a base material, optimal in adhesion property to the base material, good in binding property and hardness for the base material and very good in scratch resistance effect.

Owner:NIPPON PAINT TIANJIN +1

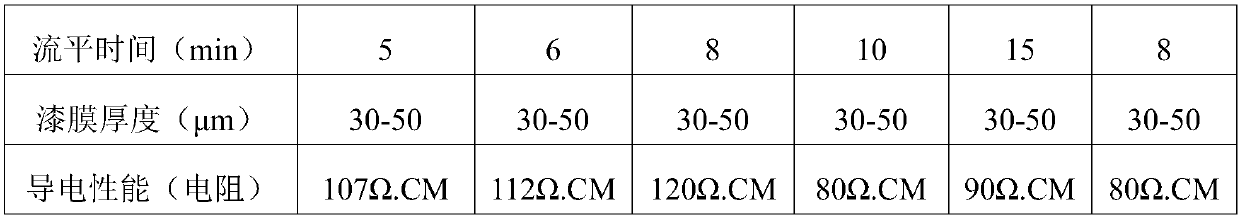

Waterborne multifunctional paint for electrical appliance and preparation method thereof

ActiveCN107629593AImprove conductivityImprove hardness performanceElectrically-conductive paintsWater basedEmulsion

The invention provides a waterborne multifunctional paint for electrical appliance. The waterborne multifunctional paint comprises nano glass resin, a water-based hydroxyl acrylic emulsion, amino resin, organic silicone powder, superconductive carbon black, acetylene carbon black, graphene and carbon nanotube. Specifically, the mass ratio of the superconductive carbon black, acetylene carbon blackand graphene and the mass of carbon nanotube are in a ratio of 8-11 / 1. According to the invention, the paint emulsion is added with organic silicone powder, superconductive carbon black, acetylene carbon black, graphene and carbon nanotube in the paint emulsion to form a paint film with a conductive network structure, thus realizing anti-explosion, antistatic and self-cleaning functions.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

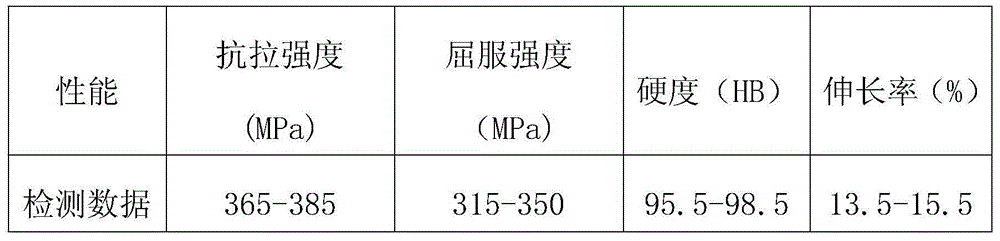

Material of cylinder body of pneumatic actuating mechanism and preparation method thereof

ActiveCN104975206AImprove hardness performanceImprove corrosion resistanceManufacturing technologyWear resistant

The invention relates to a material of the cylinder body of a pneumatic actuating mechanism and a preparation method thereof. The material is composed of the following components in percentage by weight: 0.4 to 0.7% of Fe, 1 to 2.5% of Cu, 0.6 to 1.0% of Mg, 0.15 to 0.2% of Mn, 1 to 2% of Ni, 1.5 to 2.5% of Zn, 0.4 to 0.6% of B2O3, 1.5 to 2.5% of SiO2, 1 to 3% of TiC, and the balance being Al. The cylinder body is prepared by the following steps of blank preparation, blank pretreatment, mould pretreatment, forging and stamping, and moulding. The prepared cylinder body has the characteristics of high hardness, good corrosion resistant performance, little thermal expansion coefficient, low friction index, and high wear resistant performance. At the same time, the manufacture technology is improved to enable the cylinder body to have a good mechanical performance.

Owner:WUXI CHENGTIANNUO ACTUATOR MFG CO LTD

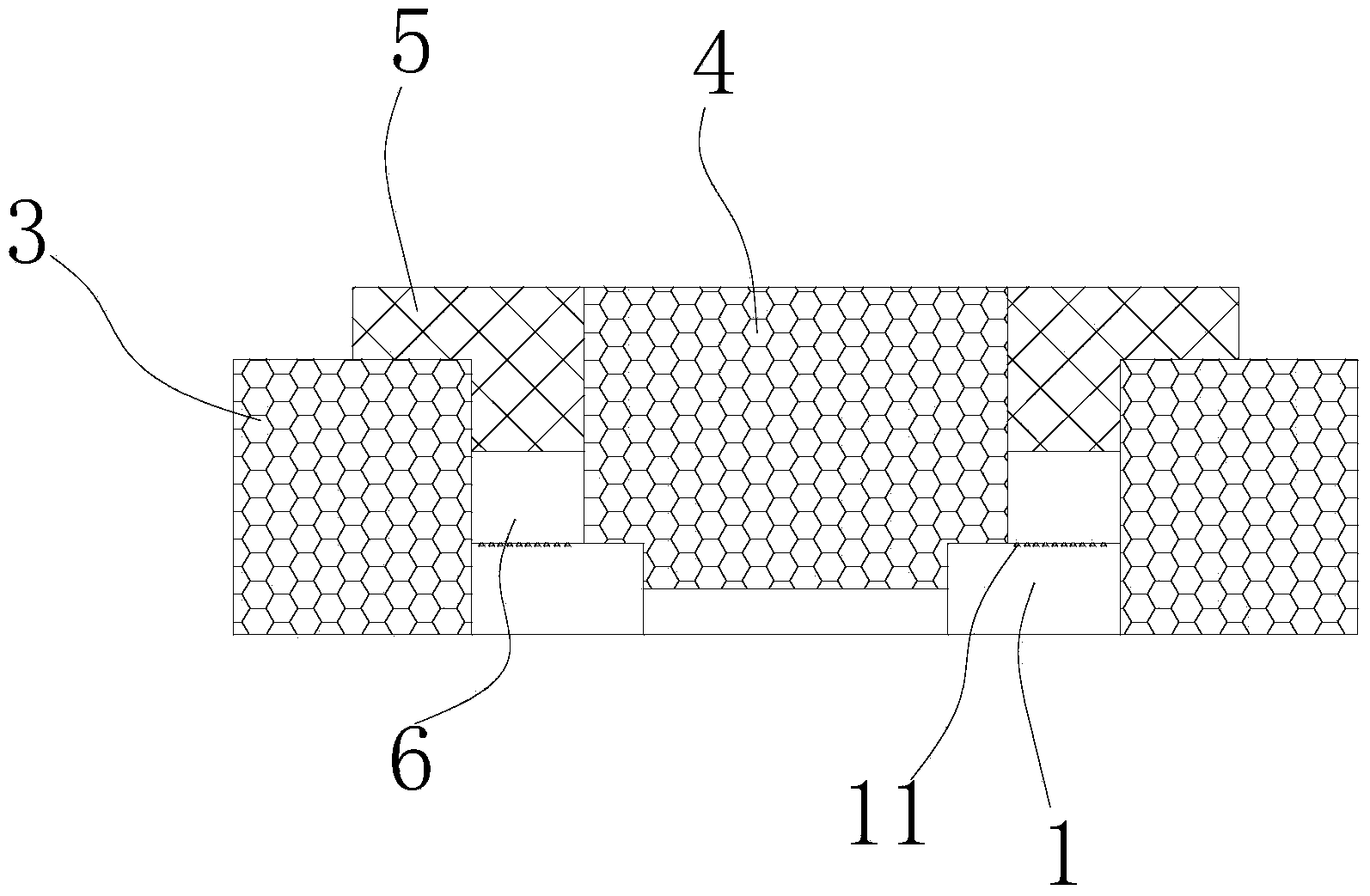

Dry grinding wheel and manufacturing method thereof

InactiveCN103962977AMaterials are readily availableImprove hardness performanceAbrasion apparatusGrinding devicesPolyvinyl alcoholPolyvinyl chloride

The invention discloses a dry grinding wheel. The dry grinding wheel comprises a substrate and a grinding head arranged on the substrate. The grinding head is prepared from, by weight, 130 parts to 200 parts of diamond, 100 parts to 130 parts of silicon carbide, 60 parts to 100 parts of polyvinyl chloride resin powder, 5 parts to 10 parts of coupling agents, 200 parts of silicon carbide micro powder, 10 parts to 20 parts of anti-abrasion agents, and 60 parts to 100 parts of polyvinyl alcohol gelatine powder. The invention discloses a manufacturing method of the dry grinding wheel. The raw materials are weighed according to the formula of the grinding head, then, an evenly mixed mixture is obtained through the mixing technology, and finally the dry grinding wheel is obtained through the forming technology. The dry grinding wheel has the advantages that the materials are easy to obtain, grinding sharpness and hardness performance of a grinding wheel matrix are good, and the service life is long. The manufacturing method has the advantages of being low in sintering temperature, low in manufacturing cost and capable of achieving energy conservation and environmental protection.

