High-hardness epoxy-polyester powder coating composition, preparation method and application thereof

A powder coating, high hardness technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of incomparable coating surface hardness, low cross-linking density of polyester system, coating scratches, etc. Achieve the effects of avoiding poor performance, good adhesion, and unaffected weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

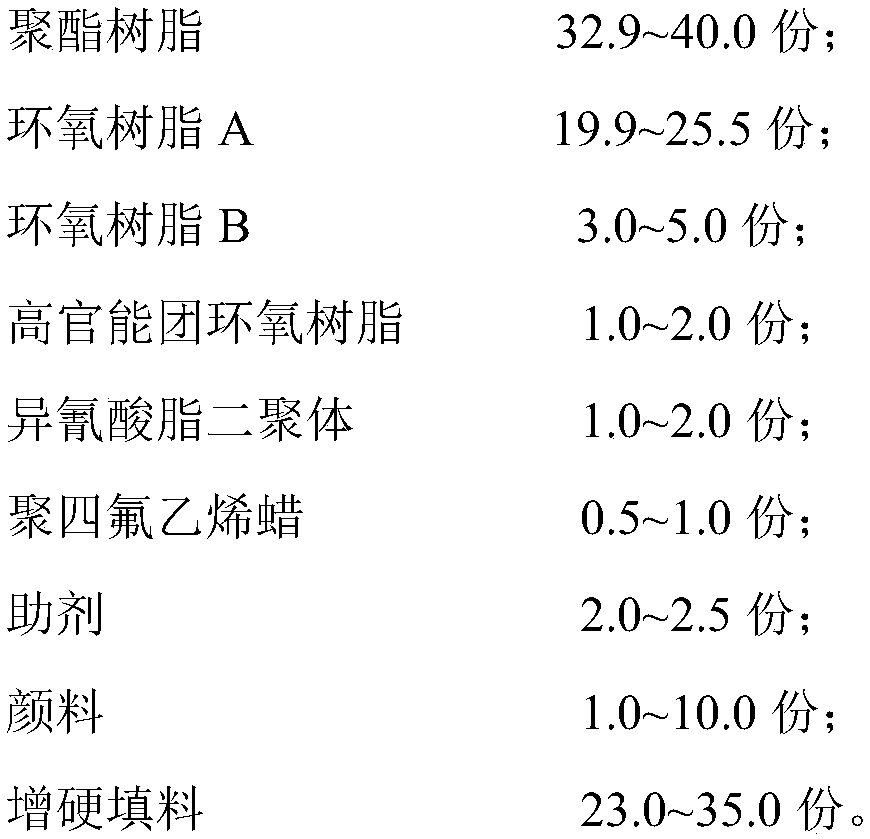

[0064] A kind of high hardness epoxy-polyester type powder coating composition, comprises the component of following parts by weight shown in table 1:

[0065] Table 1

[0066] components

parts by weight

P5086

33

Epoxy resin A

303L

23.9

Epoxy resin B

NPCN704

3

High functional epoxy

4135CE

1.0

B1530

1.0

PTFE wax

SST-3D

1.0

Auxiliary

GLP588+701+benzoin

2.1

HB2185

1.0

Hardening filler

CP30

35

[0067] First, accurately weigh the raw materials according to the formula components in Table 1, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5 to 10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 90-100°C, passed through cooling rolls and pressed into tablets, aft...

Embodiment 2

[0071] A kind of high hardness epoxy-polyester type powder coating composition, comprises the component of following parts by weight shown in table 2:

[0072] Table 2

[0073]

[0074]

[0075] First, accurately weigh the raw materials according to the formula components in Table 2, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5 to 10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 90-100°C, passed through cooling rolls and pressed into tablets, after the tablets were cooled at natural temperature, the tablets were coarsely crushed with a pulverizer, and the obtained materials were cooled and ground with a pulverizer Finely pulverize, sieve with a 180-mesh sieve, and sieve through the 180-mesh sieve for natural cooling to finally obtain the high-hardness epoxy-polyester powder coating composition with uniform particle size.

[0076] Degrease the a...

Embodiment 3

[0079] A kind of high hardness epoxy-polyester type powder coating composition, comprises the component of following weight parts shown in table 3:

[0080] table 3

[0081] components

parts by weight

P5086

37.1

Epoxy resin A

303L

25.1

Epoxy resin B

NPCN704

4

High functional epoxy

4135CE

1.0

Isocyanate dimer

B1530

2.0

PTFE wax

SST-3D

0.7

Auxiliary

GLP588+701+benzoin

2.1

HB2185

1.0

Hardening filler

CP30

27

[0082] First, accurately weigh the raw materials according to the formula components in Table 3, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5 to 10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed , melted and extruded at 90-100°C, passed through cooling rolls and pressed into tablets, afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com