Low alloy high tenacity Q-P-T wear-resistant steel plate and manufacturing method thereof

A technology of Q-P-T and wear-resistant steel plate, which is applied in the direction of metal rolling, manufacturing tools, heat treatment equipment, etc., can solve the problems of insignificant improvement of toughness, unguaranteed hardness, complex process, etc., to reduce the formation and expansion of cracks , reduce weight and improve transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A low-alloy high-toughness Q-P-T wear-resistant steel plate, the mass percentage of its chemical composition is shown in Table 1.

[0027] Table 1 embodiment wear-resistant steel chemical composition (wt.%)

[0028]

[0029] The specific preparation process of the wear-resistant steel plate is as follows:

[0030] (1) Smelting and casting: each raw material is weighed respectively according to the design composition, mixed evenly, and smelted and casted to obtain a slab;

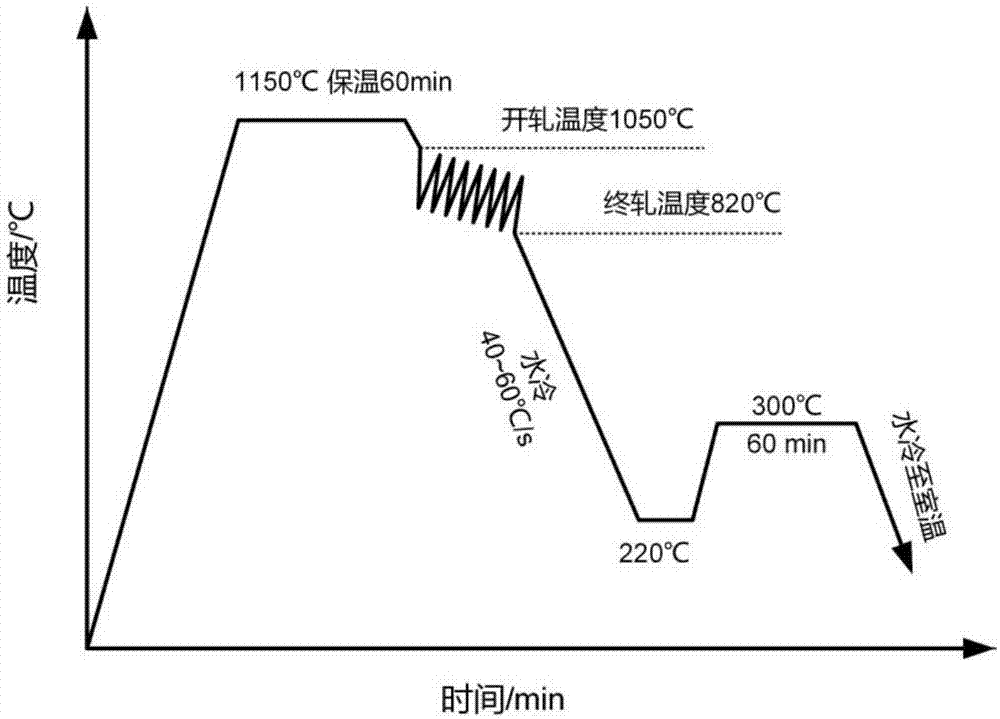

[0031] (2) Hot rolling process: heat the slab prepared in step 1 from room temperature to 1150° C., and keep it warm for 1 hour. The rolling start temperature is 1050° C., the hot rolling finish rolling temperature is 820° C., and the thickness of the hot rolled plate is 10 mm.

[0032] (3) Q-P-T heat treatment process: water-cool the hot-rolled slab to 220°C on the cooling line, and control the cooling rate at 40-60°C / s. Then the cooled slab is quickly sent to a constant temperature furnace at ...

Embodiment 2

[0039] A low-alloy high-toughness Q-P-T wear-resistant steel plate, the mass percentage of its chemical composition is shown in Table 1.

[0040] The specific preparation process of the wear-resistant steel plate is as follows:

[0041] (1) Smelting and casting: each raw material is weighed respectively according to the design composition, mixed evenly, and smelted and casted to obtain a slab;

[0042](2) Hot rolling process: heat the slab prepared in step 1 from room temperature to 1150° C., and keep it warm for 1 hour. The rolling start temperature is 1050° C., the hot rolling finish rolling temperature is 820° C., and the thickness of the hot rolled plate is 10 mm.

[0043] (3) Q-P-T heat treatment process: water-cool the hot-rolled slab to 220°C on the cooling line, and control the cooling rate at 40-60°C / s. Then the cooled slab is quickly sent to a constant temperature furnace at 350°C for tempering for 1 hour, and then cooled to room temperature.

[0044] Table 3 is a...

Embodiment 3

[0048] A low-alloy high-toughness Q-P-T wear-resistant steel plate, the mass percentage of its chemical composition is shown in Table 1.

[0049] The specific preparation process of the wear-resistant steel plate is as follows:

[0050] (1) Smelting and casting: each raw material is weighed respectively according to the design composition, mixed evenly, and smelted and casted to obtain a slab;

[0051] (2) Hot rolling process: heat the slab prepared in step 1 from room temperature to 1150° C., and keep it warm for 1 hour. The rolling start temperature is 1050° C., the hot rolling finish rolling temperature is 820° C., and the thickness of the hot rolled plate is 10 mm.

[0052] (3) Q-P-T heat treatment process: water-cool the hot-rolled slab to 220°C on the cooling line, and control the cooling rate at 40-60°C / s. Then the cooled slab is quickly sent to a constant temperature furnace at 400°C for tempering for 1 hour, and then cooled to room temperature.

[0053] Table 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com