Waterborne multifunctional paint for electrical appliance and preparation method thereof

A multi-functional, water-based technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of unstable conductivity, poor corrosion resistance, easy settlement, etc., and achieve the effects of good toughness, high decoration, and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

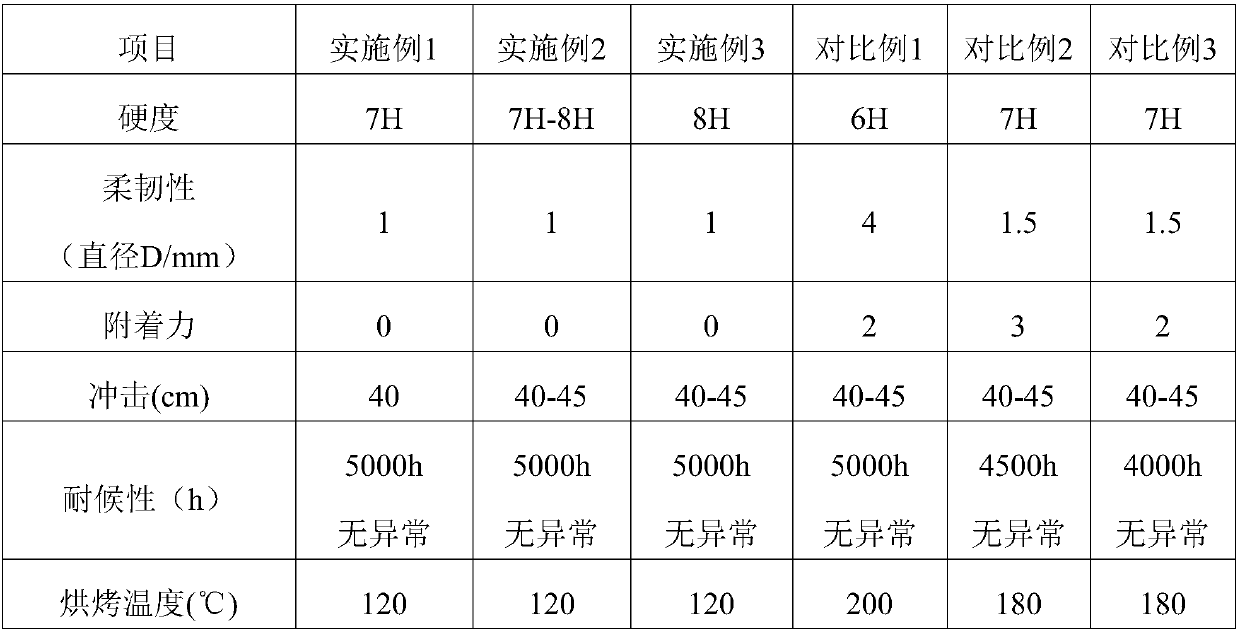

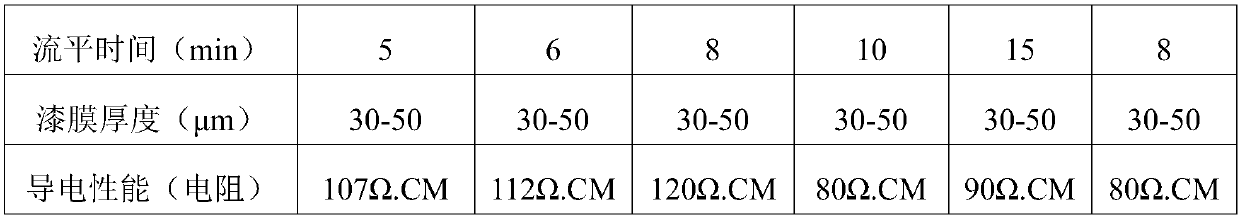

Examples

Embodiment 1

[0055] A water-based multifunctional coating for electrical appliances, which includes, in terms of mass fraction, 15 parts of nano glass resin, 10 parts of water-based hydroxyacrylic acid emulsion, 5 parts of methyl etherified amino resin containing high imino group, 1 part of organic Silicone powder, 1 part of superconducting carbon black, 0.1 part of acetylene black, 0.05 part of graphene, 0.05 part of ionic liquid, 0.1 part of carbon nanotube, 0.1 part of pH regulator, 0.1 part of defoamer, 2 parts of coalescent, 0.3 parts of dispersant, 0.3 parts of substrate wetting agent, 5 parts of deionized water and 0.5 parts of thickener.

[0056] Wherein, the ratio of the sum of the mass of the superconducting carbon black, the acetylene carbon black and the graphene to the mass of the carbon nanotube is 11 / 1.

[0057] Preparation steps:

[0058] (1) half of water, half of pH regulator, dispersant, half of defoamer, superconducting carbon black, ionic liquid, graphene, carbon nano...

Embodiment 2

[0063] A water-based multifunctional coating for electrical appliances, which includes 30 parts of nano glass resin, 30 parts of water-based hydroxyacrylic acid emulsion, 20 parts of methyl etherified amino resin containing high imino group, 5 parts of organic silicone powder, 5 parts of superconducting carbon black, 3 parts of acetylene black, 0.5 part of graphene, 0.5 part of ionic liquid, 1 part of carbon nanotube, 0.2 part of pH regulator, 0.2 part of defoamer, 5 parts of film-forming aid agent, 0.5 parts of dispersant, 0.5 parts of substrate wetting agent, 10 parts of deionized water and 1.0 parts of thickener.

[0064] Wherein, the ratio of the sum of the mass of the superconducting carbon black, the acetylene carbon black and the graphene to the mass of the carbon nanotube is 8 / 1.

[0065] In the above scheme, 25 parts of polyphenyl polymethyl polyisocyanate is also included, and the mass ratio of polyphenyl polymethyl polyisocyanate to the organic silicone powder is 5 / ...

Embodiment 3

[0073] A water-based multifunctional coating for electrical appliances, which includes 20 parts of nano glass resin, 15 parts of water-based hydroxyacrylic acid emulsion, 12 parts of methyl etherified amino resin containing high imino group, 5 parts of organic silicone powder, 5 parts of superconducting carbon black, 1 part of acetylene black, 0.4 part of graphene, 0.3 part of ionic liquid, 0.7 part of carbon nanotube, 0.2 part of pH regulator, 0.1 part of defoamer, 3 parts of film-forming aid agent, 0.4 parts of dispersant, 0.4 parts of substrate wetting agent, 5 parts of deionized water and 0.5 parts of thickener.

[0074] Wherein, the ratio of the sum of the mass of the superconducting carbon black, the acetylene carbon black and the graphene to the mass of the carbon nanotube is 9 / 1.

[0075] In the above scheme, 15 parts of polyphenylpolymethyl polyisocyanate is also included, and the mass ratio of the polyphenylpolymethyl polyisocyanate to the organic silicone powder is 3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com