Patents

Literature

88results about How to "Reduce enrichment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

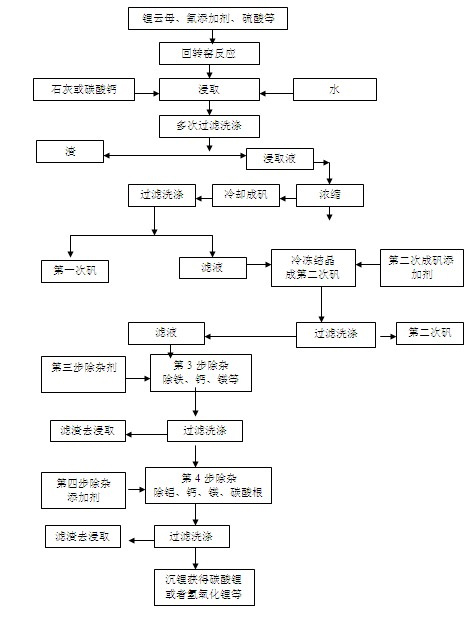

Process for removing impurities from lepidolite leaching solution

The invention relates to a process for removing impurities from a lepidolite leaching solution. The process is completed by carrying out impurity removal on alumina twice and adjusting pH values for twice. Lithium salt precipitation products are obtained by adding additives to a lithium sulfate solution after impurity removal, and corresponding refined lithium salts can be prepared as required. The process has the advantages that the cost of impurity removal is low, by-products with high added values can be obtained, the extraction rate of lithium is high, various useful components of lepidolite ores can also be fully utilized when lithium salts are produced, and the recycling of resources is realized.

Owner:江西海汇龙洲锂业有限公司

Method for concentrating and purifying titanium dioxide waste acid by using complex acid

InactiveCN103011272AHigh yieldReduce enrichment costsSulfur compoundsEnergy inputPhysical chemistryAcid concentration

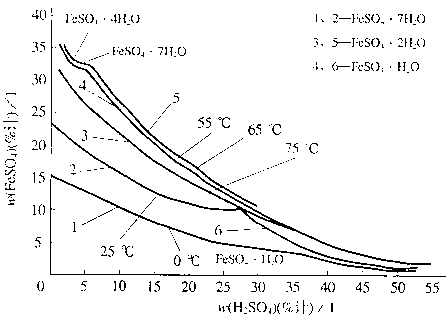

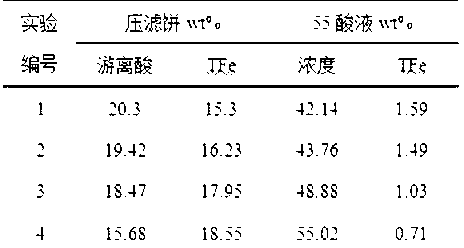

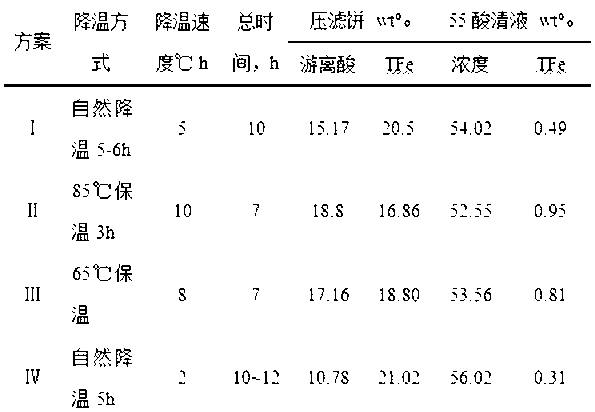

The invention discloses a method for concentrating and purifying titanium dioxide waste acid by using complex acid. The method comprises the following specific steps of: titanium recovery: primarily concentrating waste acid produced in a titanium dioxide production process by using waste heat of calcining tail gas of a ring kiln to achieve the mass concentration being 25-32%, and then recovering titanium; acid mixing: uniformly mixing the waste acid subjected to titanium recovery and concentrated sulfuric acid in an acid mixing tank according to a mass proportion of (1.2-4):1 to obtain mixed acid; and crystallization: carrying out gradient cooling, crystallizing, curing and filtering on the mixed acid gradually in the acid mixing tank, and when the temperature of the mixed acid is reduced to 60-65 DEG C, pumping the mixed acid into a filter press for solid-liquid separation to obtain concentrated sulfuric acid and ferrous dregs. The method disclosed by the invention has the advantage of changing the traditional method for concentrating the titanium dioxide waste acid by depending on natural gas, steam, fire coal hot gas and other heat sources, is free from consuming a large amount of energy sources and capable of reducing the cost in waste acid concentration, and is high in recovery rate of the waste acid.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

High-desalting-rate seawater desalination method and device based on liquefied natural gas cold energy

ActiveCN104891593AHigh desalination rateReduce engineering costsGeneral water supply conservationSeawater treatmentLiquid stateEngineering

