Patents

Literature

78results about How to "Play a role in precipitation strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Hot-rolled steel wire rod for large bridge cable rope zinc-plated steel wire over 2000 MPa level and production method

ActiveCN109468530APlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWater bathsIngot

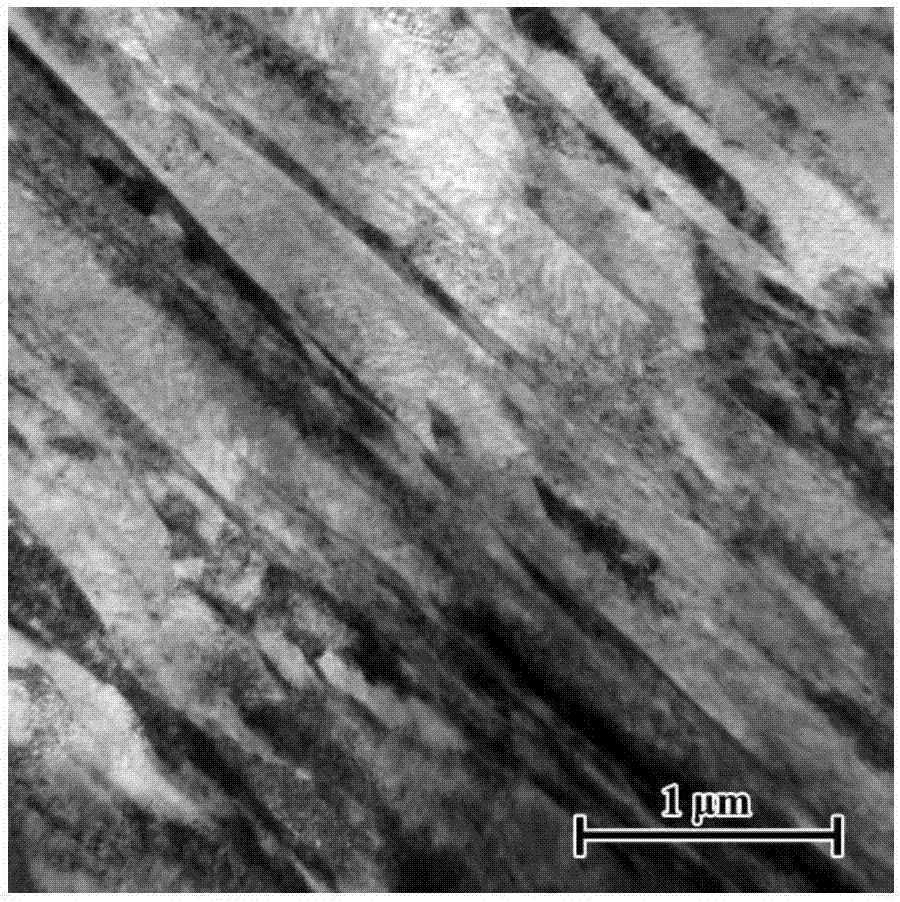

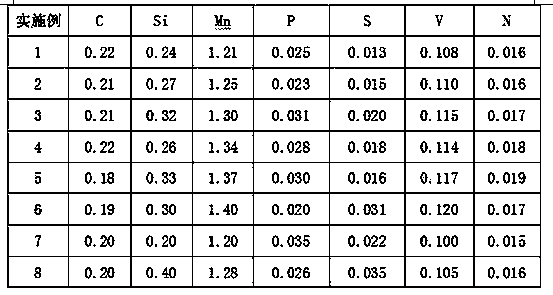

The invention relates to a hot-rolled steel wire rod for a large bridge cable rope zinc-plated steel wire over the 2000 MPa level. Chemical components of the steel wire rod comprise, by weight percentage, 0.90-1.10% of C, 0.20-0.60% of Si, 0.30-0.90% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.10-0.40% of Cr, 0.010-0.070% of Al, 0.02-0.15% of V, smaller than or equal to 0.05% of Cu, 20-40 ppm of Ca, 20-90 ppm of N and the balance Fe and inevitable residual elements. The content of sorbite texture of the steel wire rod is larger than or equal to 95%. Thethrough ring range of the tensile strength is smaller than or equal to 70 MPa (uniformity). After the steel wire rod is subjected to drawing and zinc plating, the tensile strength of the zinc-platedsteel wire is larger than or equal to 2000 MPa, and the number of torsions is larger than or equal to 12. According to the technical flow of the steel wire rod, pretreatment of molten iron is carriedout, steel is smelted through a converter or an electric furnace, LF refining is carried out, RH degassing treatment is carried out, continuous casting of 390*510 cogged ingot is carried out, a blankis reheated, the blank is rolled, the surface of an intermediate billet is subjected to finishing, the intermediate billet is reheated, the intermediate billet is rolled, the steel wire rod is subjected to EDC water bath toughening treatment, and the steel wire rod is collected and packed.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

