High-performance high-temperature-resistant modified epoxy resin

An epoxy resin, modified technology, applied in the field of modified epoxy resin and its preparation, can solve the problems of affecting the thermal properties of the material, reducing the glass transition temperature of the material, and the brittleness of the cured resin restricting the use, etc., to achieve good processing performance and the effect on the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

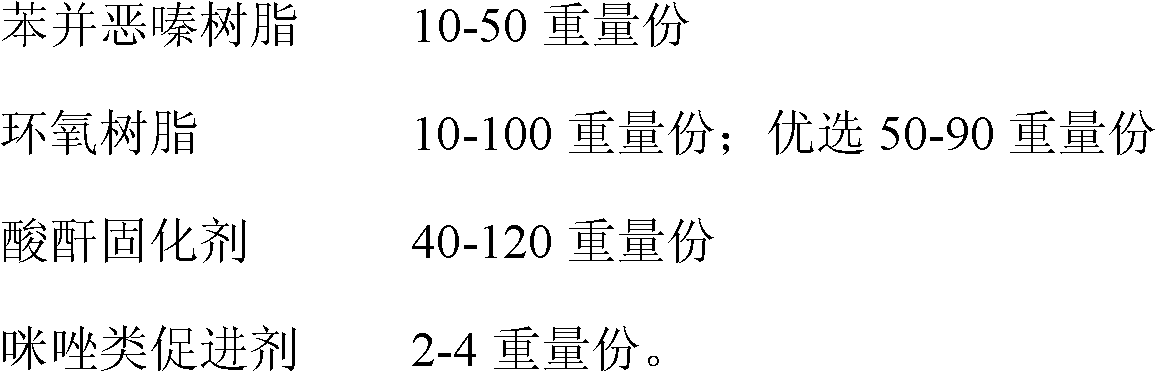

[0037] In this embodiment, the epoxy resin is selected from DER 331 and the benzoxazine resin is selected from BENA, the anhydride curing agent is selected from MTHPA, and the curing agent is selected from 2E4MZ. The specific performance and formula (parts by weight) are as shown in Table 1:

[0038]

Embodiment 2

[0040] In this embodiment, epoxy resin selects epoxy 2021P for use, benzoxazine resin selects BENF for use, anhydride curing agent selects MTHPA for use, and curing agent selects 2MZ for use, and specific performance and formula (weight parts) are as shown in Table 2:

[0041] Table 2

[0042]

Embodiment 3

[0044] In this embodiment, the epoxy resin is selected from DER 354, the benzoxazine resin is selected from BENF, the anhydride curing agent is selected from MTHPA, and the curing agent is selected from 2P4MZ. The specific performance and formula (parts by weight) are as shown in Table 3:

[0045] table 3

[0046]

[0047]The above examples are illustrated by taking three imidazole accelerators 2E4MZ, 2MZ and 2P4MZ as examples, and other imidazole accelerators such as: 2PZ, C11Z, C17Z, 1B2MZ, SFZ, FFZ, 2MZL, 2MZ-CN, 2PZ-CN, C11Z-CN, 2E4MZ-CN, 2MZ-CNS, 2PZ-CNS, 2E4MZ-CNS, C11Z-CNS and 2MZ-A can also obtain the same effect by replacing the above three imidazole accelerators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com