Owner:FOSHAN DINGSHUN TECH CO LTD

Manufacturing method of self-drilling anchor rod bit

InactiveCN103028720AImprove hardness performanceDrilling speed is fast and wear-resistantTurbinesOther manufacturing equipments/toolsElemental compositionAlloy

The invention discloses a manufacturing method of a self-drilling anchor rod bit, and belongs to a production method of an anchor rod. The manufacturing method comprises the following steps that: a cemented carbide material briquette is placed in a casting mold of the anchor rod bit, and molten iron or molten steel is injected into the casting mold; and after the molten iron or molten steel is cooled in the mold, a shape of a matrix of the anchor rod bit is formed, and the matrix is in fusion welding with the cemented carbide material briquette into a whole. According to the nominal content of each elemental composition, the iron-based cemented carbide briquette formed by uniformly mixing and sintering tungsten carbide particles, vanadium pentoxide, colloidal graphite, diamond particles with iron matrix pre-alloy powder can replace the traditional cemented alloy manufactured by metal cobalt and tungsten carbide which are adhered to each other to prepare the self-drilling anchor rod bit. The blade of the anchor rod bit is in fusion welding on the matrix directly, and the subsequent mechanical processing of the anchor rod bit is not needed; and meanwhile, the operation of the method is simple, the production efficiency of the anchor rod bit is obviously improved, and the production cost is effectively reduced because of using the iron-based cemented carbide briquette.

Owner:CHENGDU MODERN WANTONG ANCHOR TECH +1

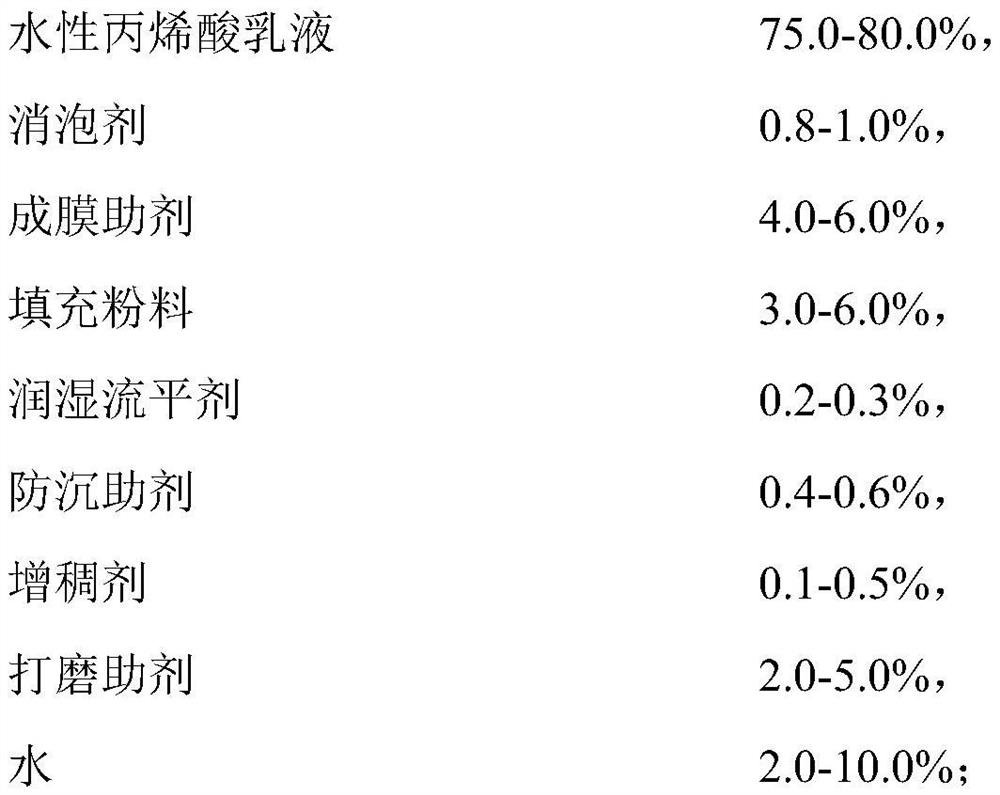

High-hardness and quick-drying water-based two-component filling clear primer and preparation method thereof