The invention discloses a high-desalting-rate seawater desalination method based on liquefied natural gas cold energy, which comprises the following steps: sufficiently carrying out indirect heat exchange on liquefied natural gas and a gas-state secondary coolant, and sufficiently carrying out indirect heat exchange on the obtained liquid-state secondary coolant and seawater to obtain ice and concentrated seawater; (2) taking the ice obtained in the step (1), standing under atmospheric pressure until the melting rate of ice is 10-50%, recovering the liquid, and taking the residual ice for later use; (3) crushing the residual ice obtained in the step (2) to obtain ice crystal granules, centrifuging, recovering the liquid, and taking the ice crystal granules for later use; and (4) completely melting the ice crystal granules obtained in the step (3). The invention also discloses a seawater desalination plant based on liquefied natural gas cold energy. The method utilizes the cold energy released in the liquefied natural gas gasification process, comprehensively utilizes the freeze desalting, gravity desalting and centrifuging desalting techniques, has the advantages of simple steps, energy saving and environment friendliness, and enhances the seawater desalting rate on the basis of freeze desalting.

Owner:CHINA PETROLEUM & CHEM CORP +1

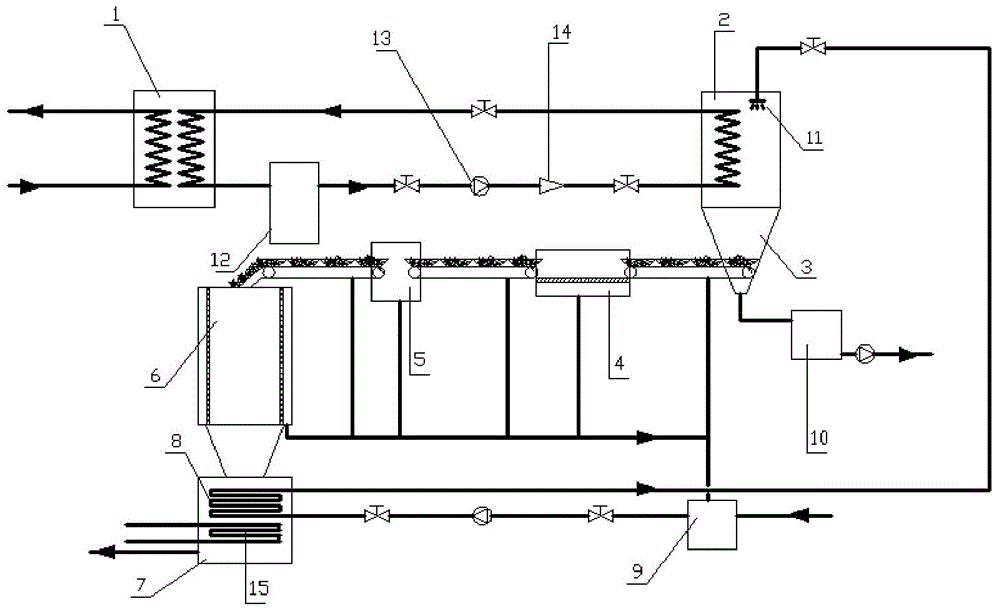

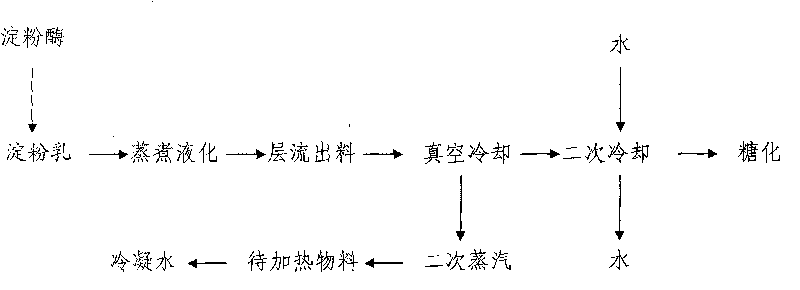

Method for recovering waste heat during processing of starchy material

ActiveCN101736059AIncrease concentrationReduce dosageEnergy inputFermentationSocial benefitsEmulsion

The invention relates to a method for recovering waste heat during processing of a starchy material, which belongs to the technical field of starchy material saccharification. The method for recovering the waste heat during the processing of the starchy material comprises the following steps: boiling and steaming a liquefied starchy emulsion, discharging after the laminar flow and heat preservation, vacuumizing and cooling the discharging to obtain the cooled starchy emulsion, and then recovering the waste heat and condensate water of the secondary steam obtained by vacuumizing through a heat-exchange device. The invention also provides a device special for the method. The method for recovering the waste heat during the processing of starchy material has the advantages of comprehensively recycling the waste heat in the saccharification process of the starchy material, reducing the demands for the condensate water, meeting the requirement of energy saving and emission reduction of the state, and having remarkable economic and social benefits.

