Fluorine-containing polymer, waterproof and oil-proof treating agent, preparation method of waterproof and oil-proof treating agent and protection film

A polymer and treatment agent technology, applied in the direction of coating, etc., can solve problems such as insufficient surface hardness, unsatisfactory use effect, and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

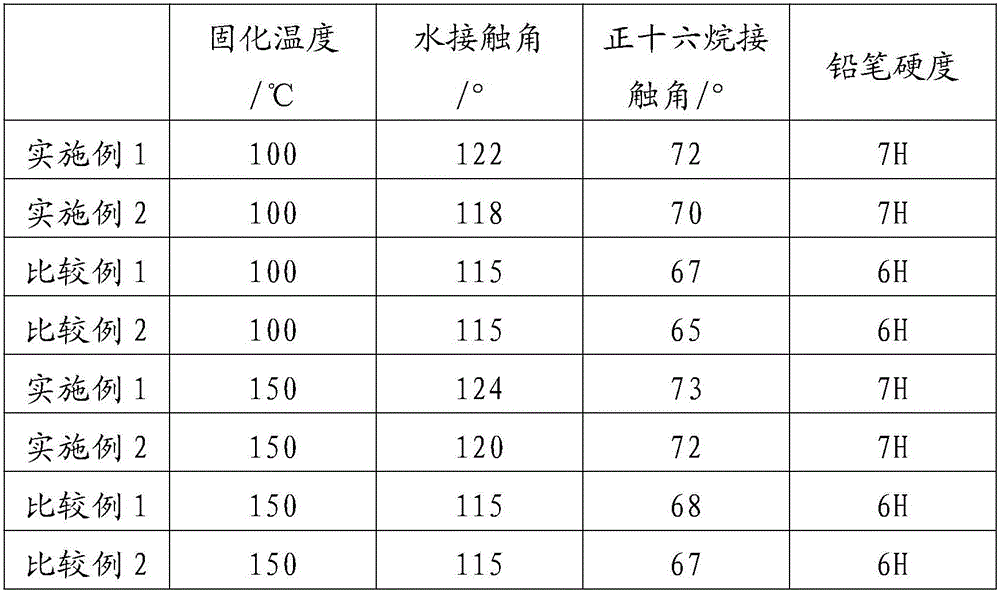

Examples

preparation example Construction

[0107] The preparation method of this water and oil repellent treatment agent is: under the situation that polymerization initiator and chain transfer agent exist simultaneously, fluorine-containing monomer (a) and crosslinking monomer (b) are dissolved in the organic solvent, use nitrogen The air was replaced, and the mixture was stirred and heated at a temperature of 50-120° C. for 1-48 h. Generally speaking, the organic solvent is inert to the monomer and can dissolve the monomer, so it can be a ketone, such as acetone, methyl ethyl ketone; it can be an ester, such as ethyl acetate, n-butyl acetate, tert-acetic acid Butyl ester, isobutyl acetate, methyl acetate; also alcohols such as ethanol, isopropanol.

[0108] It should be noted that the water and oil repellent treatment agent can be prepared in any form, such as solution or aerosol, which can be prepared by diluting or dispersing fluorine-containing polymers in organic solvents, and prepared according to actual needs. ...

preparation example 1

[0118] Will CF 3 CF 2 (CF 2 CF 2 ) 6 CH 2 CH 2 OOCCH=CH 2 (80g), octadecyl methacrylate (13g), n-butyl methacrylate (26g), glycidyl methacrylate (1.3g), acrylamide (5.4g), hydroxyethyl methacrylate (1.3g), dodecylmercaptan (0.2) and ethyl acetate (240g) were mixed to obtain a mixture; the mixture was loaded into a 500mL flask, and the air was replaced with nitrogen; subsequently, azobisisobutyl Nitrile (0.4 g); polymerized while stirring at 60°C for 3 hours to prepare a copolymer solution. The composition of the resulting polymer is nearly identical to the formulation of the added monomers.

