Patents

Literature

33 results about "Electrical insulation paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical insulation papers are paper types that are used as electrical insulation in many applications due to pure cellulose having outstanding electrical properties. Cellulose is a good insulator and is also polar, having a dielectric constant significantly greater than one. Electrical paper products are classified by their thickness, with tissue considered papers less than 1.5 mils (0.0381 mm) thickness, and board considered more than 20 mils (0.508 mm) thickness.

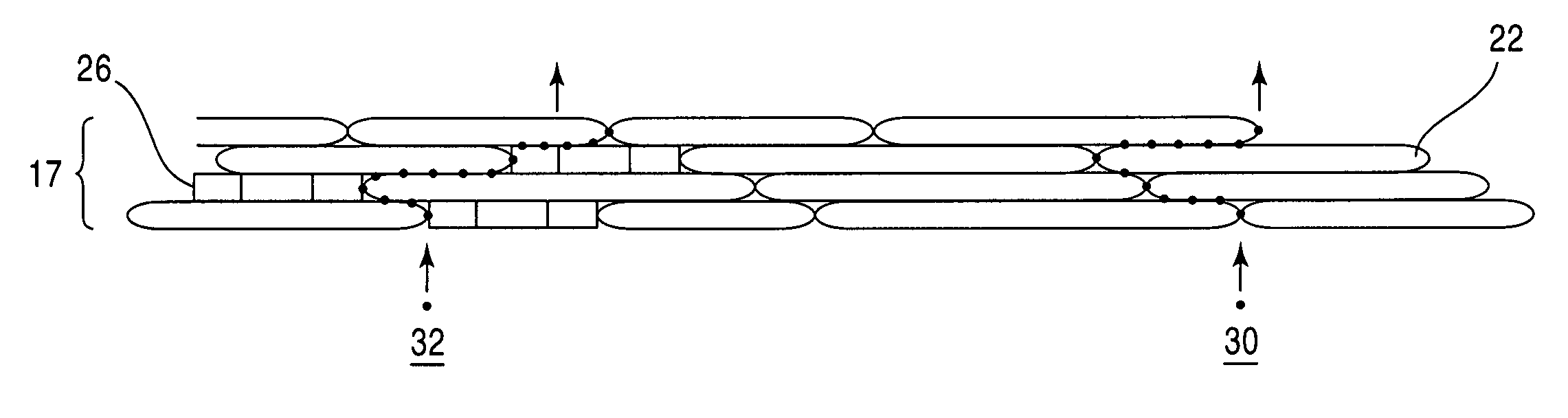

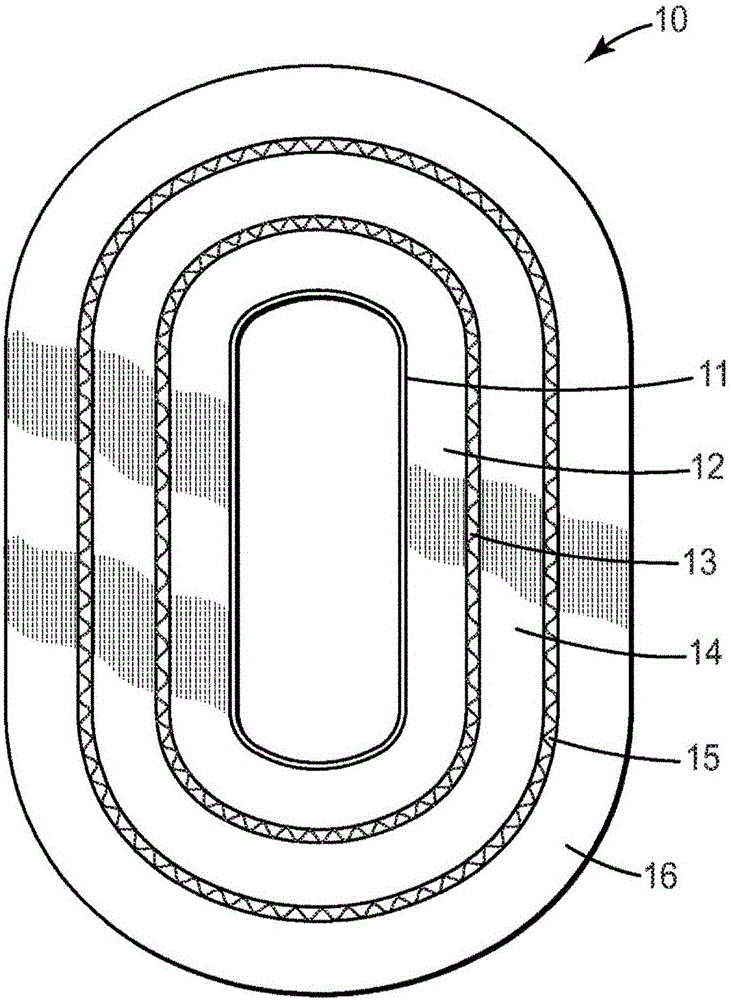

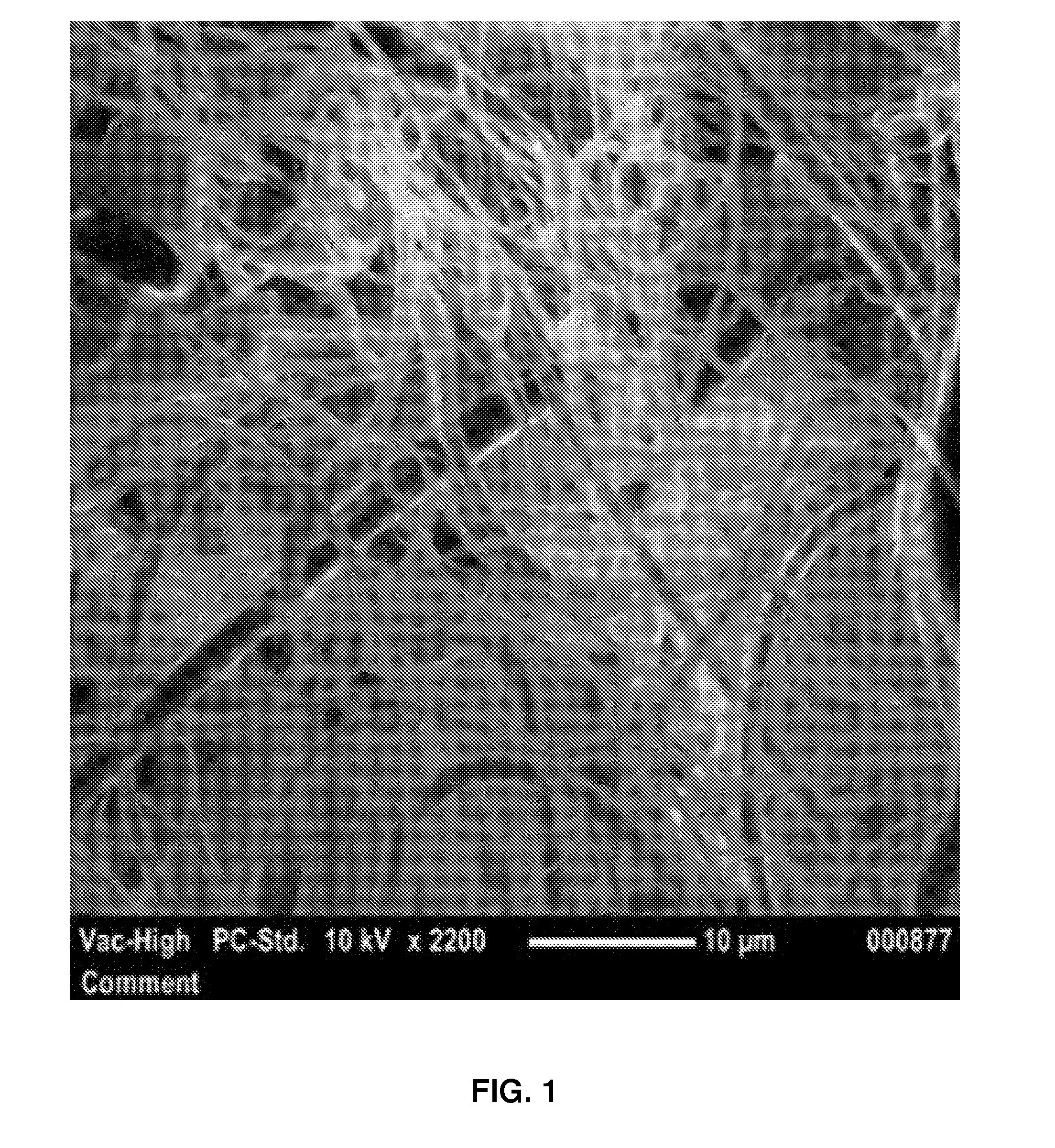

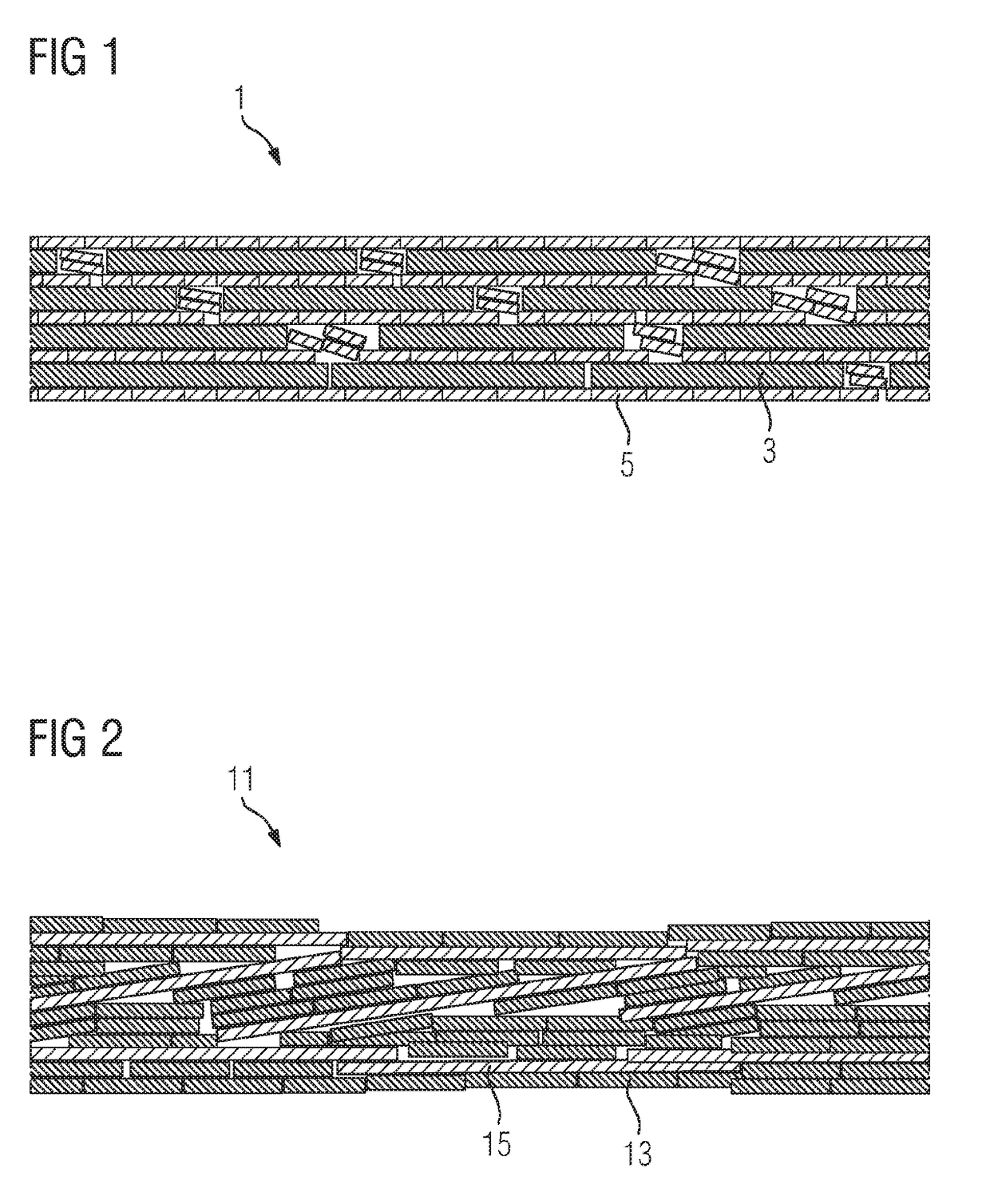

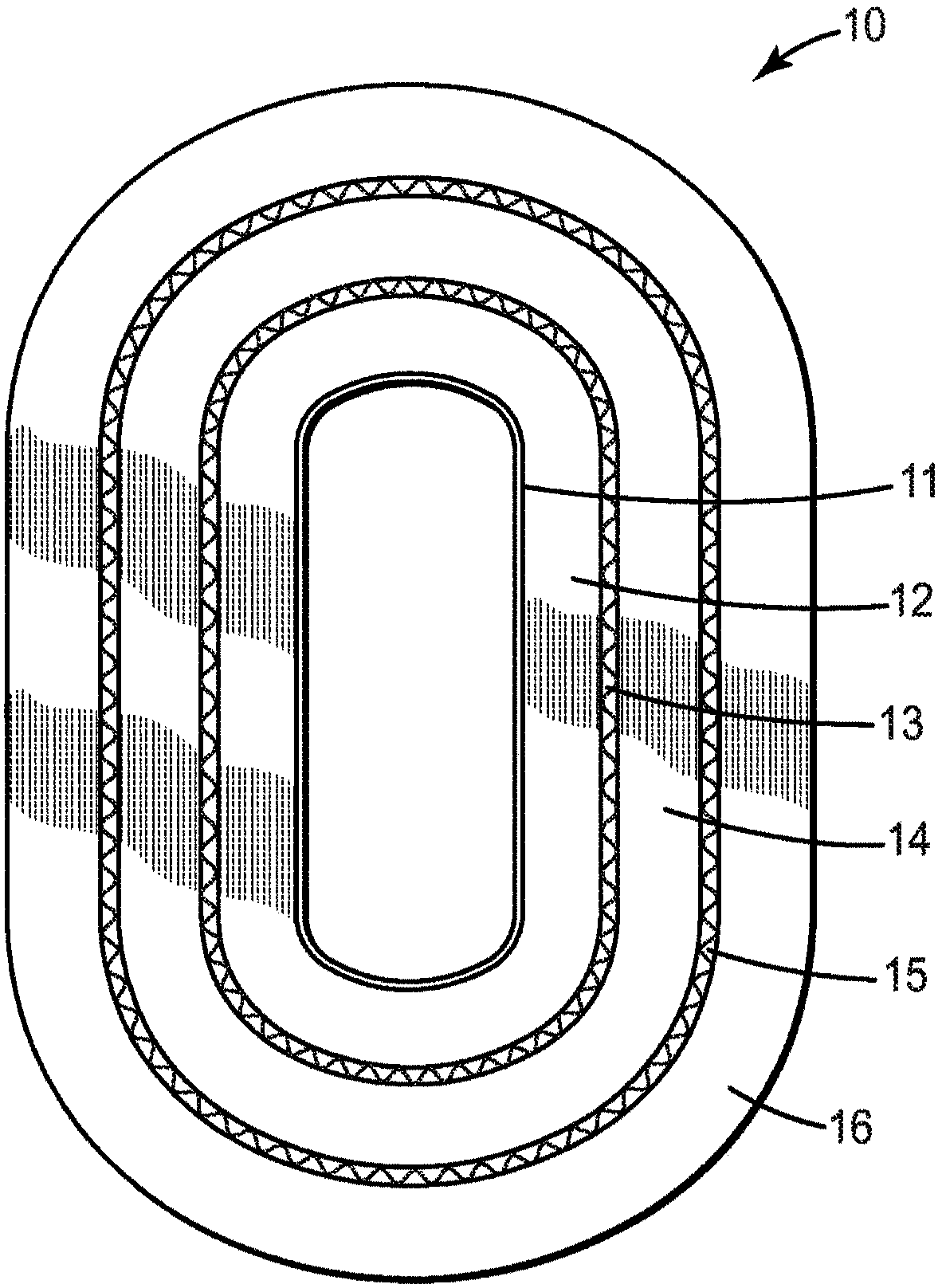

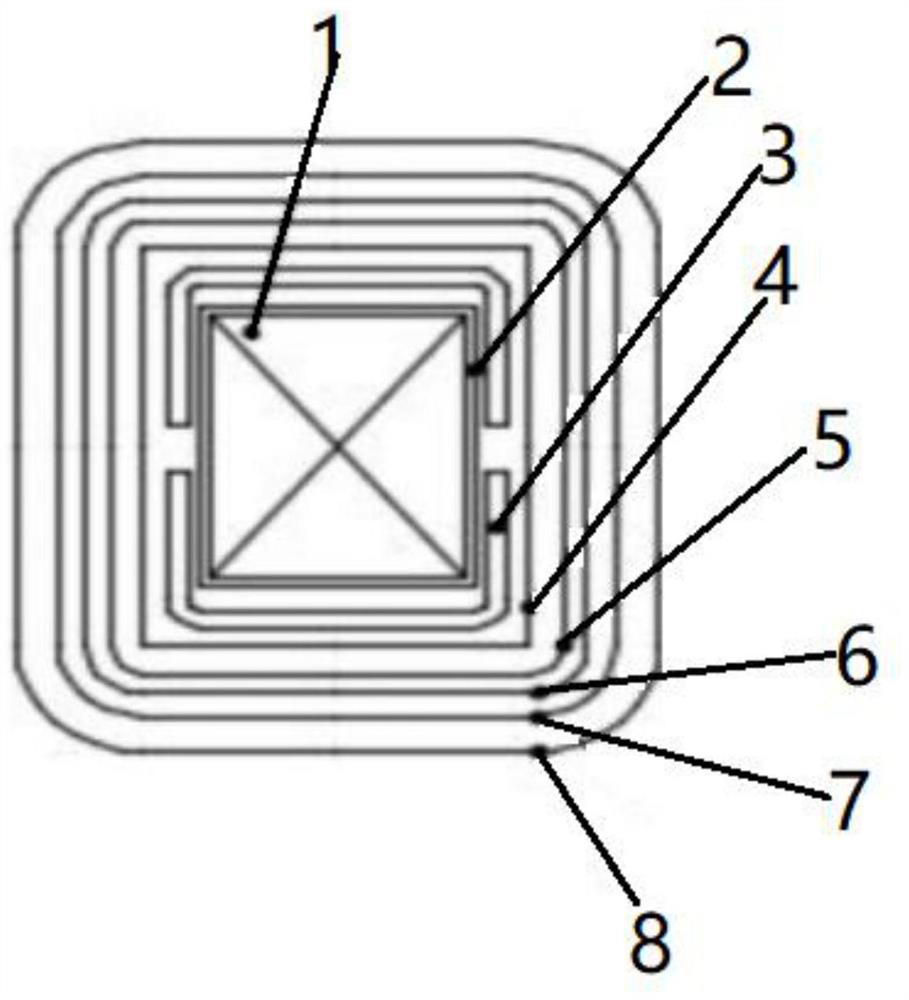

Multi-layered platelet structure

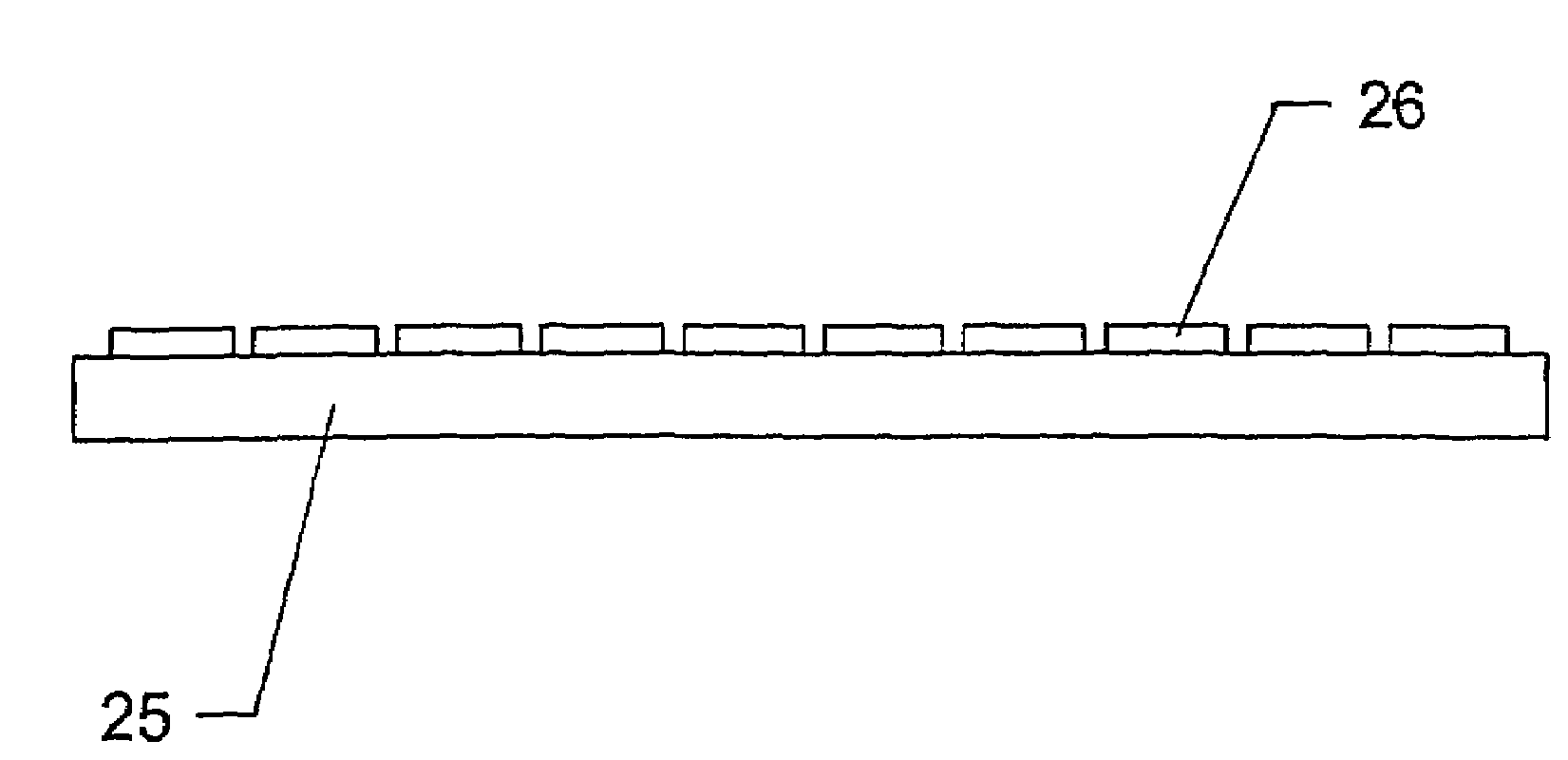

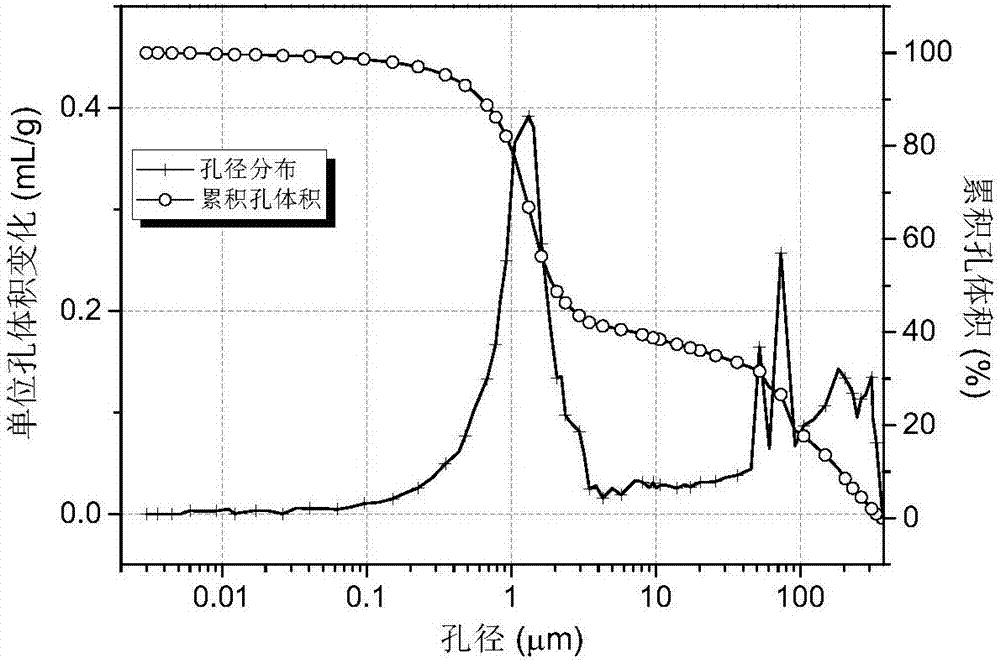

ActiveUS20070141324A1Improve thermal conductivityHigh viscositySynthetic resin layered productsMicaHexagonal boron nitrideElectrical insulation paper

