New technology for recycling sulfuric acid in production of 2-cyano-4-nitroaniline

A technology of nitroaniline and a new process, which is applied in the new process field of sulfuric acid recycling, can solve the problems of high energy consumption of sulfuric acid and low concentration of waste acid, and achieve the effect of reducing the cost of acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

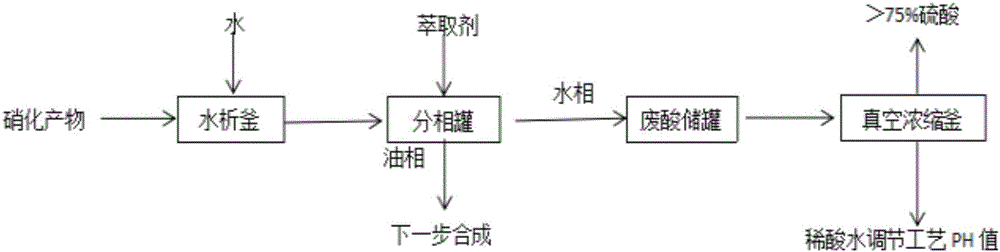

Method used

Image

Examples

Embodiment 1

[0023] Major equipment:

[0024] serial number

Specification

material

use

1.

Water analysis kettle

10000L

enamel

dilute with water

2.

Extraction and phase separation tank

10000L

enamel

Extraction with benzene chloride

2.

Acid Concentrator

10000L

enamel

dilute acid concentration

[0025] The amount and quality of extraction raw materials

[0026] process

Weight (Kg)

Water analysis

process water

4000

extraction

Extractant: Chlorinated benzene

5500

[0027] Add 4,000 kg of process water into the water analysis kettle, start stirring, slowly put in the nitrated nitrated product, and control the temperature at 30-35°C. Add 5,500 kilograms of chlorinated benzene after discharging the material, stir for half an hour and let it stand for half an hour to obtain dilute sulfuric acid by separation.

[0028] Test res...

Embodiment 2

[0034] Major equipment:

[0035] serial number

Specification

material

use

1.

Water analysis kettle

10000L

enamel

dilute with water

2.

Extraction and phase separation tank

10000L

enamel

Extraction with benzene chloride

2.

Acid Concentrator

10000L

enamel

dilute acid concentration

[0036] The amount and quality of extraction raw materials

[0037] process

Weight (Kg)

Water analysis

process water

4000

extraction

Extractant: Chlorinated benzene

5500

[0038] Add 4,000 kg of process water into the water analysis tank, start stirring, slowly put in the nitrated nitrated product, and control the temperature at 40-45°C. Add 5,500 kilograms of chlorinated benzene after discharging the material, stir for half an hour and let it stand for half an hour to obtain dilute sulfuric acid by separation.

[0039] Test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com