Owner:鲁洲生物科技(陕西)有限公司

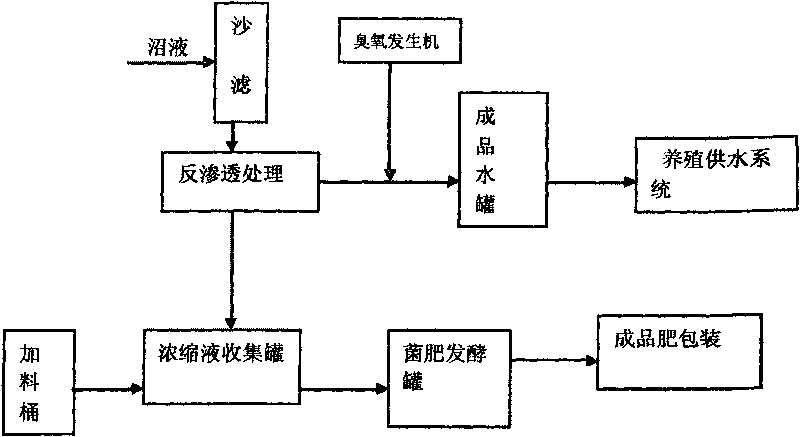

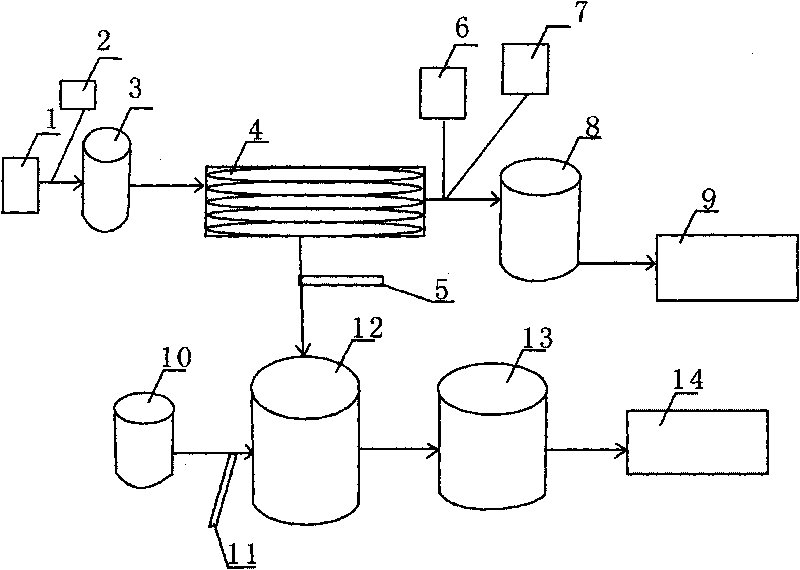

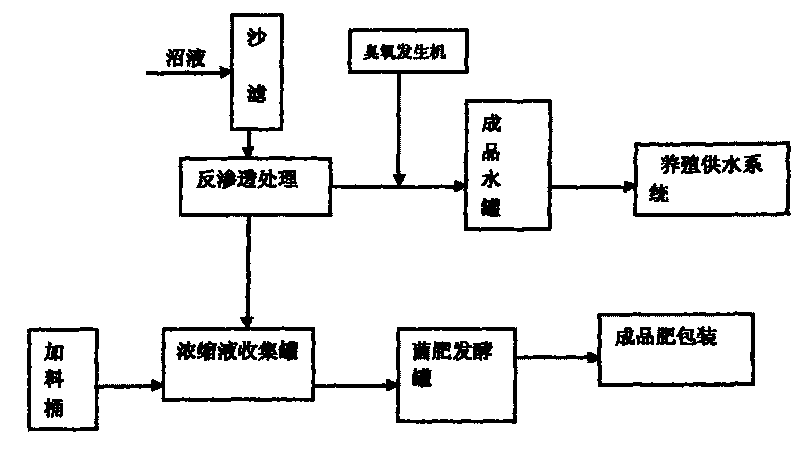

Production scheme and preparation method of converting biogas slurry into organic fertilizer

InactiveCN101712565AReduce enrichment costsHigh degree of automationClimate change adaptationSewage/sludge fertilisersChemistryOrganic manure

The invention relates to the field of preparation of high-quality organic fertilizer by recycling waste, and concentrates biogas slurry to obtain organic fertilizer and reusable water by utilizing the principle of reverse osmosis. The invention particularly relates to a production scheme and a preparation method of converting biogas slurry into organic fertilizer. The production scheme and the preparation method of converting biogas slurry into organic fertilizer are characterized by comprising the following steps: (A) sand filtration treatment: pumping the biogas slurry into a steel tank filled with quartz sand, and filtering out the large dross; (B) reverse osmosis treatment: pressurizing the biogas slurry, and separating water from the biogas slurry by using the principle of reverse osmosis, thereby obtaining the biogas slurry concentrate; (C) ozone sterilization: sterilizing the water obtained through the reverse osmosis with ozone, and recycling the water; (D) addition of effective ingredients: recycling the concentrated biogas slurry, carrying out the chemical examination, and adding corresponding ingredients according to different operating requirements; and (E) fermentation with beneficial bacteria: fermenting the prepared concentrate with beneficial bacteria and packaging.