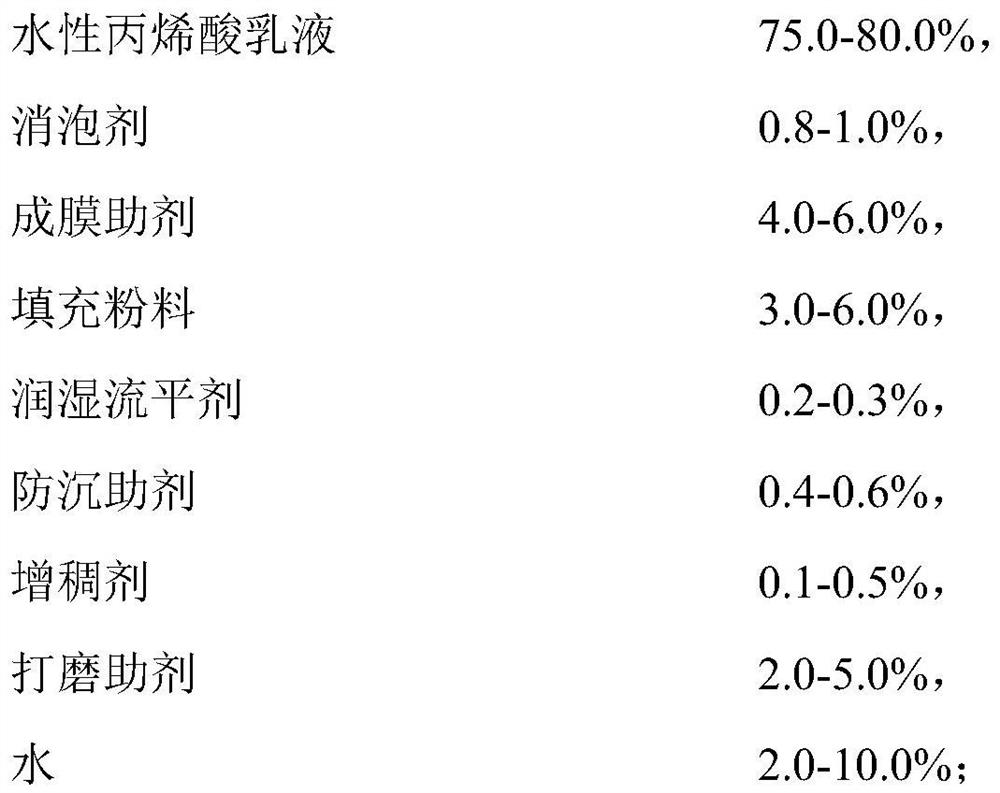

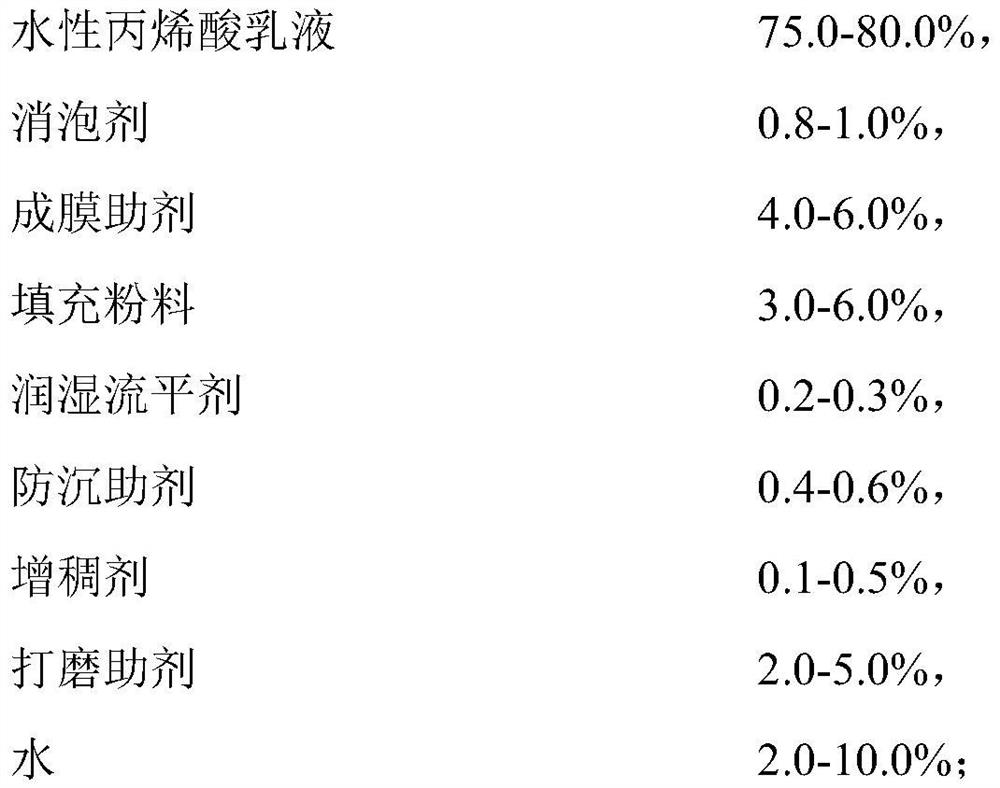

InactiveCN111961398AHigh hardnessHigh molecular weightPolyurea/polyurethane coatingsPriming paintsSolid woodPolymer science

The invention provides a high-hardness and quick-drying water-based two-component filling clear primer. The high-hardness and quick-drying water-based two-component filling clear primer comprises a component A and a component B which are uniformly mixed according to an equivalent ratio of n (-NCO) to n (-OH) of 1.5-1.8, wherein the component A is prepared from the following components in percentage by weight: 75.0 to 80.0 percent of water-based acrylic emulsion; 0.8%-1.0% of an antifoaming agent, 4.0%-6.0% of a coalescing agent, 3.0%-6.0% of filling powder, 0.2%-0.3% of a wetting leveling agent, 0.4%-0.6% of an anti-settling agent, 0.1%-0.5% of a thickener, 2.0%-5.0% of a polishing agent and 2.0%-10.0% of water. And the component B is prepared from the following components in percentage byweight: 30%-40% of modified IPDI polyisocyanate and 60%-70% of modified HDI polyisocyanate. The -OH in the primer emulsion component and -NCO in the curing agent component are subjected to a deep cross-linking reaction to generate a urethane bond, the coating film is compact, and the hardness of the paint film is improved. In addition, the minimum film forming temperature MFFT is larger than or equal to 30 DEG C, the high drying speed is provided for a product system, and the requirement for changing oil into water in solid wood paint can be met; the invention also provides a preparation method of the water-based two-component filling clear primer.

Owner:HUIZHOU CHANGRUNFA PAINT

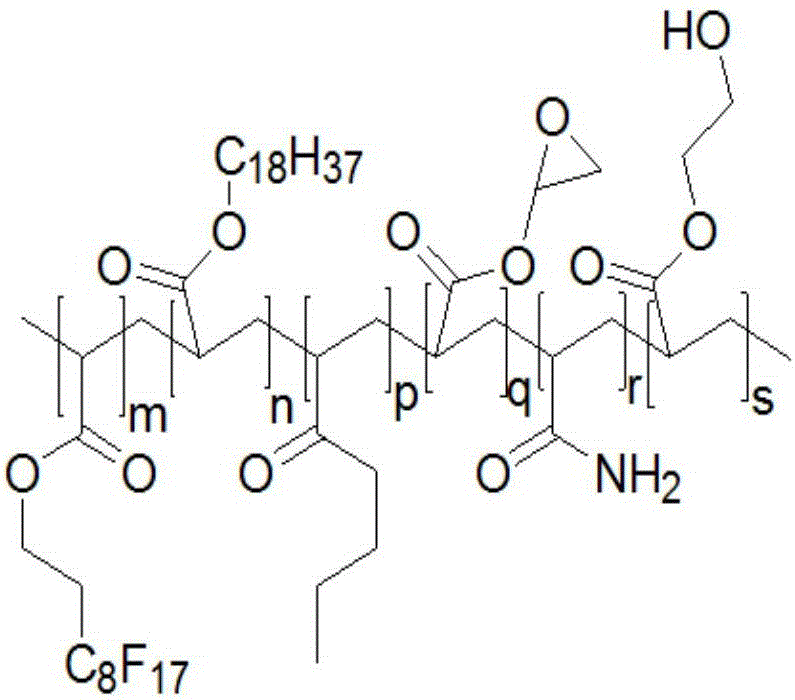

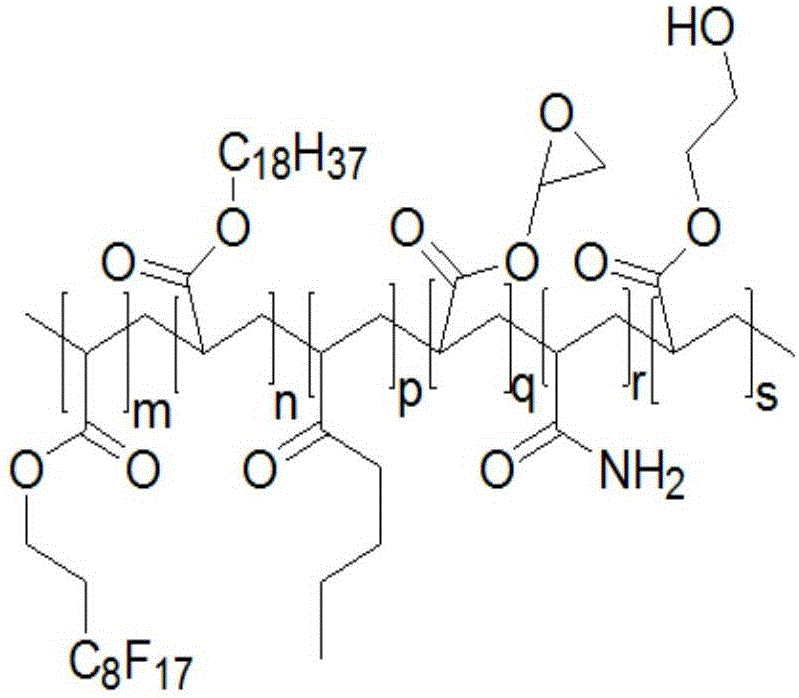

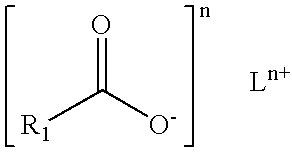

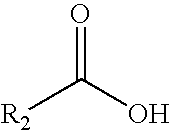

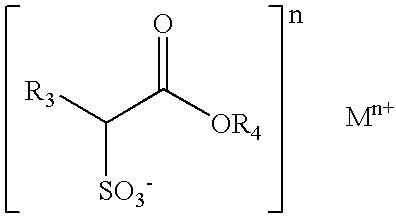

Fluorine-containing polymer, waterproof and oil-proof treating agent, preparation method of waterproof and oil-proof treating agent and protection film

The invention provides a fluorine-containing polymer, a waterproof and oil-proof treating agent, a preparation method of the waterproof and oil-proof treating agent and a protection film. The fluorine-containing polymer comprises a fluorine-containing monomer (a) and a crosslinking monomer (b), wherein the fluorine-containing monomer (a) and the crosslinking monomer (b) are polymerized under the existence of a polymerization initiator and a chain transfer agent; the general formula (I) of the fluorine-containing monomer (a) is CH2=C(-X)-C(=O)-Y-Z-Rf; the crosslinking monomer (b) is a compound with at least two carbon-carbon double bonds or a compound with at least one carbon-carbon double bond and at least one reaction group. After the waterproof and oil-proof treating agent containing the fluorine-containing polymer is used for treating the protection film, the obtained protection film has excellent hardness performance and better waterproof and oil-proof performance; the dirt residue since fingers contact the surface of the protection film can be reduced.

