Preparation method of PPTA-MPIA in-situ composite fibrid

A technology of precipitating fibers and in-situ compounding, which is applied in the field of synthetic fibers and can solve problems such as inability to compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

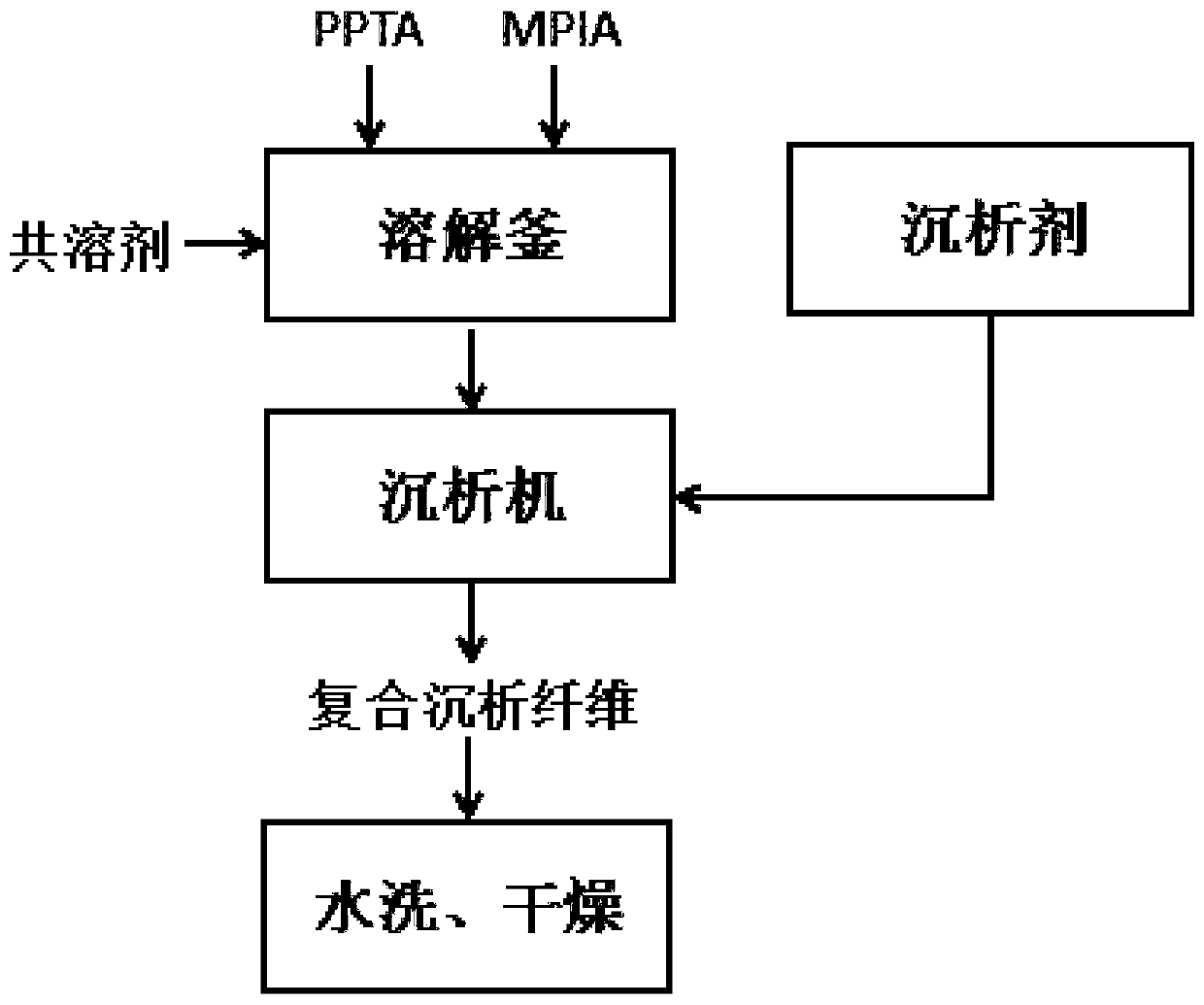

Method used

Image

Examples

Embodiment 1

[0021] First, weigh 50.0 g of the raw materials PPTA (intrinsic viscosity: 3.0 dL / g) and MPIA (intrinsic viscosity: 1.0 dL / g) according to the mass ratio of 1:1, and add them to the dissolution tank. Then a co-solvent (concentrated sulfuric acid, 900.0 g) was added to the dissolution kettle, the temperature was raised to 90° C., and stirred for 30 minutes to dissolve.

[0022] Use a small metering pump to drain the mixed solution in the kettle to the sedimentation machine with a flow rate of 30.0g / min. The coagulation bath in the settling machine is 10% dilute sulfuric acid, the rotating speed of the turntable is 1000r / min, and the settling residence time is 1min. Finally, the obtained composite fibrids are washed with distilled water several times and dried.

[0023] The PPTA-MPIA composite precipitated fiber obtained by this method has good dispersion in water, the beating degree is 30°SR, and the specific surface area is 7.0m 2 / g, the average fiber length is 0.8mm.

Embodiment 2

[0025] First, weigh 40.0g and 20.0g of the raw materials PPTA (intrinsic viscosity: 2.3dL / g) and MPIA (intrinsic viscosity: 0.8dL / g) according to the mass ratio of 2:1, respectively, and add them to the dissolution tank. Any one or more of the co-solvents are subsequently added.

[0026] In a preferred embodiment of the present invention, the capping agent is preferably any one or more of methanol and ethanol.

[0027] In a preferred embodiment of the present invention, the intrinsic viscosity of the raw material or puree of PPTA and MPIA is 0.5-8.0 dL / g. Preferably 0.5-3.0 dL / g.

[0028] In a preferred embodiment of the present invention, it is characterized in that, in the mixed solution prepared in step 1, the total solid content of PPTA and MPIA accounts for 0.5-20%. Preferably it is 0.5 to 10%.

[0029] In a preferred embodiment of the present invention, the dissolution temperature in the first step is 40-90° C., and the dissolution time is 0.5-10 hr.

[0030] In a pr...

Embodiment 3

[0038] First, weigh 20.0 g and 40.0 g of the raw materials PPTA (intrinsic viscosity: 3.0 dL / g) and MPIA (intrinsic viscosity: 1.0 dL / g) according to the mass ratio of 1:2, respectively, and add them into the dissolution tank. Then the co-solvent (concentrated sulfuric acid, 1140.0 g) was added to the dissolution tank, the temperature was raised to 90° C., and stirred for 30 minutes to dissolve. Use a small metering pump to drain the mixed liquid crystal solution in the kettle to the sedimentation machine with a flow rate of 40.0g / min. The coagulation bath in the settling machine is 5% dilute sulfuric acid, the rotating speed of the turntable is 2000r / min, and the settling residence time is 1min. Finally, the obtained composite fibrids are washed with distilled water several times and dried.

[0039] The PPTA-MPIA composite precipitated fiber obtained by this method has good dispersion in water, the beating degree is 35°SR, and the specific surface area is 6.3m 2 / g, the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com