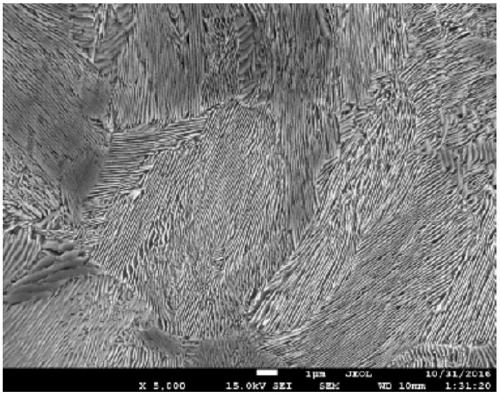

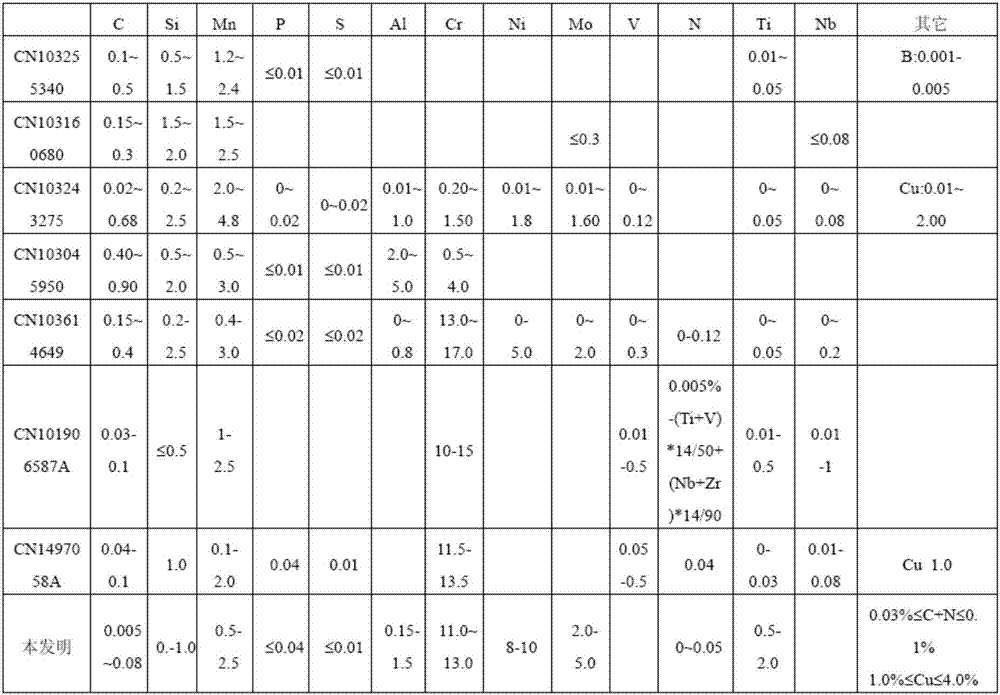

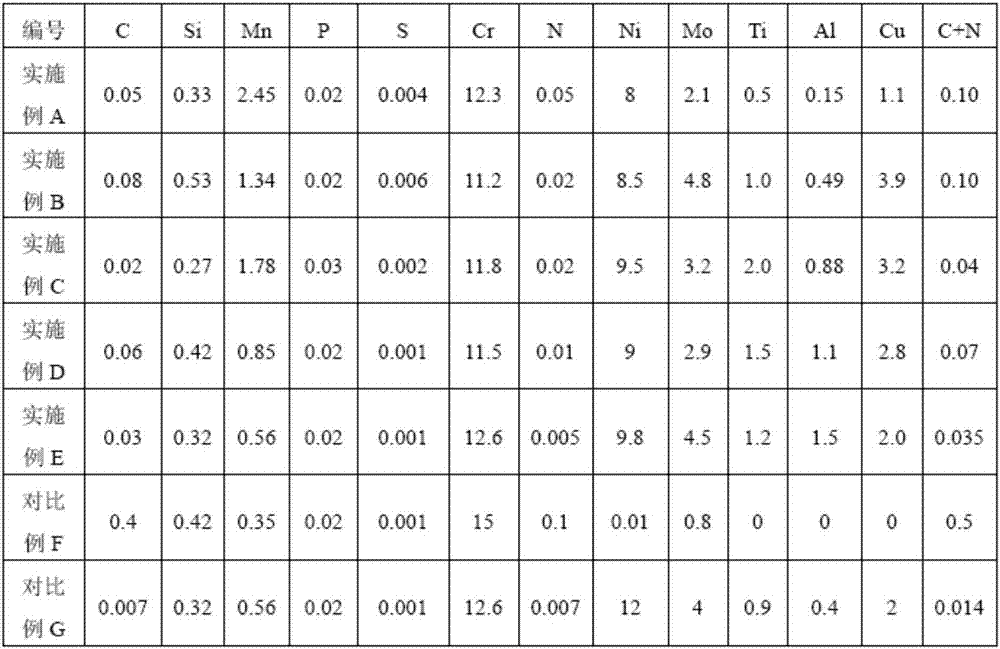

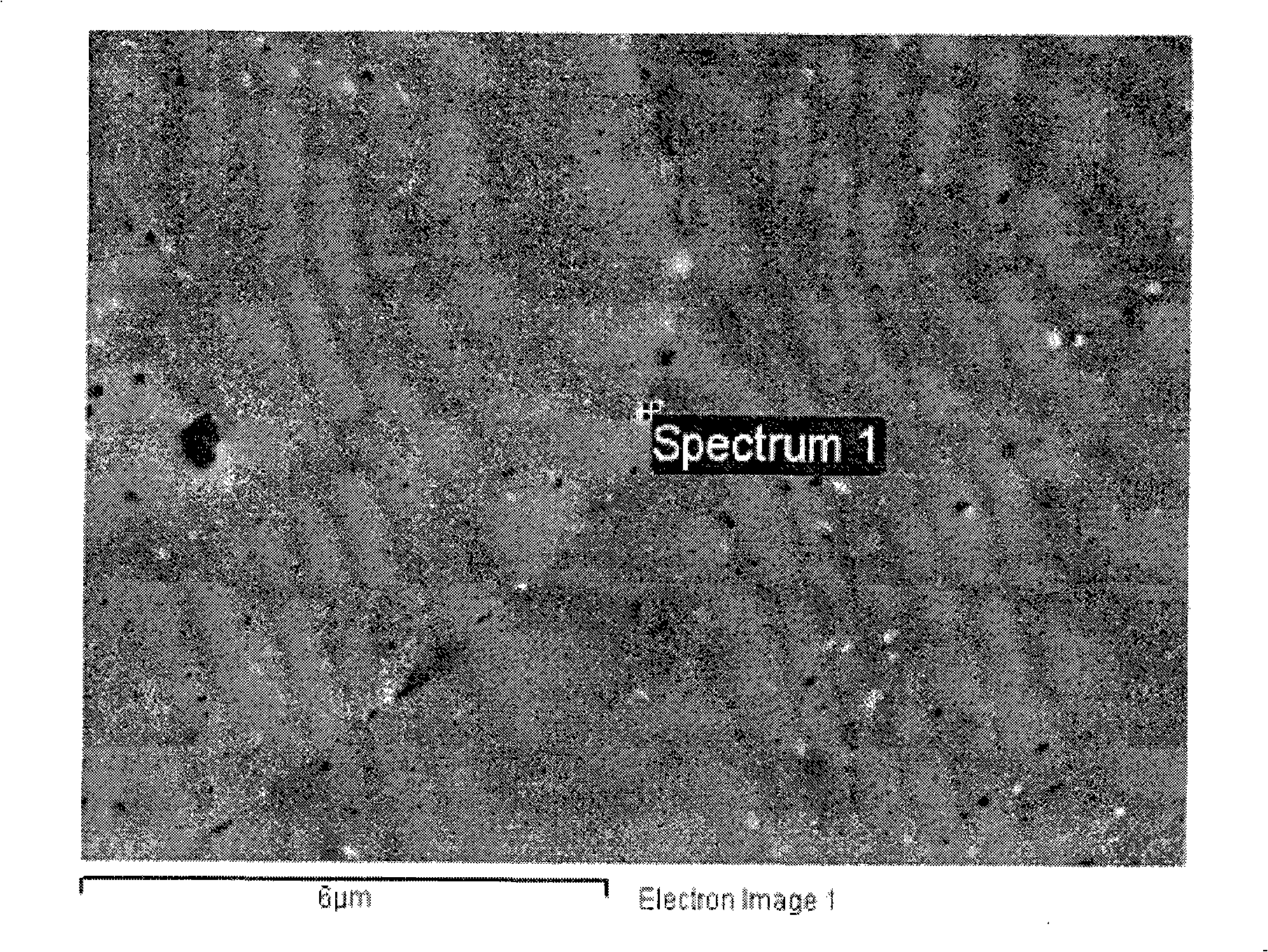

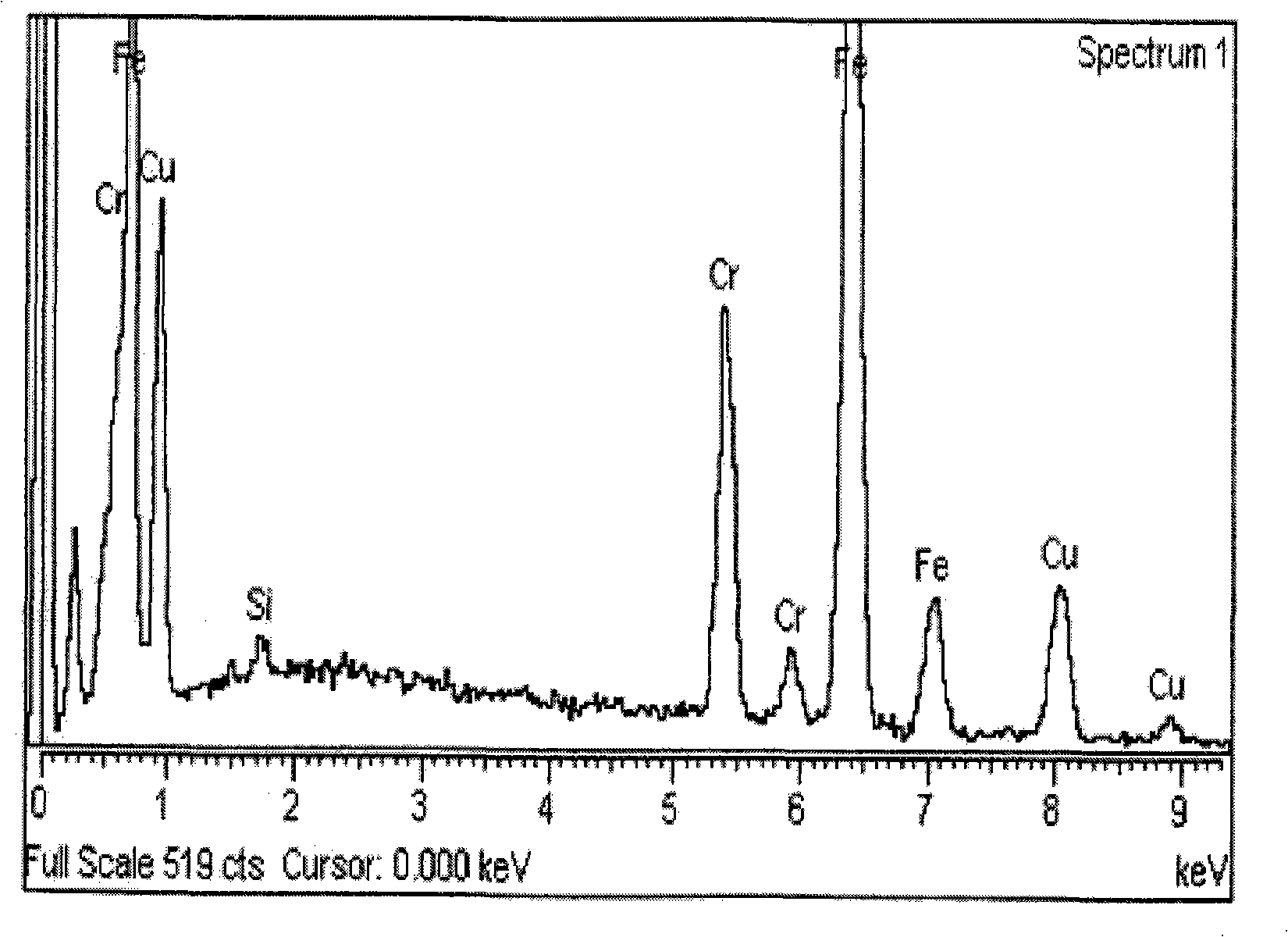

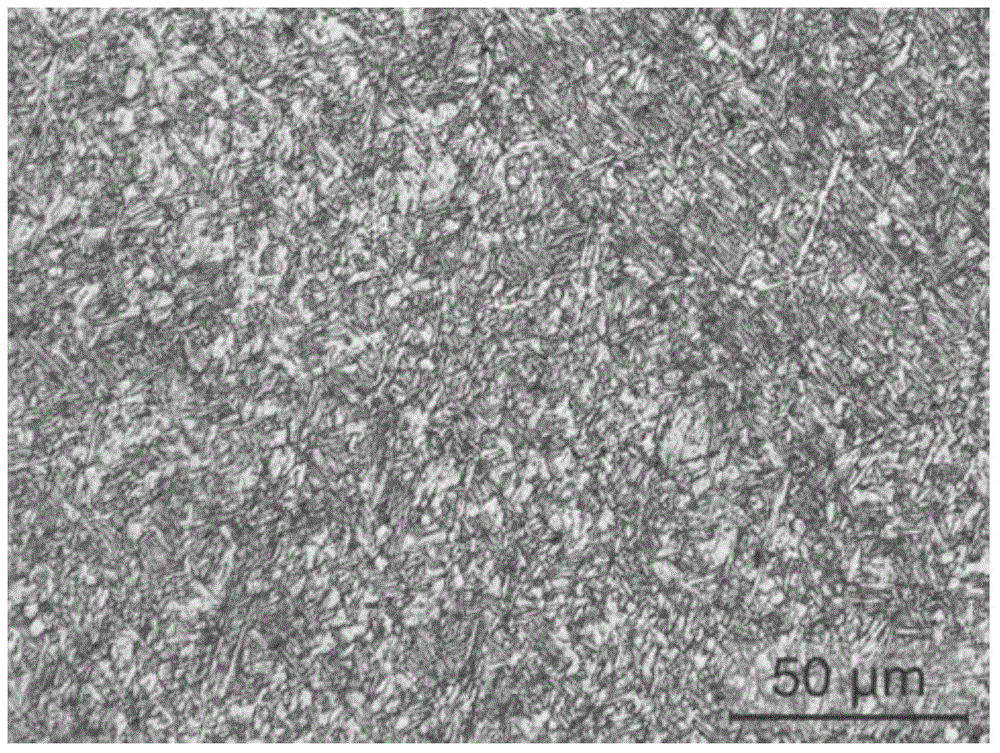

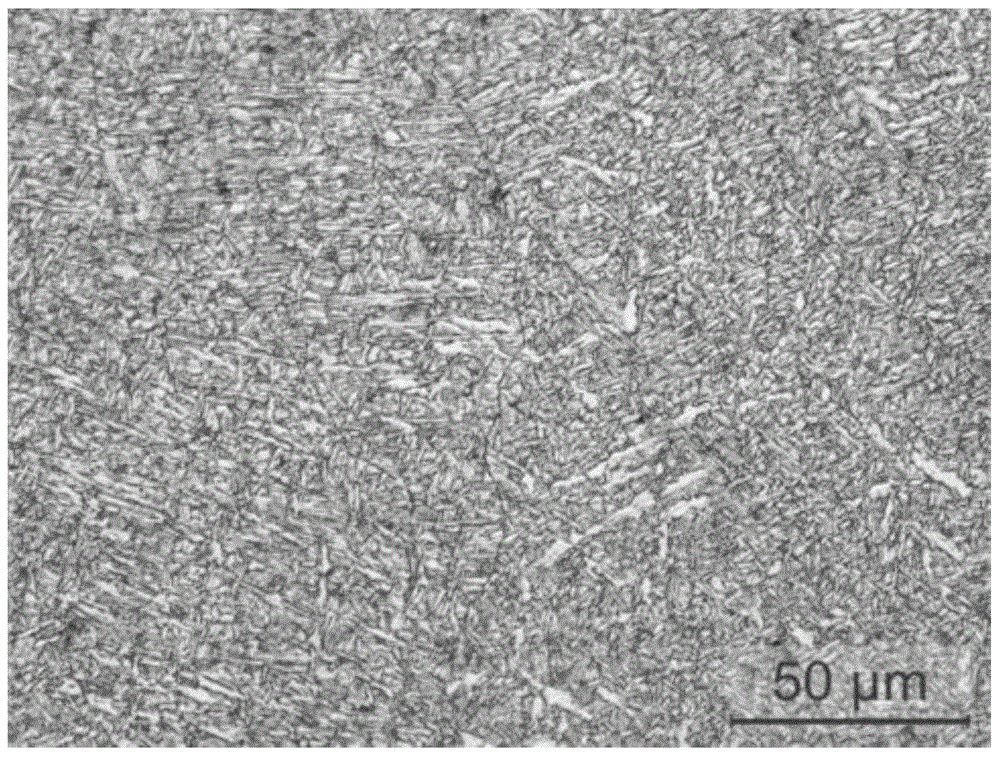

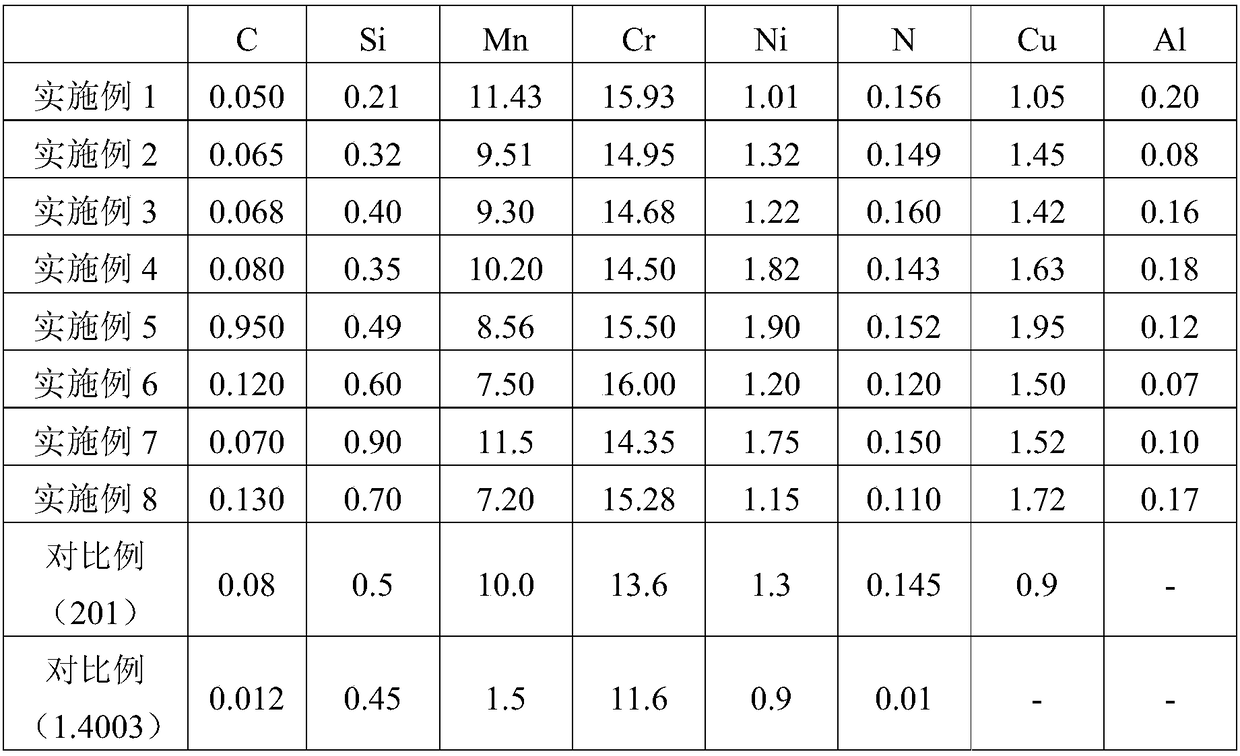

Precipitation-hardened stainless steel for cutting tool and manufacturing method of precipitation-hardened stainless steel

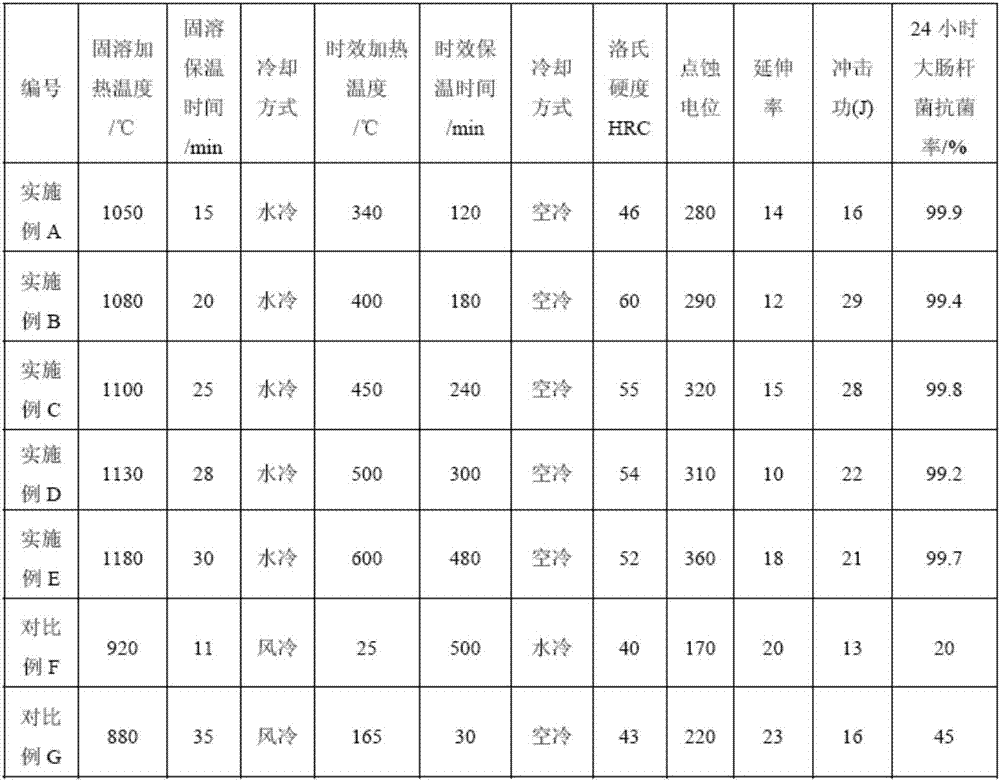

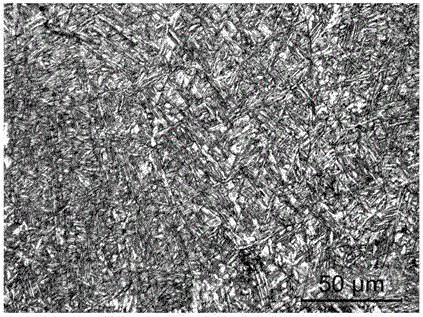

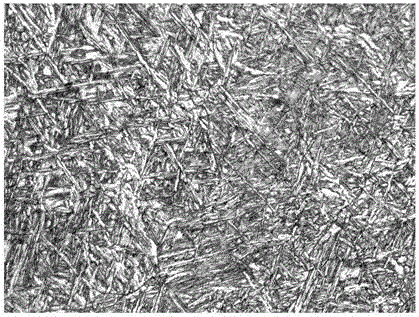

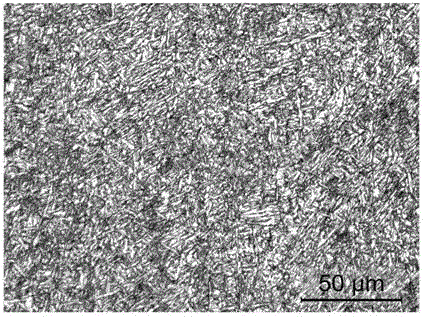

The invention discloses a precipitation-hardened stainless steel for a surgical instrument with excellent corrosion resistance and mechanical performance and a manufacturing method of the precipitation-hardened stainless steel. The indexes of the hardness, the toughness, the corrosion resistance, the mold resistance and the like of the precipitation-hardened stainless steel are all superior to martensitic stainless steel of the same kind. The precipitation-hardened stainless steel comprises the following components of, by weight, 0.005-0.08% of C, less than or equal to 0.05% of N, less than orequal to 1.0% of Si, 0.5-2.5% of Mn, less than or equal to 0.04% of P, less than or equal to 0.01% of S, 11.0-13.0% of Cr, 8.0-10.0% of Ni, greater than or equal to 0.03% and less than or equal to 0.10% of the sum of C and N, 2.0-5.0% of Mo, 1.0-4.0% of Cu, 0.5-2.0% of Ti, 0.15-1.5% of Al, less than or equal to (5*10<-4>)% of the product of Ti and N and the balance unavoidable impurities and Fe.The preparation method comprises the steps that (1) the set components are subjected to alloy smelting by adopting an electric furnace and an external refining mode, so that a steel ingot is formed; (2) the steel ingot is forged to be a steel slab after scalping is conducted, the heating temperature of the forging process is 1050-1250 DEG C, the heating time is 2-5 hours, and the finish forging temperature is 900-980 DEG C; (3) the steel slab is subjected to hot rolling by using a hot rolling machine, so that a hot rolled steel plate or steel belt is prepared, the hot rolling heating temperature is 1000-1200 DEG C, the heat preservation time is 2-5 hours, and the finish rolling temperature is 850-930 DEG C; (4) high-temperature solution treatment is conducted on the steel plate by adoptingsolid solution annealing furnace equipment, the solid solution temperature is 1000-1200 DEG C, the solid solution heat preservation time is 15-30 min, and a cooling mode is water cooling; and (5) aging treatment is conducted on the steel plate which is subjected to solid solution by adopting a heat treatment technology scheme at the temperature of 300-650 DEG C, the aging time is 2-8 hours, and the cooling mode is air cooling after ageing is conducted.