Owner:GUANGZHOU LEHMAN BROS ELECTRONICS TECH CO LTD

Preparation method for architectural glass heat insulation coating

InactiveCN105131743AGood weather resistanceGood chemical resistanceHyaluronic acid coatingsChitin coatingsArchitectural glassAntioxidant

The invention provides a preparation method for an architectural glass heat insulation coating. The preparation method includes the steps that ATO nanometer powder, lecithin, triethoxy-1H,1H,2H,2H-tridecafluoro-n-octylsilane and dioctyl sodium sulfosuccinate are added into deionized water and stirred, then silicon carbide whiskers are added, a sodium hydroxide solution with the mass concentration of 1% is dripped on the stirring condition, stirring continues to be carried out until no precipitation is generated, and precipitation is filtered, washed with deionized water and dried to obtain heat insulation powder; the heat insulation powder, SiO2 particles and a silane coupling agent KH-570 are mixed, and the mixture is ground on a ball grinder to obtain functional powder; the functional powder, polytetrafluoroethylene wax powder, perchlorovinyl resin, zinc phosphate, polyacrylamide, mannitol, chitosan, an uvioresistant agent and an antioxidant are mixed and stirred to obtain the architectural glass heat insulation coating. The coating has excellent weather resistance, chemical resistance, waterproof performance and hardness performance.

Owner:江苏耀兴安全玻璃有限公司

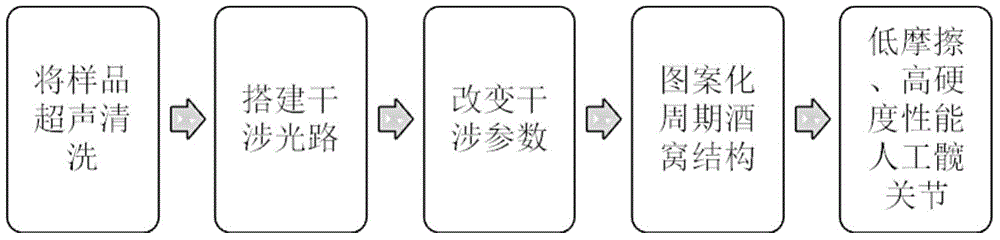

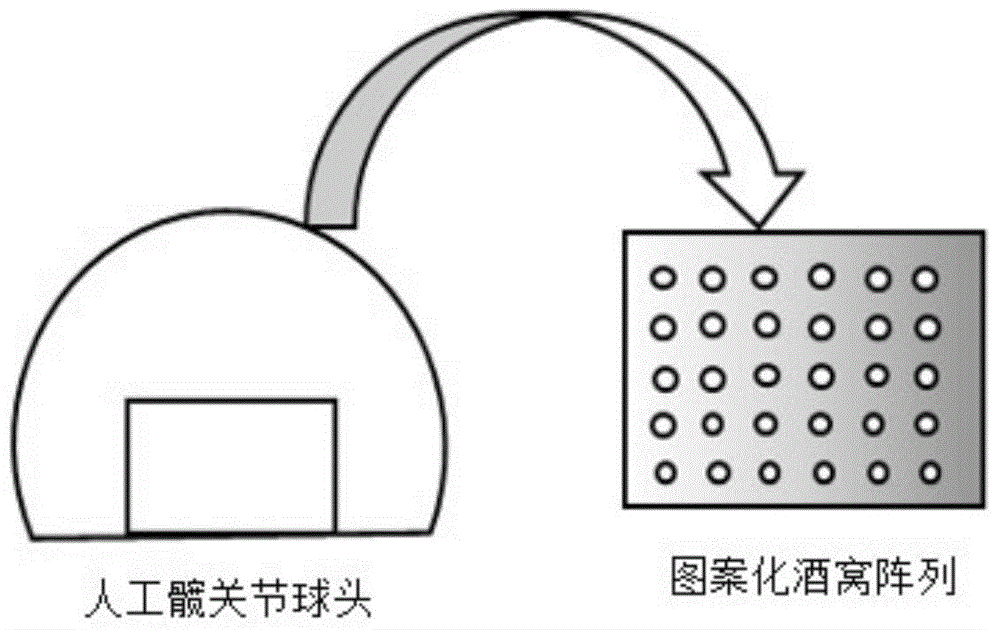

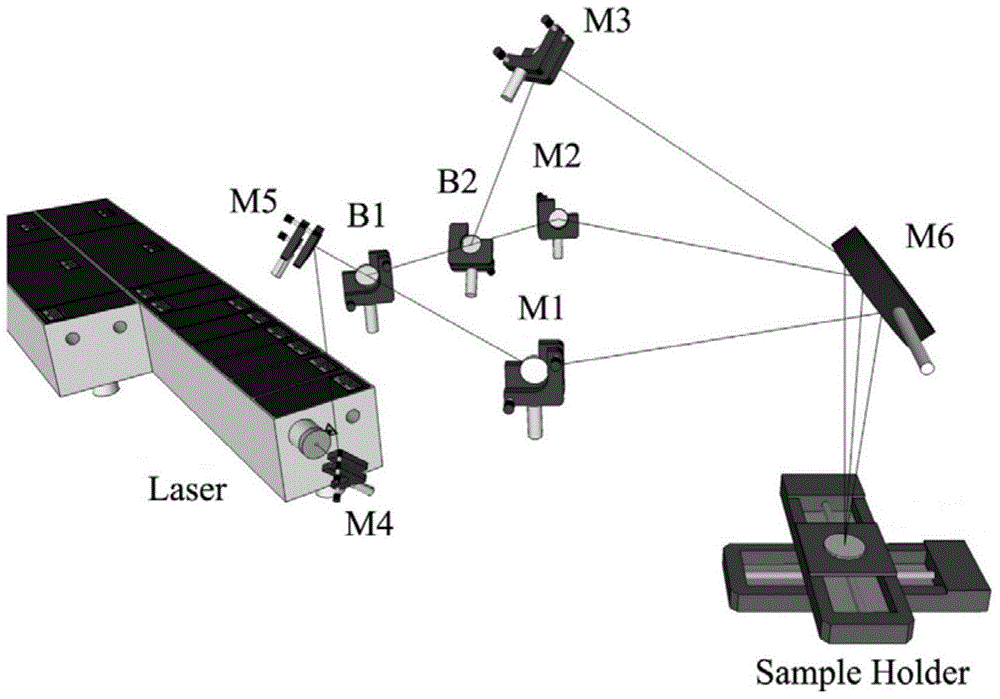

Method for preparing low-friction and high-hardness artificial hip joint ball through surface patterning

ActiveCN105055050AImprove tribological performanceHigh hardnessJoint implantsHip jointsFriction effectTissue fluid

The invention relates to a method for preparing a low-friction and high-hardness artificial hip joint ball through surface patterning. The low-friction and high-hardness artificial hip joint ball is made from a CO-Cr-Mo alloy material, and the method is characterized in that patterned dimple arrays are formed on the surface of the artificial hip joint ball, namely the patterned dimple arrays are made on the friction surface of the artificial hip joint ball through laser interferometric lithography to form a small temporary synovial fluid or tissue fluid storage device, and meanwhile the actual contact area between friction pairs is decreased and abrasive grains produced in the friction process are accommodated to achieve the friction-reducing purpose. The instantaneous high temperature of laser enables the grains to be refined, the material hardness is enhanced, and the artificial hip joint with low friction and high hardness is obtained. The low-friction and high-hardness artificial hip joint ball has good lubricating property and can reduce the friction effect between interfaces of the friction pairs of the artificial hip joint and reduce friction. In addition, the hardness is improved, the abrasion is reduced, and the friction and abrasion resisting performance of an existing artificial hip joint ball is optimized.

