Method for preparing naphthyl autocatalytic poly-cyanophenyl resin

A polybenzonitrile resin and naphthyl self-catalysis technology is applied in the field of new high temperature resistant polymer material preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

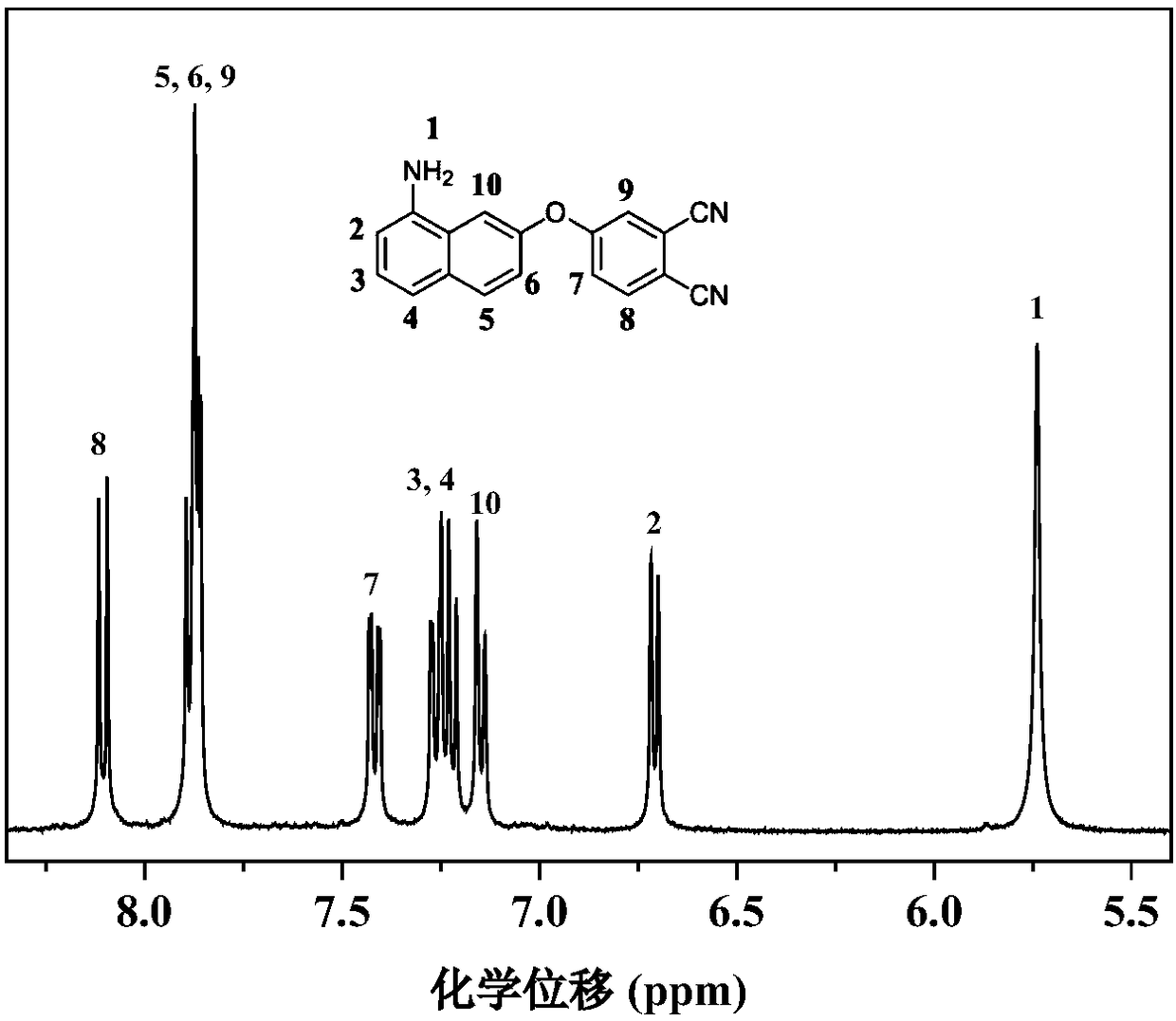

[0022] Synthesis of monomer: Add 10.05g (63.14mmol) 1-amino-7-naphthol, 9.03g (65.35mmol) anhydrous potassium carbonate and 40mL N,N-dimethylformamide in a 250mL three-necked flask as a solvent, and then The mixture was heated up to 60° C., and after 1 hour of reaction, 10.93 g (63.14 mmol) of 4-nitrophthalonitrile was added, and the reaction was continued for 6 hours. Remove the solvent by distillation under reduced pressure, and finally transfer the product from the flask to 500mL deionized water, filter under reduced pressure, and wash the filter cake repeatedly with deionized water until the filtrate is clear and transparent, then put the filter cake in a vacuum drying oven at 60°C Dry under vacuum for 24 hours and set aside.

[0023] Curing: Take about 15g of the above-mentioned monomers and melt them in a 250mL glass reactor at 150°C, and stir continuously to react for 30min to obtain a prepolymer. Grind the prepolymer into powder (100 mesh) and pour it into the prepare...