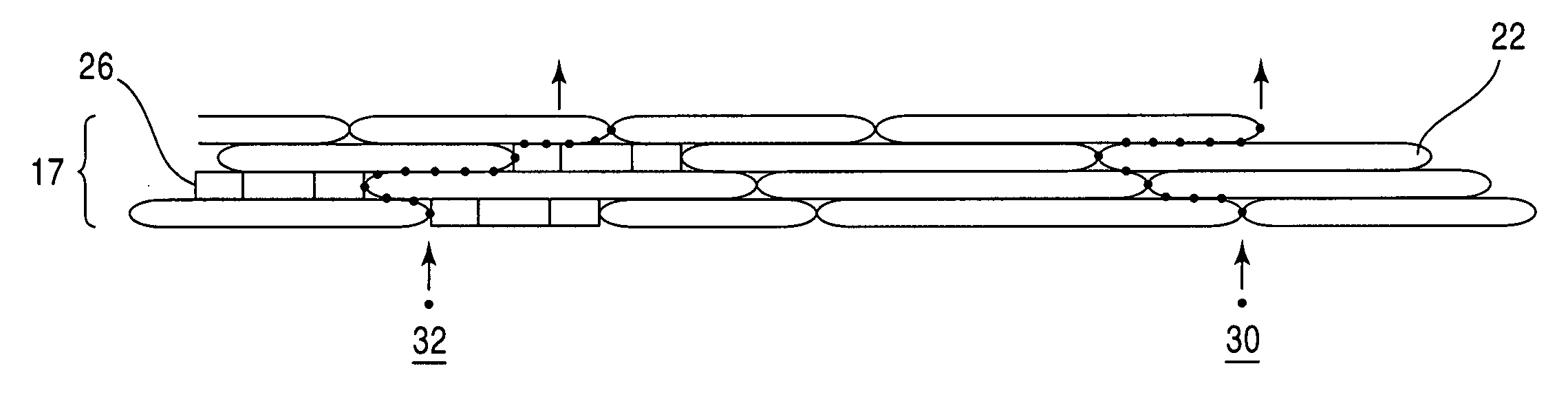

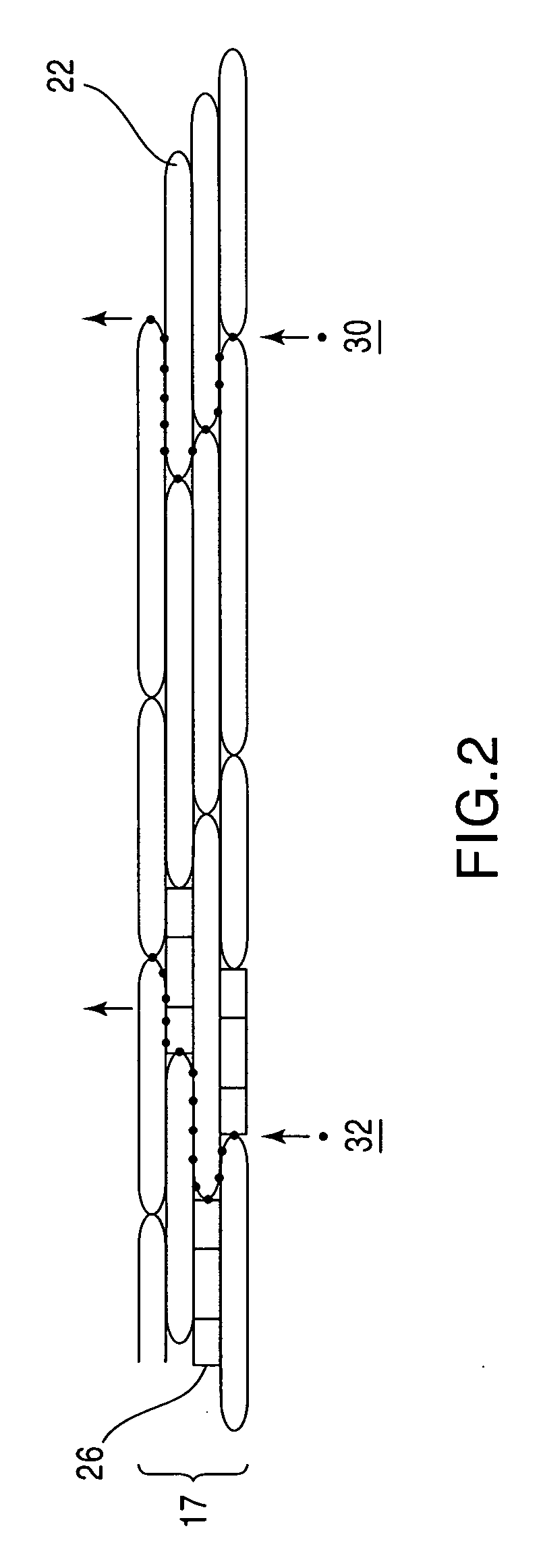

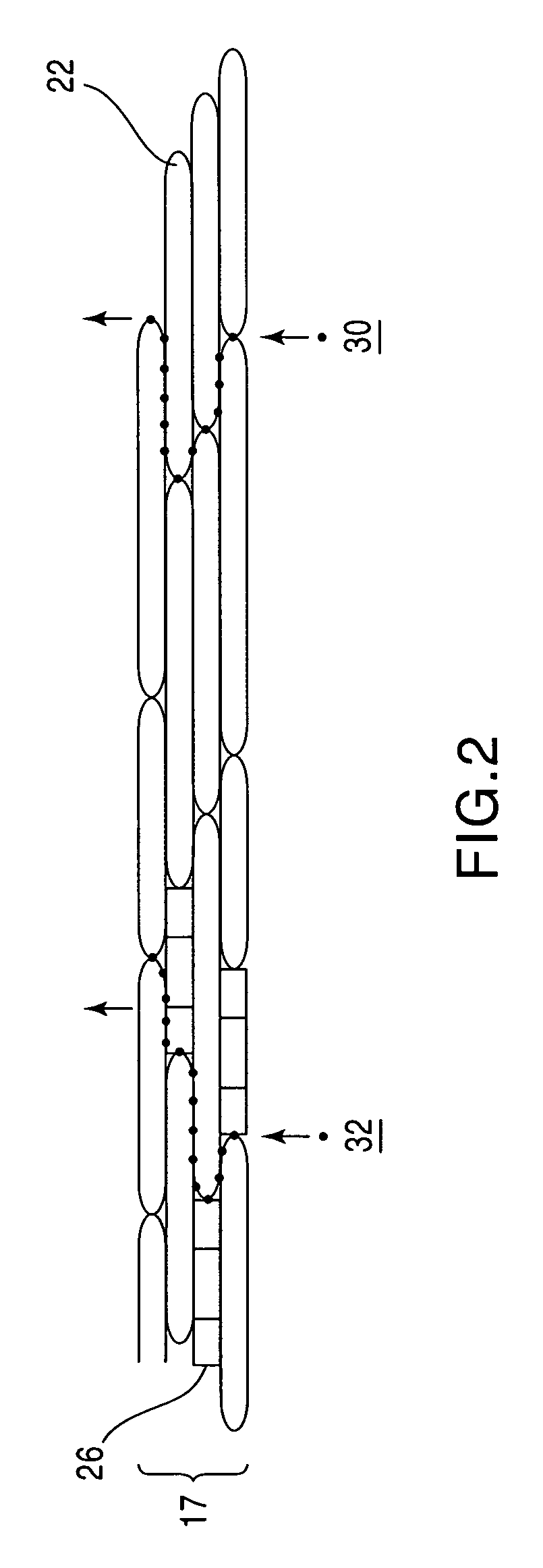

An electrical insulation paper that is made of mica flakelets (22), having an average size range of 0.01 to 0.05 mm in their thinnest dimension, hexagonal boron nitride (26), which has an average size range of 10 to 1,000 nm in their longest dimension, and a resin matrix. The mica flakelets and the hexagonal boron nitride are mixed and formed into a paper (17), and the resin is added to the paper after formation, the ratio by weight of the hexagonal boron nitride to the mica flakelets is directly proportional to the average size of the hexagonal boron nitride compared to the average size of the mica flakelets, within an adjustment factor.

Owner:SIEMENS ENERGY INC

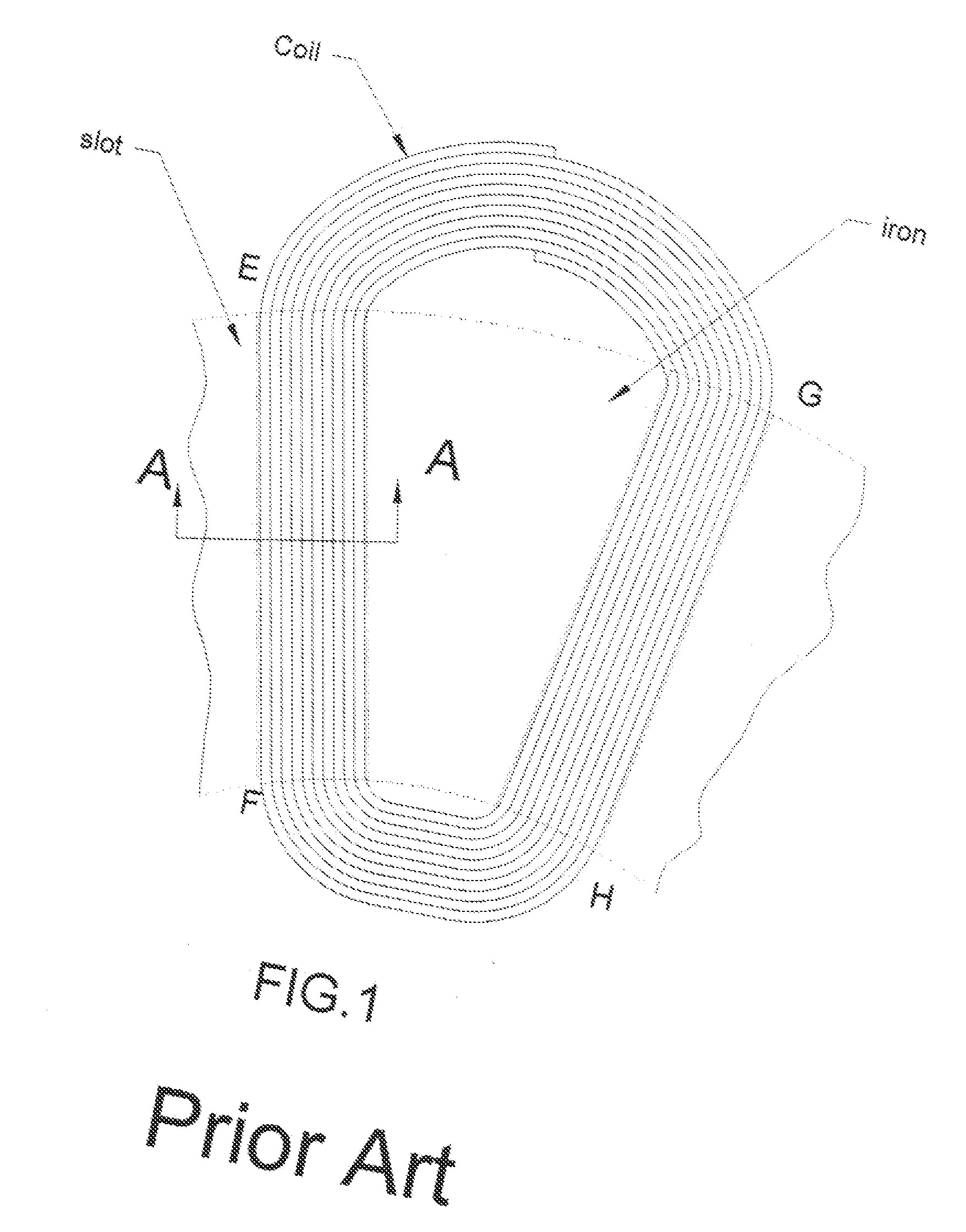

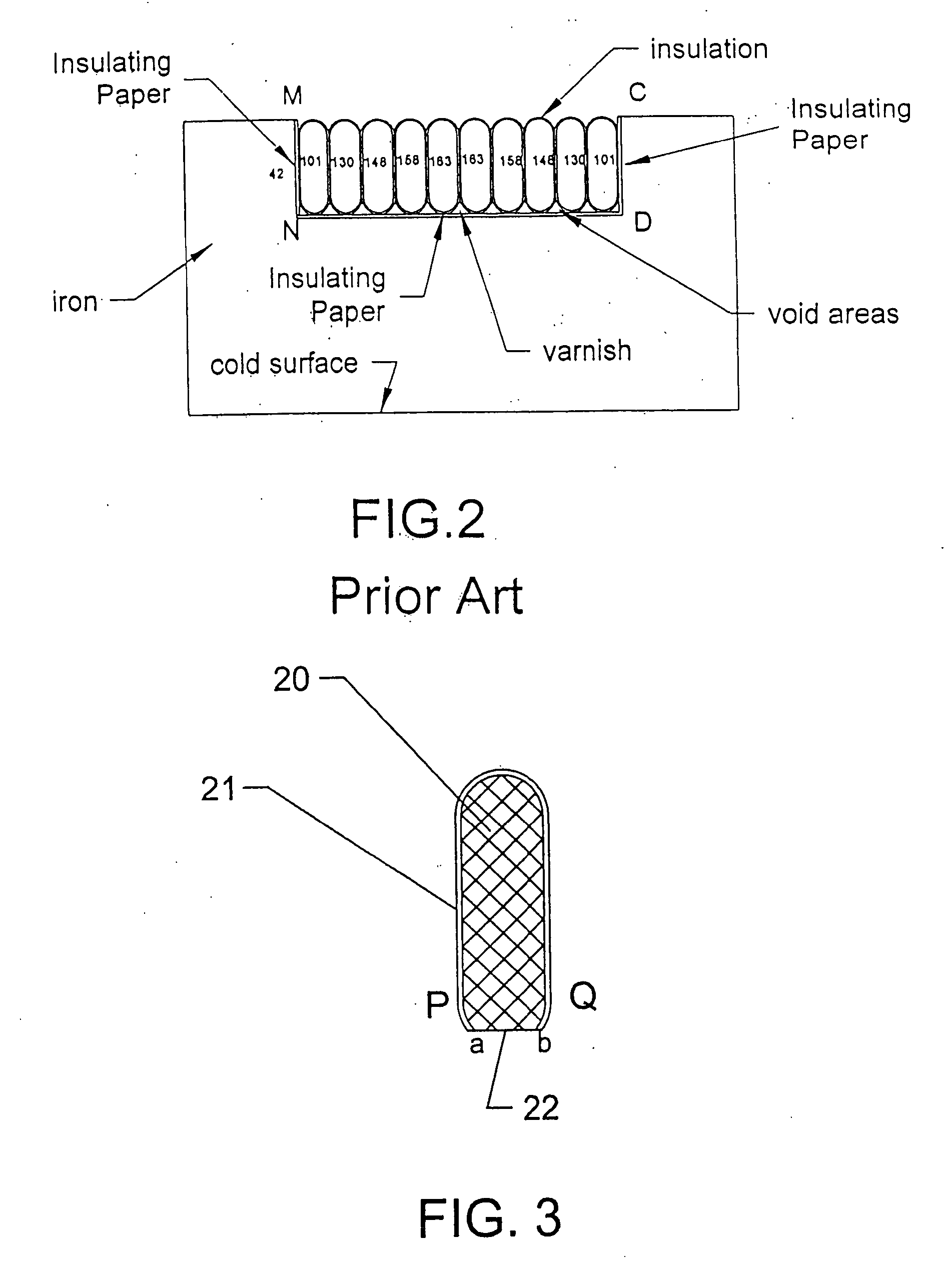

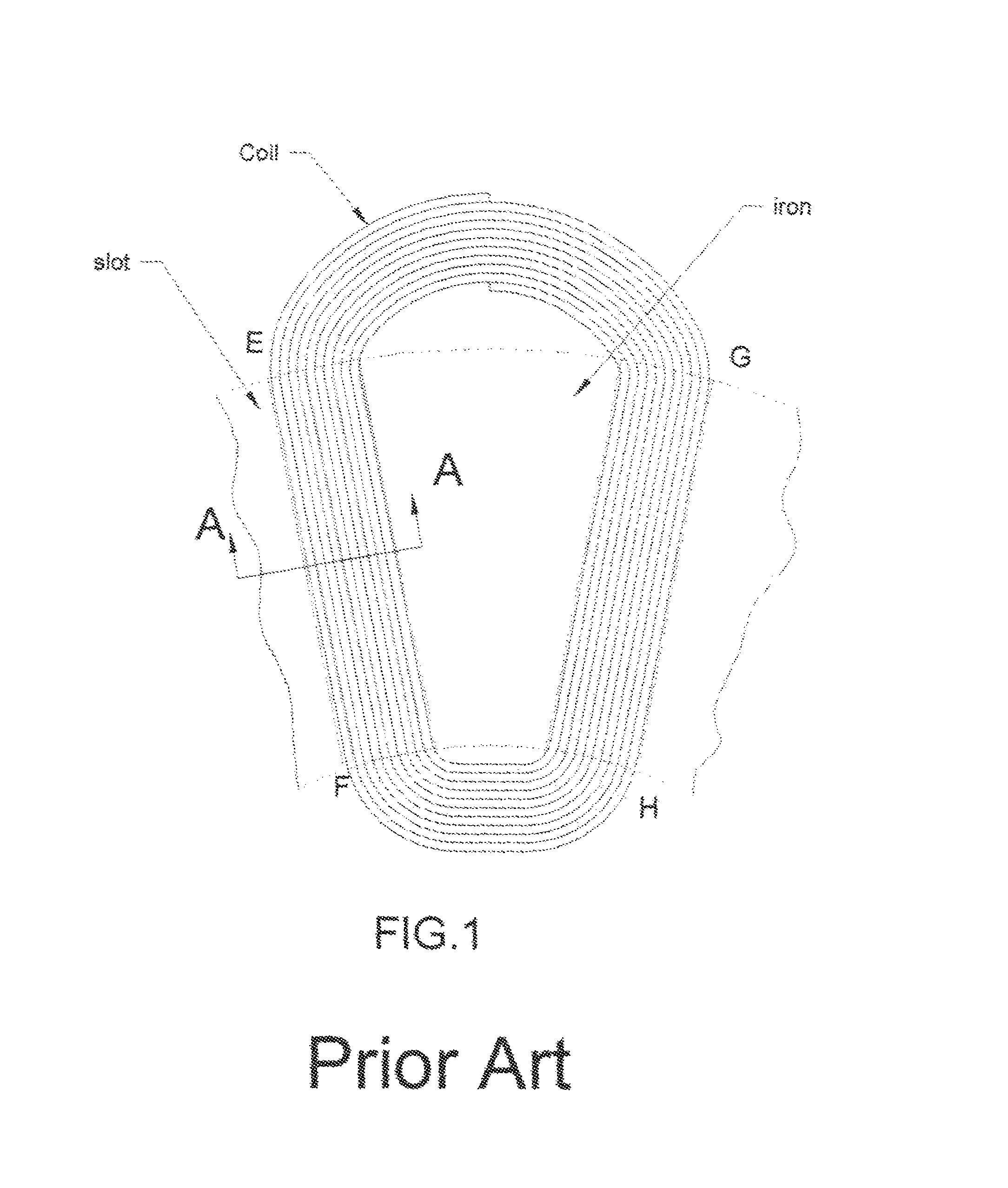

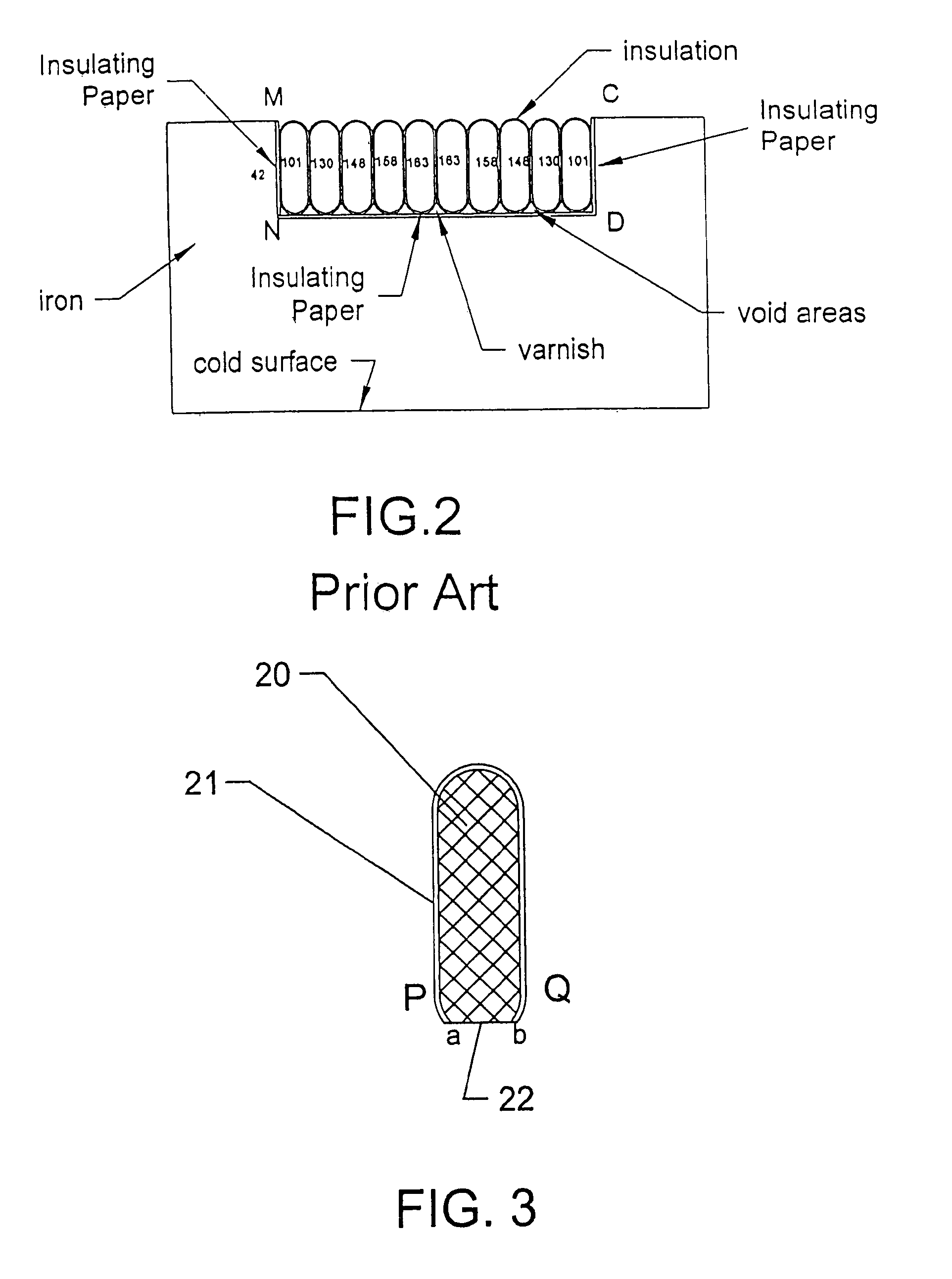

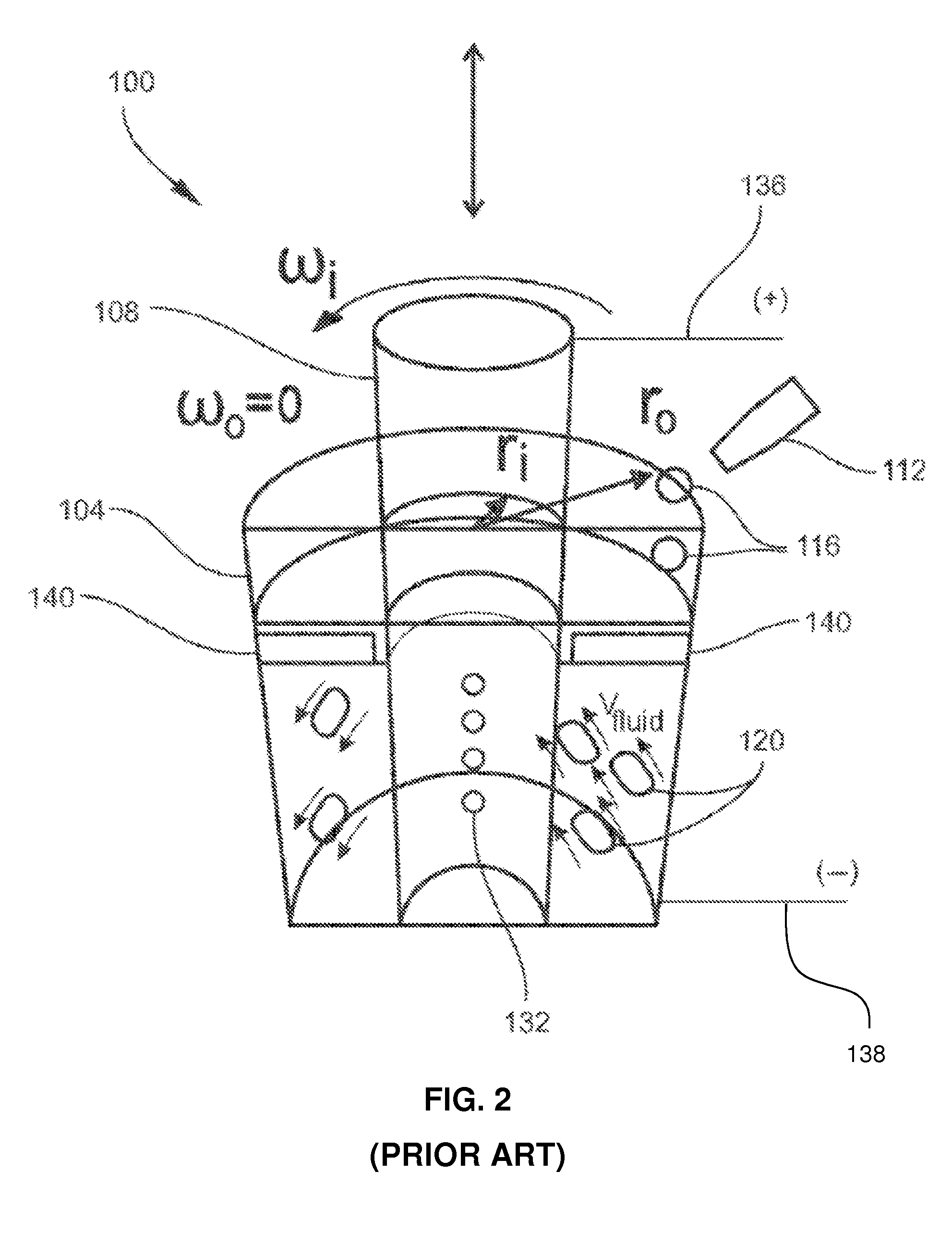

Cooling of stator windings

InactiveUS20070228846A1Reduce the temperatureImprove thermal conductivityWindings insulation shape/form/constructionMagnetic circuit rotating partsCopper conductorEpoxy

