Method for producing magnesium calcium ramming material for AOD furnace from waste magnesia-calcium bricks

A technology of waste magnesia-calcium brick and ramming material is applied in the field of refractory material production, which can solve the problems of no application of industrial production, etc., and achieve the effects of saving resources, prolonging the shelf life and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] [embodiment 1] produce a kind of magnesia-calcium ramming material by method of the present invention;

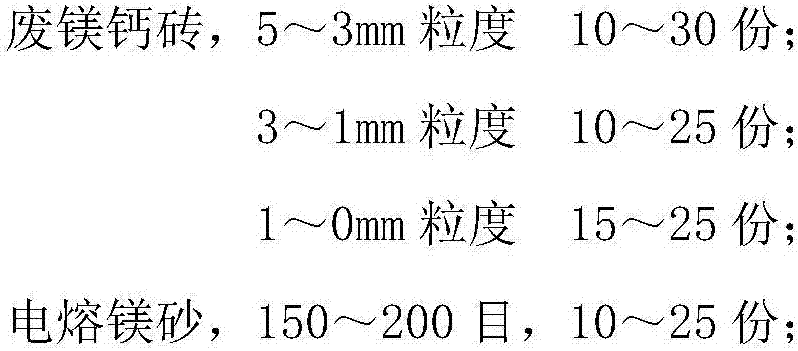

[0046] 1. the magnesium-calcium ramming material described in the present embodiment is made up of following raw material by weight ratio:

[0047] Waste magnesia-calcium bricks (20% by weight of CaO): 5-3mm particle size, 30 parts; 3-1mm particle size, 20 parts; 1-mm particle size, 25 parts.

[0048] Fused magnesia (97% by weight of MgO): 200 meshes, 25 parts.

[0049] The binder is composed of the following components in proportion by weight: 1 part of boric acid, 3 parts of vegetable oil, 2 parts of high-temperature asphalt powder, and 1.5 parts of zirconia powder.

[0050] 2. Put the waste magnesia-calcium bricks in a closed container, add waterproofing agent to soak, and add 0.2MPa / cm 2 pressure to achieve pressurized penetration; the water repellent agent uses organic silicon solution; dry after soaking.

[0051] The waste magnesia-calcium brick soaked in the ...

Embodiment 2

[0055] [embodiment 2] produce a kind of magnesium-calcium ramming material by the method for the present invention.

[0056] 1. the magnesium-calcium ramming material described in the present embodiment is made up of following raw material by weight ratio:

[0057] Waste magnesia-calcium bricks (30% by weight of CaO): 5-3mm particle size, 25 parts; 3-1mm particle size, 25 parts; 1-mm particle size, 20 parts.

[0058] Fused magnesia (97% by weight of MgO): 200 meshes, 25 parts.

[0059] The binder is composed of the following components in proportion by weight: 2 parts of boric acid, 3 parts of vegetable oil, 1 part of high-temperature asphalt powder, and 2 parts of zirconia powder.

[0060] 2. Put the waste magnesia-calcium bricks in a closed container, add waterproofing agent to soak, and add 0.3MPa / cm 2 pressure to achieve pressurized penetration; the waterproofing agent uses organic silicon solution, which is naturally dried after soaking.

[0061] The waste magnesia-cal...

Embodiment 3

[0066] According to the method of the present invention, a magnesium-calcium ramming material is produced.

[0067] 1. the magnesium-calcium ramming material described in the present embodiment is made up of following raw material by weight ratio:

[0068] Waste magnesia-calcium bricks (CaO weight percentages are 20% and 30%, according to any ratio): 5-3mm particle size, 20 parts; 3-1mm particle size, 25 parts; 1-mm particle size, 15 parts.

[0069] Fused magnesia (97% by weight of MgO): 200 mesh, 10 parts.

[0070] The binder is composed of the following components in proportion by weight: 4 parts of borax, 5 parts of vegetable oil, 3 parts of high-temperature asphalt powder, and 2 parts of zirconia powder.

[0071] 2. Put the waste magnesia-calcium bricks in a closed container, add waterproofing agent to soak, and add 0.1MPa / cm 2 pressure to achieve pressurized penetration; the waterproofing agent uses organic silicon solution, which is dried after soaking.

[0072] The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com