A ku/ka dual-band high-transparency bulletproof radome and its manufacturing method

A manufacturing method and radome technology, applied in the direction of the radiation unit cover, etc., can solve the problems of unfinished product reports, etc., and achieve the effect of good main chain combination, light weight and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

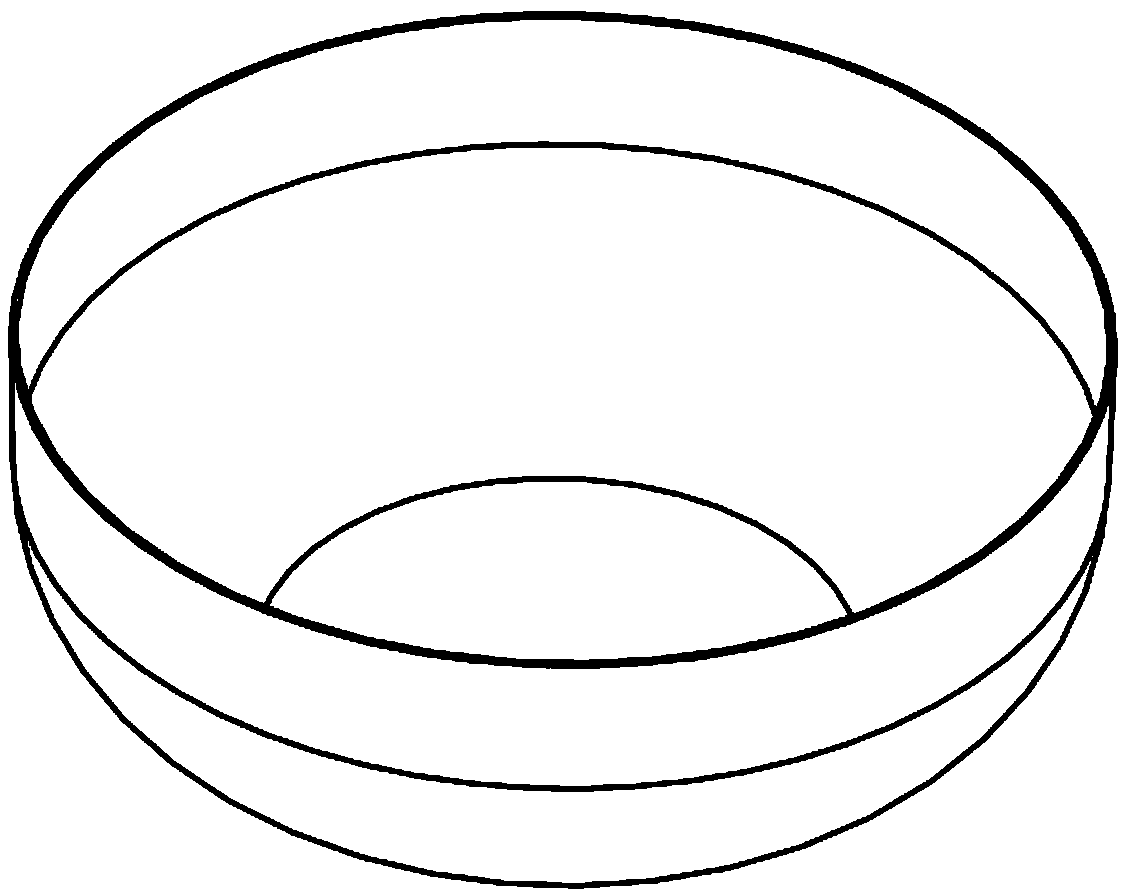

[0019] Below, combine figure 1 The present invention will be further described with specific examples.

[0020] A Ku / Ka dual-band high-transmission bulletproof radome, the bulletproof radome is formed by pressing ultra-high molecular weight polyethylene with a single-layer structure, and the thickness of the wave-transparent surface of the bulletproof radome is 6-8mm.

[0021] The manufacturing method of the above Ku / Ka dual-band high-transparency bulletproof radome comprises the steps of: placing ultra-high molecular weight polyethylene in the mold of the bulletproof radome; setting the temperature during pressing to be lower than the melting point temperature of ultra-high molecular weight polyethylene by 20°C From ℃ to 30℃, the pressure is controlled at 0.5-16.5Mpa, and the heat preservation time is set; the pressure is maintained during the cooling process, and the pressure can only be released when it is lower than 60℃.

[0022] In the embodiment, the temperature during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com