Owner:上海落日新材料科技有限公司 +1

Ultrahigh strength gas protection welding wire and manufacturing method thereof

ActiveCN104607819APlay a role in solid solution strengtheningPlay a role in precipitation strengtheningWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyUltimate tensile strength

The invention discloses an ultrahigh strength gas protection welding wire. The chemical components include, by mass percentage, 0.06-0.12 percent of C, 0.55-0.80 percent of Si, 1.60-1.95 percent of Mn, 0-0.20 percent of Cu, 0.10-0.35 percent of Cr, 0.10-0.50 percent of Mo, 1.00-1.60 percent of Ni, 0.01-0.20 percent of Ti, 0.0005-0.0060 percent of B, and the balance Fe and other unavoidable impurities. Accordingly, the invention further discloses a manufacturing method of the ultrahigh strength gas protection welding wire. The welding wire is small in alloy content and carbon content. Welding joint metal formed after the welding wire is welded has high strength, high low-temperature toughness and good plasticity, and the three priorities are matched well. The welding joint metal formed after the welding wire is welded further has good anti-cracking performance and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

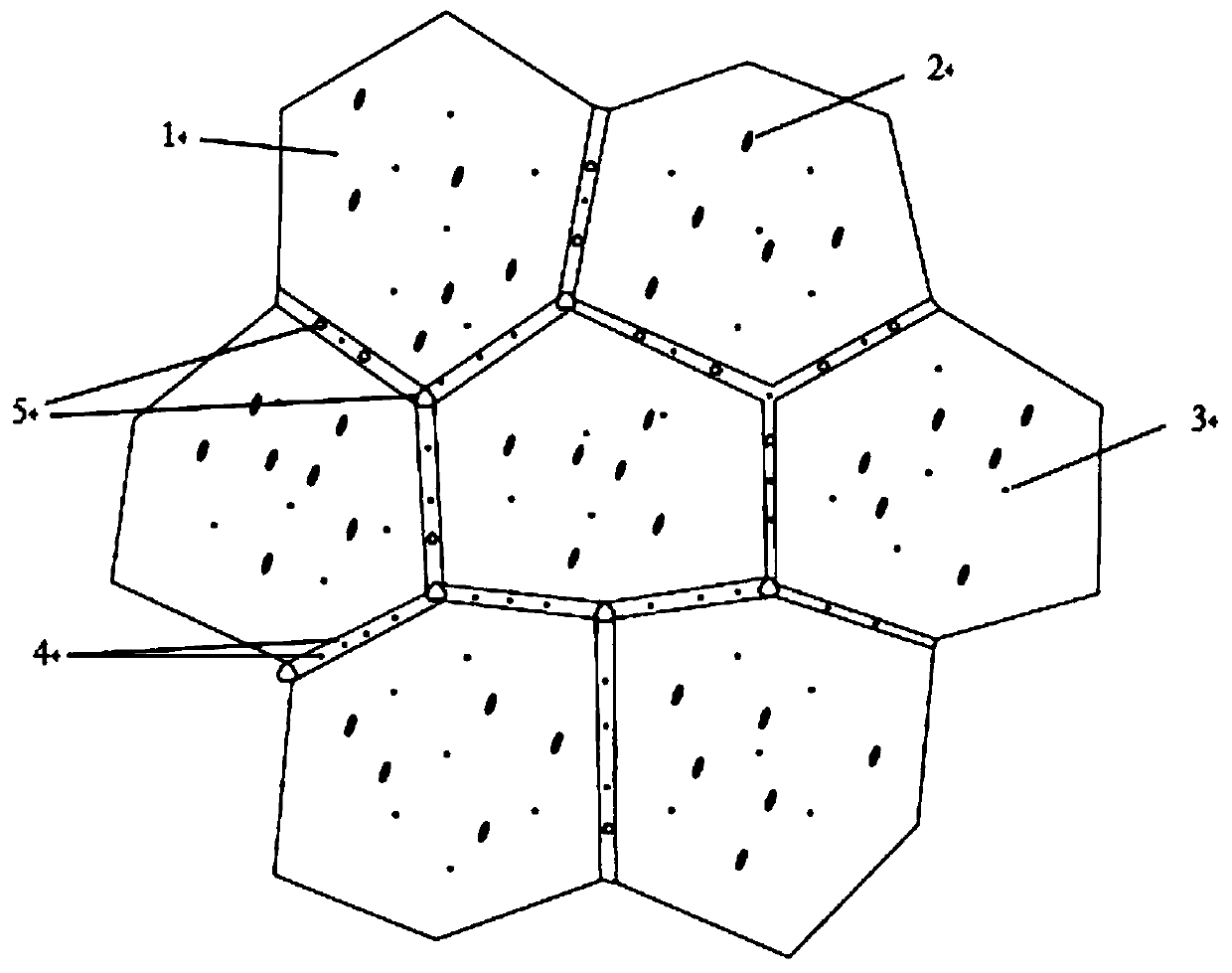

Chromium ferritic stainless steel in precipitation strengthening, strip steel and making method thereof

InactiveCN101328561AHigh yield strengthInhibition of segregationTemperature control deviceMetal rolling arrangementsChemical compositionSS - Stainless steel

The invention provides a precipitated and strengthened medium chromium ferritic stainless steel, a strip steel manufactured by a steel grade and a method for manufacturing the strip steel. The precipitated and strengthened medium chromium ferritic stainless steel consists of the following chemical compositions: less than or equal to 0.04 weight percent of C, 0.2 to 0.6 weight percent of Si, 0.25 to 0.6 weight percent of Mn, less than or equal to 0.02 weight percent of S, less than or equal to 0.03 weight percent of P, 16.0 to 18.0 weight percent of Cr, 1.2 to 1.6 weight percent of Cu, less than or equal to 0.02 weight percent of N, the balance being Fe and inevitable impurities. Electromagnetic stirring is adopted to carry out smelting and casting to the steel grade; and a proper hot rolling temperature, a crimping temperature, a cold rolling reduction and other process conditions are controlled, thereby manufacturing the precipitated and strengthened medium chromium ferritic stainless steel. The ferritic stainless strip steel has high yielding strength and tensile strength and good plastic extendibility and meets the requirement of deformation machining.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-strength gas protection welding wire containing V and manufacturing method thereof

InactiveCN104551441APlay a role in solid solution strengtheningPlay a role in precipitation strengtheningArc welding apparatusWelding/cutting media/materialsChemical elementUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

E-level extra-thick high-intensity steel plate produced by using continuous casting billet and production method thereof

The invention discloses an E-level extra-thick high-intensity steel plate produced by using continuous casting billet and a production method thereof. The steel plate includes the following chemical components by weight percent: 0.16-0.19% of C, 0.15-0.55% of Si, 1.45-1.58% of Mn, less than or equal to 0.018% of P, less than or equal to 0.015% of S, 0.020-0.025% of Nb, 0.020-0.050% of Alt, and the balance of Fe and unavoidable impurities; carbon equivalent CEV is 0.40-0.46%. According to the production method, optimized components, an advanced smelting technology, an optimized continuous casting process (low super-heat degree for casting, low casting speed and reasonable light pressure), and an improved heating and rolling process (heating by stages) are adopted to smelt high-quality continuous casting billet; continuous casting billet is directly used as blank instead of steel ingots, and deficiencies of the prior art are overcome; compared with the steel plate produced by using steel ingots, the E-level extra-thick high-intensity steel plate produced by using continuous casting billet has the advantages that the production process is simplified, the production cost is reduced, and the production period is shortened; compared with the steel plate produced by composite billet, the E-level extra-thick high-intensity steel plate produced by using continuous casting billet has the advantages that the plate billet composition process is eliminated; the method of using continuous casting billet to produce the high-intensity steel plate enables the thickness of the steel plate to be enlarged to 240 mm and the compression ratio to decrease to 1.38 for the first time.

Owner:WUYANG IRON & STEEL

Deformation magnesium alloy with high yield ratio and high-ductility

The invention discloses a wrought magnesium alloy with high yield tensile ratio and high plasticity, wherein the percentage by weight of each component of the alloy comprises zinc 1.0%-2.0%, zirconium 0.1%-0.6%, rare earth erbium 0.1%-0.8%, and others are magnesium and unavoidable impurities. Erbium and impurity element, magnesium and oxygen which is rolled alloy liquid in alloy are combined to form small and dispersed precipitation phase which effectively purifies alloy, promotes dynamic recrystallization in the process of thermal deformation, and blocks recrystallized grain to grow. Zinc plays a solution strength effect in alloy. The wrought magnesium alloy of the invention not only has high yield tensile ratio, but also has excellent plasticity, when the yield tensile is not less than traditional commercial wrought magnesium alloy ZK60 with high intensity, the wrought magnesium alloy of the invention greatly improves the plasticity of magnesium alloy, which fully mines application potential of material.

Owner:CHONGQING UNIV

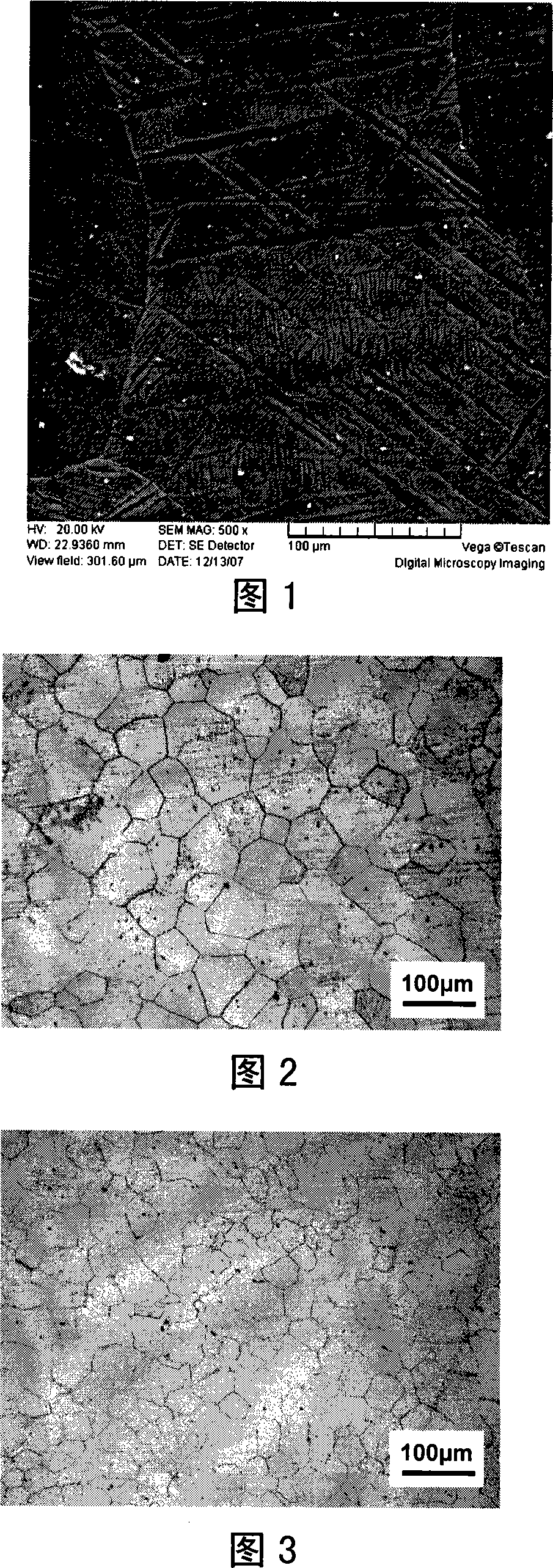

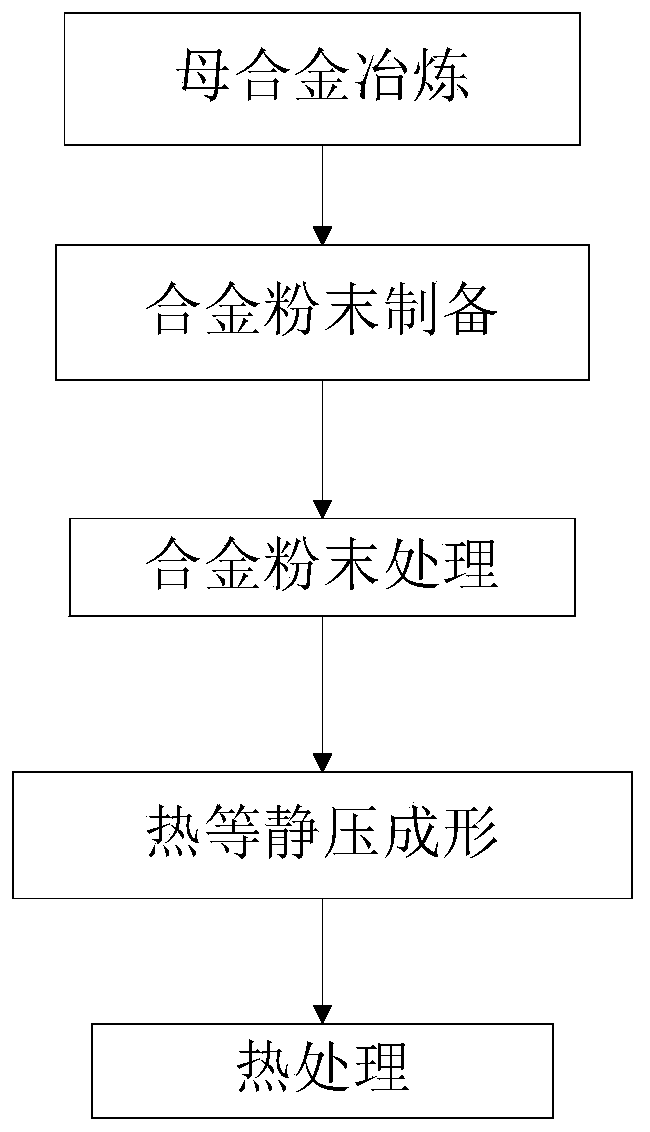

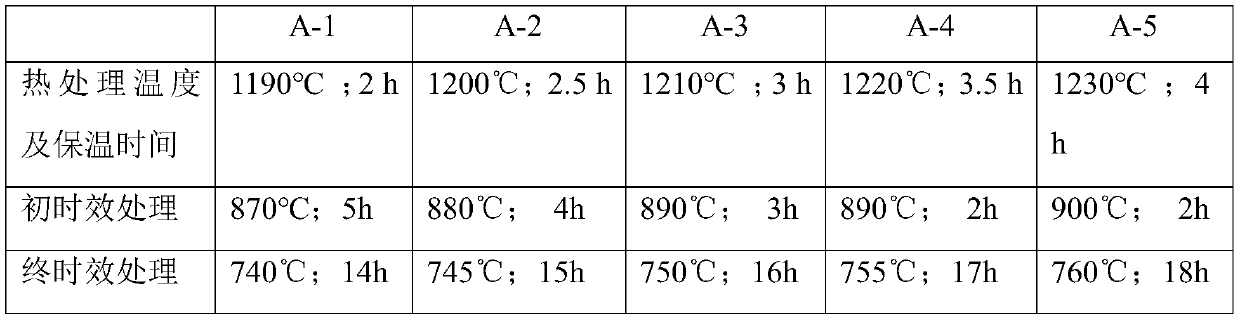

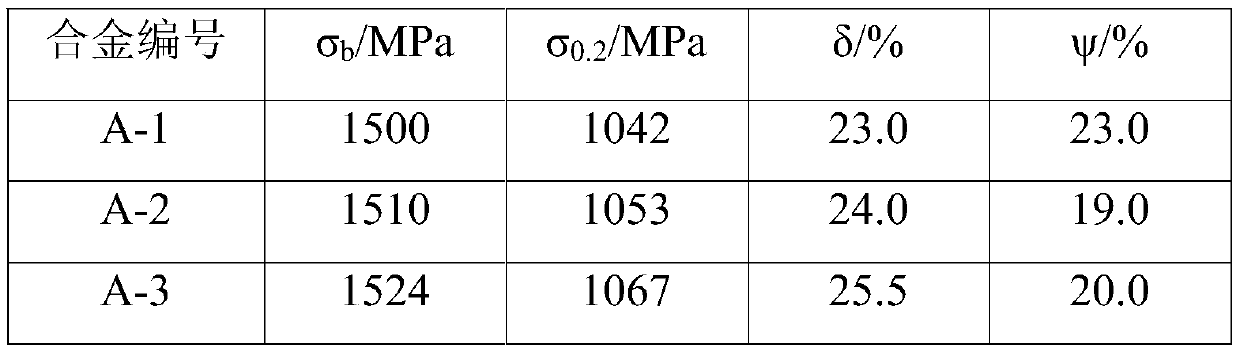

Nickel base powder high-temperature alloy with high tensile strength and preparation method thereof

ActiveCN110205523AImprove high temperature durabilityImprove acceleration performanceUltimate tensile strengthTurbine

The invention relates to a nickel base powder high-temperature alloy with high tensile strength and a preparation method thereof, belongs to the technical field of high-temperature alloys, and solvesthe technical problems of strict requirements on high-temperature alloy materials by such hot end parts as turbine discs in traditional engines and incapability of meeting the performance requirementsby traditional high-temperature alloy materials. The powder high-temperature alloy comprises the following chemical components in percentage by mass: 0.04-0.08 of C, 17.0-19.0 of Co, 11.0-13.0 of Cr,6.0-6.7 of W, 4.3-5.0 of Mo, 4.9-5.4 of Al, 1.5-1.9 of Ti, 2.5-2.9 of Nb, 0.2-0.5 of Hf, B less than 0.03, Zr less than 0.03, Mg less than 0.005, Ce less than 0.002, and the balance of Ni and other inevitable impurities. The powder high-temperature alloy achieves high tensile strength and excellent high-temperature creep resistance and high-temperature endurance, and is mainly used for preparingsuch hot end parts as aeroengine turbine discs.

