Patents

Literature

63results about How to "Enhanced wave performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of quartz fiber/chrome aluminum phosphate-based high temperature wave-transmitting material

InactiveCN102514346AImprove mechanical propertiesGood physical propertiesLamination ancillary operationsLaminationMoisture resistanceALUMINUM PHOSPHATE

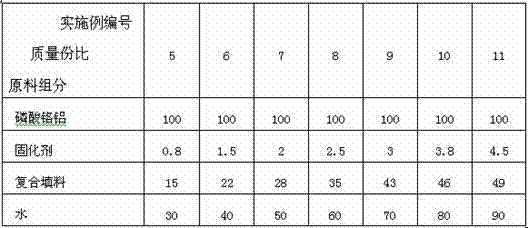

The invention discloses a reparation method of quartz fiber / chrome aluminum phosphate-based high temperature wave-transmitting material, characterized by comprising the following steps of: heating quartz fiber cloth at a temperature of 200-800 DEG C, cooling the quartz fiber cloth, and coating a protection coating on the surface of the quartz fiber cloth; mixing the chrome aluminum phosphate, curing agent, composite stuffing and water to prepare a chrome aluminum phosphate binding material; coating the chrome aluminum phosphate binding material on the surface of the quartz fiber cloth having the protection coating, drying at a temperature of 80-100 DEG C, and flatly laying the quartz fiber cloth; and processing more than two pieces of flatly laid and overlapped high temperature wave-transmitting material monomers by a mould press forming technique to obtain the product, namely, quartz fiber / chrome aluminum phosphate-based high temperature wave-transmitting material. The preparation method of the invention has the advantages of simple technique, good availability of raw materials and convenience for operation; besides, the prepared quartz fiber reinforced chrome aluminum phosphate-based high temperature wave-transmitting material has excellent moisture resistance, heat-resisting stability, mechanical property and dielectric property, so that the material is suitable for the use as a high temperature resistant wave-transmitting material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Triazine-containing benzoxazine, triazine-containing benzoxazine polymer, and preparation method thereof

ActiveCN102219785AIncrease contentImprove heat resistanceOrganic chemistryTriflic acidStructural formula

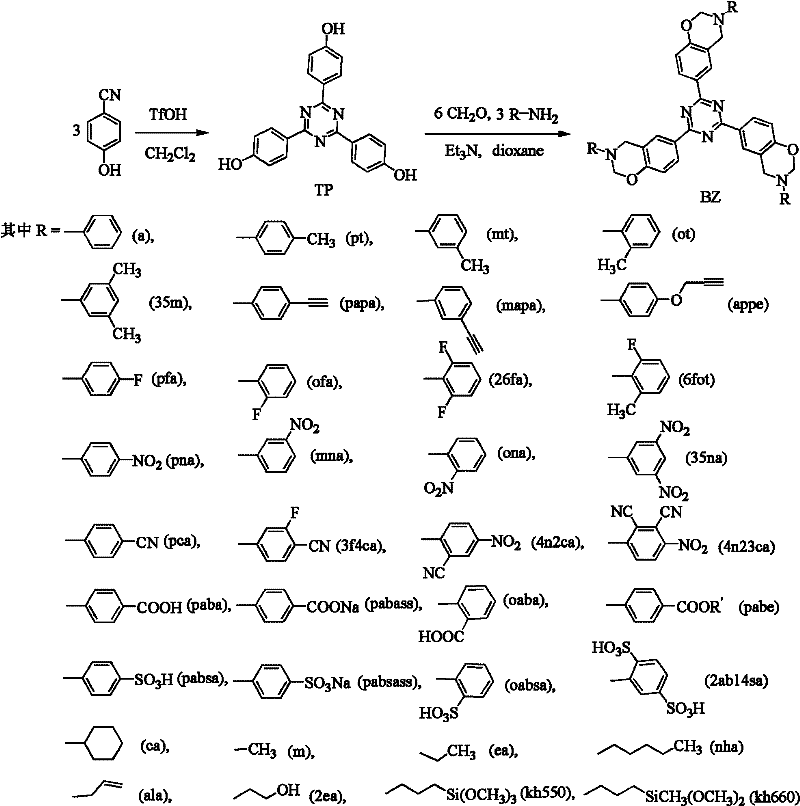

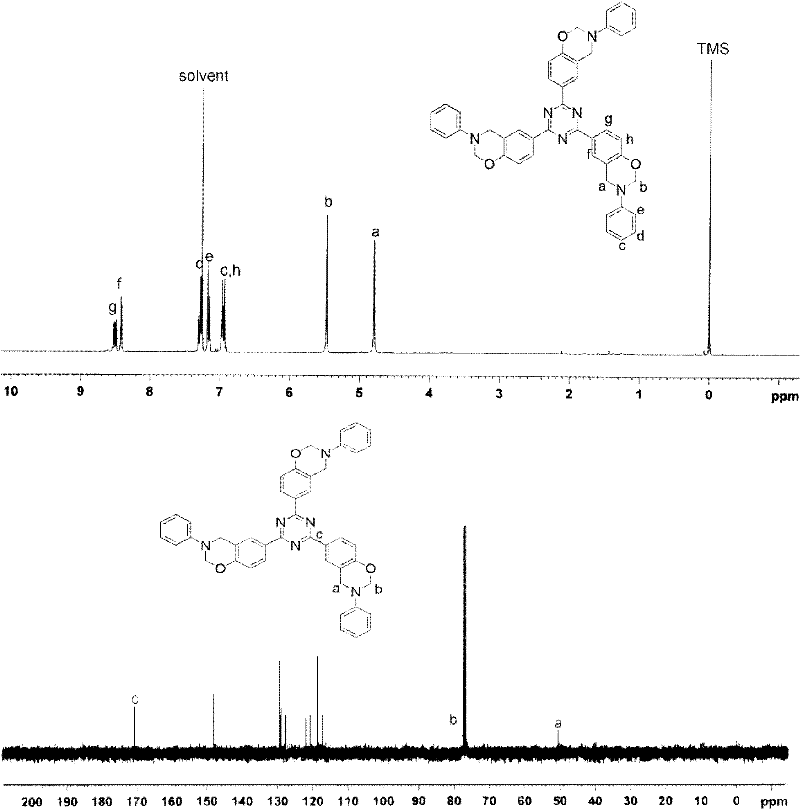

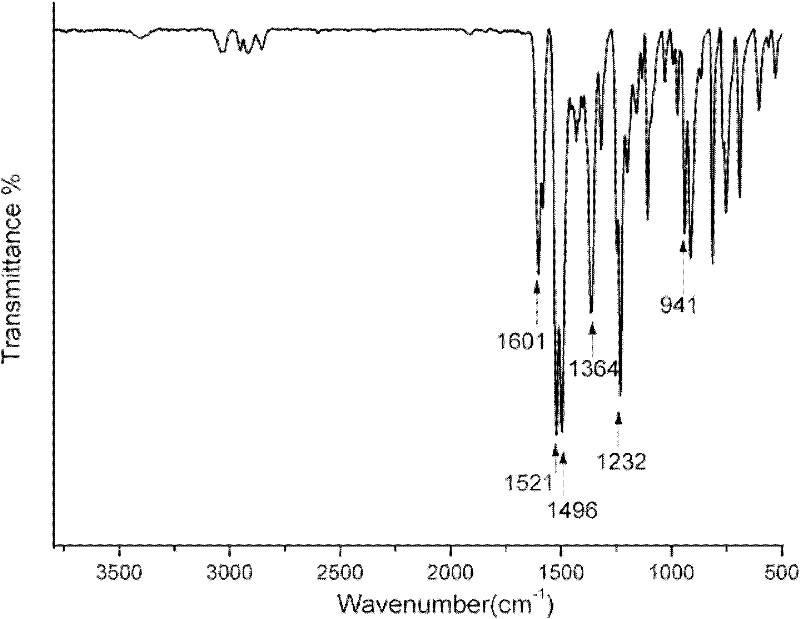

The invention relates to triazine-containing benzoxazine, a triazine-containing benzoxazine polymer, and a preparation method thereof. The preparation method is characterized by: adopting cyanophenol as a raw material; adopting trifluoromethanesulfonic acid or trifluoroacetic acid as a catalyst; synthesizing triazine-containing trihydric phenol (TP for short) in dichloromethane or chloroform or acetone at a common temperature; adopting the synthesized TP, formaldehyde and aminated compounds as reaction raw materials; adopting a alkali as the catalyst, and carrying out a reaction in a alcohol solvent or a ether solvent to synthesize a series of triazine-containing polycyclic benzoxazine monomers (BZ for short) which have not been reported; heating the BZ to carry out a ring-opening polymerization to form polybenzoxazine (PBZ for short). A structural formula of the monomer BZ is shown as follow, substituents R are shown in the specification. The synthesized novel monomer provided by the present invention contains a triazine ring structure, such that the triazine content in the PBZ resin can be substantially raised so as to notably improve heat resistance, residual carbon rate, fire resistance property and wave transmission property of the PBZ.

Owner:SHANDONG UNIV

Carbon-based composite building wave absorption and heat preservation material and preparation method thereof

The invention discloses a carbon-based composite building wave absorption and heat preservation material and a preparation method thereof. According to the preparation method, carbon-based wave absorbing agent, common silicate cement, expanded and vitrified small balls, re-dispersible latex powder, hydroxypropyl methyl cellulose, wood fiber, polypropylene fiber, surfactant, foam stabilizer, waterreducing agent, coupling agent, water and the like are adopted; and the material is obtained by adopting the steps of stirring, pouring molding, curing and the like. The material has the advantages of good wave absorption performance and heat insulation performance, low apparent density, low cost, high fire resistance, durability and the like, and is easy to construct. The material can be used for pouring roofs and walls of buildings, so that aims of electromagnetic radiation protection and energy conservation of the buildings are fulfilled.

Owner:CHONGQING UNIV

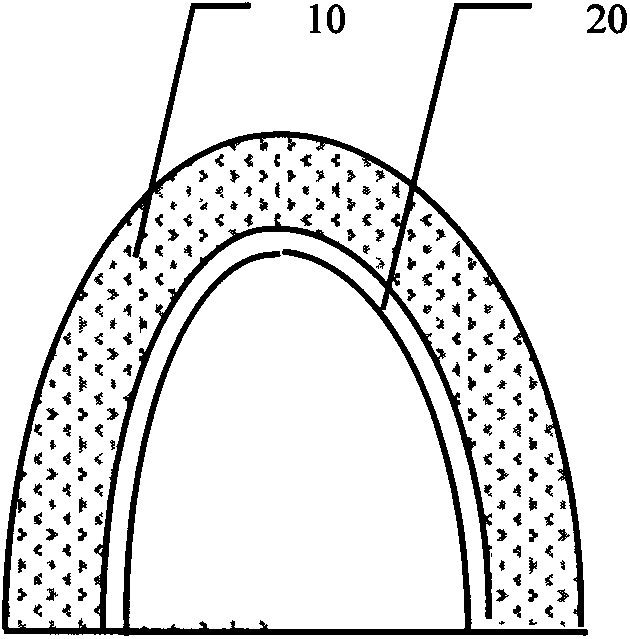

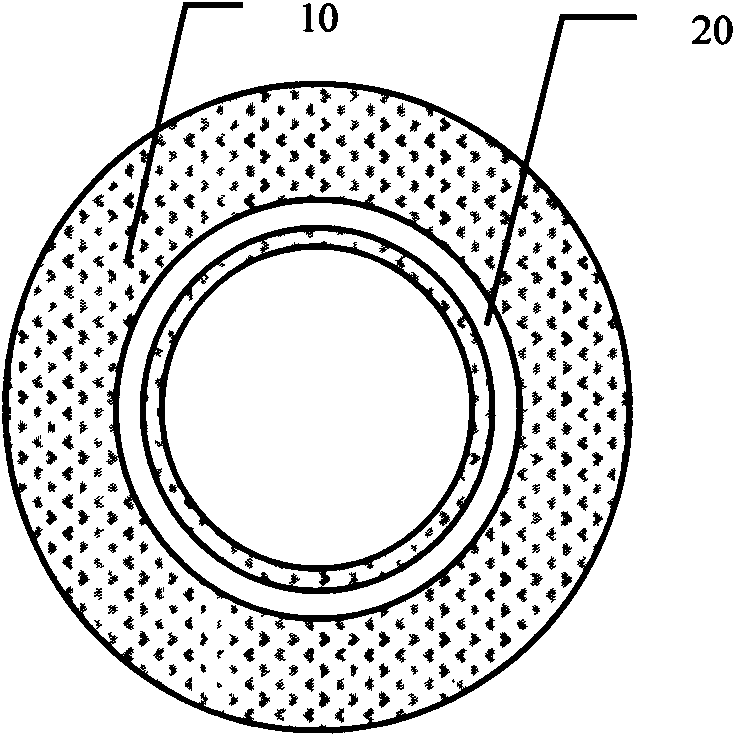

Method for preparing double-layer wave-permeable heat proofing and insulating composite structural part

The invention discloses a method for preparing a double-layer wave-permeable heat proofing and insulating composite structural part. The structural part comprises an inner heat insulation material and an outer heat-proof +material. The method includes steps of preparation of the outer heat-proof material, preparation of silicon oxide hollow microspheres, preparation of chopped fiber reinforced silicon oxide hollow microsphere slurry, casting of the chopped fiber reinforced silicon oxide hollow microsphere slurry and thermal treatment of a structural part blank material. Quartz fiber reinforced quartz composite ceramic serves as the outer heat-proof material, chopped fiber reinforced silicon oxide hollow microsphere ceramic serves as the inner heat insulation material, compact combination of the inner and outer materials is realized by means of slurry casting and high-temperature sintering moulding, and integration of advantageous performances of high temperature resistance, heat proofing, heat insulation, wave permeability and the like is realized.