Owner:CHANGCHUN UNIV OF SCI & TECH

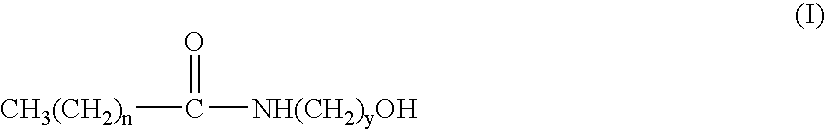

Soap bar compositions comprising alpha sulfonated fatty acid alkyl estersand polyhydridic alcohols and process for producing same

InactiveUS20050124515A1Easy to processGood foaming effectInorganic/elemental detergent compounding agentsCosmetic preparationsAlcoholPolyol

Disclosed are improved cleaning compositions comprising soap&com ma; fatty acid, synthetic detersive surfactant, salt and a polyhydridic alcohol, which are suitable for formation into precursor cleansing / laundry bar “soap noodles,” personal cleansing bars and laundry detergent bars. The compositions comprise: (a) from about 58% to about 93% by weight of an approximately 70% aqueous soap slurry; (b) from about 1% to about 15% by weight of a fatty acid; (c) from about 2% to about 30% by weight of an approximately 55% aqueous mixture of anionic surfactants comprising i) an alpha sulfonated alkyl ester, and ii) a sulfonated fatty acid or salts thereof, wherein the ratio of i) to ii) is from about 10:1 to about 1:10; (d) from about 0.5% to about 2% by weight of a salt; (e) from about 0.5% to about 5% by weight of a 25 polyhydridic alcohol; and (f) from 0 to about 10% by weight of an alkanolamide of the formula O CH3(CH2)nCNH(CH2)yOH wherein n=6-16, and y is 2-4; The invention additionally relates to an improved process for producing both precursor cleansing / laundry bar “soap noodles” and personal cleansing / laundry detergent bars 35 comprising combining (a)-(e) to form a liquid mixture at a temperature of about 65° C. to about 105° C., removing from about 50% to about 90% by weight of the water from the liquid mixture, by heating up to 150° C. under vacuum conditions or 105° C. at normal conditions to form a thickened mixture, extruding the thickened mixture to form flaked solid or semi-solid pellets or noodles, and optionally, plodding the flaked solid or semi-solid pellets or noodles to form plodded pellets or noodles,f extruding the plodded pellets or noodles to form a billet, cutting the billet, and stamping the cut billet to yield a personal cleansing / laundry detergent bar.

Owner:OSPINAL CARLOS E +5

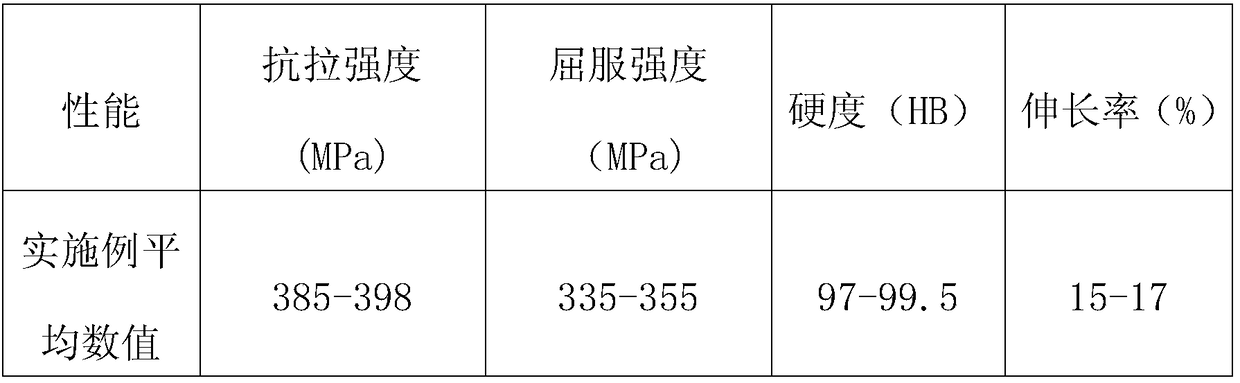

Special cylinder for large hydraulic machines and molding machines, and production method thereof

The invention relates to a special cylinder for large hydraulic machines and molding machines, and a production method thereof. The oil cylinder comprises 1.8 wt% of Cu, 0.9 wt% of Mg, 0.32 wt% of Mn,1.5 wt% of Ni, 1.7 wt% of Zn, 0.65 wt% of B2O3, 1.9 wt% of SiO2, 1.8 wt% of TiC, 0.025 wt% of C, and the balance of Fe. The production method of the special cylinder for large hydraulic machines andmolding machines comprises the following steps: blank production, blank pretreatment, molding, quenching treatment and polishing treatment. The special cylinder for large hydraulic machines and molding machines has the advantages of e excellent hardness performance, good corrosion resistance, small thermal expansion coefficient, low friction coefficient and high wear resistance, and also has the characteristics of reliable quality, strong pressure resistance and long service life.