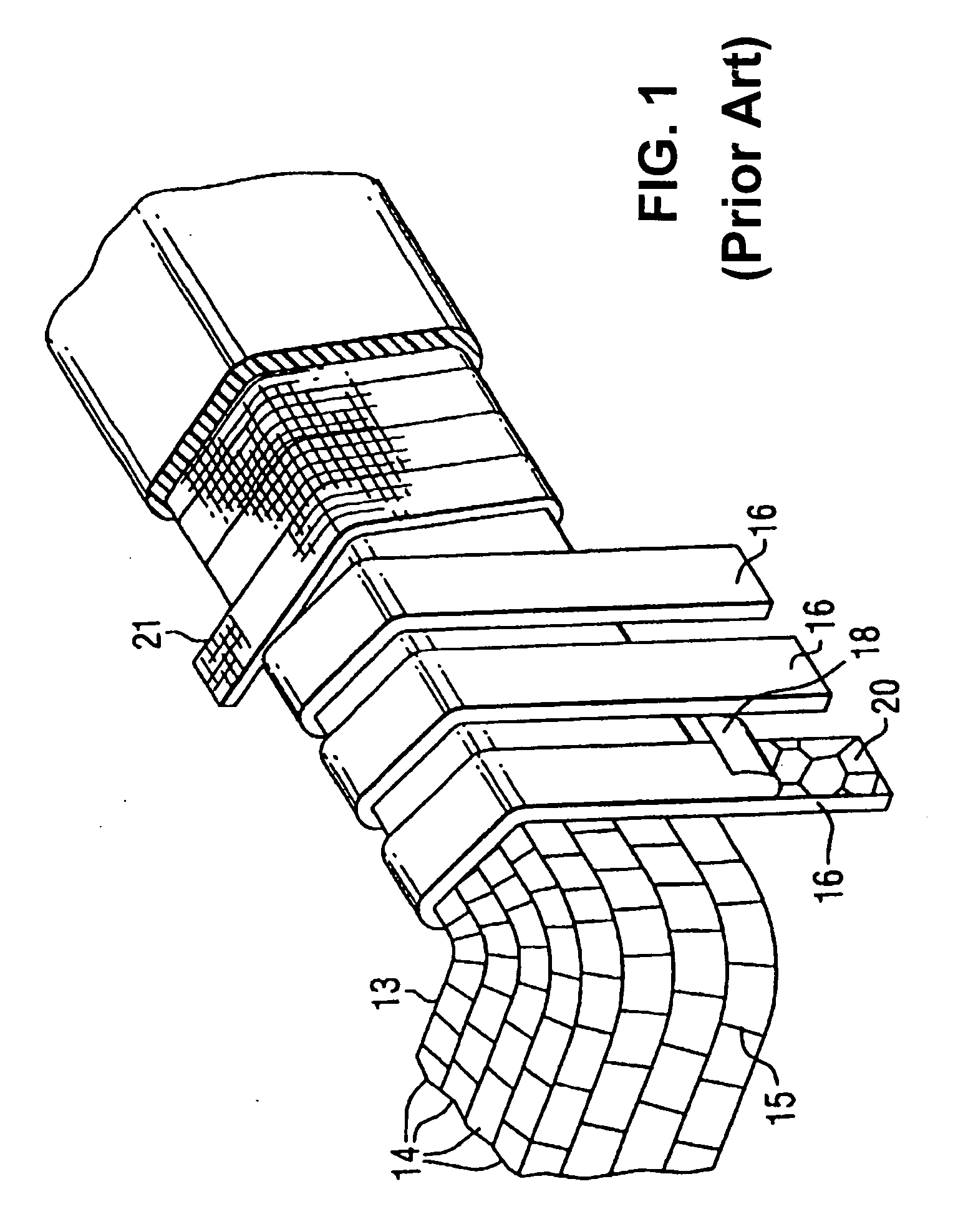

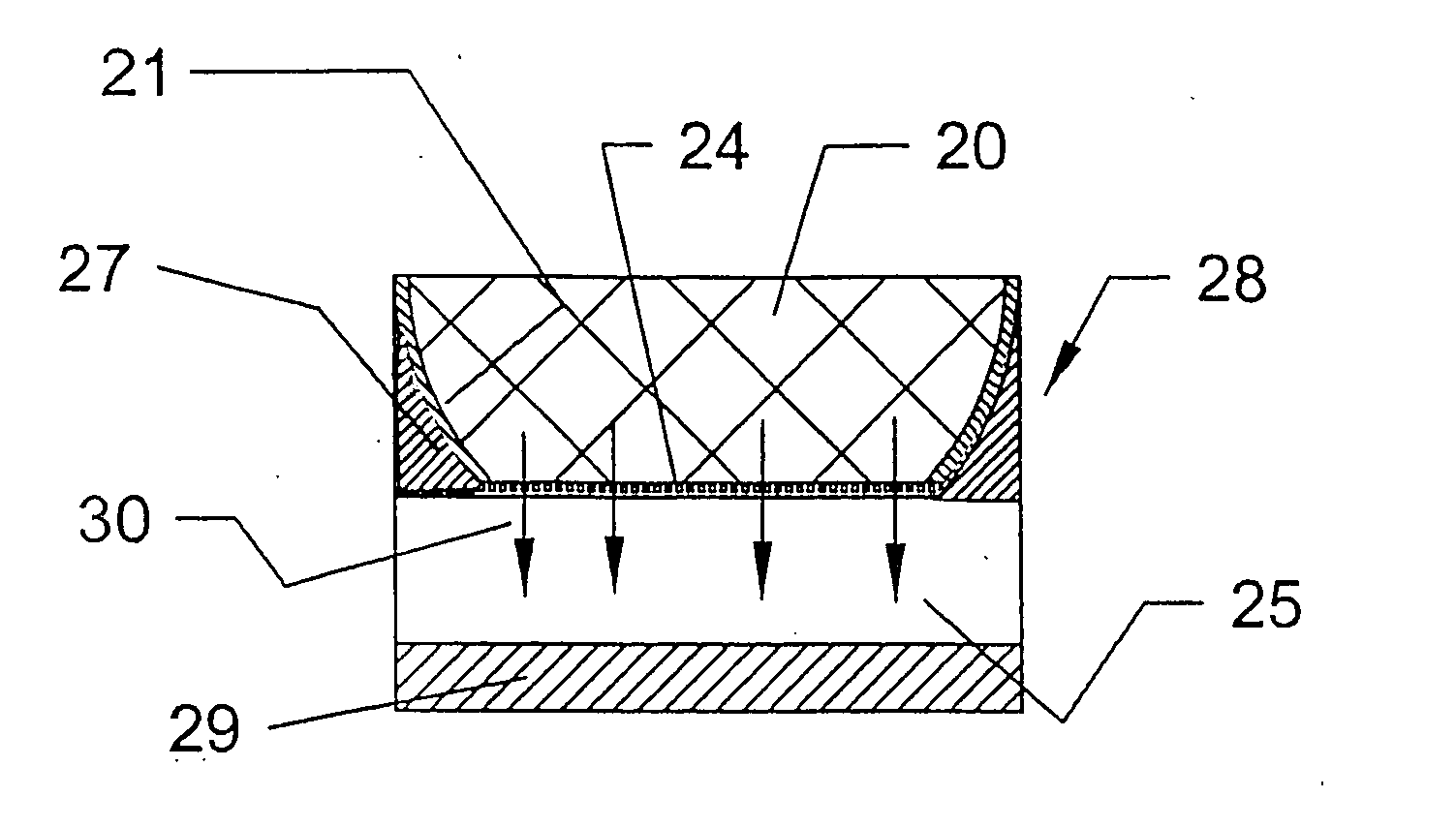

An arrangement for cooling an electric motor's stator winding coil is described. One area of a conductor insulation is removed to expose the copper conductor. The conductor is wound into a coil with bared, exposed conductor areas facing inward. The vertical edges of a slot or recess in an iron stator are lined with electrically insulating paper. A thermally conductive electrically insulating, ceramic substrate is bonded to the floor or base of the slot. The coil is inserted within the slot over the ceramic substrate with the exposed conductor facing and contacting the ceramic substrate. The coil is bonded to the ceramic substrate by thermally conductive and electrically insulative epoxy that fills the voids between the two. Heat flows from the conductor, through the bared copper surface, into the ceramic and the iron core stator with little resistance. A ceramic strip can be used alone or with copper traces bonded to the ceramic or conductor bared surface. Using a thermally conductive epoxy bond reduces resistance due to epoxy smear and reduces thermal resistance of the heat transfer path.

Owner:PRECISION MAGNETIC BEARING SYST

Multi-layered platelet structure

ActiveUS7846853B2High viscositySynthetic resin layered productsMicaHexagonal boron nitrideElectrical insulation paper

An electrical insulation paper that is made of mica flakelets (22), having an average size range of 0.01 to 0.05 mm in their thinnest dimension, hexagonal boron nitride (26), which has an average size range of 10 to 1,000 nm in their longest dimension, and a resin matrix. The mica flakelets and the hexagonal boron nitride are mixed and formed into a paper (17), and the resin is added to the paper after formation, the ratio by weight of the hexagonal boron nitride to the mica flakelets is directly proportional to the average size of the hexagonal boron nitride compared to the average size of the mica flakelets, within an adjustment factor.

Owner:SIEMENS ENERGY INC

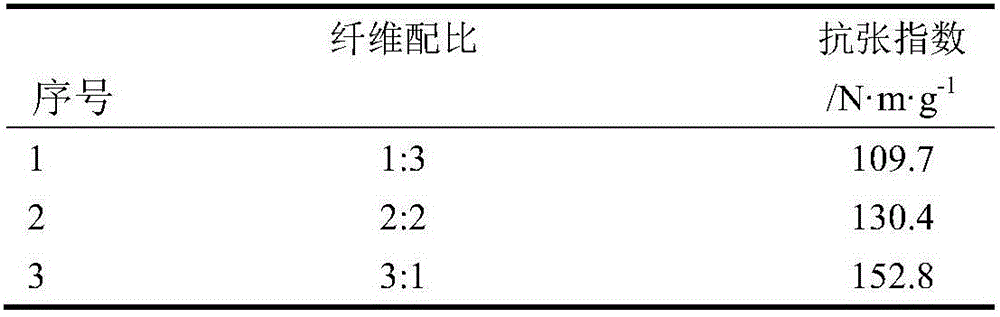

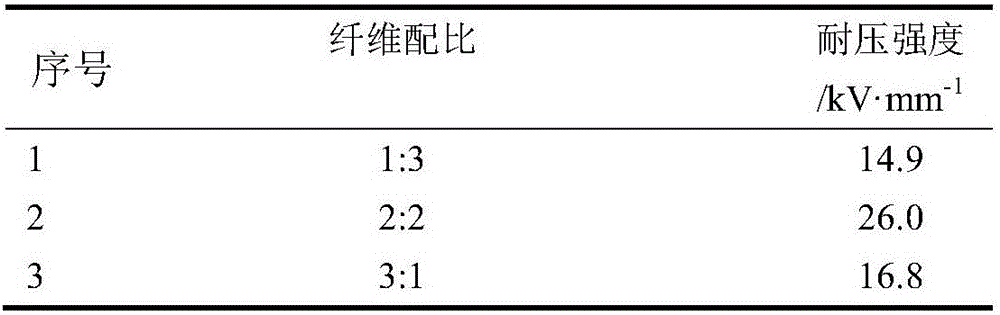

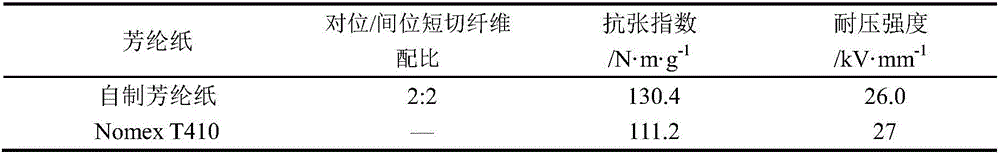

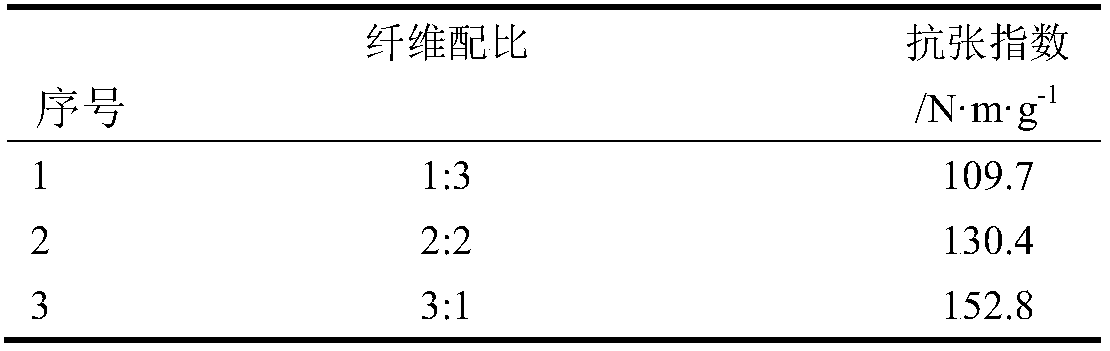

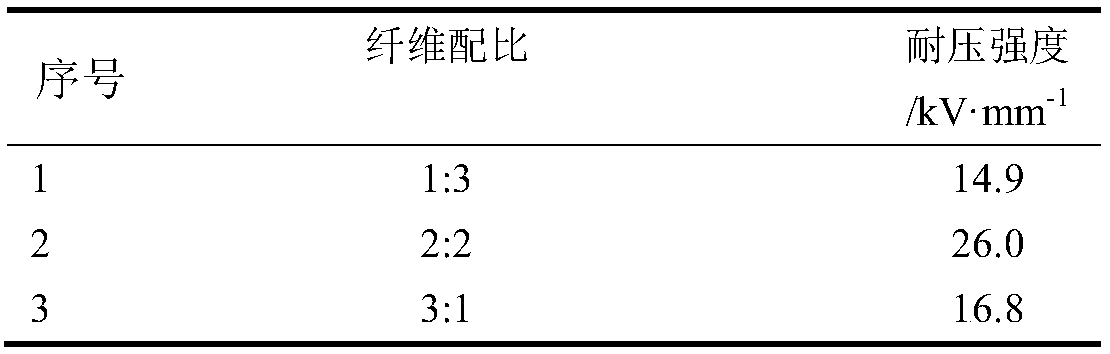

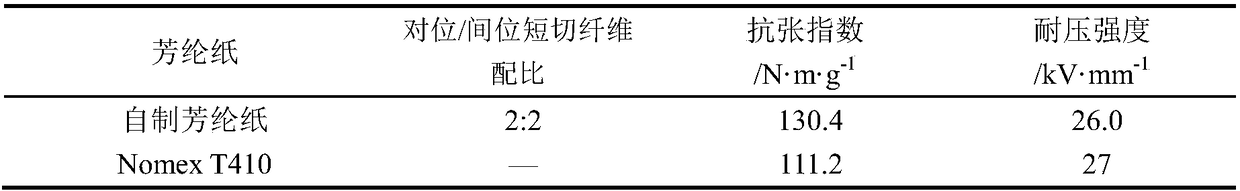

Preparation method of para-aramid and meta-aramid electrical insulation paper

ActiveCN106223129AIncreased tensile indexHigh strengthPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperHigh intensity

The invention discloses a preparation method of para-aramid and meta-aramid electrical insulation paper. The method comprises the following steps that para-aramid chopped fibers are preprocessed for use; meta-aramid chopped fibers are preprocessed; the preprocessed para-aramid chopped fibers and the preprocessed meta-aramid chopped fibers are mixed in a fluffer for primary defibering; then meta-aramid pulp fibers are added for secondary defibering; lastly, a dispersing agent is added for third defibering, and suspension liquid is obtained; the obtained suspension liquid is injected into a sheet forming device for dewatering forming, and body paper of the aramid electrical insulation paper is obtained after pressing and drying treatment; the obtained body paper of the aramid electrical insulation paper is subjected to hot press molding, and the aramid electrical insulation paper is obtained. According to the preparation method of the aramid electrical insulation paper, different ratios of the para-aramid chopped fibers to the meta-aramid chopped fibers are adopted, and the aramid electrical insulation paper with high strength and good dielectric properties is prepared.