Owner:BEIJING CISRI GAONA TECH

Steel for high strength automobile axle housing for cold stamping and production method thereof

ActiveCN110669914AAvoid it happening againReduce loadFurnace typesHeat treatment furnacesStampingMaterials science

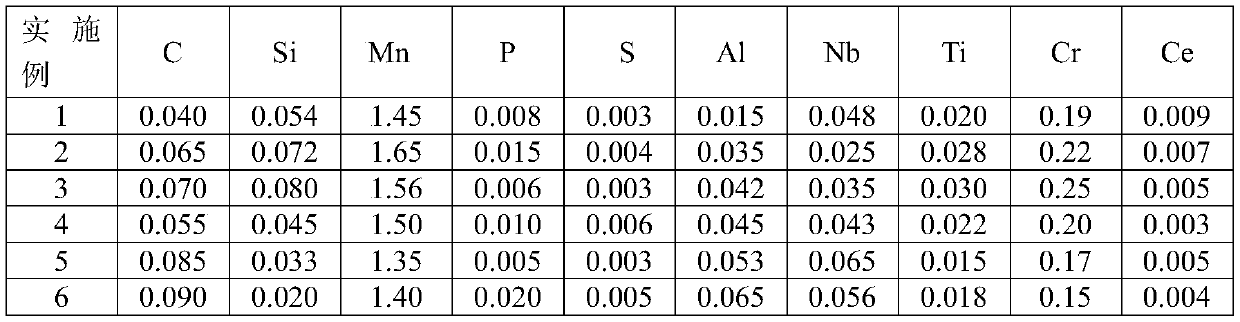

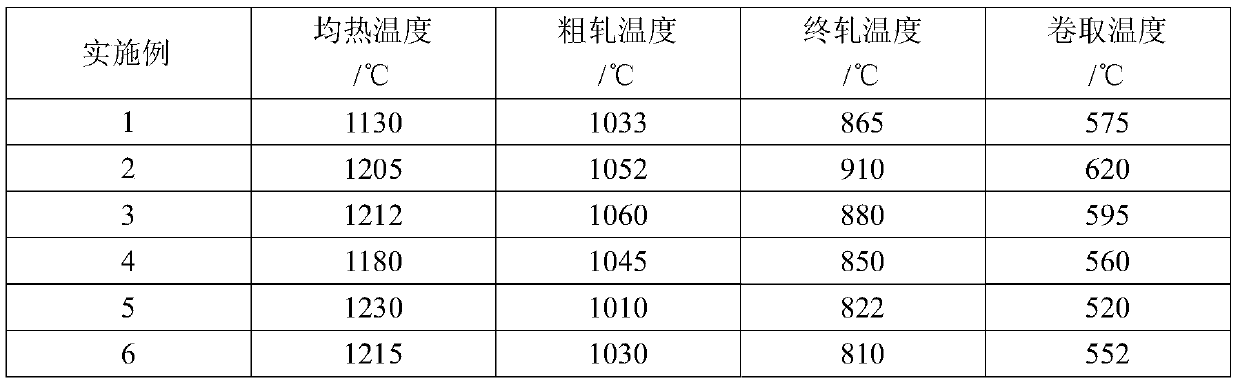

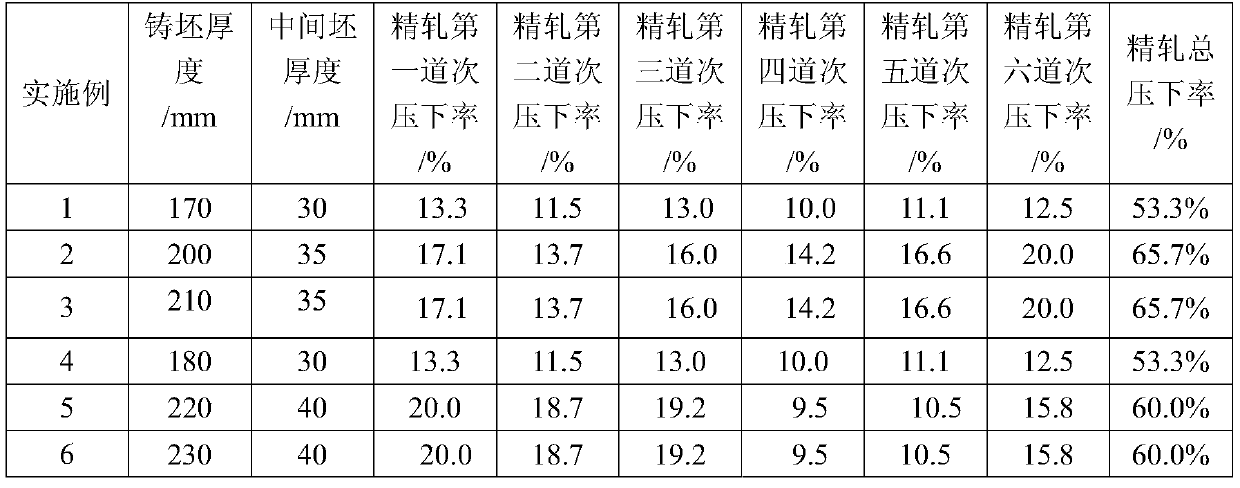

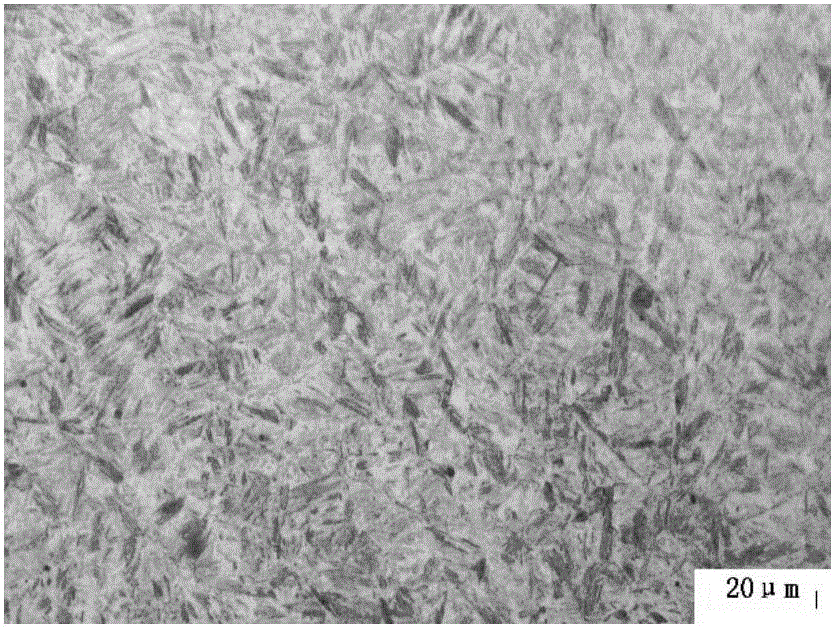

The invention provides steel for a high strength automobile axle housing for cold stamping and a production method thereof. The steel is prepared from the following components in percent by weight: 0.040-0.090% of C, 0.020-0.080% of Si, 1.35-1.65% of Mn, 0.010-0.065% of Al, 0.025-0.065% of Nb, 0.015-0.030% of Ti, 0.15-0.25% of Cr, 0.003-0.01% of Ce, less than or equal to 0.020% of P, less than orequal to 0.06% of S and the balance Fe and inevitable impurities. The production method comprises smelting, continuous casting, heating, rolling, cooling and coiling. A steel plate produced by the production method has relatively high ductility and impact value at high tensile strength of 710 MPa, and the transverse ductility A is greater than or equal to 31% and the impact value at 0 DEG C is greater than or equal to 172 J.

Owner:ANGANG STEEL CO LTD

Silicon vanadium steel plate with promoted bulletproof performance and manufacturing method

ActiveCN106319347APlay a role in precipitation strengtheningImprove ballistic performanceChemical elementSilicon

The invention relates to a silicon vanadium steel plate with promoted bulletproof performance and a manufacturing method. The bulletproof performance means the capacity of the silicon vanadium steel plate to resist against bullet shooting or glass breaking. The silicon vanadium steel plate can meet the practical requirements of stability and light weight. The silicon vanadium steel plate comprises the following chemical elements by weight percent: 0.28-0.43% of C, 0.3-2.0% of Si, 0.3-1.0% of Mn, 0.3-1.5% of Cr, 0.3-3.0% of Ni, 0.1-0.6% of Mo, 0.03-0.12% of V, not more than or equal to 0.03% of inevitable impurities and the balance of Fe.

Owner:国研(淮安)新材科技有限公司 +1

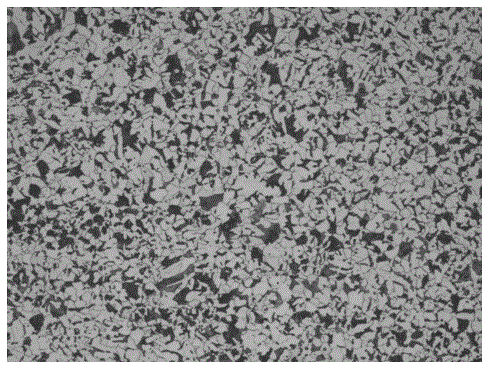

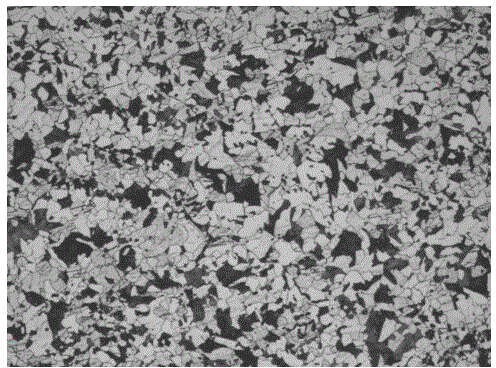

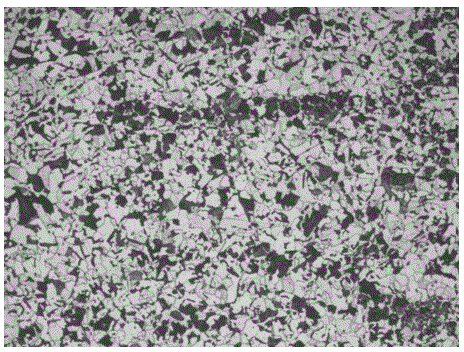

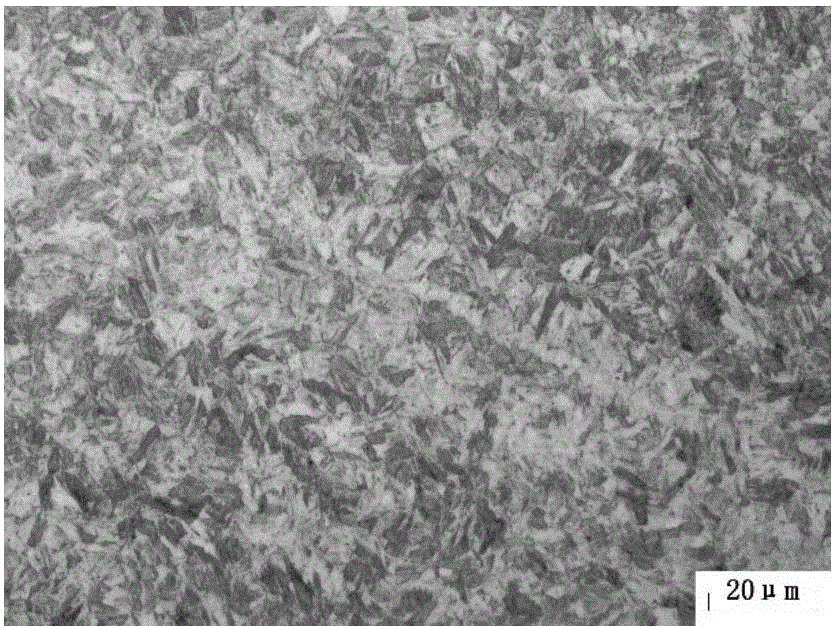

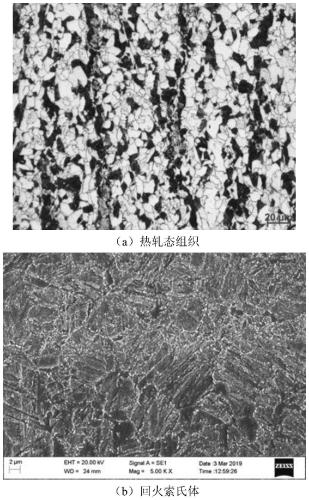

Low alloy high tenacity Q-P-T wear-resistant steel plate and manufacturing method thereof

The invention relates to the field of material heat treatment, and discloses a low alloy high tenacity Q-P-T wear-resistant steel plate and a manufacturing method thereof. The low alloy high tenacityQ-P-T wear-resistant steel plate comprises, by mass, 0.2-0.4% of C, 0.1-0.5% of Si, 0.5-1.5% of Mn, 0.5-1.2% of Cr, 0.1-0.3% of Mo, 0.02-0.08% of Ni, 0.04-0.1% of Cu, 0.001-0.008% of V, 0.01-0.04% ofTi, 0.01-0.05% of Nb, 0.001-0.003% of B, less than 0.015% of P, less than 0.005% of S, less than 0.006% of N, and the balance Fe and inevitable impurities. The low alloy high tenacity Q-P-T wear-resistant steel plate adopts the technique of Q-P-T heat treatment to manufacture the high tenacity wear-resistant steel. Microstructures are martensite, bainite, and retained austenite. Microalloy elements of V, Ti and Nb have effects of fine grain strengthening and precipitation strengthening. Therefore, the wear-resistant steel is good in abrasion performance, and high in tenacity.

