New method for additive preparation of metal product

A new method, metal technology, applied in the field of additive manufacturing of metal products, can solve the problems of inconspicuous strengthening, limited laser penetration ability, and lack of actual operation functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the present embodiment prepares die cutter according to the method provided by the present invention, and concrete steps are as follows:

[0043] Step 1. Draw a 3D model:

[0044] According to the two-dimensional drawing of the cutting die, use drawing software such as Solidworks to draw the corresponding three-dimensional model, and generate a file in stl format, such as figure 1 shown;

[0045] Step 2, material selection:

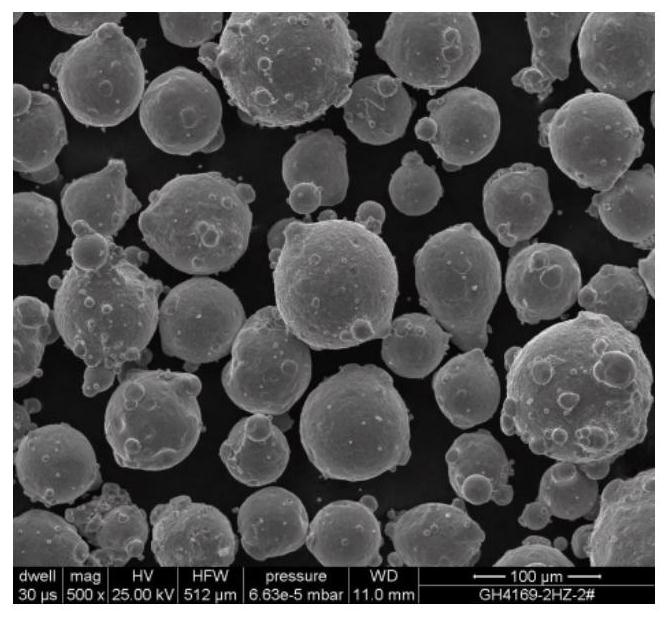

[0046] According to the cutting material of the tool, select the corresponding material. In this example, GH4169 spherical powder is selected, the particle size is 75-150 μm, and the raw material is as microscopic as figure 2 As shown, the base material is 316L stainless steel, and the base thickness is 10mm.

[0047] Step 3, parameter setting:

[0048] Import the stl file into the slicing software, set the laser power to 600W, the scanning speed to 600 mm / min, the powder feeding rate to 0.3r / min, the layer thickness to 0.3mm, an...

Embodiment 2

[0060] The present embodiment prepares a kind of knife die product, and preparation process comprises the following steps:

[0061] Step 1. Draw a 3D model:

[0062] According to the two-dimensional drawing of the cutting die, use drawing software such as Solidworks to draw the corresponding three-dimensional model, and generate a file in stl format, such as Figure 9 shown;

[0063] Step 2, material selection:

[0064] According to the cutting material of the tool, select the corresponding material. In this example, 420 stainless steel spherical powder is selected, the particle size is 75-150 μm, and the raw material is as microscopic as Figure 10 As shown, the base material is 316L stainless steel, and the base thickness is 10mm;

[0065] Step 3, parameter setting:

[0066] Import the stl file into the slicing software, set the laser power to 450W, the scanning speed to 400 mm / min, the powder feeding rate to 0.2r / min, and the layer thickness to 0.2mm. Impact strengthen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com