Owner:湖北城东再生资源科技发展有限公司

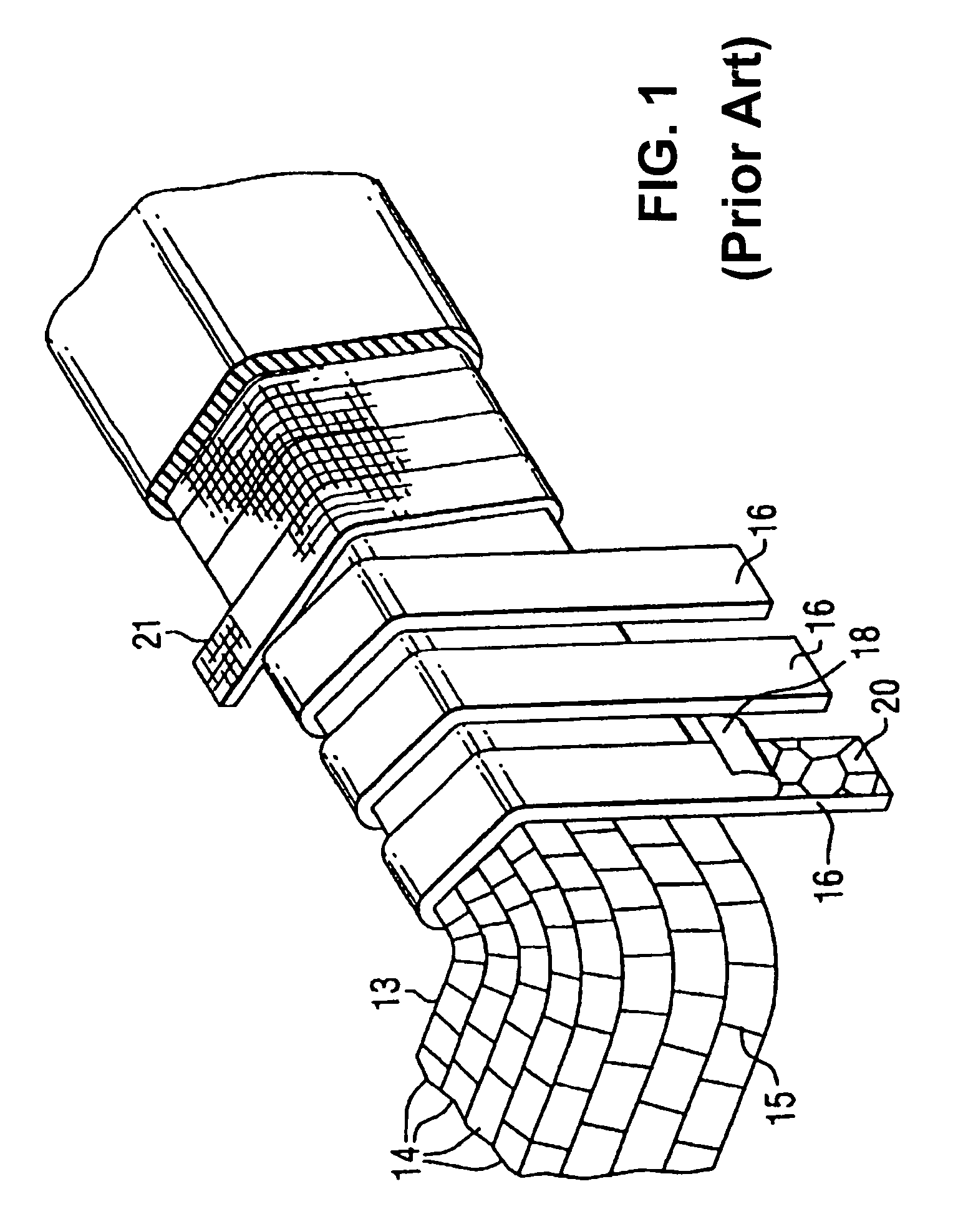

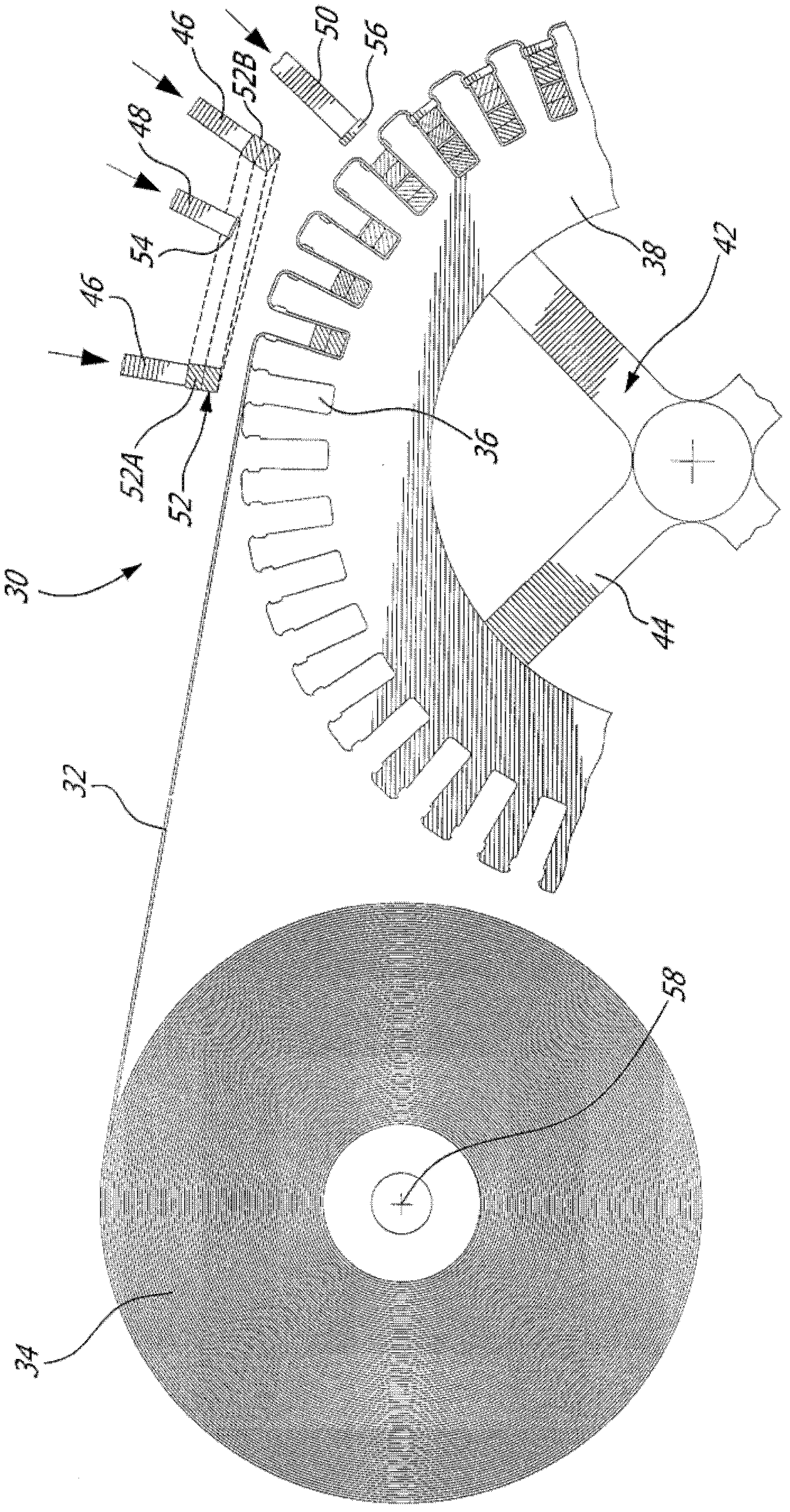

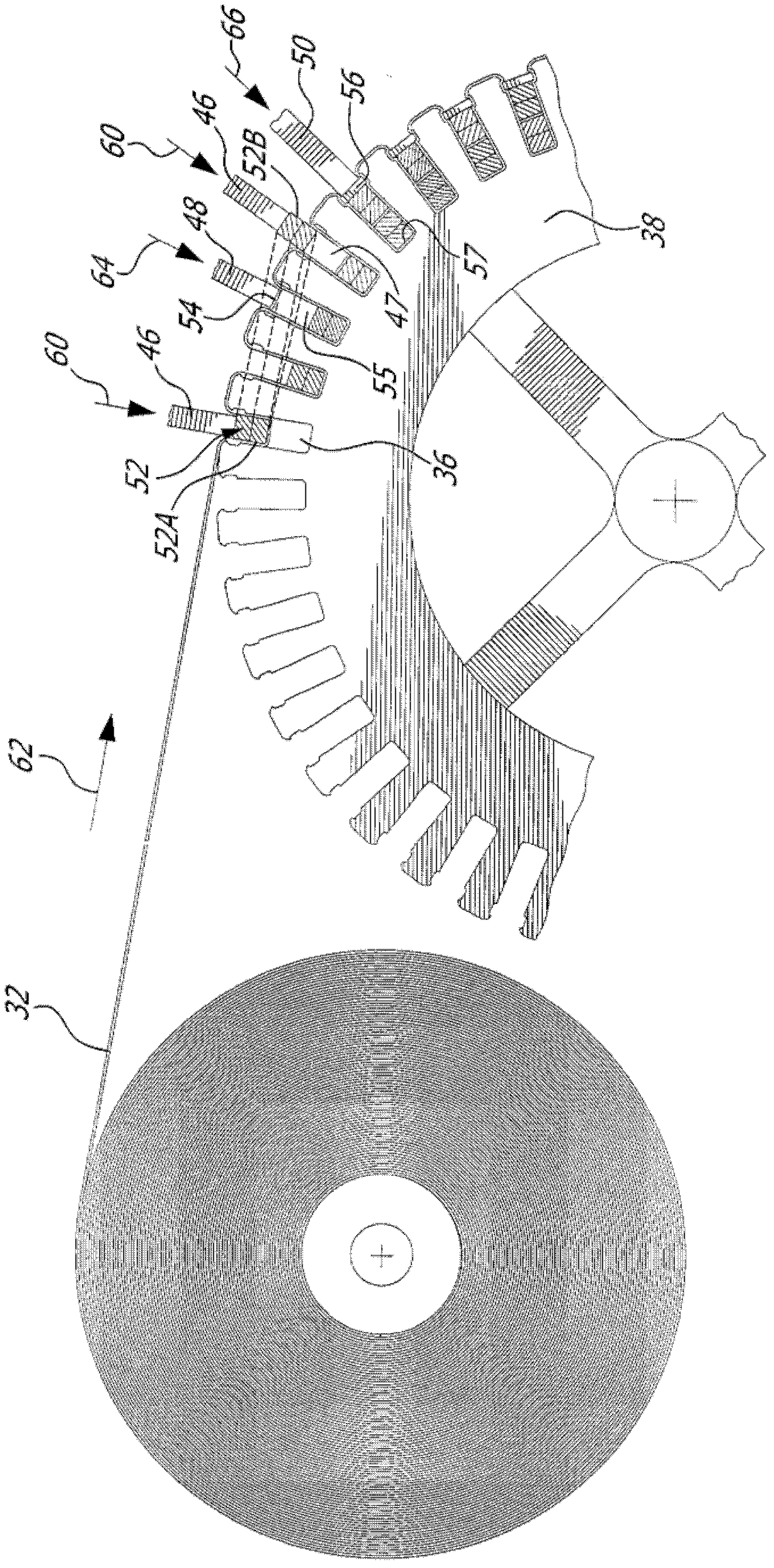

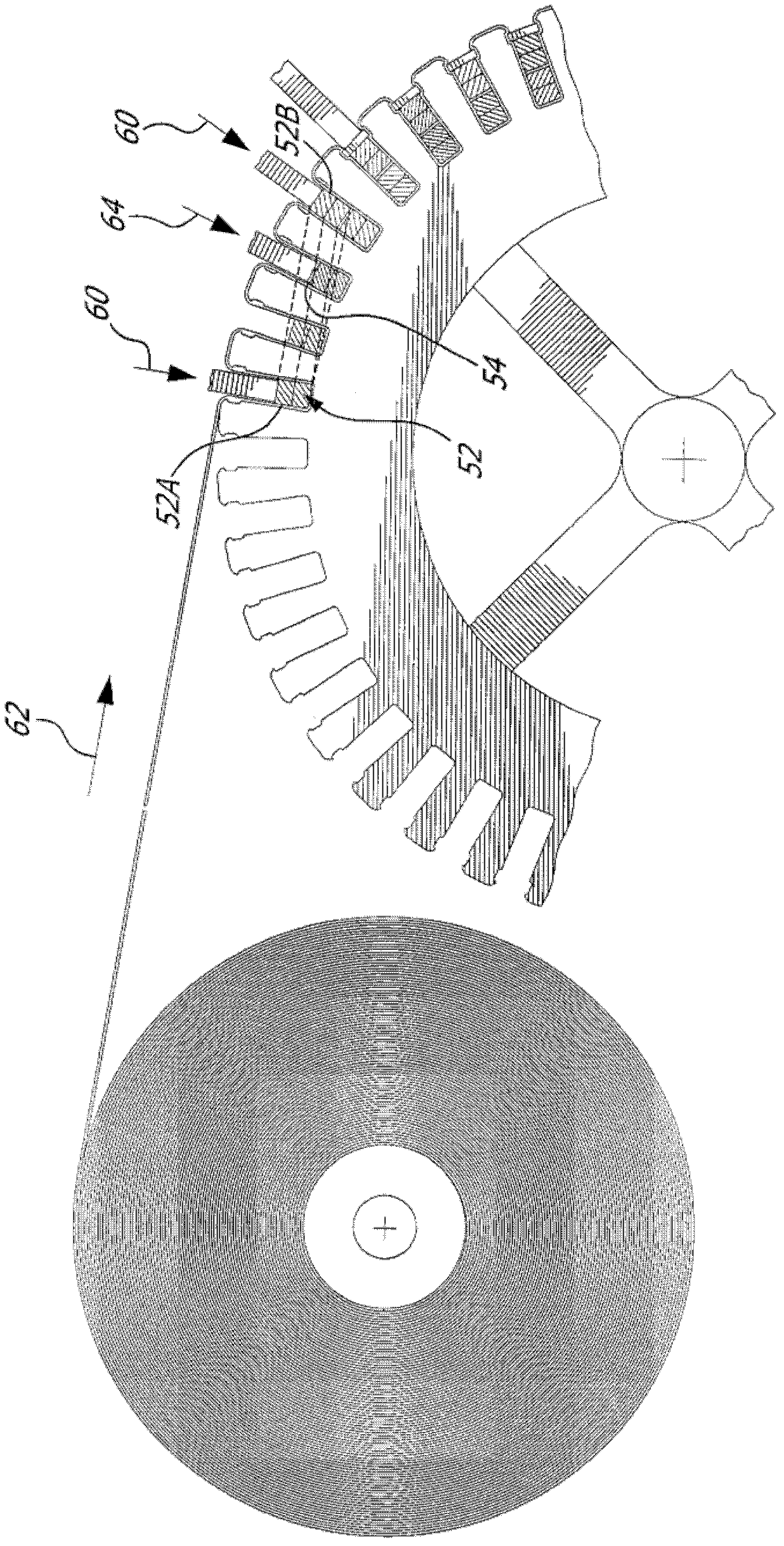

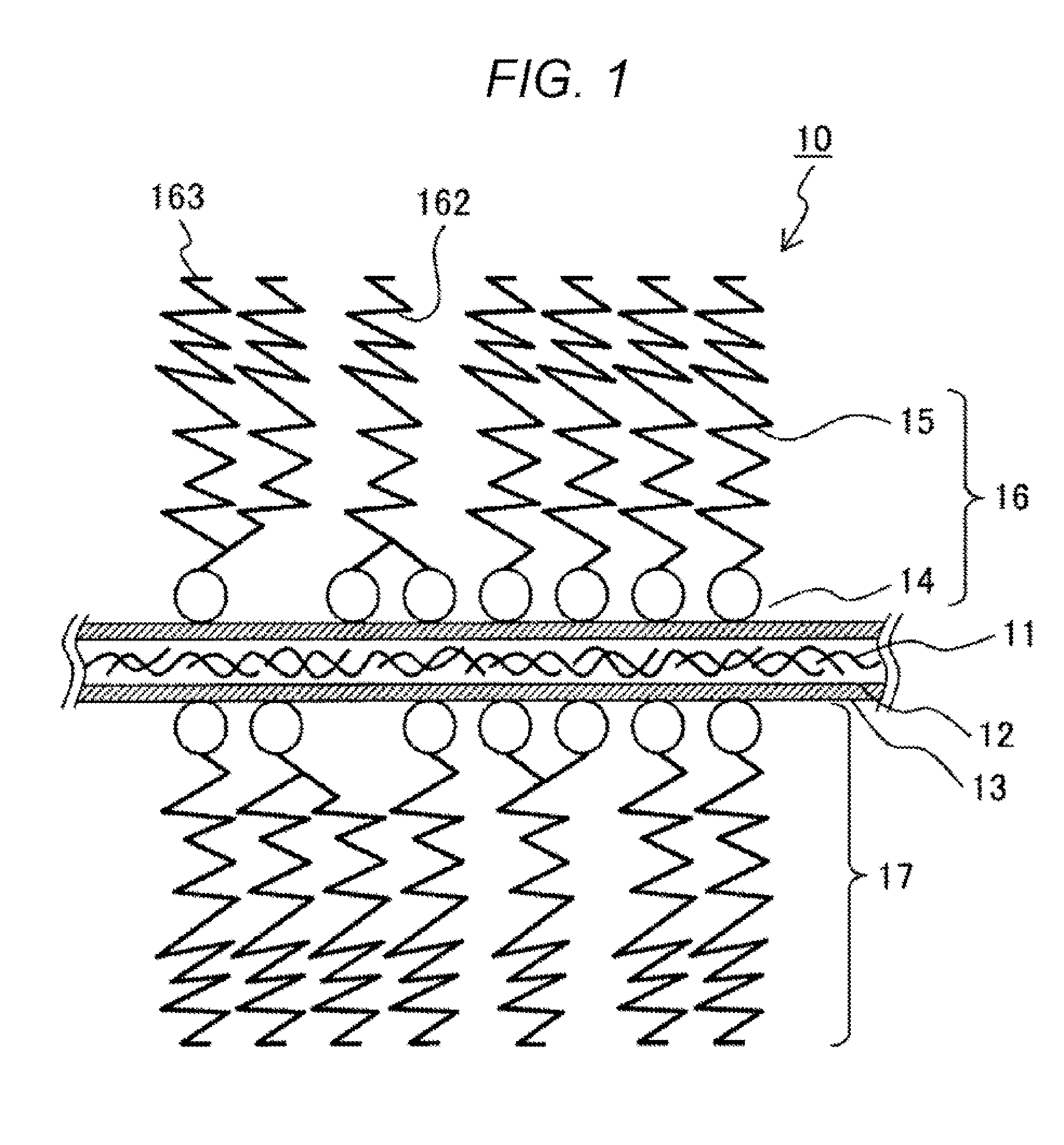

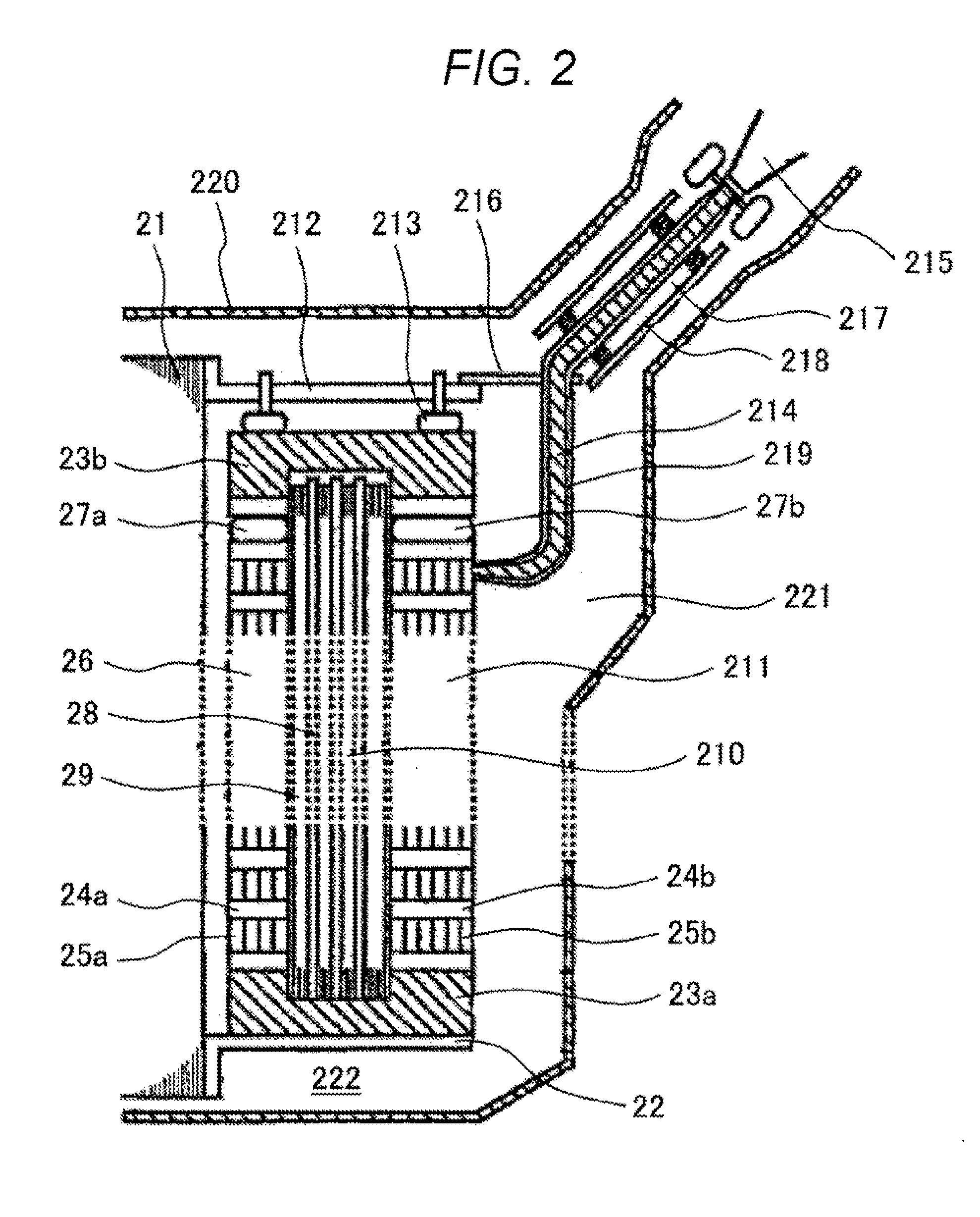

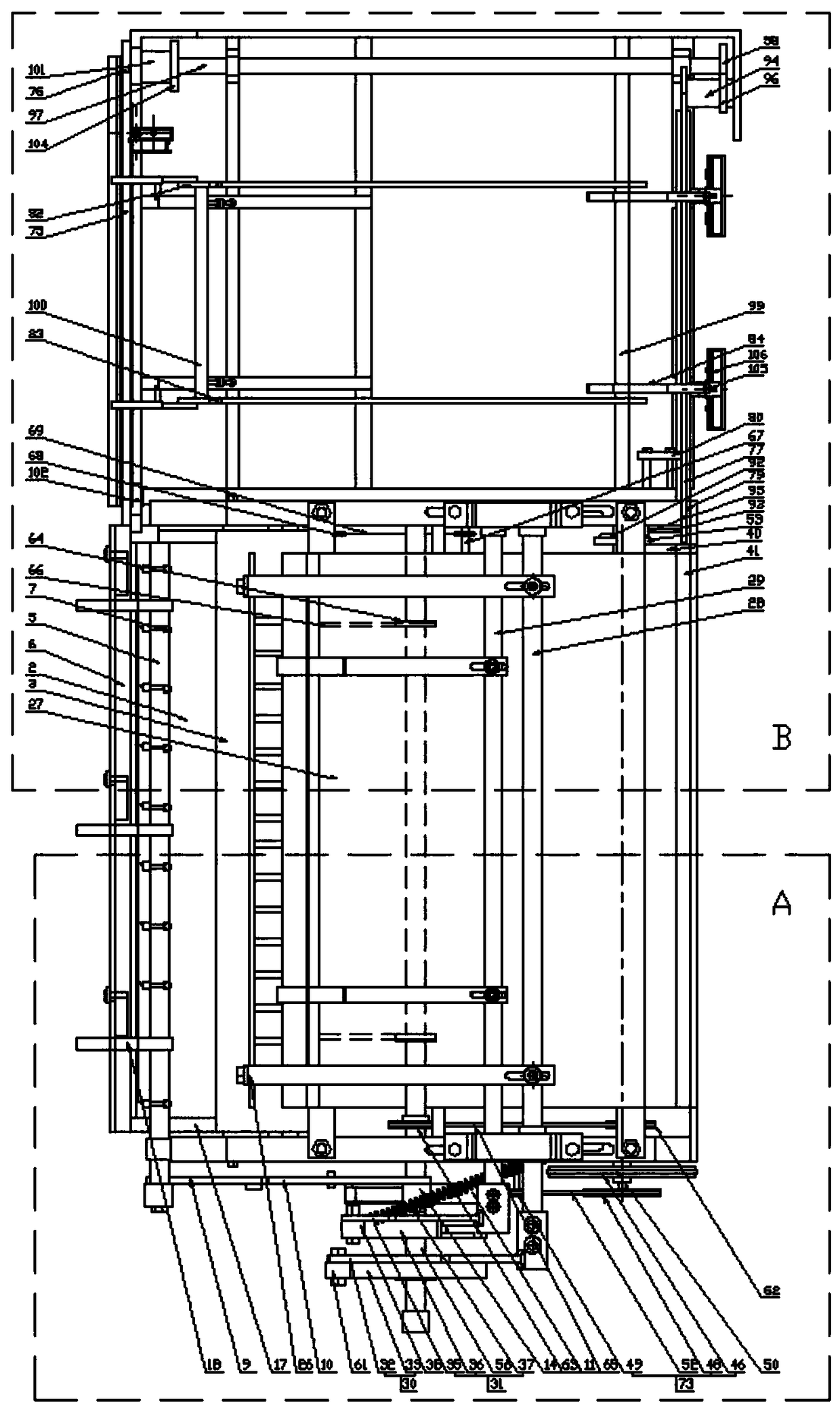

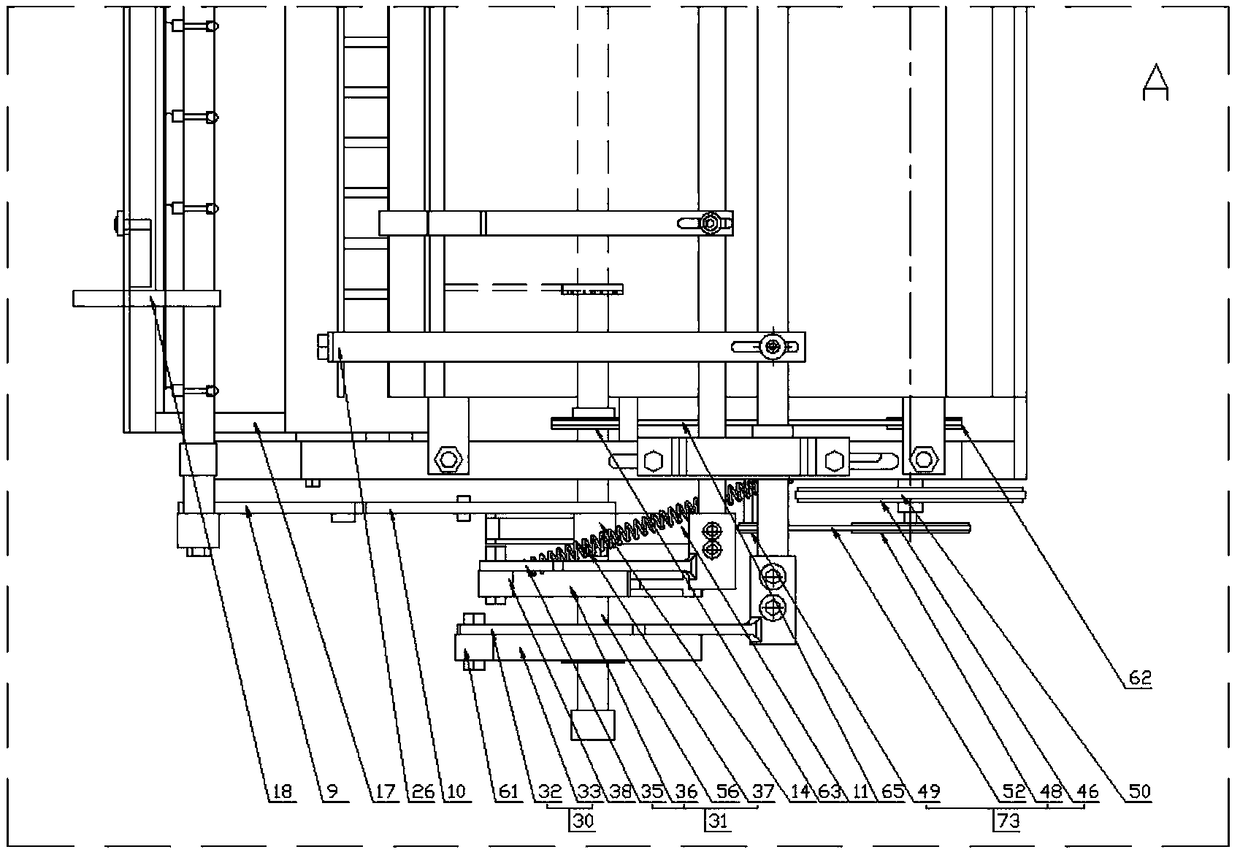

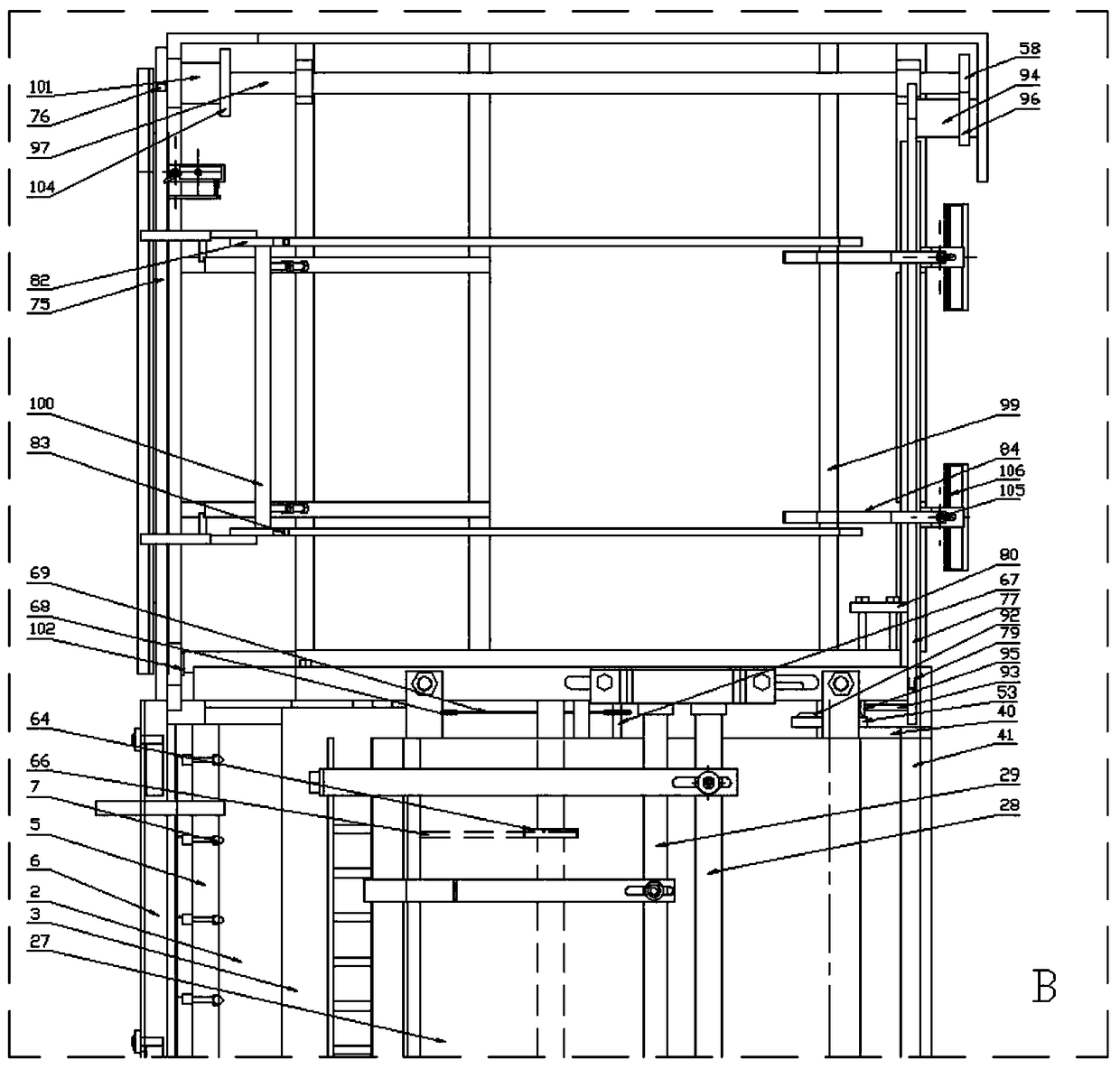

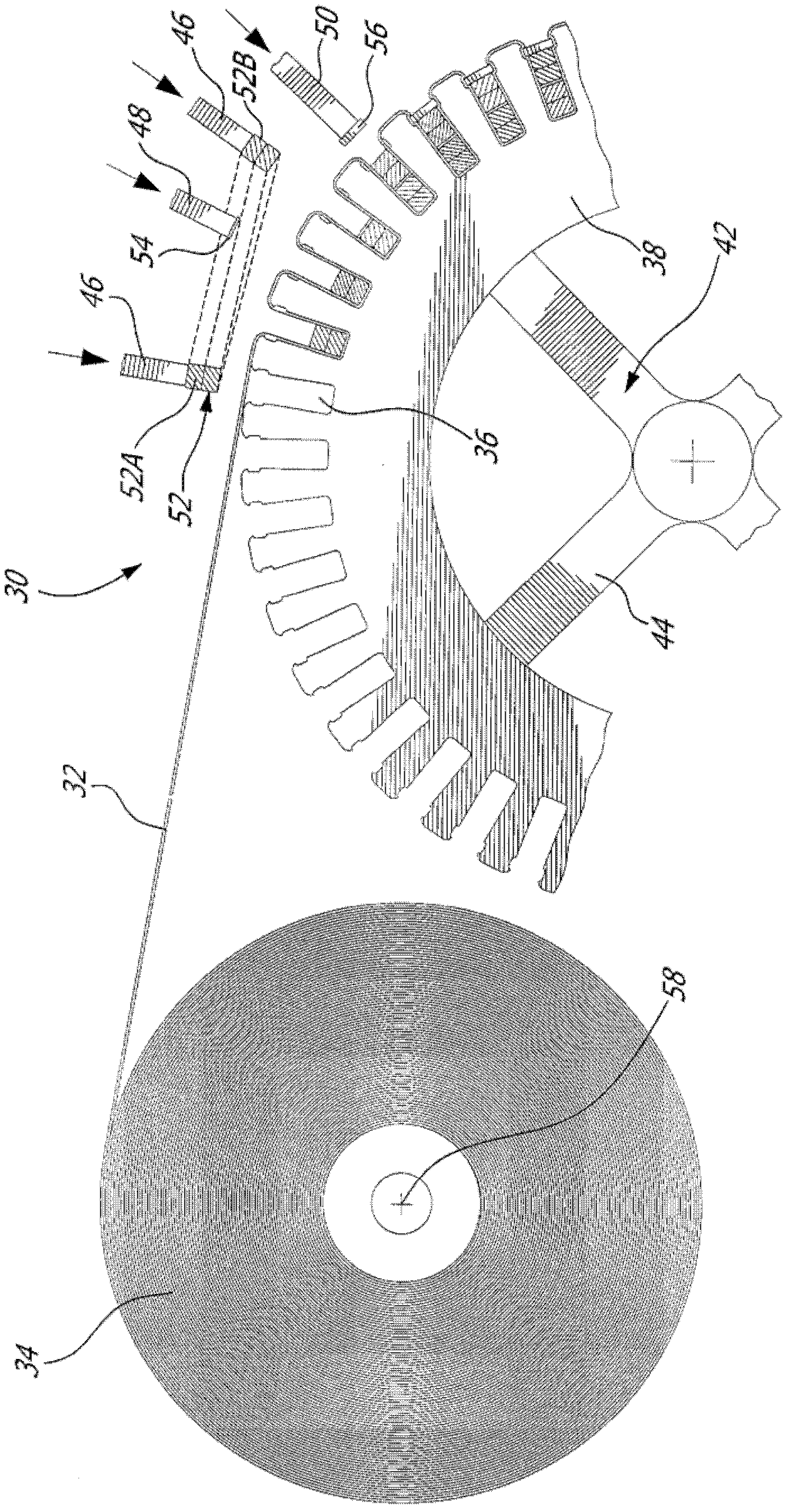

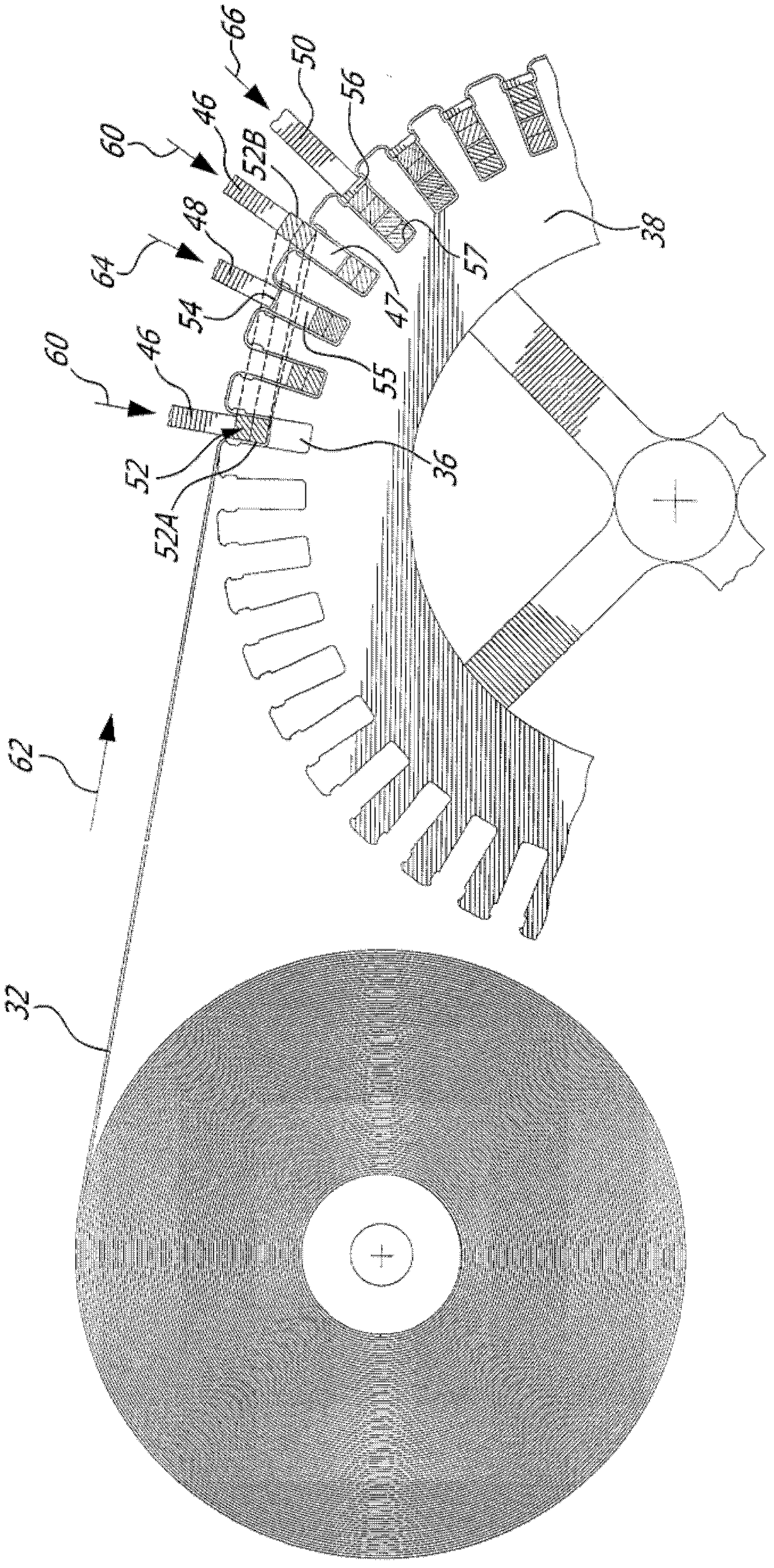

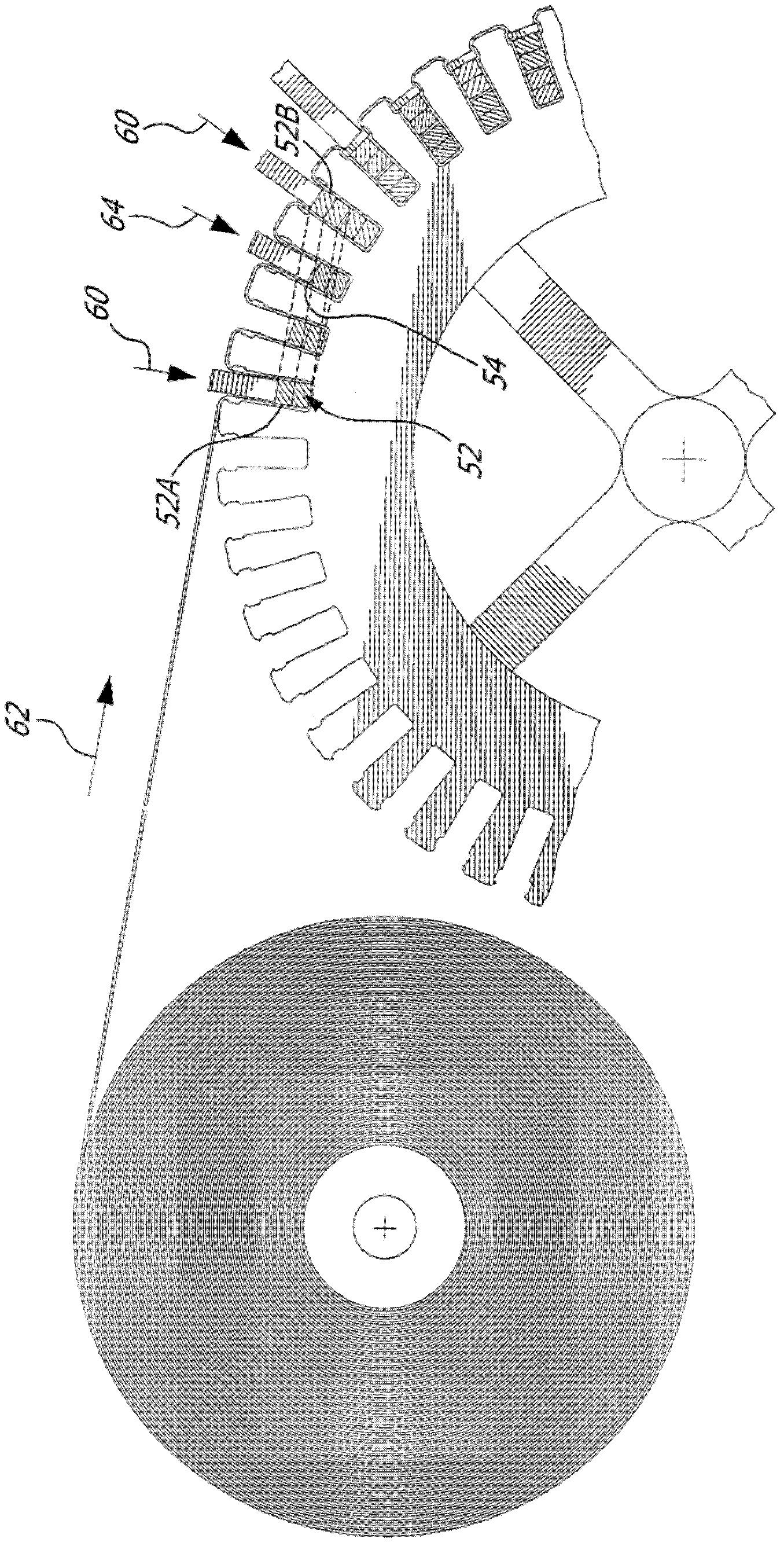

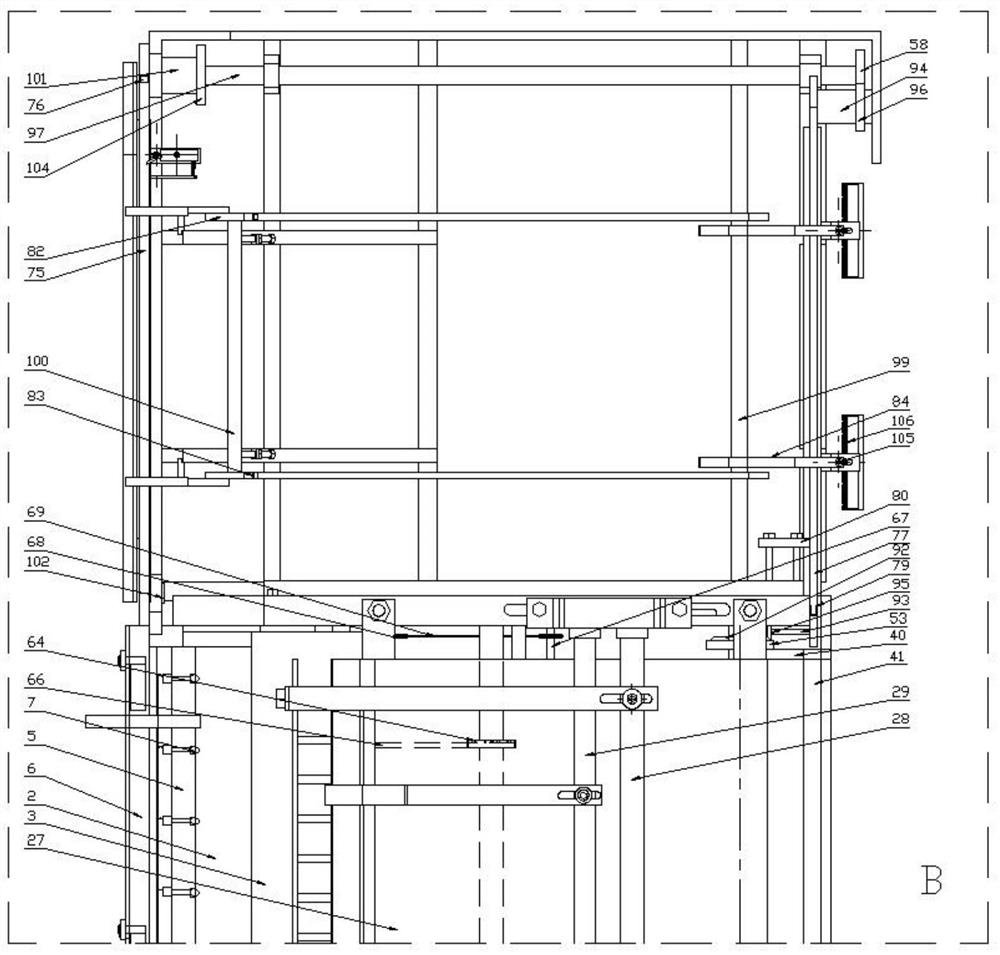

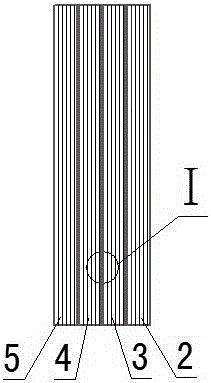

Insertion system and method to insert insulators and coils in the slots of the stator of an electric machine

ActiveCN102474161AOther goals are obviousThe goal is obviousWindingsEmbedding prefabricated windingsElectrical insulation paperEngineering

The insertion of electrically insulating paper from a continuous roll into slots of a stator created by outwardly projecting teeth is described herein. The insertion of the insulating paper is done by the insertion of prewound coils in the stator slots. The electrically insulating paper is not cut prior to its insertion in the slots, thereby completely covering the outer surface of the stator. The insertion systems and methods described herein are also optionally concerned with the insertion of interphase insulation paper between the different coils inserted in the stator slots and with the insertion of slot closing wedges.

Owner:TM4 INC

Cooling of stator windings

InactiveUS7498710B2Reduce the temperatureImprove thermal conductivityWindings insulation shape/form/constructionMagnetic circuit rotating partsCopper conductorEpoxy

An arrangement for cooling an electric motor's stator winding coil is described. One area of a conductor insulation is removed to expose the copper conductor. The conductor is wound into a coil with bared, exposed conductor areas facing inward. The vertical edges of a slot or recess in an iron stator are lined with electrically insulating paper. A thermally conductive electrically insulating, ceramic substrate is bonded to the floor or base of the slot. The coil is inserted within the slot over the ceramic substrate with the exposed conductor facing and contacting the ceramic substrate. The coil is bonded to the ceramic substrate by thermally conductive and electrically insulative epoxy that fills the voids between the two. Heat flows from the conductor, through the bared copper surface, into the ceramic and the iron core stator with little resistance. A ceramic strip can be used alone or with copper traces bonded to the ceramic or conductor bared surface. Using a thermally conductive epoxy bond reduces resistance due to epoxy smear and reduces thermal resistance of the heat transfer path.

