Epoxy functionalized organosilicon conductive adhesive for light emitting diode (LED)

A silicone, functionalized technology, applied in conductive adhesives, adhesives, epoxy resins, etc., can solve the problems of small chip thrust and poor adhesion of conductive adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The epoxy-functionalized silicone conductive adhesive for LEDs of this embodiment comprises components with the following parts by weight:

[0074] SiMAET n=1 10 SiMDH n=1 8.0 2E4MZ 0.5 silver powder 80 Z6040 0.5

[0075] After testing, the epoxy functional silicone conductive adhesive for LEDs in this embodiment has a refractive index of 1.43, a glass transition temperature of 98°C, a 2 mm × 2 mm chip thrust of 7.0 Kgf (25°C), and a conductivity of 3.0 × 10 -4 W. cm.

Embodiment 2~6

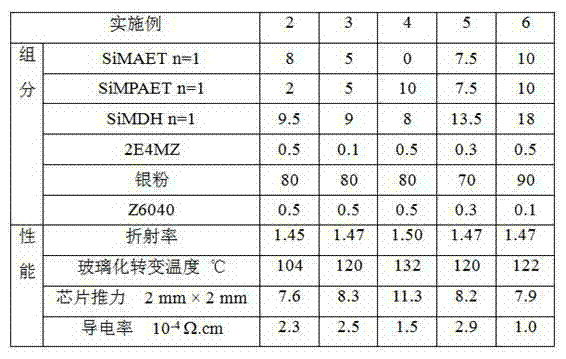

[0077] The components (parts by weight) and properties of the epoxy-functionalized silicone conductive adhesives for LEDs in Examples 2-6 are shown in Table 1. The refractive index is 1.45-1.50, and the glass transition temperature is 104-132°C. The thrust force of the mm × 2 mm chip is 7.6~11.3 Kgf (25°C), and the conductivity is 1.0× 10 -4 ~3.0 × 10 -4 W. cm.

Embodiment 7~12

[0079] The components (parts by weight) and properties of the epoxy-functionalized silicone conductive adhesives for LEDs in Examples 7-12 are shown in Table 2. The refractive index is 1.43, the glass transition temperature is 29-98°C, 2 mm × The thrust force of 2 mm chips is 5.4~7 Kgf (25℃), and the conductivity is 1.0×10 -4 ~3.0 × 10 -4 W. cm.

[0080] Table 1 Components and properties of Examples 2 to 6

[0081]

[0082] Components and properties of Table 2 Examples 7-12

[0083]

[0084] Table 3 Components and properties of Examples 13 to 18

[0085]

[0086] Components and properties of Table 4 Examples 19 to 24

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thrust | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com