Owner:UNIV OF SCI & TECH BEIJING

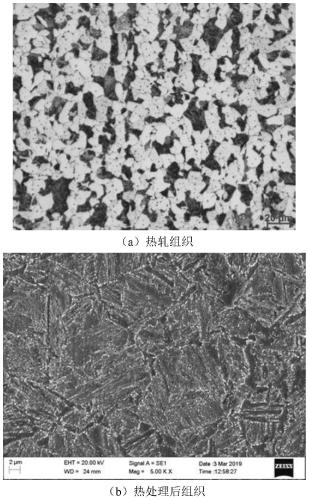

Low-temperature-resistant corrosion-resistant H-shaped steel with yield strength of 800 MPa and preparation method thereof

ActiveCN109972042AMeet the needs of usePlay a role in precipitation strengtheningChemical compositionMetallic materials

The invention discloses low-temperature-resistant corrosion-resistant H-shaped steel with the yield strength of 800 MPa and a preparation method thereof, and belongs to the technical field of metal material processing. The H-shaped steel comprises the following chemical components of, by mass, 0.10%-0.20% of C, 0.20%-0.40% of Si, 1.20%-1.60% of Mn, 0.2%-0.4% of Ni, 0.2%-0.6% of Cr, 0.06%-0.10% ofV, 0-0.04% of Nb, 0.01%-0.02% of Ti, 100-150ppm, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance Fe and inevitable impurities. The preparation process comprises the following steps of first blank preparing, second hot rolling and quenching and tempering treatment after hot rolling, wherein the hot rolling temperature is 1180-1150 DEG C, the final rolling temperature is 800 DEG C-890 DEG C, the quenching treatment temperature is 900 DEG C, the cooling speed is 30-100 DEG C / s, and the tempering treatment temperature is 450-600 DEG C. The obtained H-shaped steel has the yield strength larger than or equal to 800 MPa, the tensile strength of 860-940 MPa, the elongation rate after fracture larger than or equal to 14.0, and the low-temperature impact at minus20 DEG C larger than or equal to 50J.

Owner:UNIV OF SCI & TECH BEIJING

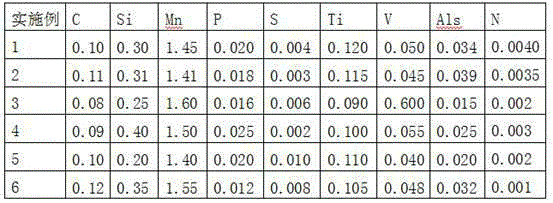

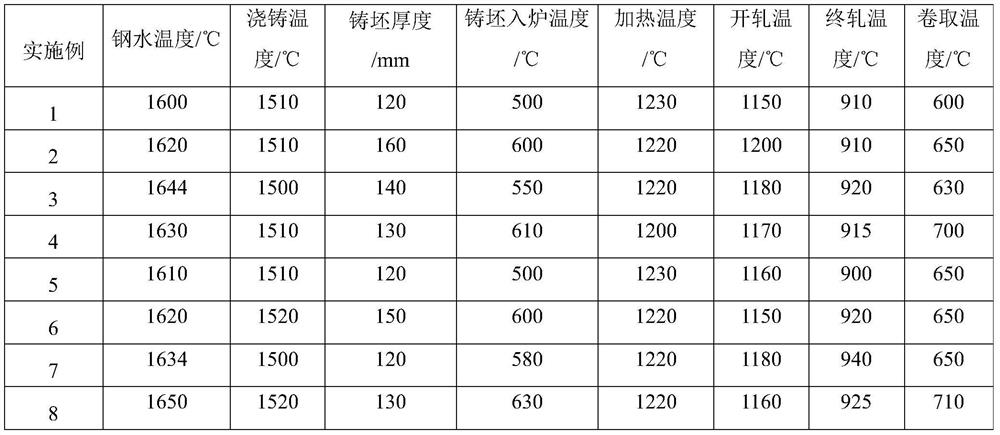

800MPa grade automobile box steel and production method thereof

The invention discloses an 800MPa grade automobile box steel and a production method thereof. The production method comprises the steps of heating, rough rolling, finish rolling, cooling and coiling; the slab adopted contains the following components in percentage by mass: 0.08-0.12% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, less than or equal to 0.025% of P, less than or equal to 0.010% of S, 0.040-0.060% of V, 0.090-0.120% of Ti, greater than or equal to 0.015% of Als, less than or equal to 0.004% of N and the balance of Fe and inevitable impurities. The steel is strengthened by both vanadium and titanium and a precipitation strengthening effect can be developed more thoroughly, and the overall properties of the steel plate can be improved; besides, the load of rolling can be reduced thoroughly and the production difficulty can be reduced; the steel has the characteristics of low cost, high quality and easiness in machining. According to the method, the precipitation of carbon and carbonitrides, the recrystallization of the austenite and the deformation state of the austenite are controlled by controlling the tapping temperature of the rolled steel, the temperature of the intermediate slab, the finish rolling temperature and the coiling temperature; the strength index and the overall properties of the obtained product are guaranteed, and the product is low in production cost and easy to machine.

Owner:HEBEI IRON AND STEEL

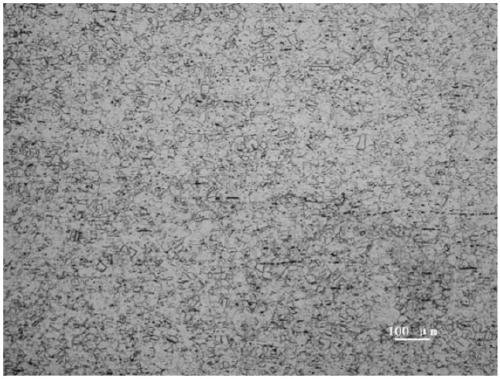

Low-cost high-strength low nickel austenitic stainless steel and manufacturing method thereof

The invention relates to a low-cost high-strength stainless steel and a manufacturing method thereof. The stainless steel comprises the following the chemical components by weight percentage: 0.05-0.15% of C, 0.2-1.0% of Si, 7-12% of Mn, 14-16% of Cr, 1. 0 to 2.0% of Ni, less than or equal to 0.045% of P, less than or equal to 0.02% of S, 0.1-0.2% of N, 1.0-2.0% of Cu, and 0.05-0.2% of Al, and thebalance of Fe and inevitable impurities. By adding an Al element and controlling the content of Al in the steel, and under small deformation variable, only a small amount of martensite is induced when the steel is subjected to deformation (the formation of a large amount of martensite increases the delayed cracking sensitivity of the steel), high plasticity and elongation percentage can achieve more than 30%, and due to three effects of the precipitation strengthening of AlN and the deformation strengthening and phase-transformation strengthening of steel, the yield strength of steel is morethan 800 MPa, and the tensile strength is above 1000 MPa, the stainless steel meets the requirements of high strength and high plasticity of an automobile frame and an automobile beam steel and structural parts, and achieves the objects of lightweight, high safety performance and high corrosion resistance of automobiles.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High magnesium-manganese-chromium-cobalt-aluminum alloy for manufacturing welding wires and preparation method thereof

ActiveCN109732239AHigh strengthIncrease Mg contentWelding/cutting media/materialsSoldering mediaHigh magnesiumTrace element

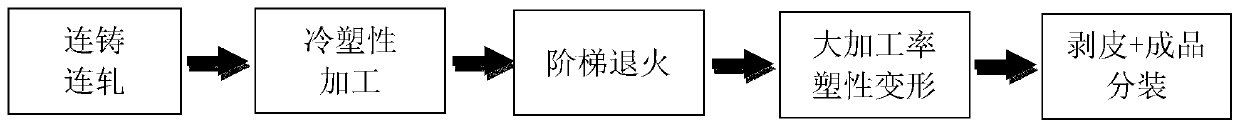

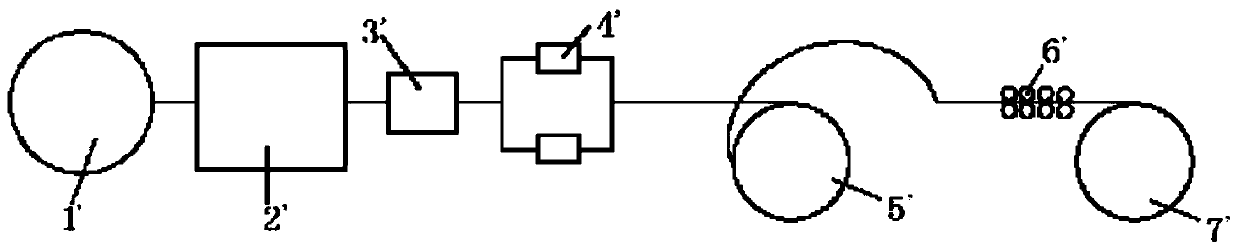

The invention discloses a high magnesium-manganese-chromium-cobalt-aluminum alloy for manufacturing welding wires and a preparation method thereof. The the alloy is characterized by comprising the following components of, in percentage by weight, 4.5-7.5 wt% of magnesium, 0.0005-0.85 wt% of manganese, 0.1-1.0 wt% of chromium, 0.01-0.10 wt% of zirconium, 0.005-0.1 wt% of cobalt, 0.0005-0.01 wt% oftrace elements W1, 0.0001-0.01wt% of trace elements W2, less than 0.001 wt% of any one element in Li, Na, K, Ca, Rb, and Cs, the balance aluminum and inevitable impurity elements. A blank rod is manufactured by adopting a continuous casting continuous rolling process for the high magnesium-manganese-chromium-cobalt-aluminum alloy, multi-pass plastic processing, stepped annealing, peeling, and split-packaging process are carried out to manufacture a finished product, the manufactured finished product is little in splashing during welding, the performance is stable, the strength of the weld joint is improved, the cost is appropriate, and the method has a wide market application prospect.

Owner:NINGBO BODE HIGHTECH CO LTD

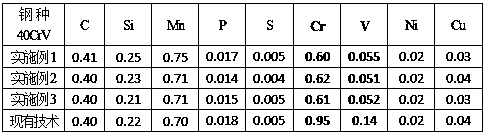

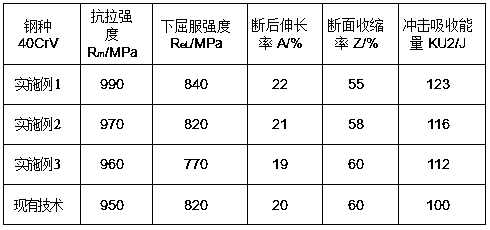

Low-cost 40CrV tool steel and production method thereof

The invention discloses low-cost 40CrV tool steel and a production method thereof. The low-cost 40CrV tool steel is prepared from the following components in percentage by weight: 0.38%-0.43% of C, 0.15%-0.35% of Si, 0.60%-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, less than or equal to 0.20% of Cu, 0.50%-0.70% of Cr, 0.05%-0.08% of V, 0.010%-0.030% of Al, less than or equal to 0.04% of Ti and the balance of Fe. According to the composition ratio and the production method of the low-cost 40CrV tool steel, through the perfect combination of the optimizeddesign of the chemical components, the stable control of the steelmaking and steel rolling production processes and the controlled rolling and controlled cooling technology (rolling parameters), the smelting process, the starting and finishing rolling temperatures and the cooling mode of the formula are strictly controlled to realize the production of the low-cost 40CrV tool steel.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

500E Australian standard wire and production method thereof

InactiveCN104213018AIncrease dislocation resistanceHigh yield strengthTransition temperatureAustenite

The invention discloses a 500E Australian standard wire and a production method thereof. The 500E Australian standard wire is produced by performing procedures of heating, rough rolling, finish rolling, spinning and cooling for a steel billet; the steel billet comprises the following components in percentage by mass: 0.18-0.22% of C, 0.20-0.40% of Si, 1.20-1.40% of Mn, P not higher than 0.035%, S not higher than 0.035%, 0.10-0.12% of V, 0.015-0.019% of N, and the balance of Fe and inevitable impurities. The contents of C, Si, and Mn are optimized and adjusted, and the microalloy element V is added, so that the precipitation temperature and the brittle transition temperature of carbonitride can be reduced, the strength, the toughness and the yield strength of the wire are effectively improved, and the 500E Australian standard wire with qualified performance indexes is obtained. The method controls the finish rolling temperature, the spinning temperature, the cooling speed and the coiling temperature of steel rolling to control the precipitation of the carbonitride, the recrystallization of austenite and the deformation state of the austenite to obtain the finally requested structure, so that the strength index and the performance deviation of a rolled product are guaranteed, and the wire product satisfying the Australian standard requirement is obtained.

Owner:HEBEI IRON AND STEEL

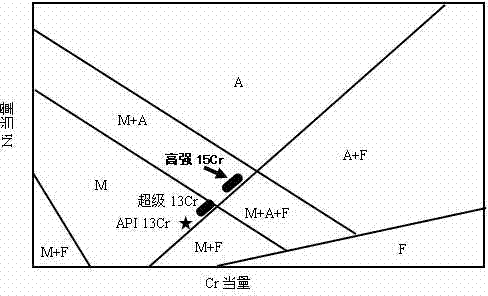

CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells

InactiveCN103938124AWith anti-H

<sub>2</sub>

S stress corrosion cracking performanceIncrease costRigid pipesMartensiteAntimony

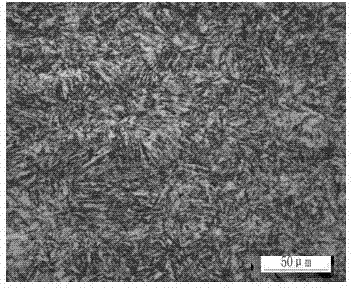

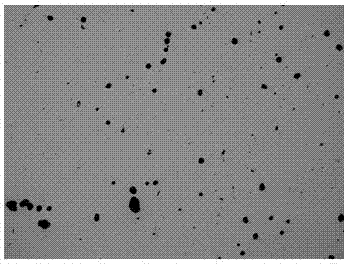

A CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells comprises the following compositions in percent by weight: carbon, <=0.03 wt%; silicon, 0.2-0.5 wt%; manganese, 0.2-0.6 wt%; phosphorus, <= 0.02 wt%; sulfur, <= 0.005 wt%; chromium, 14.5-15.3 wt%; molybdenum, 1.7-2.4 wt%; copper, 0.6-1.0 wt%; nickel, 6.5-7.5 wt%; tungsten, 0.4-0.7 wt%; titanium, 0.002-0.007 wt%; boron, 0.001-0.005 wt%; niobium, 0.04-0.09 wt%; vanadium, 0.03-0.07 wt%; nitrogen, 0.01-0.1%; oxygen, <= 0.001 wt%; hydrogen, <= 0.000005 wt%; controlled compositions: arsenic, <=0.03 wt%; antimony, <=0.03 wt%; and antimony, <=0.03 wt%; and the balance iron. According to the 15Cr oil pipe, the minimum yield strength is 925 MPa (125ksi steel grade), the critical usage temperature is 210 DEG C, the CO2 partial pressure can be 10 MPa or more, the Cl<-> concentration can be 120000 mg / L, the 15Cr oil pipe has certain H2S stress corrosion cracking resistant performance, and compared with a super II type 13Cr martensite stainless steel oil pipe material, the increased cost is not large.

Owner:XI'AN PETROLEUM UNIVERSITY

Shape memory alloy and preparation method thereof

InactiveCN101705440AGood shape memory effectInhibition of plastic deformationShape-memory alloyUltimate tensile strength

The invention provides a shape memory alloy and a preparation method thereof, belonging to the technical field of materials. The shape memory alloy comprises the following components in percent by weight: 14-15% of Mn, 6-7% of Si, 9-10% of Cr, 5-6% of Ni, 0.05-0.1% of C, and the balance of Fe. The preparation method of the shape memory alloy comprises the following steps: firstly, according to the weight percentages of all components of the shape memory alloy, respectively taking the following raw materials, such as ultra low carbon steel, Mn, Si, Cr and Ni, or respectively taking low carbon steel, Fe, Mn, Si, Cr and Ni; secondly, melting all raw materials except Mn by vacuum induction; and thirdly, adding Mn in the mixture and conducting melting in the inert gas and obtaining the shape memory alloy by natural cooling. The strength and recoverable strain of the shape memory alloy is obviously higher than those of the normal Fe-Mn-Si alloy, the corrosion resistance of the shape memory alloy is good, the recoverable strain of the shape memory alloy is 3% under a casting condition and is further increased after solution-quenching treatment; furthermore, the preparation process of the shape memory alloy is simple.