Embodiment 2

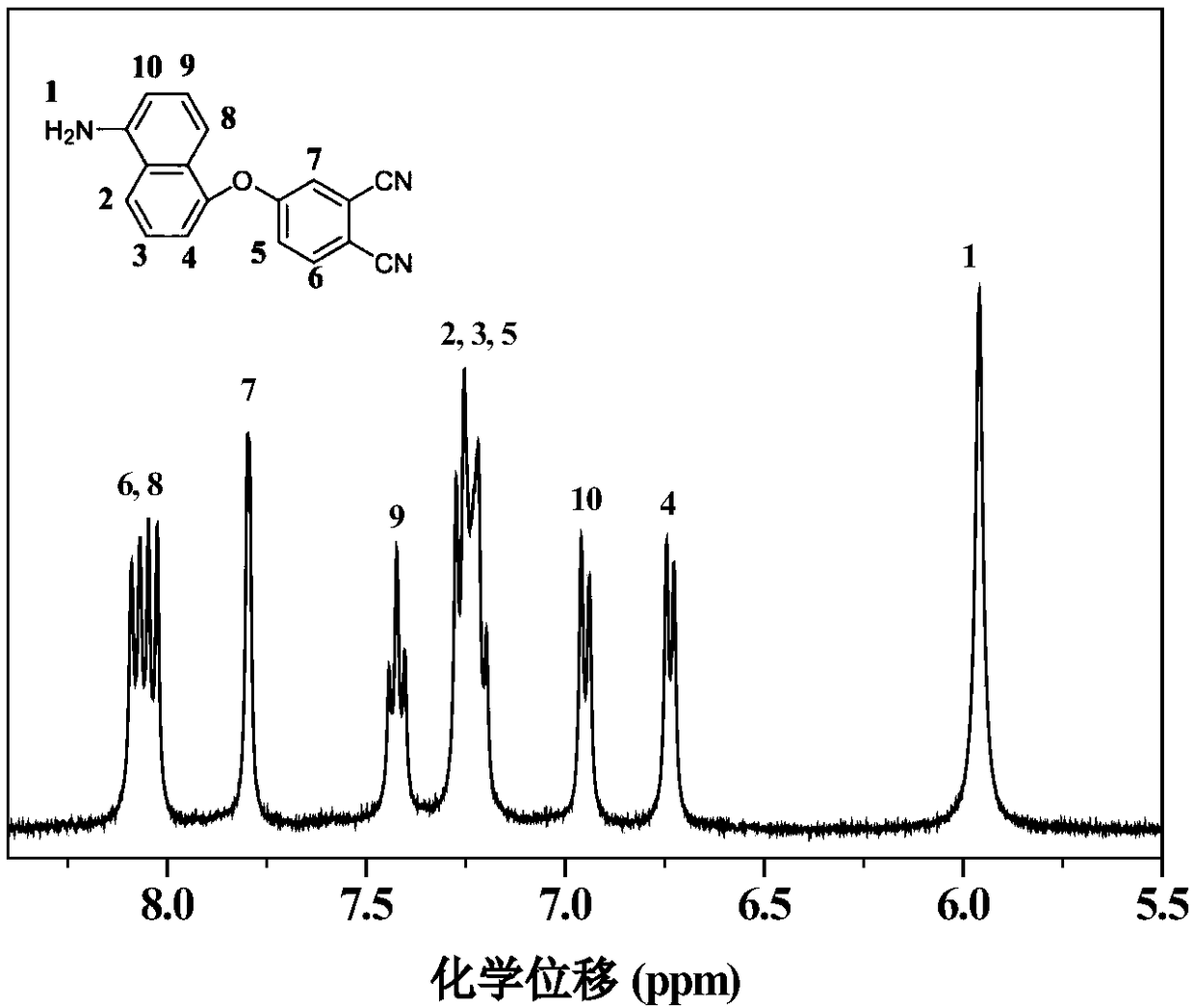

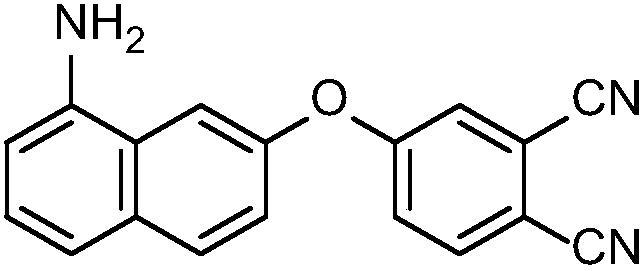

[0030] Synthesis of monomer: Add 12.06g (75.76mmol) 1-amino-5-naphthol, 11.06g (80.00mmol) anhydrous potassium carbonate and 45mL N,N-dimethylformamide in a 250mL three-necked flask as a solvent, and then The mixture was heated up to 60° C., and after 1 hour of reaction, 13.11 g (75.82 mmol) of 4-nitrophthalonitrile was added, and the reaction was continued for 6 hours. Remove the solvent by distillation under reduced pressure, and finally transfer the product from the flask to 500mL deionized water, filter under reduced pressure, and wash the filter cake repeatedly with deionized water until the filtrate is clear and transparent, then put the filter cake in a vacuum drying oven at 60°C Under vacuum drying 24 hours, standby, its structural formula is as follows:

[0031]

[0032] Curing: Take about 15g of the above-mentioned monomers and melt them in a 250mL glass reactor at 210°C, and keep stirring to react for 30min to obtain a prepolymer. Grind the prepolymer into powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com