Patents

Literature

179results about How to "Meet the conditions of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

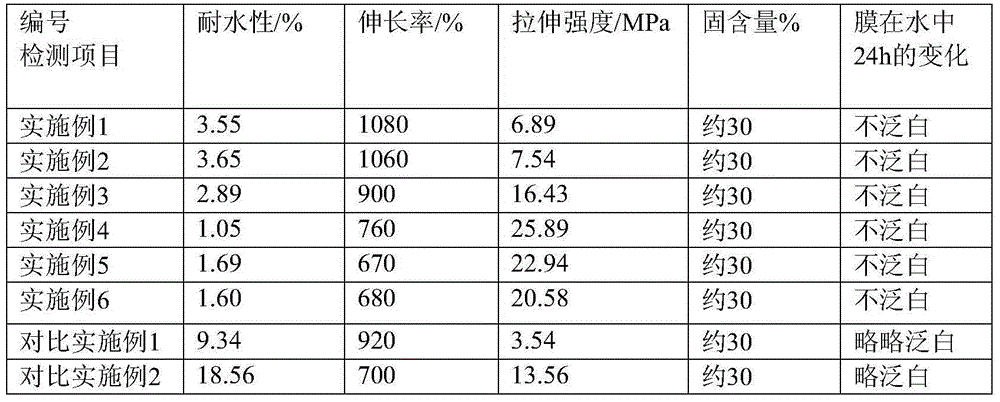

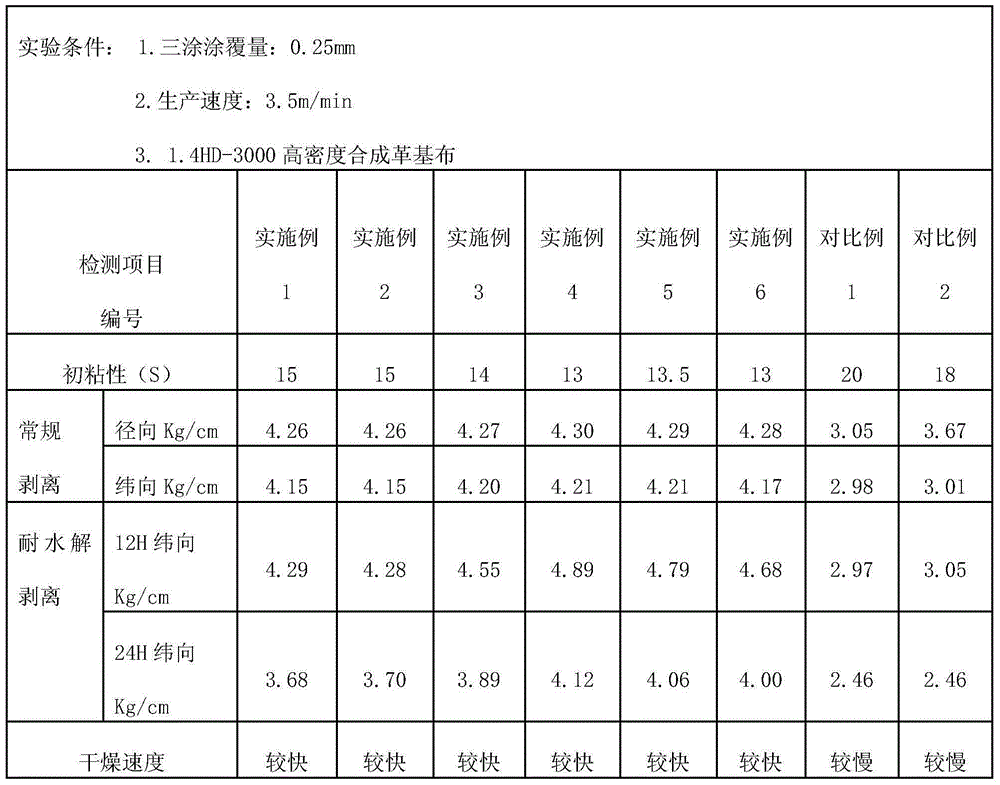

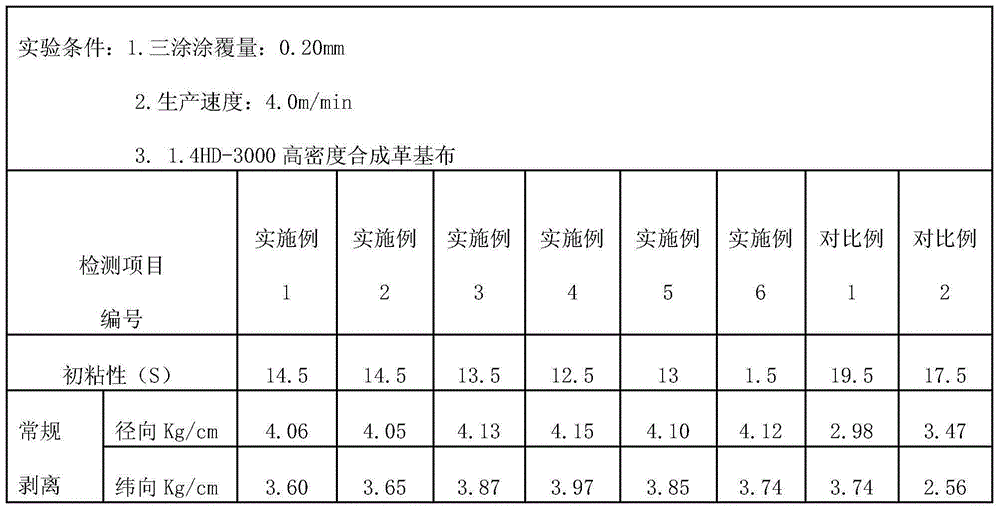

Synthetic leather binding agent and preparation method thereof

ActiveCN105062403AGood light fastnessImprove initial tack performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAlcohol

The invention provides a synthetic leather binding agent and a preparation method thereof. The synthetic leather binding agent is mainly prepared from polyhydric alcohol, diisocyanate, catalysts, epoxy resin and the like. According to the synthetic leather binding agent and the preparation method thereof, chemical modification is conducted on waterborne polyurethane through the epoxy resin, the high degree of branching of the epoxy resin is introduced into a main chain of polyurethane, and the initial adhesion, the peel strength, the drying rate and the water resistance of a dispersion liquid film are improved. The synthetic leather binding agent prepared through the method has good environment protectability. Dispersion liquid has the advantages of being high in initial adhesion, good in peel strength, high in drying rate and excellent in water resistance. Meanwhile, the good levelling property and spreadability are achieved. The using condition of the synthetic leather binding agent is met.