Owner:SHANGHAI JIAO TONG UNIV

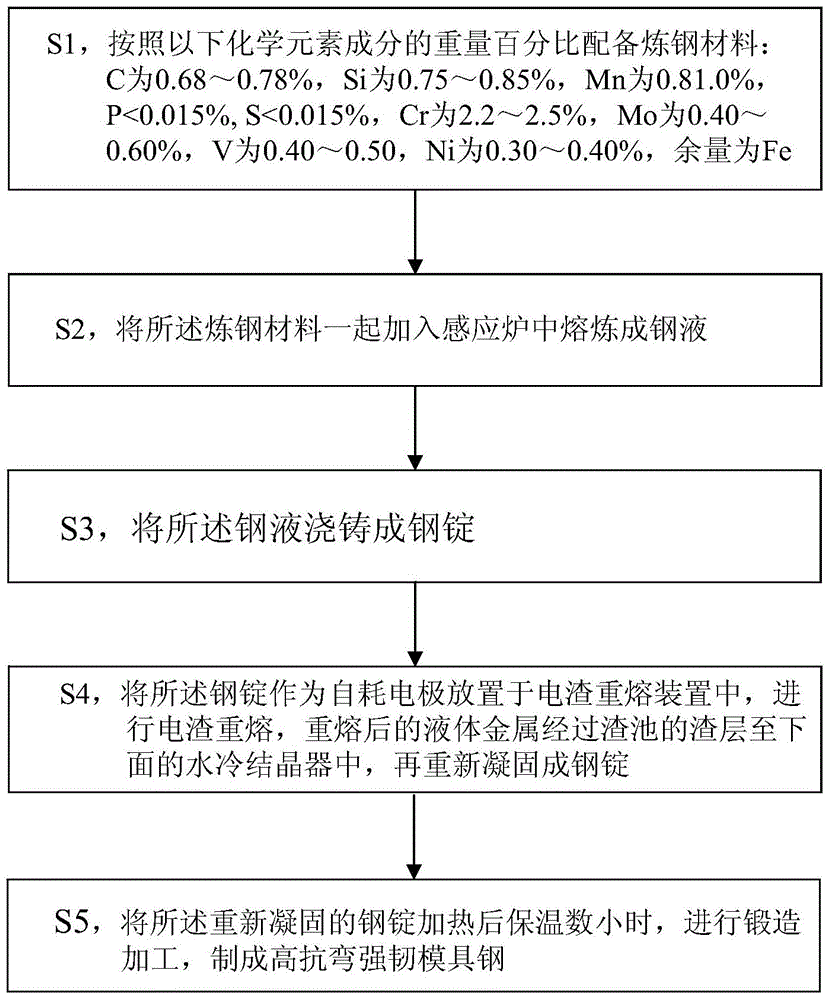

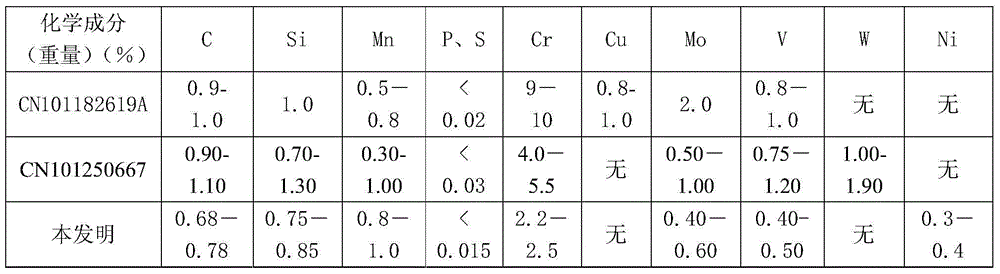

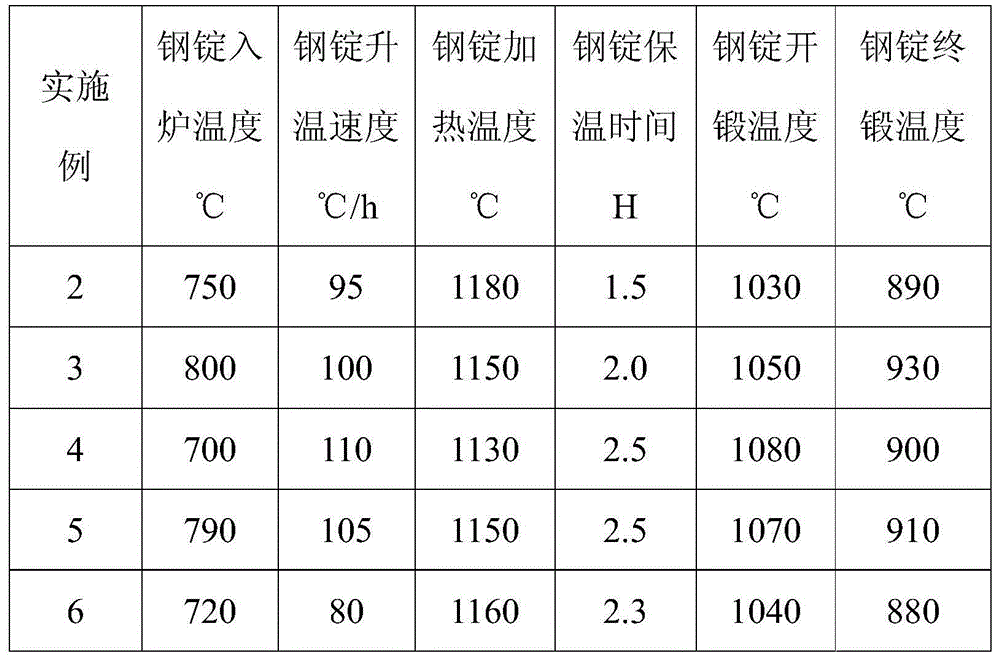

High-bending-resistance, high-strength and high-toughness die steel and manufacturing method thereof

The invention relates to high-bending-resistance, high-strength and high-toughness die steel and belongs to the technology of cold stamping die materials. The problem that existing die steel is poor in bending resistance and fracture preventing capacity is solved. The die steel comprises, by weight, 0.68%-0.78% of C, 0.75%-0.85% of Si, 0.8%-1.0% of Mn, less than 0.015% of P, less than 0.015% of S, 2.2%-2.5% of Cr, 0.40%-0.60% of Mo, 0.40%-0.50% of V, 0.30%-0.40% of Ni, and the balance Fe. Compared with the prior art, the die steel is advantageous in that the content of C, Cr, Mo, V, P and S is reduced, the content of Si is increased, the content of Ni is controlled, and thus the structure segregation condition of the steel is greatly relieved, and the bending resistance, fracture preventing capacity and other performance indexes of the high-strength and high-toughness cold work die steel are improved.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

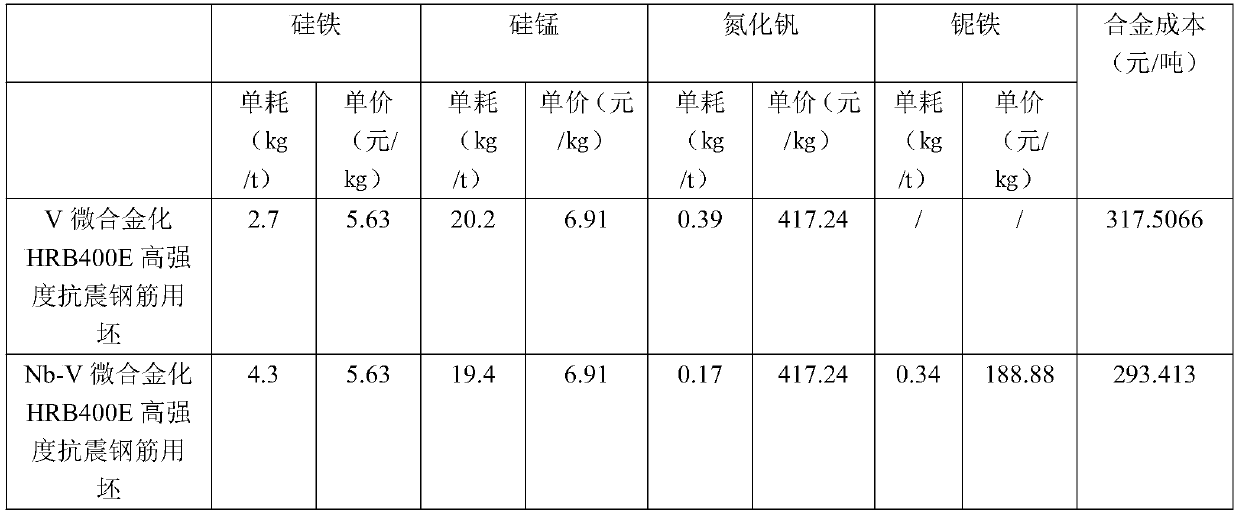

Production method of HRB400E high-strength anti-seismic steel bars containing vanadium element and niobium element and steel

The invention discloses a production method of HRB400E high-strength anti-seismic steel bars containing a vanadium element and a niobium element. The production method comprises the following steps that the dosage of each raw material is calculated according to the proportion of the elements of the steel bars to be prepared and the content of each element in the raw materials, and the raw materials are prepared for later use; a converter is shaken to a molten iron mixing position, scrap iron is added into the converter, molten iron is added again, and twice blowing is carried out until the temperature of the molten steel in the converter ranges from 1,670 DEG C to 1,680 DEG C, wherein the content of C element in the molten iron is greater than or equal to 0.06%, the content of P element isless than or equal to 0.035%, and the content of S element is less than or equal to 0.040%; tapping is carried out, and a steel ingot can be obtained by tapping and stabilizing for 5 to 10 minutes; and continuous casting and rolling are carried out in sequence to obtain the niobium-vanadium micro-alloyed HRB400E high-strength anti-seismic steel bars. According to the production method, on the premise of ensuring the strength of the steel bars, the use amount of V element in the high-strength anti-seismic steel bars is reduced, so that the production cost is further reduced.

Owner:SHAANXI LONGMEN IRON & STEEL

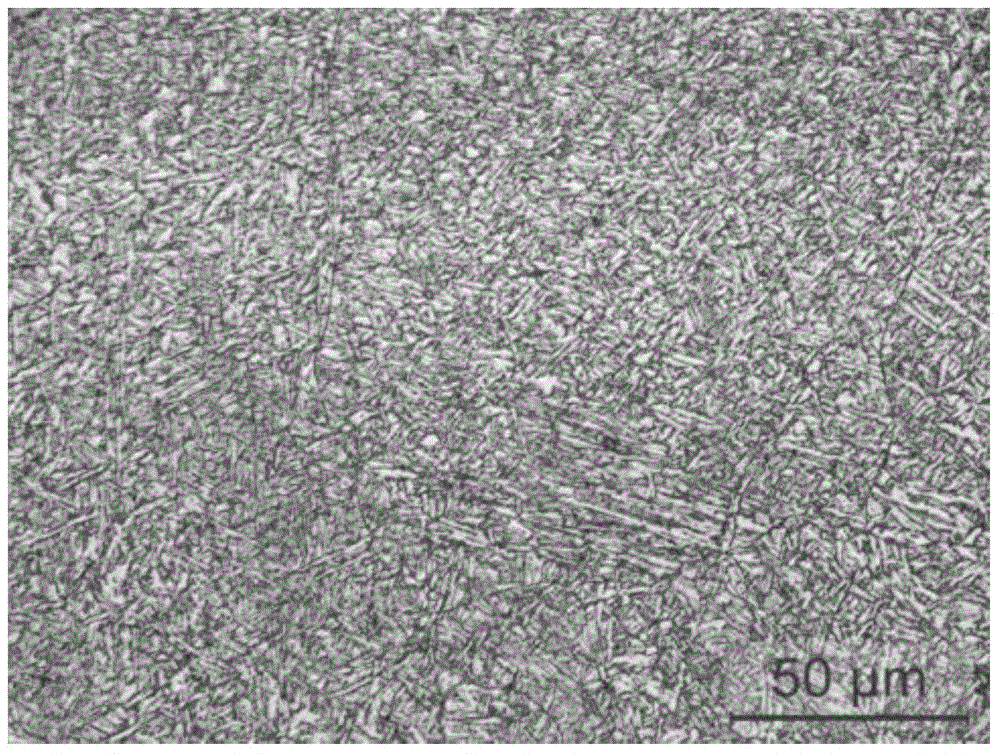

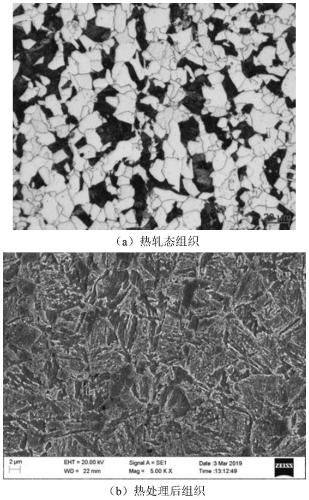

800MPa-grade hot-rolled complex-phase steel and production method thereof

InactiveCN113481436AAchieving fine grain strengtheningRealized with fine grain strengtheningTemperature control deviceWork cooling devicesLaminar coolingHeating furnace

The invention relates to steel for manufacturing automobile structures, in particular to 800MPa-grade hot-rolled complex-phase steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.055%-0.112% of C, 0.08%-0.40% of Si, 1.15%-2.02% of Mn, 0.10%-0.30% of Al, 0.10%-0.62% of Cr, 0.0020%-0.0050% of B, 0.015%-0.056% of V and / or 0.030%-0.145% of Ti, less than or equal to 0.020% of P, less than or equal to 0.007% of S and the balance of Fe and inevitable impurities. The method comprises the following steps that (1) a continuous casting sheet billet with the thickness of 80-300 mm is placed in a heating furnace, and the temperature is kept for 5-6 hours; (2) a controlled rolling means is adopted, the rough rolling temperature is not higher than 1080 DEG C, the thickness of an intermediate billet is 25-50 mm, the finish rolling temperature is controlled, the thickness of a finished product is 2.0-5.0 mm, and the total reduction rate is larger than or equal to 80%; (3) after finish rolling, front-section rapid continuous stream cooling is adopted, and coiling is conducted; and (4) after being coiled, a steel plate immediately enters a slow cooling cover to be slowly cooled to 120 DEG C or below, the slow cooling speed is not larger than 15 DEG C / h, and a steel coil is taken out and air-cooled to the room temperature. The steel has high strength and good formability, and is suitable for manufacturing automobile structural parts, reinforcements and safety parts.

Owner:ANGANG STEEL CO LTD

Material for high-performance TBM cutter disc residue scraping plate and preparation method thereof

ActiveCN109338226AReduce temper brittlenessImprove hardenabilityCleaning using toolsProcess efficiency improvementChemical compositionHardness

The invention discloses material for a high-performance TBM cutter disc residue scraping plate and a preparation method thereof. The material comprises the chemical components of, by weight, 0.35%-0.45% of C, 0.80%-1.20% of Si, 1.10%-1.30% of Mn, 1.80%-2.45% of Cr, 0.70%-1.0% of Mo, 0-0.04% of S and P, and the balance Fe. The material hardness is improved significantly, a TBM cutter disc residue scraping plate prepared from the material through smelting-casting-annealing-quenching-tempering steps is good in toughness and high in hardness and has good abrasion resistance, service life of the TBM cutter disc residue scraping plate is prolonged, and the replacement deadline is prolonged.

