Special cylinder for large hydraulic machines and molding machines, and production method thereof

A hydraulic press and forming machine technology, applied in the field of machinery, can solve the problems of material hardness, wear resistance, poor corrosion resistance, affecting the service life of hydraulic cylinders, and restricting the production efficiency of enterprises, so as to achieve excellent hardness performance, reliable quality, and small thermal expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

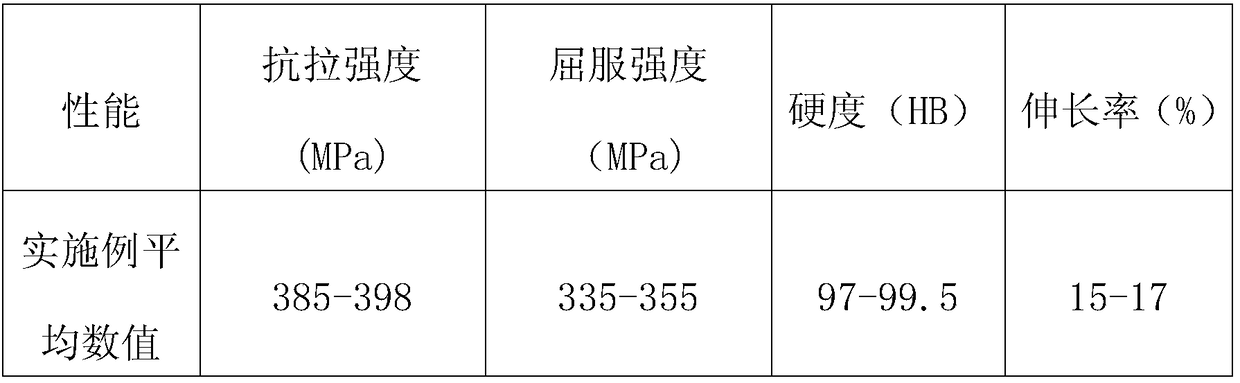

Examples

Embodiment 1

[0017] A special oil cylinder for a large-scale hydraulic press and a molding machine and a preparation method thereof according to the present invention, the distribution ratio of each component in terms of weight percentage is as follows: Cu: 1.8%, Mg: 0.9%, Mn: 0.32%, Ni: 1.5%, Zn: 1.7%, B 2 o 3 : 0.65%, SiO 2 : 1.9%, TiC: 1.8%, C: 0.025%, and the rest are Fe.

[0018] A method for preparing a special oil cylinder for large hydraulic presses and forming machines, comprising the following steps:

[0019] (1) Embryo making: Mix the prepared raw materials of each component evenly and put them into the melting furnace, heat up to melt first, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 750°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 700°C, perform refining treatment first, and at the same time apply lubricating oil around the inner wall of the pre-prepared steel m...

Embodiment 2

[0025] A special oil cylinder for a large-scale hydraulic press and a forming machine and a preparation method thereof according to the present invention, the distribution ratio of each component in terms of weight percentage is: Cu: 1.6%, Mg: 0.8%, Mn: 0.35%, Ni: 1.6%, Zn: 1.6%, B 2 o 3 : 0.7%, SiO 2 : 2.0%, TiC: 1.7%, C: 0.02%, and the rest are Fe.

[0026] A method for preparing a special oil cylinder for large hydraulic presses and forming machines, comprising the following steps:

[0027] (1) Embryo making: Mix the prepared raw materials of each component evenly and put them into the melting furnace, heat up to melt first, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 760°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 710°C, perform refining treatment first, and at the same time apply lubricating oil around the inner wall of the pre-prepared steel mold, then pou...

Embodiment 3

[0033] A special oil cylinder for a large-scale hydraulic press and a forming machine and a preparation method thereof according to the present invention, the distribution ratio of each component in terms of weight percentage is: Cu: 2.2%, Mg: 1.0%, Mn: 0.4%, Ni: 1.8%, Zn: 1.8%, B 2 o 3 : 0.75%, SiO 2 : 2.2%, TiC: 2.0%, C: 0.03%, and the rest are Fe.

[0034] A method for preparing a special oil cylinder for large hydraulic presses and forming machines, comprising the following steps:

[0035](1) Embryo making: Mix the prepared raw materials of each component evenly and put them into the melting furnace, heat up to melt first, and after the raw materials are completely melted, adjust the internal temperature of the melting furnace to 780°C for refining treatment, and then Adjust the internal temperature of the melting furnace to 720°C, perform refining treatment first, and at the same time apply lubricating oil around the inner wall of the pre-prepared steel mold, then pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com