Preparation method of quartz fiber/chrome aluminum phosphate-based high temperature wave-transmitting material

A high-temperature wave-transmitting, chromium-aluminum phosphate technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem of weak mechanical properties of silicon-based composite materials, limiting the application of silicon-based composite materials, and bearing loads Limited capacity and other issues, to achieve the effect of reducing the dielectric constant, good heat resistance, and improving coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

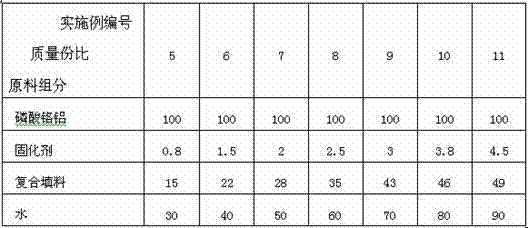

Examples

Embodiment 1

[0030] A method for preparing a quartz fiber / chromium aluminum phosphate-based high-temperature wave-transmitting material, comprising the following steps:

[0031] a. Take the quartz fiber cloth and heat it at 200°C for 2 hours to remove impurities such as wetting agent and wax layer on the surface of the quartz fiber cloth, cool down, and then coat the surface of the quartz fiber cloth (by brushing, spraying, etc., (preferably evenly coated) protective coating to obtain a protective coated quartz fiber cloth;

[0032] b. According to the mass ratio of 100 parts by mass of chromium aluminum phosphate (units can be kilograms, the same below), 0.5 parts by mass of curing agent, 10 parts by mass of composite filler, and 10 parts by mass of water, each raw material component is taken, mixed, and mixed at 100 Stirring at ℃ for 4h, cooling to obtain chromium aluminum phosphate cementitious material;

[0033] c. Coat the surface of the quartz fiber cloth with a protective coating (...

Embodiment 2

[0037] A method for preparing a quartz fiber / chromium aluminum phosphate-based high-temperature wave-transmitting material, comprising the following steps:

[0038] a. Take the quartz fiber cloth and heat it at 800°C for 20 minutes to remove impurities such as wetting agent and wax layer on the surface of the quartz fiber cloth, cool down, and then coat the surface of the quartz fiber cloth (by brushing, spraying, etc., (preferably evenly coated) protective coating to obtain a protective coated quartz fiber cloth;

[0039] b. According to the mass ratio of 100 parts by mass of chromium aluminum phosphate (units can be kilograms, the same below), 5 parts by mass of curing agent, 50 parts by mass of composite filler, and 100 parts by mass of water, each raw material component is taken, mixed, and mixed at 100 Stir at ℃ for 1 hour, cool to prepare chromium-aluminum phosphate cementitious material;

[0040] c. Coat the surface of the quartz fiber cloth with a protective coating (...

Embodiment 3

[0044] A method for preparing a quartz fiber / chromium aluminum phosphate-based high-temperature wave-transmitting material, comprising the following steps:

[0045] a. Take the quartz fiber cloth and heat it at 500°C for 1 hour to remove impurity such as wetting agent and wax layer on the surface of the quartz fiber cloth, cool down, and then coat the surface of the quartz fiber cloth (by brushing, spraying, etc., (preferably evenly coated) protective coating to obtain a protective coated quartz fiber cloth;

[0046] b. According to the mass ratio of 100 parts by mass of chromium aluminum phosphate (units can be kilograms, the same below), 2.7 parts by mass of curing agent, 30 parts by mass of composite filler, and 55 parts by mass of water, each raw material component is taken, mixed, and mixed at 70 Stir at ℃ for 2.5h, and cool to prepare the chromium aluminum phosphate cementitious material;

[0047] c. Coat the surface of the quartz fiber cloth with a protective coating (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com