Owner:PRECISION MAGNETIC BEARING SYST

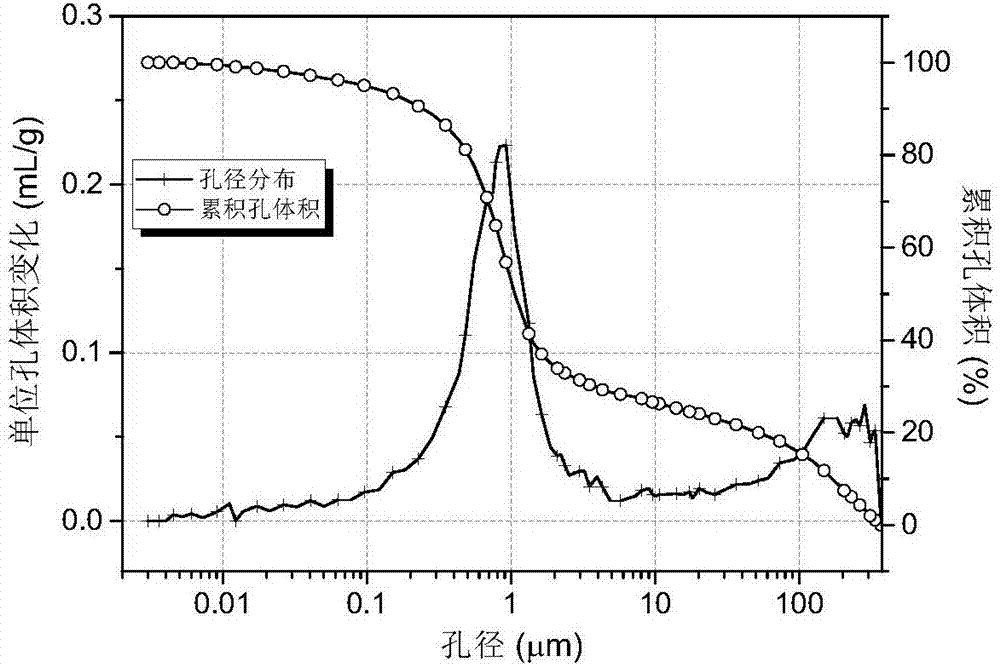

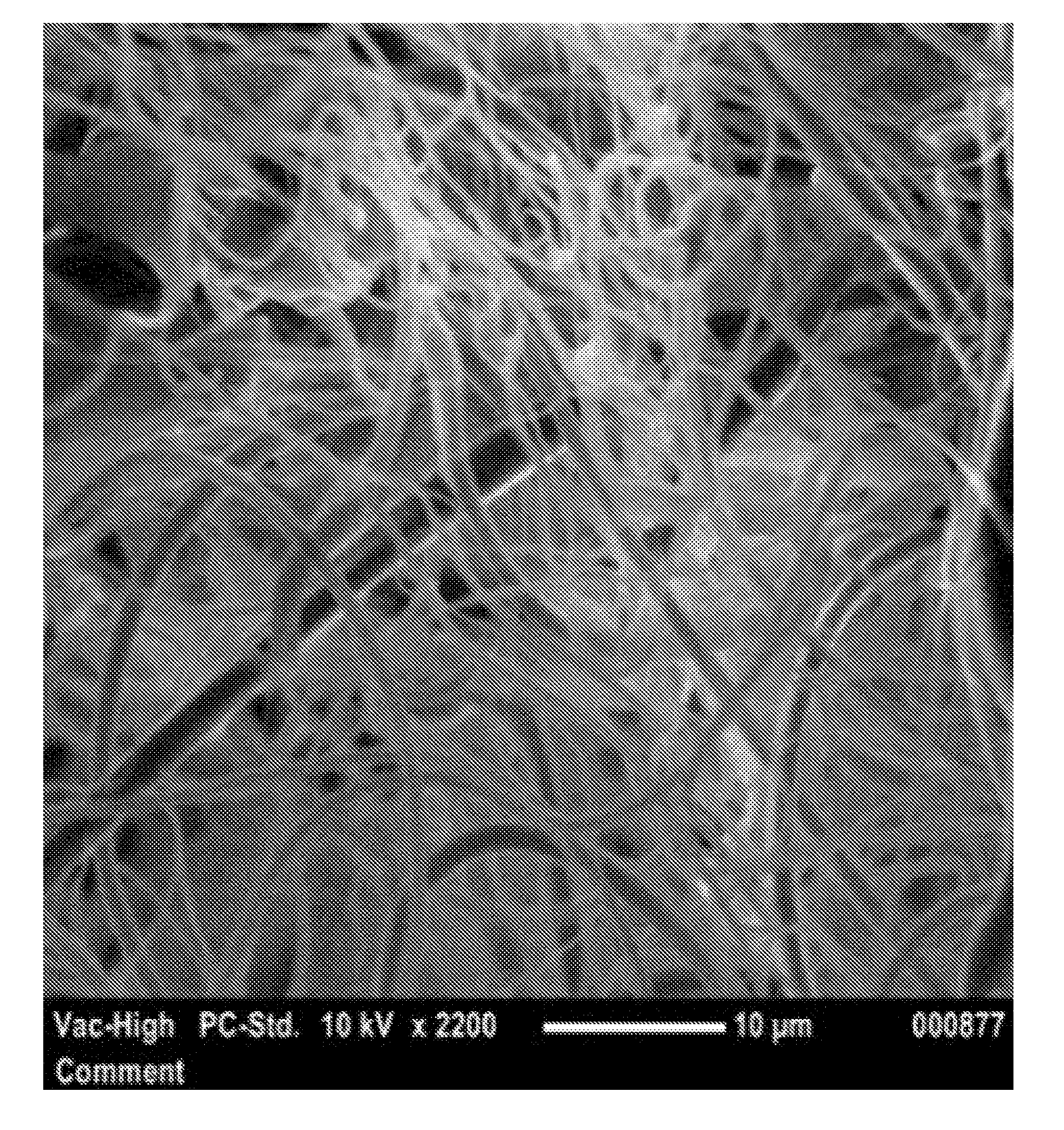

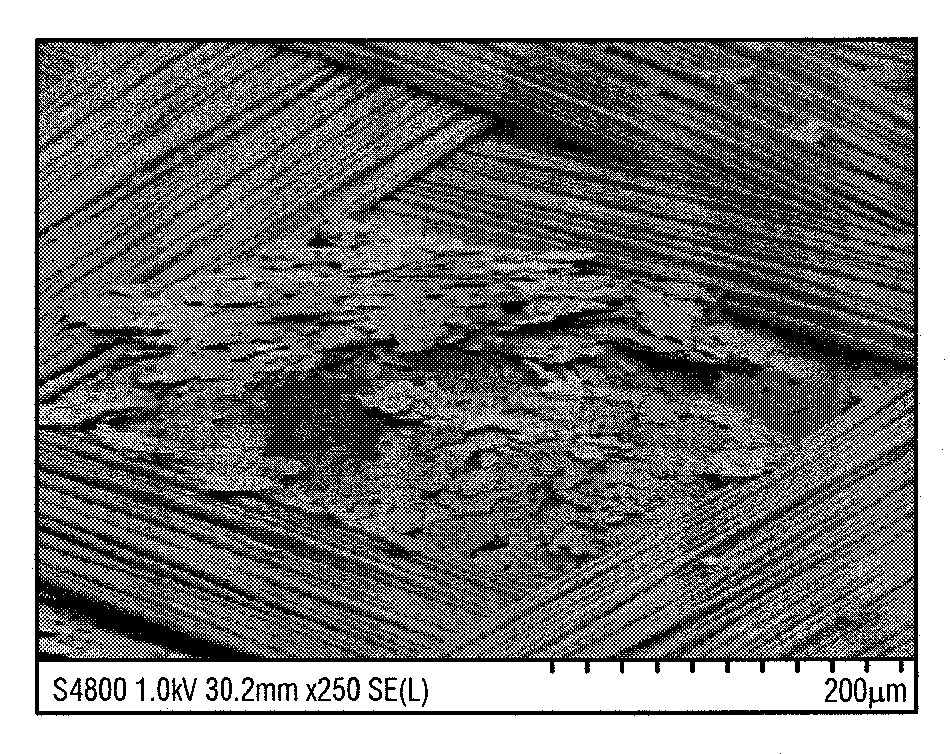

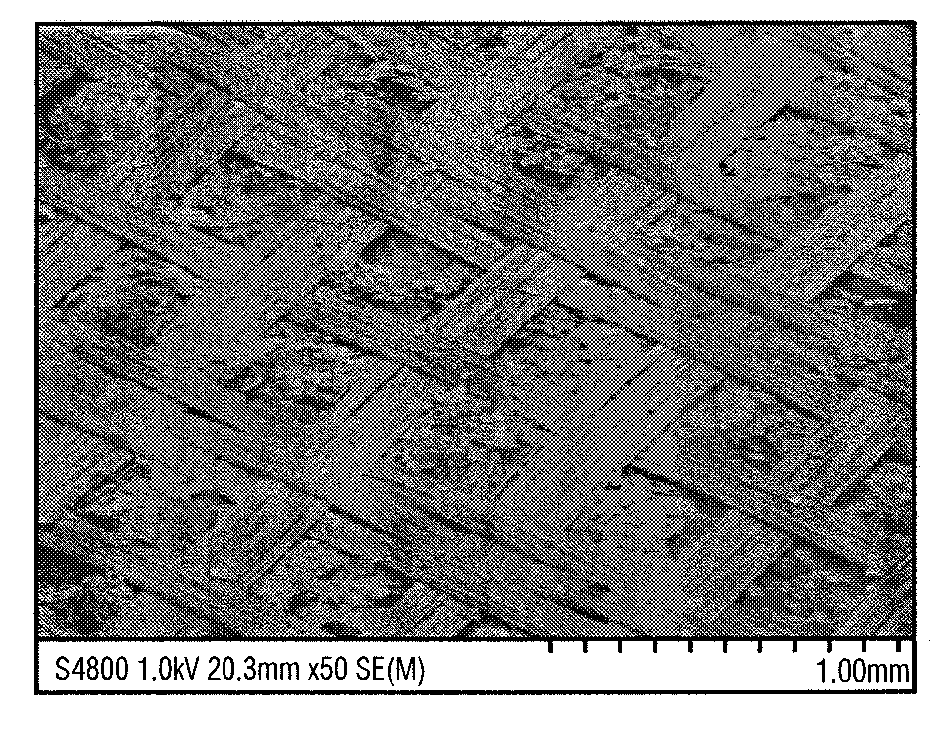

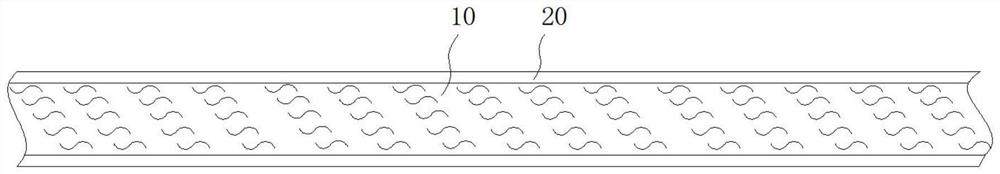

Preparation method of micro/nano composite fiber electrical insulation paper

ActiveCN107287988AHigh tensile strengthHigh breakdown field strengthPlastic/resin/waxes insulatorsSpecial paperFiberElectrical insulation paper

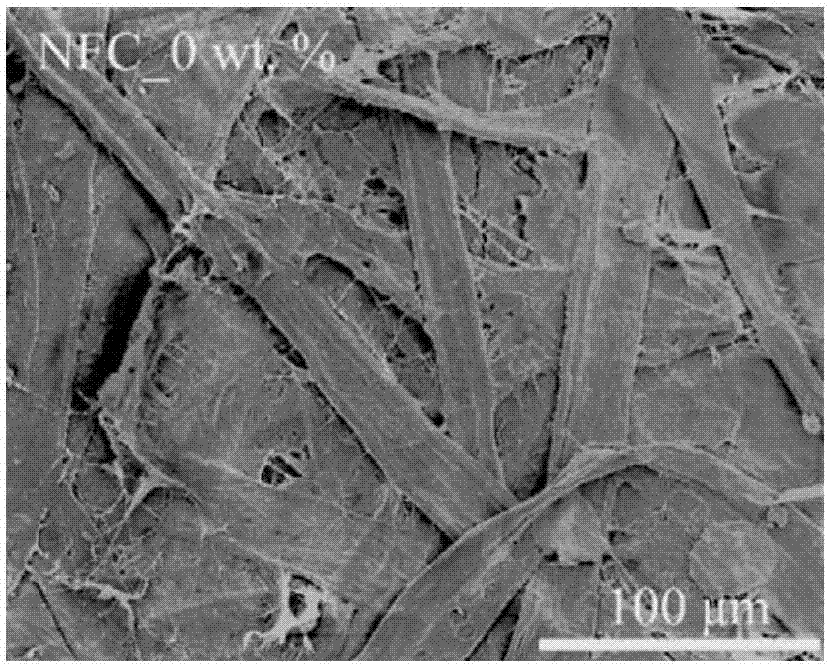

The invention relates to a preparation method of a micro / nano composite fiber electrical insulation paper, and belongs to the technical field of electrical insulation paper. The preparation method comprises the following steps: individually soaking a dry pulp board of softwood pulp and a dry pulp board of other micro fiber pulp in deionized water for 12 hours, after soaking, tearing the pulp boards into pieces with a size of 25 mm*25 mm; then decomposing and beating the processed softwood pulp board and other micro fiber pulp board by a beating machine; carrying out an ultrasonic dispersion treatment, mixing a proper amount of softwood pulp, other micro fibers, and nano fibers, and processing the mixture for 5 to 20 minutes by a stirring device. A mixing beating mode can also be adopted. Namely, preprocessed softwood pulp board and other micro fiber pulp board are directly mixed according to a certain ratio, then the mixture is decomposed and beaten by a beating machine, and the Schopper-Riegler beating degree is controlled in a range of 10 to 60 degrees SR. The process is simple, the operation is easy, and the tensile strength and breakdown field strength of prepared electrical insulation paper are both improved effectively.

Owner:TSINGHUA UNIV

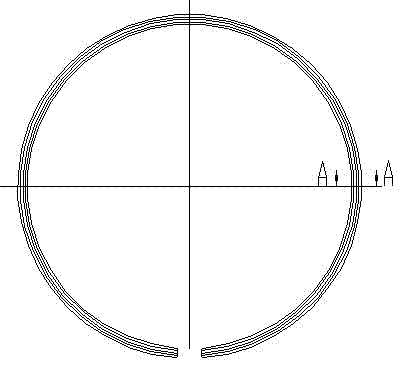

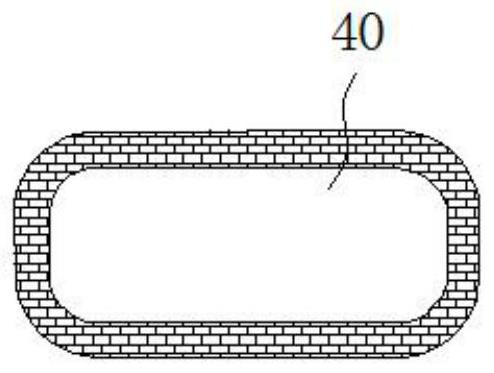

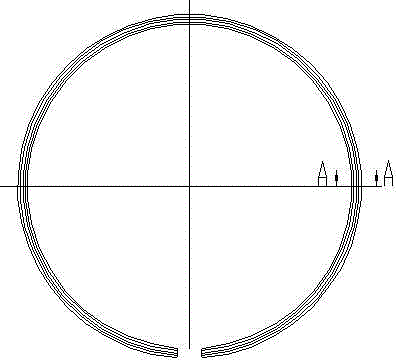

Large oil-immersed transformer insulated end ring and manufacturing technology thereof

ActiveCN103117159AAvoid or greatly reduce the amount of partial dischargeReduce partial dischargeTransformers/inductances coils/windings/connectionsCoils manufactureManufacturing technologyElectrical insulation paper

The invention discloses a large oil-immersed transformer insulated end ring and a manufacturing technology thereof. The large oil-immersed transformer insulated end ring comprises casein glue layers and a plurality of layers of paperboards, and every two adjacent layers of paperboards are glued via one of the casein glue layer. The manufacturing technology includes: A, utilizing a board shearing machine to shear needed large electrical insulating paperboards into regulated dimension so as to obtain semi-finished paperboards; B, evenly spraying distilled water on the surfaces of the semi-finished paperboards, guaranteeing the paperboards to have certain bending capability, utilizing a roller press to roll the paperboards into cylinders according to technical requirements; and C, selecting casein glue which is strong in permeability on the insulated paperboards to glue the layers of the paperboards according to a single-face gluing technique, tightening the layers of the paperboards via a binding strap, placing in a drying furnace to be subjected to drying and vacuum oil spraying, and finally disassembling the binding strap. The large oil-immersed transformer insulated end ring and the manufacturing technology thereof have the advantages of simple technology, convenience in operation, reliability in performance, and capability of effectively avoiding or greatly reducing of transformer partial discharge magnitude caused by closed air bubbles in insulating parts.

Owner:SHANDONG DACHI ELECTRIC

Insulating tape material, method for production and usage thereof

InactiveUS20150140885A1Low thermal conductivityReduce conductivityWindings insulation materialWindings insulation shape/form/constructionElectrical insulation paperHigh pressure

An insulating tape material, a method for production and usage thereof, for producing electrical insulation paper such as mica paper, which is contained in thermally conductive insulating tapes that are used for high-voltage insulation, for example. The insulating tape material has fiber reinforcement by means of a fabric, wherein the meshes of the fabric are filled by a particle composite which is preferably thermally conductive.