Owner:湖北三江航天江北机械工程有限公司

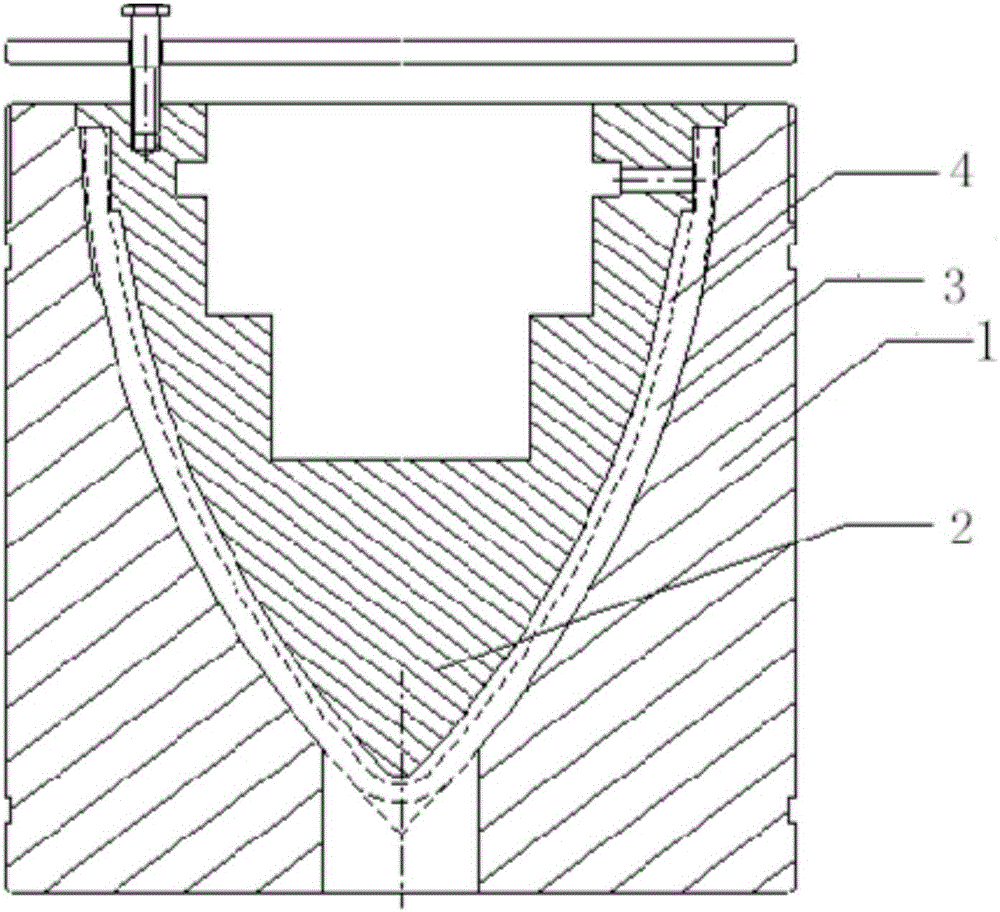

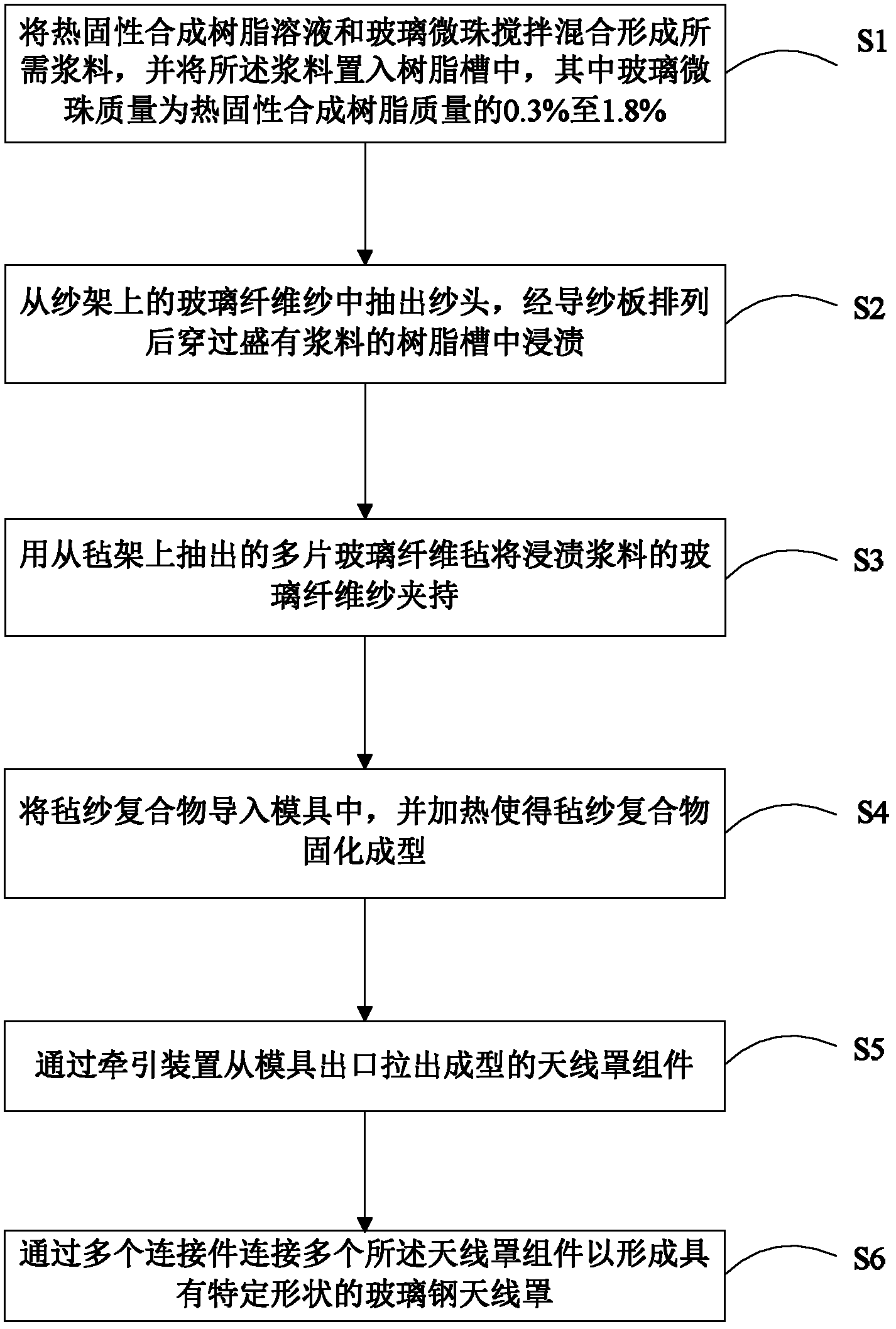

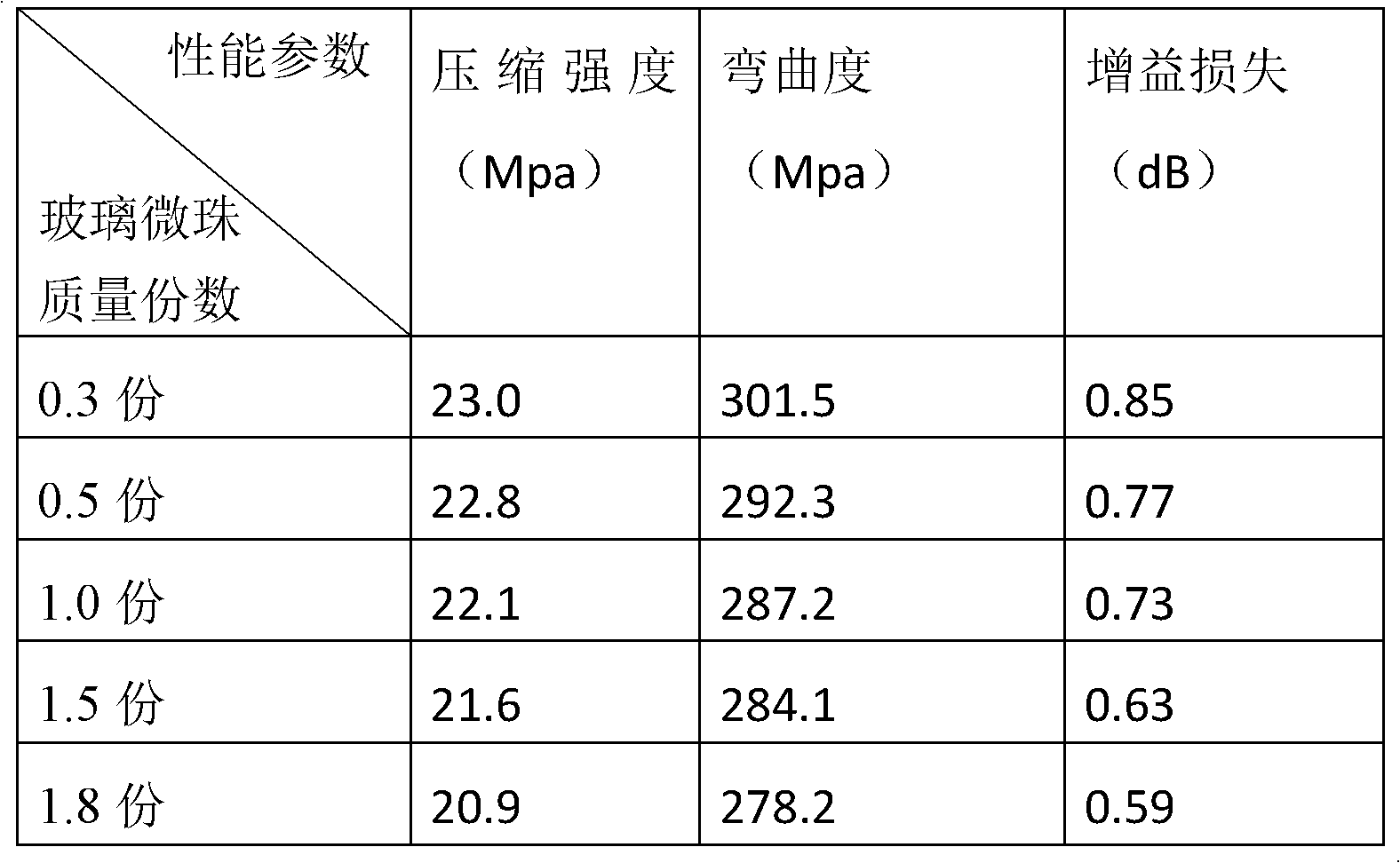

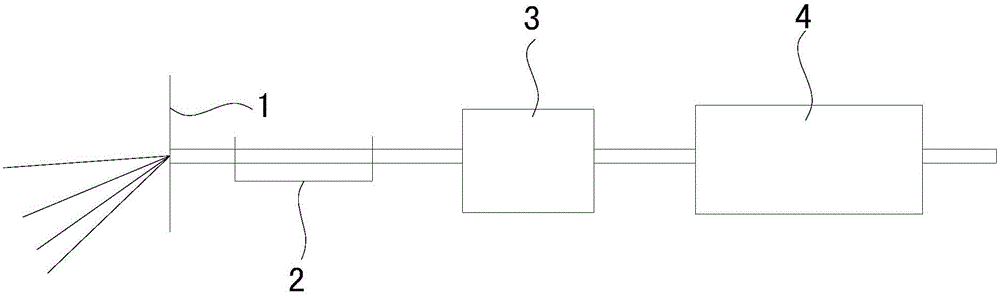

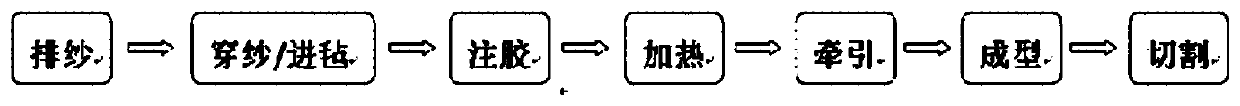

Glass fiber reinforced plastic antenna housing and preparation method thereof

The invention discloses a glass fiber reinforced plastic antenna housing and a preparation method thereof. The glass fiber reinforced plastic antenna housing comprises the following raw materials, by mass, 100 parts of thermosetting synthetic resin, 0.3-1.8 parts of glass bead, 0.6-1.9 parts of release agent and 0.5-4 parts of curing agent. The preparation method includes that a thermosetting synthetic resin solution and the glass beads are stirred and mixed to form required slurry, and the slurry is placed in a resin groove. A yarn end is drawn out from glass fiber yarn on a yarn support, and the glass fiber yarn is arranged through a yarn guiding plate to penetrate through the resin groove containing the slurry to be soaked. A plurality of sheets of glass fiber mats drawn out from a mat support clamp the glass fiber yarn soaked in the slurry. Mat yarn composite is led to a mold and heated to be cured and molded. A molded antenna housing assembly is drawn out from a mold outlet through a dragging device and assembled to form the glass fiber reinforced plastic antenna housing. The glass beads are added in the resin, the mechanical strength is improved, dielectric loss and cost are reduced, and wave penetrating effect is improved. Surface modification processing is conducted on the fiber mats and the glass beads, and bond between the fiber mats and the glass beads is improved.

Owner:KUANG CHI INST OF ADVANCED TECH

Making method of amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on metal surface

The invention relates to a making method of a high temperature-resistant wave transmitting ceramic coat on a metal surface, and concretely relates to a making method of an amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on the metal surface. The purpose of the invention is solving the problems of low high temperature resistance temperature and low wave transmittance of present organic coat systems. The method comprises the following steps: 1, weighing a raw material; 2, preparing an amorphous AlPO4 adhesive solution; 3, preparing a wave transmitting ceramic coating; and 4, preparing the amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on the metal surface. The coat obtained in the invention has good dielectric properties, and the dielectric constant is small, so the dielectric loss angle is small, thereby the electromagnetic wave transmittance is improved, and the wave transmittance is greater than 80% in 1-18GHz; and the high temperature resistance is good, the high temperature resistance temperature is 500-1300DEG C, and the amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat has the advantages of environmentally-friendly and nontoxic raw material, good film forming property, low cost, simple preparation method and short period.

Owner:HARBIN INST OF TECH

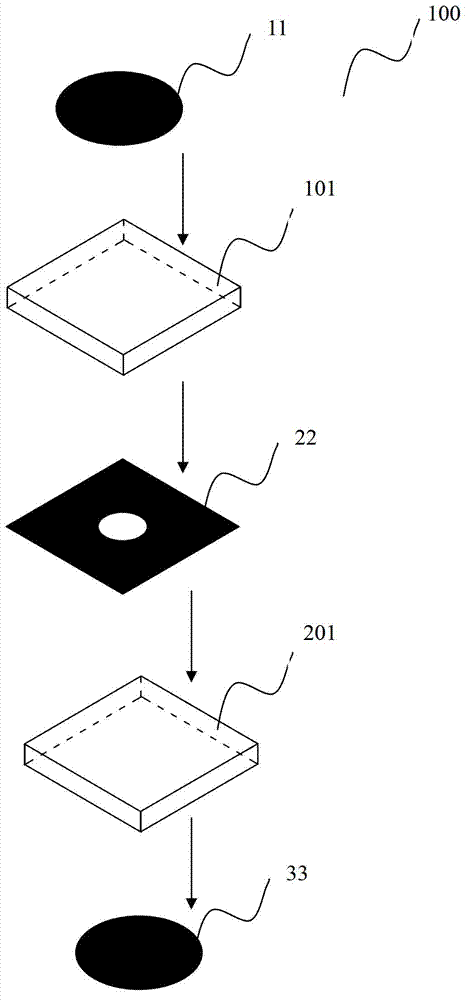

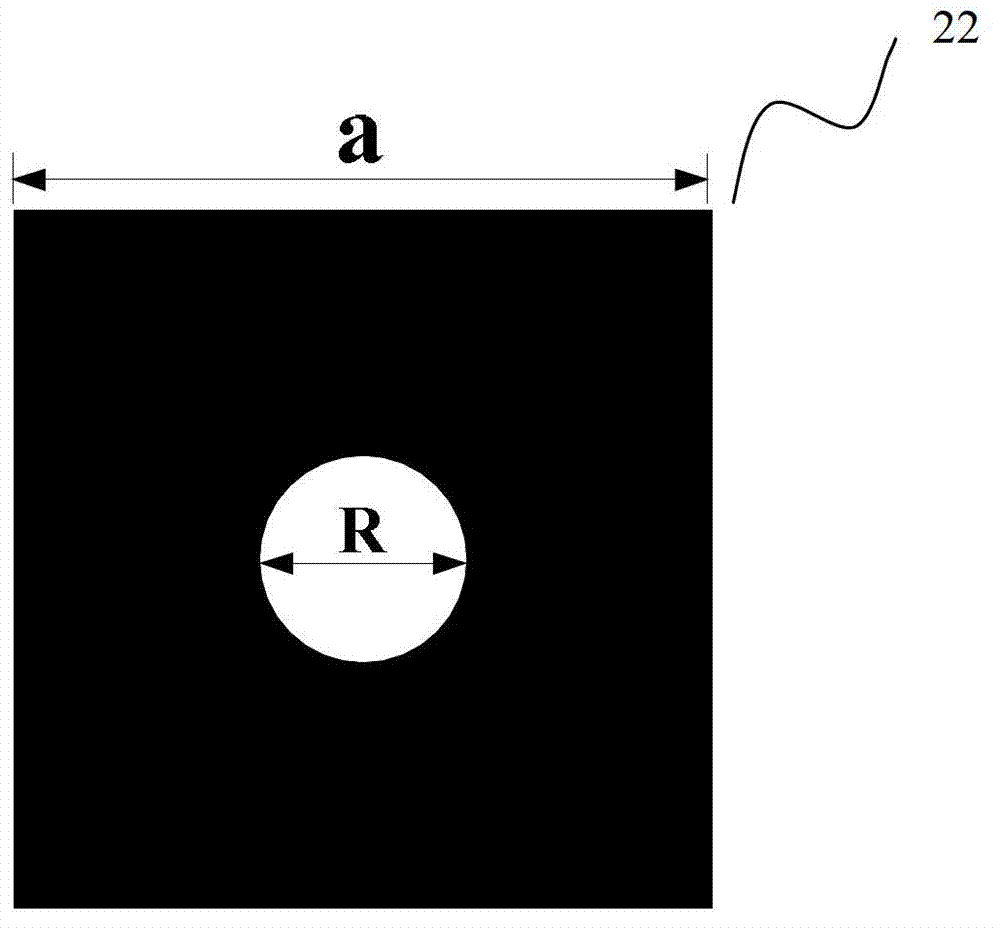

Wave-transmitting meta-material and antenna cover and antenna system with material

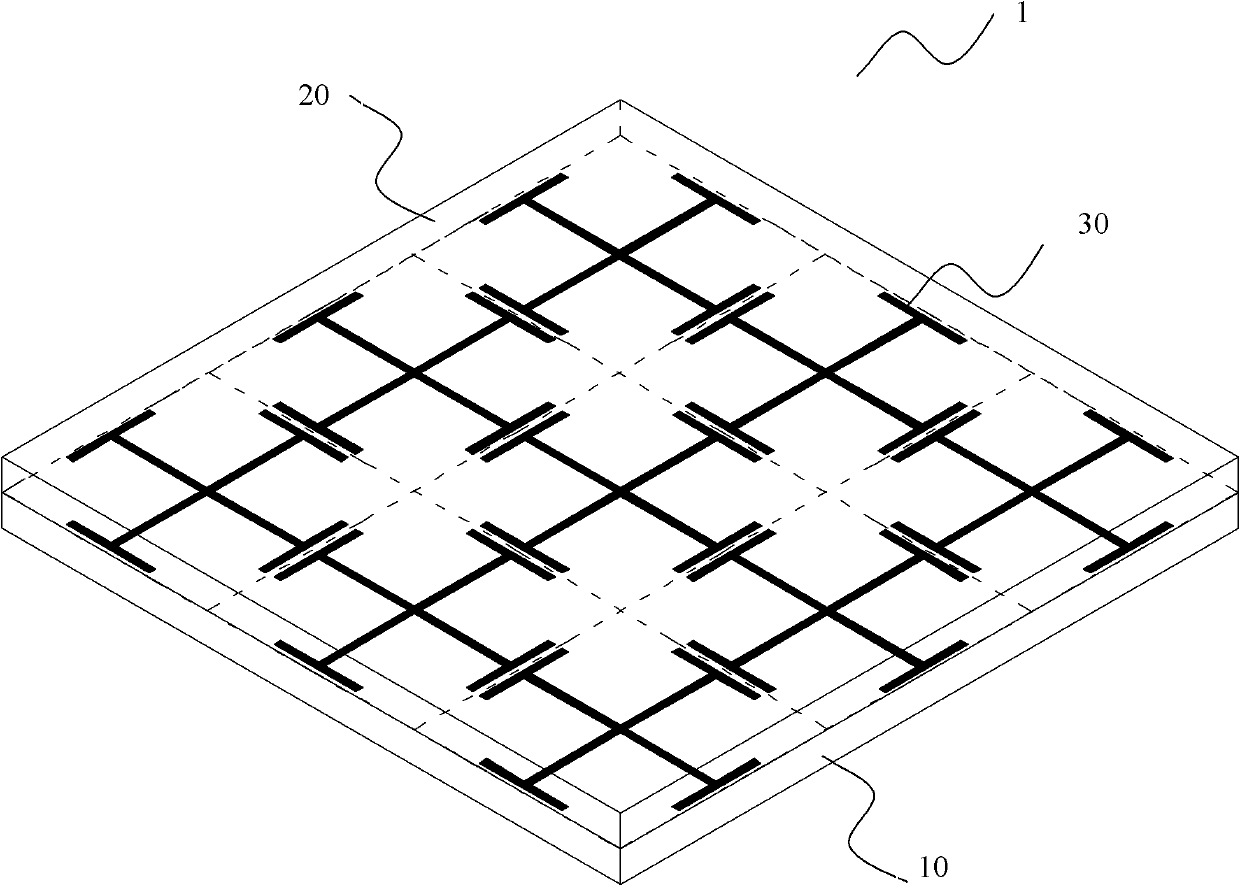

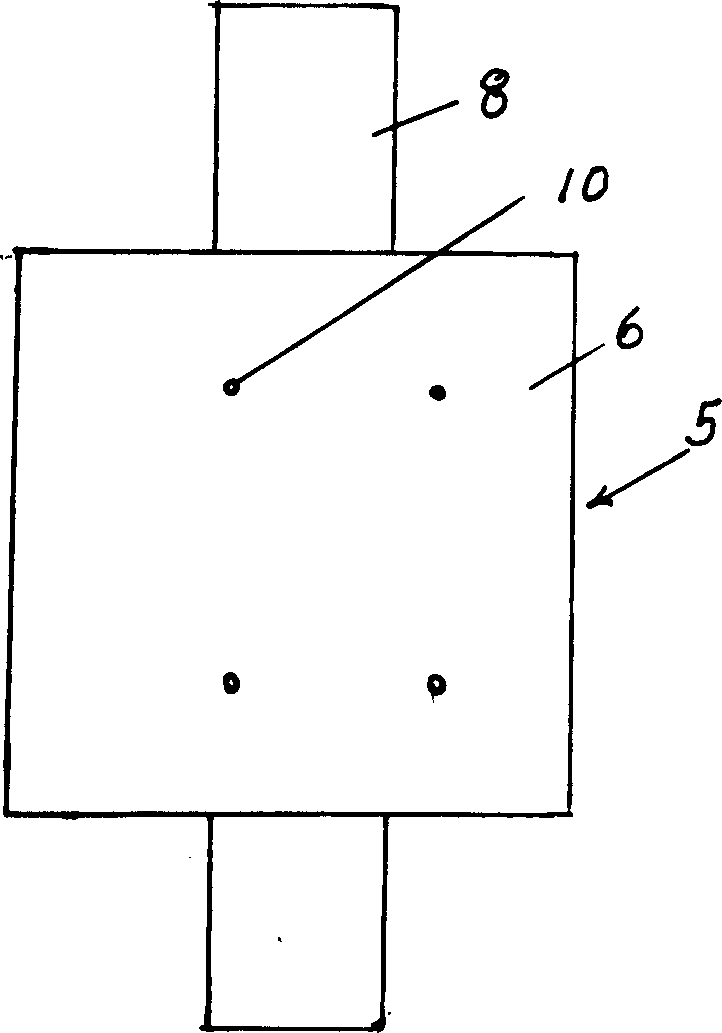

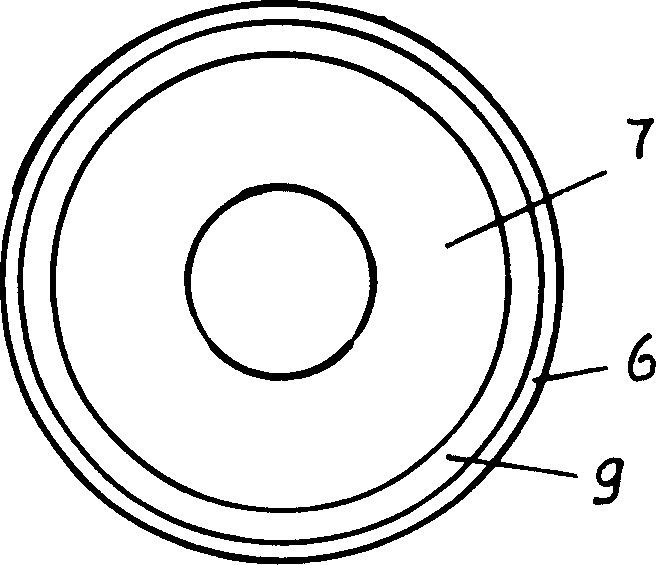

InactiveCN102760964AEnhanced wave performanceImprove anti-interference abilityRadiating element housingsElectrical and Electronics engineeringMetamaterial

The invention relates to a wave-transmitting meta-material and an antenna cover and an antenna system with the material. The wave-transmitting meta-material comprises a first substrate and a second substrate, wherein one layer of square patches with holes at the centers are clamped between the first substrate and the second substrate in an array manner; and circular patches which are arranged in an array manner are arranged on the outer surfaces of the first and second substrates. According to the wave-transmitting meta-material and the antenna cover and the antenna system with the material disclosed by the invention, the wave-transmitting efficiency is high, the loss is small, and the selective wave-transmitting function is realized.