Owner:SHANDONG TIANQING TECH DEV

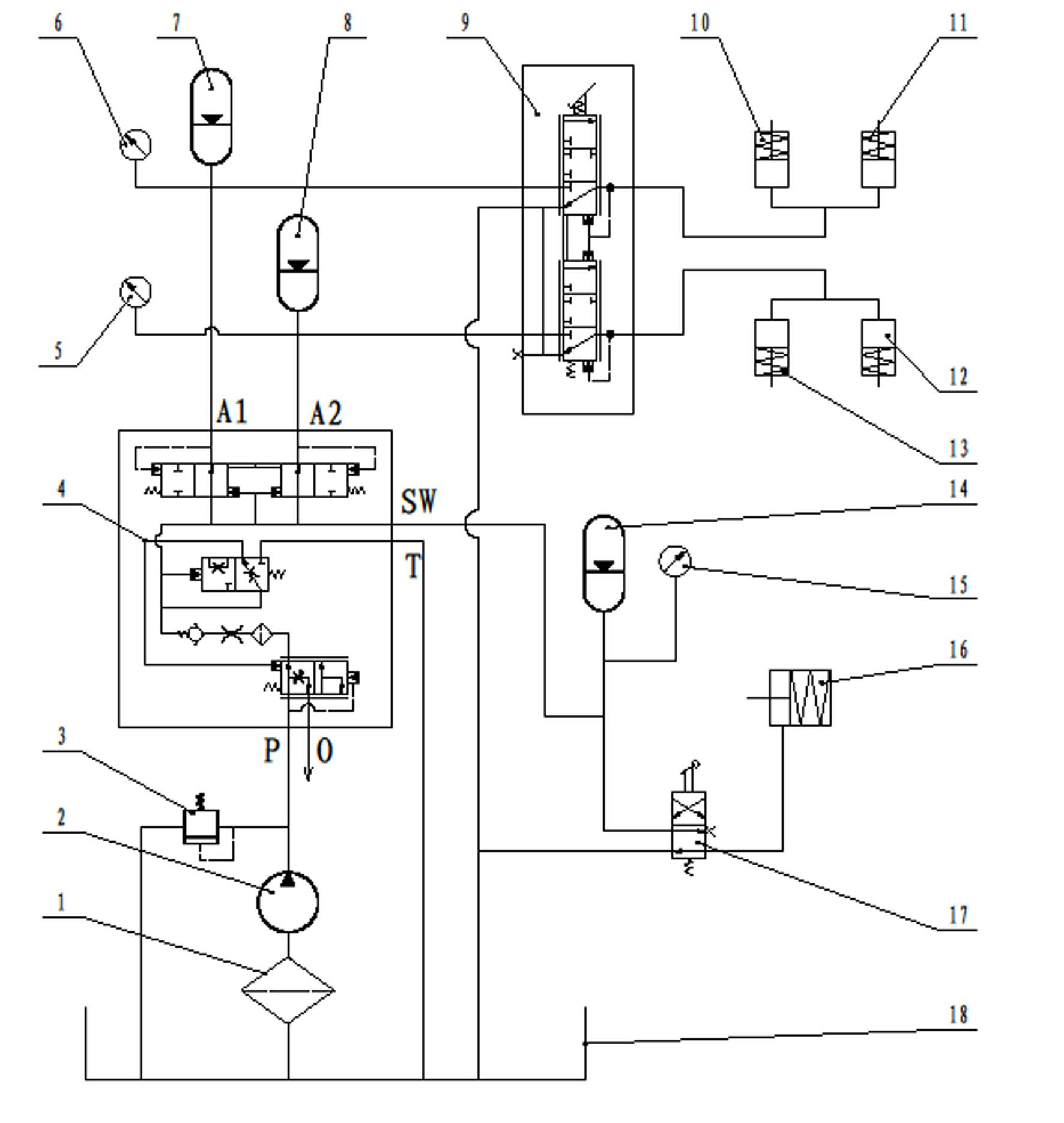

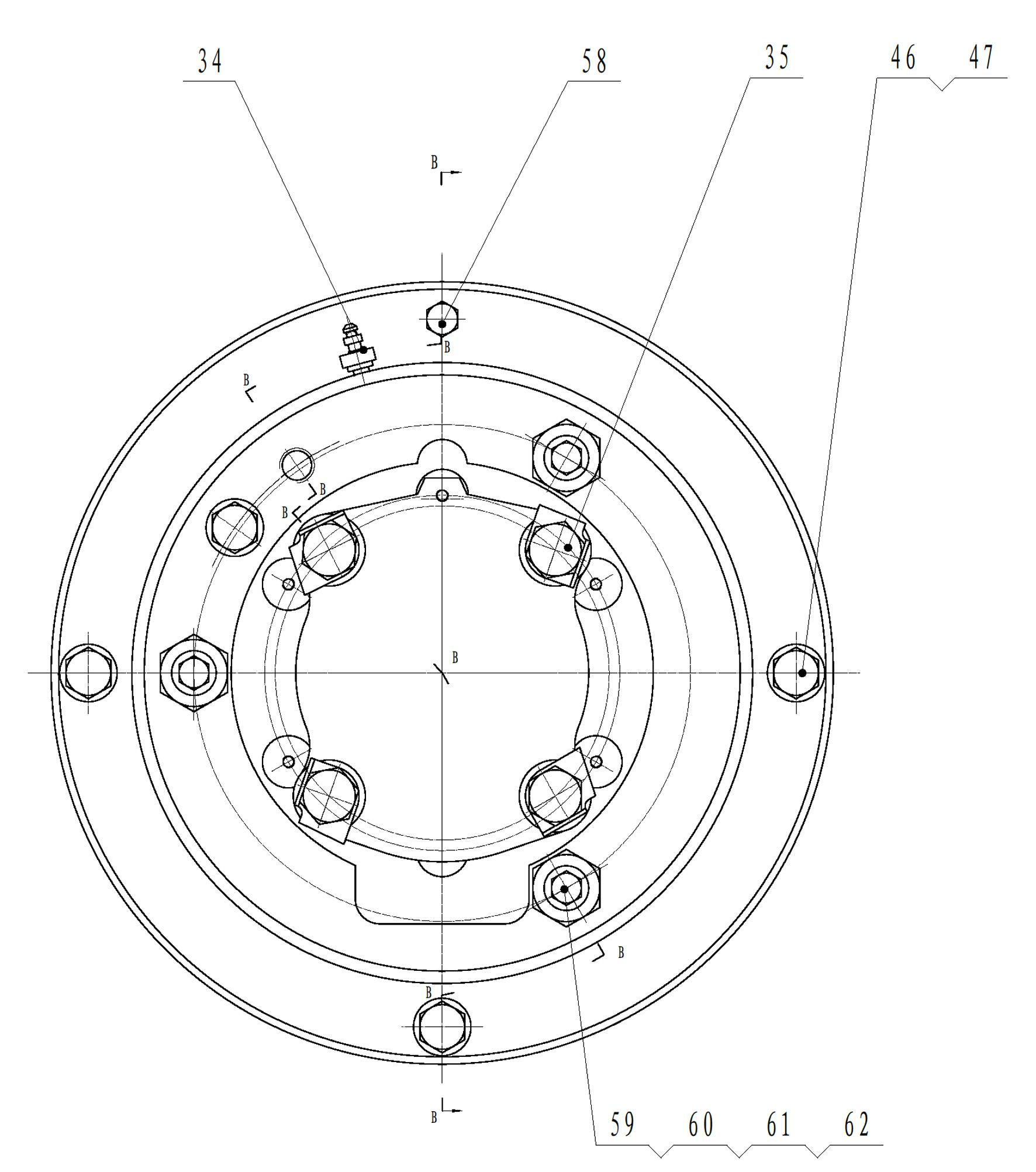

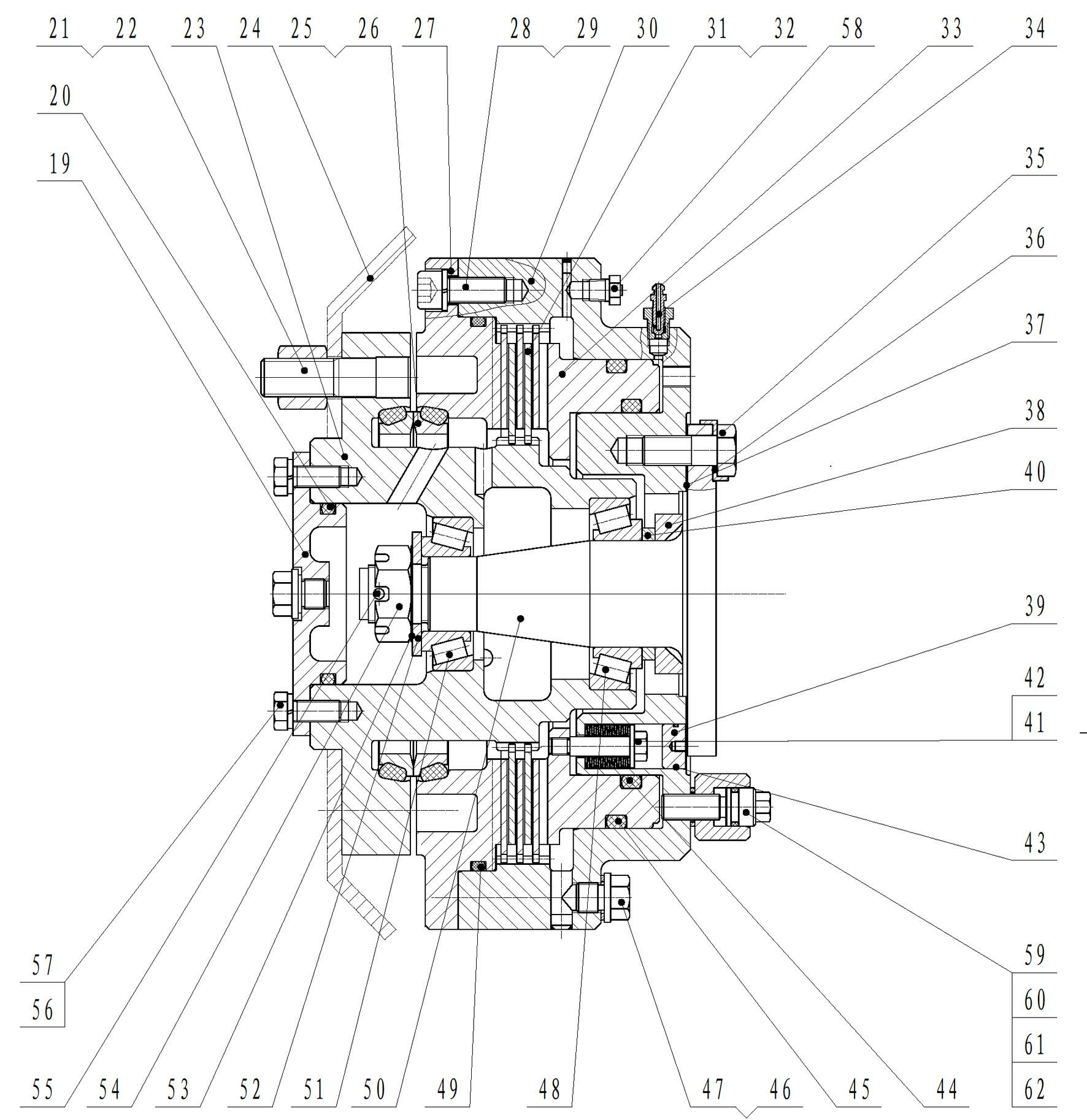

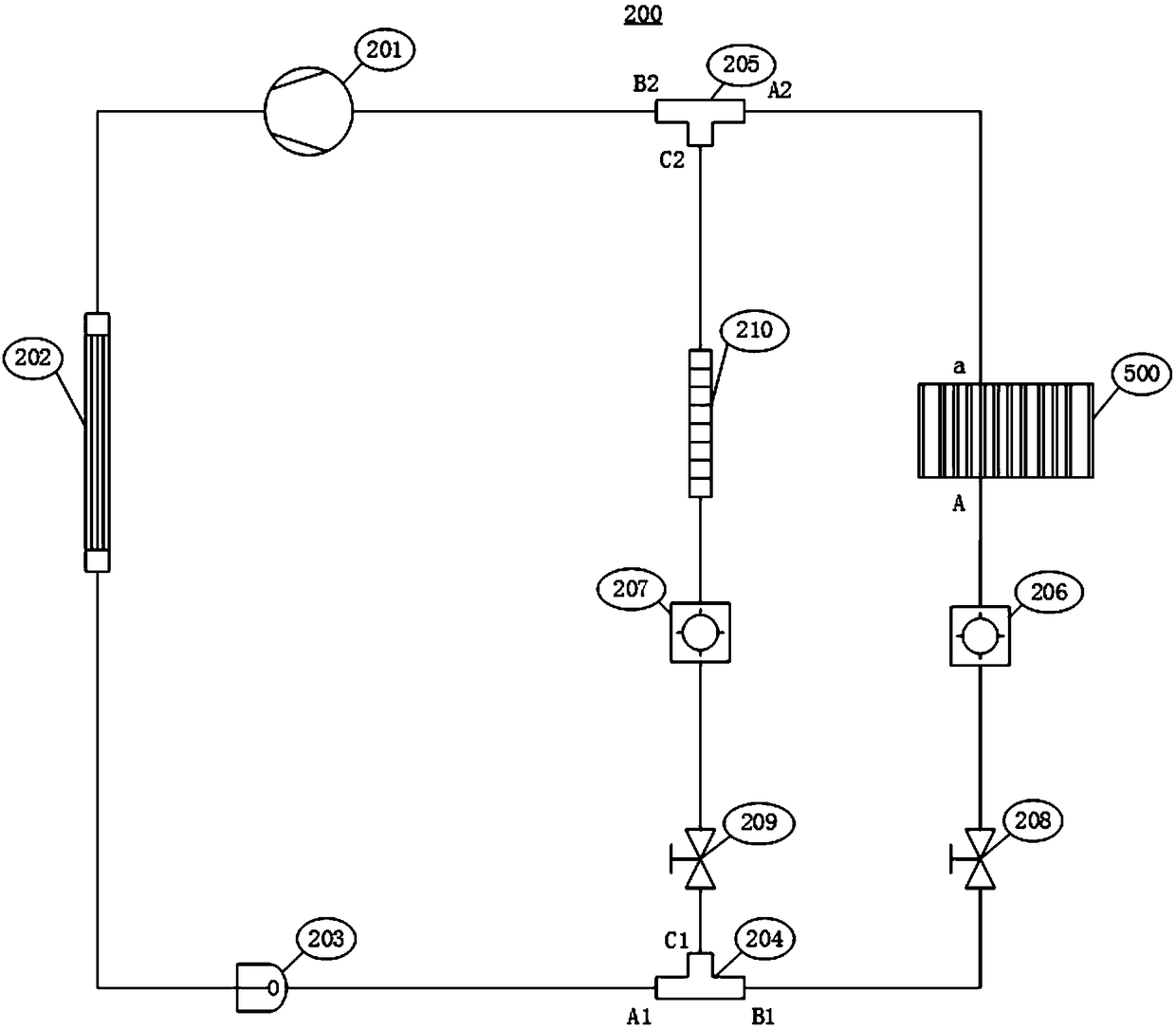

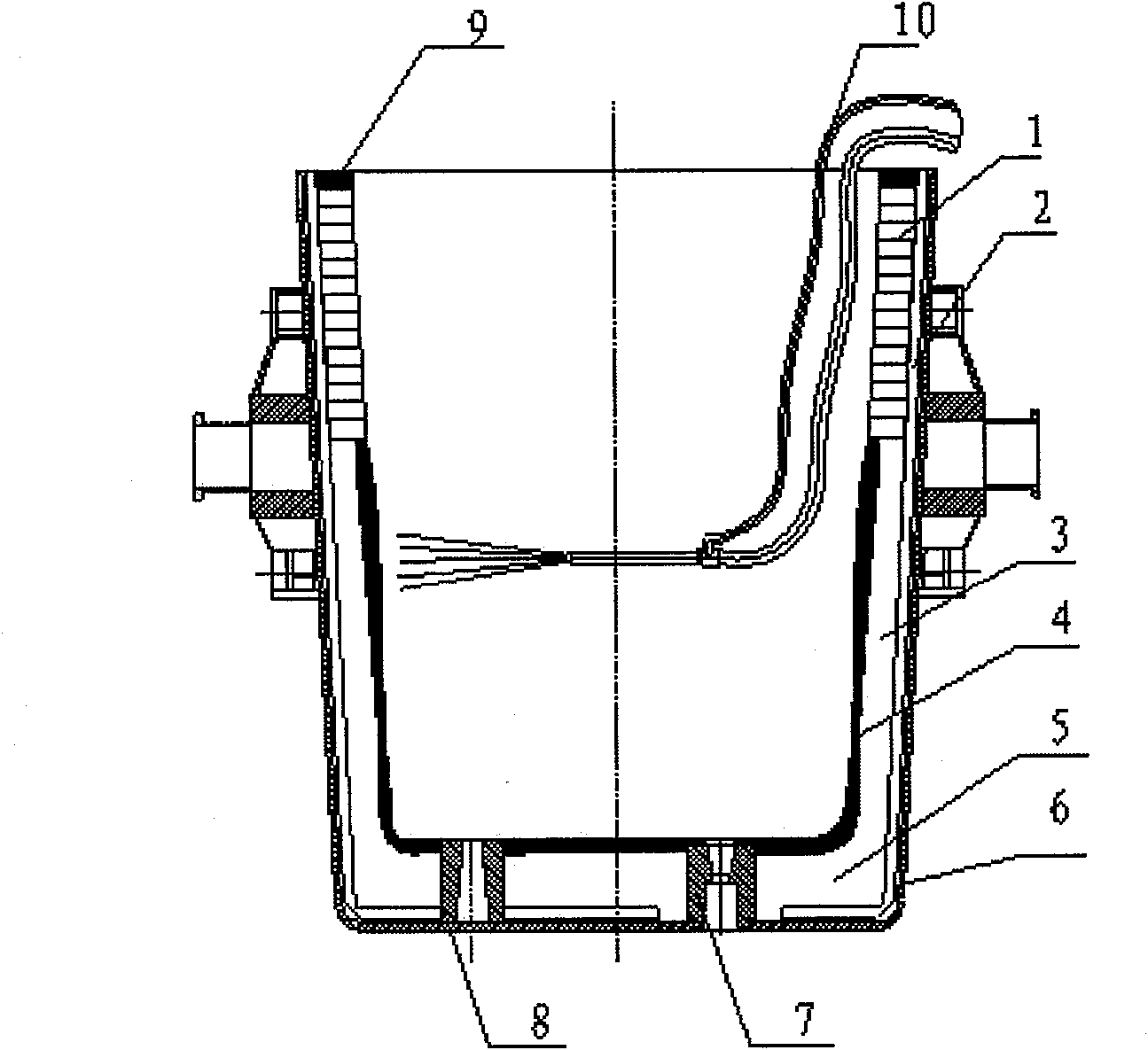

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Ultra-high molecular weight polyethylene composition and process method for producing an ultra-high molecular weight polyethylene composition tubular product

ActiveCN104045901ASmall coefficient of linear expansionImprove mechanical propertiesRigid pipesPolymer scienceHigh density

The invention relates to an ultra-high molecular weight polyethylene composition with the advantages of low melt viscosity, good flowability and high mechanical strength and softening temperature and a process method for producing an ultra-high molecular weight polyethylene composition tubular product. The composition comprises the following components in parts by mass: 100 parts of ultra-high molecular weight polyethylene of which the viscosity-average molecular weight is 3000000-5000000, 0.5-10 parts of polyethylene wax of which the molecular weight is 1000-5000, 10-40 parts of high-density polyethylene of which the molecular weight is 100000-500000, 20-50 parts of ultra-high molecular weight polyethylene of which the molecular weight is 8 millions-11 millions, 0.5-3 parts of a lubricant, 1-10 parts of a filling enhancer, 0.5-2 parts of nucleating agent, and 0.1-2 parts of a compound antioxidant. According to the invention, problems of high viscosity, poor flowability and difficulty in processing of the ultra-high molecular weight polyethylene melt in the prior art solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

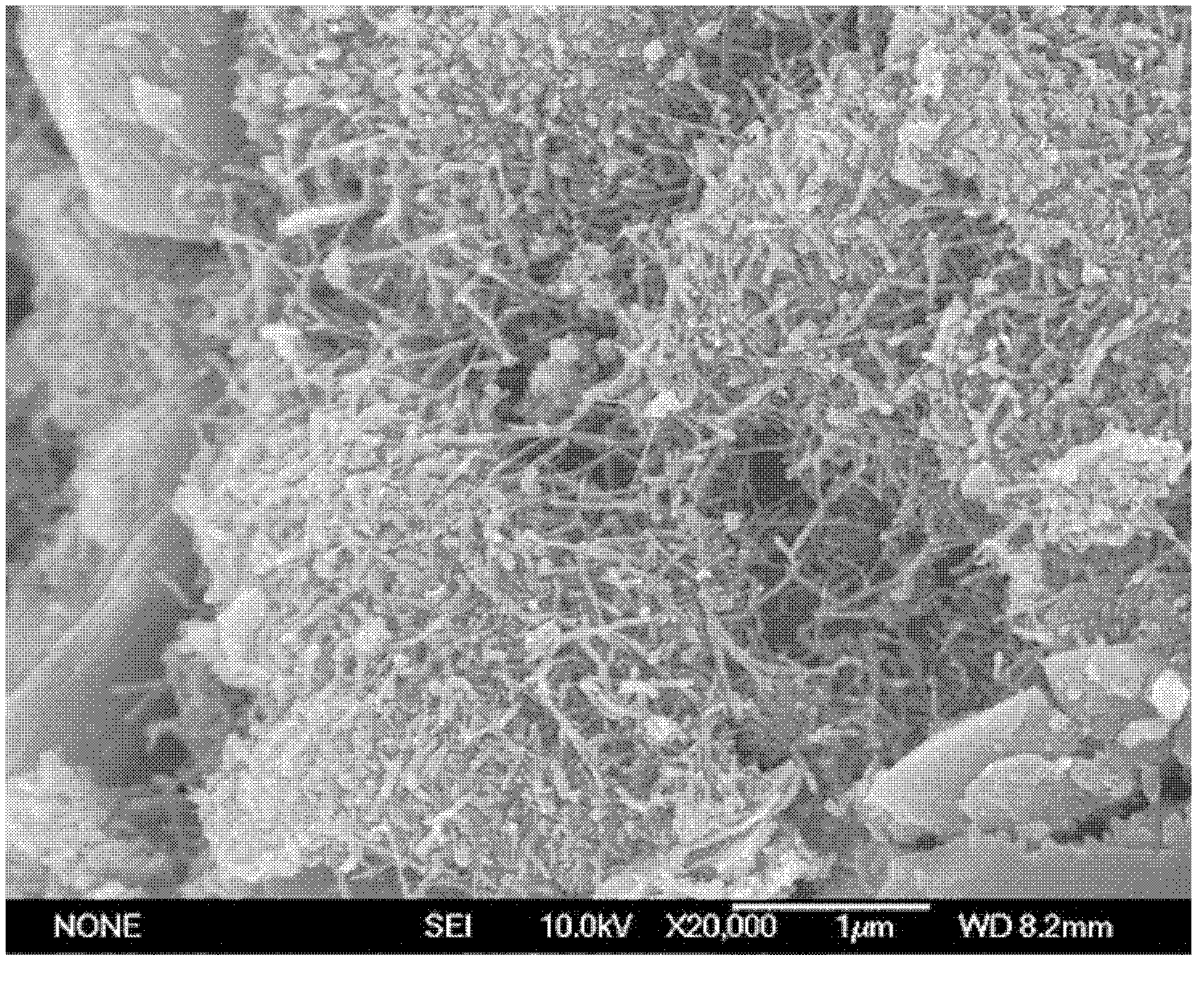

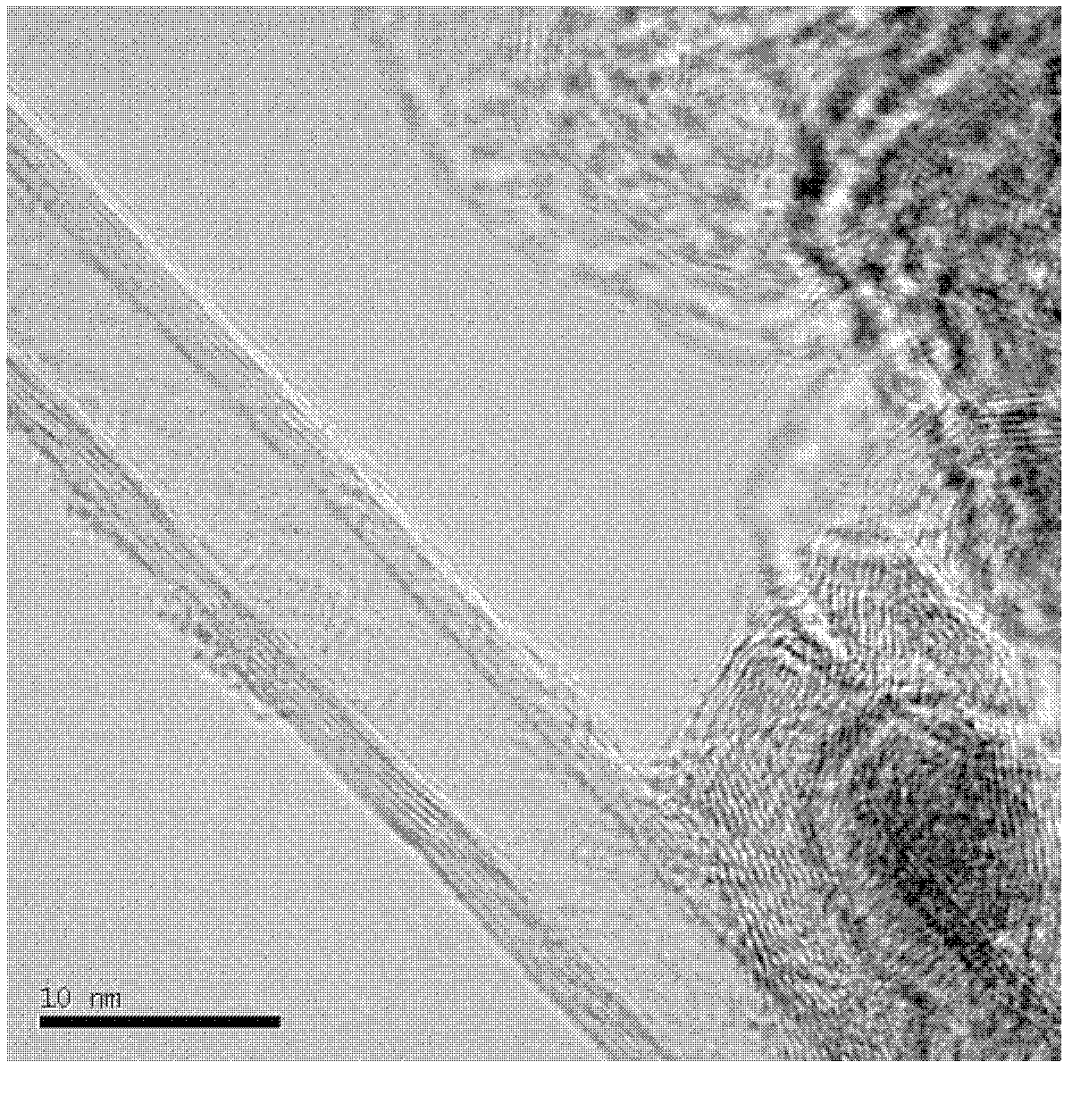

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

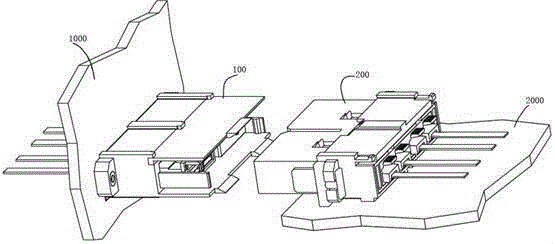

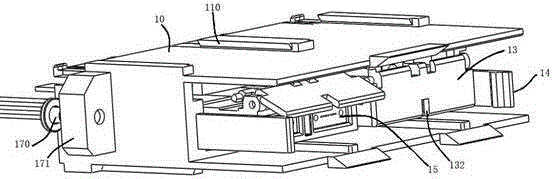

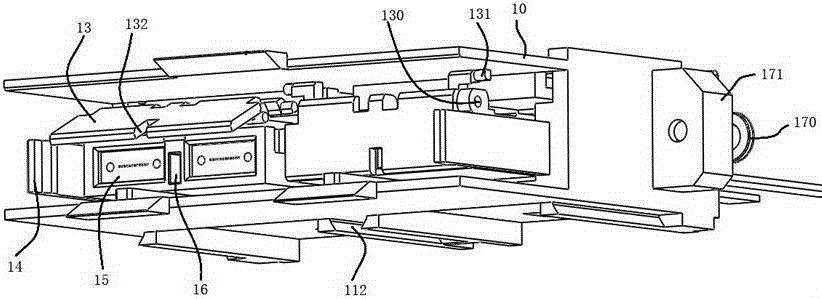

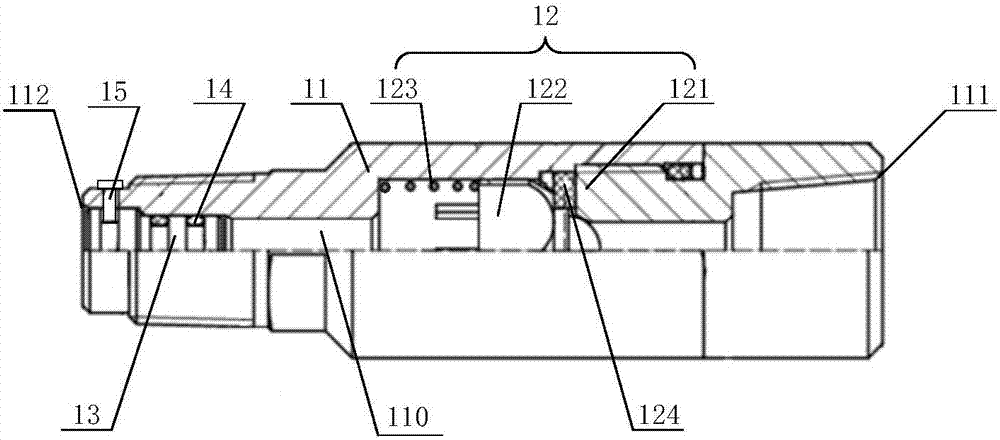

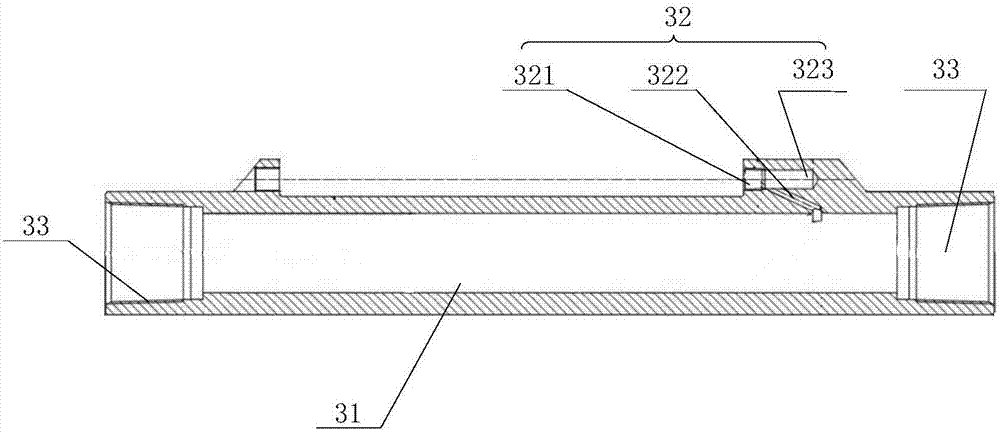

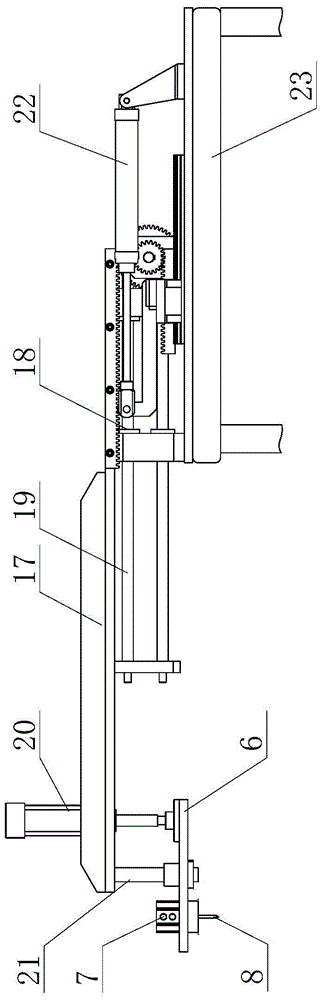

Socket and connector assembly

ActiveCN105242356ACompact structureDoes not increase in lengthCoupling light guidesEngineeringMechanical engineering

The invention provides a socket and a connector assembly. The connector assembly comprises a plug and the socket. An axis which is extended towards left and right directions of a front end of a socket shell is rotatably assembled with a dust cover. The socket shell is also provided with a spring driving mechanism which provides an elastic force for the dust cover overturning towards a closing position. The spring driving mechanism comprises a straight push spring extended forward and backward and a force transmission component which transmits a force between the straight push spring and the dust cover. The dust cover possesses a closed bearing portion. The force transmission component possesses a closed top pressing portion which pushes the closed bearing portion. The spring driving mechanism of the socket in the invention comprises the straight push spring and the force transmission component which transmits the force between the straight push spring and the dust cover; when the straight push spring is set, a space on a length direction of the socket shell can be used, wherein the length direction is a front and back direction; a height of the socket shell and a length of the socket shell are not increased so that the whole socket structure is compact and a usage condition of an integrated and miniature socket connector can be satisfied.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