Owner:中铁工程装备集团隧道设备制造有限公司

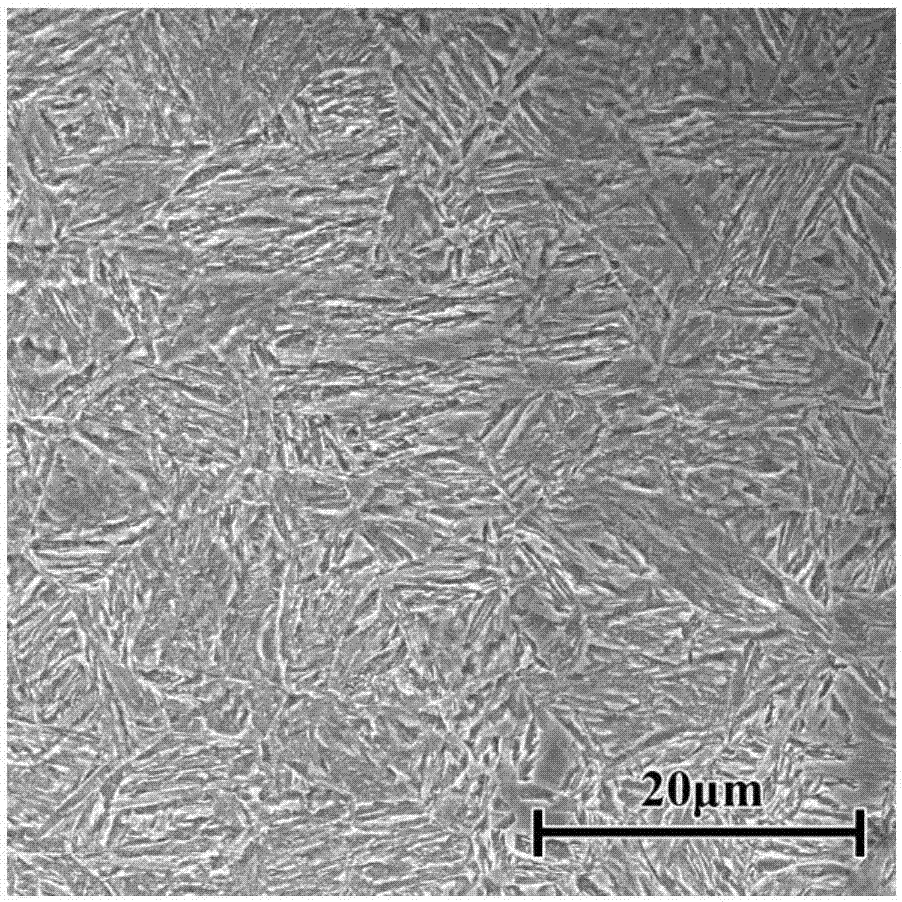

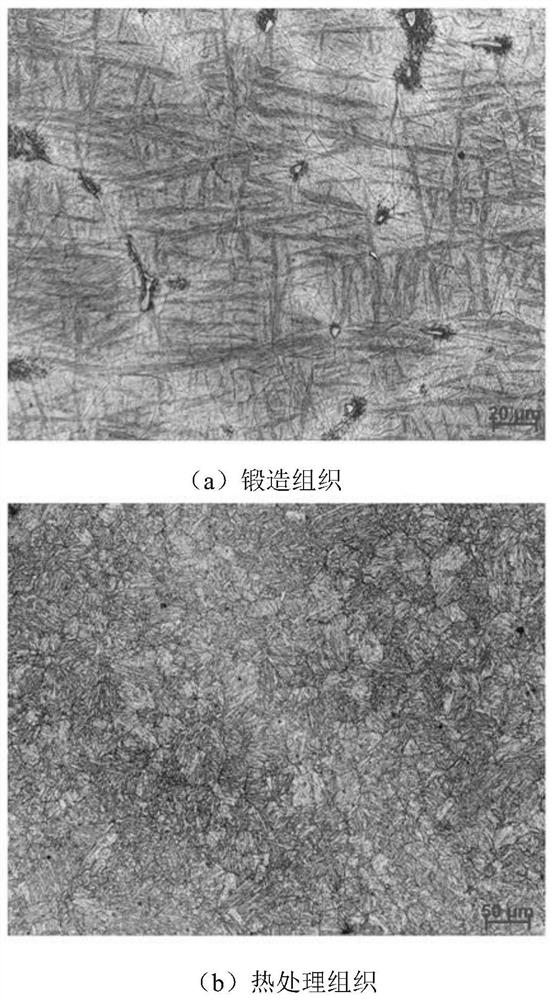

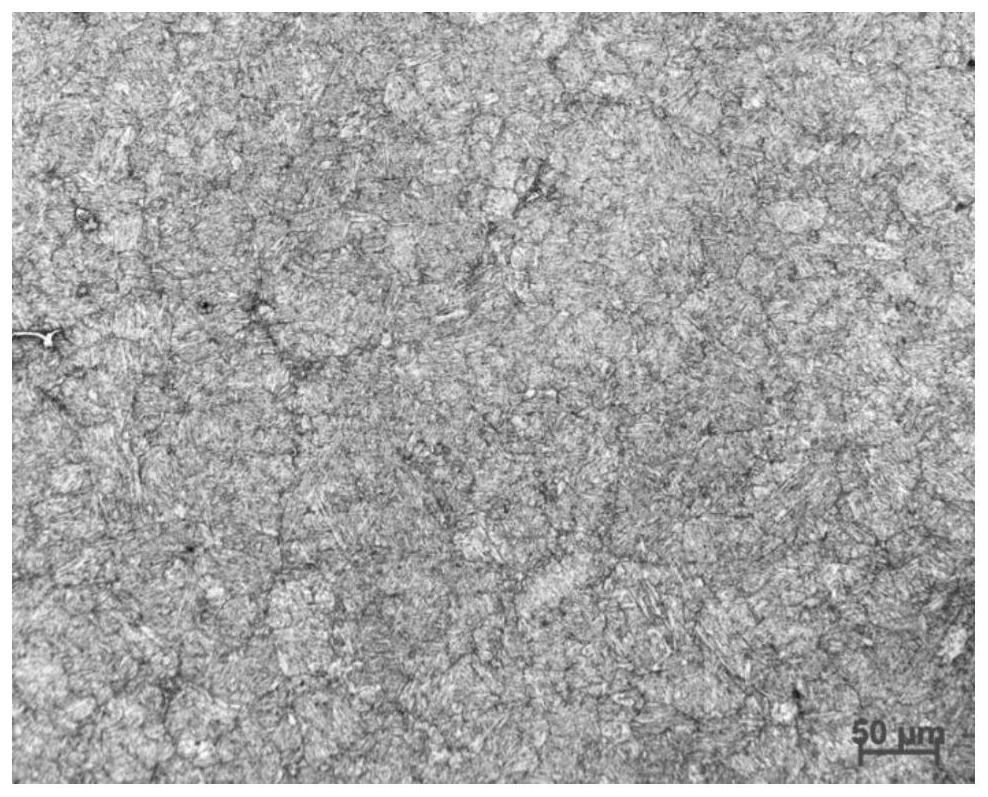

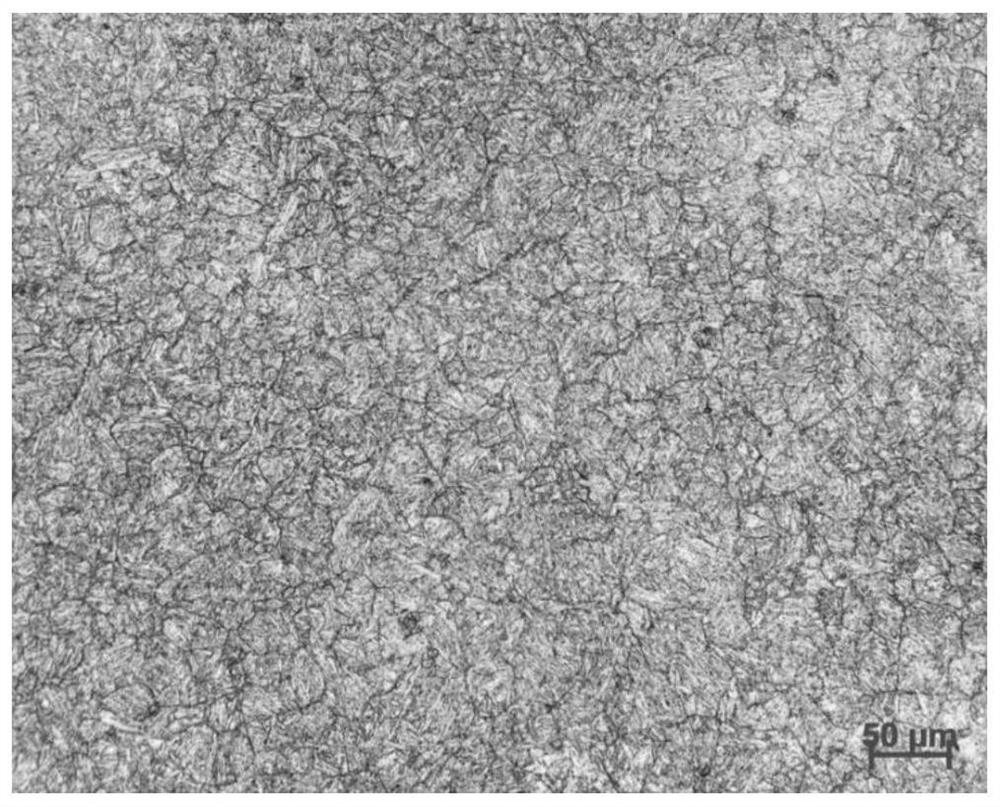

Steel for high-hardness shield cutter and manufacturing method thereof

The invention relates to steel for a high-hardness shield cutter and a preparation method thereof, and belongs to the field of alloy steel manufacture. The steel comprises the following alloy elementsof, in percentage by mass, 0.40-0.60% of C, 0.80-1.20% of Si, 0.20-0.60% of Mn, 4.00-6.00% of Cr, 1.10-1.30% of Mo, 0.45-1.0% of V, 0.30% of Ni, 0.10-0.60% of Ti, the balance Fe and inevitable impurity elements, wherein the content of S in the impurity elements is smaller than or equal to 0.005%, and the content of P in the impurity elements is smaller than or equal to 0.020%. The steel for the high-hardness shield cutter is forged, carbon is allocated to retained austenite through quenching and allocation heat treatment processes, finally, a martensite and retained austenite complex phase structure stable at the room temperature is obtained, the hardness can reach 55 HRC or above, the room-temperature impact energy exceeds 28 J, the tensile strength is 1800 MPa or above, and a good strength and toughness ratio is achieved. The obtained cutter steel has excellent impact resistance, the technological process is simple, the production period is shortened, energy conservation and environmental protection are achieved, the cost is reduced, and the enterprise competitiveness is improved.

Owner:UNIV OF SCI & TECH BEIJING

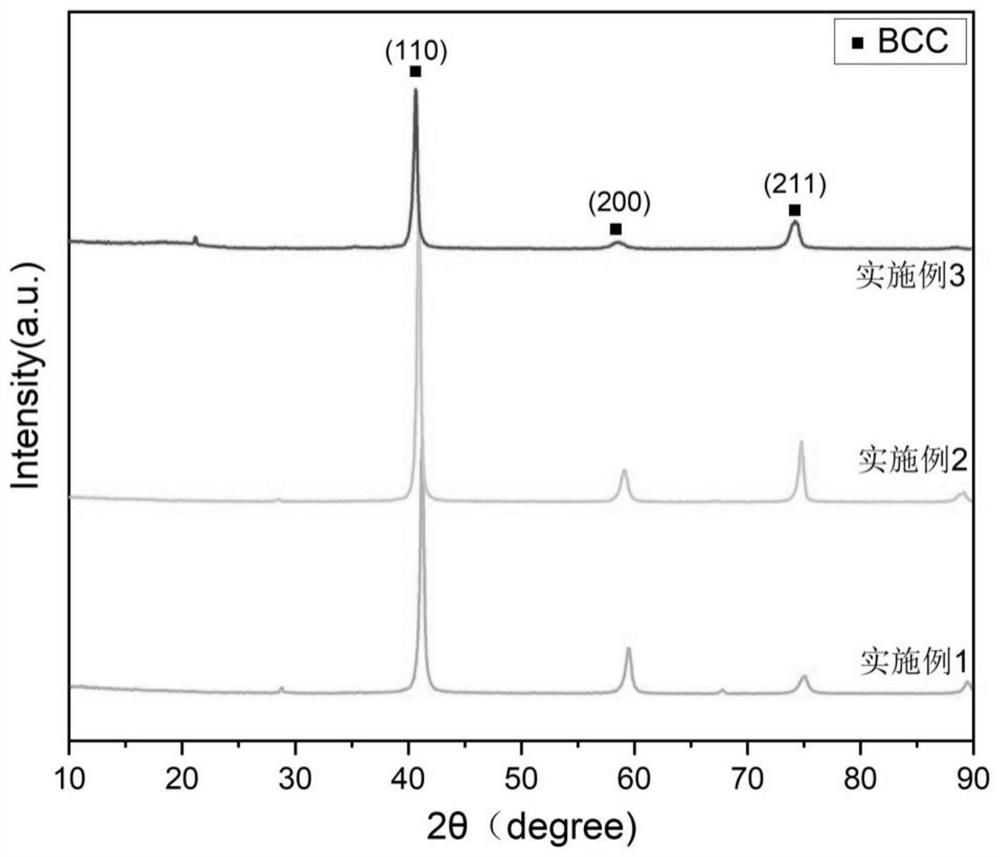

Refractory Al-Cr-Ti-V-Nb light high-entropy alloy and preparation method thereof

PendingCN114350989AHigh hardnessPlay a role in precipitation strengtheningHigh entropy alloysMetallic materials

The invention provides a refractory Al-Cr-Ti-V-Nb light high-entropy alloy and a preparation method thereof, and belongs to the field of metal materials and preparation. The refractory light-weight high-entropy alloy mainly comprises the following elements in percentage by atom: 22 to 25 percent of Al, 22 to 25 percent of Cr, 22 to 25 percent of Ti, 22 to 25 percent of V and 0 to 12 percent of Nb. And performing vacuum arc melting and direct casting to obtain an alloy ingot. According to the refractory high-entropy alloy, the components of the alloy are uniform, segregation and precipitation phases are avoided, the alloy is of a single BCC phase structure and shows high hardness, the hardness is 540 HV or above, the density is about 5.24 g / cm < 3 >-5.52 g / cm < 3 >, and compared with a traditional refractory high-entropy alloy, the refractory high-entropy alloy has the lower density. The alloy is subjected to homogenizing annealing, and the annealed alloy shows a typical amplitude-modulated decomposition structure of the refractory high-entropy alloy. The hardness is also improved, and the highest hardness can reach 631 HV. The preparation method has the advantages of no pollution, low energy consumption and low cost.