Owner:王耘

Method for digesting tobacco concrete from tobacco ribs

InactiveCN103416840ASolve the shortageDoes not contain does not exceed the standardTobacco treatmentEssential-oils/perfumesUltrafiltrationDesalination

The invention relates to a method for digesting tobacco concrete from tobacco ribs. The method for digesting the tobacco concrete from the tobacco ribs is characterized by comprising the first step of preprocessing and digesting the tobacco ribs, the second step of removing suspended solids and soluble macromolecule organic matter impurities, the third step of ultrafiltration, separation and purification, the fourth step of nanofiltration, desalination and dehydration, the fifth step of electrodialysis desalination and the sixth step of concentration. According to the method, deionized water serves as a reagent, an organic reagent is not used, cost is greatly reduced, the effect on the quality of the concrete from the organic reagent impurities is eradicated, and the safety of the concrete is improved.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

Dilute sulfuric acid vacuum concentration device and method

ActiveCN108358176AReduce consumptionReduce enrichment costsSulfur compoundsEnergy inputWater vaporTherapeutic effect

The invention relates to a dilute sulfuric acid vacuum concentration device and method. The method comprises the following steps: performing metering control on 65-75% of dilute sulfuric acid, enabling the dilute sulfuric acid to enter an acid-acid heat exchanger, preheating the raw material acid by utilizing waste heat of acid discharged by a secondary sulfuric acid thickener, and treating in a primary sulfuric acid thickener; overflowing the treated acid in the secondary sulfuric acid thickener to be treated; enabling acid-containing water vapor produced by the primary sulfuric acid thickener to enter a primary tail gas condenser, overflowing condensed and separated water vapor to enter a wastewater collection tank, and discharging noncondensable gas, acid gas and a small amount of watervapor by a multistage steam jet vacuum pump set and feeding into an accident chlorine tail gas tower to be purified; enabling the acid-containing water vapor produced by the secondary sulfuric acid thickener to enter a secondary tail gas condenser, overflowing the condensed and separated water vapor to enter a wastewater collection tank, and discharging the noncondensable gas, acid gas and a small amount of water vapor by the multistage steam jet vacuum pump set and feeding into the accident chlorine tail gas tower to be purified. The dilute sulfuric acid vacuum concentration device disclosedby the invention has the advantages of being low in cost, low in energy consumption, good in treatment effect, high in reliability, stable in operation and the like.

Owner:杭州东日节能技术有限公司

High-content jujube cyclic adenosine monophosphate extract and preparation method thereof

ActiveCN103623080AImprove extraction transfer rateIncrease productivityOrganic active ingredientsAntinoxious agentsLife qualityHigh pressure

The invention provides a high-content jujube cyclic adenosine monophosphate extract and a preparation method thereof. The concentration of cyclic adenosine monophosphate in the extract is more than 15mg / 100g, solid or semi-solid jujubes are taken as raw materials, and the preparation method comprises the steps of extracting by a continuous low-temperature extractor with high pressure difference, concentrating an extraction solution, performing vacuum drying and crushing to obtain a jujube crude extract; extracting the crude extract by adopting a supercritical extraction technology to obtain the jujube cyclic adenosine monophosphate extract. The jujube cyclic adenosine monophosphate extract has prominent effects in the aspects of hypoxia resistance, fatigue resistance and improvement of life quality. The preparation method has the following obvious advantages: (1) the extraction transfer rate is high; (2) the production efficiency is high; (3) the quality controllability is high; (4) the operation controllable degree is high; (5) the comprehensive utilization rate of resources is high; (6) the comprehensive operation cost is low; (7) the degree of automation is high; (8) the environmental pollution is little.