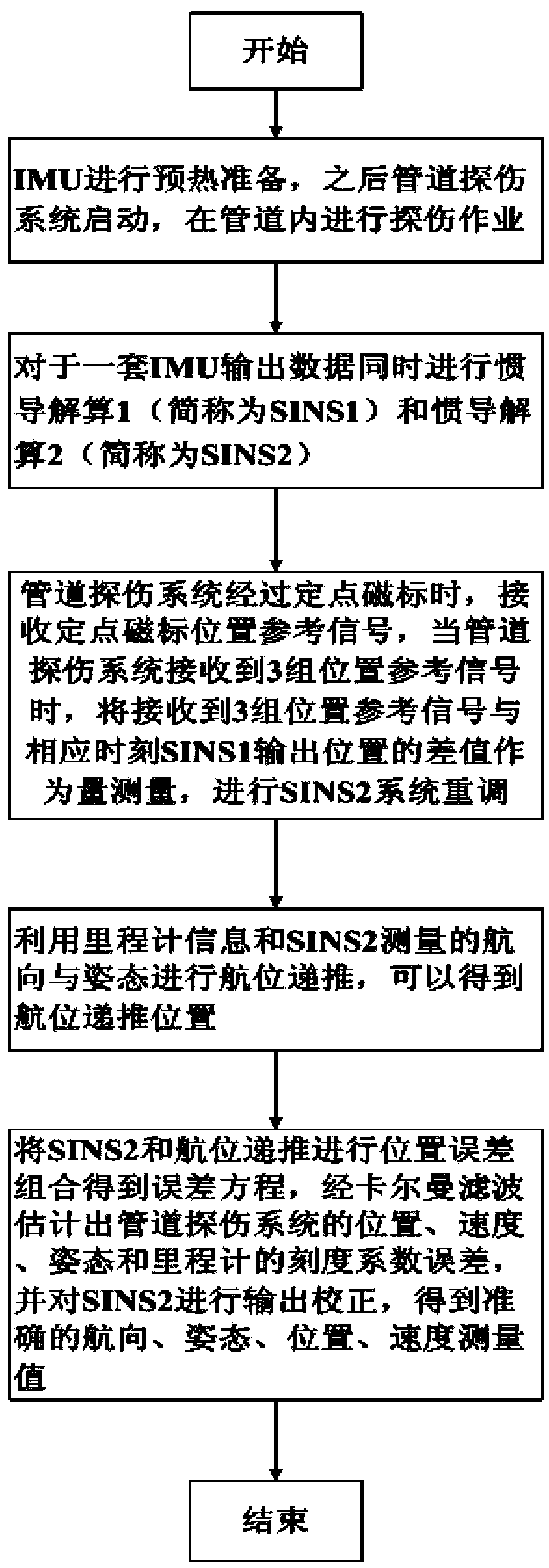

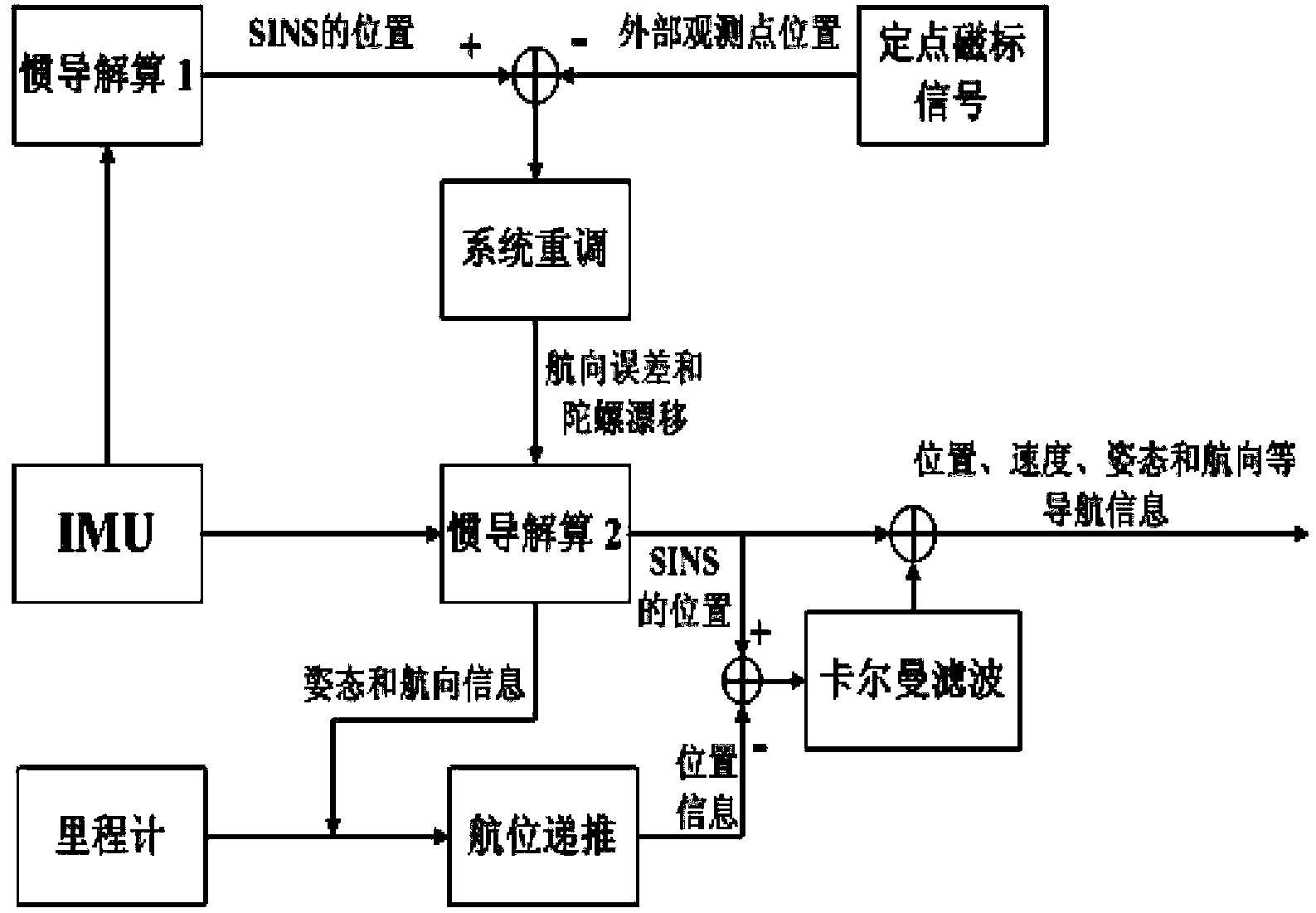

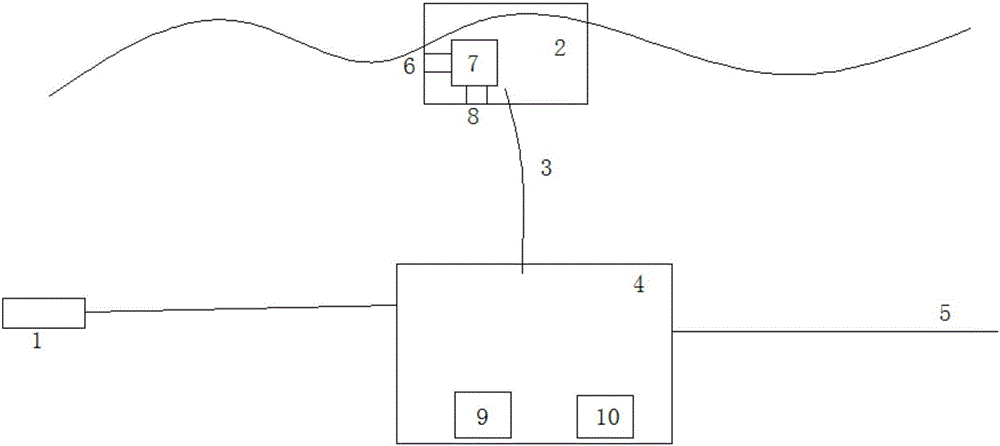

Pipeline flaw detection system navigation and location method based on IMU (Inertial Measurement Unit)

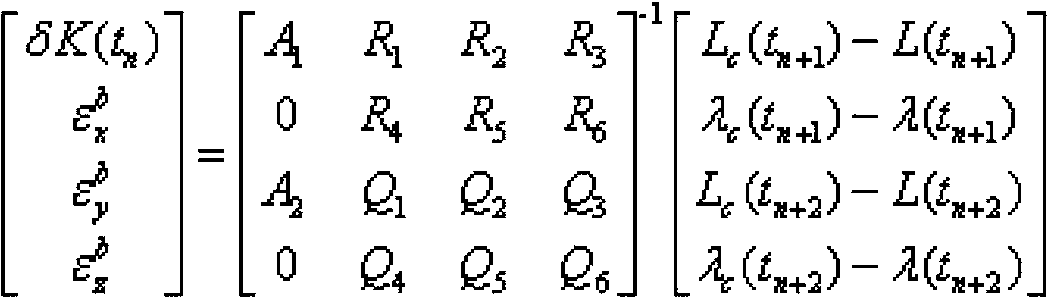

InactiveCN103453903ALimit error divergenceHigh precisionNavigation by speed/acceleration measurementsGreek letter epsilonPosition error

The invention discloses a pipeline flaw detection system navigation and location method based on an IMU (Inertial Measurement Unit). The pipeline flaw detection navigation and location method comprises the following steps: carrying out two groups of inertial navigation calculation simultaneously on one set of IMU output data; when a pipeline flaw detection system passes through a fixed magnetic tag, receiving position reference signals of the fixed magnetic tag, when the pipeline flaw detection system receives three groups of position reference signals, readjusting an SINS2 (Strapdown Inertial Navigation System 2) by using a difference between three groups of received position reference signals and SINS1 output positions at corresponding moment as a measurement amount: measuring a course error delta K(tn+2) and a gyroscopic drift Epsilon and compensating, and correcting a position error of the SINS2; carrying out dead reckoning by using the speedometer information and a course and a gesture which are measured by the SINS2 to obtain a dead reckoning position; and carrying out position error combination on the SINS2 and the dead reckoning to obtain an error equation, estimating a position, a speed and a gesture of the pipeline flaw detection system and a calibration factor error of a speedometer through Kalman filtering, and carrying out output correction on the SINS2 to obtain accurate course, gesture, position and speed measurement values.

Owner:HARBIN ENG UNIV

Double temperature quenching and strong toughening treatment method for cold forging die

The present invention relates to cold forging die toughening method and is especially one double temperature cold forging die-toughening quenching process. The double temperature cold forging die-toughening quenching process includes high temperature quenching and crystal fining quenching at relatively low temperature. In the high temperature quenching, the cold forging die is first vacuum heated, then oil quenched for 10-20 min while air is filled and tempered at 250-550 deg.c. In the subsequent crystal fining quenching at relatively low temperature, the cold forging die is first vacuum heated slowly to 850 deg.c, maintained for 20-60 min, further heated to 970-1160 deg.c and maintained, then oil quenched for 10-20 min while air is filled, and finally tempered at 450-550 deg.c for three or four times. The said process can raise the toughness and increase the service life of cold forging die obviously.

Owner:WUHAN UNIV OF TECH

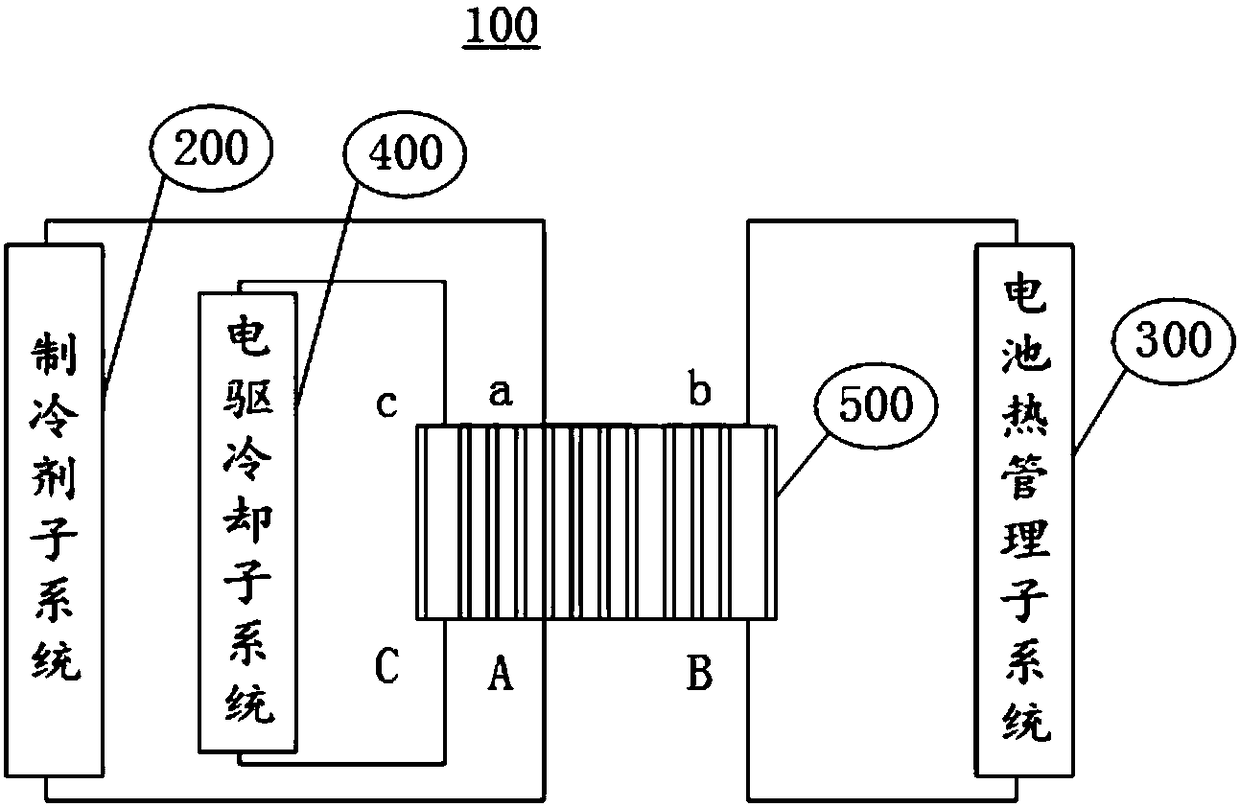

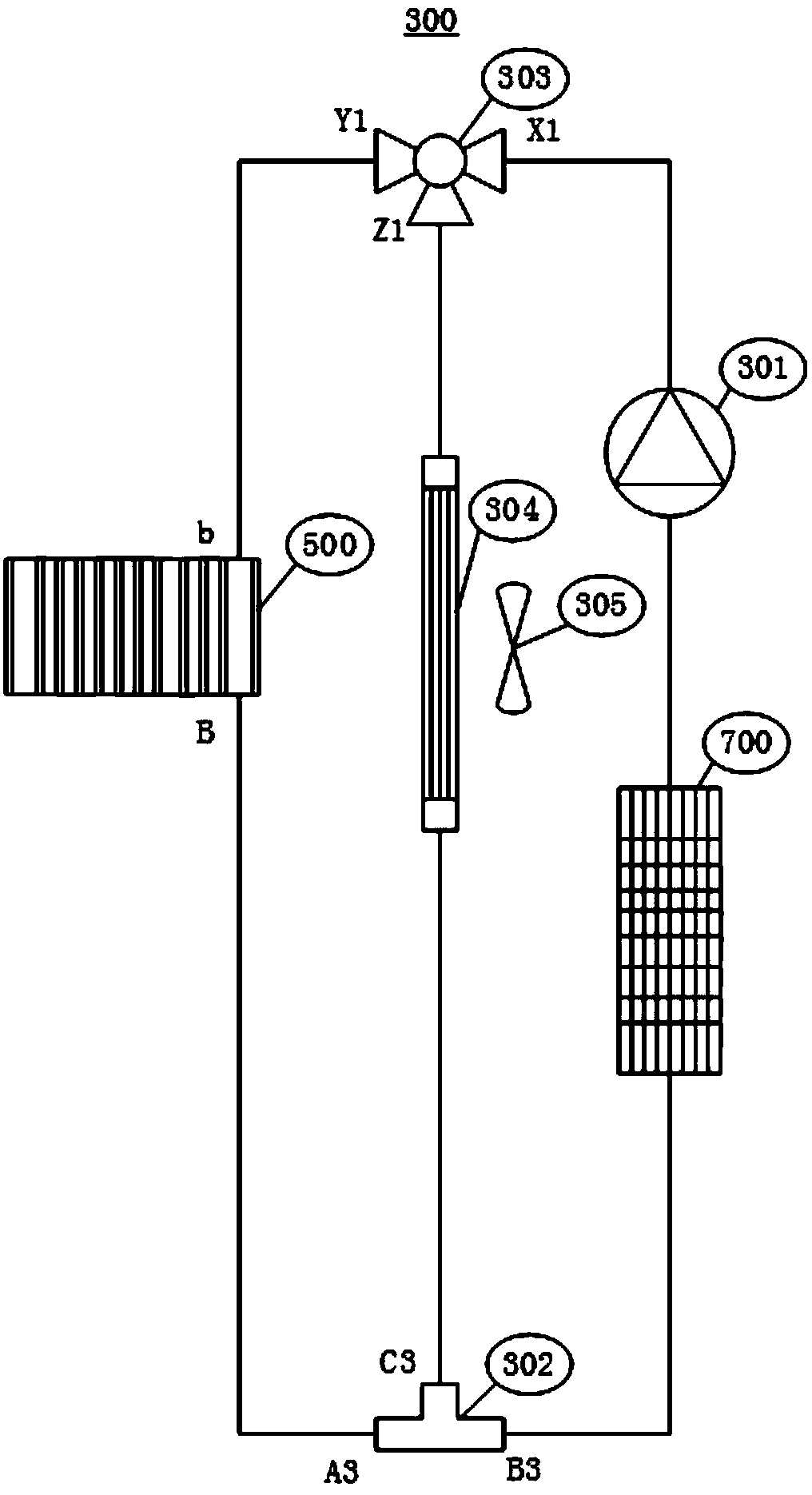

Automobile heat management system and battery electric vehicle

ActiveCN108407568ATake advantage ofEasy to installAir-treating devicesVehicle heating/cooling devicesElectricityPlate heat exchanger

The invention provides an automobile heat management system and a battery electric vehicle and relates to the technical field of electric automobiles. The battery electric vehicle comprises the aboveautomobile heat management system. In the automobile heat management system, a refrigerating agent subsystem, a battery heat management subsystem and an electric drive cooling subsystem are all connected to a heat exchanger; the refrigerating agent subsystem is used for refrigerating a passenger compartment or used for releasing heat to the heat exchanger or absorbing heat from the heat exchanger;the battery heat management subsystem is used for absorbing heat from the heat exchanger and heating a battery pack or used for refrigerating the battery pack; and the electric drive cooling subsystem is used for refrigerating an automobile electric drive device or used for heating the passenger compartment or used for releasing heat to the heat exchanger. The heating capacity and the refrigerating capacity of the automobile heat management system are high, the energy use rate is high, and cost is low.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Novel automatic jet floating type breakwater and wave eliminating method thereof

ActiveCN105951669AImprove wave suppression performanceLow costBreakwatersQuaysElectricityEngineering

The invention discloses a novel automatic jet floating type breakwater. The breakwater comprises a base which sinks underwater and a floating body which floats on the water; the base is connected with the floating body by an anchor chain; a water pump is disposed in the floating body; the water inlet of the water pump is arranged on the lower part of the floating body, and the water outlet is arranged on the head sea side of the floating body; a single-chip microcomputer is mounted in the base; a pressure type wave height gauge is disposed on the front of the head sea side of the base; and the single-chip microcomputer is electrically connected with the pressure type wave height gauge and the water pump, and controls the switch on / off and volume of the water pump based on the data from the pressure type wave height gauge. The invention also discloses a wave eliminating method using the novel automatic jet floating type breakwater mentioned above, wherein, the wave elimination is performed by the floating body itself according to the designed wave condition of the breakwater. The novel automatic jet floating type breakwater disclosed by the invention can normally eliminate waves by the floating type breakwater itself, and can jet horizontal flow on the head sea side to enhance wave elimination performance when the single-chip microcomputer detects an extreme wave condition by the pressure type wave height gauge, therefore saves cost and meets the practical needs well at the same time.