Owner:KUANG CHI CUTTING EDGE TECH LTD

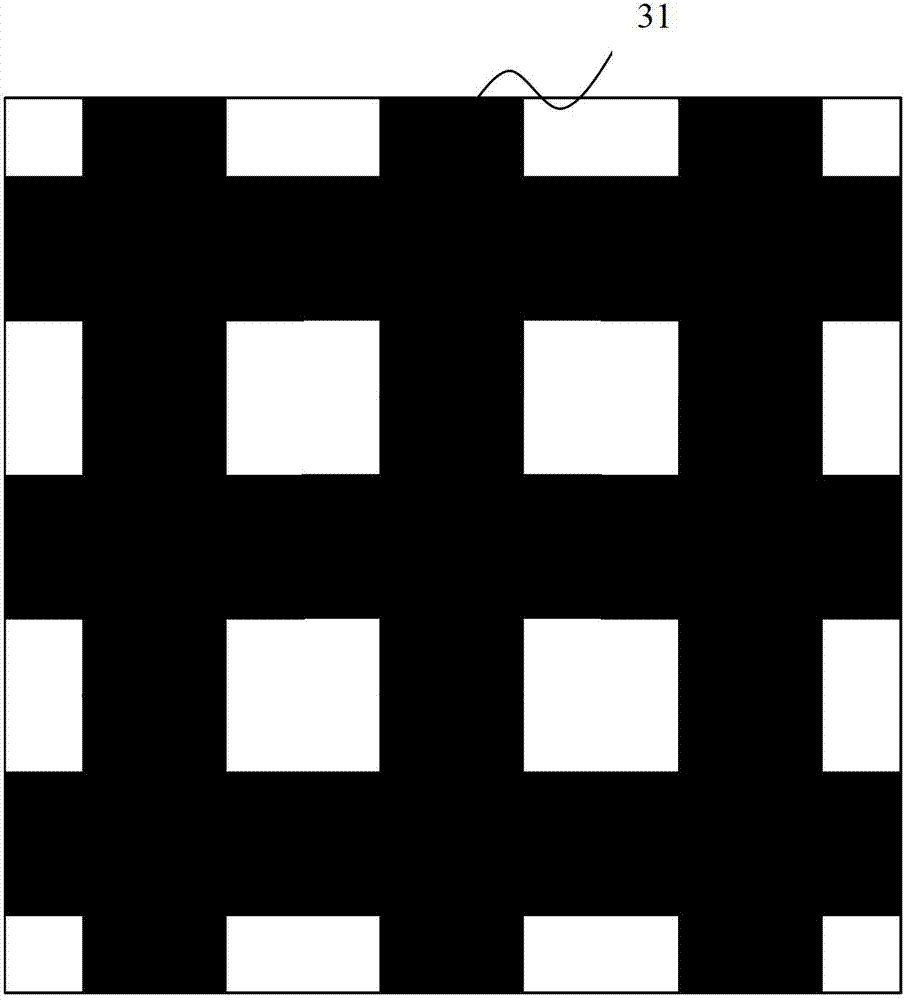

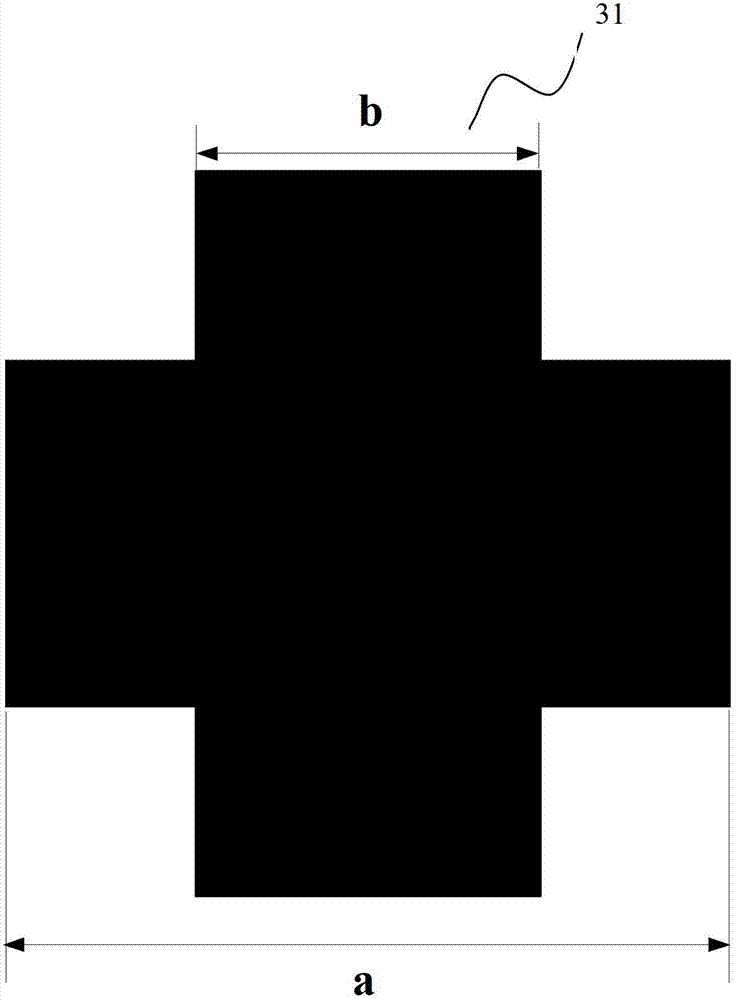

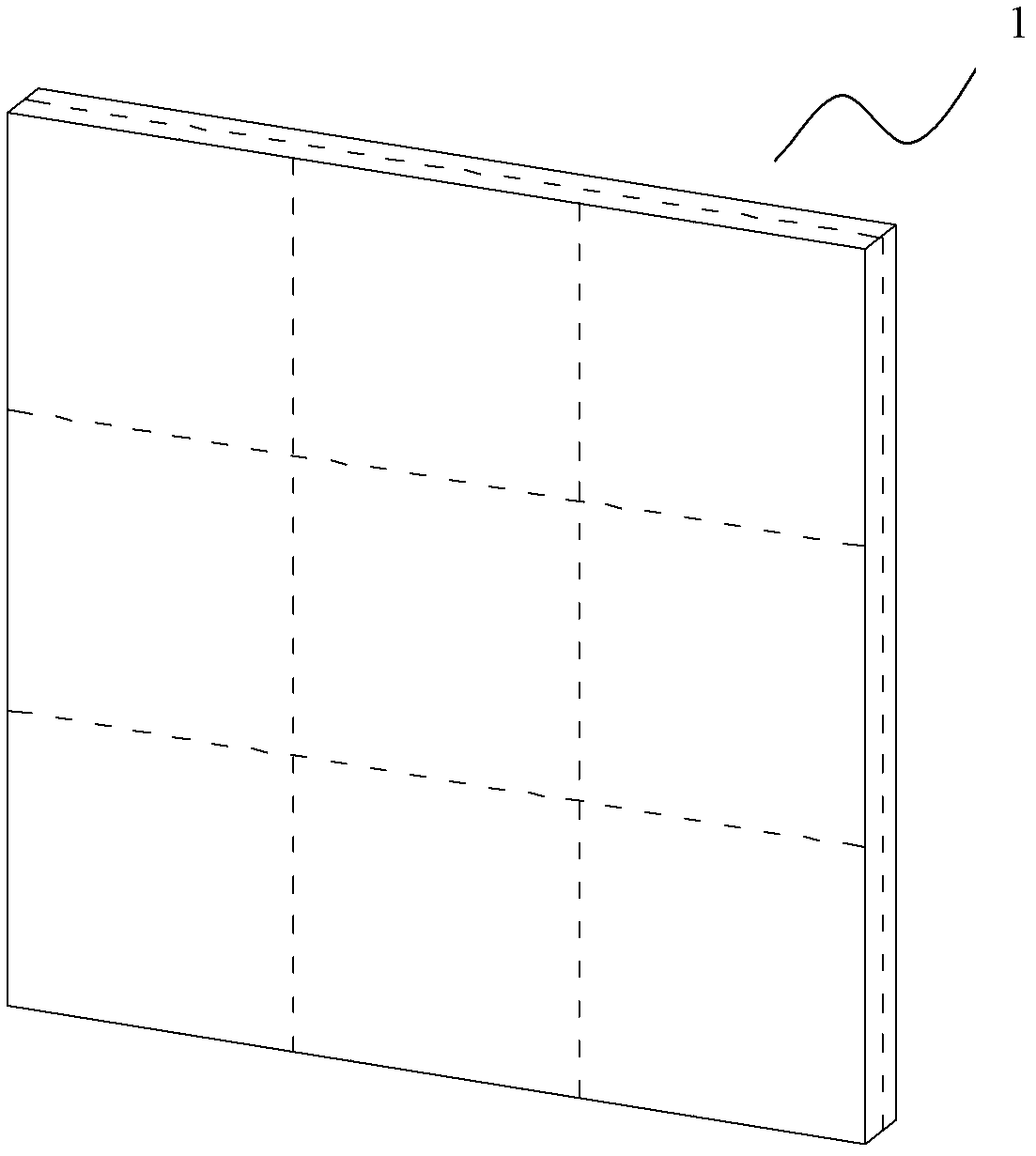

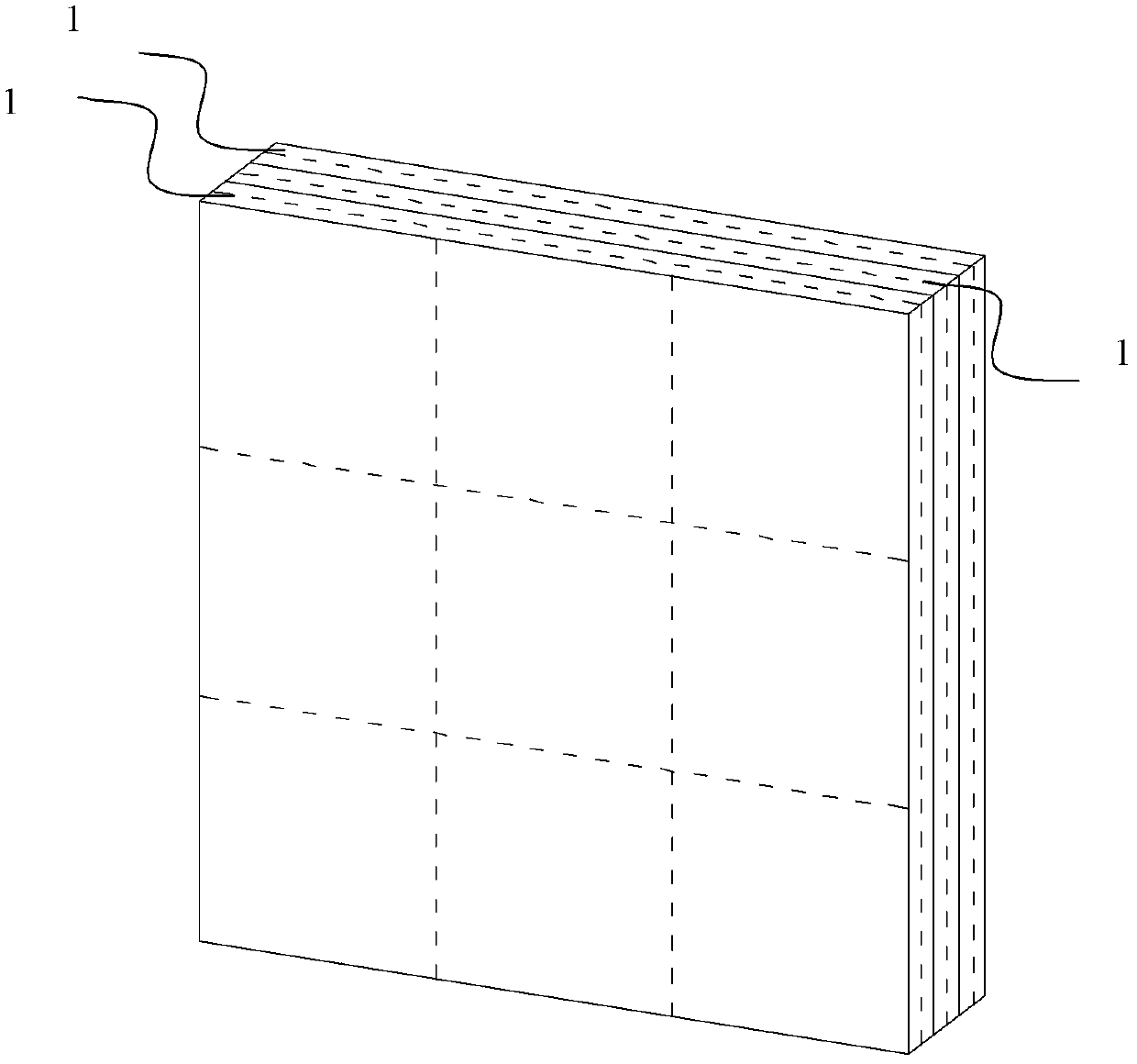

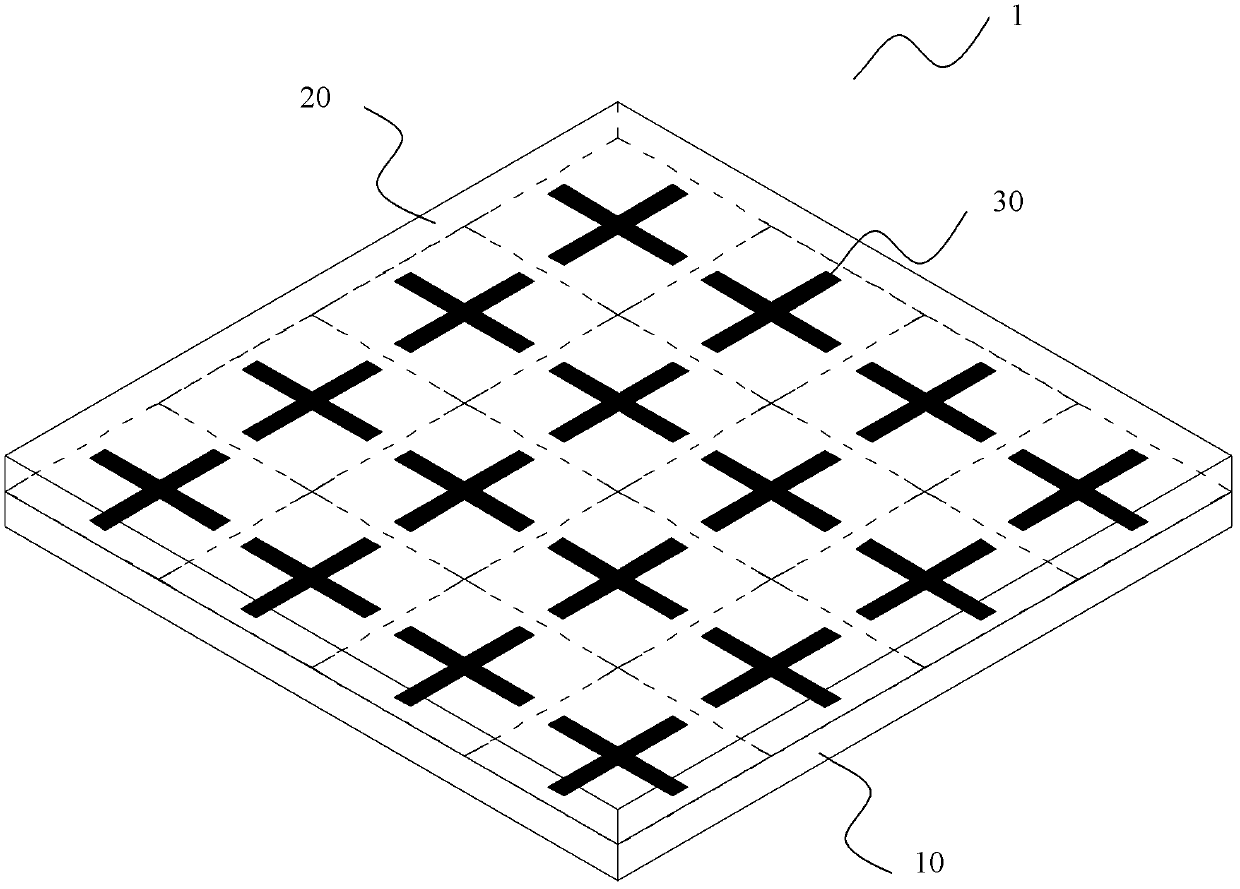

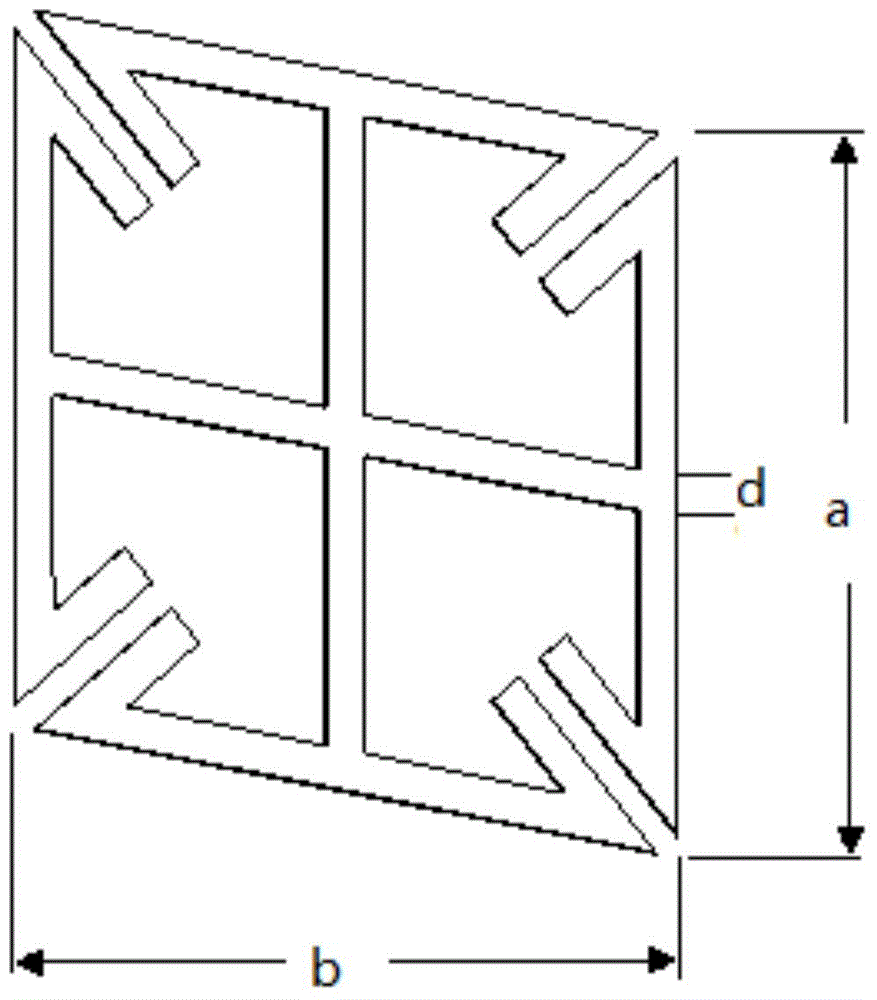

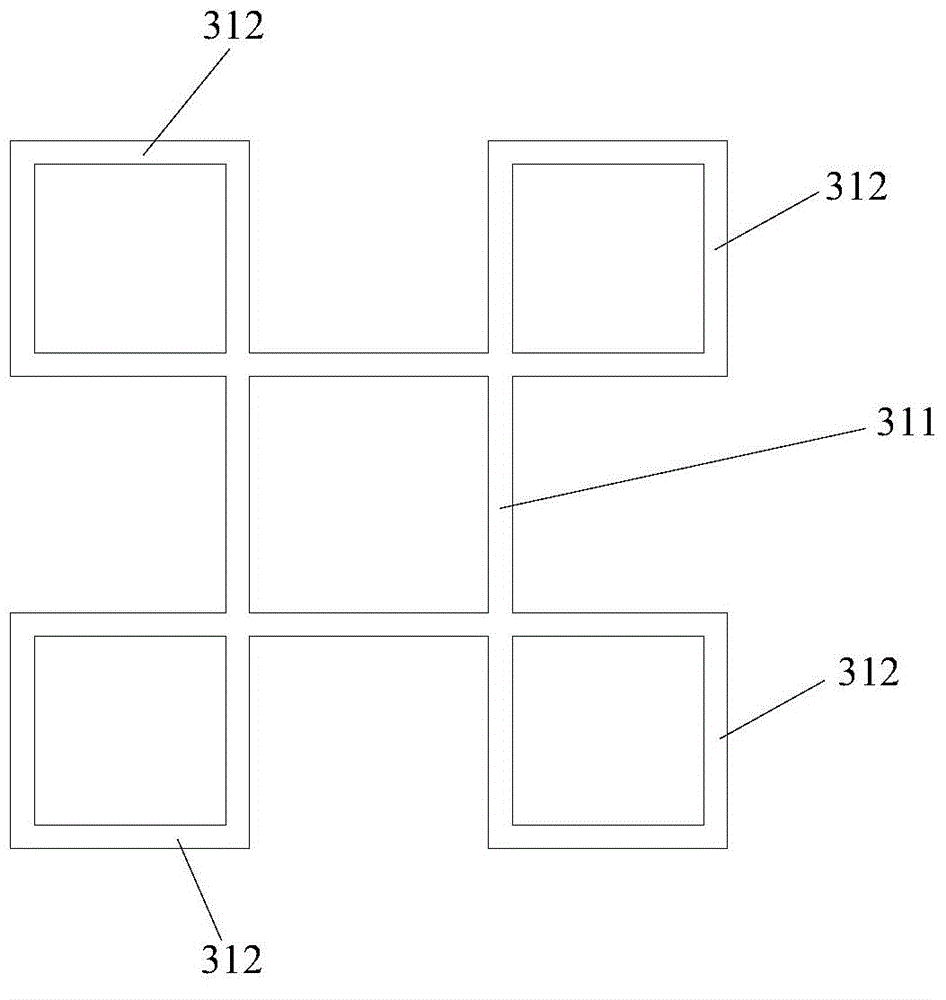

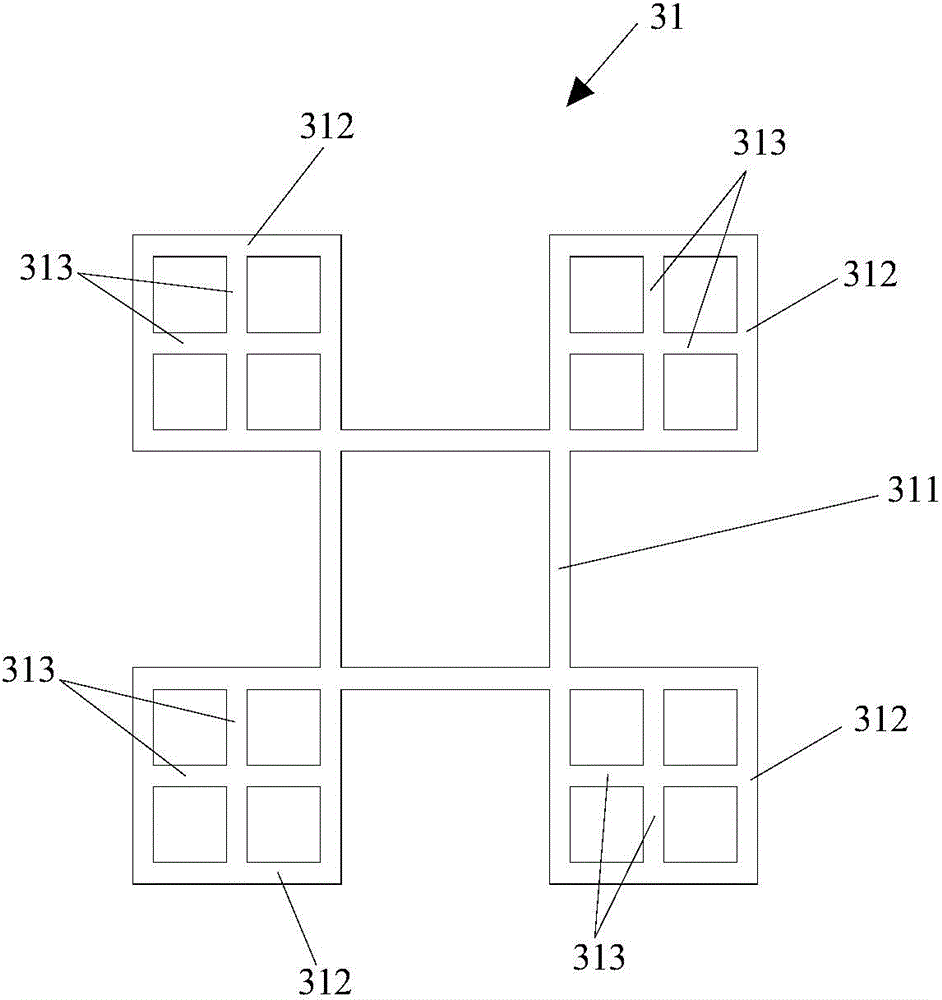

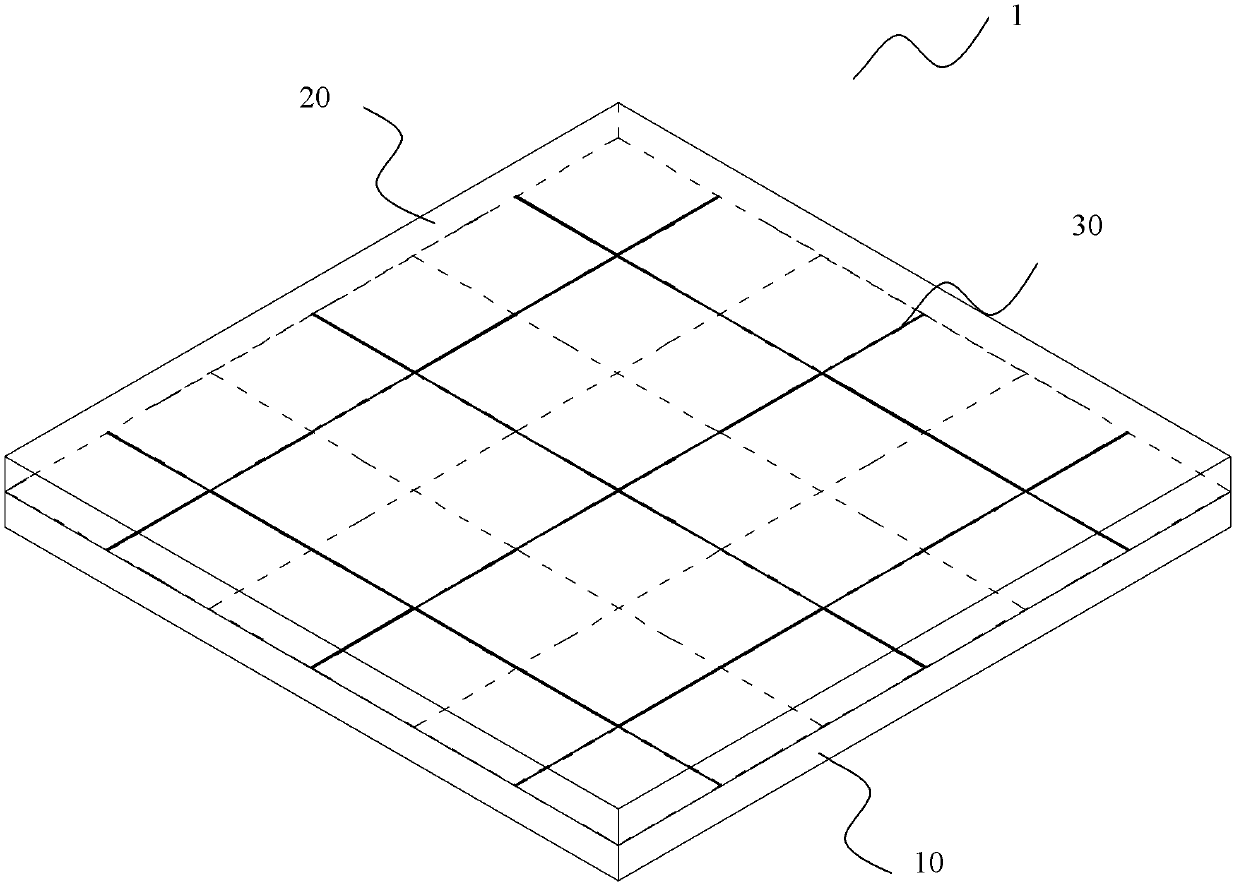

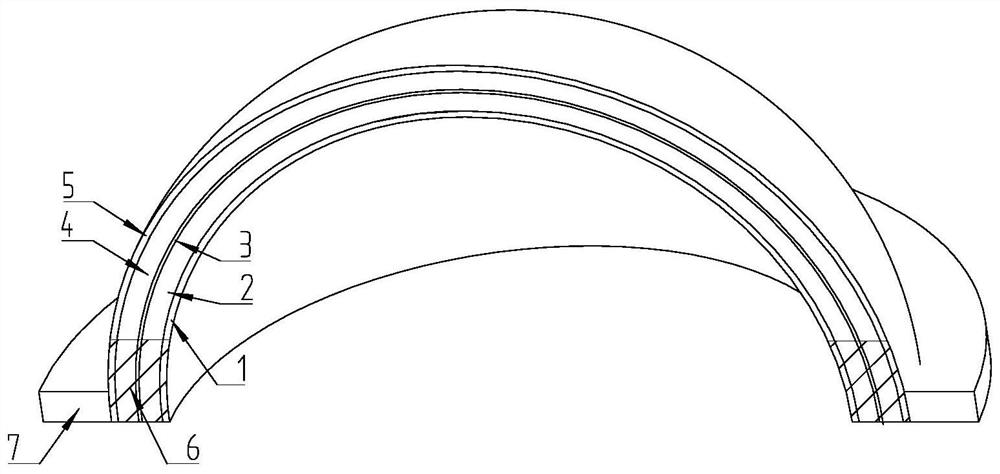

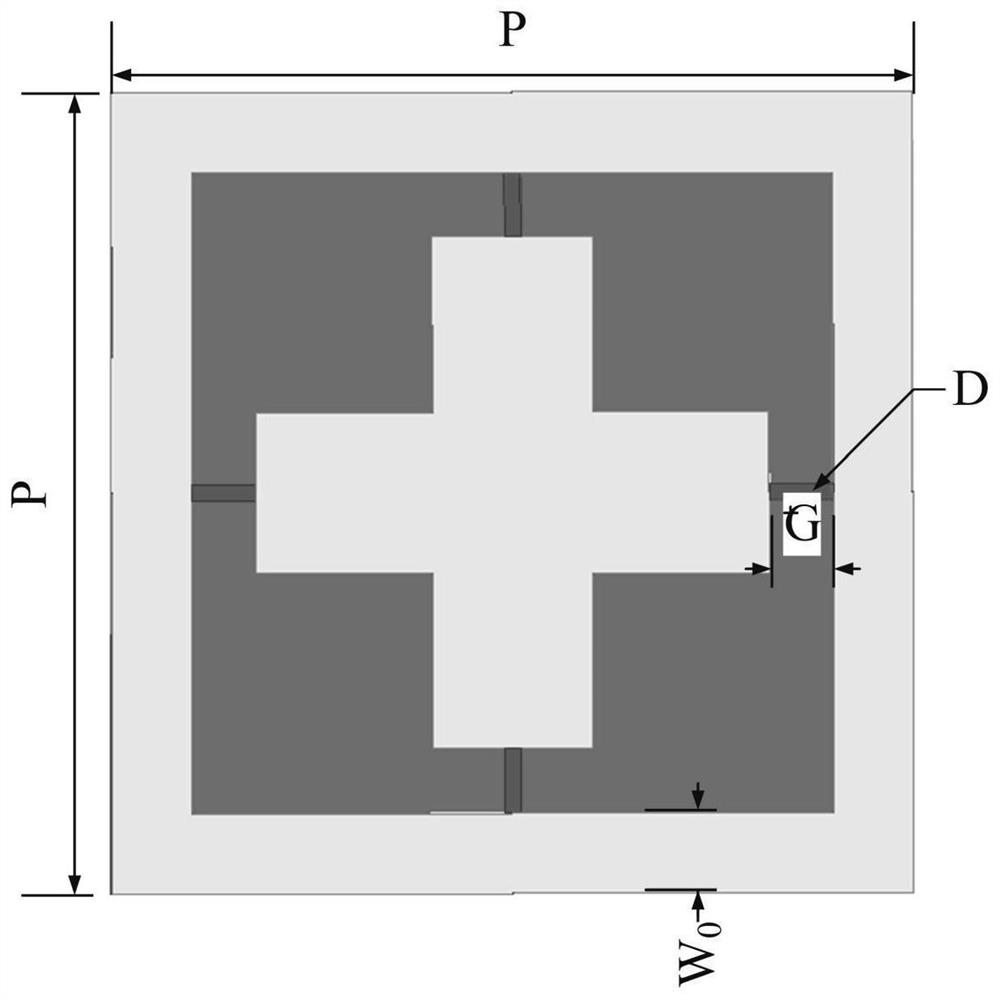

Dual-passband wave-transmitting material, radome and antenna system

ActiveCN102769160AEnhanced wave performanceImprove anti-interference abilityRadiating element housingsWaveguide type devicesFrequency bandRadome

The invention relates to a dual-passband wave-transmitting material, a radome and an antenna system. The dual-passband wave-transmitting material comprises a first substrate and a second substrate which are made of non-metal materials, and a plurality of first metal micro-structures clamped between the first substrate and the second substrate and arranged in a latticed manner, wherein no gap is reserved between the adjacent first metal micro-structures; and the first metal micro-structures adopt cross-shaped structures. The invention also provided a radome and an antenna system. The dual-passband wave-transmitting material, the radome and the antenna system, provided by the invention, can work in two frequency bands, have high wave-transmitting efficiency in the two frequency bands, and can shield other frequency bands, thereby eliminating interference and ensuring favorable work environments of the antenna. After the antenna is equipped with the radome, the radiating capacity of the antenna is enhanced and the gain is effectively improved.

Owner:KUANG CHI INST OF ADVANCED TECH

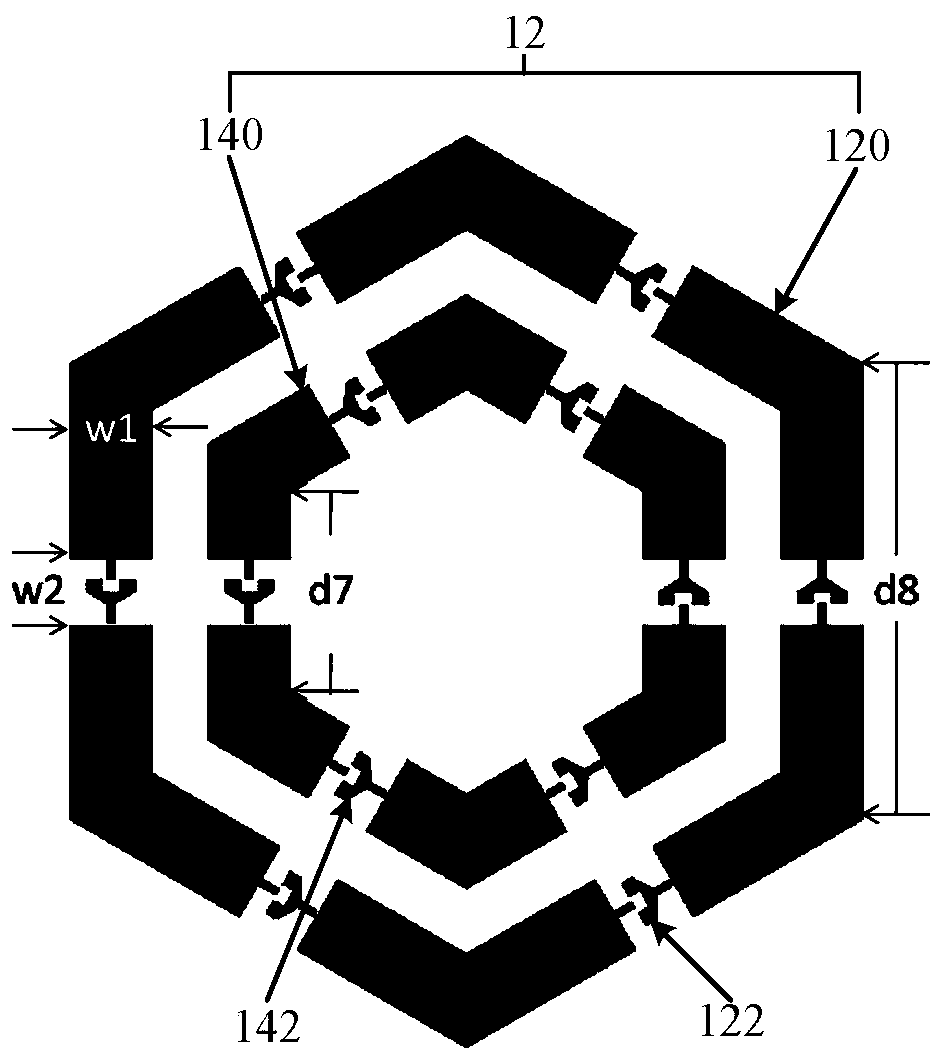

Broadband metamaterial antenna housing and antenna system

InactiveCN103296419AEnhanced wave performanceImprove anti-interference abilityRadiating element housingsFrequency bandBroadband

The invention relates to a broadband metamaterial antenna housing and an antenna system. The metamaterial antenna housing works in the Ku wave band. The broadband metamaterial antenna housing comprises at least one metamaterial sheet layer, wherein each metamaterial sheet layer comprises a first substrate and a plurality of artificial microstructures which are arranged on the first substrate in an array mode, and the sizes of the artificial microstructures are the same. Each artificial microstructure comprises a snowflake-shaped structure, and each snowflake-shaped structure comprises a cross-shaped structure and four straight-line-shaped structures which are same in size and arranged on four end points of the cross-shaped structure respectively. According to the broadband metamaterial antenna housing, the artificial microstructures in specific shapes are attached to the first substrates to