Electrical insulation material and transformer

A technology of electrical insulating paper and oil-immersed transformers, applied in the direction of heterogeneous insulating materials, insulators, parts of transformers/inductors, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

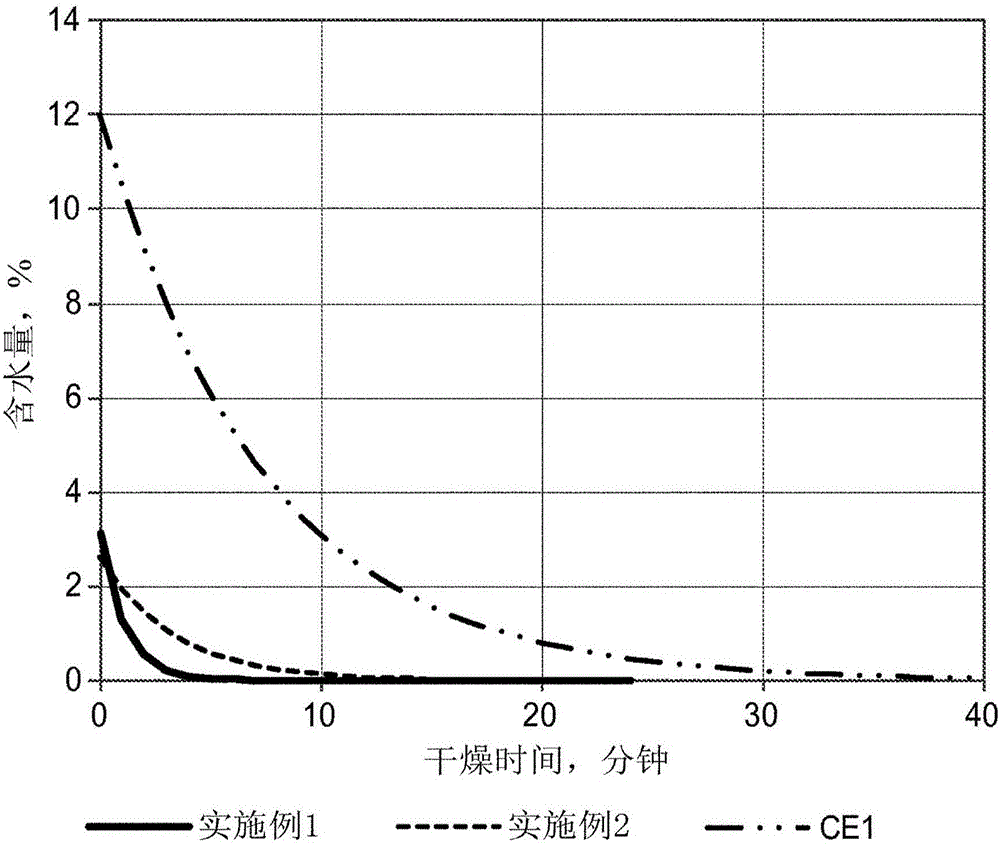

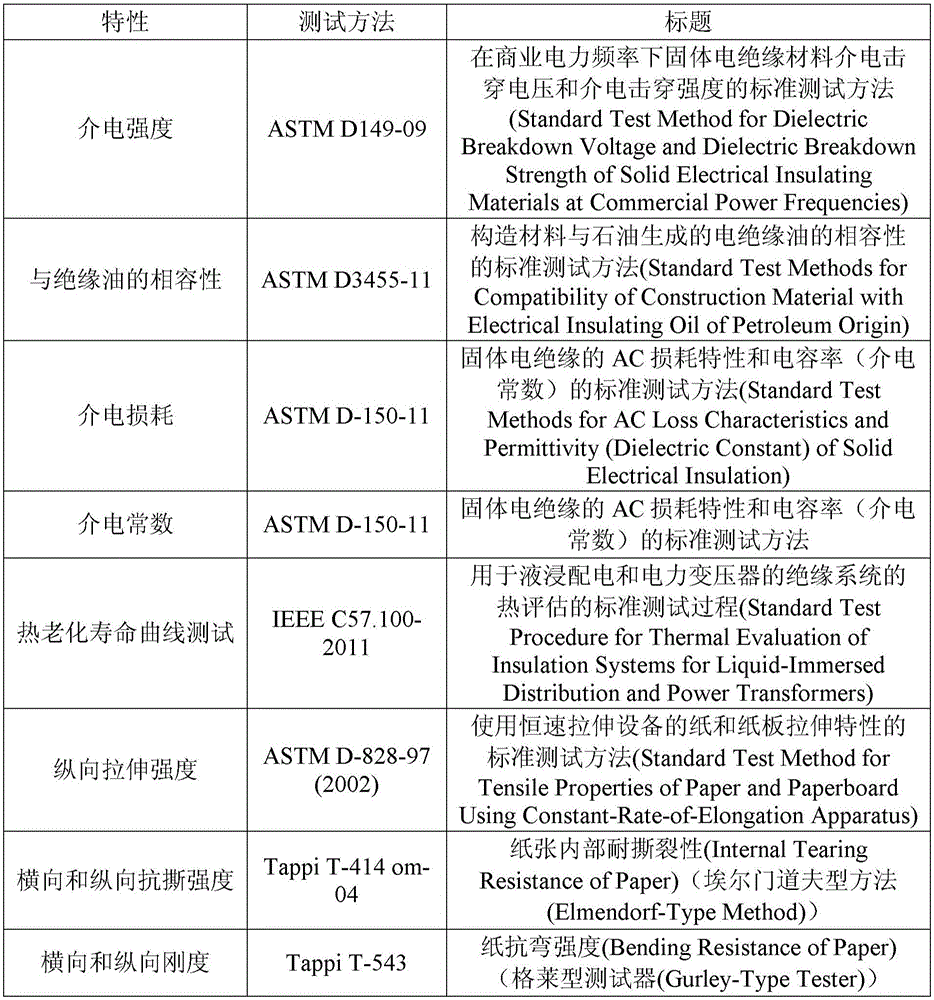

[0043] Examples and comparative examples provided below are provided to facilitate the understanding of the present invention, and these examples and comparative examples should not be construed as limiting the scope of the present invention. All parts and percentages are by weight unless otherwise indicated. The following illustrative examples and comparative examples were evaluated using the test methods and protocols described below.

[0044] Sample Preparation :

[0045] Exemplary electrically insulating nonwoven papers were made using methods known in the art, as follows:

[0046] 6% by weight of microglass (B-04 from Lauscha Fiber International), 64% by weight of exfoliated kaolin (HYDRAPRINT from KaMin, LLC, USA), 13% poly(vinyl alcohol) fibers (from Minifibers Inc, USA, fully hydrolyzed, 1.8 denier x 6 mm, fiber tenacity of 13 g / denier) and 17 wt% of (HYCAR 26362 from Lubrizol Corp) was dispersed in water to form a slurry with a solids content of about 2% by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com