Industrial wastewater treatment device and treatment method

A technology for industrial wastewater and treatment devices, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. Not easy to secondary pollution, high removal rate, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

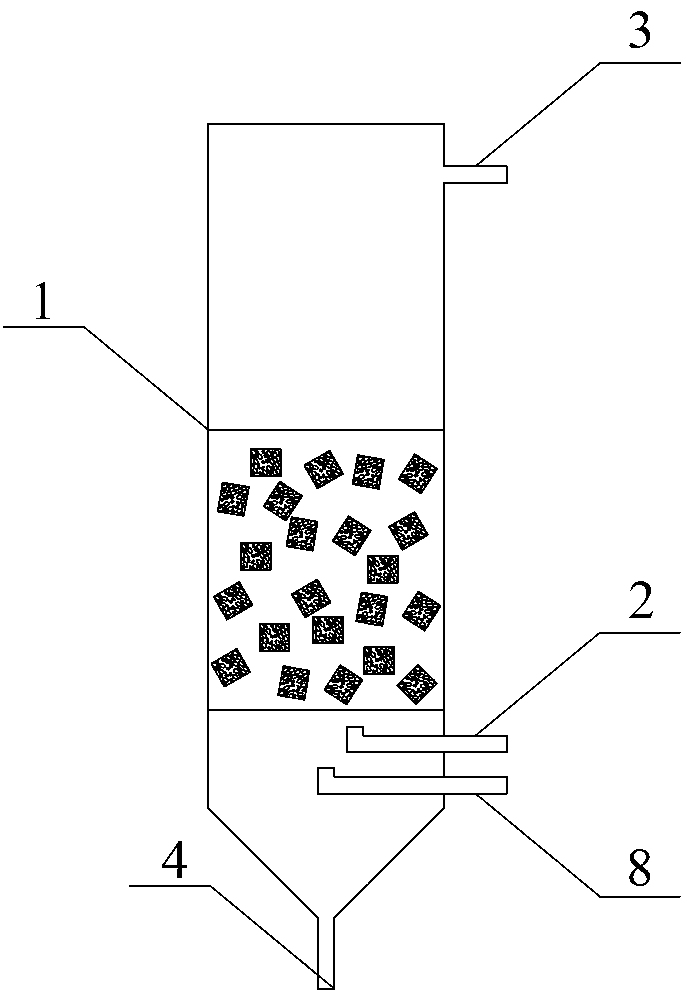

[0055] Such as figure 1 Shown, a kind of industrial waste water treatment device, described device is fixed-bed reactor, comprises:

[0056] Reactor body 1, the reactor body 1 has a wall, and has a closed bottom and an upwardly open top, the inside of which is fixed and filled with 2.5cm×2.5cm polyurethane filler through a mesh plate;

[0057] The water inlet pipe 2 runs through the wall of the reactor main body 1, opens into the inner space of the reactor main body 1, and is located at the lower part of the reactor main body 1, for allowing waste water to enter the reactor;

[0058] The water outlet pipe 3 runs through the wall of the reactor main body 1, opens into the inner space of the reactor main body 1, and is located at the upper part of the reactor main body 1, and is used to discharge the treated waste water;

[0059] The aeration pipe 8 is arranged through the wall of the reactor main body 1, is located at the bottom of the reactor main body 1, and opens into the i...