obtain needed electromagnetic responses, wave-transparent performance of the antenna housing based on metamaterials is strengthened, and anti-interference capacity is increased. The working band of the antenna housing is the Ku wave band (12-18GHz), wave-transparent efficiency within the band is high, and losses are fewer. Furthermore, the working band of the antenna housing still has good wave-transparent performance when an electromagnetic wave band incomes in a certain angle.

Owner:KUANG CHI INNOVATIVE TECH

Low-loss metamaterial antenna housing

InactiveCN103296402AEnhanced wave performanceImprove anti-interference abilityRadiating element housingsAnti jammingEngineering

The invention relates to a low-loss metamaterial antenna housing which comprises at least one metamaterial piece layer. Each metamaterial piece layer comprises a first substrate and a plurality of man-made micro-structures with the same size, wherein the man-made micro-structures are distributed on each first substrate in an array mode. The man-made micro-structures are of cross-shaped structures. Due to the fact that the man-made micro-structures in specific shapes are attached to the substrates, required electromagnetic response is obtained, the wave-transparent performance of the antenna housing based on the metamaterial is strengthened, and anti-jamming capability is improved. Meanwhile, the loss of the antenna housing nearby the frequency point range of 30GHz is quite low, and wave-transparent efficiency is quite high.

Owner:KUANG CHI INNOVATIVE TECH

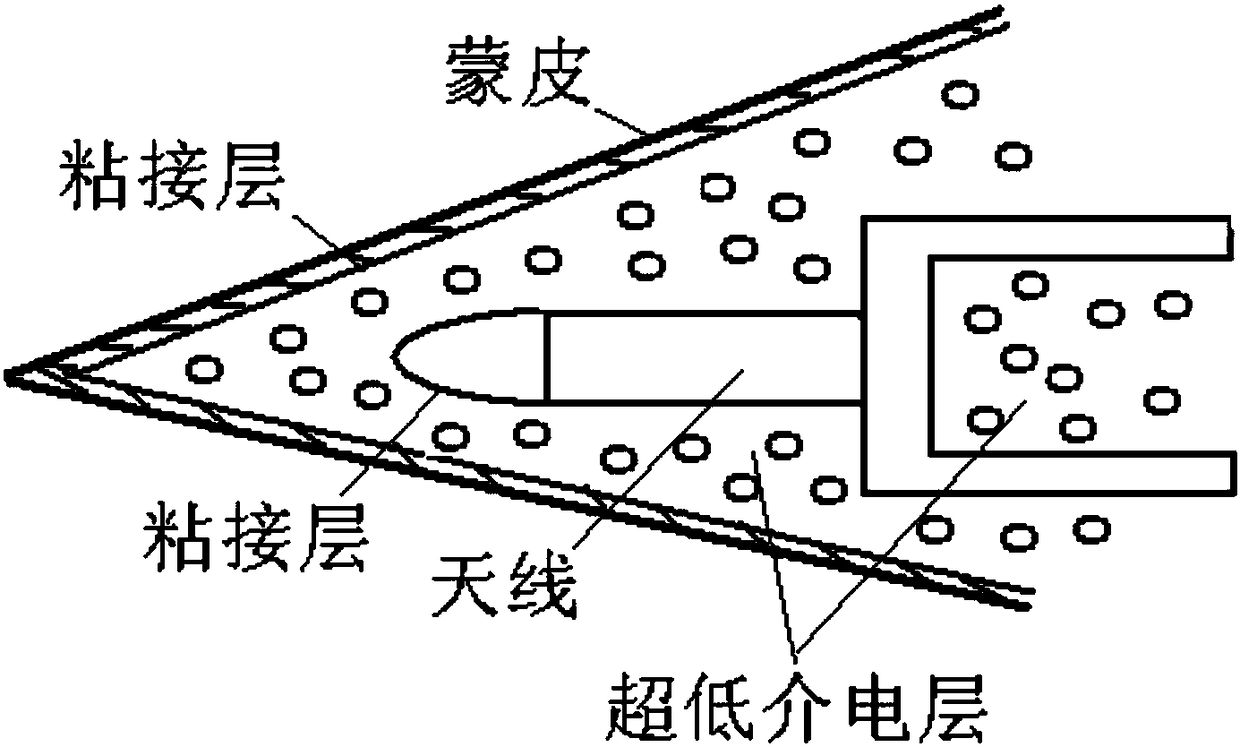

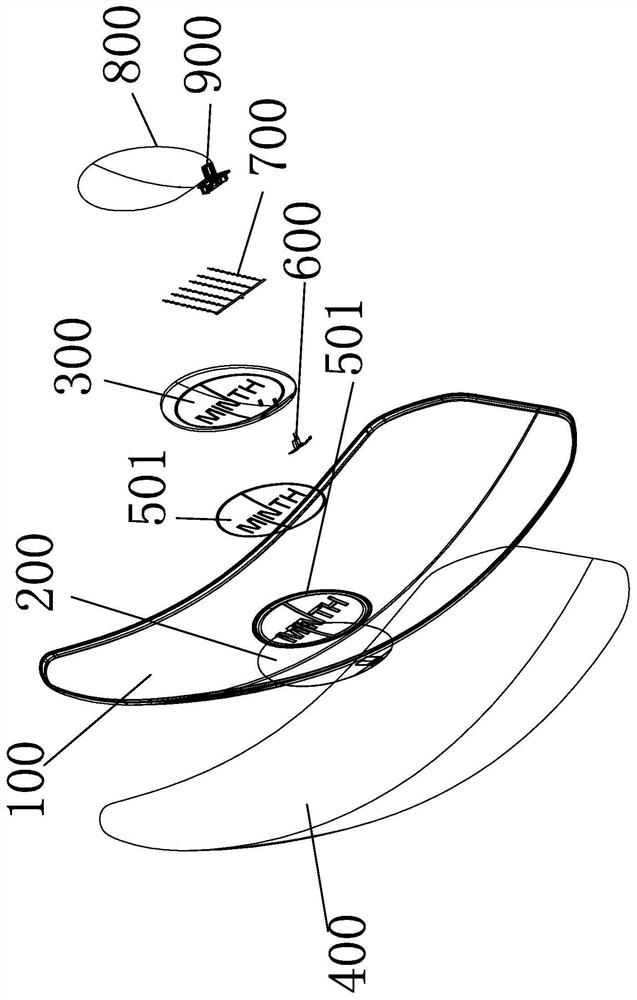

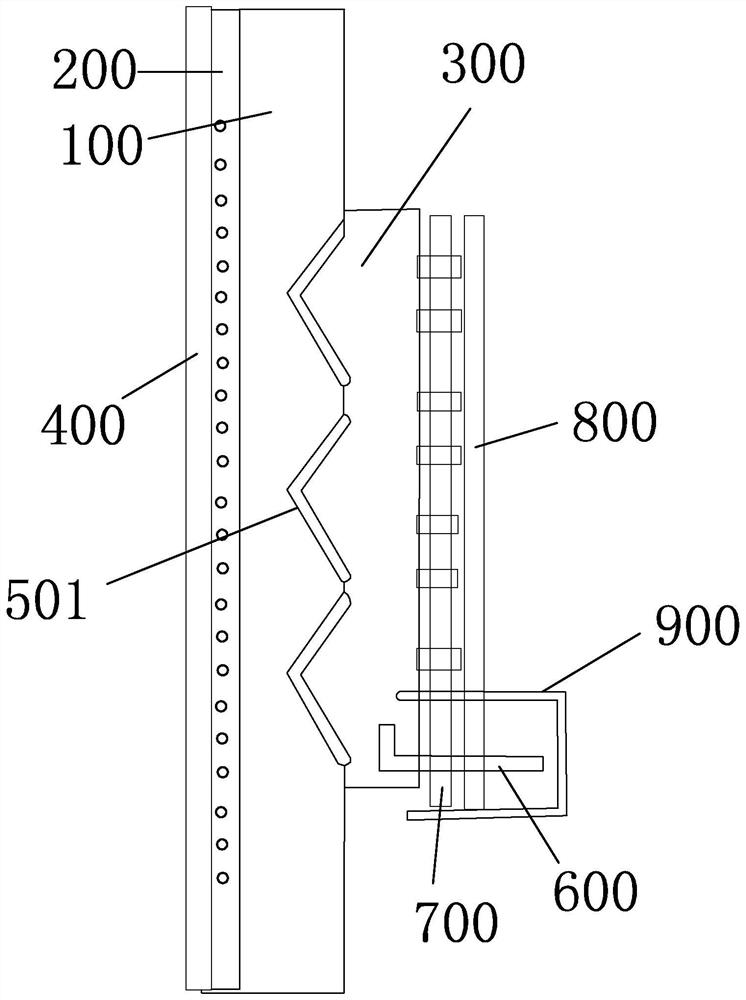

V-shaped radar radome structure and preparation method thereof

The invention provides a "V"-shaped radar radome structure and a preparation method thereof. The radome structure is obtained by co-curing of an antenna, a skin and a filling core layer, the skin andthe filling core layer are adhered by using an adhesive layer so as to form the radome, and the antenna and the filling core layer are adhered by using the adhesive layer and wrapped in the radome. The influence of multilayer reflection interference of the conventional interlayer radome surface can be weakened by the integral design of the radome and the antenna. Besides, compared with the multilayer skin core layer structure, only one skin is required, the wave permeability can be enhanced by the ultrathin skin design and the error of aiming can be greatly reduced. Meanwhile, the antenna pattern and phase consistency can be enhanced, and the problems of reduction of the wave permeability and pattern distortion under the broadband condition of the "V"-shaped radome can be solved, and the wave permeability, the pattern and the phase consistency of the "V"-shaped radome are enabled to meet the working requirements of the radar antenna.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