Owner:JIANGSU UNIV

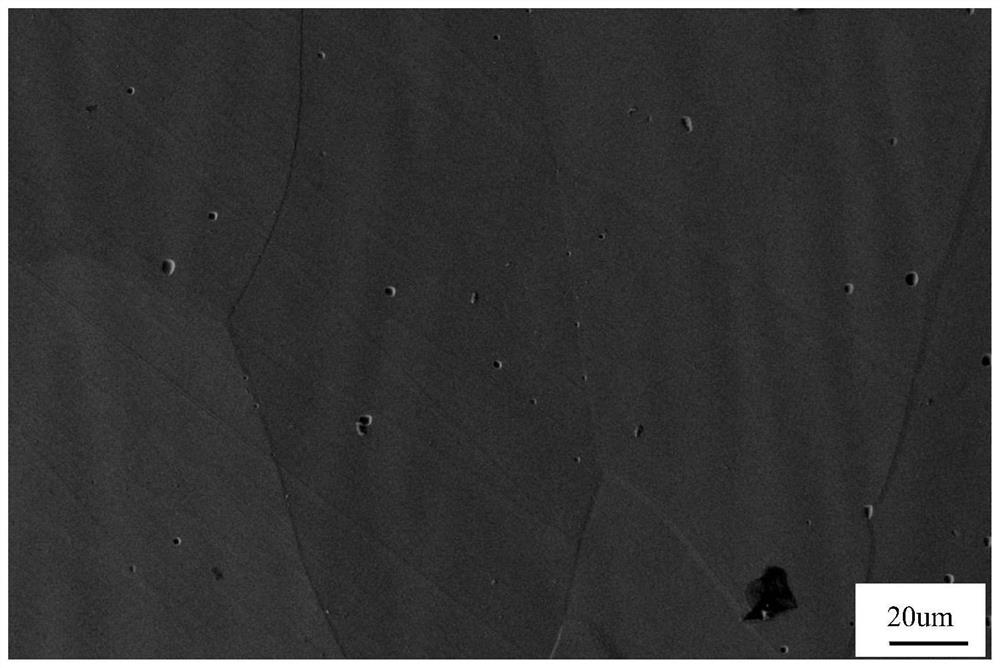

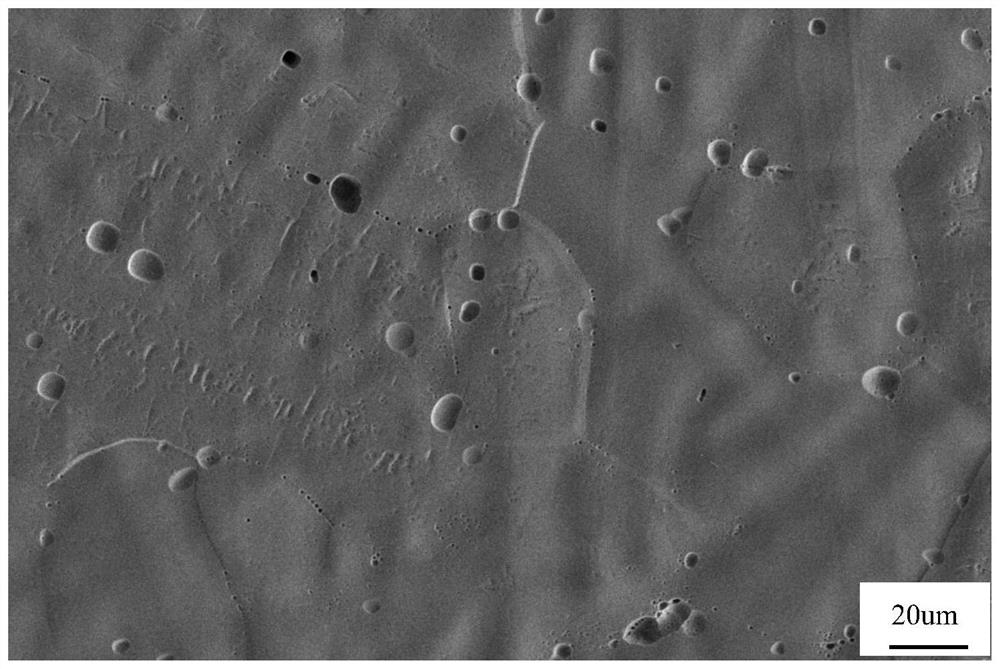

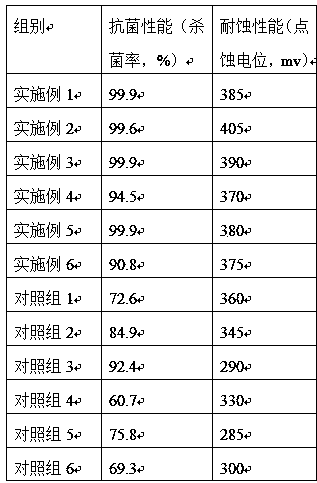

Preparation method of antibacterial corrosion-resistant stainless steel

ActiveCN109943781APlay a role in precipitation strengtheningImprove corrosion resistanceQuenching agentsHolmiumIngot

The invention belongs to the technical field of antibacterial stainless steel processing, and particularly relates to a preparation method of antibacterial corrosion-resistant stainless steel. The preparation method comprises the steps of preparing an alloy material, smelting a 304 stainless steel raw material sample and an alloy material to obtain an ingot, and carrying out heat treatment under an appropriate condition after multiple hot rolling. Compared with the prior art, the preparation method has the following advantages that in the preparation method, the alloy material is prepared froma copper ingot and a holmium ingot under a certain condition, then the alloy material and the 304 stainless steel raw material are simultaneously smelted to obtain the stainless steel material with asmaller grain size, and the stainless steel material is directly transferred into a bell-type furnace after final rolling, so that a plate is subjected to heat treatment under a certain condition, the dynamic recrystallization is carried out in a structure, and enough rich-phase copper is precipitated out by matching multi-stage cooling condition; the low-melting-point holmium ingot is added after being smelted with the copper ingot and can exist in the alloy as an intermetallic compound, therefore, the precipitation is strengthened, and meanwhile, good corrosion resistance is guaranteed, theuse value of the steel is increased, and the method is suitable for popularization.

Owner:TAIZHOU XINLONGXIANG METAL PROD

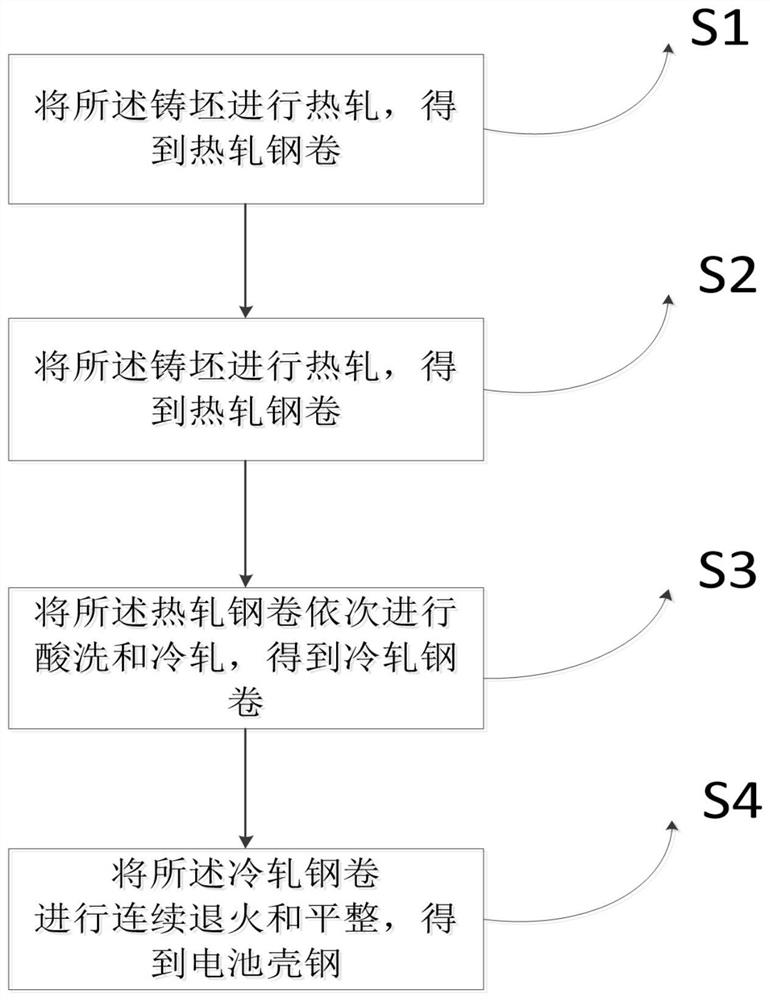

Low-cost well-formed battery shell steel and production method thereof

ActiveCN113774274AImprove toughnessExcellent formabilityCell component detailsSteelmakingUltimate tensile strength

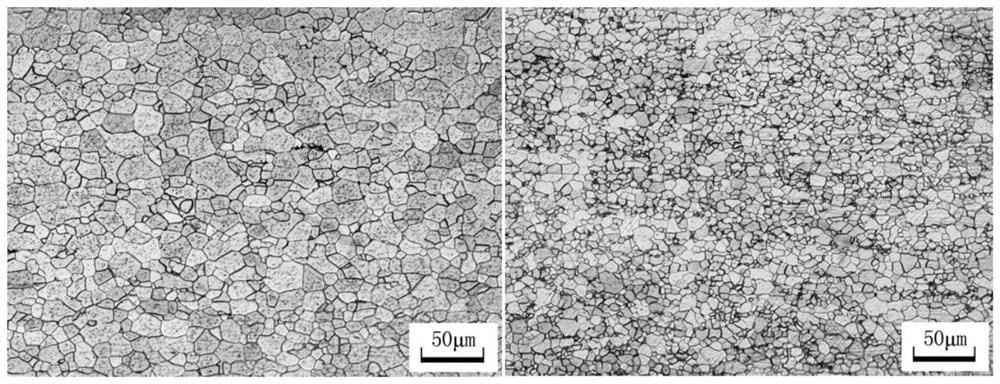

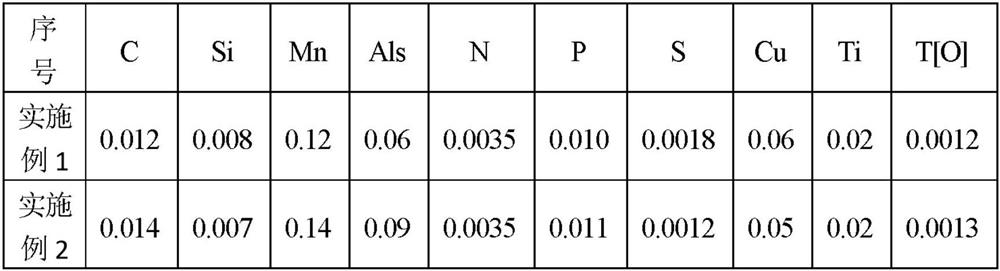

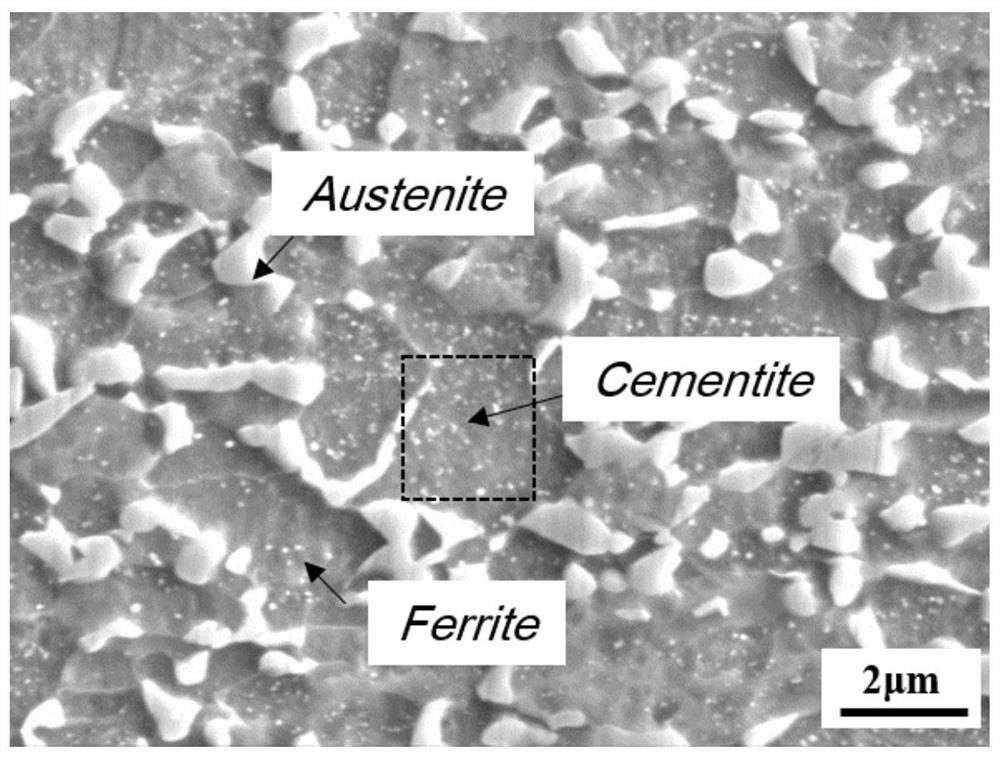

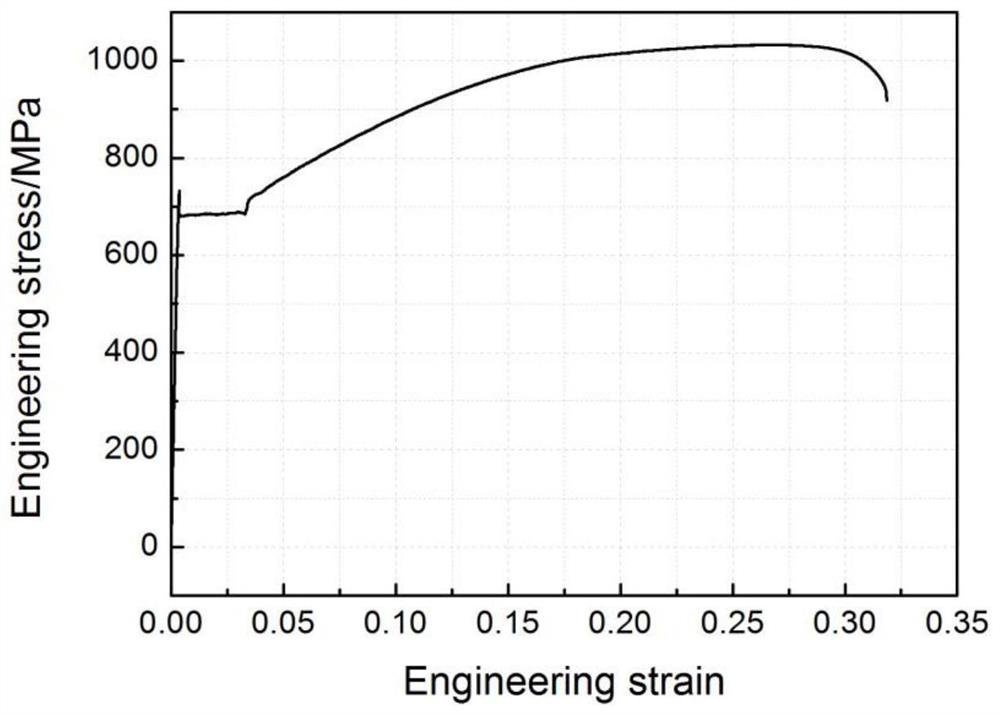

The invention relates to the field of iron and steel smelting, in particular to a low-cost well-formed battery shell steel and a production method thereof. The low-cost well-formed battery shell steel is prepared from components in percentage by mass, 0.008%-0.02% of C, 0.1%-0.3% of Mn, smaller than or equal to 0.01% of Si, 0.050%-0.10% of Als, smaller than or equal to 0.015% of P, smaller than or equal to 0.0020% of S, smaller than or equal to 0.004% of N, smaller than or equal to 0.01% of Cu, smaller than or equal to 0.01% of Ti, smaller than or equal to 0.002% of T [O] and the balance of Fe and inevitable impurities, wherein T [O] is an oxidation inclusion; T [O] in steelmaking is the content of oxidation series inclusions, the deoxidation time can be shortened, the inclusions in steel are reduced, and a steel plate formed through follow-up punch forming has more excellent machining forming performance; the steel toughness is improved, the steel anisotropy is reduced, and the process is matched, so that the steel has good yield strength elongation and good forming performance.

Owner:武汉钢铁有限公司

Deep-cold-rolled steel plate with high product of strength and elongation and preparation method

ActiveCN113186461AReduce the ratioImprove strong plasticityTemperature control deviceTRIP steelChemical composition

The invention relates to a deep-cold-rolled steel plate with high product of strength and elongation and a preparation method thereof. The steel comprises the following chemical components in percentage, by mass, 0.18%-0.25% of C, 0.3%-1.5% of Si, 2.8%-3.5% of Mn, 0.5%-1.5% of Al, less than or equal to 0.05% of P, less than or equal to 0.05% of S, 0.10%-0.15% of V and the balance of Fe and inevitable impurities, wherein the sum of Si and Al is less than or equal to 2.0%. Compared with traditional medium manganese steel, the alloy proportion of the low-manganese Mn-TRIP steel plate manufactured through deep cold rolling is greatly reduced, and the plasticity is remarkably improved; compared with a traditional cold-rolled structure, equiaxed ferrite obtained through deep cold rolling is obviously refined and is reduced to be smaller than 1 micron, and the yield strength of the steel plate is improved; meanwhile, VC precipitation is promoted, and the precipitation strengthening effect is achieved; and the austenite content is remarkably increased, the stability of room-temperature austenite is optimized, and the work hardening capacity of the steel plate is enhanced.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com