Owner:SIEMENS AG

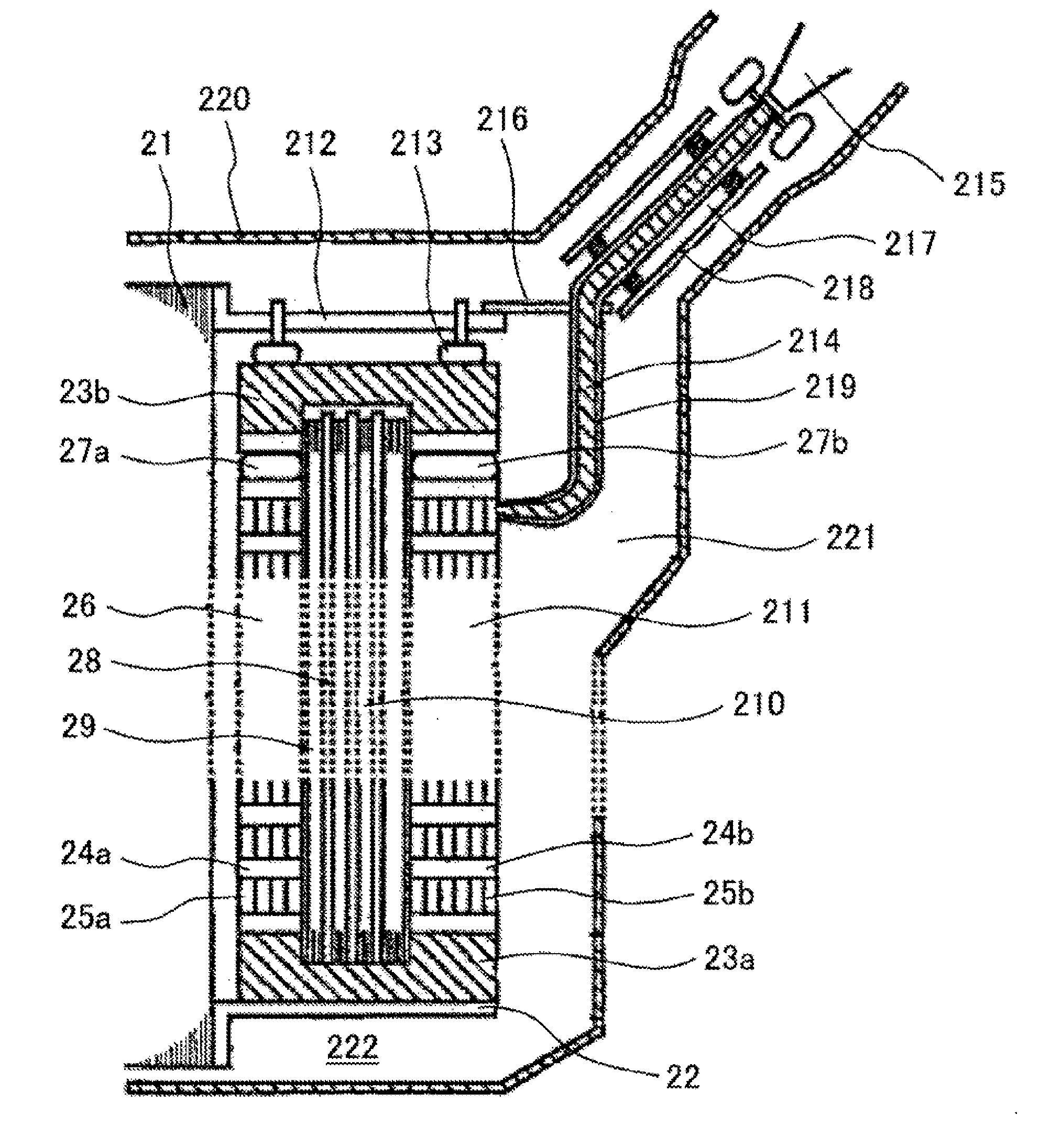

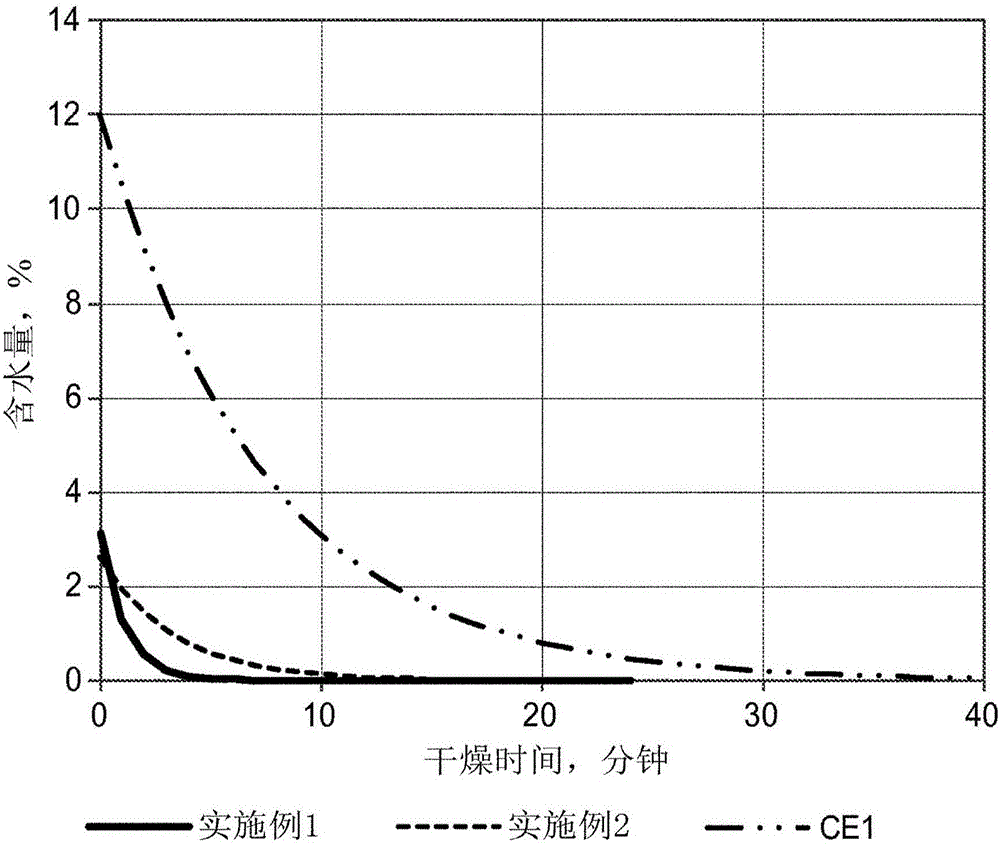

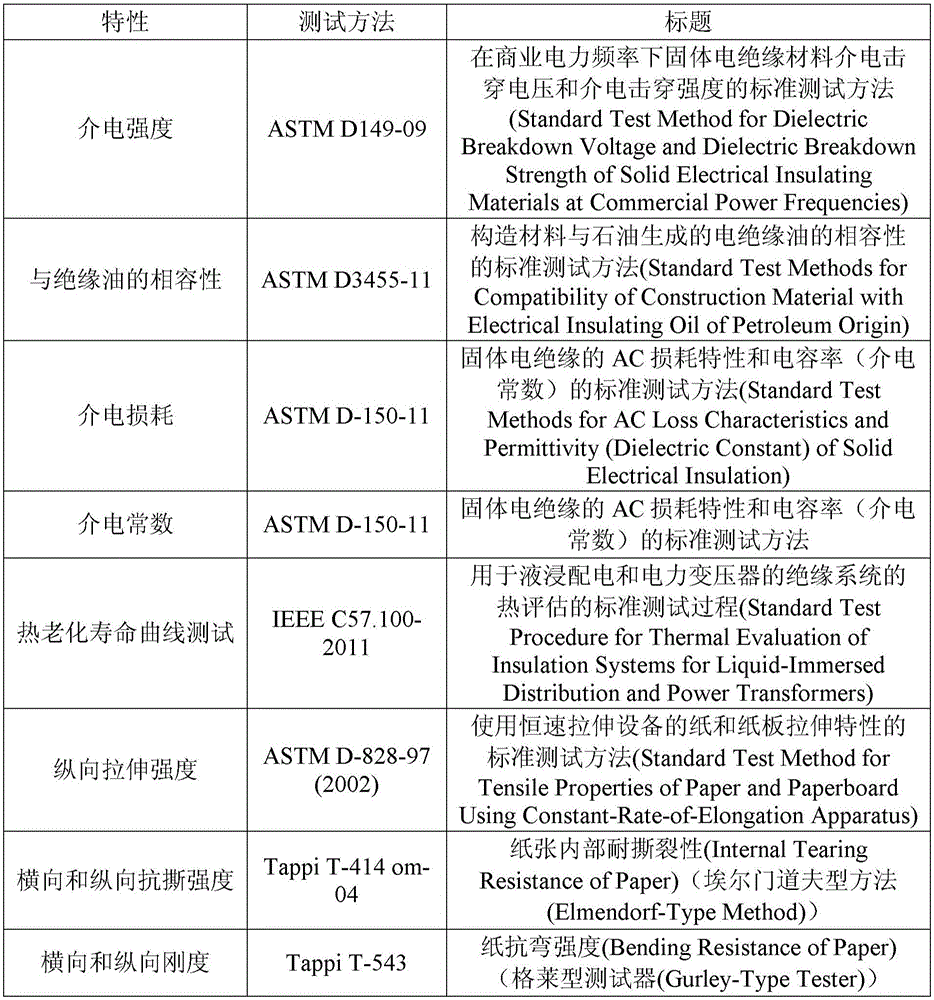

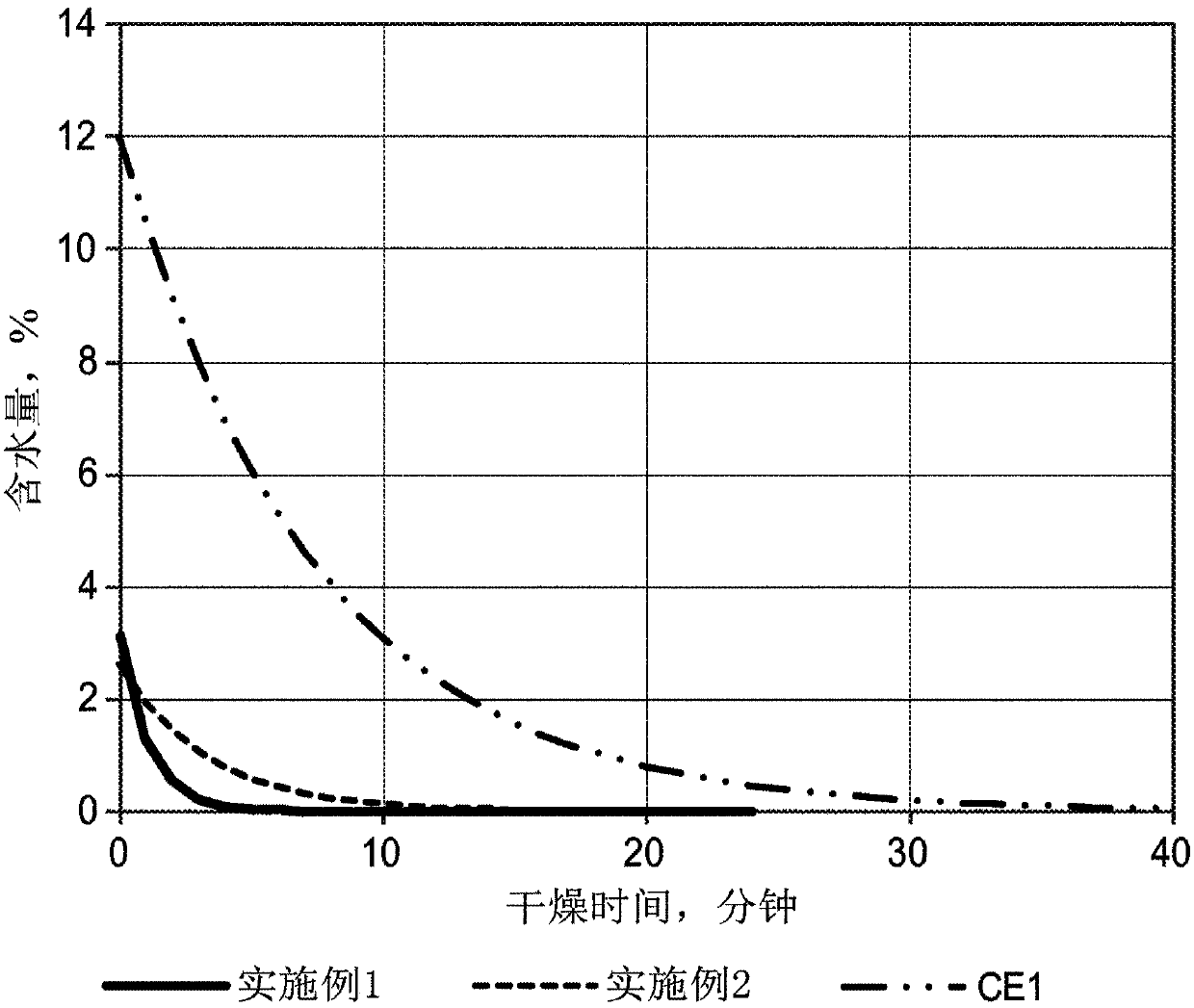

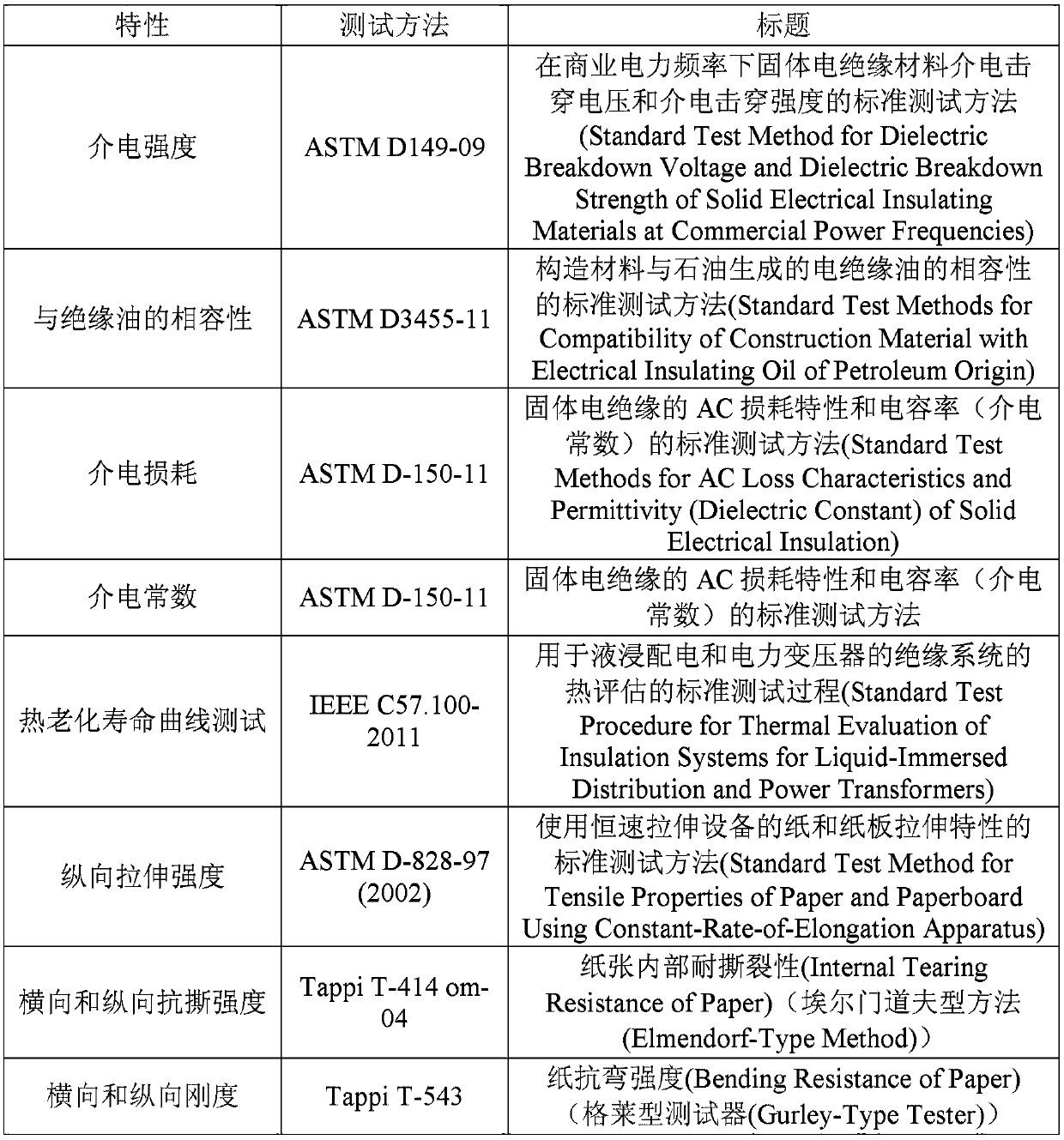

Electrical Insulating Paper and Stationary Induction Electrical Apparatus Using the Same

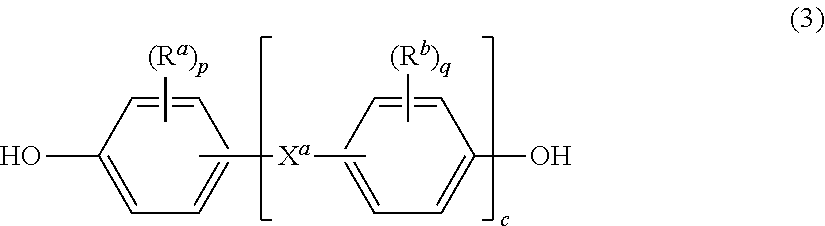

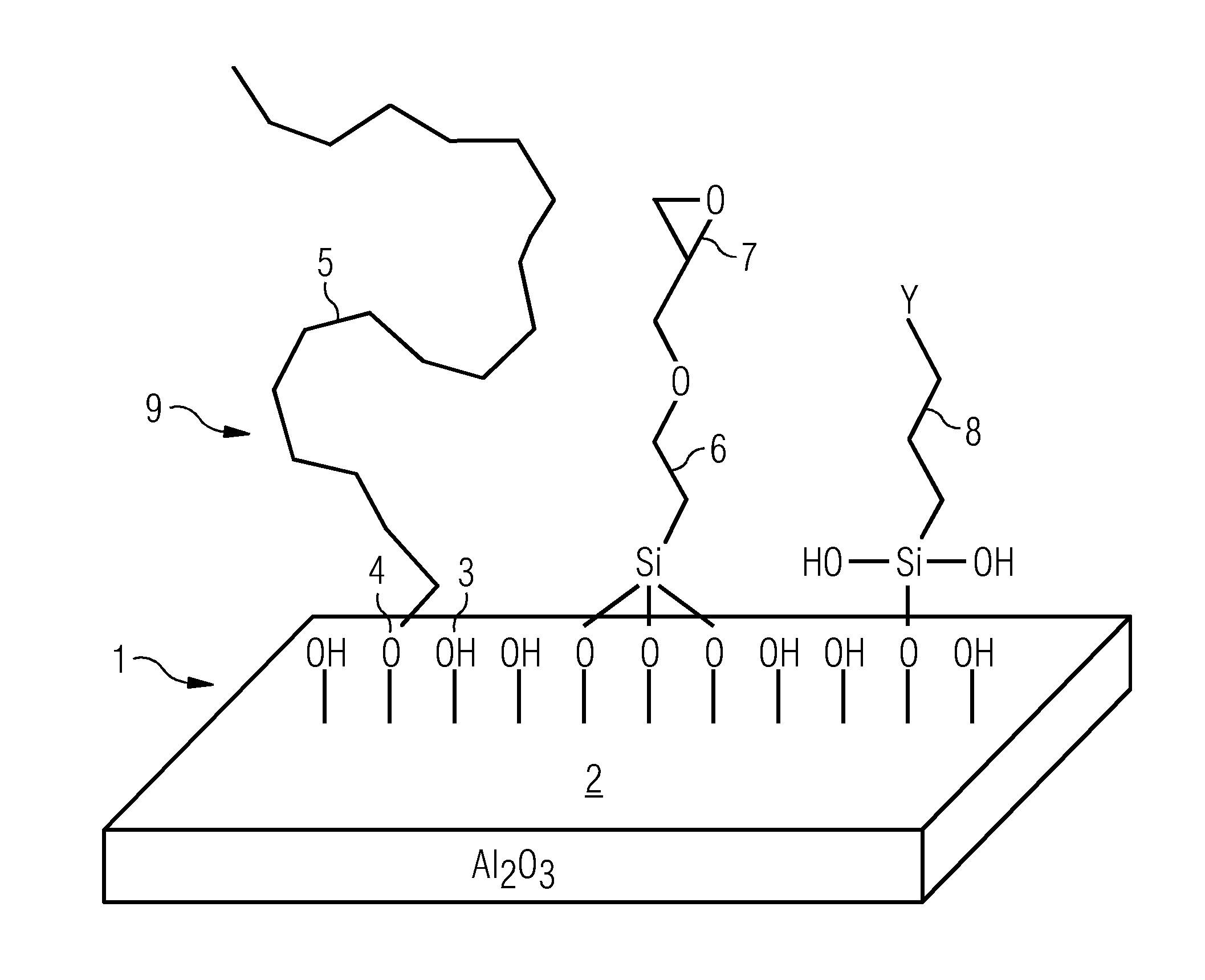

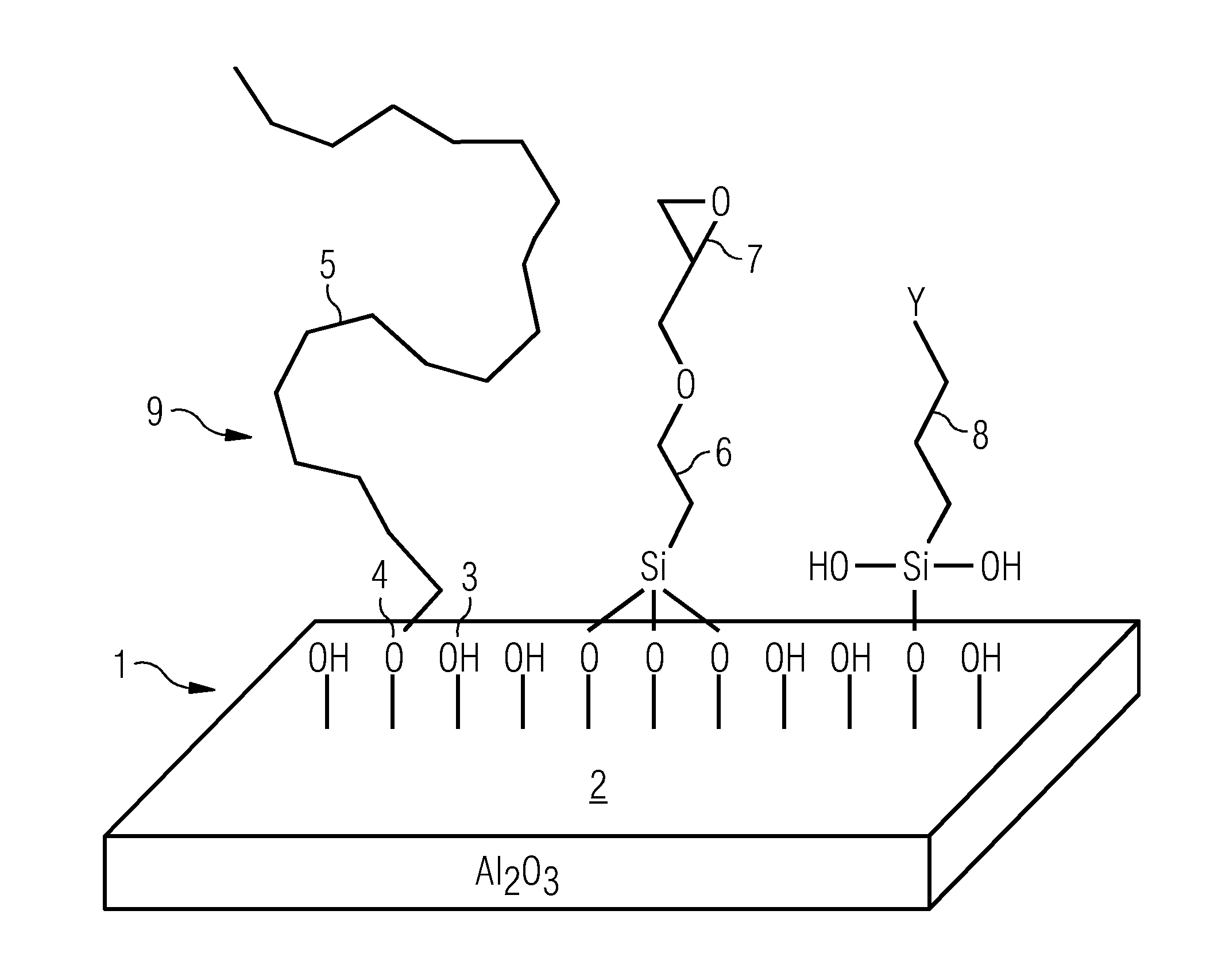

ActiveUS20150371730A1Increased durabilityImprove heat resistanceFibreboardWater-repelling agents additionCelluloseElectrical insulation paper

Electrical insulating paper according to an embodiment of the present invention is used while being immersed in electrical insulating oil, and includes a paper base material mainly containing cellulose, an adsorption layer formed on an entire surface of the paper base material by adsorption, and a moisture barrier layer formed by being chemically bonded to the adsorption layer. The moisture barrier layer includes an amphipathic molecule containing both a hydrophobic hydrocarbon group and a hydrophilic functional group in one molecule. The amphipathic molecule is chemically bonded to the adsorption layer via the hydrophilic functional group. The hydrophobic hydrocarbon group covers the surface of the paper base material.

Owner:HITACHI LTD

Electrical insulation material and transformer

ActiveCN105934801ALow moisture absorptionReduced thermal stabilityRubber insulatorsPlastic/resin/waxes insulatorsCelluloseFiber

An article comprises an inorganic filler, fully hydrolyzed polyvinyl alcohol fibers, a polymer binder, and high surface area fibers. The article can be formed as an electrically insulating paper for electrical equipment, such as a liquid filled transformer, which can thereby be substantially cellulose free.

Owner:3M INNOVATIVE PROPERTIES CO

Electrical insulation paper, methods of manufacture, and articles manufactured therefrom

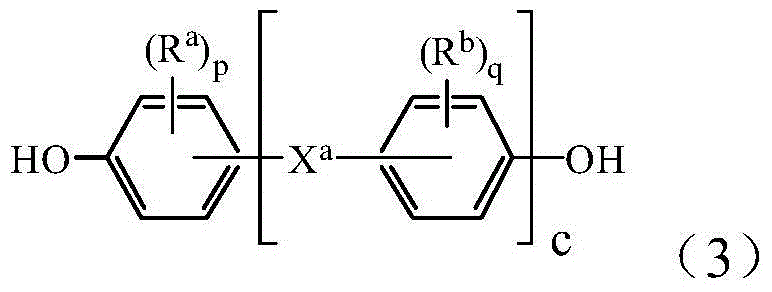

InactiveUS20130260124A1Plastic/resin/waxes insulatorsPrinted circuit aspectsPolyetherimideElectrical insulation paper

Fibrous substrates containing polyetherimides and other synthetic fibers are disclosed, along with methods of preparing electrical insulation paper and articles comprising the fibrous substrates.

Owner:SABIC GLOBAL TECH BV

Aramid paper, manufacturing method therefor, and use thereof

ActiveUS10407829B2Improve mechanical propertiesReduce weightPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperAramides

Owner:KOLON IND INC

Electrical insulation paper, methods of manufacture, and articles manufactured therefrom

InactiveUS20170030020A1Plastic/resin/waxes insulatorsSynthetic cellulose/non-cellulose material pulp/paperPolyetherimideElectrical insulation paper

Fibrous substrates containing polyetherimides and other synthetic fibers are disclosed, along with methods of preparing electrical insulation paper and articles comprising the fibrous substrates.

Owner:SABIC GLOBAL TECH BV

Method for producing a porous particle composite for an electrical insulating paper

InactiveUS20140060386A1Improve thermal conductivityEnhanced interactionInorganic fibres/flakesNon-fibrous pulp additionChemical reactionCoupling

A method is provided for producing an electrical insulation paper having a particle composite. The method involves mixing a dispersion of particles in platelet form, a carrier fluid and a functionalizing agent which is distributed in the carrier fluid and has a proportion by mass in the dispersion corresponding to a predetermined mass ratio based on the proportion by mass of the particles. The dispersion is sedimented, such that the particles in platelet form are arranged in essentially plane-parallel layers in the sediment. The carrier fluid is removed from the sediment. Energy is introduced into the sediment to overcome the activation energy of that chemical reaction of the functionalizing agent with the particles which forms the particle composite from the sediment with coupling of the particles via the functionalizing agent. The mass ratio is predetermined such that the particle composite has a porous structure. The insulation paper is thereby produced.