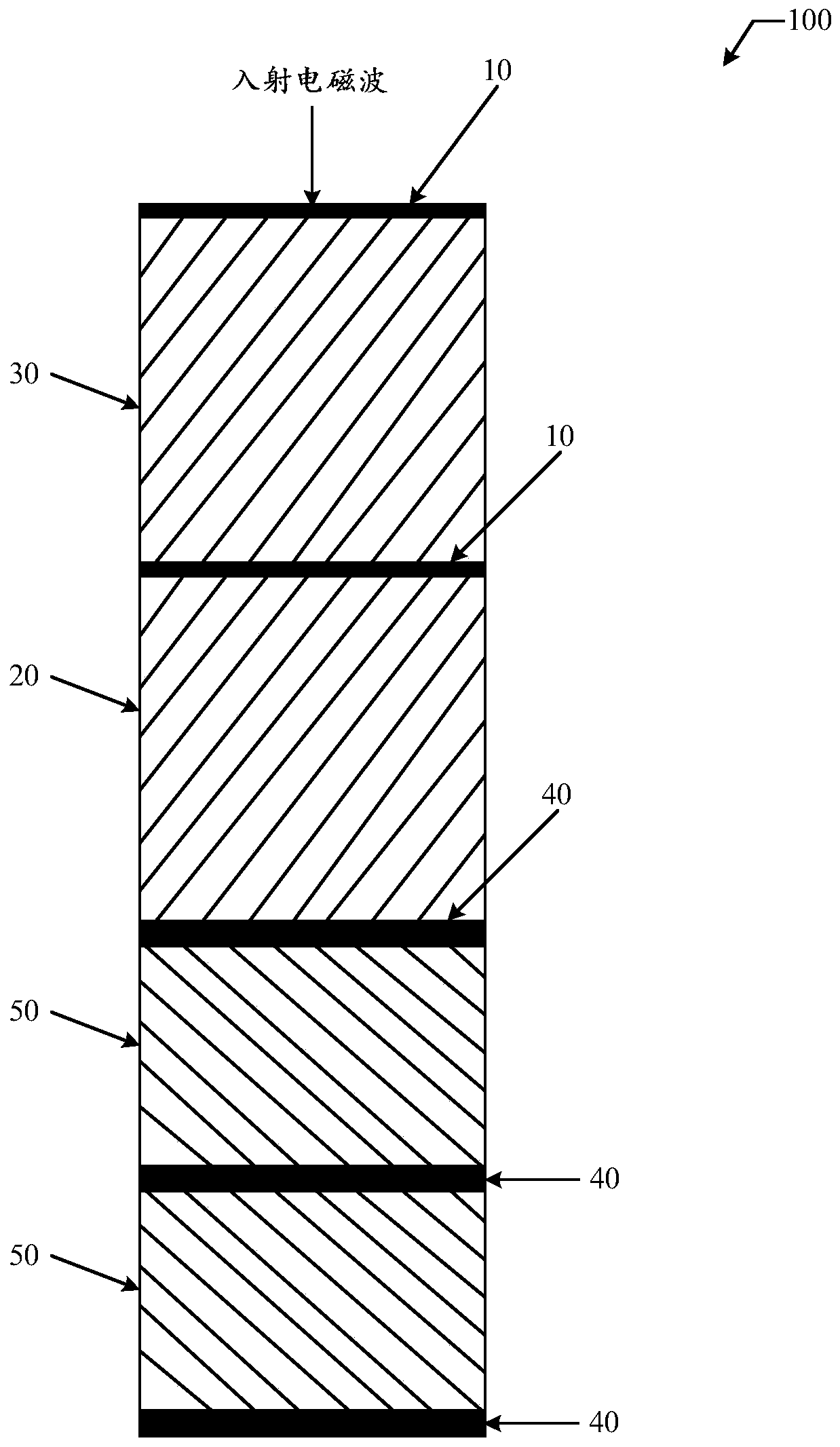

Wave-absorbing and wave-transparent super material structure and aircraft

PendingCN110416738AImprove absorbing performanceEnhanced wave performanceAntenna adaptation in movable bodiesRadiating element housingsKu bandWave band

An embodiment of the present invention provides a wave-absorbing and wave-transparent super material structure and an aircraft. The structure comprises at least one first microstructure array, at least one second microstructure array and a first dielectric layer, the at least one first microstructure array, the first dielectric layer and the at least one second microstructure array are stacked inorder. Each first dielectric microstructure array comprises multiple wave-absorbing microstructures, and each second microstructure array comprises multiple wave-transparent reflection microstructures. The structure has high wave-absorbing performance for incident electromagnetic waves in an X band and a Ku-band or the X-band and has high wave-transparent performance for incident electromagnetic waves in a P band.

Owner:KUANG CHI CUTTING EDGE TECH LTD

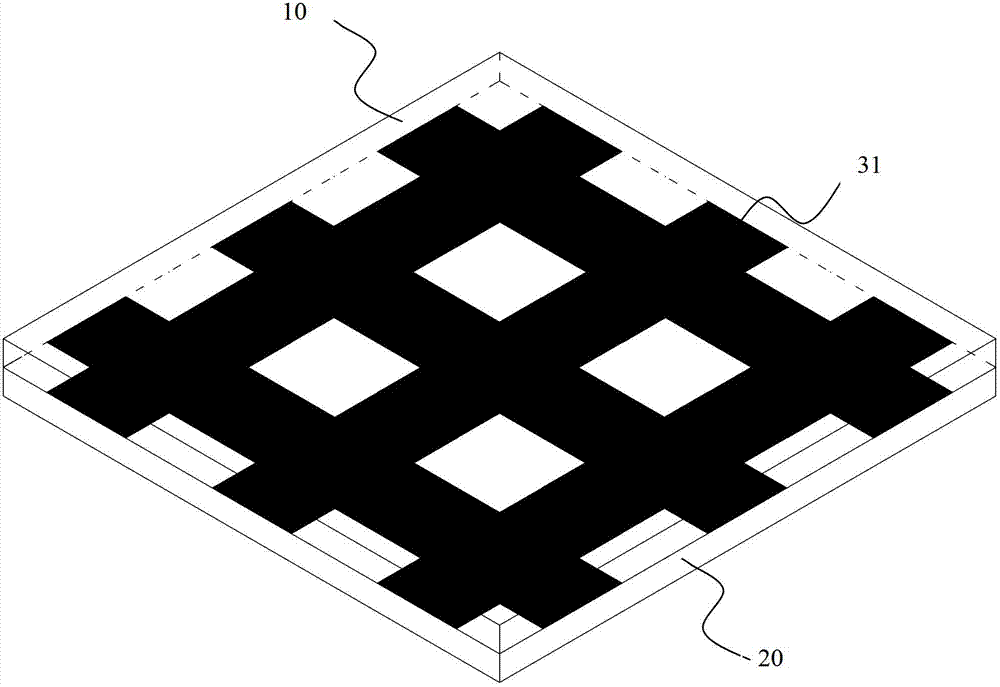

Bandpass filter metamaterial, antenna cover and antenna system

PendingCN104934705AImprove permeabilitySolve the problem of poor wave transmission effectRadiating element housingsBandpass filteringDielectric layer

The invention discloses a bandpass filter metamaterial, an antenna cover and an antenna system, wherein the bandpass filter metamaterial comprises a plurality of functional layers. Each functional layer comprises a dielectric layer and a conductive geometric structure which is arranged on the dielectric layer, wherein the conductive geometric structure on the dielectric layer of at least one functional layer in the multiple functional layers is a conductive sheet, and the geometric structure on the dielectric layer of another functional layer is grid-shaped. The bandpass filter metamaterial, the antenna cover and the antenna system improve wave penetrating effect of the antenna cover.

Owner:KUANG CHI INST OF ADVANCED TECH

High-wave-transparent porous quartz/quartz ceramic-based composite material and preparation method thereof

ActiveCN103724037AEnhanced wave performanceEffect on mechanical propertiesCeramicwareTransmittanceCeramic

The invention discloses a high-wave-transparent porous quartz / quartz ceramic-based composite material and a preparation method thereof. The composite material comprises a quartz fiber-reinforced body, a quartz base body and pores, and is characterized in that the pores are uniformly existent in the part of the composite material, close to the inner surface. Pure iron wires are prefabricated in a reinforced structure formed by weaving or stacking quartz fibers, a quartz-based composite material is synthesized through a sol-gel method, and the iron wires in the composite material are etched off by a mixed solution of nitric acid and sulfuric acid to obtain the high-wave-transparent porous quartz / quartz ceramic-based composite material. The composite material has the advantages of high strength and good mechanical property and wave transmittance.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

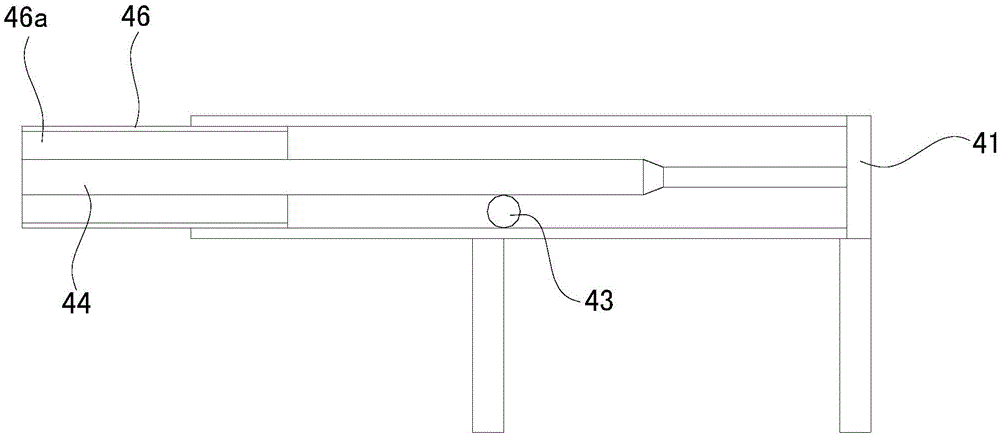

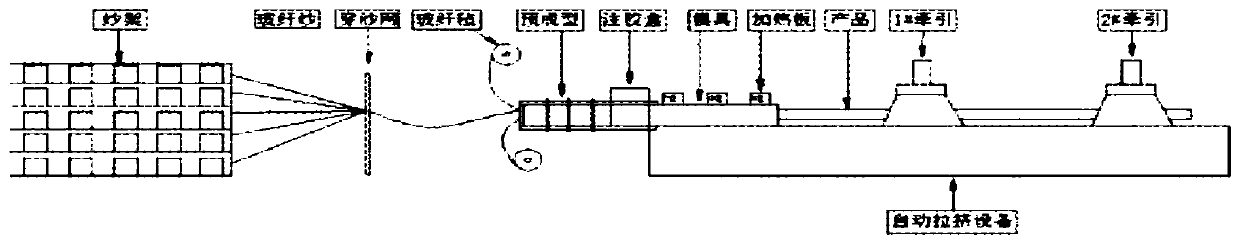

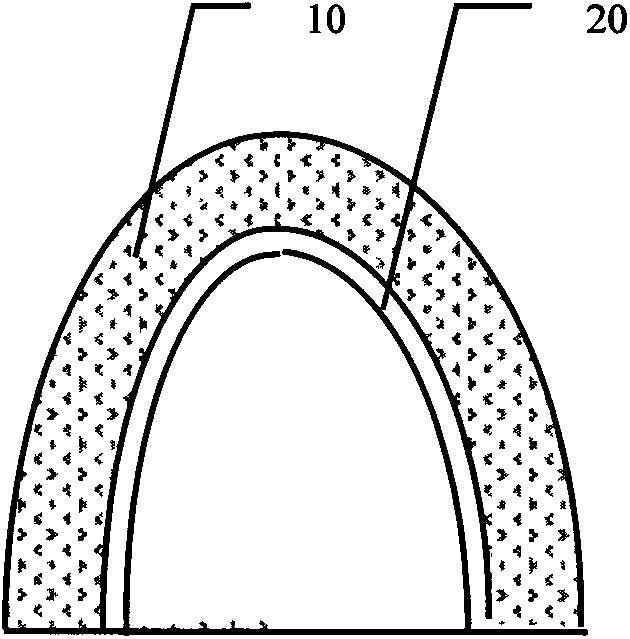

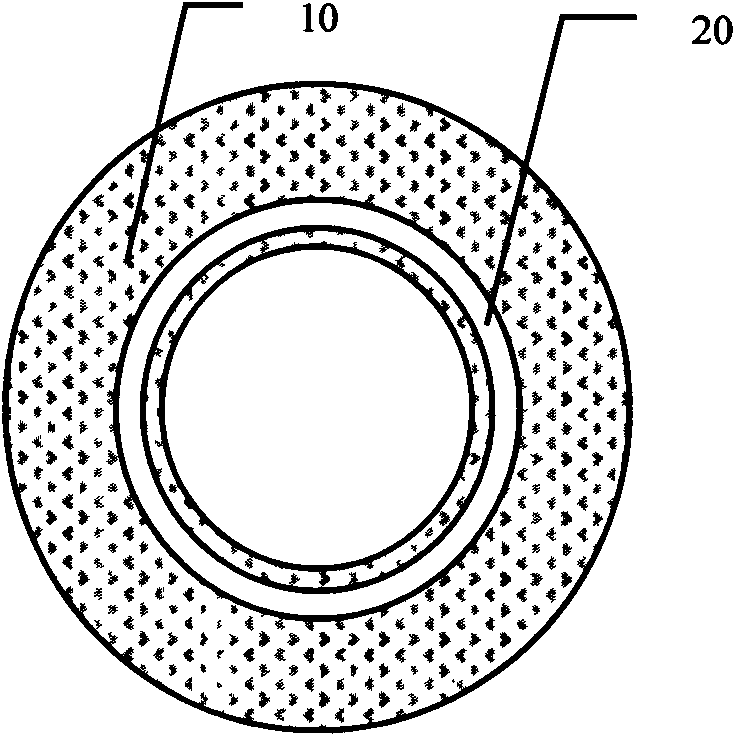

Glass fiber reinforced plastic radome and preparation method thereof

The invention discloses a glass fiber reinforced plastic radome and a preparation method thereof. The glass fiber reinforced plastic radome is formed by glass fiber yarns, a glass fiber mat, thermosetting resin, and fillers by the adoption of pultrusion process, the glass fiber yarns are composite yarns of glass fiber straight yarns and glass fiber bulk yarns, and the mass percent of the glass fiber straight yarns to the glass fiber bulk yarns is 45-55%:45-55%. According to the glass fiber reinforced plastic radome, the glass fiber yarns are the composite yarns of the glass fiber straight yarns and the glass fiber bulk yarns, on one hand, by the adoption of the bulk yarns, the strength of the composite material is enhanced, the contents of the glass fiber yarns and the glass fiber mat can be reduced, the gross weight of the product is reduced, the strength cost of an outdoor fixing rack is reduced, the installation difficulty is reduced, the content of glass fiber is reduced, the dielectric constant is reduced, and the wave transmission performance of antennas can be improved; on the other hand, the resin filling content is increased via the bulkiness of the bulk yarns, and good product surface effect can be obtained.

Owner:珠海国能新材料股份有限公司

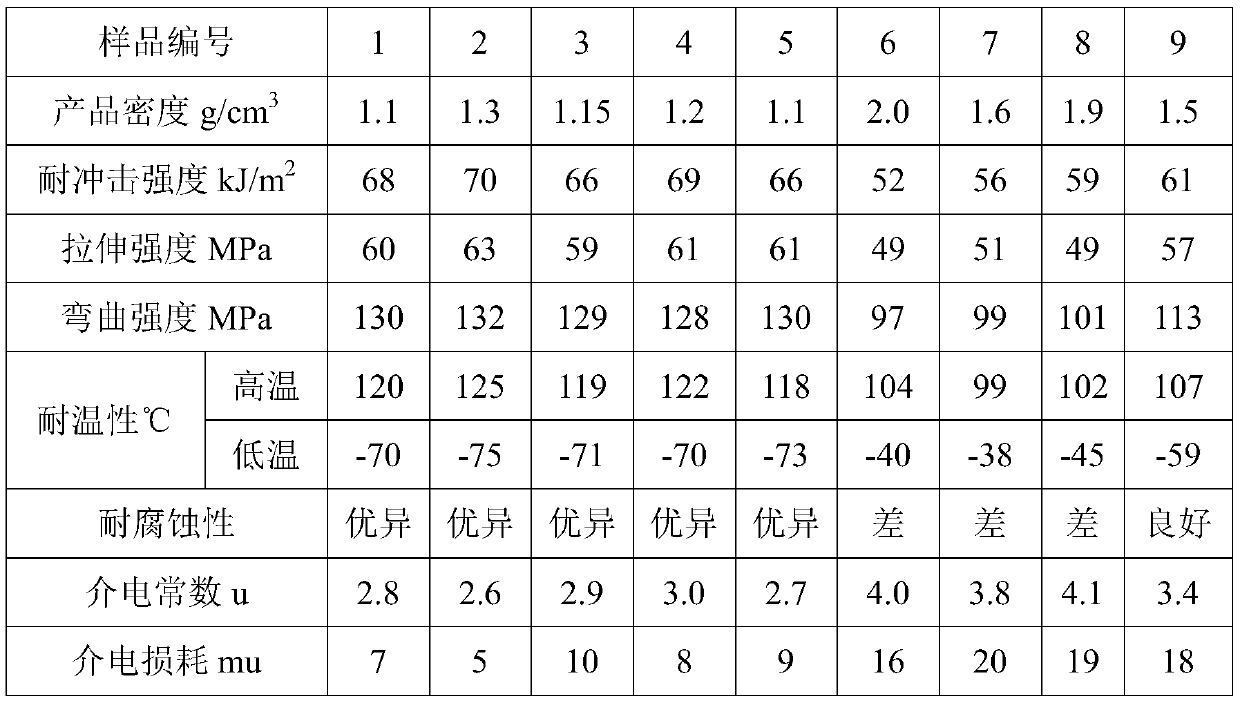

Glass fiber reinforced plastic pultrusion radome for 5G base stations and preparation method thereof

ActiveCN111393818AEnhanced wave performanceFilled tightlyAntenna supports/mountingsRadiating element housingsPolymer scienceUltraviolet lights

The invention belongs to the technical field of radomes, and particularly relates to a glass fiber reinforced plastic pultrusion radome for 5G base stations and a preparation method thereof. The glassfiber reinforced plastic pultrusion radome for 5G base stations is formed by pultrusion of glass fibers, unsaturated polyester resin, a flame retardant, aluminum hydroxide, filler, PE powder, an ultraviolet light absorber UV-2, an antioxidant, a release agent, a high-temperature curing agent, a medium-temperature curing agent and a low-temperature curing agent. The density of the glass fiber reinforced plastic pultrusion radome product for 5G base stations is 1.1-1.3 g / cm<3>, the dielectric constant is 2.8+ / -0.2 u, the dielectric loss is 5-10 mu, the material is suitable for construction requirements of 5G base stations, the same performance requirements of plastic radomes can be met, and the mechanical properties, corrosion resistance and high and low temperature resistance of the material are superior to those of the plastic radomes. In addition, the cost of the glass fiber reinforced plastic pultrusion radome for 5G base stations is lower, and the construction cost of a 5G base station is greatly reduced.