Owner:中恩(天津)医药科技有限公司

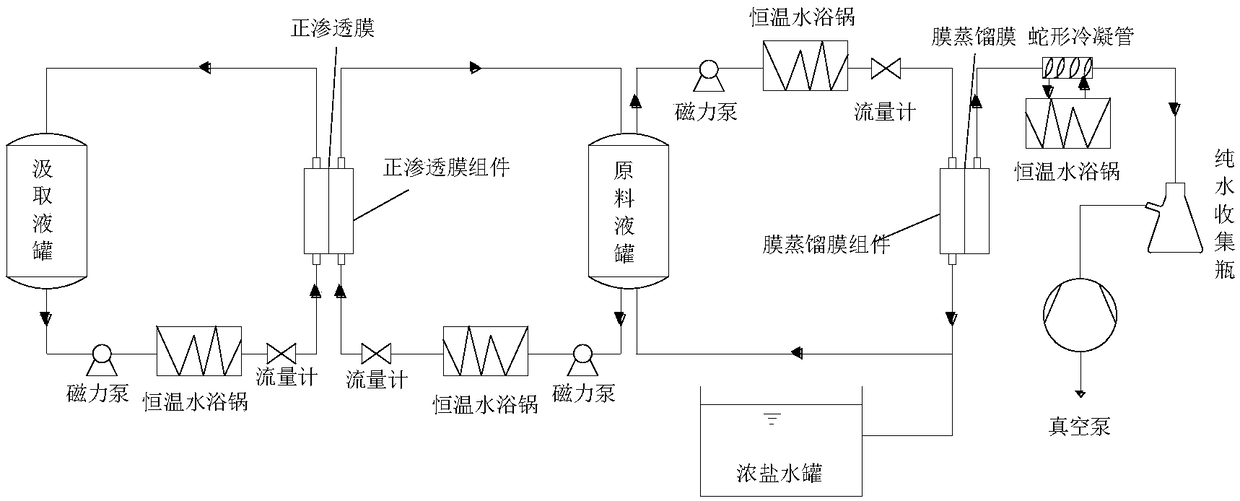

Reverse osmosis strong brine concentration method and equipment

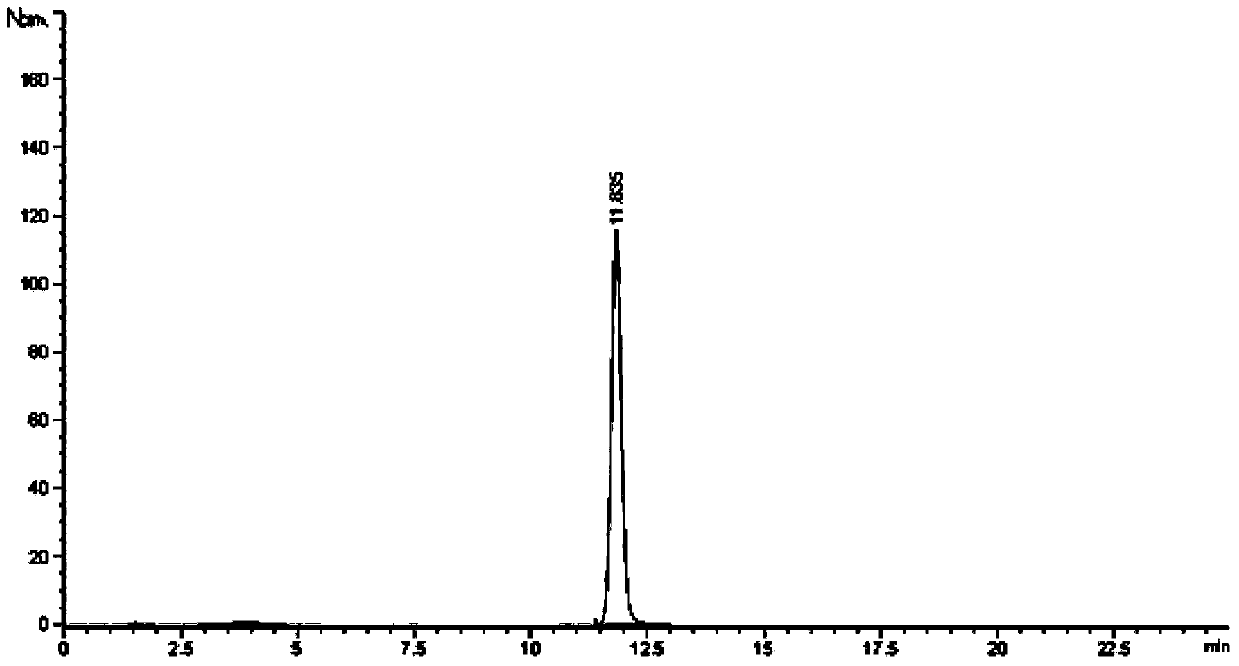

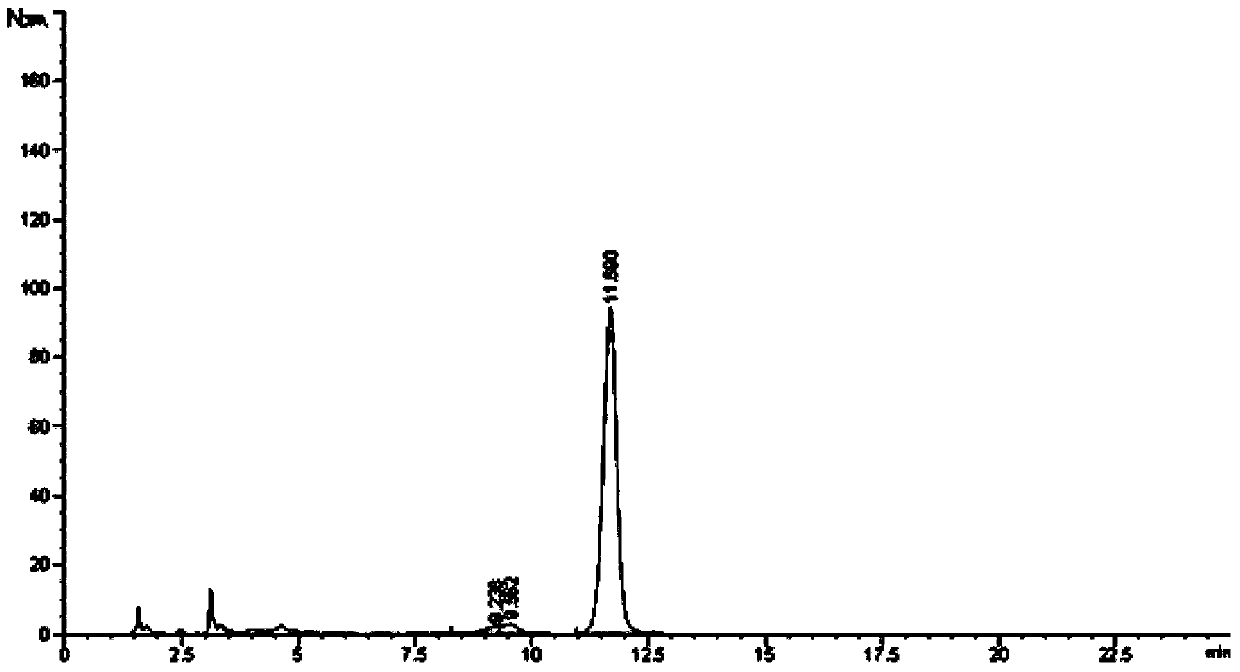

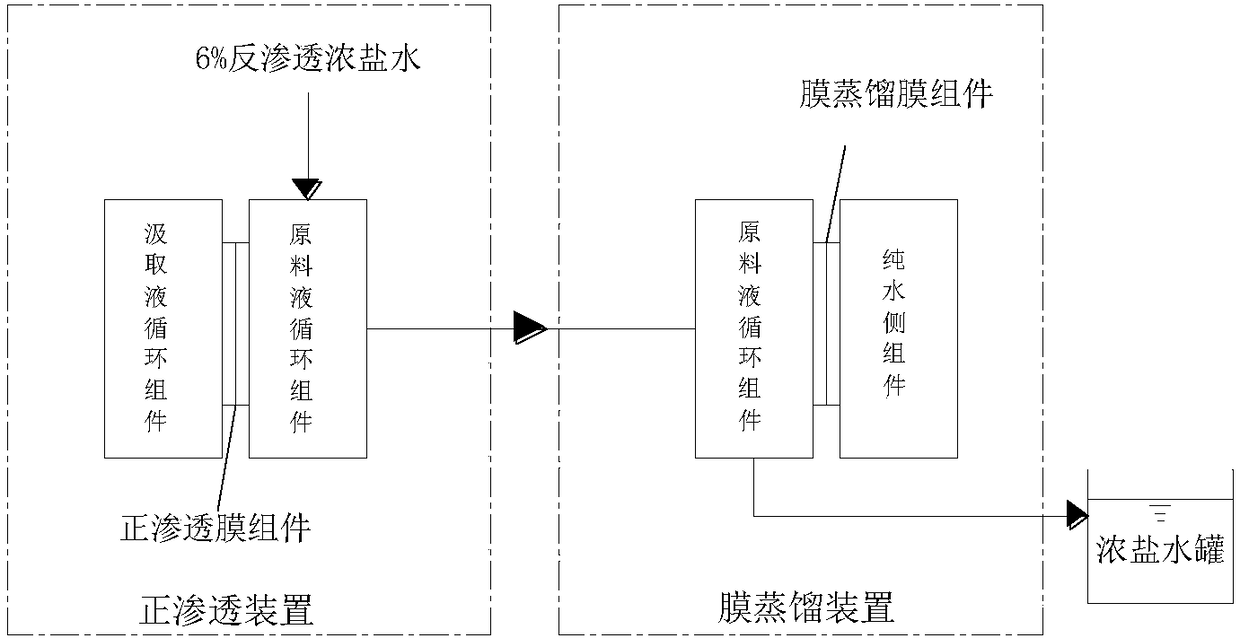

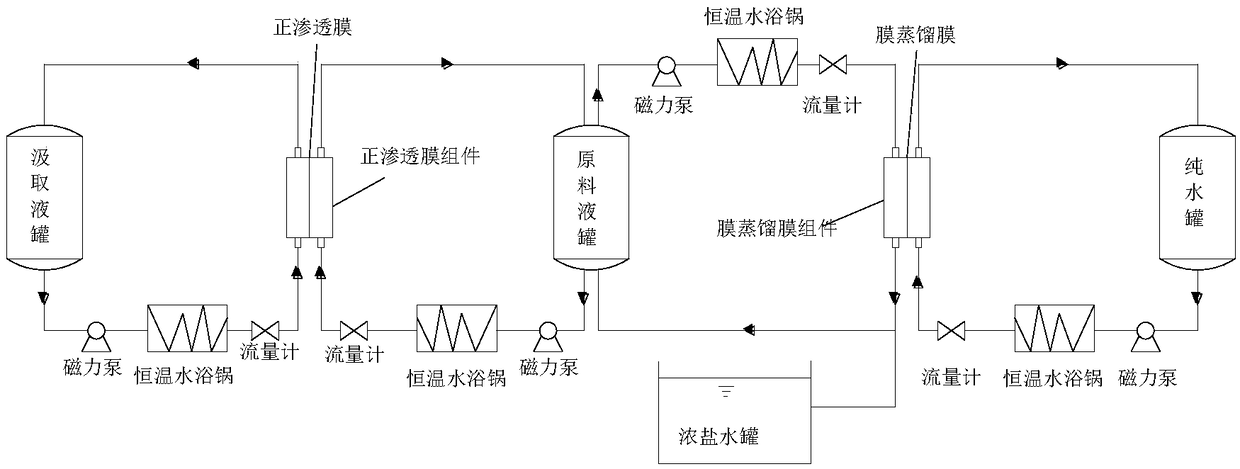

ActiveCN108328831AReduce overall energy consumptionReduce enrichment costsWater treatment parameter controlWater/sewage treatmentPre treatmentChemistry

The invention discloses a reverse osmosis strong brine concentration method and equipment. The concentration method comprises the following processes of (1) a positive osmosis concentration process: using reverse osmosis strong brine as raw material liquid, so that the water in the raw material liquid passes through a positive osmosis film to enter the liquid suction side through the effect of suction liquid, salt