Owner:OCEAN UNIV OF CHINA

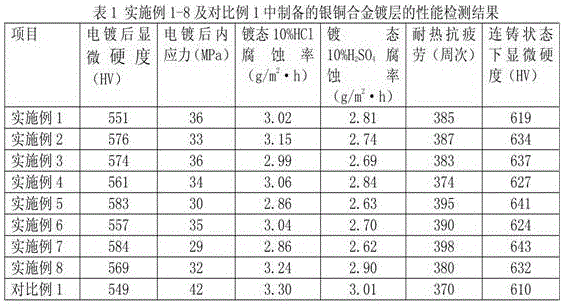

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

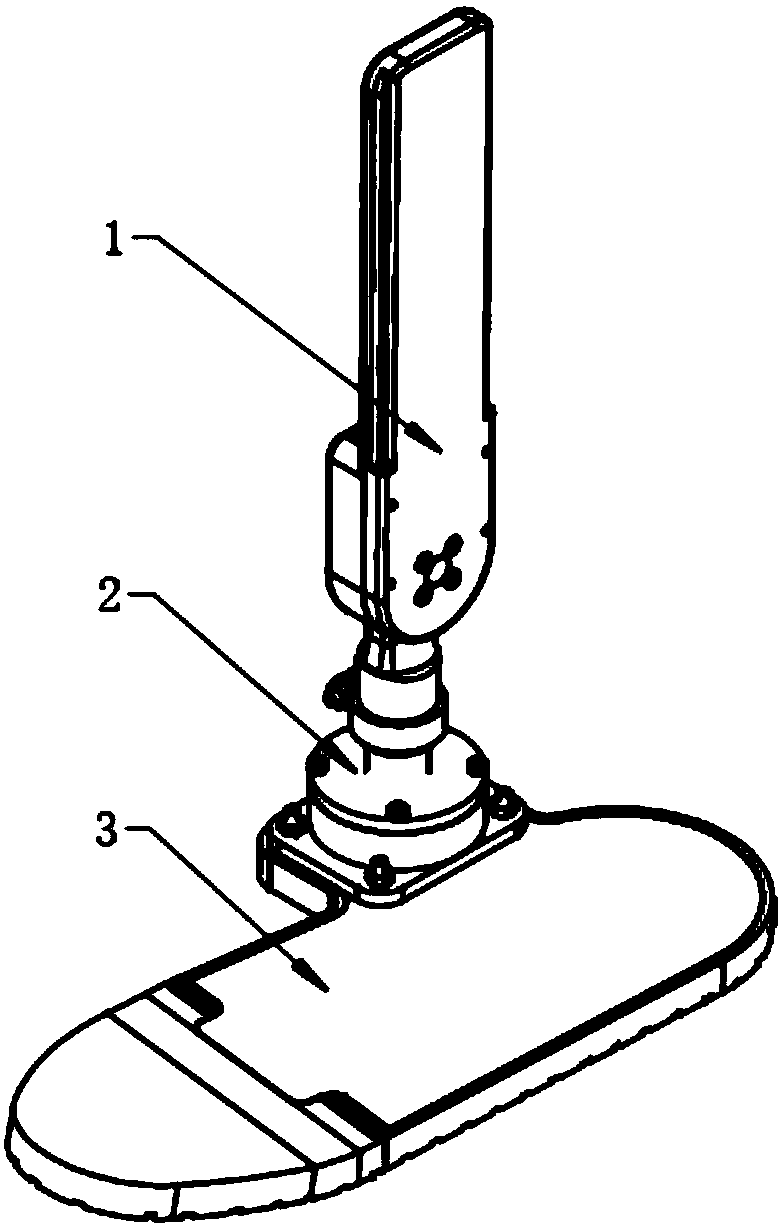

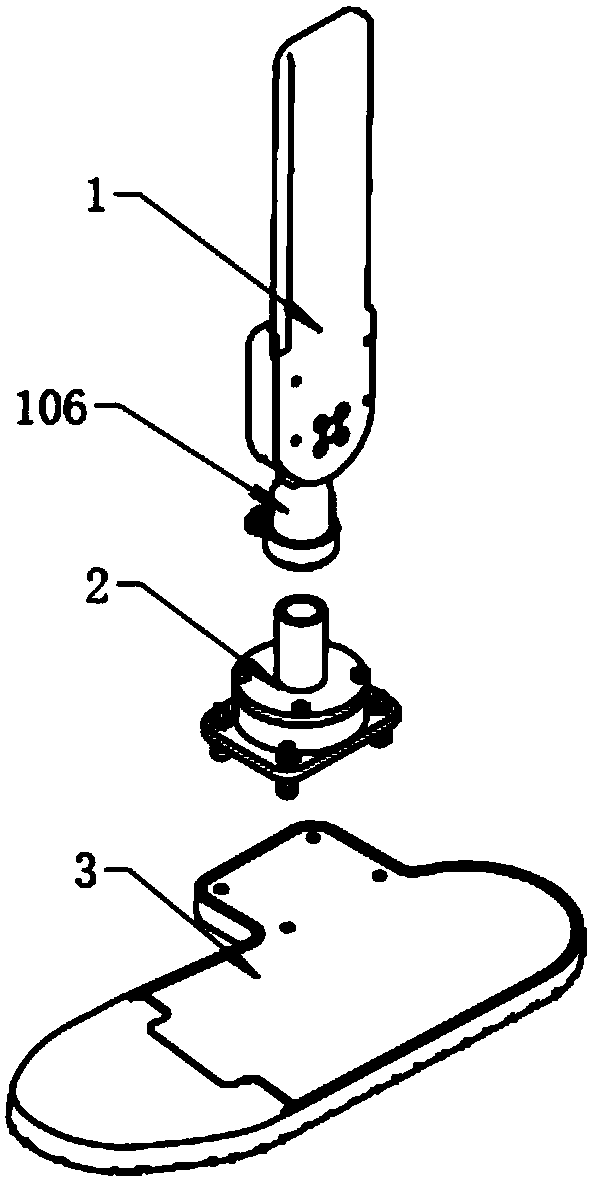

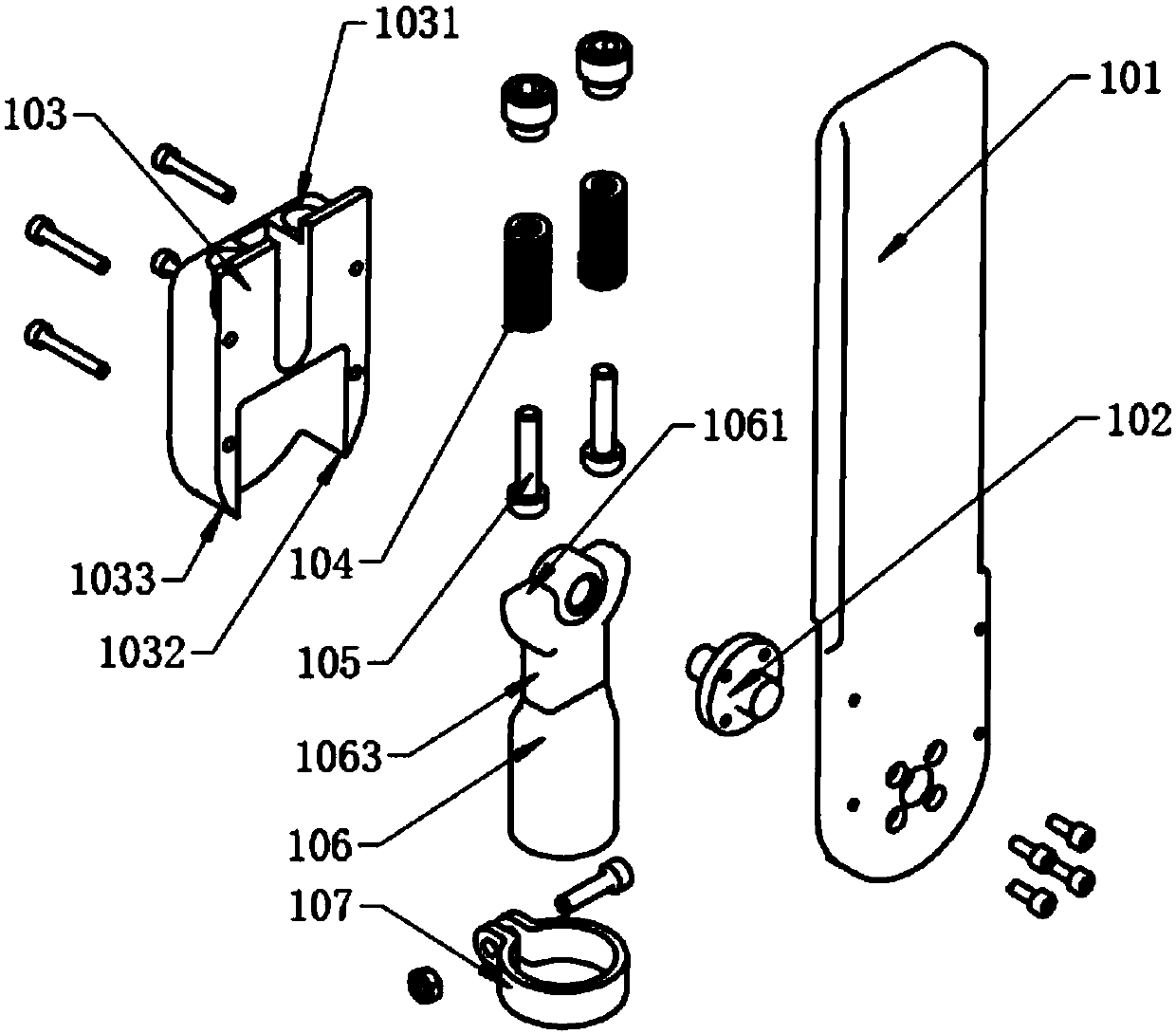

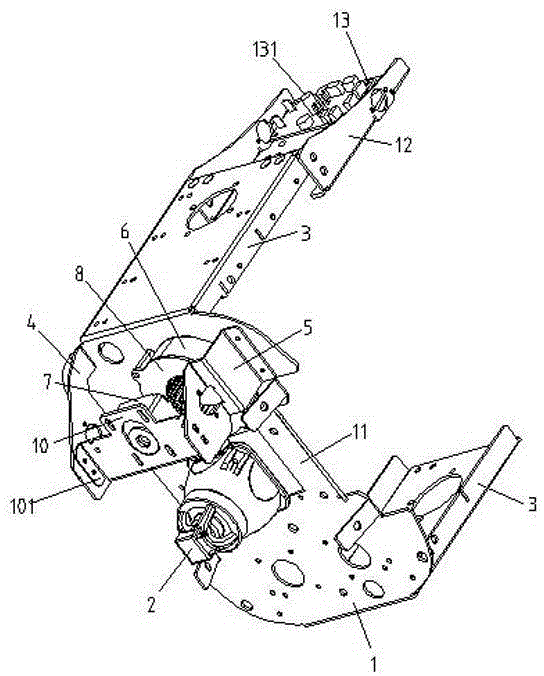

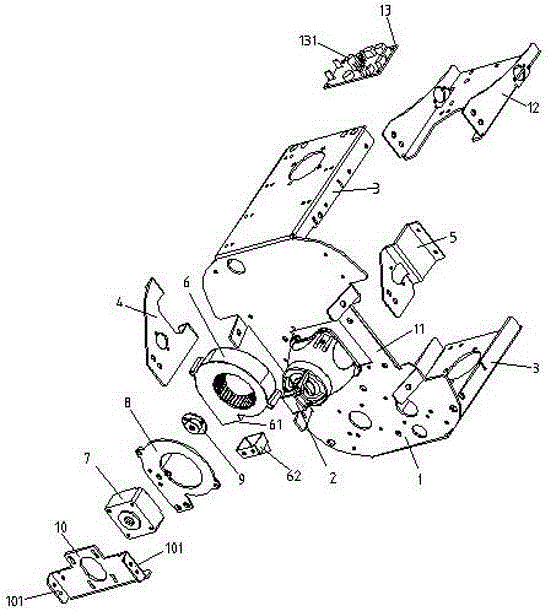

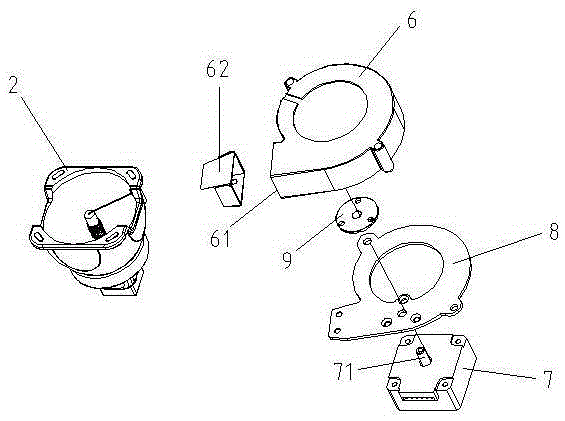

Three-degree-of-passive-freedom exoskeleton ankle joint mechanism

ActiveCN107928994AWill not affect walkingRetain degrees of freedomProgramme-controlled manipulatorWalking aidsExoskeleton robotThree degrees of freedom

The invention discloses a three-degree-of-passive-freedom exoskeleton ankle joint mechanism, which comprises an ankle joint link device, an ankle joint base device and a foot sole device which are sequentially connected from top to bottom. A plantar flexion / dorsal extension degree-of-freedom mechanism is constituted by the ankle joint link device by virtue of a calf rod piece, an ankle joint shaftand a first ankle joint link; a passive internal rotation / external rotation degree-of-freedom mechanism is constituted between a second ankle joint link and an ankle joint base in the ankle joint base device by virtue of a torsion spring; and a supinating / pronating degree-of-freedom mechanism is constituted in the foot sole device by virtue of a spring sheet and a shoe sole. The exoskeleton anklejoint mechanism provided by the invention, as a pure mechanical structure, is compact and simple in structure, light and durable and is free from an additional power source or transmission system, and an unpowered ankle joint on a current exoskeleton robot can be replaced; three degrees of freedom of an ankle joint are reserved, and meanwhile, the degree that the exoskeleton ankle joint fits to the human ankle joint is improved to the extent; and the exoskeleton ankle joint mechanism is simple to operate and free from influence to walking of the exoskeleton robot.

Owner:布法罗机器人科技(成都)有限公司

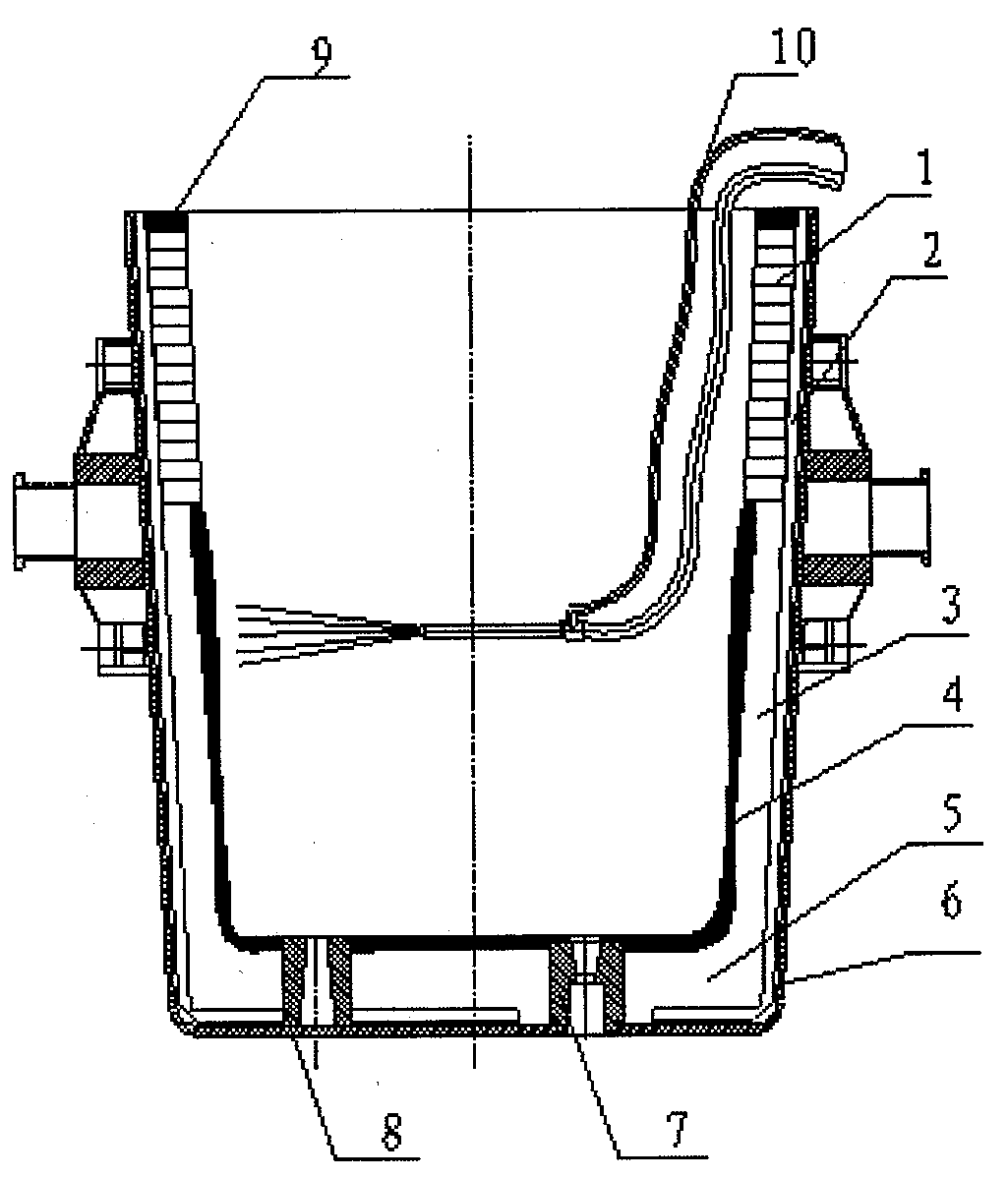

Method for building steel ladle pouring working lining

InactiveCN102019417AImprove bindingMeet the conditions of useMelt-holding vesselsEnergy consumptionMetallurgy

The invention relates to a method for building a steel ladle pouring working lining, which comprises 7-9 building circulations, wherein each building circulation comprises three times of gunning maintaining replenishing lining minor repairing and one time of peeling pouring medium repairing. The residual lining pervious courses of the steel ladle working lining ladle wall pouring material and ladle bottom pouring material are not removed, the building mode of gunning maintainment replenishing lining is adopted for the three times of minor repairing; when the residue thickness of the steel ladle working lining ladle wall pouring material is about 90 mm, the residual lining deformation courses of the steel ladle working lining ladle wall pouring material and ladle bottom pouring material are performed with one time of peeling pouring medium reqairing; the circulated building is performed, and synchronous pouring is performed for 7-9 times for the working lining ladle wall pouring material and ladle bottom pouring material. The service life of the steel ladle working lining after three-time minor repairing reaches 190 times, and refractory energy consumption per ton steel for the working lining can be lowered by above 0.60 kg / t compared with the common pouring technology.

Owner:SHANDONG IRON & STEEL CO LTD

Heat dissipation method and device for stage lamp and stage lamp

ActiveCN105333356AMeet the conditions of useExtended service lifeLighting applicationsMechanical apparatusCold spotEngineering

The invention discloses a heat dissipation method and device for a stage lamp and the stage lamp. A gravity sensor is arranged in the stage lamp and is used for judging and recognizing the change angle of a bulb and feeds back the information to an integrated circuit control panel, the integrated circuit control panel controls a motor to change the air direction of a fan, and then the heat of a bulb ball body can be uniformly dissipated. According to the heat dissipation method, the high heat dissipation requirement of high-power platinum cup bulbs can be met, the heat of bulb ball bodies can be dissipated uniformly, great temperature difference between the upper part and the lower part can be avoided, cold spots can be avoided, the use requirement of the bulb can be met, and the service life of the bulb can be prolonged.

Owner:GUANGZHOU FINEART LIGHTING

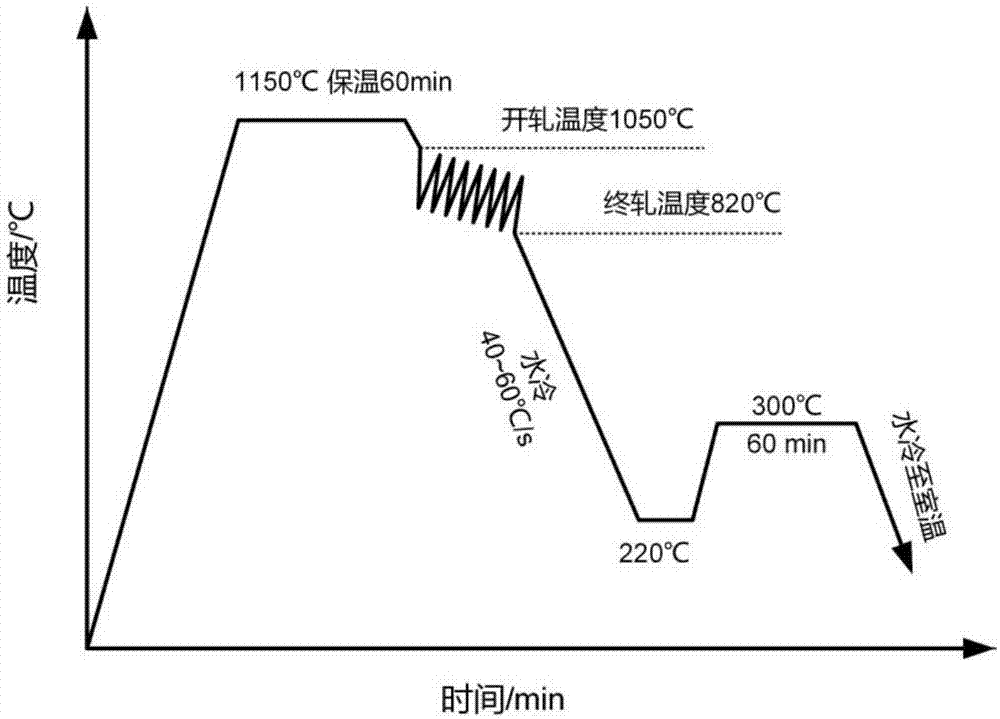

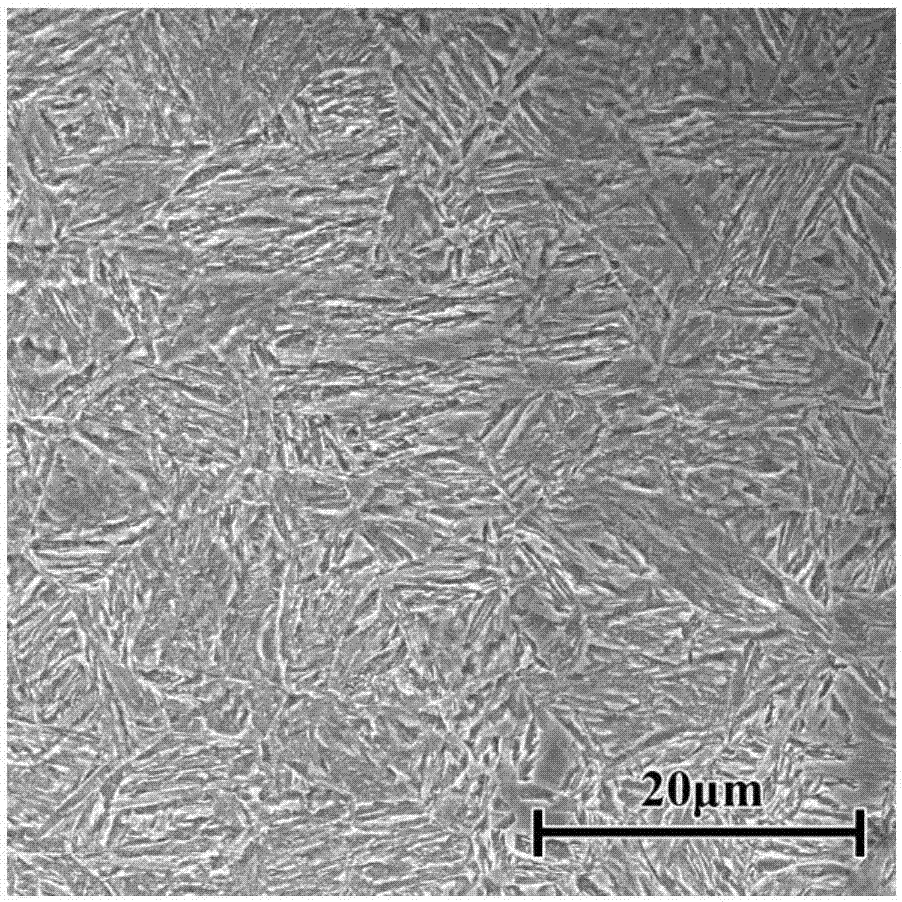

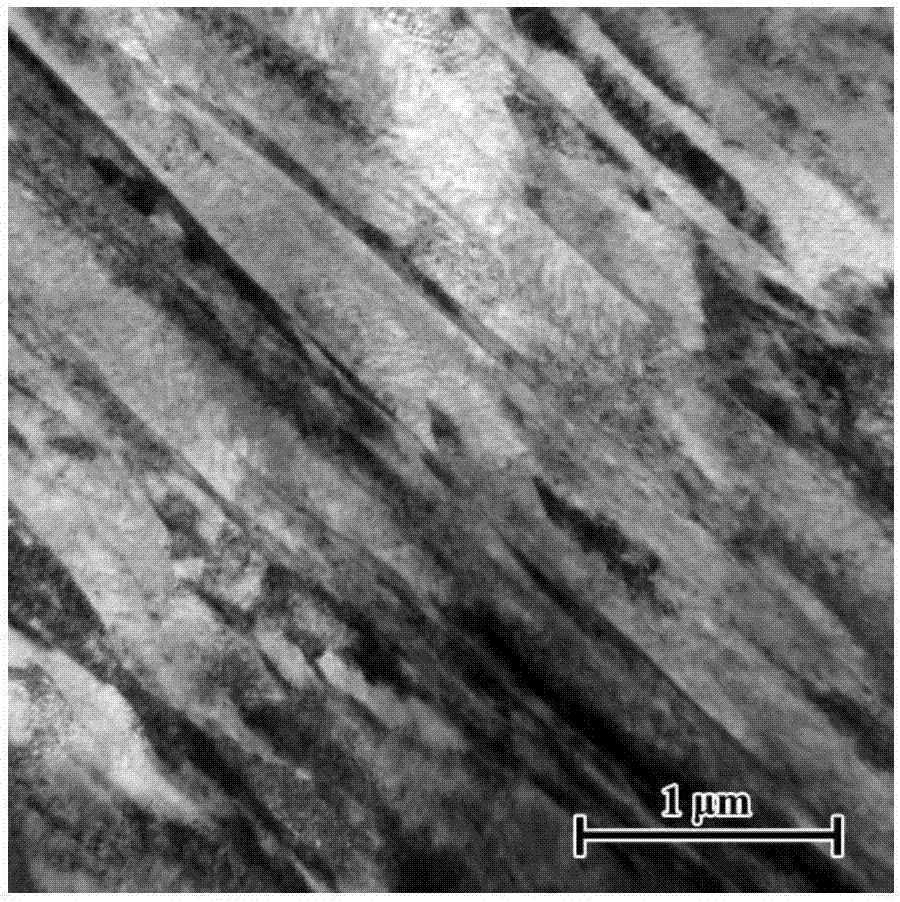

Low alloy high tenacity Q-P-T wear-resistant steel plate and manufacturing method thereof

The invention relates to the field of material heat treatment, and discloses a low alloy high tenacity Q-P-T wear-resistant steel plate and a manufacturing method thereof. The low alloy high tenacityQ-P-T wear-resistant steel plate comprises, by mass, 0.2-0.4% of C, 0.1-0.5% of Si, 0.5-1.5% of Mn, 0.5-1.2% of Cr, 0.1-0.3% of Mo, 0.02-0.08% of Ni, 0.04-0.1% of Cu, 0.001-0.008% of V, 0.01-0.04% ofTi, 0.01-0.05% of Nb, 0.001-0.003% of B, less than 0.015% of P, less than 0.005% of S, less than 0.006% of N, and the balance Fe and inevitable impurities. The low alloy high tenacity Q-P-T wear-resistant steel plate adopts the technique of Q-P-T heat treatment to manufacture the high tenacity wear-resistant steel. Microstructures are martensite, bainite, and retained austenite. Microalloy elements of V, Ti and Nb have effects of fine grain strengthening and precipitation strengthening. Therefore, the wear-resistant steel is good in abrasion performance, and high in tenacity.