Owner:珠海国能新材料股份有限公司

A kind of highly transparent porous quartz/quartz ceramic matrix composite material and its preparation method

ActiveCN103724037BEffect on mechanical propertiesEnhanced wave performanceCeramicwareTransmittanceUltimate tensile strength

The invention discloses a high-wave-transparent porous quartz / quartz ceramic-based composite material and a preparation method thereof. The composite material comprises a quartz fiber-reinforced body, a quartz base body and pores, and is characterized in that the pores are uniformly existent in the part of the composite material, close to the inner surface. Pure iron wires are prefabricated in a reinforced structure formed by weaving or stacking quartz fibers, a quartz-based composite material is synthesized through a sol-gel method, and the iron wires in the composite material are etched off by a mixed solution of nitric acid and sulfuric acid to obtain the high-wave-transparent porous quartz / quartz ceramic-based composite material. The composite material has the advantages of high strength and good mechanical property and wave transmittance.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

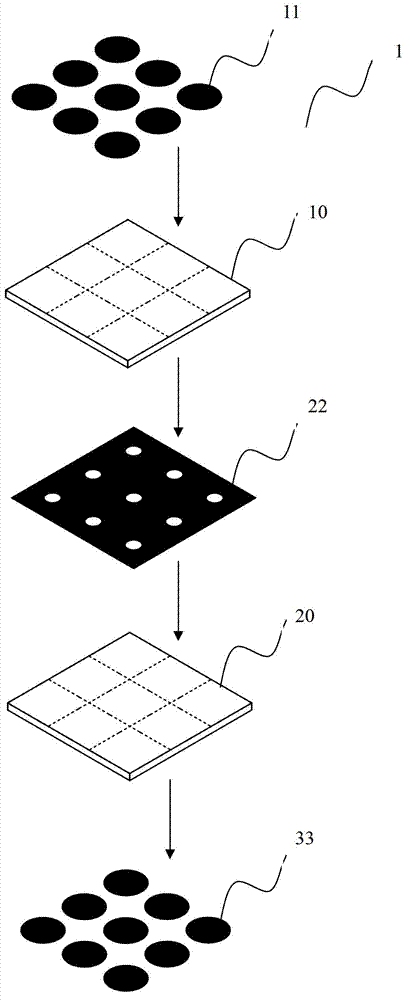

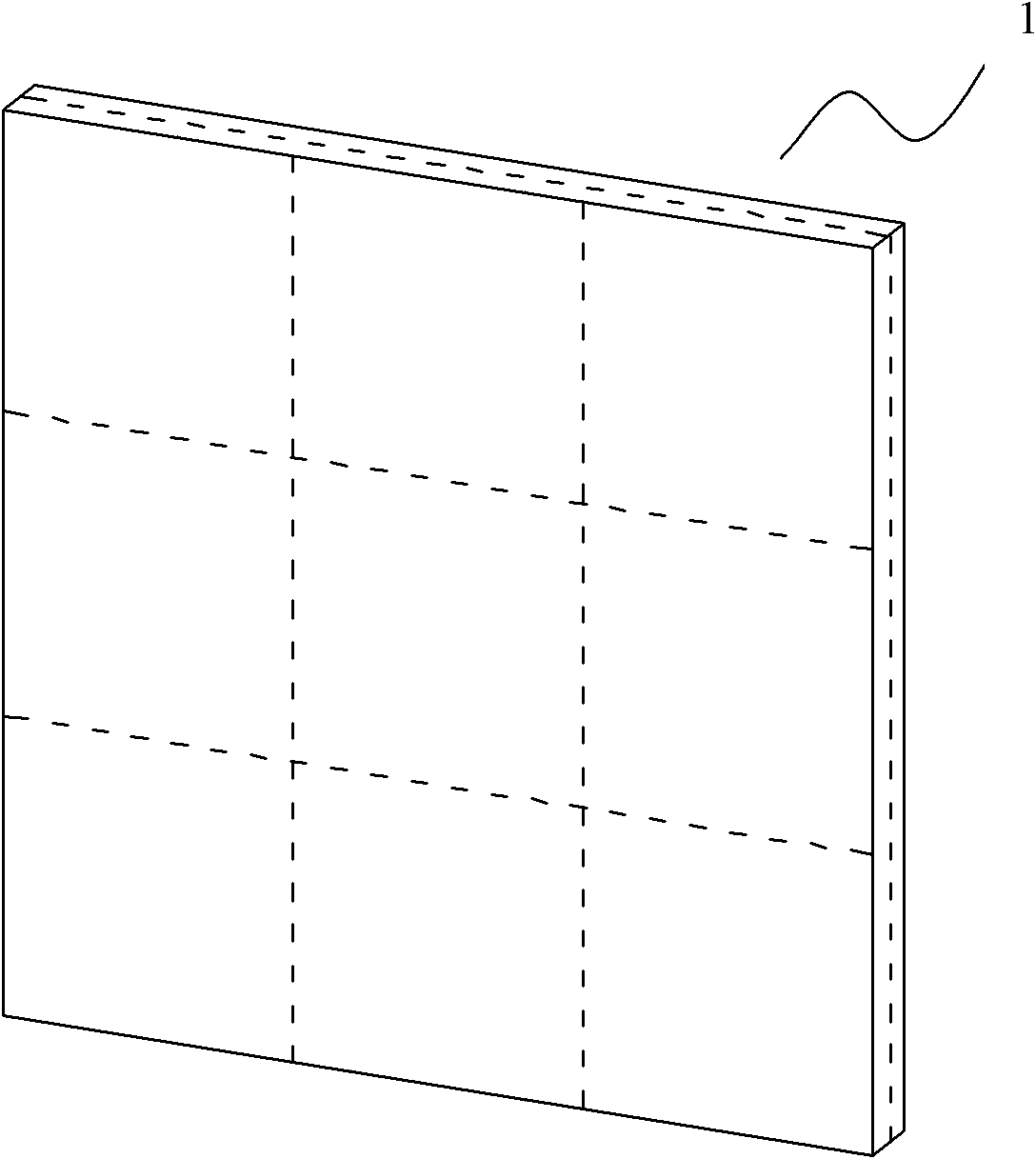

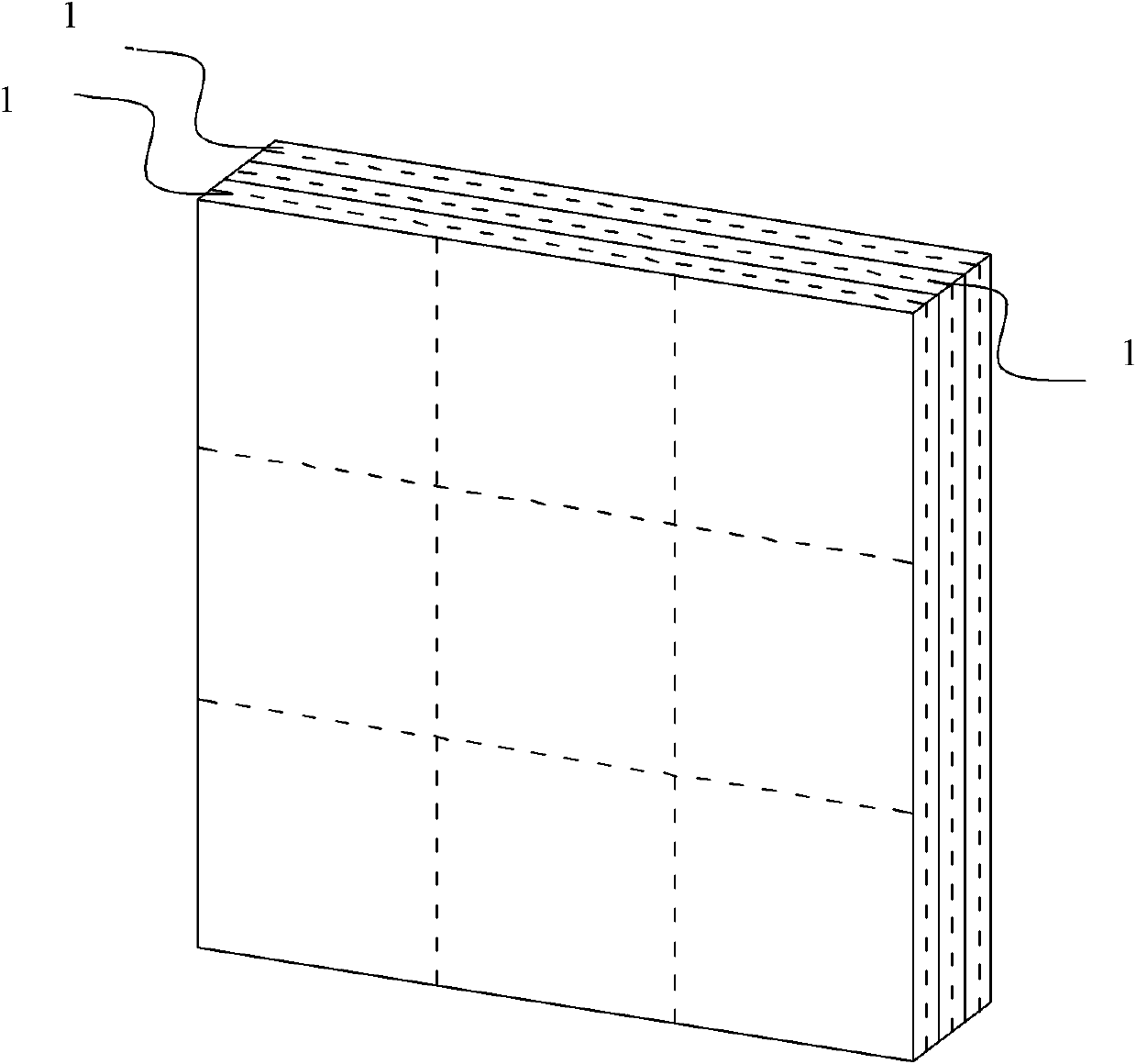

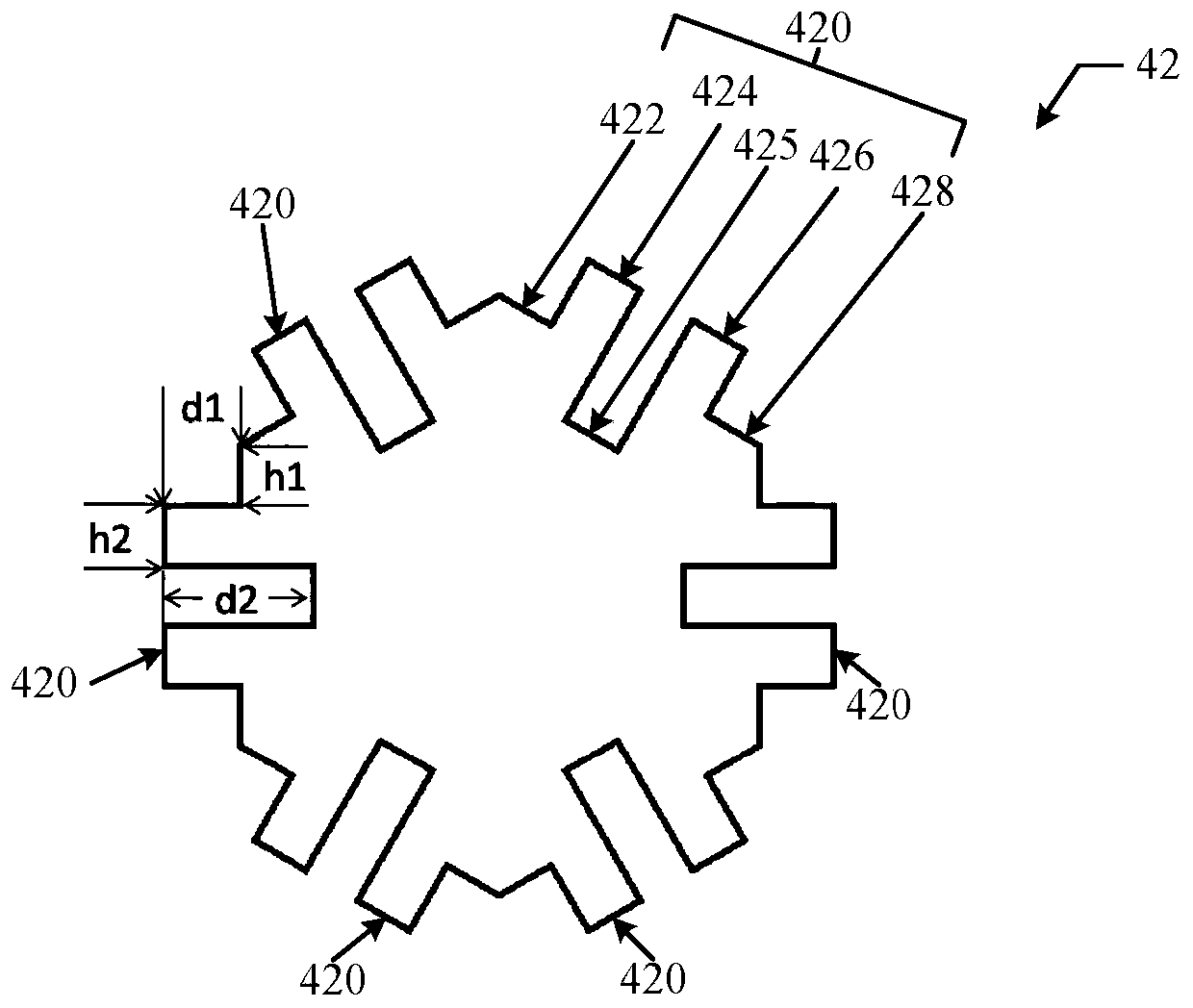

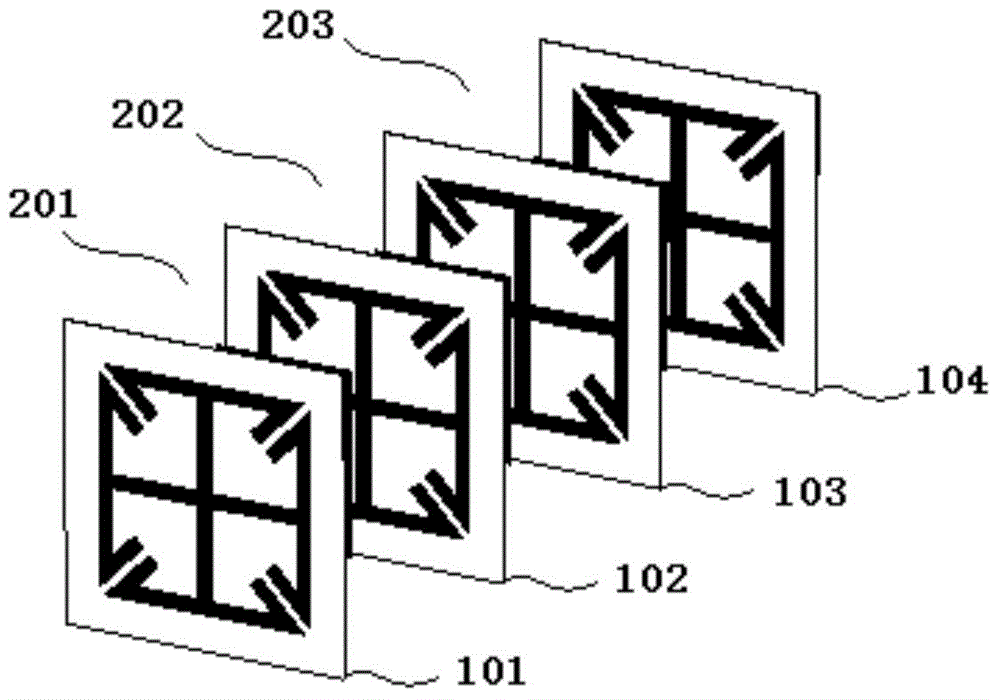

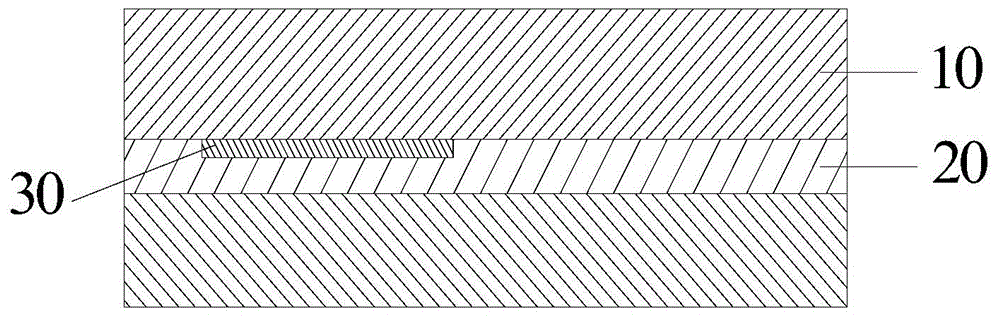

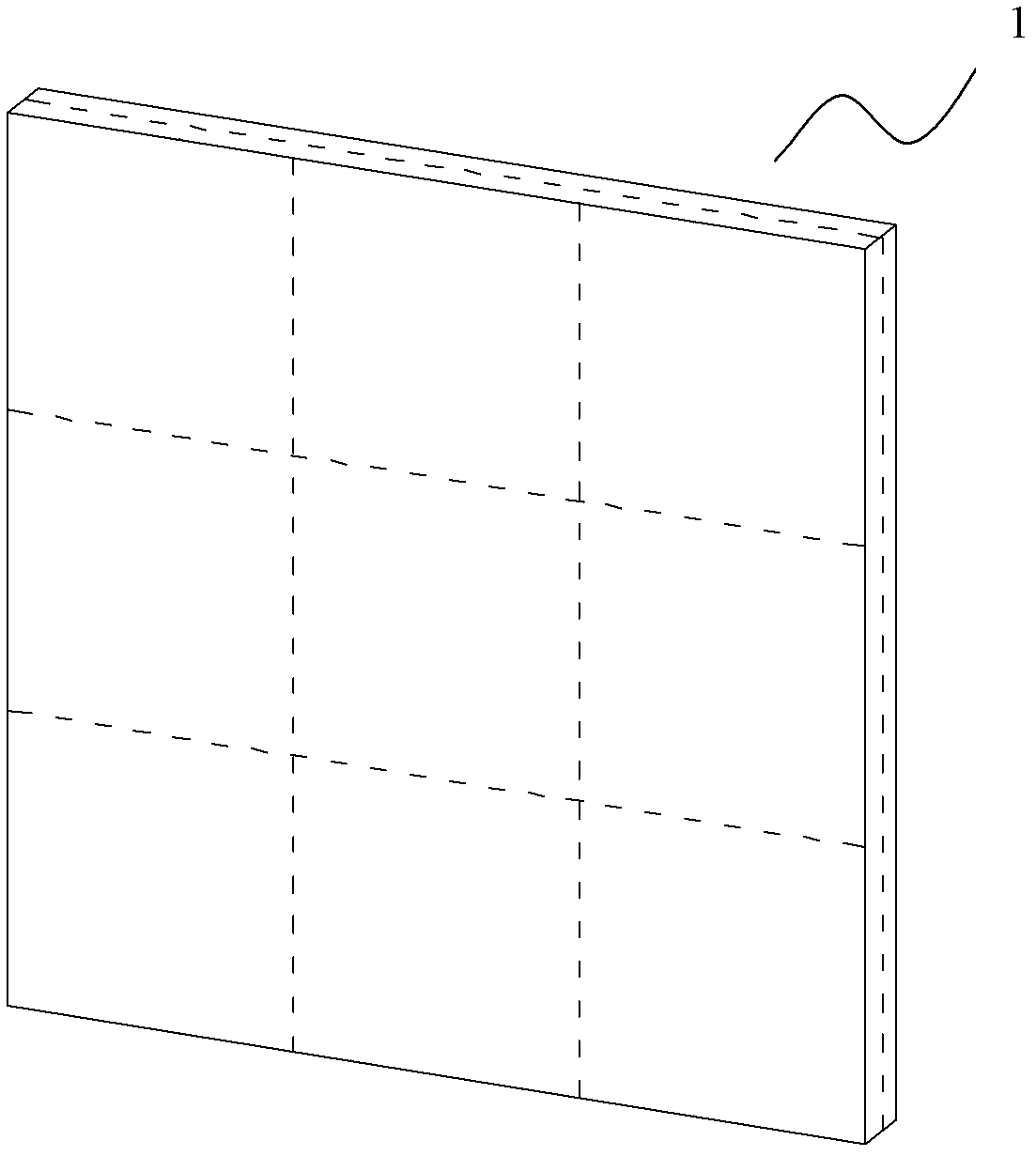

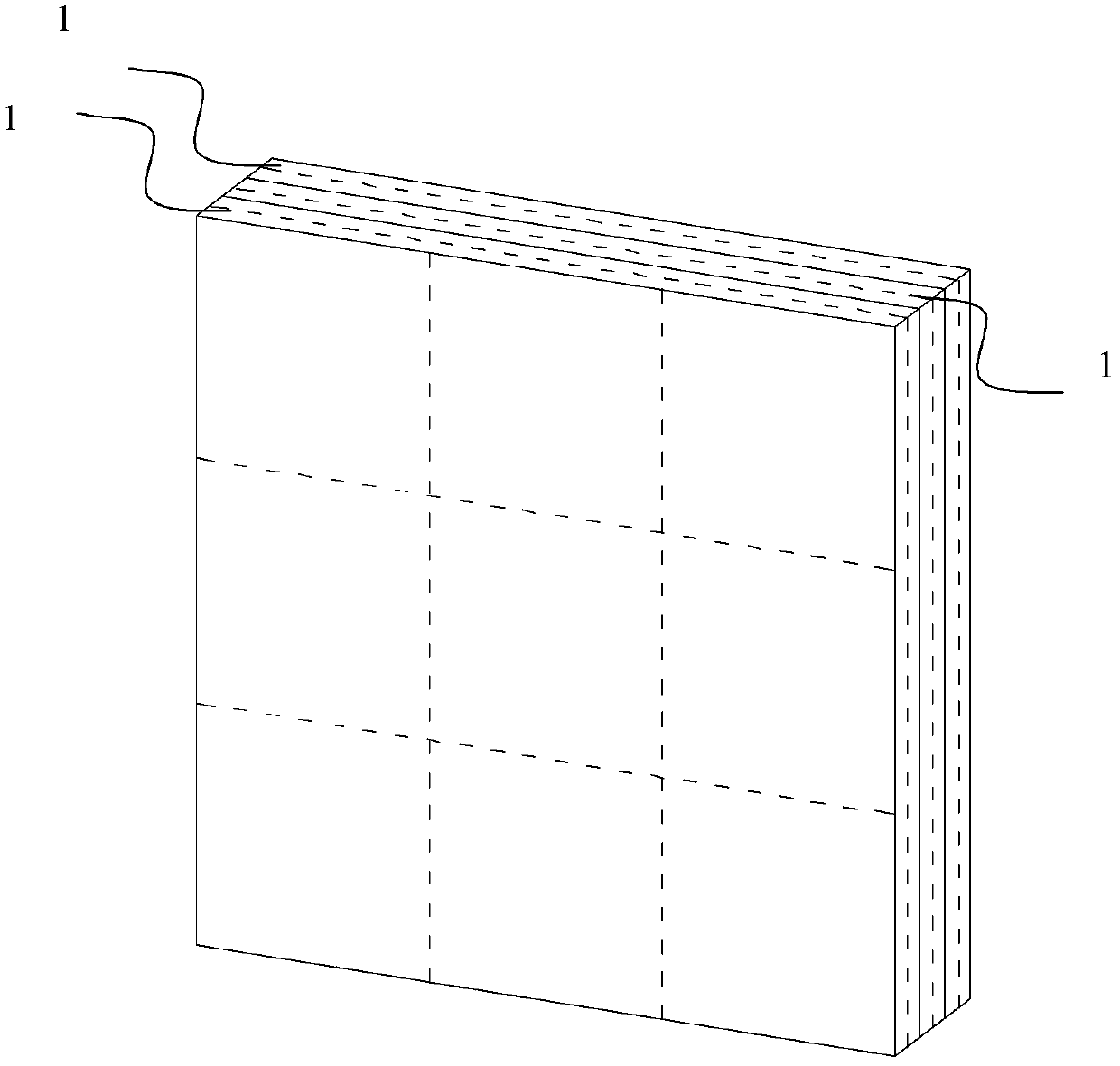

Metamaterial and preparation method thereof

The invention provides a metamaterial and a preparation method thereof. The metamaterial comprises substrates and a tape casting piece, which are arranged in a laminated manner in sequence. The surface of the tape casting piece is provided with a metal microstructure. The substrate is a quartz-fiber-reinforced silicon dioxide base body. The quartz-fiber-reinforced silicon dioxide base body is a sintering compound of silica-sol-based slurry and quartz fiber. The substrate is the quartz-fiber-reinforced silicon dioxide base body, and the quartz-fiber-reinforced silicon dioxide base body is the sintering compound of the silica-sol-based slurry and the quartz fiber, so that the formed metamaterial is low in sintering shrinkage rate, can be co-fired with the silver-based paste, and has higher strength and lower loss; and the metamaterial has higher wave transmissivity.

Owner:SHENZHEN KUANG CHI GANG DA INNOVATIVE TECH LTD

Metamaterial antenna housing and antenna system

ActiveCN103296411AEnhanced wave performanceImprove anti-interference abilityRadiating element housingsMicrostructureMetamaterial antenna

The invention relates to a metamaterial antenna housing and an antenna system. The metamaterial antenna housing comprises at least one metamaterial sheet layer. The metamaterial sheet layer comprises a first substrate and a plurality of artificial microstructures which are arranged on the first substrate in an array mode, and are identical in size. Each artificial microstructure is of a crossed structure, and no gap exists between every two adjacent crossed structures. Needed electromagnetic response is obtained by attaching the metamaterial antenna housing through the artificial microstructures with specific shapes to the substrates, wave-transparent performance of the antenna housing is improved, and capacity of resisting disturbance of the antenna housing based on a metamaterial is improved. In the range of 3.6-18GHz, the metamaterial antenna housing is quite low in loss, and quite high in wave-transparent efficiency.

Owner:KUANG CHI INST OF ADVANCED TECH

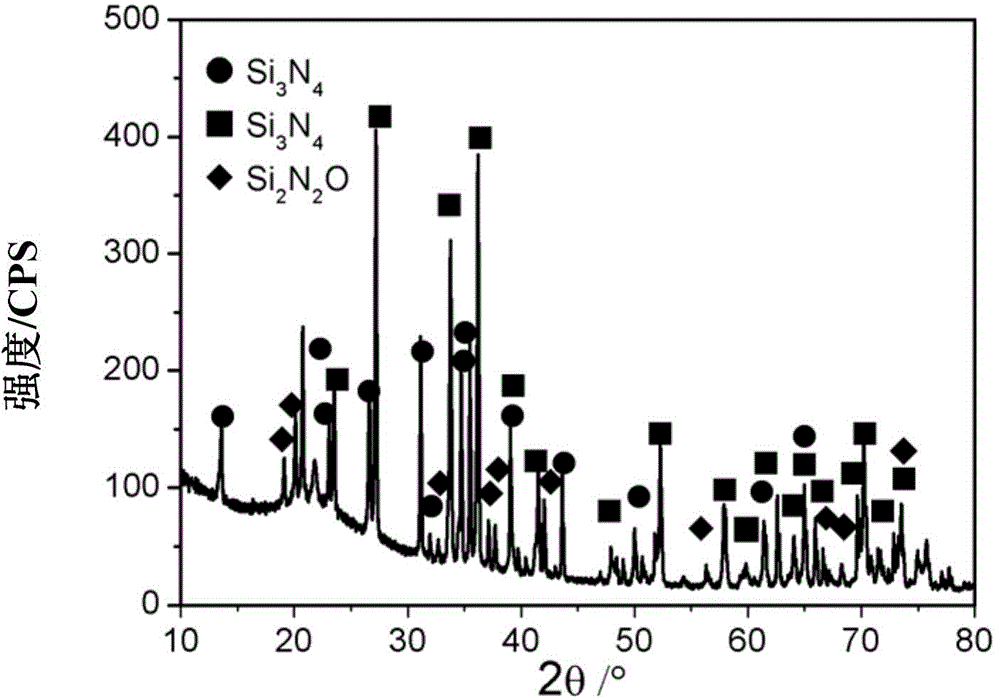

Periclase-silicon oxynitride composite refractory for microwave metallurgy kiln car

ActiveCN107459342AGood wave permeabilityGood volume stability at high temperatureDielectricPericlase

