Socket and connector assembly

A technology of connector components and sockets, which is applied in the field of optical transmission components, can solve the problems of increasing the height of the connector, the volume of the first connector housing, and the inability to meet the requirements of use, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

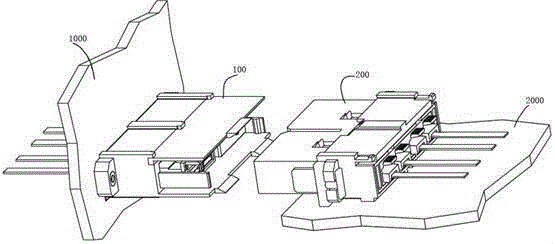

[0028] Embodiment 1 of the connector assembly of the present invention: as figure 1 As shown, it includes a plug 200 and a socket 100, the connector assembly is a connector assembly for backplane connection, the plug 200 is installed on the sub-board 2000, the socket 100 is fixedly connected to the backplane 1000, and the sub-board 2000 is a horizontal board , the backplane 1000 is a vertical board, and the plug 200 and the socket 100 respectively include a plug housing 20 and a socket housing 10 extending forward and backward.

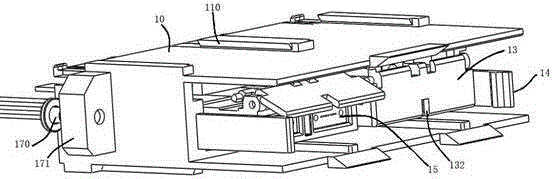

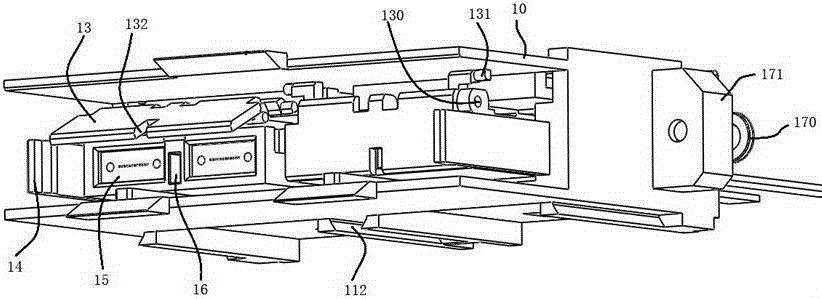

[0029] The structure of the socket 100 is as Figure 2-6 As shown, the socket housing 10 and the socket contact part 15 arranged in the socket housing 10 are included. The socket housing 10 is a rectangular housing, and two mounting structures for installing the socket contact part 15 are arranged side by side inside the socket housing 10. The socket contact part 15 is installed in the socket housing 10 and extends in the front-rear direction; the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com