Self-cleaning aramid fiber film, preparation method thereof, and applications thereof in gas separation

A self-cleaning and aramid fiber technology, applied in the field of self-cleaning aramid fiber film and its preparation, can solve the problems of low reaction efficiency and poor durability, and achieve high temperature resistance, excellent performance and good molecular structure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

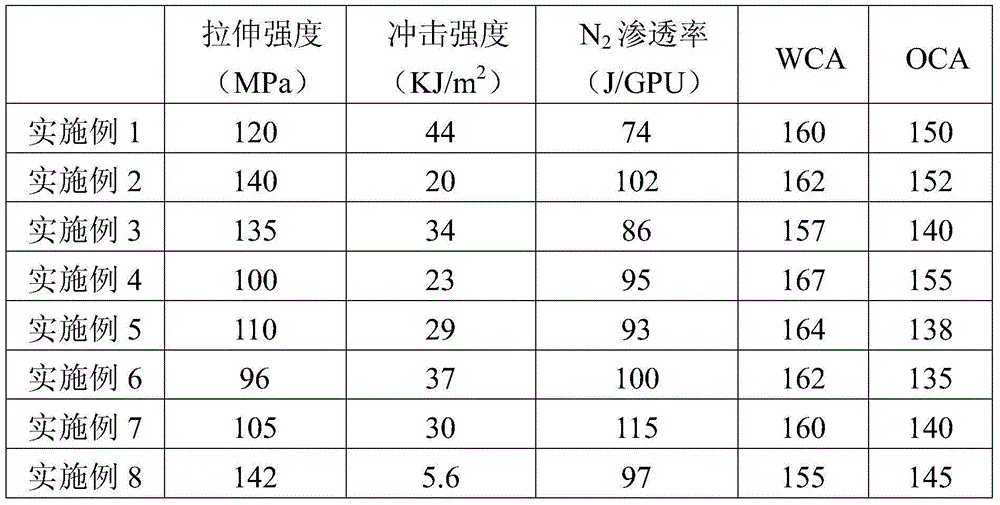

Embodiment 1

[0040] Example 1: Preparation of a self-cleaning aramid film

[0041] (1) Add KOH to dimethyl sulfoxide (DMSO), stir until KOH is completely dissolved, then add aramid II, stir at room temperature to form a 4% solution, the amount of KOH is N equivalent of aramid II 1 times. Then add PEG-1000 with 10% aramid mass to the above solution, stir evenly to form a casting film, and then vacuum degas the casting liquid for use. Then spread the casting solution on a smooth glass plate, and scrape out a 300-400um film with a scraper. The scraped film was evaporated at 20°C for 10 seconds, and then submerged into the gel in the water until the film separated from the glass plate to obtain a gel film. The gel film was soaked in water for 4 days to completely remove the porogen and solvent. Finally, it is processed at 120°C until the film is completely dry, and the aramid film is obtained.

[0042] (2) Put the aramid film prepared in (1) into the fluorine-containing epoxy resin dispersed in ...

Embodiment 2

[0046] Example 2: Preparation of a self-cleaning aramid film

[0047] (1) Add potassium tert-butoxide to N,N-dimethylformamide, stir until potassium tert-butoxide is completely dissolved, then add Aramid II, stir at room temperature to form a solution with a mass fraction of 5%, tert-butyl The amount of potassium alkoxide is 0.8 times the N equivalent in Aramid II. Then add PVP-25 with 20% aramid mass to the above solution, stir evenly to form a casting film, and then vacuum degas the casting liquid for use. Then spread the casting solution on a smooth glass plate, and scrape out a 300-400um film with a scraper. After the scraped film, the solvent was evaporated at 30°C for 30 seconds, and then submerged into the water to gel to obtain a gel film. The gel film was soaked in water for 7 days to completely remove the pore former and solvent. Finally, it is processed at 150°C until the film is completely dry, and the aramid film is obtained.

[0048] (2) Put the aramid film prepare...

Embodiment 3

[0049] Example 3: Preparation of a self-cleaning aramid film

[0050] (1) Add NaH to N-methylpyrrolidone, stir until NaH is completely dissolved, then add aramid Ⅲ, stir at room temperature to form a solution with a mass fraction of 8%, the amount of NaH is 1.5 times the N equivalent in aramid Ⅲ . Then add PEG-600 with 30% aramid mass to the above solution, stir evenly to form a casting film, and then vacuum degas the casting liquid for use. Then spread the casting solution on a smooth glass plate, and scrape out a 300-400um film with a scraper. The scraped film, evaporate the solvent at 25°C for 20 seconds, and then sink into the water to gel to obtain a gel film. The gel film is soaked in water for 7 days to completely remove the pore former and solvent. Finally, it is processed at 80°C until the film is completely dry, and the aramid film is obtained.

[0051] (2) Put the aramid film prepared in (1) into a toluene-dispersed fluorine-containing epoxy resin (preparation is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com