The invention discloses a periclase-silicon oxynitride composite refractory with the characteristics of low electromagnetic absorption rate, excellent wave permeability, high-temperature volume stability, good thermal shock resistance and excellent corrosion resistance for a microwave metallurgy kiln car, and a preparation method of the periclase-silicon oxynitride composite refractory. The adding amount of starting materials in parts by weight are as follows: 65 to 70 parts of magnesia aggregate, 15 to 23 parts of magnesia fine powder, 2 to 6 parts of SiO2 micro powder and 10 to 15 parts of Si powder; the adding amount of a binding agent is 3 to 6 percent of the total weight of the starting materials. The periclase-silicon oxynitride composite refractory disclosed by the invention has the following properties that the volume density is 2.8 to 2.95g / cm<3>, the cold compressive strength is 80 to 120MPa, the cold bending strength is 15 to 25MPa, and hot modulus of rupture is about 5 to 10MPa at the temperature of 1400 DEG C; according to the YB / T 376.1-1995 standard, water-cooling times is 10 to 20 at the temperature of 1100 DEG C, and dielectric constant at normal temperature is 8 to 11; the periclase-silicon oxynitride composite refractory has good corrosion resistance.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

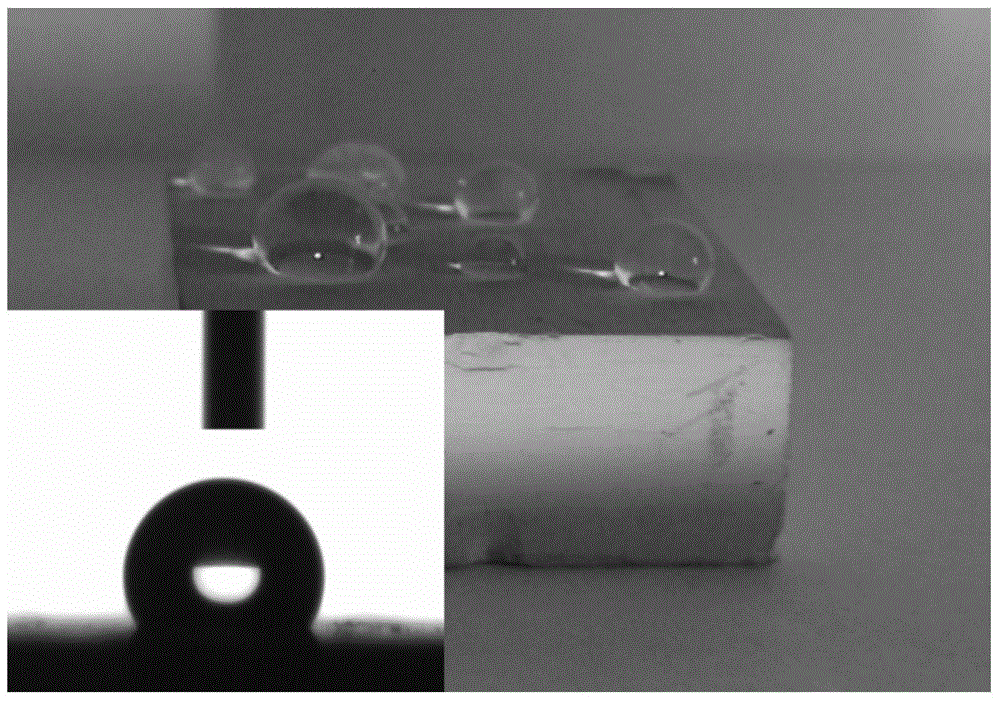

Porous silicon-nitride-based hole sealing coating and preparation method and application thereof

ActiveCN106191770AHigh mechanical strengthLow dielectric constantVacuum evaporation coatingSputtering coatingBound propertyPorous silicon

The invention discloses a porous silicon-nitride-based hole sealing coating and a preparation method and application thereof. In one embodiment, the method comprises: selecting a single crystal silicon target as a cathode, and using a magnetron sputtering deposition technology to prepare a silicon nitride hole sealing coating under the nitrogen atmosphere; then adopting a certain heat treatment process for performing high-temperature sintering; and afterwards, using a hydrophobic modifier for performing hydrophobic treatment so as to obtain the porous silicon-nitride-based hole sealing coating. The binding property of the hole sealing coating with a porous silicon-nitride-based substrate is good, and the hole sealing coating has the advantages of compact structure, controllable thickness, high hardness, low internal stress, no macro defect, high wave permeability, and the like, and can be applied in multiple fields. According to the invention, multiple technologies are combined to prepare the silicon-nitride-based hole sealing coating, and the silicon-nitride-based hole sealing coating with excellent comprehensive performance is obtained, therefore, the effective protection for a porous silicon nitride substrate can be realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

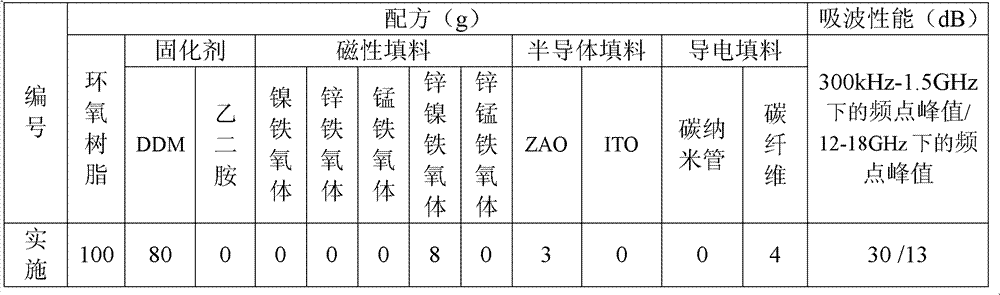

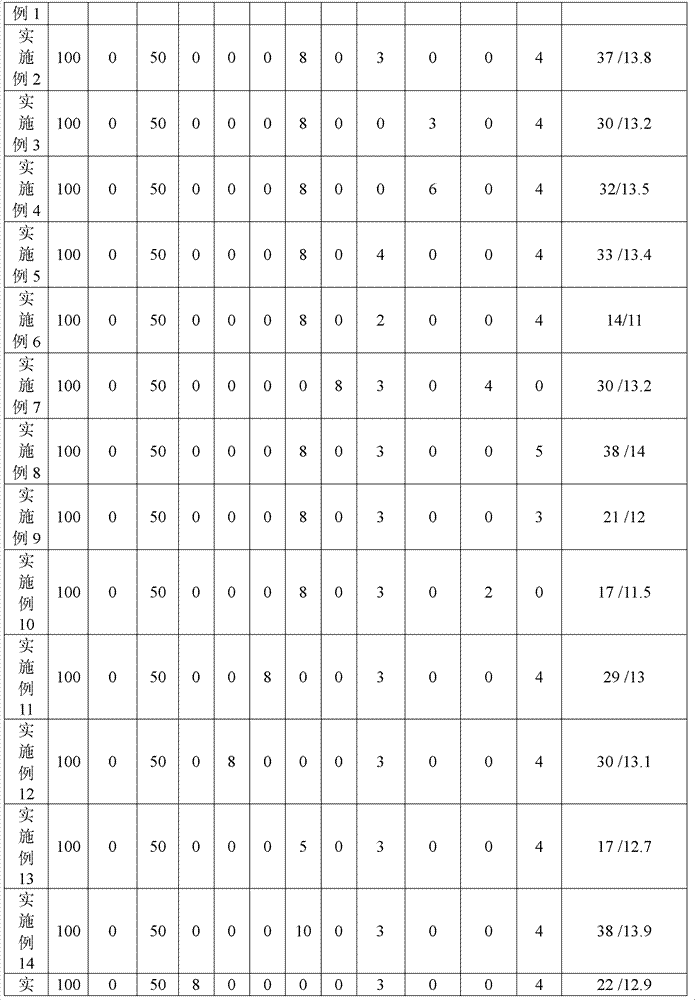

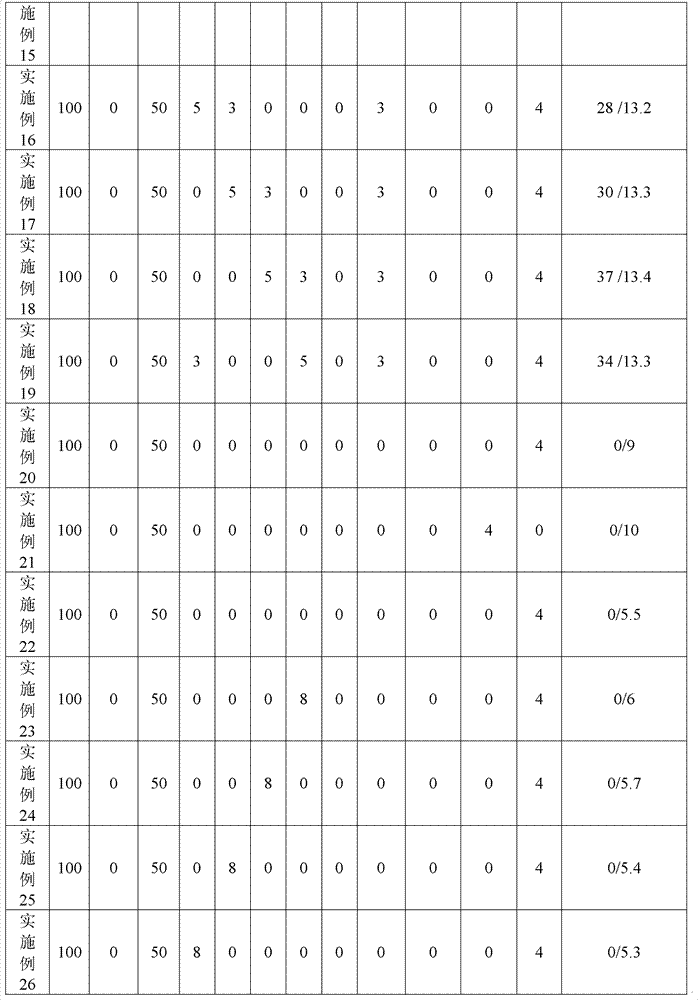

Epoxy resin composite wave-absorbing material and preparation method thereof

InactiveCN102504495BImprove absorbing performanceIncreased maximum absorptionEpoxyEpoxy resin composite

The invention discloses an epoxy resin composite wave-absorbing material and a preparation method thereof, belonging to the field of electromagnetic wave-absorbing materials. The wave-absorbing material comprises 100 parts by weight of epoxy resin, 50-100 parts by weight of a curing agent, 3-10 parts by weight of a magnetic filling material, 2-6 parts by weight of a semiconductor filling materialand 2-5 parts by weight of a conductive filling material. The preparation method comprises the following steps of: after adding the magnetic filling material, the semiconductor filling material and the conductive filling material into the heated and thinned epoxy resin, uniformly mixing, and curing by adding the curing agent. According to the invention, the semiconductor filling material is composited with the magnetic filling material and the conductive filling material to form the electromagnetic wave-absorbing material to be used, so that the wave-absorbing efficiency of the electromagnetic wave-absorbing material is increased, furthermore, the wave-absorbing frequency band can be effectively broadened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