Owner:UNIV OF SCI & TECH BEIJING

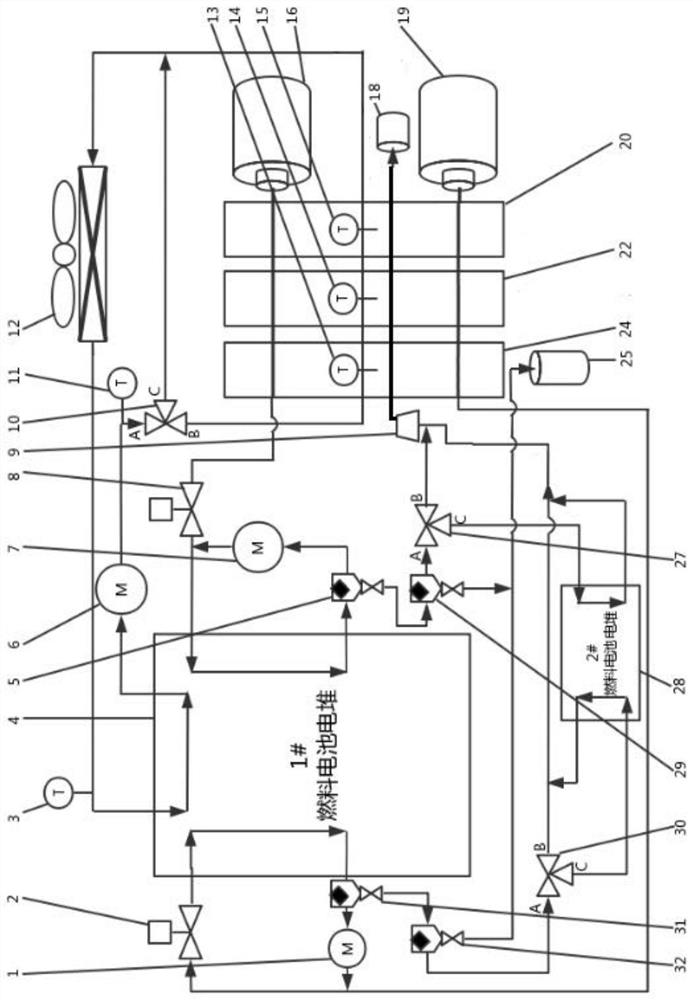

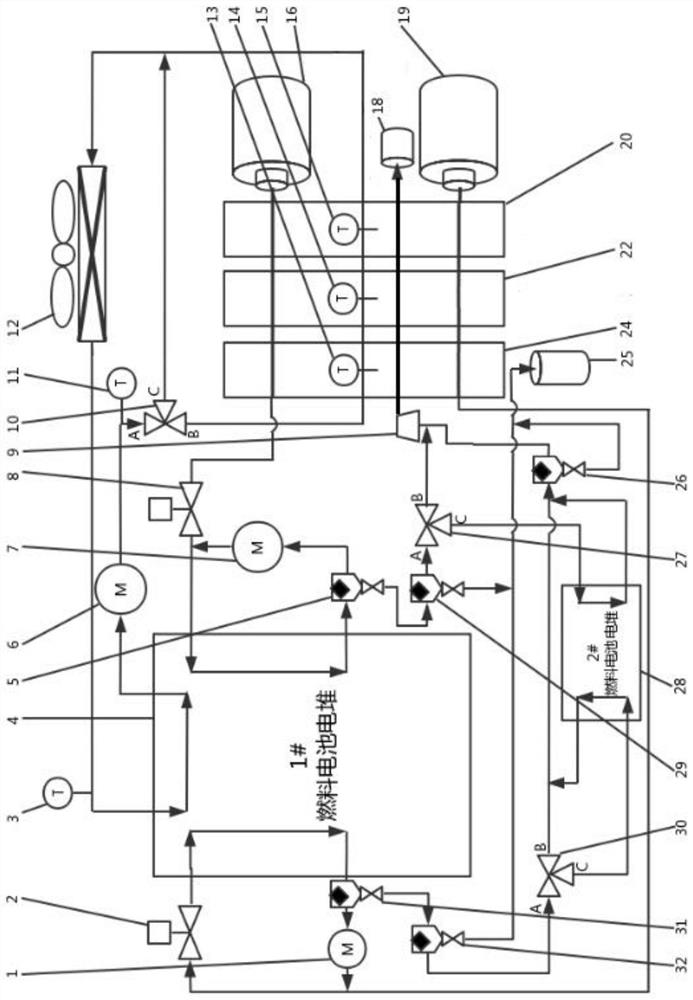

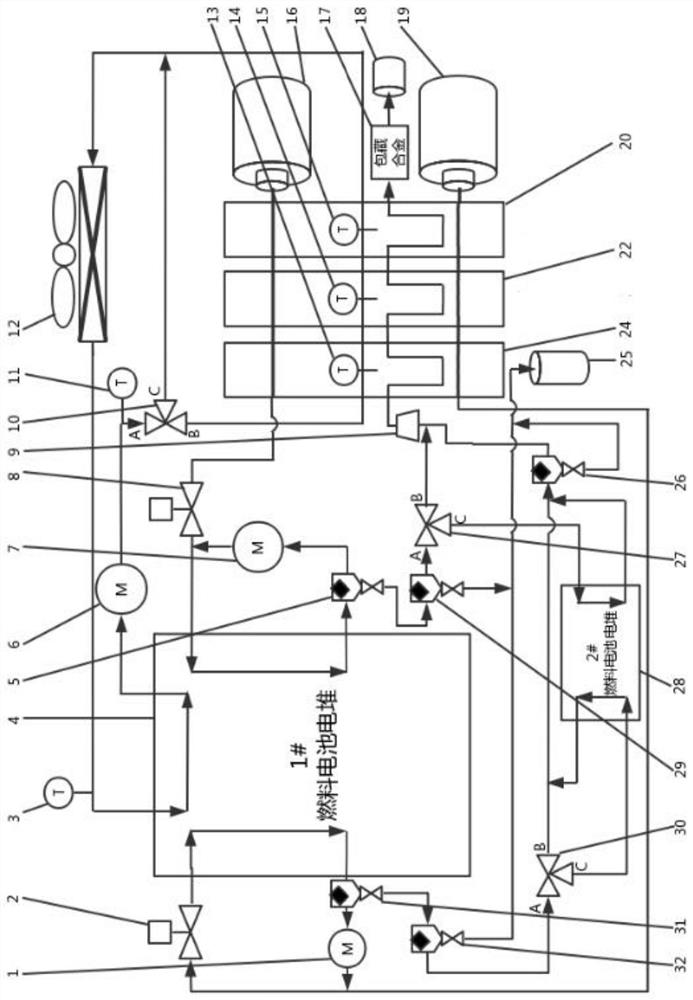

Hydrogen fuel cell tail gas recovery treatment system and method

PendingCN113363530AIncrease profitMeet the conditions of useFuel cell heat exchangeReactant parameters controlHydrogen fuel cellLiquid hydrogen

The invention discloses a hydrogen fuel cell tail gas recovery treatment system and method. Heat exchangers are arranged at outlets of a liquid hydrogen tank and a liquid oxygen tank, the rear end of a hydrogen pipeline and the rear end of an oxygen pipeline, and the heat exchangers can be cooled through the low-temperature characteristics of liquid hydrogen vaporization and liquid oxygen vaporization. A second fuel cell stack is additionally arranged at the rear end of a first fuel cell stack, so that the surplus of hydrogen and air in the hydrogen pipeline and an air pipeline can be effectively reduced, and part of electric energy can be generated and used by a low-power load. According to the invention, power can be generated again through the second fuel cell stack, and residual fuel can be classified, recycled and stored through the first to third heat exchangers and can be reused, so that the fuel utilization rate is effectively improved; and the whole set of system does not discharge any liquid or gas to the external environment during operation, is environment-friendly, and completely meets the use conditions of vehicles such as vacuum tunnel trains and submarines.

Owner:四川荣创新能动力系统有限公司

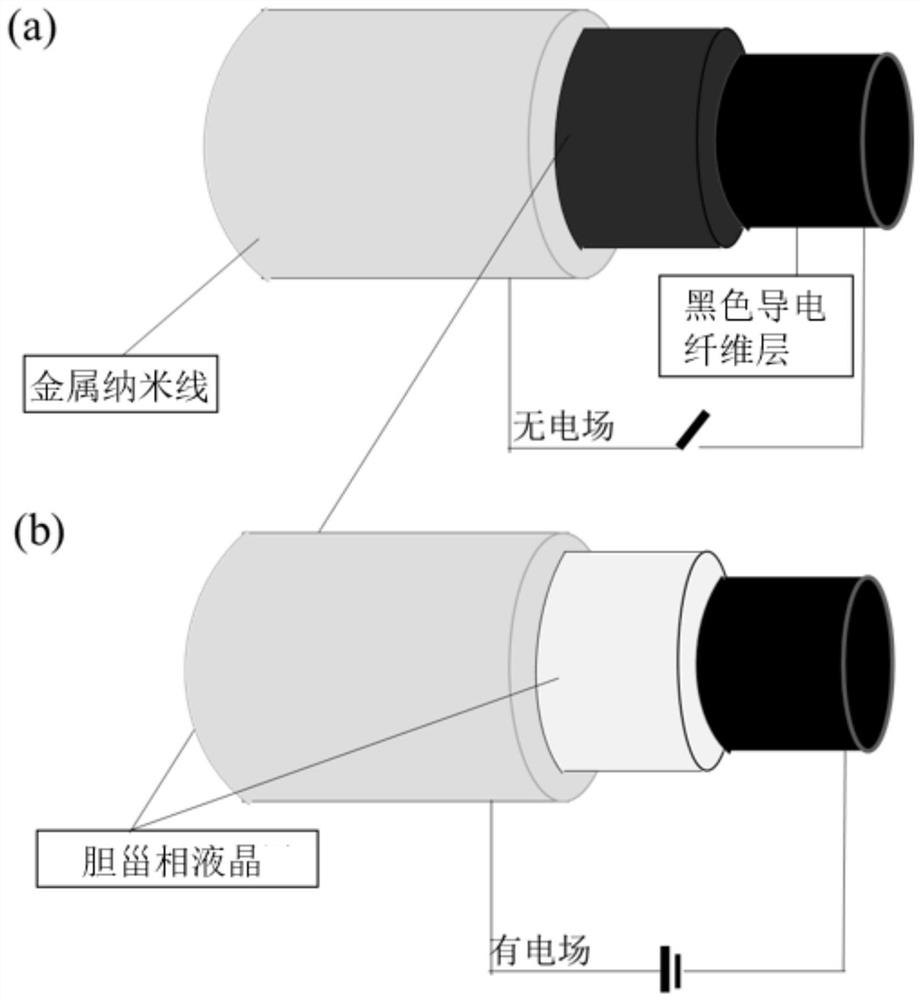

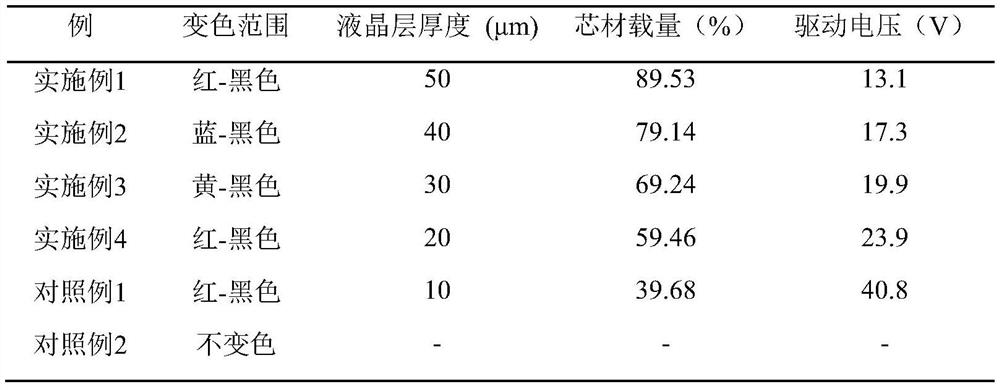

Method for preparing electrochromic fibers without additional electrodes by coaxial microfluid spinning method

ActiveCN112267174AEasy to operateEasy to scale productionElectroconductive/antistatic filament manufactureWet spinning methodsPhysicsMicro fluidic

The invention discloses a method for preparing electrochromic fibers without additional electrodes by a coaxial microfluid spinning method, and belongs to the technical field of fine chemical engineering and material science. The electrochromic liquid crystal fiber taking a black conductive polymer as an inner conductive layer, a transparent metal nanowire layer as an outer conductive layer and polymer dispersed cholesteric liquid crystal as an electrochromic layer is prepared by adopting the coaxial microflow spinning method, wherein the mass ratio of the metal nanowire layer to the black conductive layer to the cholesteric liquid crystal layer is (5-30): 100: (5-30). The electrochromic liquid crystal fiber prepared by the method disclosed by the invention can change color reversibly under the stimulation of an electric field, can realize a continuous stable state of a certain color changing state under the condition of power failure, not only is bright and variable in colors and lowin driving voltage which is lower than 23.9 V (lower than 36V of safe voltage of a human body), but also has high solvent resistance and water resistance.

Owner:JIANGNAN UNIV

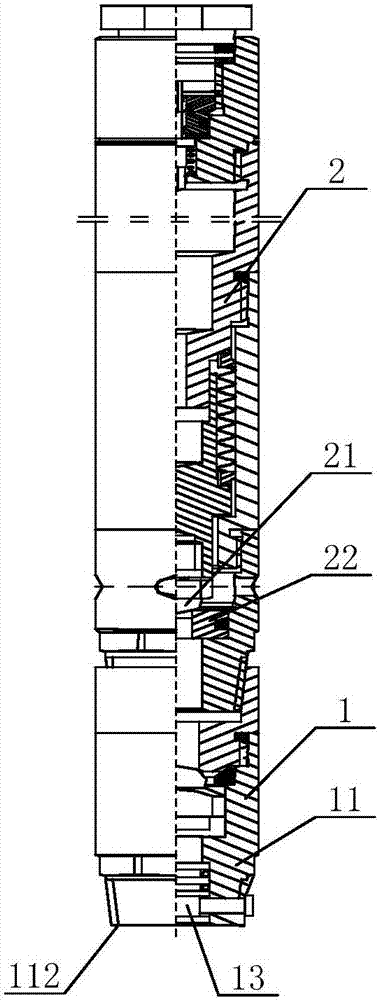

Check valve assembly, gas-lift valve, gas-lift tool and integrated string

InactiveCN107304661AImprove stress resistanceMeet the conditions of useDrilling rodsFluid removalAcid fracturingGas lift

The invention provides a check valve assembly, a gas-lift valve, a gas-lift tool and an integrated string. The check valve assembly provided by the invention comprises a valve body, a one-way assembly and an end cap; a fluid in the valve body can only flow to a second end of a through hole from a first end of the through hole through arranging the one-way assembly in the through hole of the valve body, so that one-way flowing of the fluid is achieved; the compressive property of the check valve assembly is improved through arranging the end cap at the second end of the through hole in the valve body, and the gas-lift valve can still keep normal working in an acid fracturing transformation process at high pressure, so that the one-way assembly can be directly put into a well in the acid fracturing transformation process, and the string does not need to be replaced before gas-lift production, thereby completing acid fracturing transformation and gas-lift production through running the string, shortening the operation time and improving the work efficiency.

Owner:PETROCHINA CO LTD

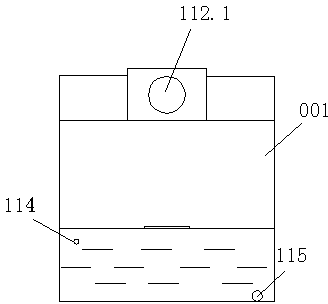

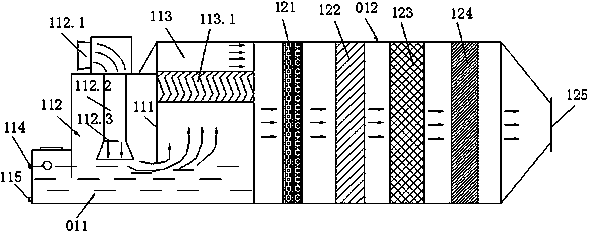

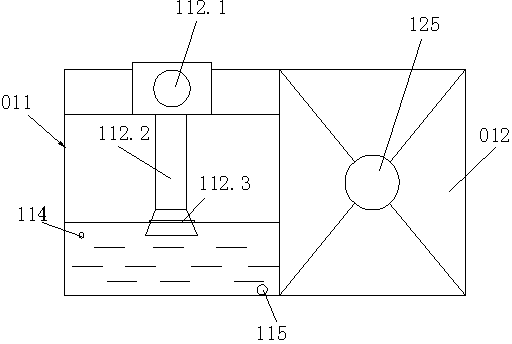

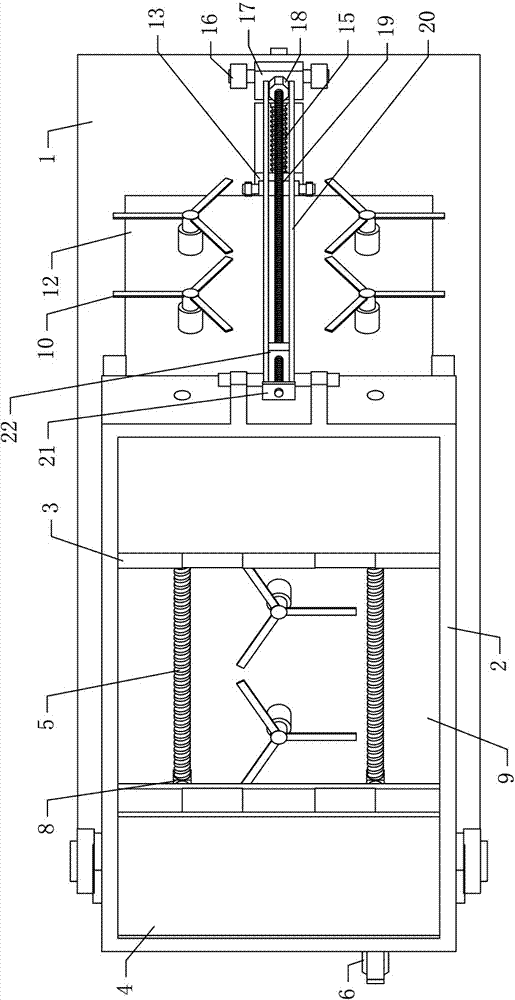

Lead fume purifier in lead-acid storage battery industry and purification method of lead fume purifier

The invention relates to a lead fume purifier in a lead-acid storage battery industry and a purification method of the lead fume purifier. The purification method comprises the following steps of introducing fume through an air inlet, controlling the speed of airflow impacting the liquid surface within 5-8 meters per second by virtue of a wind baffle, enabling the airflow to impact an S-shaped demisting baffle plate in a speed less than or equal to 1.5 meters per second after the water surface is impacted, enabling the air to pass through the section of an active carbon filter layer in the speed less than or equal to 2 meters per second after the air is purified by virtue of a primary filter material, enabling the air passing through the active carbon filter layer to pass a secondary filter material filter again, finally filtering the air by virtue of a frame type efficient filter consisting of H13-H15 or U15-U17, and exhausting the fume through an air outlet, wherein the purification level of the primary filter material is F5-F9, the purification level of the H13-H15 is HEPA (High Efficiency Particulate Air), and the purification level of the U15-U17 is ULPA (Ultra Low Penetration Air). The minimal filter fineness of the lead fume purifier can reach 0.1 micron, the lead fume purifier is applied to a plate casting process of the lead-acid storage battery industry and is used for filtering complex mixed smoke of oil gas in the lead fume, the discharging concentration of lead ions in the purified smoke is less than or equal to 0.07 milligram per cubic meter and is far lower than national emission standards, and the problem that pollutants in a pole plate casting procedure of a lead-acid storage battery are difficultly thoroughly purified is solved.

