High-hardness and quick-drying water-based two-component filling clear primer and preparation method thereof

A two-component, clear primer technology, applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve the problems of unproven, high hardness, and high crosslinking density of water-based two-component bright white paint. Achieve fast drying speed, increase hardness performance, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

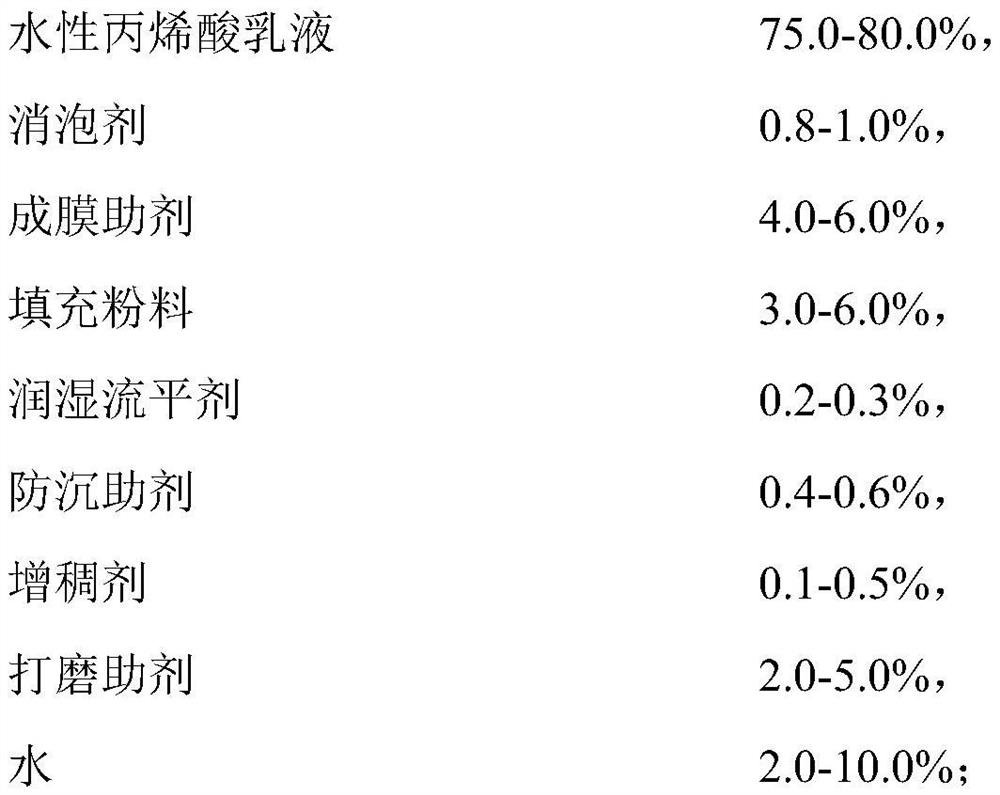

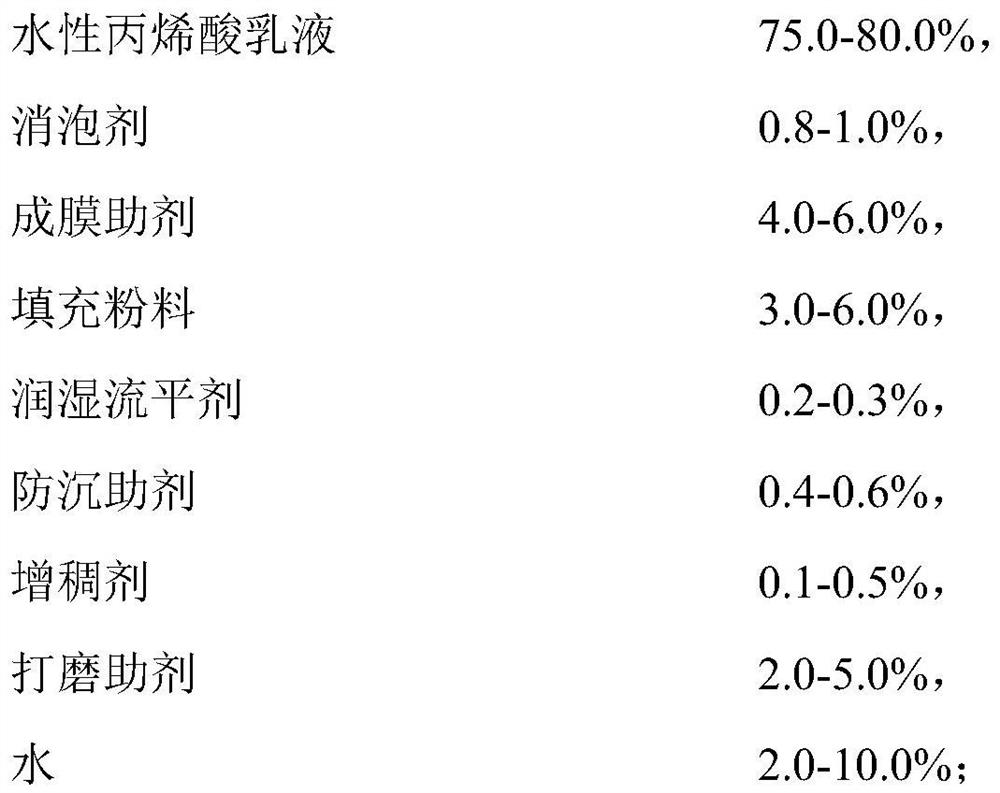

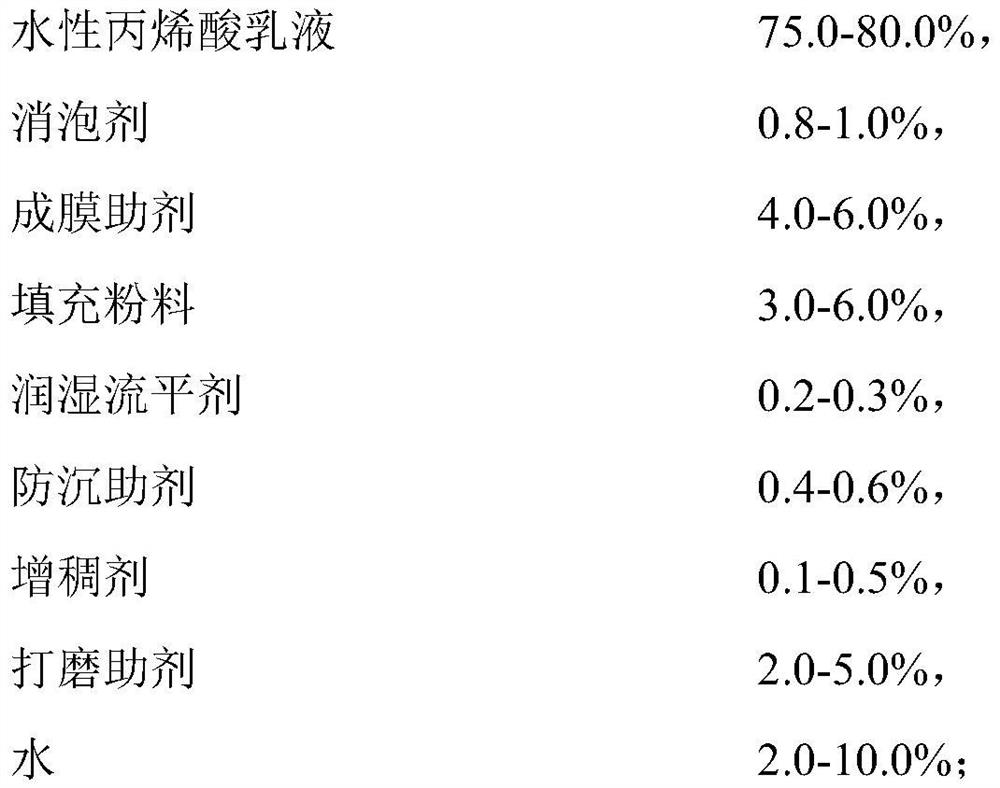

Embodiment 1

[0072] Mix component A-proportion A and component B-proportion A according to the equivalent ratio of n(-NCO):n(-OH)=1.6, mix evenly, add water to adjust to a suitable viscosity for construction, and let it stand for 5 minutes , that is, high hardness, quick-drying water-based two-component filling clear primer.

Embodiment 2

[0074] Mix component A-proportion A and component B-proportion B according to the equivalent ratio of n(-NCO):n(-OH)=1.6, mix evenly, add water to adjust the viscosity suitable for construction, and let it stand for 5 minutes , that is, high hardness, quick-drying water-based two-component filling clear primer.

Embodiment 3

[0076] Mix component A-proportion B and component B-proportion A according to the equivalent ratio of n(-NCO):n(-OH)=1.6, mix evenly, add water to adjust to a suitable viscosity for construction, and let it stand for 5 minutes , that is, high hardness, quick-drying water-based two-component filling clear primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com