Low smoke zero halogen waterproof high temperature resistant anti-corrosion armored cable

An armored cable, high temperature resistant technology, applied in the field of low smoke halogen free waterproof high temperature resistant corrosion resistant armored cable, can solve the problem of fire resistance and high temperature resistance, damage to human life safety, damage to the environment, etc., to improve the shielding performance, reduce The performance of moisture absorption and oxidation, the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

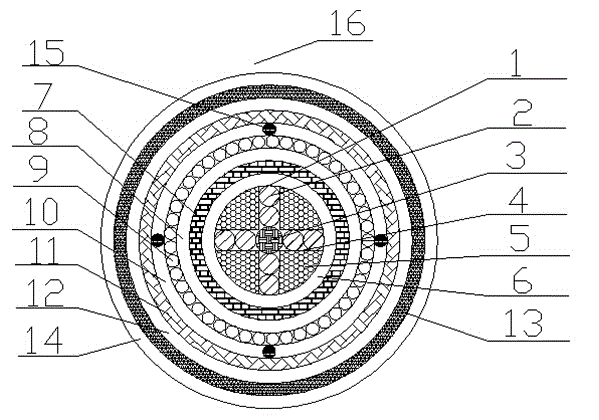

[0012] Such as figure 1 As shown, a low-smoke, halogen-free, waterproof, high-temperature and corrosion-resistant armored cable includes a cable body 16, an insulated core 2, an insulation layer 6, a shielding layer 7 and an outer sheath 14, and the cable body 16 is provided with A plurality of conductors 1; the conductor 1 is provided with an insulated wire core 2; and the conductor 1 is provided with a PVC plastic connecting rod 4; the center of the cable body 16 is provided with a drainage core 3; the conductor 1 is covered A layer of insulating layer 6; the gap between the insulating layer 6 and the conductor 1 is provided with a filler 5; the insulating layer 6 is provided with a shielding layer 7; the shielding layer 7 is extruded from the inside to the outside with resistance The water layer 8 and the armor layer 9; the armor layer 9 is provided with a stainless steel wire braided layer 11; the stainless steel wire braided layer 11 is sequentially extruded with a heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com