Owner:江苏二环环保科技有限公司

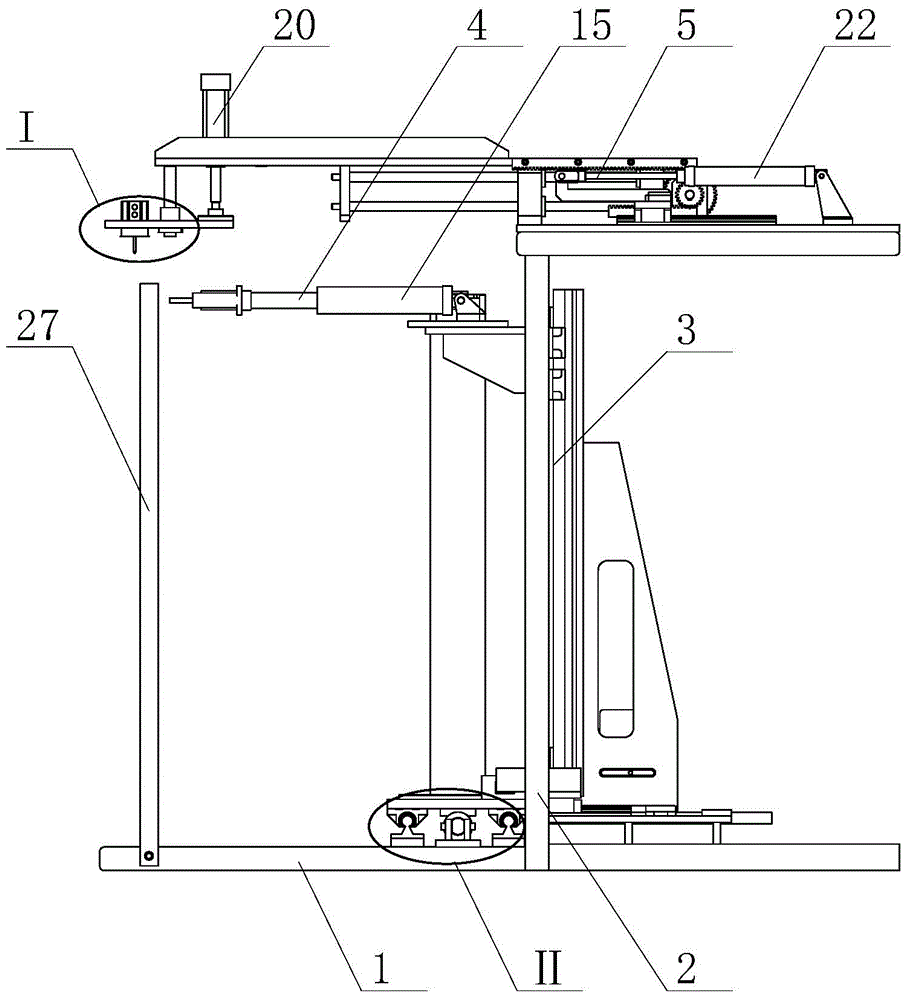

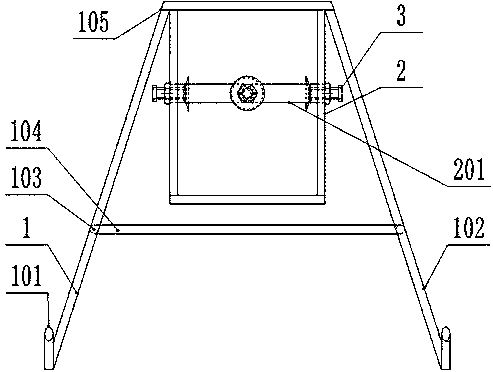

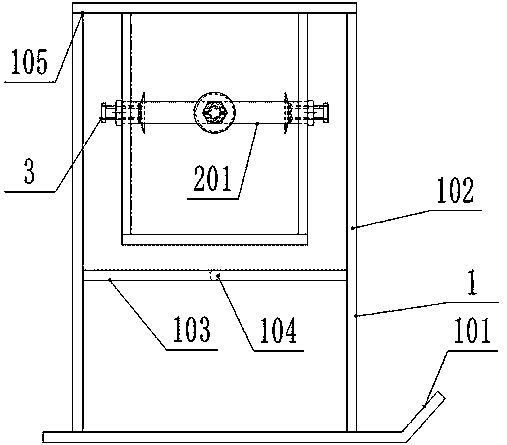

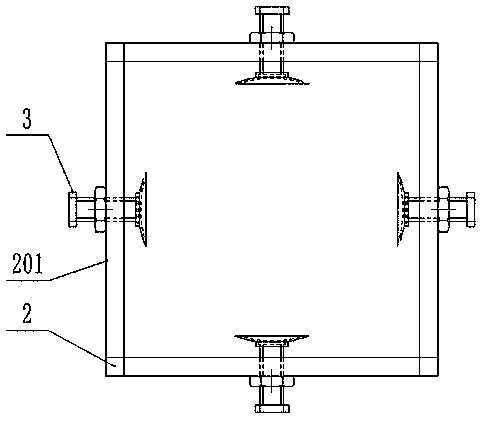

Hybrid new energy power generation device

InactiveCN108011567AReduce dependencySimple structurePhotovoltaic supportsSolar heating energyNew energyEnergy storage

The invention relates to a power generation device, in particular to a hybrid new energy power generation device comprising a mounting base. A swinging lifting frame is arranged on the top of the mounting base. The front end of the swinging lifting frame is movably connected with the mounting base through a rotating shaft. A solar module is arranged in the frame of the swinging lifting frame. A first wind power generation module is arranged on the frame on the rear side of the solar module. The rear end of the mounting base is provided with a first driving device connected with the swinging lifting frame. A second wind power generation module is movably arranged at the bottom of the swinging lifting frame. An energy storage device is arranged in the top concave chamber of the mounting base. The hybrid new energy power generation device is simple in structure, reasonable in design, and convenient to operate, operates in a mode where a variety of power generation ways are mixed, has high working efficiency, can guarantee normal power generation throughout the day, has stable working performance, reduces dependence on local climate conditions, and meets people's use conditions.

Owner:山东理工昊明新能源有限公司 +1

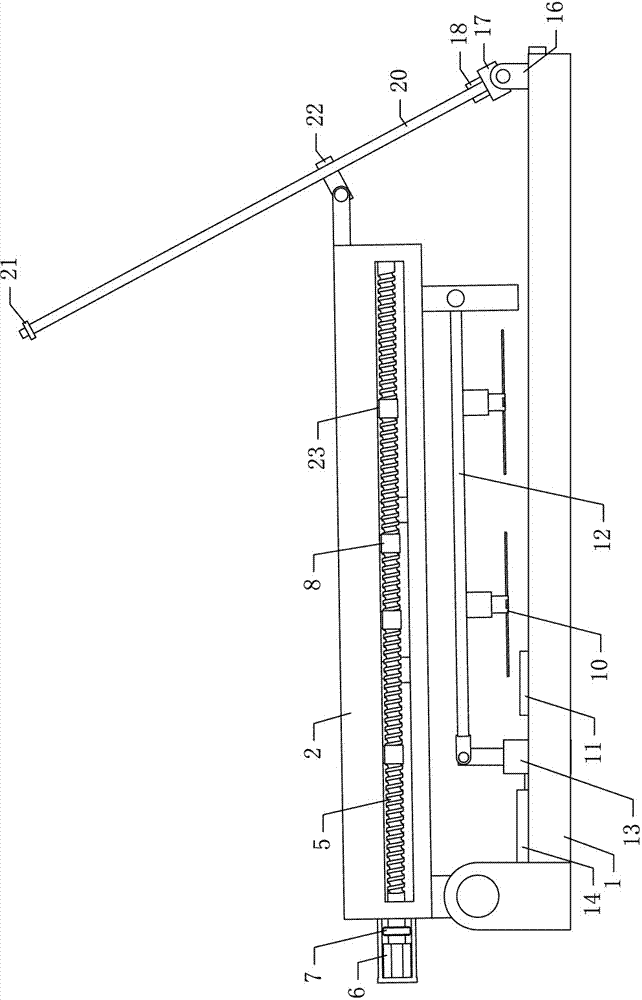

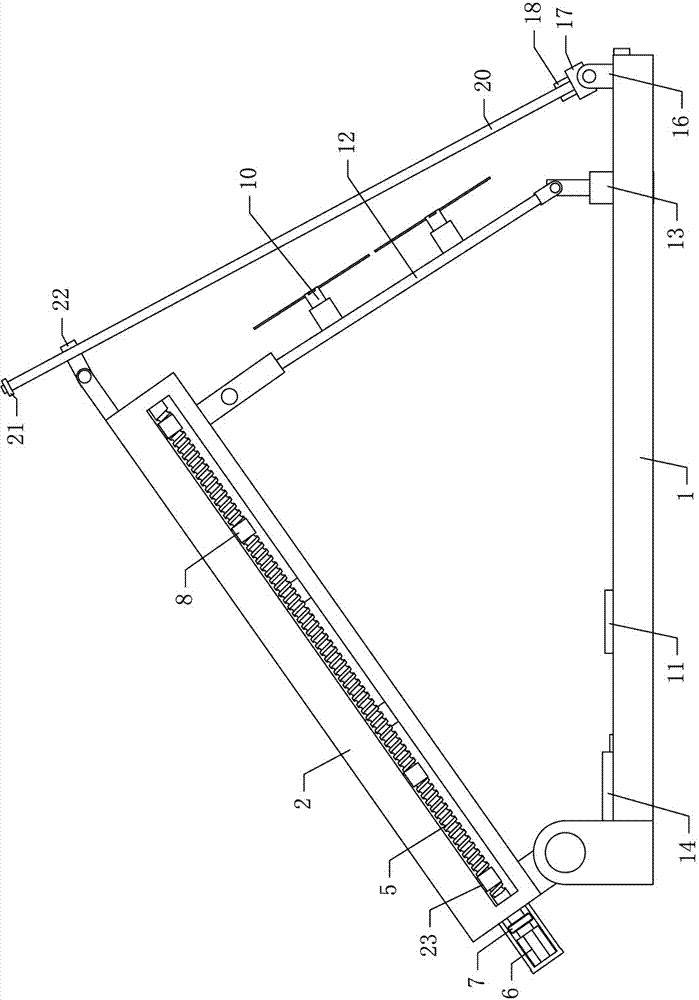

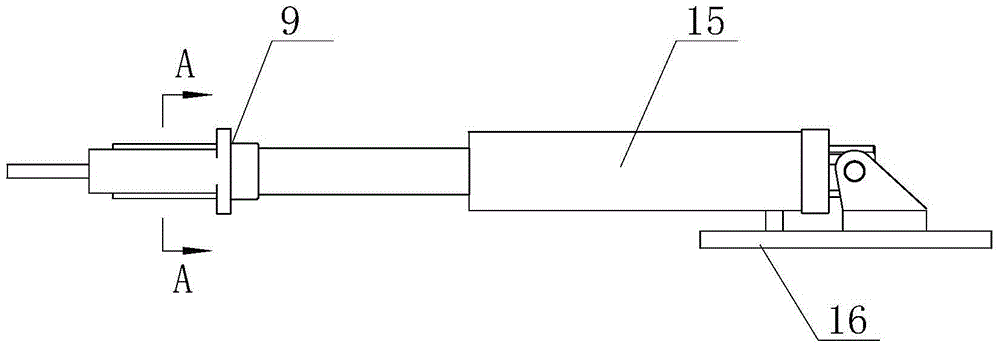

Secondary wiring auxiliary apparatus

ActiveCN105048244AHigh speedUniform insertion lengthLine/current collector detailsCable transmissionPiston rod

The invention discloses a secondary wiring auxiliary apparatus. A base is provided with a support, the support is provided with an elevating mechanism and a cable transmission mechanism, and the cable transmission mechanism is arranged at the right side of the elevating mechanism; the front end of the right side of the cable transmission mechanism is provided with a cable clamping arm, the cable clamping arm comprises a top plate, two first vertical plates which are arranged in parallel at a front position and a rear position are installed below the top plate, a second vertical plate parallel to the two first vertical plates is arranged between the two first vertical plates, the first vertical plate at a rear side is externally provided with a longitudinal clamping cylinder, the free end of the piston rod of the clamping cylinder is vertically fixed on the rear side of the second vertical plate, the clamping cylinder can drive the second vertical plate to perform longitudinal movement between the first vertical plates, and the opposite surfaces of the second vertical plate and the first vertical plate at a front side are provided with recesses for clamping a cable. According to the invention, the secondary wiring auxiliary apparatus is a special-purpose auxiliary tool for secondary wiring, can automatically finish wire transmission, insertion and fixation in a terminal interface, replaces manually hand-actuated secondary wiring, improves the wiring efficiency and quality and saves manpower resources.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

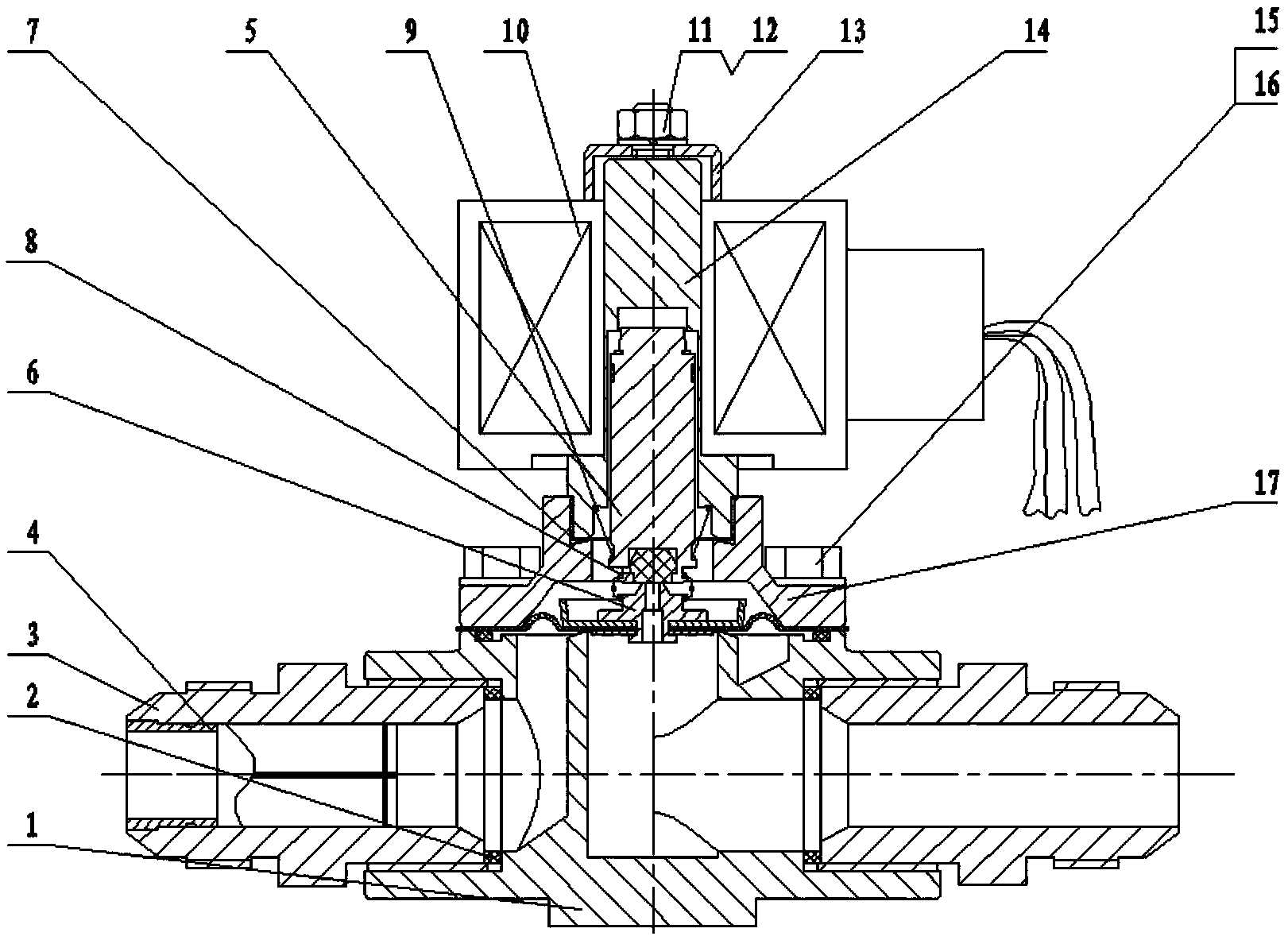

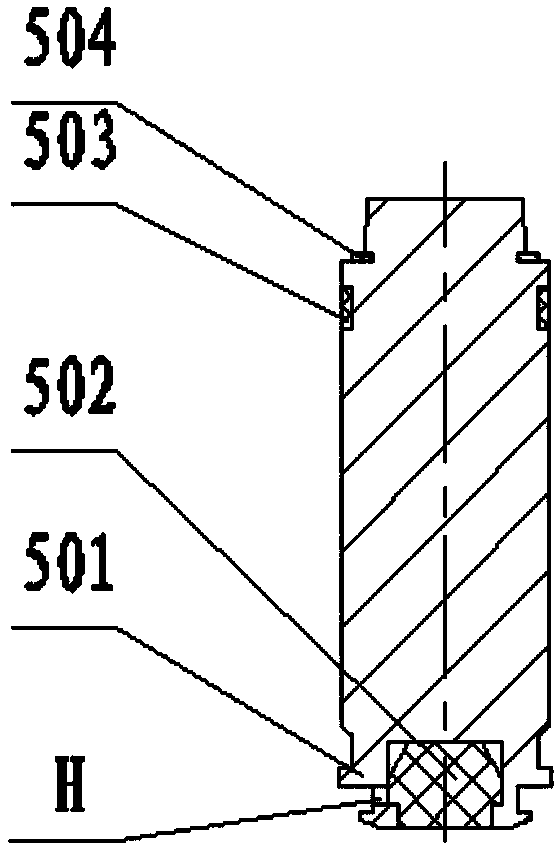

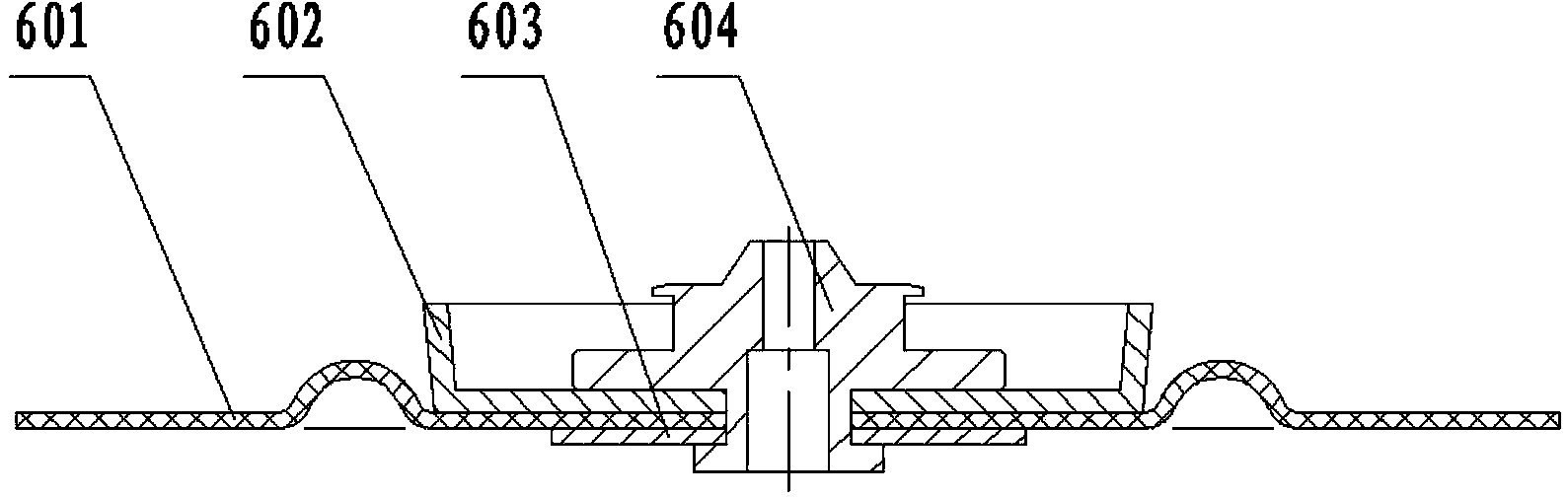

Natural gas solenoid valve

InactiveCN103644337AImprove sealingOpen quicklyDiaphragm valvesOperating means/releasing devices for valvesAutomatic controlSolenoid valve

The invention provides a natural gas solenoid valve, and belongs to the technical field of solenoid valves. The natural gas solenoid valve comprises a valve body, a hard-core membrane, a valve deck, a permeable sleeve, a guide sealing head, a tension spring and an explosion-proof solenoid coil. The hard-core membrane and the valve body are sealed. A control gas nipple of the hard-core membrane and the guide sealing head are in joint seal through the tension spring. The guide sealing head is matched with a cylindrical surface of the permeable sleeve. The explosion-proof solenoid coil is installed on the permeable sleeve. The hard-core membrane is formed by riveting a membrane body, a liner bowl, a liner pad and the control gas nipple, wherein the diameter of the liner bowl is 1.3-1.5 times that of a gas outlet channel of the valve body, the diameter of the liner pad is smaller than that of the gas outlet channel of the valve body, and the diameter of the control gas nipple is larger than that of a gas inlet hole of the waveform membrane body. The natural gas solenoid valve is simple in structure, fast to assemble, convenient to maintain, and capable of being widely applied to the natural gas industry. The natural gas solenoid valve realizes automatic control in the transmission process of natural gas, and is quick in response, high in reliability and particularly suitable for emergency cut-off.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

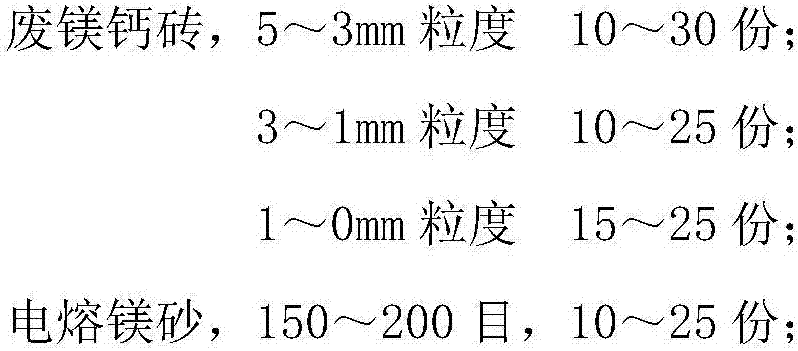

Method for producing magnesium calcium ramming material for AOD furnace from waste magnesia-calcium bricks

The invention relates to a method for producing a magnesium calcium ramming material for an AOD furnace from waste magnesia-calcium bricks. The magnesium calcium ramming material comprises 10-30 parts by weight of waste magnesia-calcium bricks having particle sizes of 5 to 3 mm, 10-25 parts by weight of waste magnesia-calcium bricks having particle sizes of 3 to 1 mm, 15-25 parts by weight of waste magnesia-calcium bricks having particle sizes of 1 to 0 mm and 10-25 parts by weight of fused magnesite of 150-200 meshes. The magnesium calcium ramming material also comprises 1.5-12% of a binder on the basis of the above raw material total weight. The waste magnesia-calcium bricks are subjected to water repellent treatment. The method realizes recycling of the waste magnesia-calcium bricks and observably improves water repellent performances of the magnesium calcium ramming material. The magnesium calcium ramming material satisfies refractory material use requirements on an AOD refining furnace, has a long storage life and effectively reduces an enterprise production cost.