Embodiment 2

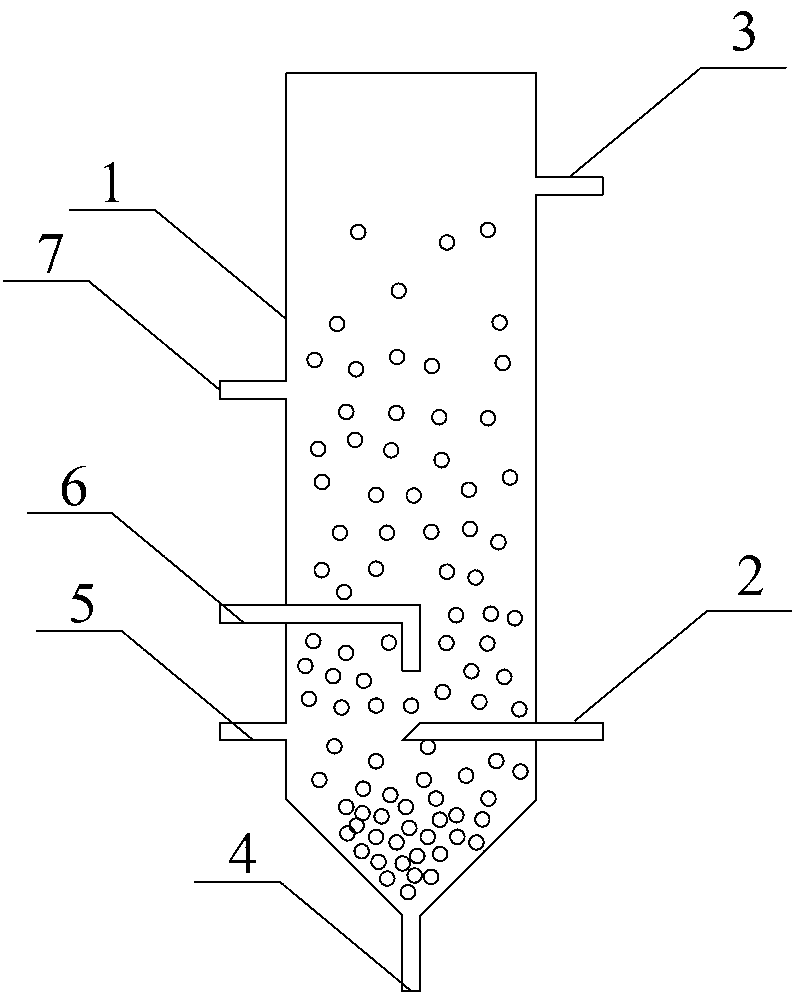

[0063] Such as figure 2 Shown, a kind of industrial waste water treatment device, described device is fluidized bed reactor, comprises:

[0064] Reactor body 1, the reactor body 1 has a wall, and has a closed bottom and an upwardly open top, which is filled with silica sand with a particle size of 0.1mm;

[0065] The water inlet pipe 2 runs through the wall of the reactor main body 1, opens into the inner space of the reactor main body 1, and is located at the lower part of the reactor main body 1, for allowing waste water to enter the reactor;

[0066] The water outlet pipe 3 runs through the wall of the reactor main body 1, opens into the inner space of the reactor main body 1, and is located at the upper part of the reactor main body 1, and is used to discharge the treated waste water;

[0067] The sewage pipe 4 is arranged through the wall of the reactor main body 1, opens in the inner space of the reactor main body 1, and is located at the bottom of the reactor main bod...

Embodiment 3

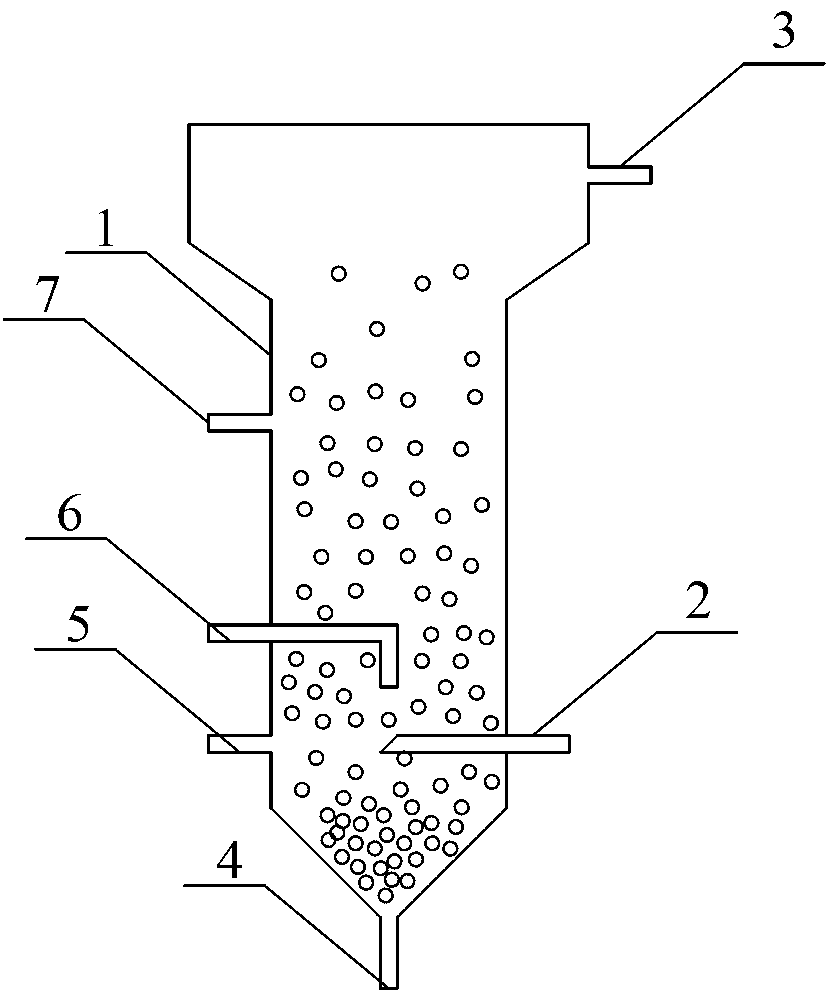

[0074] The device of this example is a fluidized bed reactor, and the difference from Example 2 is that the lower part of the main body of the reactor is cylindrical, and the upper part is cylindrical with a diameter larger than that of the lower part.

[0075] The lower part of the main body of the reactor has a diameter of 200 mm and a height of 1.5 m, and the upper part has a diameter of 300 mm and a height of 0.5 m.

[0076] The device is used to treat methanol wastewater in Xinnengda Banner. The concentration of calcium ions in high-hard methanol wastewater is 1275mg / L (calculated as calcium carbonate), the concentration of magnesium ions is 540mg / L, and the pH is adjusted to 9. The inflow of high-hard methanol wastewater is 200L / day, and the internal circulation speed is 0.06m / s. Calcium and magnesium ions gradually crystallize and grow on the calcium carbonate crystals. After stabilization, the concentration of calcium ions in the effluent of the fluidized bed is 248mg / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com