in the raw material liquid is intercepted at the raw material liquid side, and the raw material liquid can be concentrated; (2) a film distillation concentration process: conveying the raw material liquid concentrated in the step (1) to a hot side of a film distillation film; performing cooling by circulation water at the cold side of the film distillation film or vacuum suction,so that the water at the hot side passes through the film distillation film in a water vapor form to enter the cold side, the raw material liquid at the hot side loses water, and the raw material liquid is further concentrated. The concentration equipment comprises a positive osmosis device, a film distillation device and a strong brine tank. According to the concentration method and equipment, the positive osmosis is used as the film distillation pretreatment technology to perform deep concentration on the reverse osmosis strong brine, so that the whole energy consumption is reduced; the treatment of the reverse osmosis strong brine and the subsequent resource utilization are realized at low energy consumption and high concentration efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

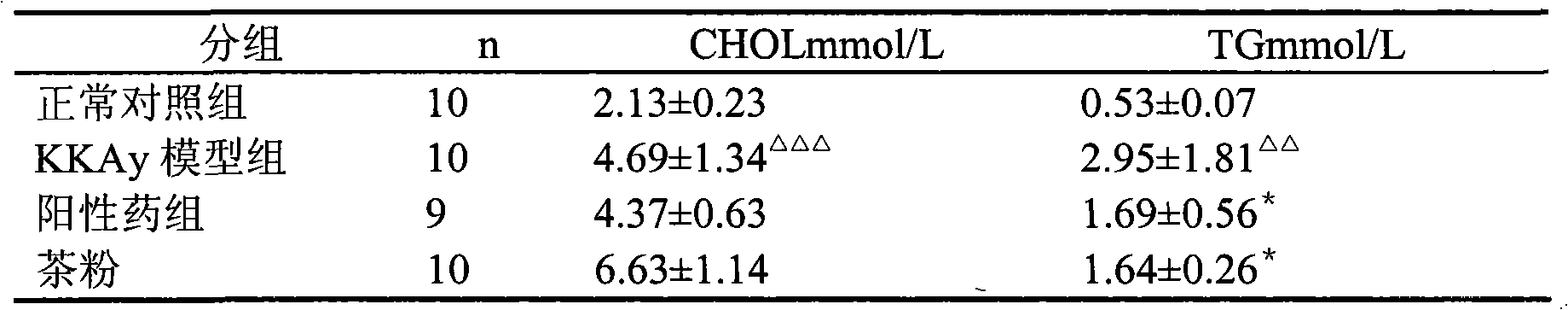

Pu-erh tea extract and preparation thereof

ActiveCN101961424APromote conversionPromote dissolutionMetabolism disorderColor/spectral properties measurementsChemistryTraditional Chinese medicine

The invention relates to a traditional Chinese medicine extract and preparation thereof, in particular to a pu-erh tea extract and preparation thereof. The preparation method comprises the following technical means: encapsulation, countercurrent extraction, membrane filtration, centrifugation and the like.