Owner:辽宁利尔镁质合成材料股份有限公司 +1

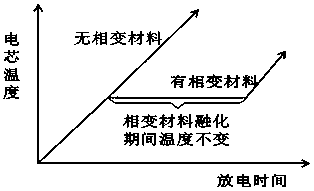

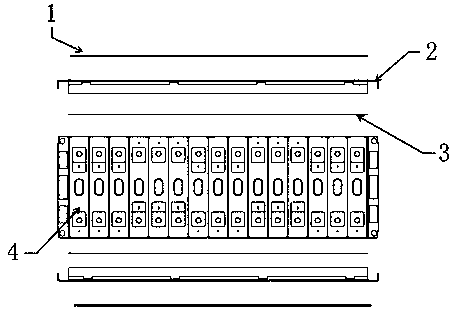

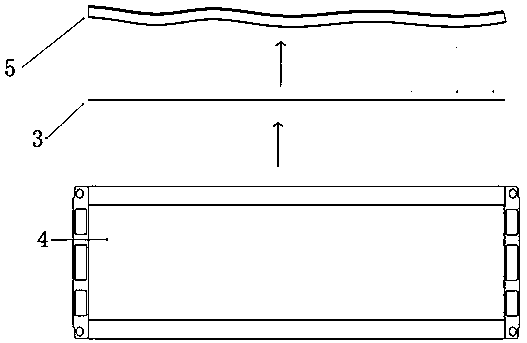

Power battery thermal management method and system based on phase change material

InactiveCN110808431APracticalSolve the disadvantages in cold and heat managementSecondary cellsPower batteryThermodynamics

The invention discloses a power battery thermal management method based on a phase change material. The battery cell of the power battery is surrounded by a PCM heat dissipation board. The thermal management method comprises a heat dissipation stage and a heating stage. In the heat dissipation stage, when the temperature of the battery cell reaches 35 DEG C, the PCM heat dissipation board absorbsthe heat generated during discharging of the battery cell and changes the form to reduce the temperature of the power battery. In the heating stage, when the temperature of the battery cell is lower than 35 DEG C, the PCM heat dissipation board conducts the stored heat to the battery cell to maintain the constant temperature state of the battery cell. The method has the characteristics of good heat dissipation and temperature equalization performance effects and simple system structure and is feasible for temperature management. Meanwhile, the method plays a very important role in the lightweight of battery PACK and the improvement of energy density. Besides, the utilization of phase change material effectively solves the disadvantages in air cooling and liquid cooling thermal management and greatly reduces the production cost and the use cost.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

Structural adhesive capable of being cured at room temperature and used for composite sandwich panel, and preparation method of structural adhesive

ActiveCN106221641AGood synergyGood mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveAntioxidant

The invention discloses a structural adhesive capable of being cured at room temperature and used for a composite sandwich panel, and a preparation method of the structural adhesive. The structural adhesive capable of being cured at room temperature and used for the composite sandwich panel comprises a component A and a component B according to a mass ratio of 100:(50-75), wherein the component A comprises the following components in percentage by mass: 98.5 to 99.9 percent of bisphenol A epoxy resin and 0.1 to 1.5 percent of a defoaming agent; the component B comprises the following components in percentage by mass: 65 to 80 percent of a curing agent, 10 to 25 percent of a toughening agent, 1 to 5 percent of a curing accelerator, 1 to 5 percent of a silane coupling agent and 0.2 to 1 percent of an antioxidant. The structural adhesive capable of being cured at room temperature and used for the composite sandwich panel, provided by the invention, has a wide use range, can select medium-temperature or normal-temperature curing according to requirements, has high mechanical properties, such as toughness and the like, and excellent temperature tolerance, and completely meets use conditions of national military standards.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

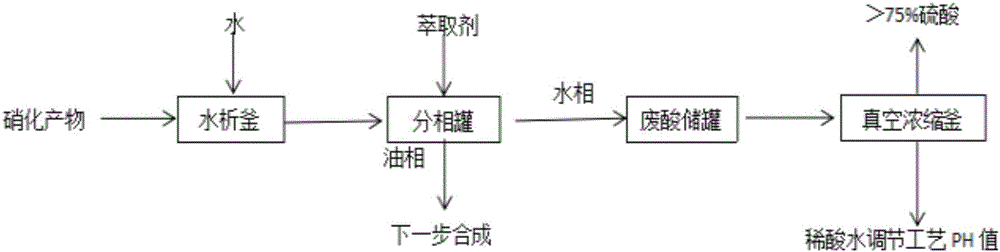

New technology for recycling sulfuric acid in production of 2-cyano-4-nitroaniline

ActiveCN105859580AEasy to useReduce enrichment costsOrganic compound preparationCarboxylic acid nitrile purification/separationChemical industryChlorobenzene

The invention belongs to the field of chemical industry, and relates to a new technology for recycling sulfuric acid in a technology of using concentrated sulfuric acid and concentrated nitric acid to nitrify o-chlorobenzonitrile so as to generate 2-cyano-4-nitro chlorobenzene. An extraction technology is used for extracting a product and nitration by-product impurities from waste acid of nitration, so that pure waste acid is obtained; dilute sulfuric acid is concentrated to 75% or more by using concentration equipment; therefore, the defects that the traditional technology is high in energy consumption, high in pollution and the like are overcome; the technology is free from generation of waste acid, thus being very environmentally friendly.

Owner:河北嘉泰化工科技有限公司

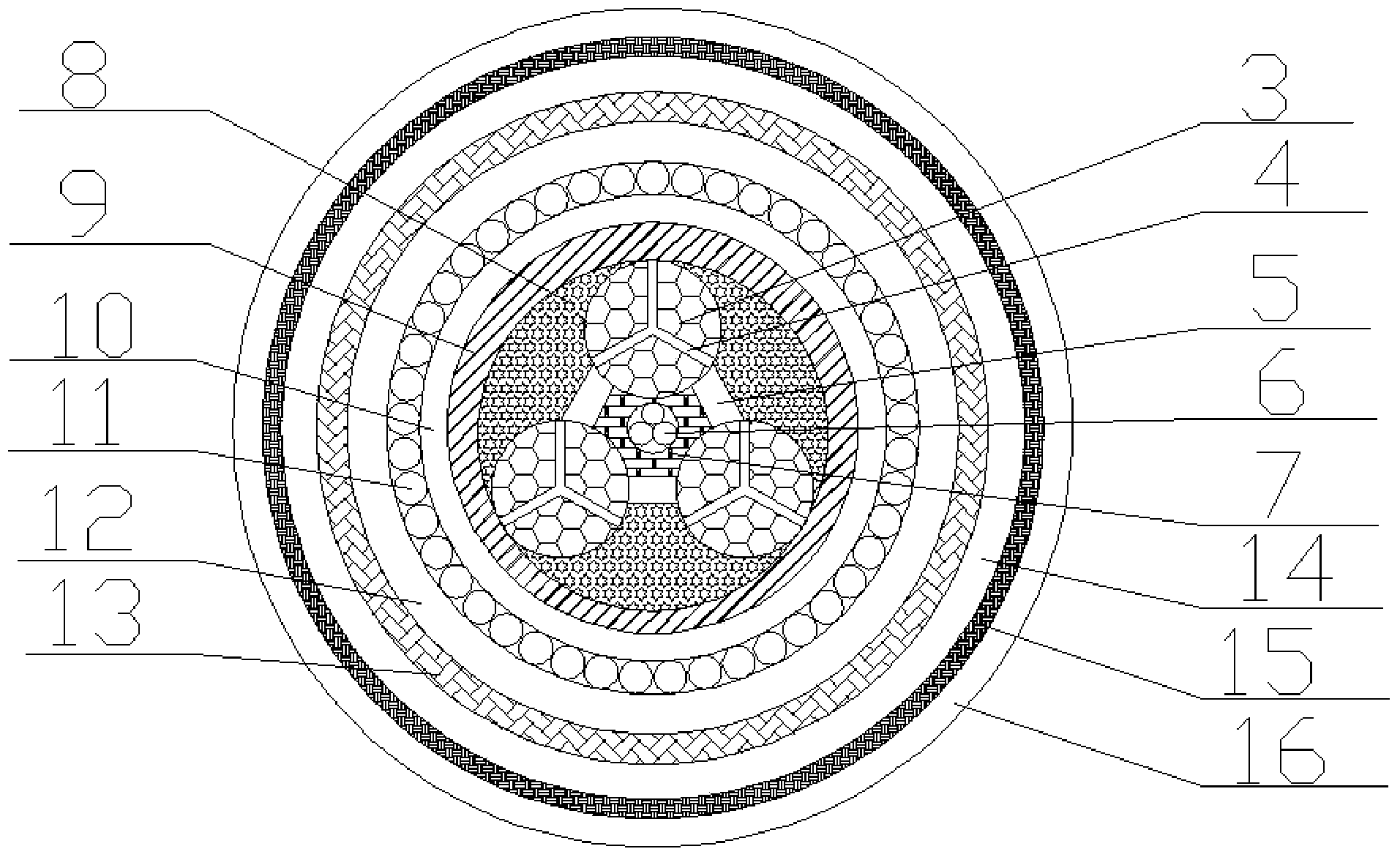

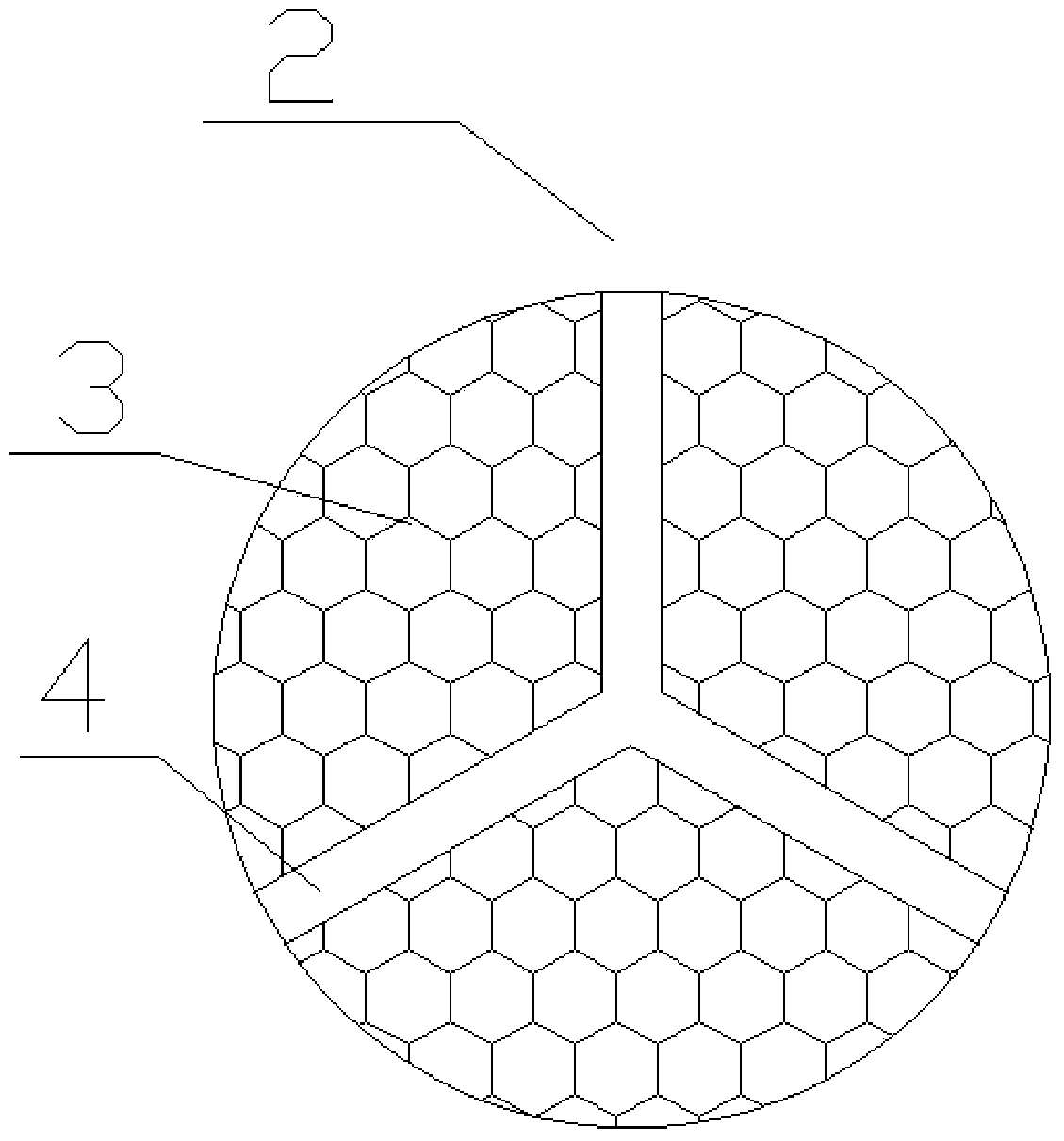

Shielding-preventive and moisture-proof data cable

ActiveCN104332246AAvoid damageImprove current carrying capacityFlexible cablesFlexible conductorsElectrical conductorMoisture

The invention discloses a shielding-preventive and moisture-proof data cable. The cable comprises conductors, insulating layers, copper-plastic composite belt shielding layers and outer sheaths; three conductors are arranged in the cable; each conductor is formed by combining a plurality of cores; the sections of the conductors are of a circular structure; three water stopping filling strips are arranged in each conductor; every two conductors are connected and fixed through a PVC plastic connecting rod; a plurality of optical units are arranged in a central clearance area among the three conductors; fillers are arranged in clearance parts between the conductors and the optical units; insulating layers are extruded at the outer parts of the conductors; elastic filling strips are arranged in the clearance parts between the insulating layers and the conductors; armored layers, the copper-plastic composite belt shielding layers and reinforced knitting layers are extruded on the outer surfaces of the insulating layers from inside to outside in a sequence; toughening layers are arranged at the outsides of the reinforced knitting layers; a seamless wrinkled knitting sleeve and each outer sheath are arranged at the outside of each toughening layer. The cable has the advantages of being great of insulating effect, high in shielding performance and long in service life.