Owner:宜兴市佳信数控科技有限公司

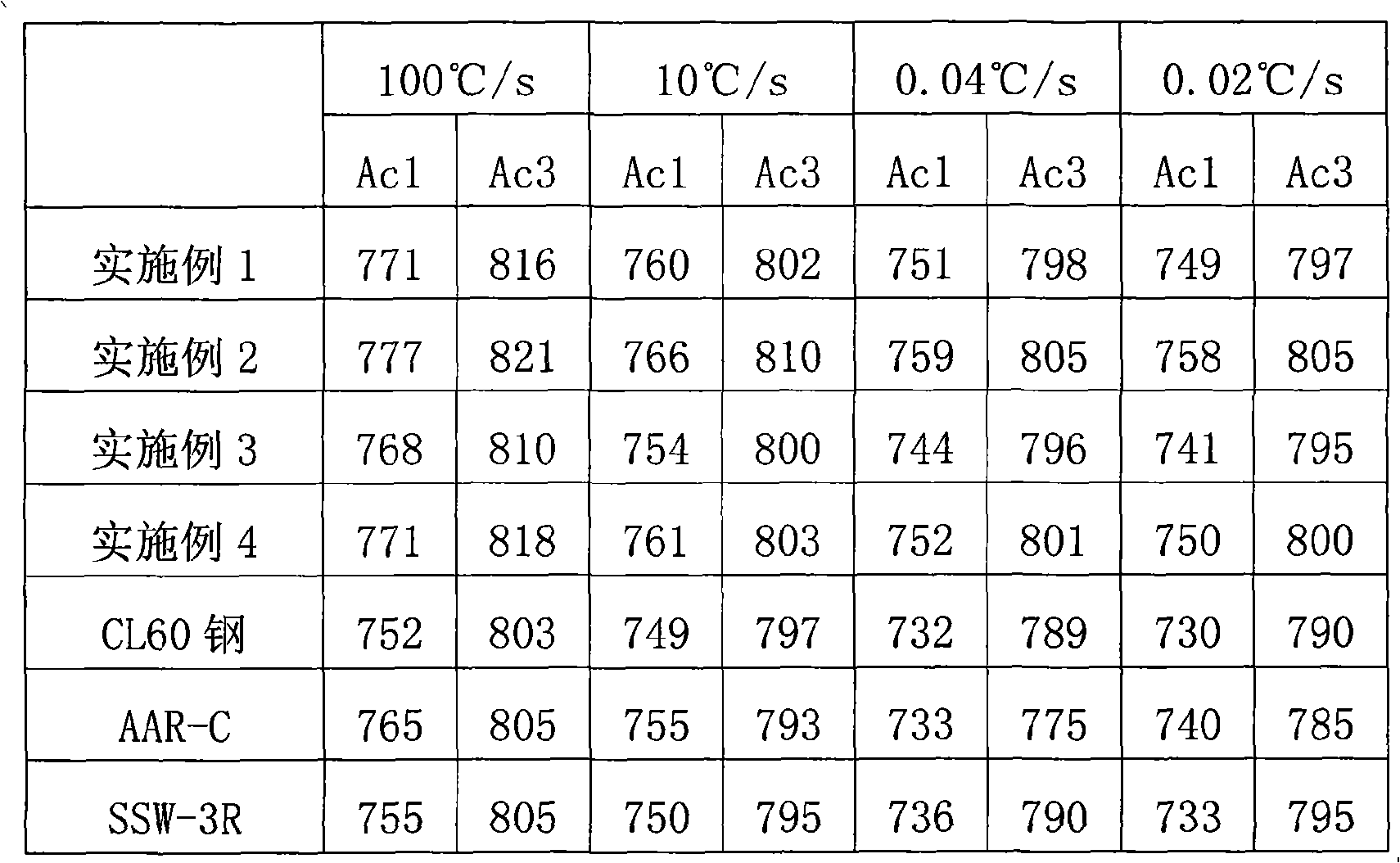

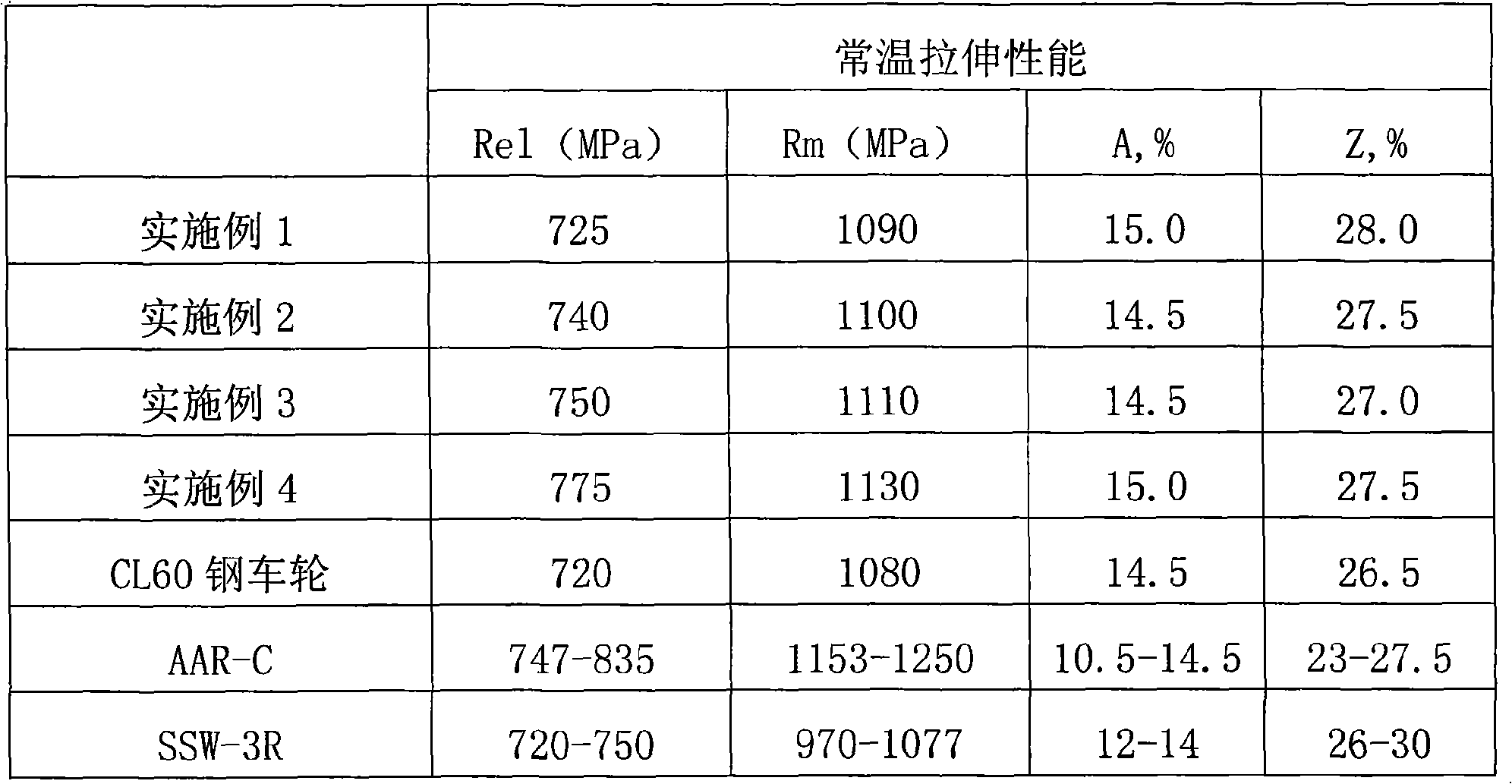

High-carbon and low-alloy wheel steel for railway wagon and manufacturing method of wheel

InactiveCN103710627AHigh strengthImprove hardness performanceFurnace typesHeat treatment furnacesChemical compositionRoom temperature

The invention discloses high-carbon and low-alloy wheel steel for a railway wagon. The high-carbon and low-alloy wheel steel comprises the following chemical ingredients by weight percent: 0.72-0.77% of C, 0.90-1.1% of Si, 0.85-0.95% of Mn, 0.03-0.05% of Mo, 0.30-0.40% of Cr, 0.010-0.025% of Als, no more than 0.015% of P, no more than 0.015% of S, and the balance of Fe and inevitable impurity elements. The invention also discloses a manufacturing method of the wheel. The method comprises a thermal treatment procedure which comprises the following steps: carrying out heat preservation at 840-860 DEG C for 2.0-2.5 hours, and then air-cooling to room temperature; carrying out heat preservation at 830-850 DEG C for 2.0-2.5 hours; spraying water to cool a rim to below 550 DEG C; cooling internal metal inside the rim at the cooling speed of 2-5 DEG C / s in an acceleration manner; and finally, carrying out tempering treatment at 500-520 DEG C for 4.5-5.0 hours.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

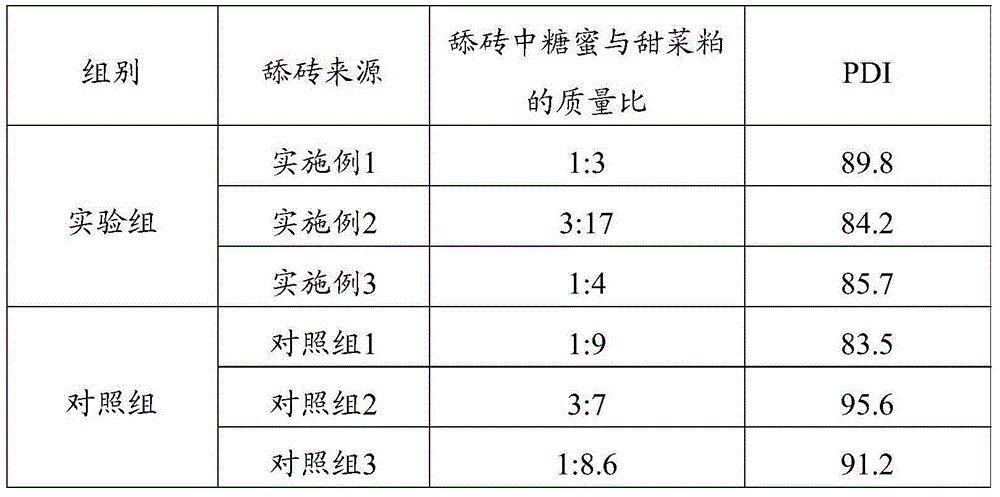

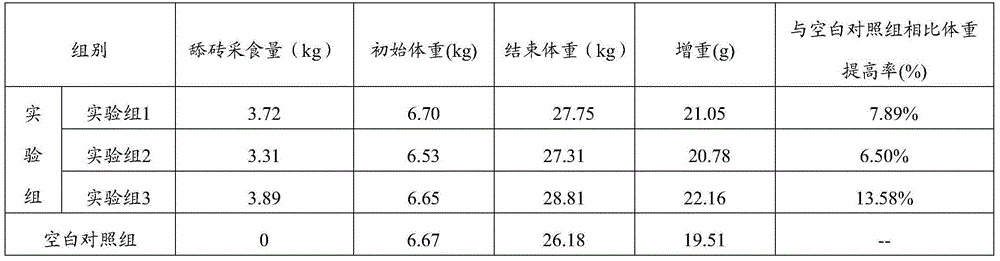

Licking brick and preparation method thereof

InactiveCN105613996AGood hardness performanceFull of nutritionAnimal feeding stuffChemistryNutrition

The present invention belongs to the technical field of animal feed and discloses a licking brick and a preparation method thereof. The provided licking brick is prepared from molasses, sugar beet pulp and premix. According to mass percentages, the content of the premix is 4%; the content of the molasses and the beet pulp are 96%; and the mass ratio of the molasses to the sugar beet pulp is (1 : 3)-(3 : 17). The provided licking brick fully uses the resources of the sugar beet pulp, so that the licking brick is good in hardness performance, rich in fibers, minerals, vitamins and sugars, and comprehensive in nutrition, can provide energy and fibers for animals, especially ruminants, provide energy and fibers, increase feed intake, improve gastrointestinal microbial fermentation status, reduce toxin production and accumulation, provides vitamins and minerals necessary for animal growth and development, contributes to the growth and development of animals, and significantly increases the weight and milk production of animals.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Soap bar compositions comprising alpha sulfonated alkyl ester and polyhydric alcohol and process for producing the same

InactiveUS20060241003A1Easy to processGood foaming effectCosmetic preparationsSurface-active detergent compositionsAlcoholPolyol

A composition suitable for use in personal cleaning or detergent soap, which includes a sulfonated fatty acid and / or alpha sulfonated alkyl ester, and methods for producing such a composition. The composition and methods exhibit efficient processing and allow for formation of cleansing or detergent bars with improved hardness, improved resistance to marring and improved processability to marring, lower wear-rate and decreased mush formation during consumer use.