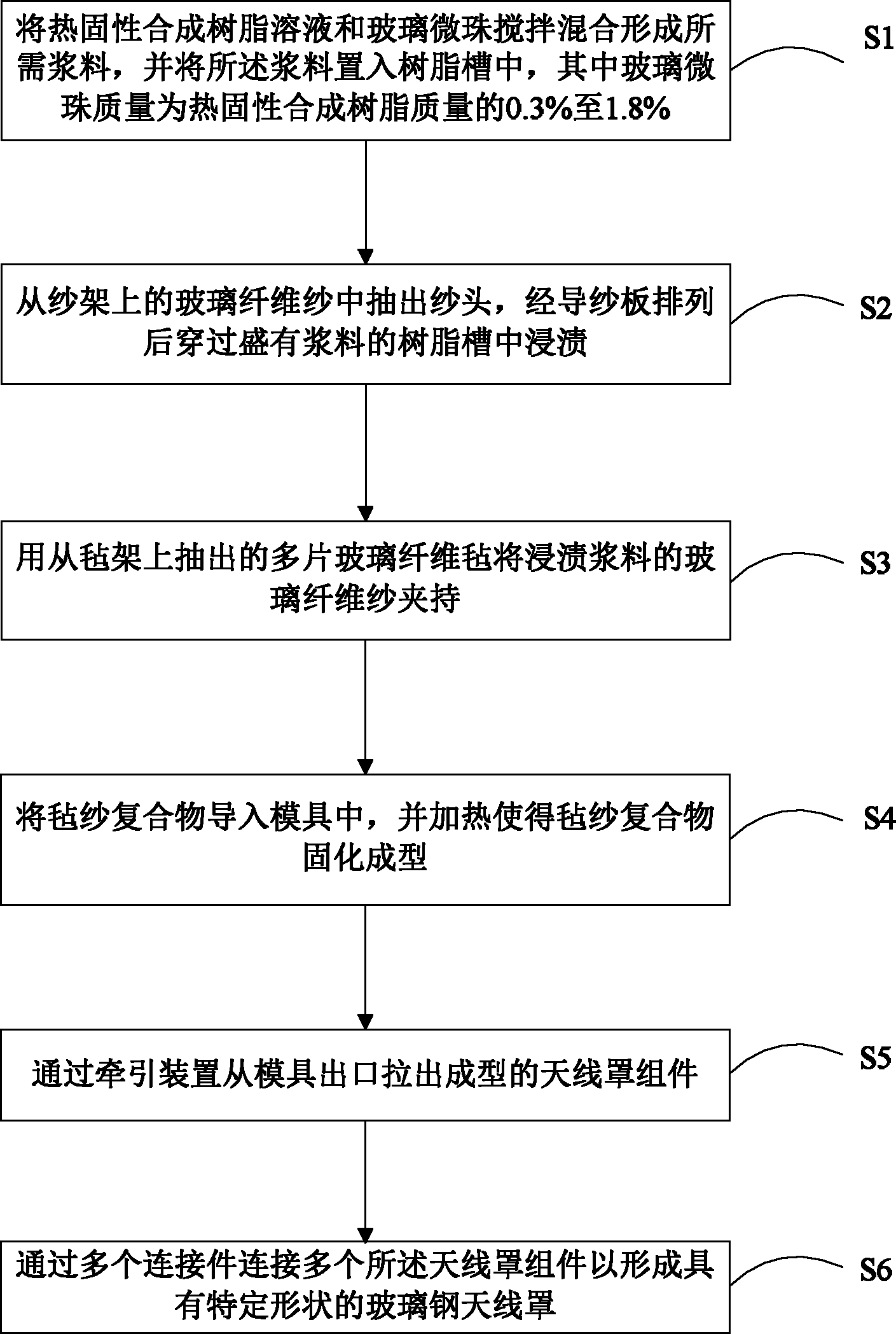

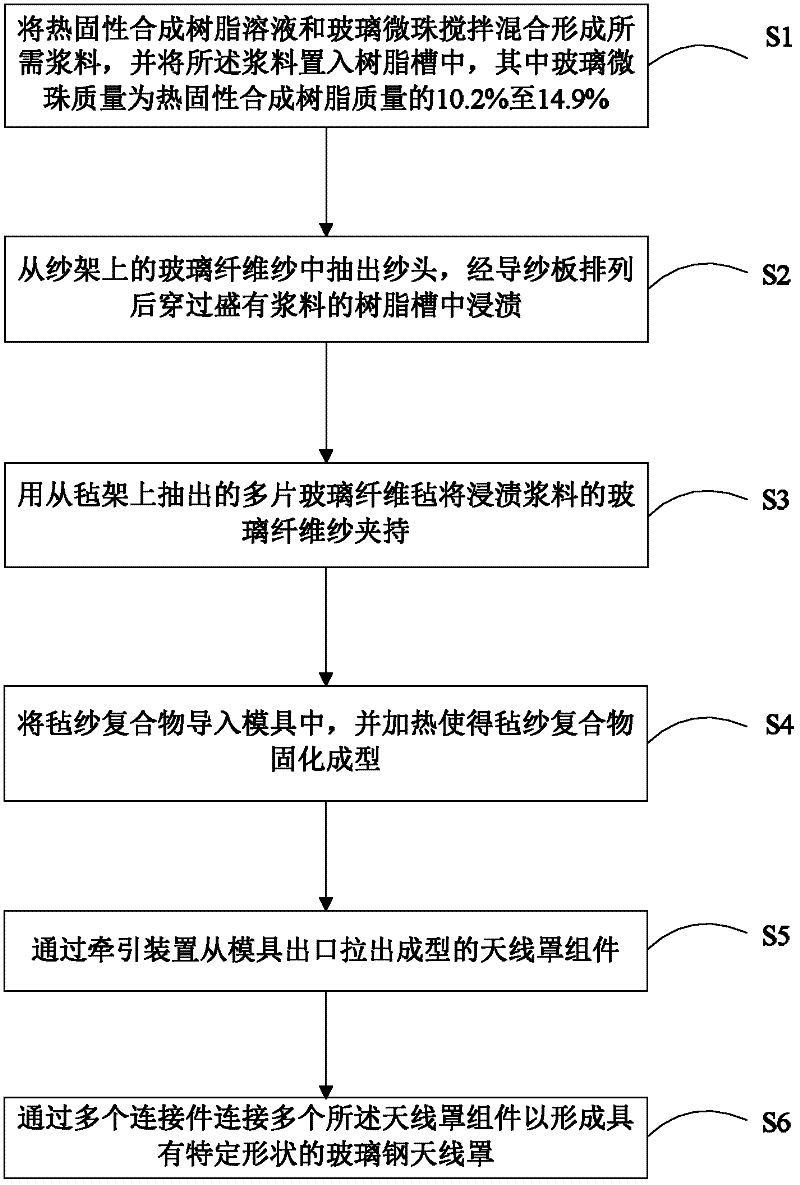

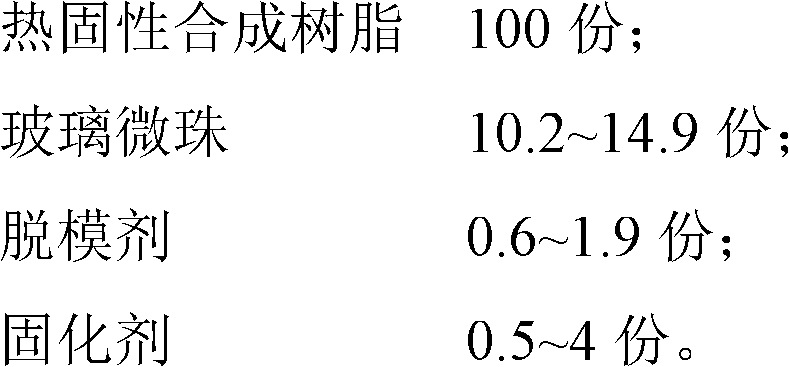

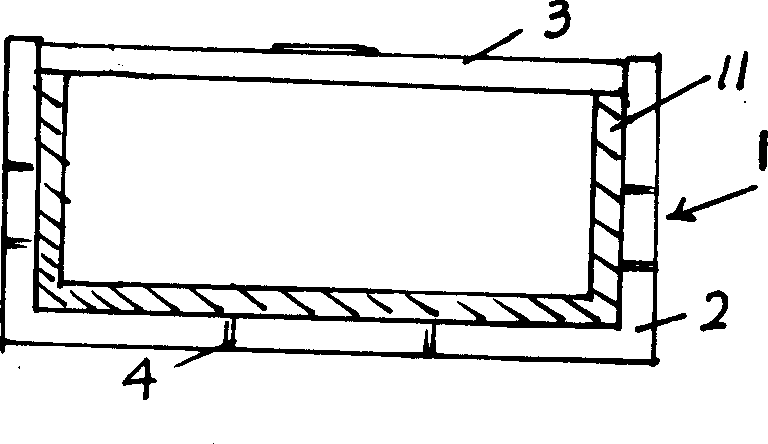

Glass fiber reinforced plastic radome and preparation method thereof

The invention discloses a glass fiber reinforced plastic radome and a preparation method thereof. The glass fiber reinforced plastic radome comprises the following raw materials by mass: 100 parts of thermosetting synthetic resin, 10.2-14.9 parts of glass beads, 0.6-1.9 parts of a release agent, and 0.5-4 parts of a curing agent. The preparation method comprises: that a thermosetting synthetic resin solution and the glass beads are stirred and mixed to form a required slurry, and the slurry is put in a resin tank; that thrums are extracted from glass fiber yarns on a creel, and the glass fiber yarns are dipped in the slurry-containing resin tank after being arranged by a yarn guide plate; that multiple sheets of glass fiber mats clamp the glass fiber yarns, wherein the glass fiber mats are extracted from a felt frame and the glass fiber yarns are dipped in the slurry; that a felt-yarn compound is introduced into a die and is heated so that the compound is cured and molded; that a draw gear draws a molded radome assembly from theoutlet of the die; and that the assembly is assembled to form the glass fiber reinforced plastic radome. The glass beads are added into the resin in the preparation method, which improves the mechanical strength, reduces the dielectric loss and the cost, and enhances wave-transparent effects. The method also carries out a surface modification treatment on the fiber mats and the glass beads, so that a bonding force between the two is strengthened.

Owner:KUANG CHI INST OF ADVANCED TECH

Solid powder composite fuel and its producing method

InactiveCN1425747AEnhanced wave performanceExtended service lifeSolid fuelsMetal chlorideThermal energy

The solid powder composite fuel is produced with graphite, ferric oxide and metal chloride. The production process includes crushing and sieving graphite, ferric oxide and metal chloride to obtain 50-120-mesh fine powder, mixing, and microwave ignition and combustion inside one 500-800 W microwave oven until glowing with organe light. The composite fuel is used in heating.

Owner:栗荣桓

Heating front face of vehicle-mounted integrated millimeter-wave radar and manufacturing method thereof

PendingCN113126034AImproved ability to adapt to harsh environmentsImprove matchWave based measurement systemsIn vehicleMillimetre wave

The invention belongs to the technical field of The invention belongs to the technical field of intelligent innovative front faces, and provides a heating front face of a vehicle-mounted integrated millimeter-wave radar, wherein the heating front face comprises a front face body, a heating diaphragm and a filling base, a groove area for displaying a decorative effect is arranged on the back surface of the front face body, a decorative coating layer covers the interior of the groove area, and a metal PIN needle is integrated below the filling base; and a millimeter wave radar antenna with a set layout is printed on the back face of the filling base, and the millimeter wave radar antenna is connected with the metal PIN needle. The millimeter-wave radar has the advantages that the whole front face has a heating function, the ability of the millimeter-wave radar to adapt to the severe environment is improved, two parts are seamlessly integrated in the structure, the millimeter-wave radar can be better matched with the front face, the wave-transparent performance is effectively improved, the millimeter-wave radar antenna is arranged behind the filling base through the printing technology; and the metal PIN needle is integrated below the filling base, the structure is simple, and the weight and the cost are obviously reduced.

Owner:NINGBO XINTAI MACHINERY

High-weather-resistant antibacterial coating layer material for castings and preparation method thereof

InactiveCN108727935AGood highlight effectImprove wettabilityFireproof paintsAntifouling/underwater paintsEscherichia coliPolyvinyl alcohol

The invention provides a high-weather-resistant antibacterial coating layer material for castings and a preparation method thereof. The coating layer material is prepared from the following raw materials in parts by weight: 40-70 parts of modified acrylic resin, 8-16 parts of bismaleimide, 3-6 parts of triallyl isocyanurate, 5-10 parts of polyvinyl alcohol, 6-12 parts of a compound antibacterial agent, 5-10 parts of a modified mixed filling, 2-5 parts of 2,2'-methylenebis(4,6-di-tert-butylphenol), 3-6 parts of 2-hydroxy-4-n-octyloxybenzophenone, 2-7 parts of soybean lecithin, 3-8 parts of ethylene glycol monoethyl ether acetate, 4-9 parts of polydimethylsiloxane and 10-25 parts of neodecanoic acid glycidyl ester. The coating layer material has ideal mechanical strength and goop weather resistance, the antibacterial rate of the coating layer material to mixed bacteria of gram-negative escherichia coli and gram-positive staphylococcus aureus reaches up to 99.35%, so that the high-weather-resistant antibacterial coating layer material has wide application prospects.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

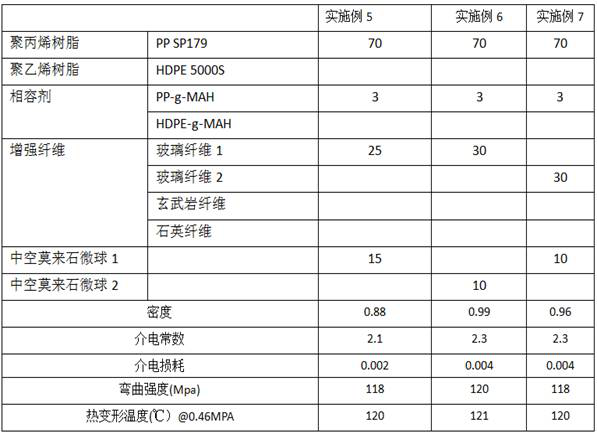

Polyolefin material as well as preparation method and application thereof

The invention discloses a polyolefin material as well as a preparation method and application thereof. The polyolefin material comprises the following components: 15-95 parts of polyolefin resin, 5-60parts of reinforcing fibers, 0.5-10 part of a compatilizer, and 5-60 parts of hollow mullite microspheres. By adding the reinforcing fibers and the hollow mullite microspheres into the polyolefin material, the reinforcing fibers and the hollow mullite microspheres have a synergistic effect, so that the density of the material can be remarkably reduced, the wave-transparent performance of the material can be improved, the strength and heat resistance of the material can be improved, and the prepared polyolefin material has the advantages of high heat resistance, high strength, low density andhigh wave transparency.

Owner:KINGFA SCI & TECH CO LTD

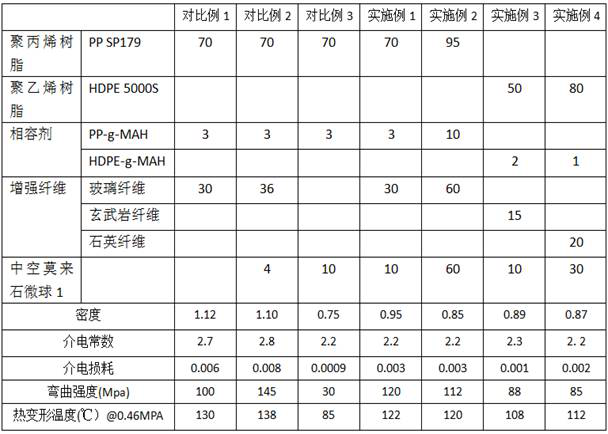

Vacuum wave-transparent radome with multi-layer structure

PendingCN112271452AAchieve wave transparencyEnhanced wave performanceRadiating element housingsEngineeringRadome

The invention discloses a vacuum wave-transparent radome with a multilayer structure, and belongs to the technical field of radomes. A radome body is of a hemispherical shell structure and comprises an inner skin layer and an outer skin layer, and the hemispherical shell structure further comprises a middle skin layer and interlayers located between the skin layers. The interlayer is of a honeycomb or foam structure, and an antenna housing flange plate is arranged at the bottom of the hemispherical shell structure. The radome can be suitable for a vacuum environment, and the wave transmissionof the radome is improved under the condition that the radome is not damaged.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

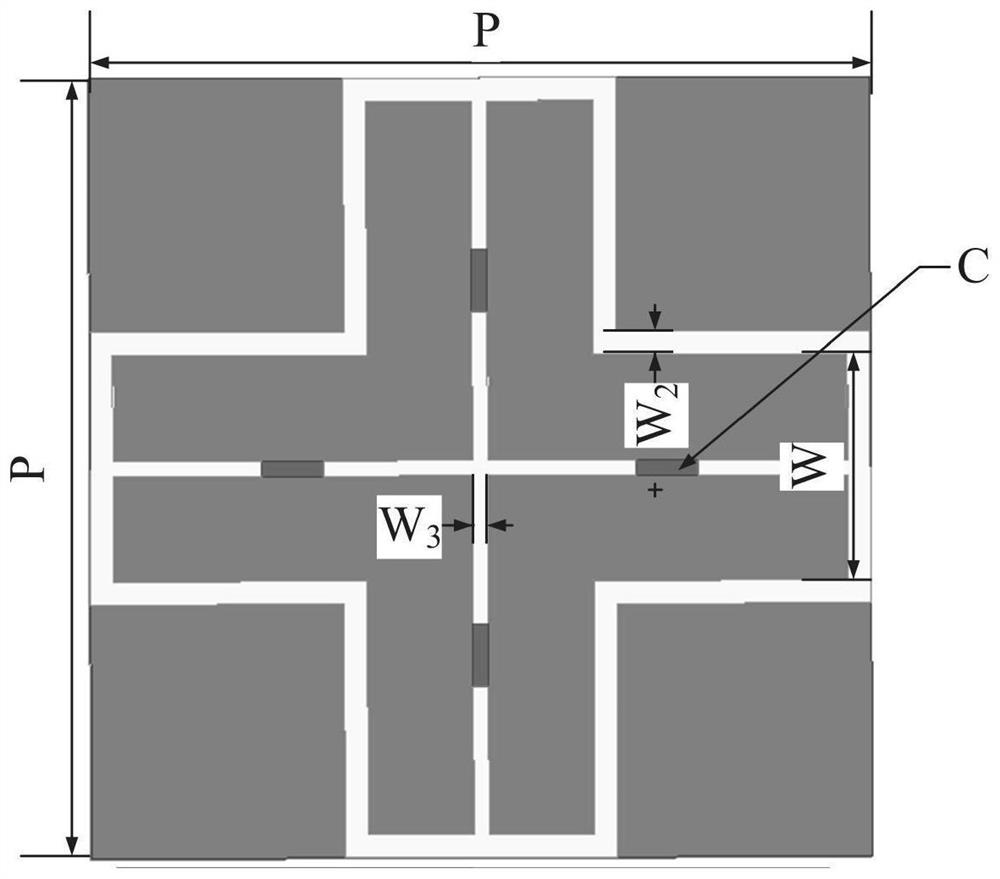

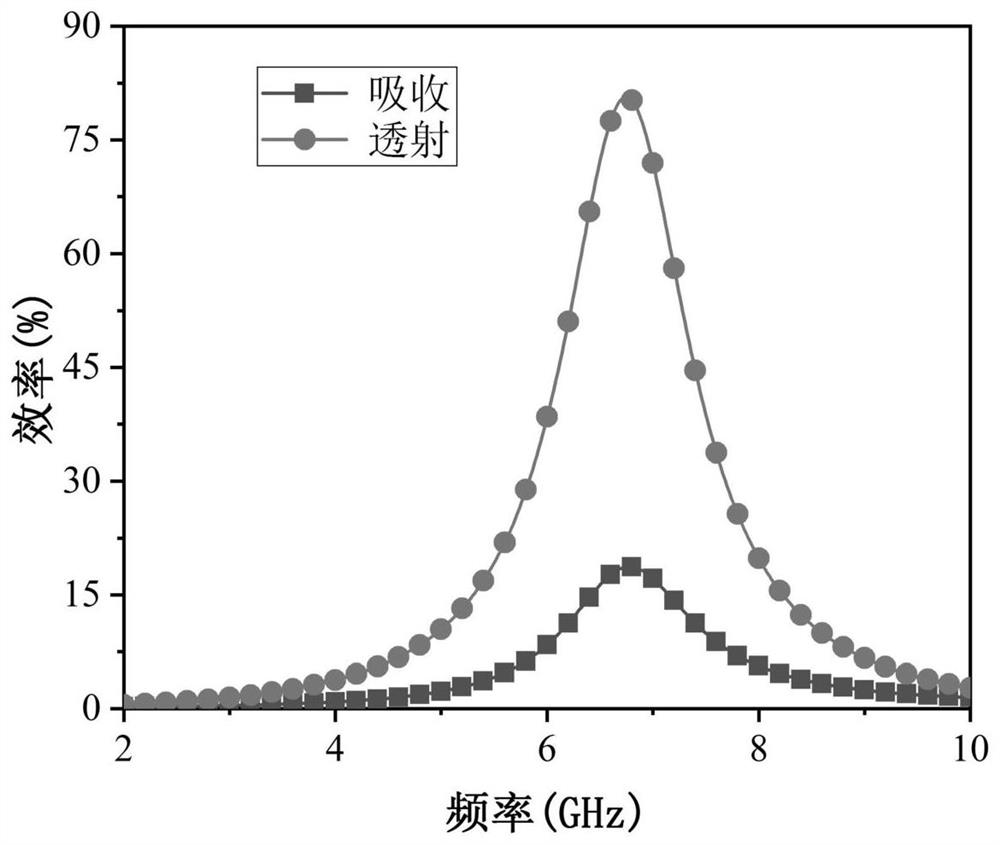

Passband reconfigurable absorption/transmission integrated frequency selective surface and basic unit

PendingCN112510376AInsensitive to incident angleEnhanced absorbingRadiating element housingsDielectric plateEngineering

The invention relates to a passband reconfigurable absorption / transmission integrated frequency selective surface and a basic unit. The basic unit comprises a dielectric plate, four variable capacitors and four PIN diodes, wherein a cross-shaped metal wire and a cross-shaped metal ring belt are arranged on the surface of one side of the dielectric plate, a variable capacitor is embedded in a metalarm forming the cross-shaped metal wire, the cross-shaped metal ring belt is arranged on the outer side of the cross-shaped metal wire in a sleeving mode, a cross-shaped metal sheet and a metal square ring are arranged on the surface of the other side of the dielectric plate, the metal square ring is arranged on the outer side of the cross-shaped metal sheet in a sleeving mode, each protruding end of the cross-shaped metal sheet is connected with the corresponding edge of the metal square ring through a PIN diode, the PIN diodes are arranged in a gap between the cross-shaped metal sheet and the metal square ring, a cathode is connected with the cross-shaped metal sheet, and an anode is connected with the metal square ring. According to the invention, the frequency selective surface and the basic units are of a suction / penetration integrated structure, and have the advantages of being small in size, small in thickness and high in practicability.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A ku/ka dual-band high-transparency bulletproof radome and its manufacturing method

ActiveCN106058459BImprove ballistic performanceGood bulletproofRadiating element housingsEngineeringRadome

The invention provides a Ku / Ka dual-band high-transparency bulletproof radome and a manufacturing method thereof. The bulletproof radome is formed by pressing a single layer of ultra-high molecular weight polyethylene, and is suitable for integral manufacturing of the bulletproof radome. The invention realizes the dual-band high wave-transmitting performance of the radome, and has better bulletproof performance.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com