Owner:广安领创华财电子科技有限公司

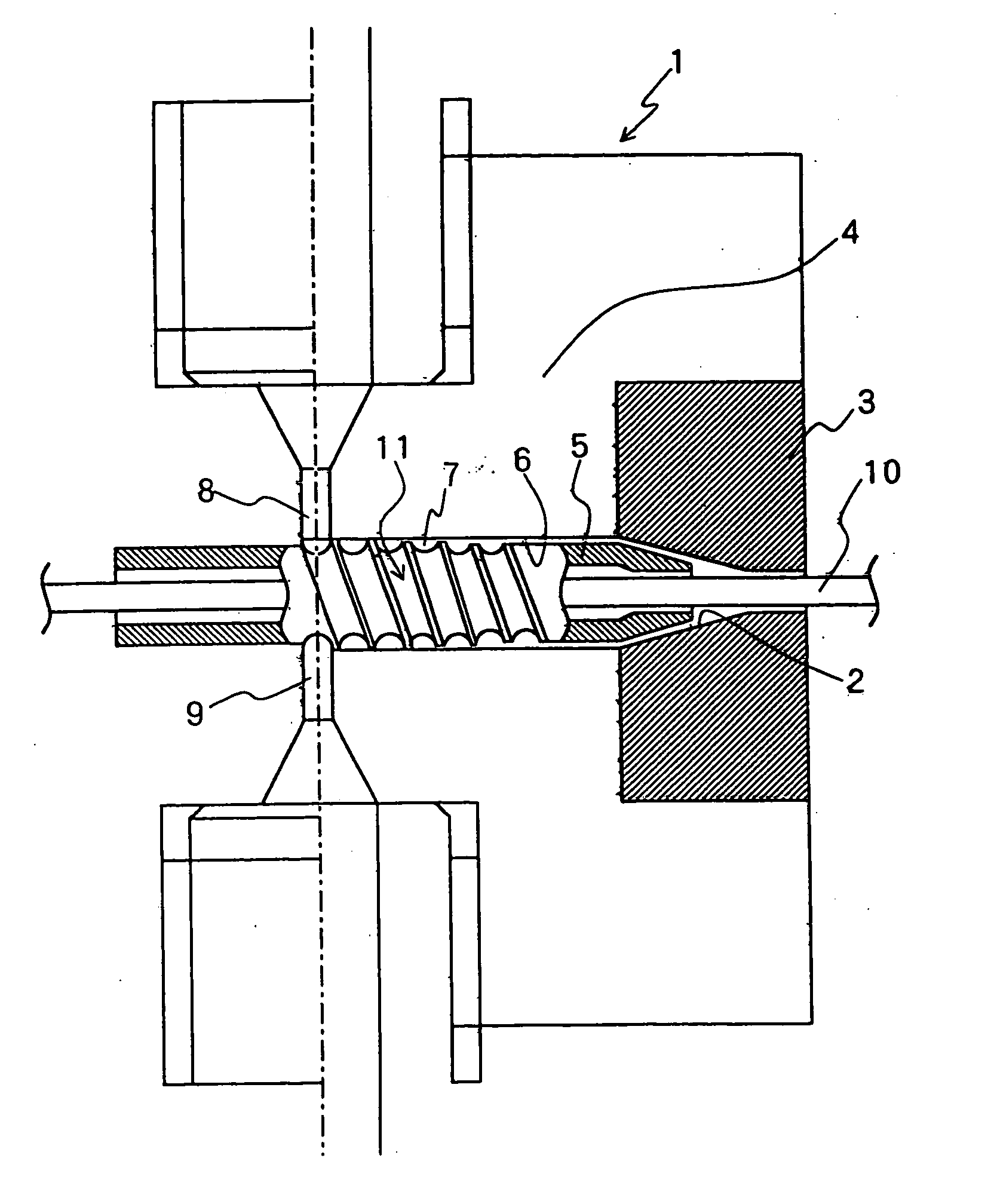

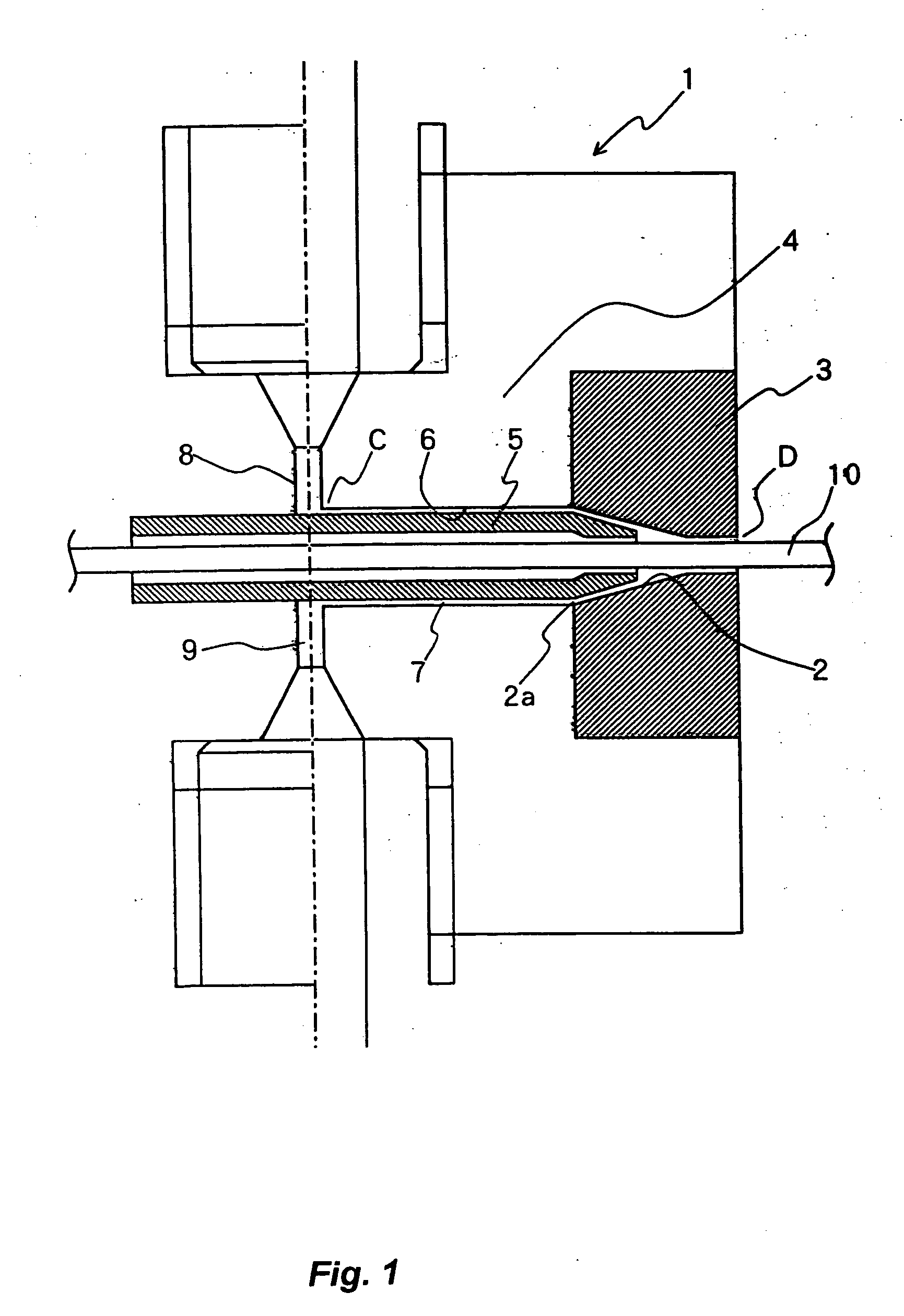

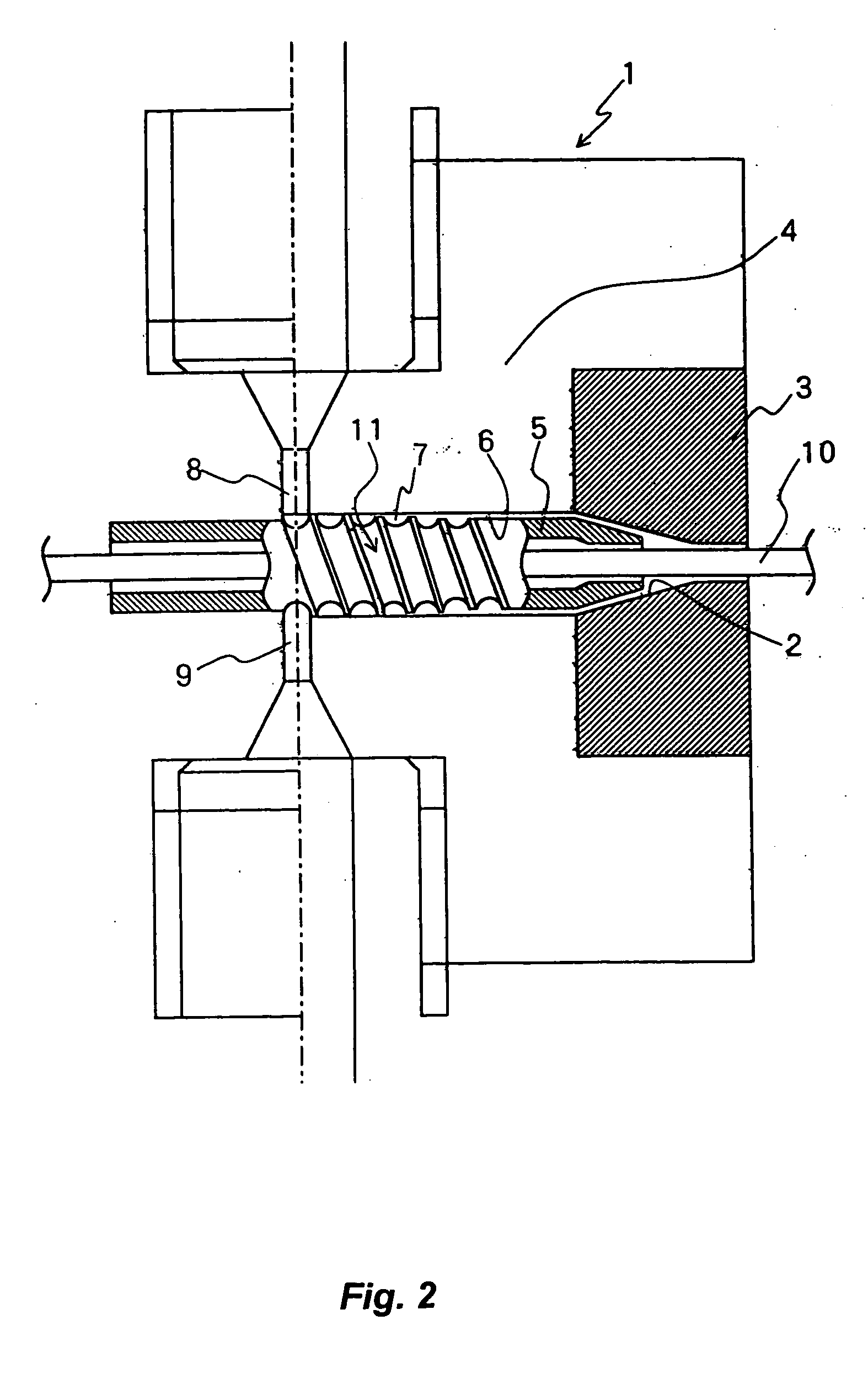

Stiffness-taper tubing and the manufacturing method, and manufacturing apparatus for such tubing

InactiveUS20050003034A1Increased strengthBonding strengthFrozen sweetsConfectioneryBonding strengthEngineering

A stiffness-taper tubing and a manufacturing method and apparatus for such, in which the bonding strength in a transition section between resins having different stiffness is increased, where the length of the transition section is shortened and operability is improved, and where the volume of residual resin when switching resins is reduced as well as the degradation of the quality of residual resin due to heating is suppressed. An apparatus for manufacturing stiffness-taper tubing may include a mandrel having a mixing portion, which is tapered and has projections formed thereon.

Owner:GMA

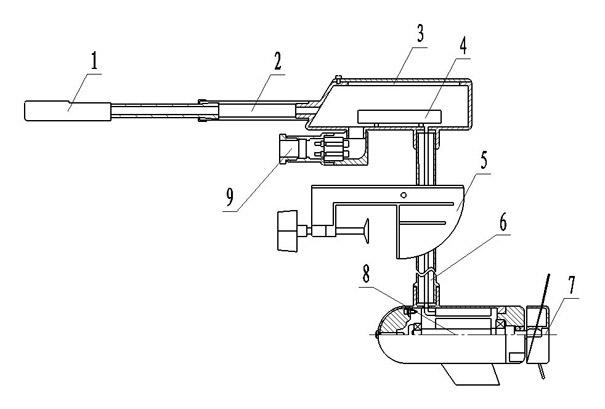

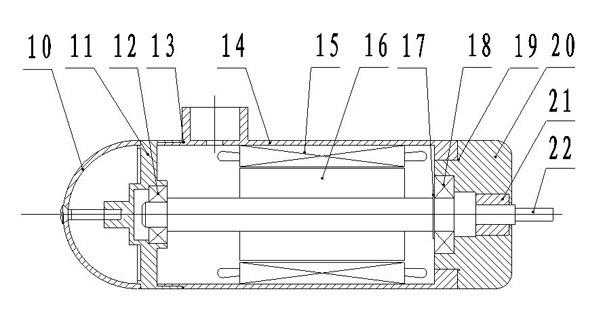

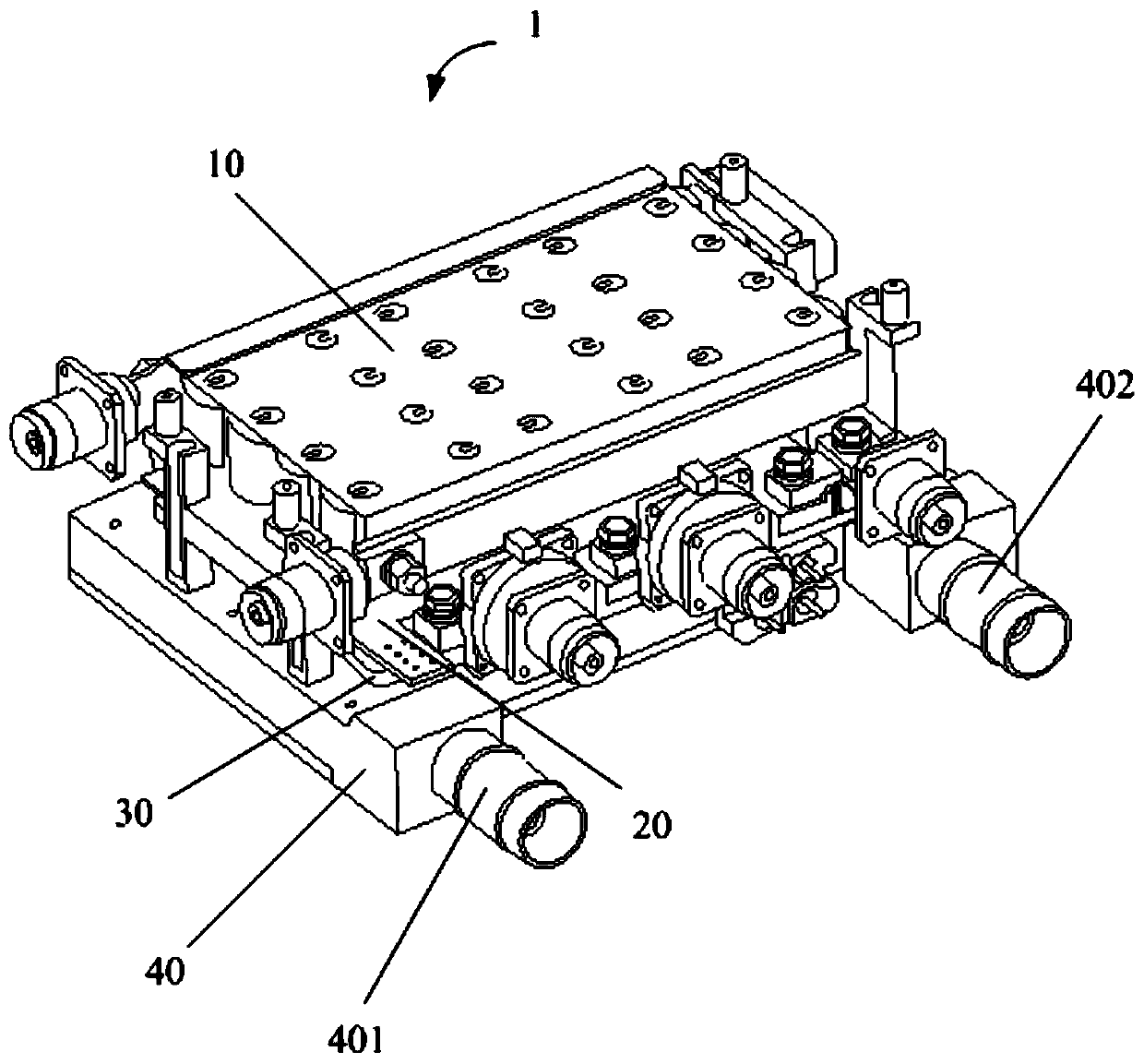

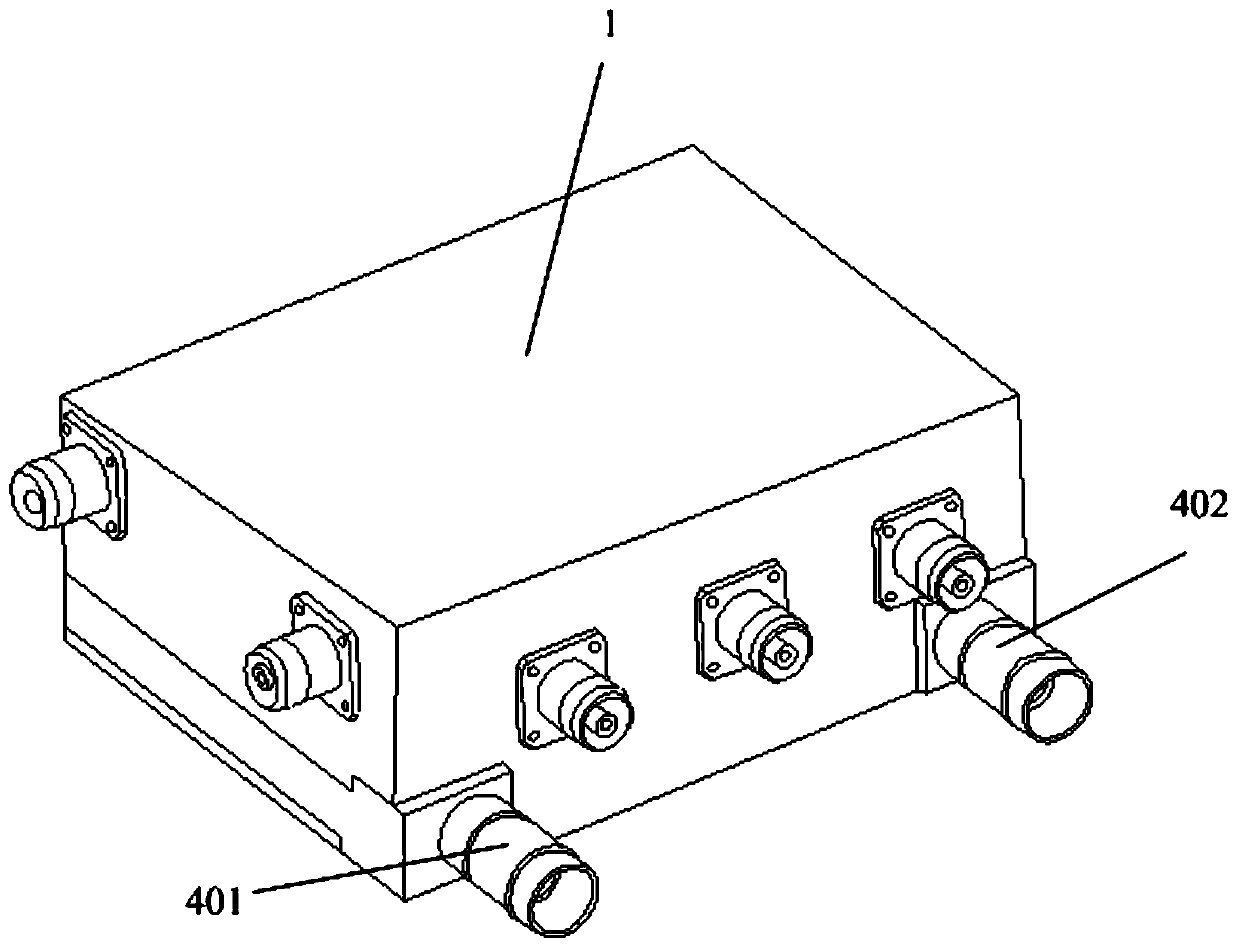

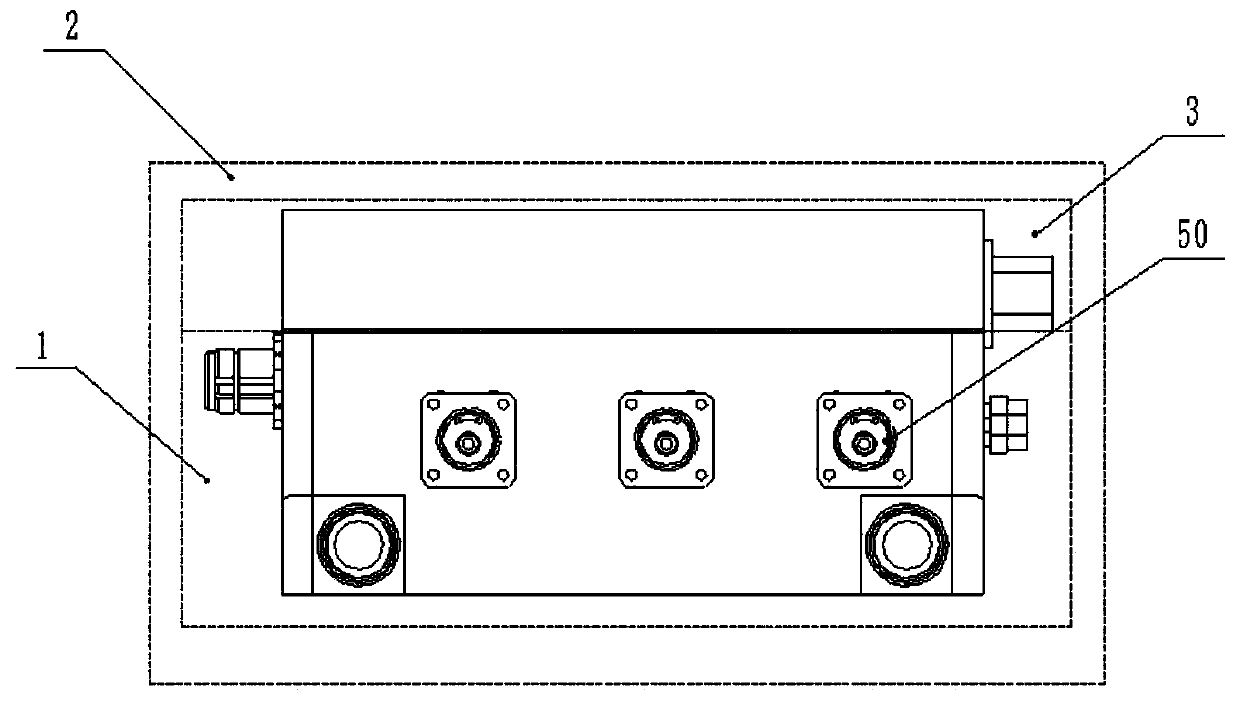

Control device of diving explosion suppression permanent magnet brushless direct current motor used in explosion-proof propeller

InactiveCN102629844AReduce volumeReduce weightSupports/enclosures/casingsElectronic commutatorsLow voltagePropeller

The invention discloses a control device of a diving explosion suppression permanent magnet brushless direct current motor used in an explosion-proof propeller, which belongs to the field of a coal mine boat-used propulsion device technology, relating to a permanent magnet brushless direct current motor and a control device thereof. The technical problem to be solved is to provide a control device of a diving explosion suppression permanent magnet brushless direct current motor of a boat-used propeller which can be used in underground coal mines. The adopted technical solution is that: an input end of an IPM inverter unit is connected to a low voltage direct current power, an output end of the IPM inverter unit is connected to the diving explosion suppression permanent magnet brushless direct current motor, a drive end of the IPM inverter unit is connected to a drive and protection module, and a control end of the IPM inverter unit is connected to a DSP control module; and the DSP control module is connected to the drive and protection module and a signal detecting module separately, and an input end of the signal detecting module is connected to a signal output end of a three-phase Hall sensor and a signal output end of a voltage current sensor separately. The control device of a diving explosion suppression permanent magnet brushless direct current motor provided by the invention is applied to rescue boats used in underground coal mines.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

Integrated plant protection unmanned aerial vehicle spraying mechanism frame

InactiveCN108820219AAvoid shakingMeet the conditions of useAircraft componentsInsect catchers and killersPesticideEngineering

The invention provides an integrated plant protection unmanned aerial vehicle spraying mechanism frame. The frame comprises a screw shaft, a thin nut and a sucker; four inclined tubes are welded to the top side faces of bottom tubes and inclined to the middle by 15 degrees; a horizontal tube is welded between longitudinal tubes and used for fixing a spraying pipe; top tubes are welded to be a rectangular frame and welded to the top side faces of the inclined tubes; a medicine chest frame is formed by welding the four vertically arranged vertical tubes to a rectangular plate at the bottom, thetops of the four vertical tubes are welded to the bottom sides of the top tubes; lug blocks are each of a circular plate structure, and two rectangular blocks are arranged on an outer circle 180 degrees apart; the thin nut is connected to the screw shaft through a thread. Accordingly, medicine chests of different shapes can be placed on the medicine chest frame and fixed, the phenomenon that the medicine chest dimension is not fit, so that shaking is generated on an unmanned aerial vehicle is prevented, the frame is matched with the medicine chests of more specifications, multiple use conditions are met, and flight stability of the plant protection unmanned aerial vehicle in the pesticide spraying process is enhanced.

Owner:BINZHOU UNIV

Power module of SIC electric automobile

PendingCN110034664AReduce installation clearancePart insulation gap is smallSpeed controllerElectric devicesMOSFETBusbar

The invention provides a power module of a SIC electric automobile. The power module comprises a SIC MOSFET device, a radiator, a low-inductance busbar, a capacitor core group, a driver, a sensor anda hydroelectric terminal; the power module is sequentially provided with the radiator, the SIC MOSFET device, the driver and the capacitor core group from bottom to top; the capacitor core group is electrically connected with the SIC MOSFET device and is arranged above the SIC MOSFET device; the driver is installed and fixed on an auxiliary terminal of the SIC MOSFET device through welding; and each component of the power module is formed by integrally packaging and filling through an epoxy resin three-layer filling and sealing technology, and a metal shell is not needed. According to the power module, a motor control unit (MCU) is detached and separated, and the motor control unit and the power module can be installed together to serve as a complete automobile controller according to therequirements of a vehicle factory in an application, and the function of the motor control unit can be integrated into a vehicle control unit (VCU) by the vehicle factory and the power module is onlyused as an execution part for use by the vehicle factory.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com