Owner:OSPINAL CARLOS E +2

Glass fiber resin composite material and preparation method thereof

The invention relates to the technical field of glass fiber composite materials, in particular to a glass fiber resin composite material and a preparation method thereof. The raw materials of the glass fiber resin composite material comprise glass fiber cloth and an epoxy resin base material glue solution, wherein the weight ratio of the glass fiber cloth to the epoxy resin base material glue solution is 7: (3-3.5), and the epoxy resin base material glue solution is prepared from the following raw materials in parts by weight: 80-110 parts of epoxy resin, 8-10 parts of porous glass micro-beads, 12-16 parts of alumina powder, 5-9 parts of a dispersing agent and 2-5 parts of an adhesive. According to the invention, porous glass micro-beads are treated to form high-strength and high-dispersity microspheres, the high-strength and high-dispersity microspheres are uniformly mixed with epoxy resin to prepare an epoxy resin base material glue solution, glass fiber cloth quickly passes through the molten epoxy resin base material glue solution, the surface of the glass fiber cloth is quickly coated with the epoxy resin base material glue solution, and the hardness and the strength of the formed glass fiber resin composite material are greatly improved.

Owner:临沂天炬节能材料科技有限公司

New method for additive preparation of metal product

InactiveCN112809022AHigh strengthImprove hardness performanceAdditive manufacturing apparatus3d printLaser peening

The invention discloses a novel method for additive preparation of a metal product. The metal product is prepared by adopting a mode of combining metal 3D printing and laser peening, laser peening treatment is introduced in the printing forming process, and the method comprises the following steps that according to a product design drawing, drawing software is used for drawing the design drawing into a three-dimensional model; the drawn three-dimensional model is substituted into slicing software, printing parameters are set, and a corresponding G code is generated; and the generated G code is substituted into an upper computer, and metal 3D printing forming equipment is controlled to carry out product printing forming. Laser shock peening is carried out under the state that each forming layer is not completely solidified, or laser shock peening is carried out on a metal cladding body while printing forming is carried out, so that the organization structure of the metal is more compact, crystal grains are further refined, the problems of holes, cracks, surface spheroidization, coarse crystal grains and the like in a formed part are eliminated, a high-strength and high-hardness metal product with excellent performance is obtained, and a 3D metal printing main force bearing part can enter a substantive use stage.

Owner:CENT SOUTH UNIV

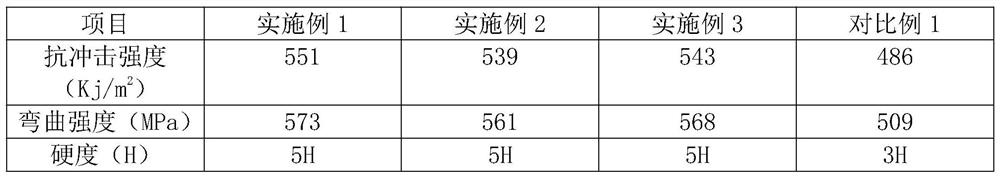

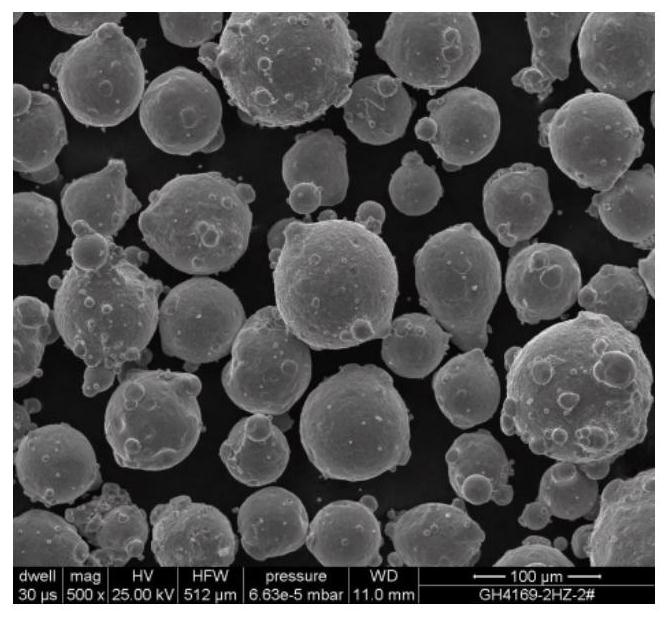

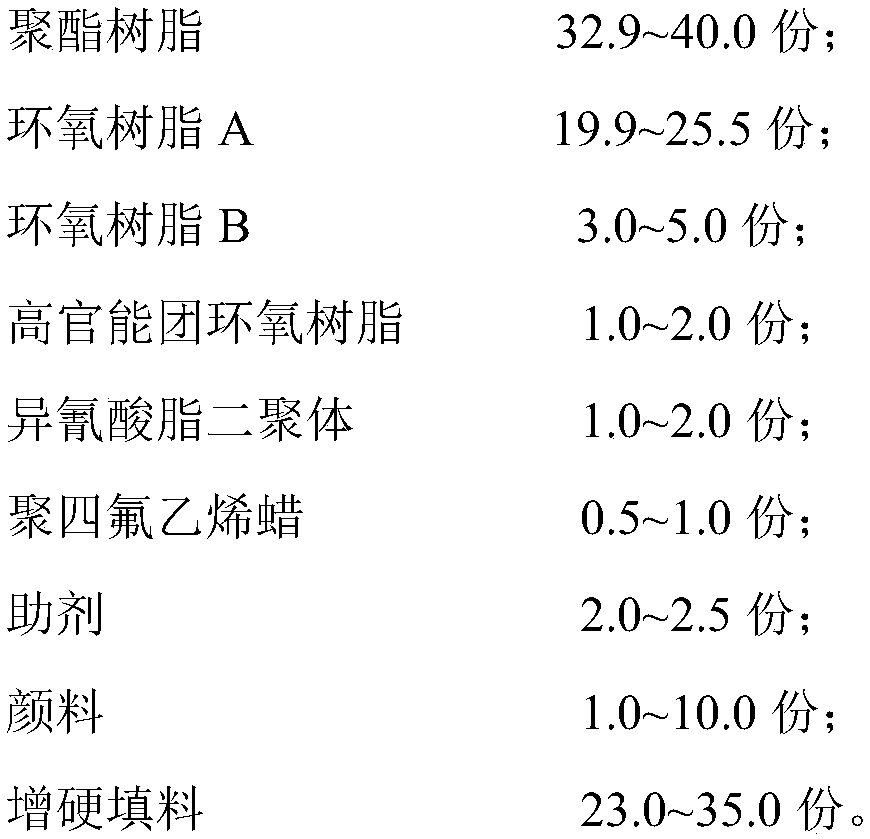

High-hardness epoxy-polyester powder coating composition, preparation method and application thereof

ActiveCN109517494AImprove hardness performanceImprove adhesionLiquid surface applicatorsPowdery paintsEpoxyWax

The invention discloses a high-hardness epoxy-polyester powder coating composition, a preparation method thereof and application of the composition in outer part coating. The coating composition is prepared from polyester resin, epoxy resin A, epoxy resin B, high functional epoxy resin, isocyanate dimer, polytetrafluoroethylene wax, auxiliaries, pigment and hardening filler. The preparation methodof the coating composition comprises the following steps: uniformly mixing the polyester resin, a triglycidyl isocyanurate curing agent, high functional epoxy resin, isocyanate dimer, polytetrafluoroethylene wax, auxiliaries, pigment and filler, sequentially performing melt extrusion, tableting, cooling, coarse breaking, fining and greening and screening. The high-hardness epoxy-polyester powdercoating has excellent hardness performance for base materials, has the optimized adhesion with the base materials, has good binding performance and hardness performance for base materials, has unaffected weather-proof performance, and has good scraping resistance.