Owner:SIEMENS AG

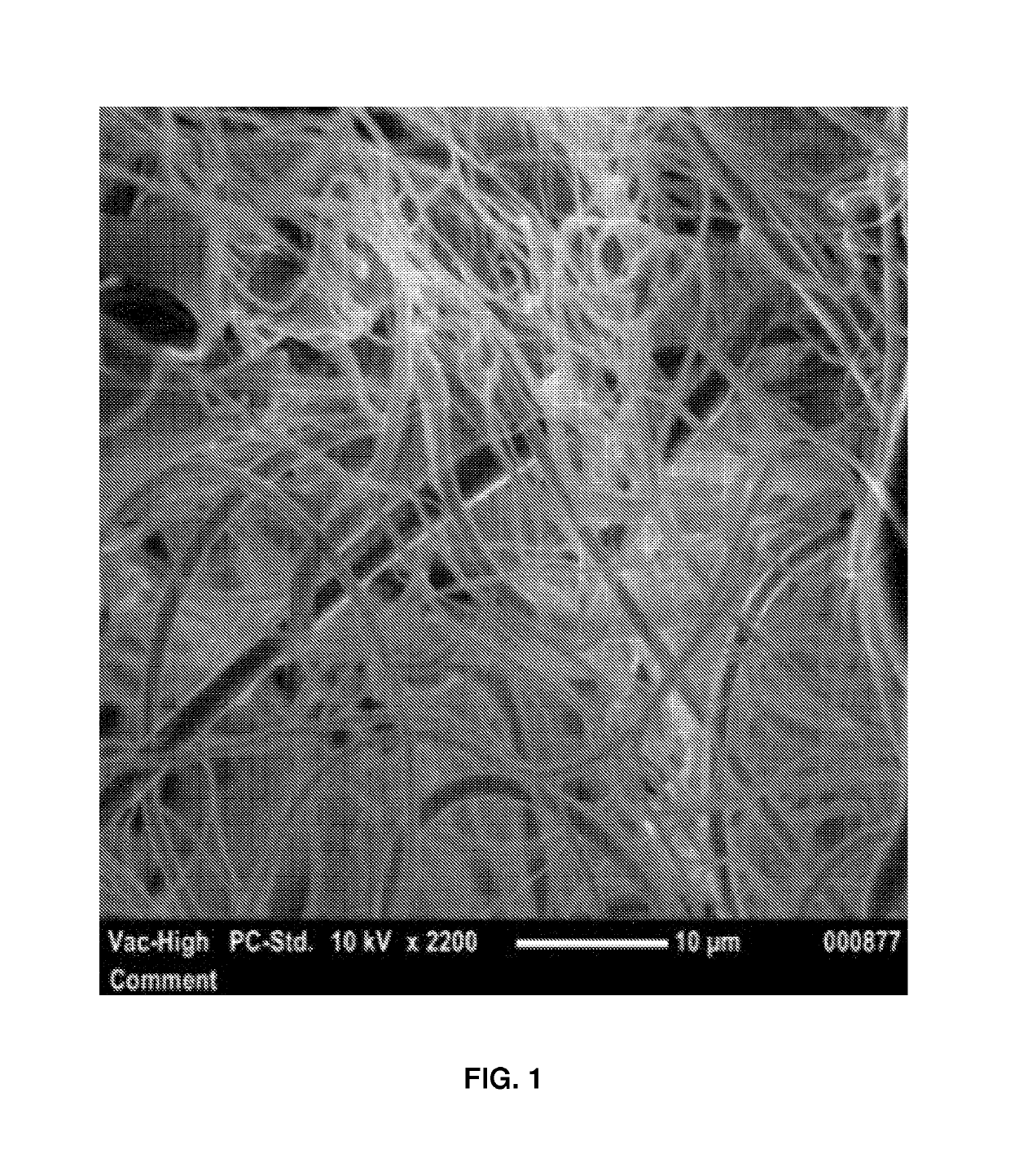

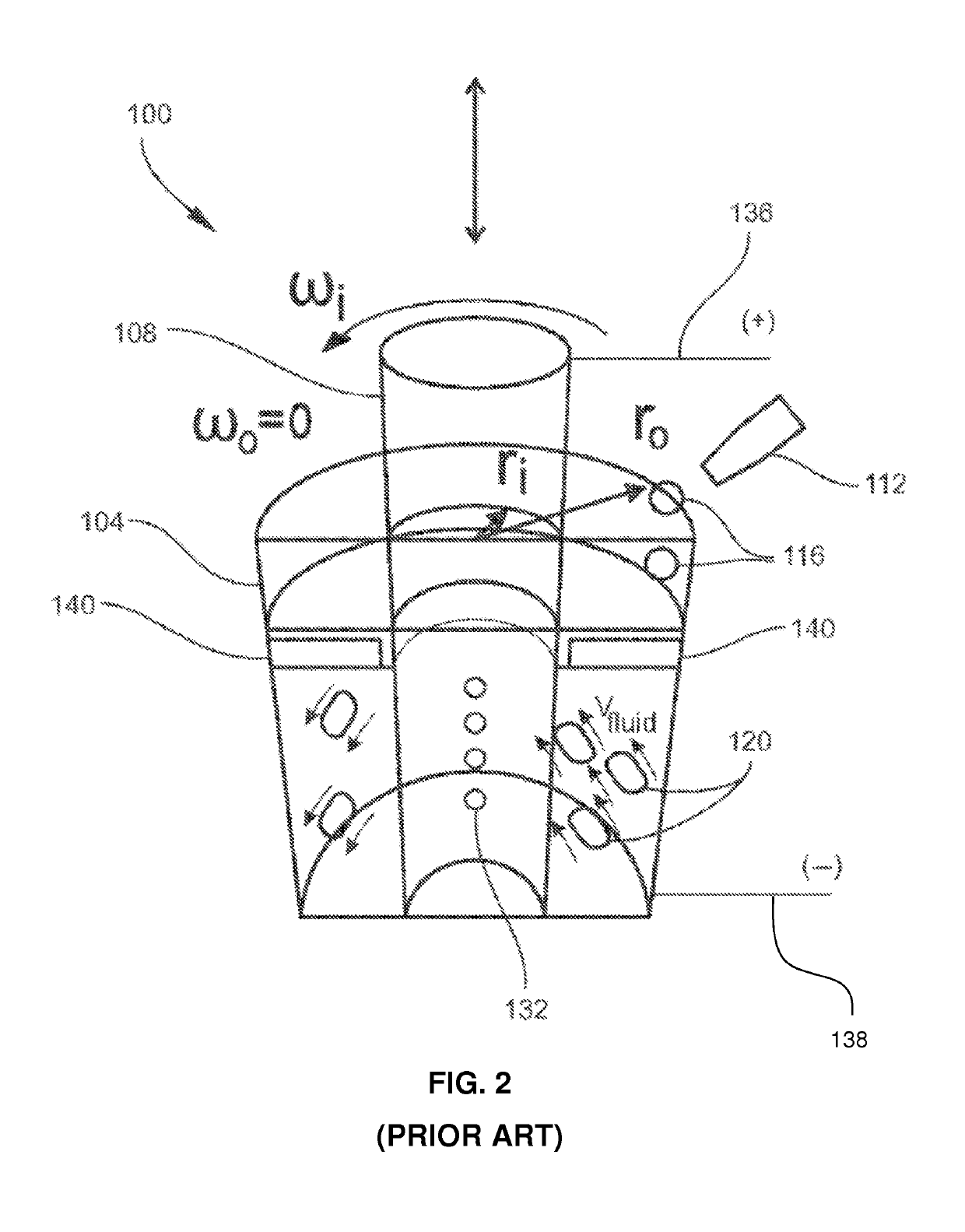

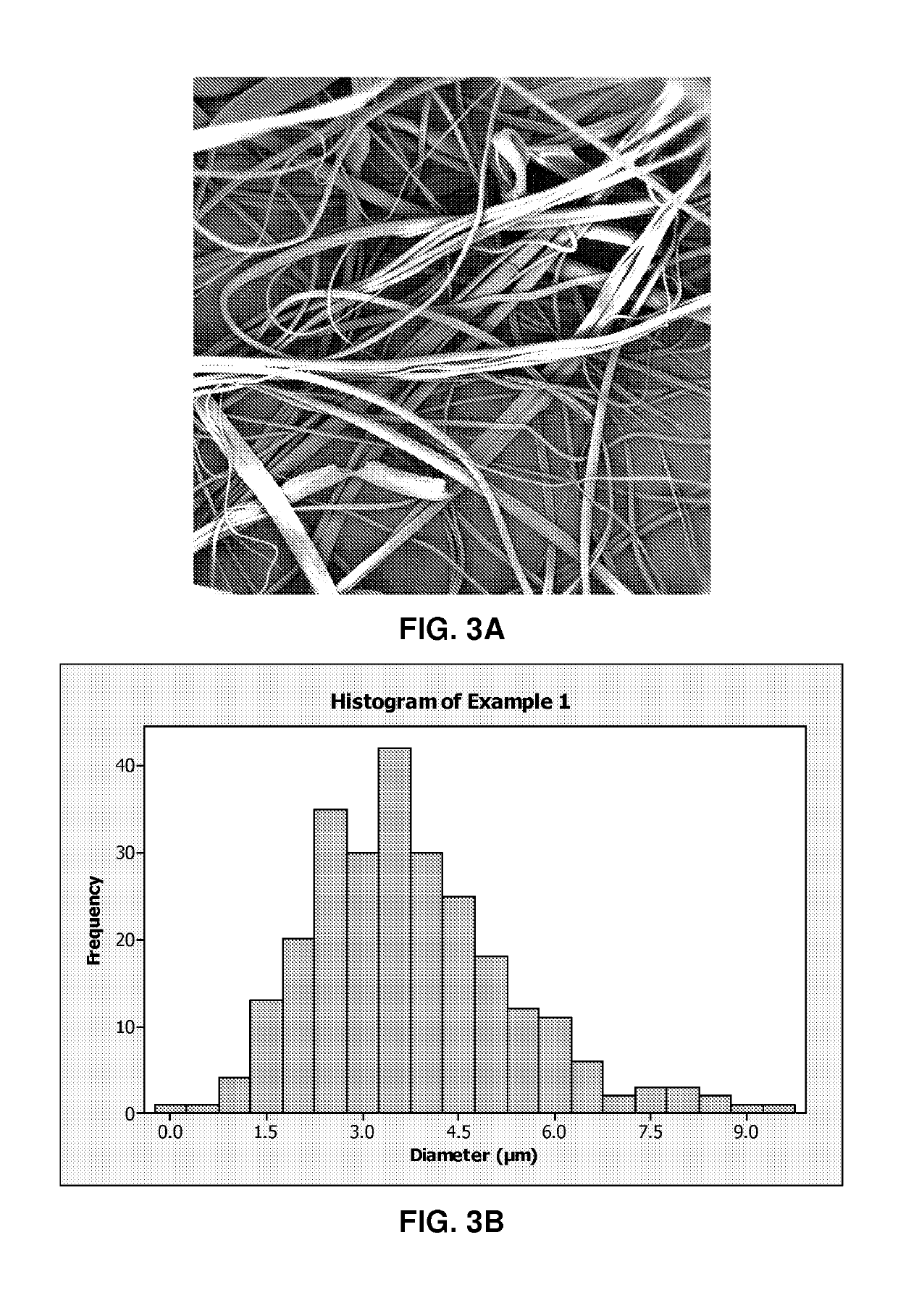

Shear spun sub-micrometer fibers

A process including shearing a first dispersion medium and a second dispersion medium under conditions that precipitate a plurality of polymeric fibers; and collecting the plurality of polymeric fibers at a rate of at least 300 grams / hour. The first dispersion medium is a solution including at least one polymeric component. The at least one polymeric component includes a poly-etherimide component selected from the group consisting of polyetherimide homopolymers, polyetherimide co-polymers, poly etherether ketones homopolymers, polyetherether ketones copolymers, polyphenylene sulfones homopolymers, polyphenylene sulfones copolymers, and combinations thereof. Products produced by the process can be non-woven paper, medical implants, ultra-fine filters, membranes, hospital gowns, electrical insulation paper, honeycomb structures and personal hygiene products, dialyzers, blood, oxygenator filters, intravenous (IV) filters, diagnostic test filters, and blood / apheresis filters.

Owner:SHPP GLOBAL TECH BV

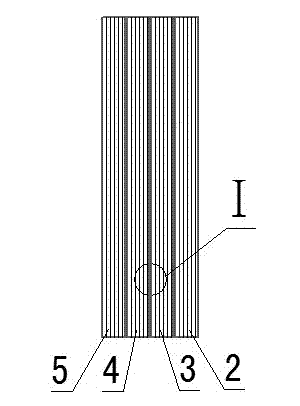

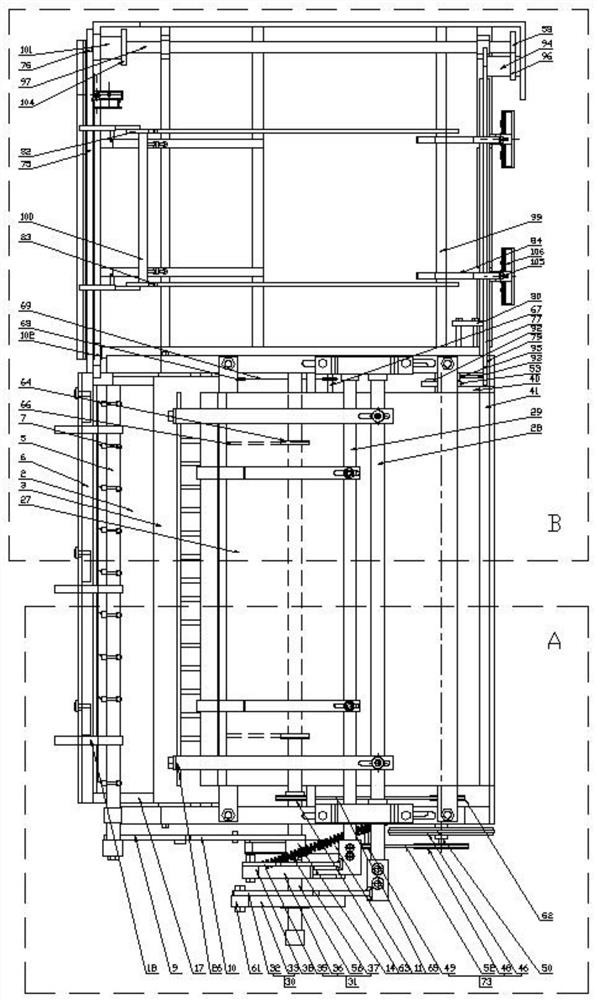

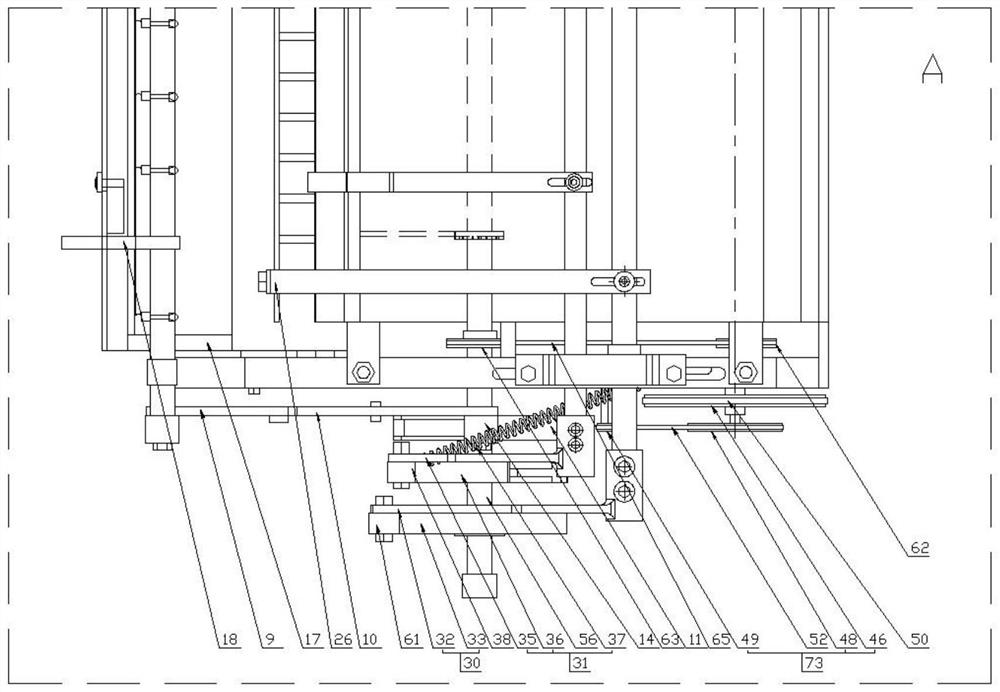

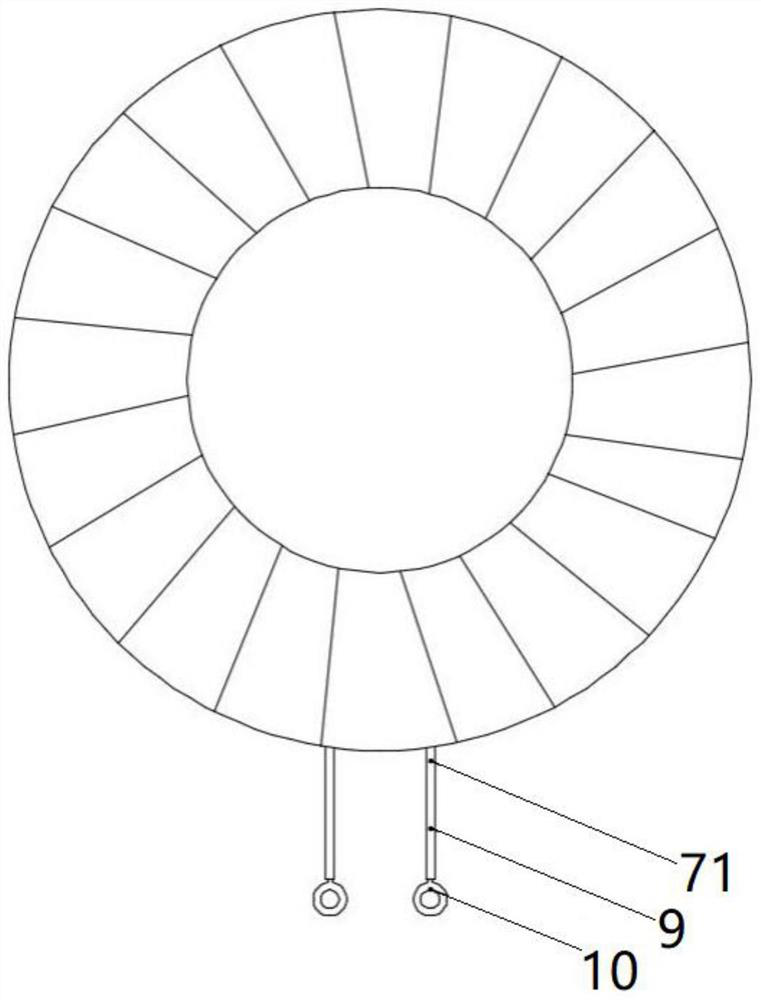

Electrical insulation paper wrinkle tube continuous processing device

ActiveCN109334113AReduce in quantityLow costPaper/cardboard wound articlesInsulatorsWrinkle skinElectrical insulation paper

The invention relates to an electrical insulation paper wrinkle tube continuous processing device. The continuous processing device comprises a machine frame, a first baffle, a guide plate, a conveying belt and a driving mechanism are arranged on the machine frame, a first shaft body with a rubber brush and a brazing frame are arranged on the top of the side of the first baffle plate, a first deflection mechanism is arranged on the first shaft body, an upper brazing chain is arranged on one side of the brazing frame, a second deflection mechanism is arranged on a brazing claw of the brazing frame, a second shaft body of a pressing frame and a third shaft body of a pushing frame are provided with a third deflection mechanism and a fourth deflection mechanism respectively, a fifth deflectionmechanism is arranged on a material frame of a second arc-shaped plate, a brazing chain is arranged on one side of the material frame, at least two return brazing chains are arranged between the brazing chain and the upper brazing chain, and a transmission mechanism is arranged on a driving roller of the conveying belt. The continuous processing device is compact in structure, the energy consumption is low, the whole machine is linked, the operation is simple, automatic and rapid continuous brazing, gluing, twisting and forming, brazing circulation and discharging and machining can be realized, so that the equipment, the brazing and the labor cost can be remarkably reduced, the production efficiency and the yield of paper tubes are improved.

Owner:镇江市鑫泰绝缘材料有限公司

Pure polyphenylene sulfide fiber high class electrical insulating paper and preparation method thereof

The invention discloses a pure polyphenylene sulfide (PPS) fiber high class electrical insulating paper and preparation method of the pure PPS fiber high class electrical insulating paper. PPS superfine fibers are prepared by adopting the method of combining melt spinning and high-temperature high-pressure air flow injection blowing net forming, are cooled by negative pressure cold-air and then agglutinated to form a net, and the fiber net finally forms pure PPS fiber high class electrical insulating paper after being processed in a high-temperature pressurization mode in a certain time. A technological process is short, no pollutant is generated in a productive process, energy consumption is low, prepared insulating paper has good insulativity, is high in temperature resistance grade, and has good fire resistance, chemical properties and mechanical properties.

Owner:SICHUAN TEXTILE SCI RES INST

Insulating tape material, method for production and usage thereof

InactiveCN104321829AImprove thermal conductivityIncreased overall thermal conductivityWindings insulation materialWindings insulation shape/form/constructionElectrical insulation paperHigh pressure

The invention relates to an insulating tape material, a method for production and usage thereof, particularly one for producing electrical insulation paper such as mica paper, which is contained in thermally conductive insulating tapes that are used for high-voltage insulation, for example. The insulating tape material has fibre reinforcement by means of a fabric, wherein the meshes of the fabric are filled by a particle composite which is preferably thermally conductive.

Owner:SIEMENS AG

Aramid paper, manufacturing method therefor, and use thereof

ActiveUS20180142415A1Improve mechanical propertiesReduce weightPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperAramides

The present disclosure relates to an aramid paper for a honeycomb, which is prepared by mixing, with an aramid floc, an aramid pulp having a fiber length equal to or longer than a predetermined length and a fibril development equal to or higher than a predetermined level, at a predetermined ratio, a wholly aromatic aramid paper for an electrical insulation paper having superior paper formation property and thus having uniform electrical insulation property, which is prepared by mixing an aramid pulp having a fines content equal to or higher than a predetermined ratio at a predetermined ratio, a laminated aramid paper having a uniform thermal expansion coefficient, uniform electrical conductivity and uniform thermal conductivity, which is prepared by laminating an aramid paper with superior paper formation property on an aramid paper with superior paper strength by calendering, and a method for preparing the same. The aramid paper according to the present disclosure is applicable to a material or a component which requires precision with little difference in physical properties such as a thermal expansion coefficient, electrical conductivity and thermal conductivity. Specifically, it is applicable to a honeycomb, an electrical insulation paper, a PCB substrate, etc. because it has superior paper strength and paper formation property. Moreover, the method for preparing an aramid paper can solve the problems of poor transfer of a base paper, nonuniformity of strength and aggregation between flocs.

Owner:KOLON IND INC

Impregnable electrical insulating paper and method for producing electrical insulating paper

InactiveUS20190035514A1Improve thermal conductivityImprove propertiesPlastic/resin/waxes insulatorsMetallic oxidesElectrical insulation paperEngineering

An impregnable electrical insulating paper for an electrical insulating body having first platelet-shaped particles which have layer silicates, and second platelet-shaped particles which have a heat conductivity at 20° C. of at least 1 W / mK. A method for producing an impregnable electrical insulating paper, an electrical insulating tape, an electrical insulating body, and the use of the electrical insulating body having first platelet-shaped particles which have layer silicates, and second platelet-shaped particles.

Owner:SIEMENS AG

Insertion system and method to insert insulators and coils in slots of stator of electric machine

InactiveCN102474161BWindingsEmbedding prefabricated windingsElectric machineElectrical insulation paper

The insertion of electrically insulating paper from a continuous roll into slots of a stator created by outwardly projecting teeth is described herein. The insertion of the insulating paper is done by the insertion of prewound coils in the stator slots. The electrically insulating paper is not cut prior to its insertion in the slots, thereby completely covering the outer surface of the stator. The insertion systems and methods described herein are also optionally concerned with the insertion of interphase insulation paper between the different coils inserted in the stator slots and with the insertion of slot closing wedges.

Owner:TM4 INC

Electrical insulating materials and transformers

The present invention discloses an article comprising an inorganic filler, fully hydrolyzed polyvinyl alcohol fibers, a polymer matrix, and high surface area fibers. The article can be made into electrical insulating paper for electrical equipment, such as liquid-immersed transformers, which can thus be substantially free of cellulose.

Owner:3M INNOVATIVE PROPERTIES CO

A continuous processing device for electrical insulation paper corrugated tube

ActiveCN109334113BReduce in quantityLow costPaper/cardboard wound articlesInsulatorsElectrical insulation paperBrush

The invention relates to an electrical insulation paper wrinkle tube continuous processing device. The continuous processing device comprises a machine frame, a first baffle, a guide plate, a conveying belt and a driving mechanism are arranged on the machine frame, a first shaft body with a rubber brush and a brazing frame are arranged on the top of the side of the first baffle plate, a first deflection mechanism is arranged on the first shaft body, an upper brazing chain is arranged on one side of the brazing frame, a second deflection mechanism is arranged on a brazing claw of the brazing frame, a second shaft body of a pressing frame and a third shaft body of a pushing frame are provided with a third deflection mechanism and a fourth deflection mechanism respectively, a fifth deflectionmechanism is arranged on a material frame of a second arc-shaped plate, a brazing chain is arranged on one side of the material frame, at least two return brazing chains are arranged between the brazing chain and the upper brazing chain, and a transmission mechanism is arranged on a driving roller of the conveying belt. The continuous processing device is compact in structure, the energy consumption is low, the whole machine is linked, the operation is simple, automatic and rapid continuous brazing, gluing, twisting and forming, brazing circulation and discharging and machining can be realized, so that the equipment, the brazing and the labor cost can be remarkably reduced, the production efficiency and the yield of paper tubes are improved.

Owner:镇江市鑫泰绝缘材料有限公司

Manufacturing method of damper for preventing ferromagnetic resonance of capacitor voltage transformer

PendingCN113884736AReduce volumeSmall footprintVoltage/current isolationInsulation layerElectrical insulation paper

The invention relates to a manufacturing method of a damper for preventing ferromagnetic resonance of a capacitor voltage transformer, and belongs to the technical field of voltage transformer production. The damper comprises an iron core, the outer surface of the iron core is coated with an electrical insulation paper layer, the iron core is arranged in a ceramic protection box, and a high-temperature-resistant insulation layer and a high-resistivity wire layer are sequentially arranged outside the ceramic protection box. The damper is compact in structure, small in occupied space and low in production cost.

Owner:山东泰开互感器有限公司

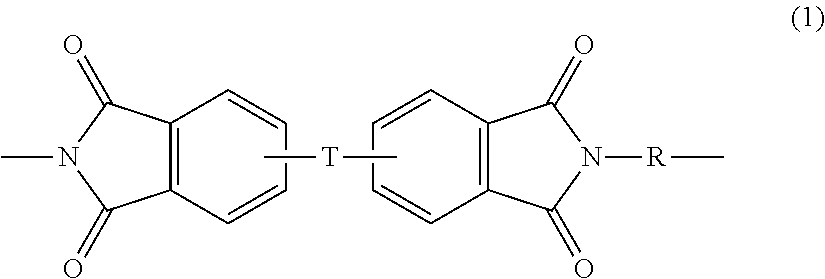

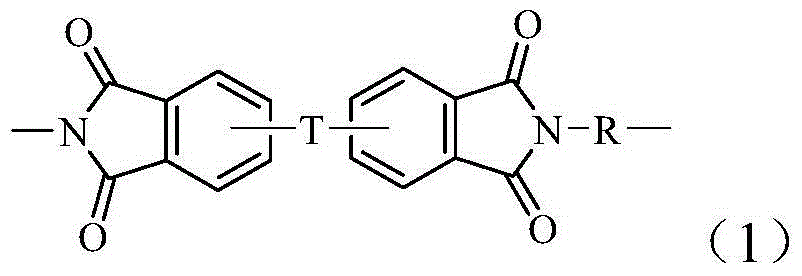

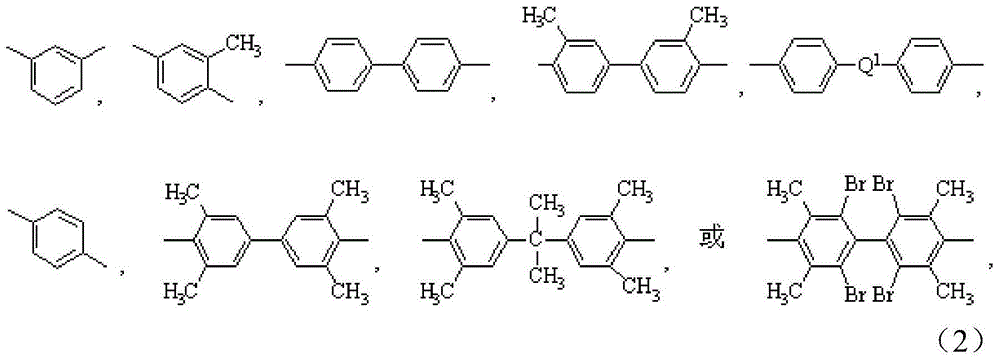

Electrical insulation paper for transformer winding, liquid-immersed transformer and preparation method

PendingCN114093630AHave mechanical propertiesHave electrical propertiesTransformers/inductances coils/windings/connectionsTransformers/inductances corrosion protectionEpoxyCellulose

The main component of the paper-based material is cellulose; the resin layer is made of epoxy resin, the paper-based material contains an amine compound, the paper-based material contains an antioxidant, and the paper-based material contains a carboxylic acid remover. The invention further discloses a liquid-immersed transformer comprising the electrical insulation paper and a preparation method of the electrical insulation paper for a transformer winding. The electrical insulation paper provided by the invention not only has mechanical characteristics, electrical characteristics, good compatibility with insulating oil and impregnation characteristics of traditional electrical insulation paper, but also has better heat resistance. Meanwhile, the transformer has good oxidation resistance and hydrolysis resistance, and is suitable for a large-capacity or small-sized liquid-immersed transformer.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Electrical insulation paper, methods of manufacture, and articles manufactured therefrom

A fibrous substrate comprising a consolidated product of a fiber composition is provided comprising polyimide fibers; fibers selected from aromatic polyamide fibrids or polycarbonate fibers; aromatic polyamide fibers. A process of preparing a fibrous substrate is disclosed, comprising forming a layer from a slurry comprising a suspension solvent; and fiber composition comprising a combination of polyimide fibers; aromatic polyamide fibers; aromatic polyamide fibrids; each based on the total weight of the fibers in the fiber composition; dewatering the layer; and consolidating the layer to form the fibrous substrate; wherein a layer of polyimide fiber aromatic polyamide fibrid is applied to each surface of the fibrous substrate either before or after said consolidating step, and the substrate and polyimide layers are together subjected to a consolidating step. In another embodiment, articles comprising the above fibrous substrates are provided.

Owner:SABIC GLOBAL TECH BV

Shear spun sub-micrometer fibers

Owner:SHPP GLOBAL TECH BV

A preparation method of para-meta-aramid electrical insulating paper

ActiveCN106223129BIncreased tensile indexHigh strengthPlastic/resin/waxes insulatorsSpecial paperElectrical insulation paperHigh intensity

Owner:湖北城东再生资源科技发展有限公司

Large-scale oil-immersed transformer insulating end ring and its manufacturing process

ActiveCN103117159BAvoid or greatly reduce the amount of partial dischargeReduce partial dischargeTransformers/inductances coils/windings/connectionsCoils manufactureManufacturing technologyDistilled water

The invention discloses a large oil-immersed transformer insulated end ring and a manufacturing technology thereof. The large oil-immersed transformer insulated end ring comprises casein glue layers and a plurality of layers of paperboards, and every two adjacent layers of paperboards are glued via one of the casein glue layer. The manufacturing technology includes: A, utilizing a board shearing machine to shear needed large electrical insulating paperboards into regulated dimension so as to obtain semi-finished paperboards; B, evenly spraying distilled water on the surfaces of the semi-finished paperboards, guaranteeing the paperboards to have certain bending capability, utilizing a roller press to roll the paperboards into cylinders according to technical requirements; and C, selecting casein glue which is strong in permeability on the insulated paperboards to glue the layers of the paperboards according to a single-face gluing technique, tightening the layers of the paperboards via a binding strap, placing in a drying furnace to be subjected to drying and vacuum oil spraying, and finally disassembling the binding strap. The large oil-immersed transformer insulated end ring and the manufacturing technology thereof have the advantages of simple technology, convenience in operation, reliability in performance, and capability of effectively avoiding or greatly reducing of transformer partial discharge magnitude caused by closed air bubbles in insulating parts.

Owner:SHANDONG DACHI ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com