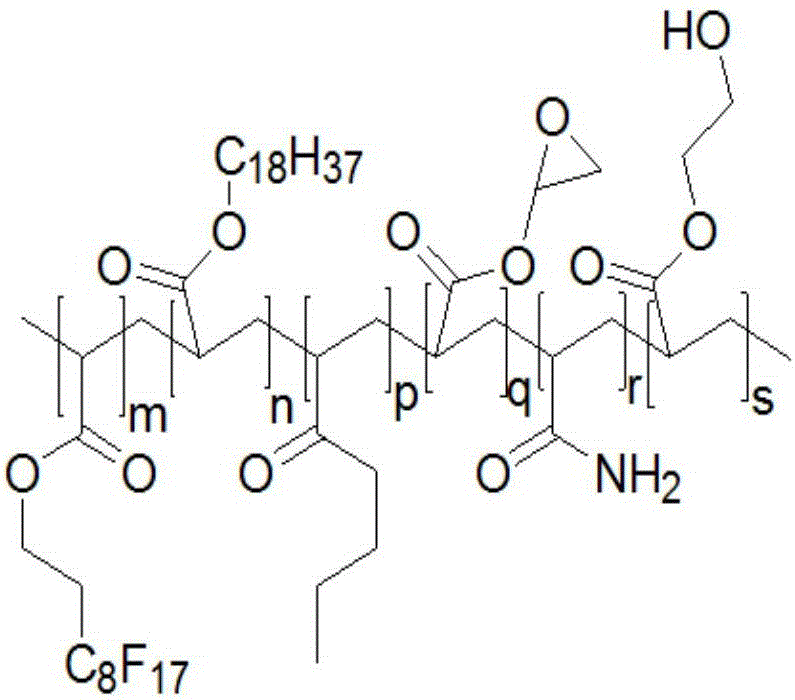

[0119] The chemical formula of the fluoropolymer prepared in this example is:

[0120]

[0121] Added monomer refers to CF 3 CF 2 (CF 2 CF 2 ) 6 CH 2 CH 2 OOCCH=CH 2 , octadecyl methacrylate, n-butyl methacrylate, glycidyl methacrylate, acrylamide, hydroxyethyl methacrylate.

[0122] The solid content of the obtained water and oil repellent was 34.5%.

preparation example 2

[0124] Will CF 3 CF 2 (CF 2 CF 2 ) 6 CH 2 CH 2 OOCCH=CH 2 (80g), octadecyl methacrylate (13g), n-butyl methacrylate (26g), glycidyl methacrylate (1.3g), acrylamide (5.4g), hydroxyethyl methacrylate (1.3g), dodecylmercaptan (0.2) and ethyl acetate (240g) were mixed to obtain a mixture; the mixture was loaded into a 500mL flask and replaced with nitrogen to remove dissolved oxygen; Azodiisobutyronitrile (0.6 g); polymerization was carried out at 60° C. while stirring for 3 hours to obtain a copolymer solution. The composition of the resulting polymer is nearly identical to the formulation of the added monomers.

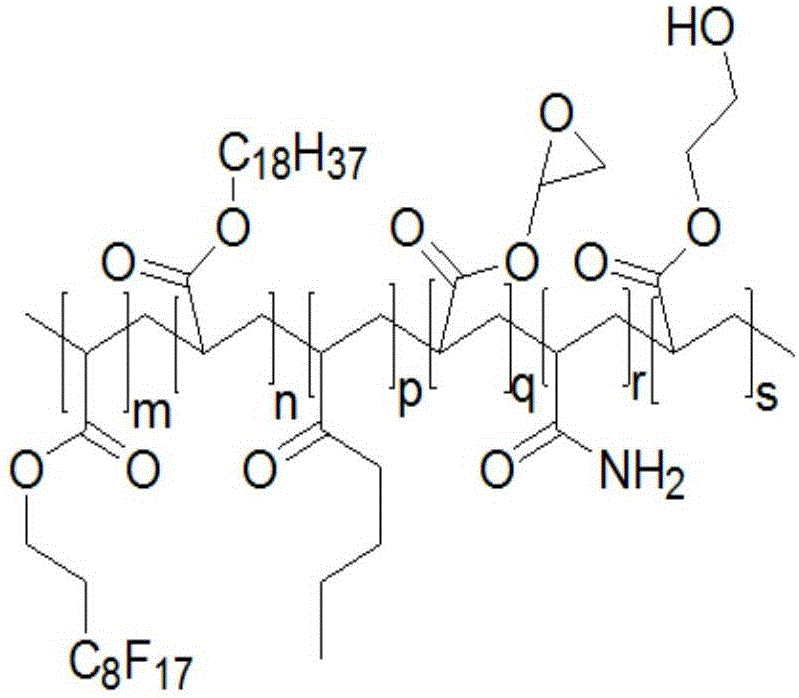

[0125] The chemical formula of the fluoropolymer prepared in this example is:

[0126]

[0127] Added monomer refers to CF 3 CF 2 (CF 2 CF 2 ) 6 CH 2 CH 2 OOCCH=CH 2 , octadecyl methacrylate, n-butyl methacrylate, glycidyl methacrylate, acrylamide, hydroxyethyl methacrylate.

[0128] The solid content of the obtained water and oil repellent was 34.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com