Owner:NIPPON PAINT TIANJIN +1

Cylinder material for electric executer and preparation method thereof

InactiveCN108396211AImprove hardness performanceImprove corrosion resistanceMechanical propertyMaterials science

Owner:WUXI CHENGTIANNUO ACTUATOR MFG CO LTD

Surface treatment method of 3D hot-bending graphite mold

ActiveCN110304944AImprove wear resistanceImprove scratch resistanceGlass reforming apparatusEvaporationGraphite

The invention relates to a surface treatment method of a 3D hot-bending graphite mold, and belongs to the technical field of surface treatment of glass processing molds. In order to solve the problemof easy abrasion and short service life of an existing graphite mold, the invention provides the surface treatment method of the 3D hot-bending graphite mold. The method comprises the following steps:placing a to-be-treated 3D hot-bending graphite mould in a cavity of evaporation equipment, enabling the surface to be plated of the 3D hot-bending graphite mold to be arranged oppositely to a sputtering source, connecting an anode of a pulse power supply of the evaporation equipment with an electrode of the sputtering source, and connecting the cathode with a workpiece electrode of the 3D hot-bending graphite mold, wherein a silicon source is adopted as the target material of the sputtering source; and vacuumizing the cavity of the evaporation equipment, carrying out cleaning by an ion source, introducing argon gas and oxygen for a period of time, turning on a pulse power supply, and opening a silicon source to carry out vacuum coating, so that a coating layer is formed on the surface ofthe mold cavity of the graphite mold, and the corresponding coated 3D hot-bending graphite mold is obtained. Wear resistance and scratch resistance of the graphite mould can be improved, and the service life is prolonged.

Owner:ZHEJIANG XINGXING TECH CO LTD

Eco-friendly composite concrete grinding body for grinding and preparation method thereof

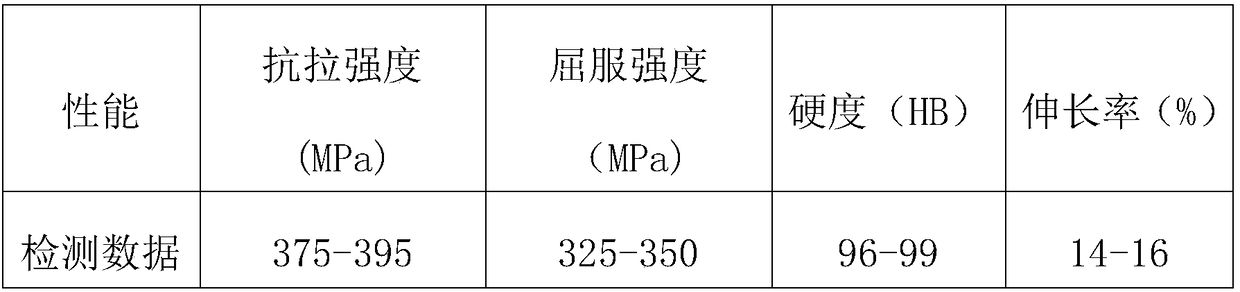

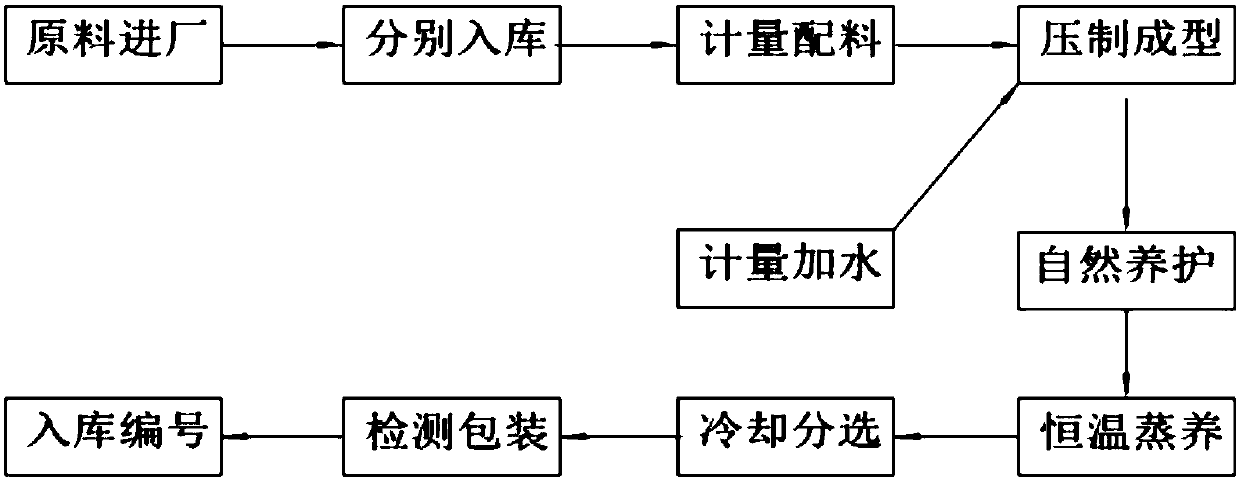

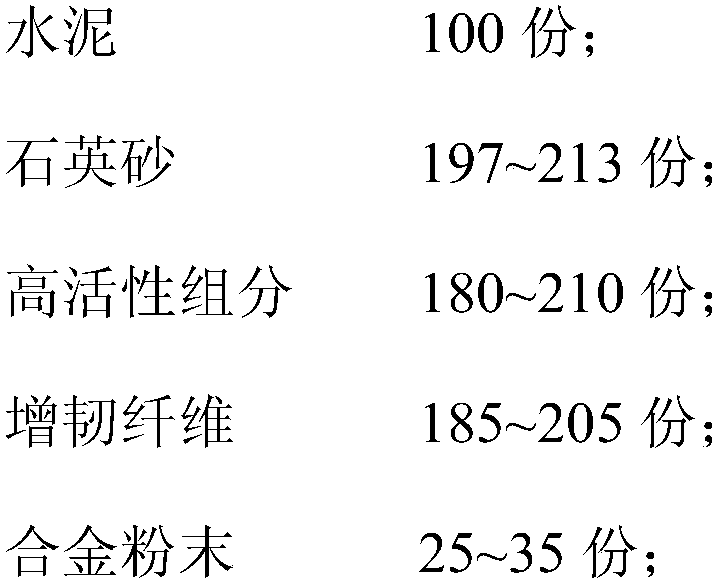

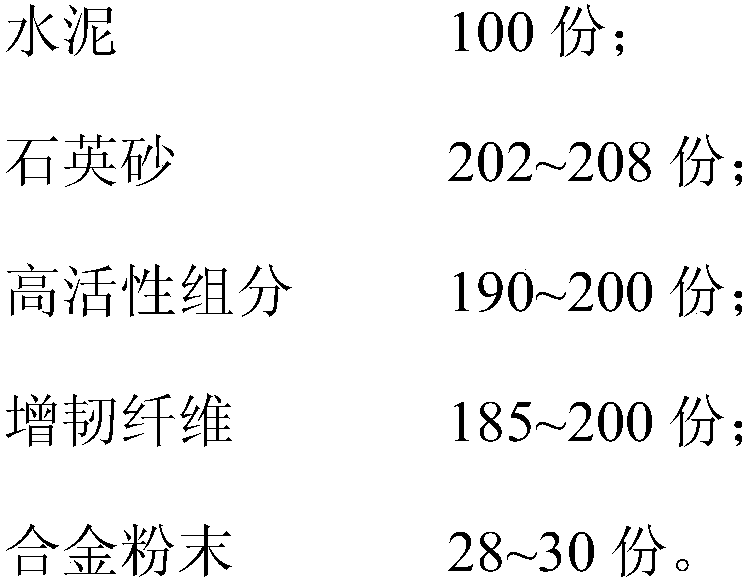

The invention relates to an eco-friendly composite concrete grinding body for grinding and a preparation method thereof. The grinding body comprises 100 parts of cement; 197-213 parts of quartz sand;180-210 parts of high active components; 185-205 parts of toughening fibers; 25-35 parts of alloy powder; the high active components include any one of silicon powder, construction waste reclaimed powder, zeolite powder, ferrite powder, nano graphene oxide and ceramic waste powder, or combination of at least two kinds of the above components; the toughening fibers include any one of steel fiber, silicon carbide fiber, calcium carbonate whisker, basalt fiber and boron nitride fiber or combination of at least two kinds of the above fibers; the alloy powder includes aluminum zinc alloy powder and / or aluminum titanium alloy powder. The grinding body integrates high strength, high toughness, high hardness, high durability, low cost, and ecological and environmental protection as a whole, and the grinding body has universality and is applicable to design and development of various wear-resistant composite products.

Owner:广州基业长青新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com