Silicon vanadium steel plate with promoted bulletproof performance and manufacturing method

A silicon vanadium steel sheet and a manufacturing method, which are applied to the silicon vanadium steel sheet and the manufacturing field for improving ballistic resistance, can solve the problem that the alloy composition does not contain vanadium and the like, and achieve the effect of improving ballistic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

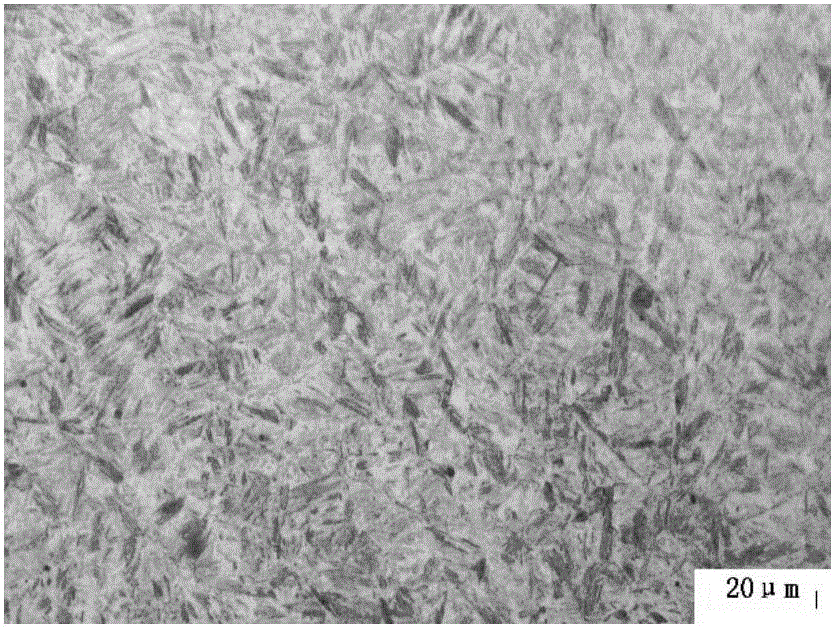

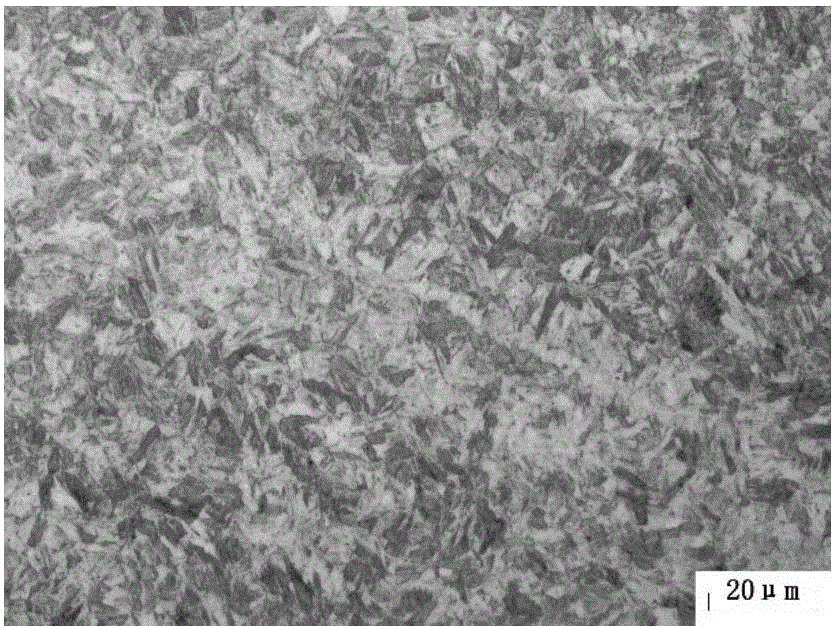

[0018] Below in conjunction with embodiment and accompanying drawing ( Figure 1-Figure 2 ) to illustrate the present invention.

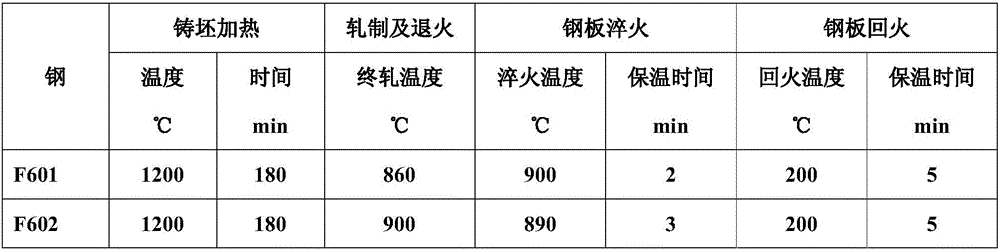

[0019] The product and method of implementing a silicon-vanadium steel plate with improved anti-ballistic performance of the present invention are as follows: smelting in a 180-ton converter, refining in an LF furnace and a RH furnace, and the chemical composition is shown in Table 1. Continuous casting is used for casting. The slab is hot-charged, the heating temperature is 1200°C, the furnace residence time is 180min, the final rolling temperature is controlled at 850-900°C, and air-cooled after rolling. The quenching temperature of the steel plate is 850-950°C, the holding time is the plate thickness × (2-3) min / mm, the tempering temperature of the steel plate is 150-220°C, and the holding time is the plate thickness × (3-5) min / mm, The specific process parameters are shown in Table 2. Table 3 is the test data of mechanical properties. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com