High-hardness powder coating as well as preparation method and application thereof

A powder coating, high hardness technology, applied in the field of coatings, can solve the problems of the use performance of the appearance parts, the surface scratches of the coating film, and the appearance of the appearance parts, etc., so as to avoid the problem of poor performance, good scratch resistance, and hardness performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

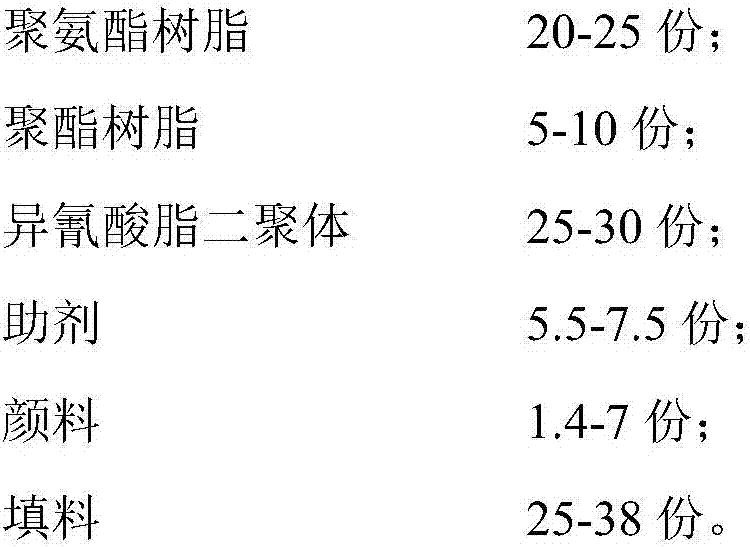

[0046] A high-hardness powder coating, comprising the following components by weight:

[0047]

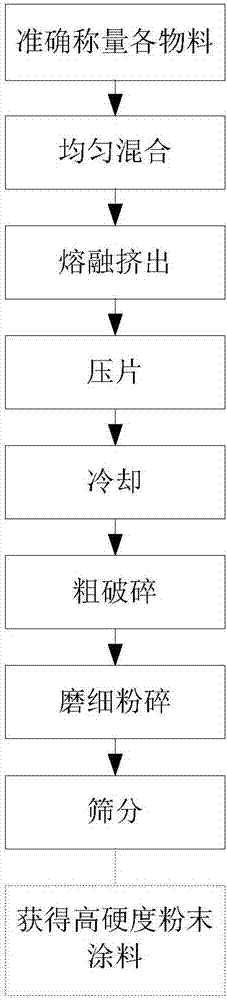

[0048] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the preparation method of the high hardness powder coating of the present invention. First, accurately weigh the raw materials according to the formula of the high-hardness powder coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the Twin-screw extruder, melted and extruded at 95-105°C, pressed into tablets by cooling rolls, cooled at natural temperature, coarsely crushed with a pulverizer, and used after cooling Grinding and pulverizing with a pulverizer, sieving with a 180-mesh sieve, and cooling naturally after sieving through a 180-mesh sieve, finally obtaining the high-hardness powder coating with a uniform particle size (25-45 μm).

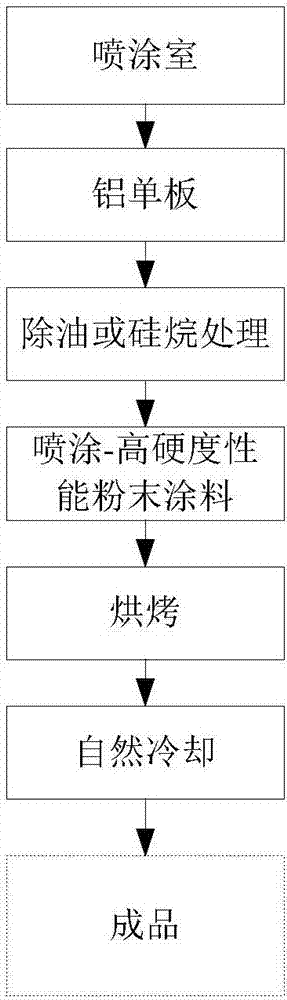

[0049] Such as figure 2 as shown, figu...

Embodiment 2

[0056] A high-hardness powder coating, comprising the following components by weight:

[0057]

[0058] First, accurately weigh the raw materials according to the formula of the high-hardness powder coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the Twin-screw extruder, melted and extruded at 95-105°C, pressed into tablets by cooling rolls, cooled at natural temperature, coarsely crushed with a pulverizer, and used after cooling Grinding and pulverizing with a pulverizer, sieving with a 180-mesh sieve, and cooling naturally after sieving through a 180-mesh sieve, finally obtaining the high-hardness powder coating with a uniform particle size (26-70 μm).

[0059] The high-hardness powder coating of the present embodiment is used as the purposes of exterior part, comprises the following steps:

[0060] Degrease the aluminum veneer (or perform other pr...

Embodiment 3

[0063] A high-hardness powder coating, comprising the following components by weight:

[0064]

[0065]

[0066] First, accurately weigh the raw materials according to the formula of the high-hardness powder coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the Twin-screw extruder, melted and extruded at 95-105°C, pressed into tablets by cooling rolls, cooled at natural temperature, coarsely crushed with a pulverizer, and used after cooling Grinding and pulverizing with a pulverizer, sieving with a 180-mesh sieve, and cooling naturally after sieving through a 180-mesh sieve, finally obtaining the high-hardness powder coating with a uniform particle size (26-70 μm).

[0067] The high-hardness powder coating of the present embodiment is used as the purposes of exterior part, comprises the following steps:

[0068] Degrease the aluminum veneer (or perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com