Solid powder composite fuel and its producing method

A technology of solid powder and manufacturing method, which is applied in the direction of solid fuel, fuel, petroleum industry, etc., and can solve the problems of polluting the environment, easily damaged magnetron, and many residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

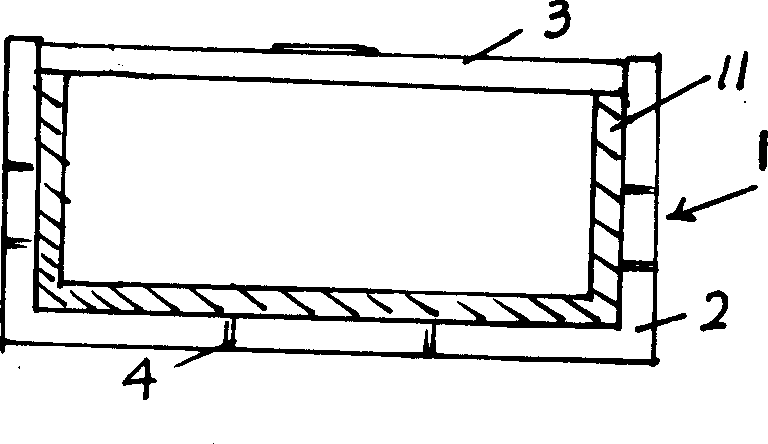

[0015] Solid powder composition fuel, 100g of mineral phosphorus flake graphite with a purity of 80%, 35g of magnetic iron ore powder with a purity of 70%, 5g of sea salt, the particle size is 60 mesh, mixed evenly, and 15g is put into figure 1 In the shown carrier 1, put the carrier 1 into a microwave oven, turn on the microwave power of 800W, ignite and burn, all orange-red, take it out and cool it down to room temperature, which is the finished product.

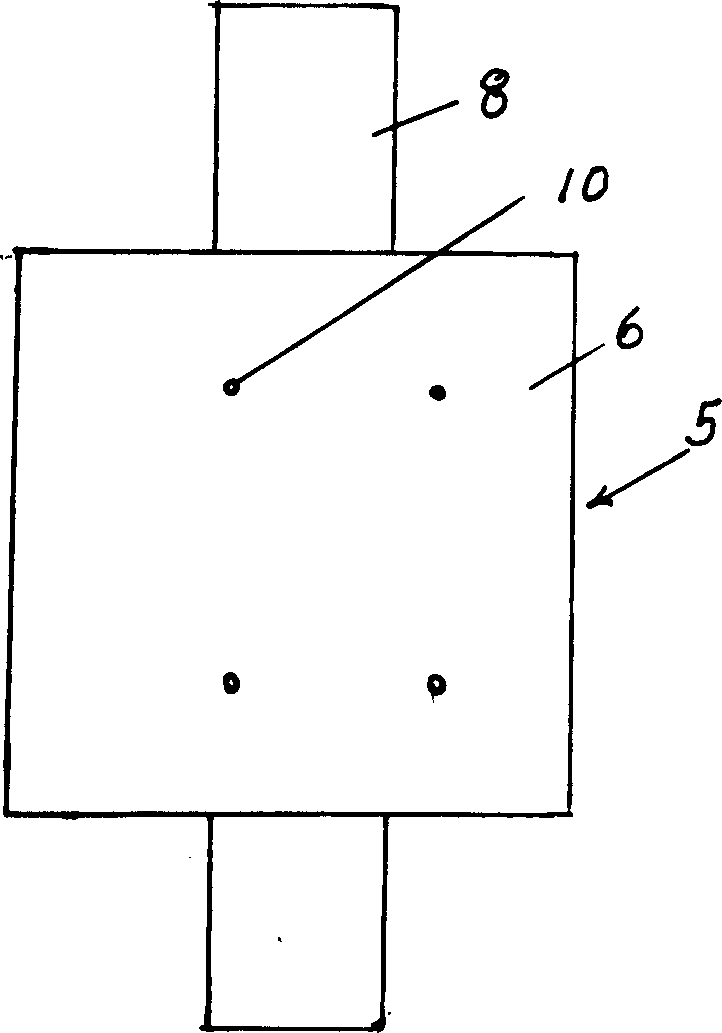

[0016] When the fuel is in use, it is still put into the carrier, ignited and burned with microwaves, and the heated object can be placed in the box body or on the upper end cover (see figure 1 ), can also be put into the working tube (see figure 2 ).

[0017] The fuel of the invention has the advantages of saving electric energy, high thermal efficiency, controllable combustion heat release, little environmental pollution and the like.

[0018] The first load carrier 1 of the present invention includes a box body 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com