Owner:TIANJIN TASLY GROUP

Method for cultivating photosynthetic bacteria in Rhodopseudomonas on large scale

InactiveCN105754903AEasy accessLow costBacteriaMicroorganism based processesBacteroidesGenus Rhodopseudomonas

The invention discloses a method for cultivating photosynthetic bacteria in Rhodopseudomonas on large scale, comprising: adding common aquatic compound feed into tap water according to a ratio of compound feed to water being 20-120 g to 1L; placing in a light-permeable container in an open lit environment at 28-45 DEG C, adding photosynthetic bacteria mother liquid for fermentation culture, wherein addition density of photosynthetic bacteria is 1.0*108-5.0*1010 cell / L at beginning, cultivating until dense photosynthetic bacteria in Rhodopseudomonas growing to 1 mm in thickness attach to the inner wall of the container, and growing high-density photosynthetic bacteria in water to obtain high-density photosynthetic bacteria in Rhodopseudomonas in both attaching and floating statuses.The compound feed can be converted into photosynthetic bacteria in Rhodopseudomonas, harmless treatment and utilization of nutrients in a water body can be promoted, conversion of the nutrients in the water body can be accelerated, and the formed photosynthetic bacteria are directly useful in aquaculture or sewage purification.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

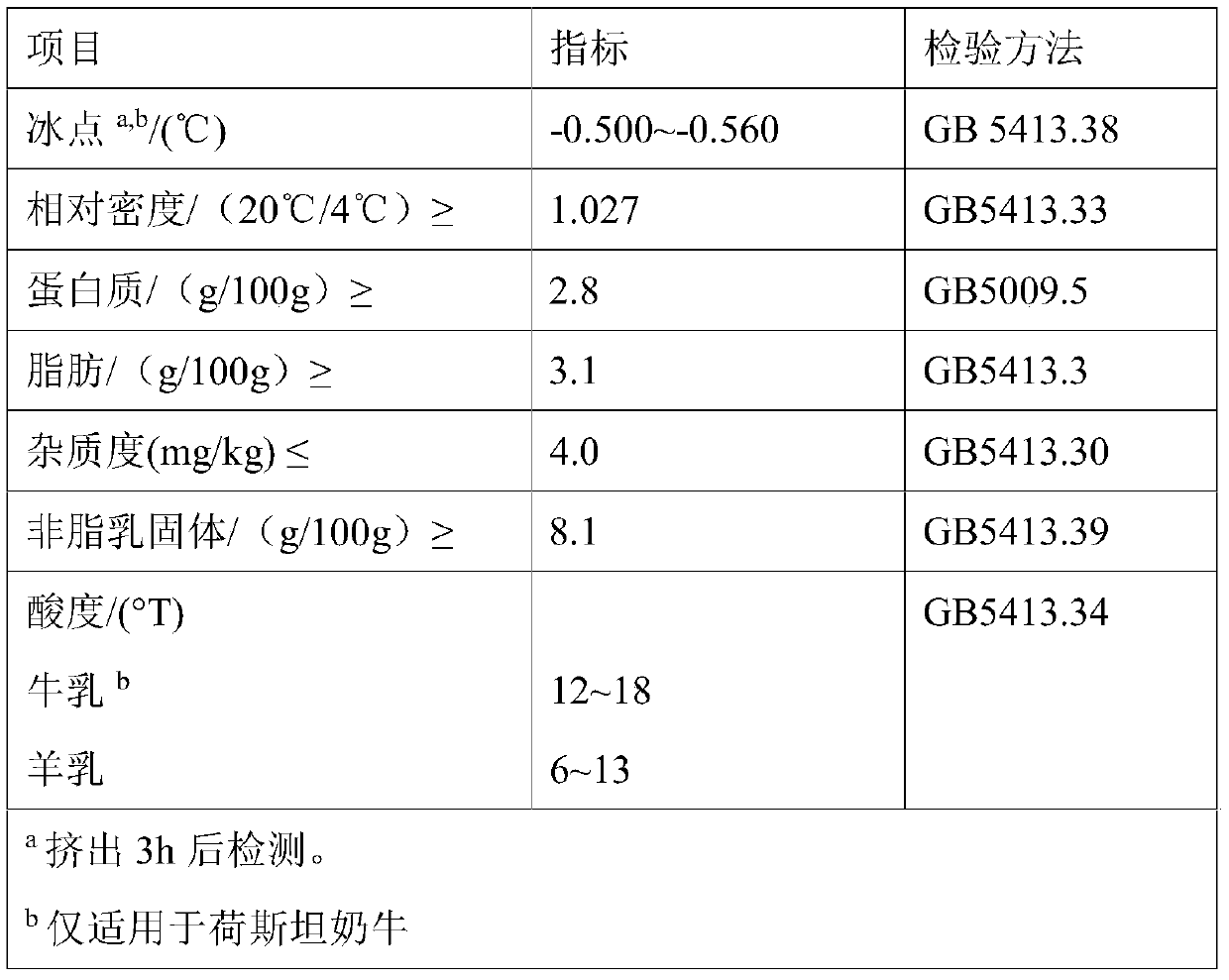

Milk concentrating method and system based on forward osmosis technology

PendingCN109692571AReduce moisture contentReduce volumeOther dairy technologyElectrodialysisHigh concentrationAdditive ingredient

The invention discloses a milk concentrating method and system based on forward osmosis technology. The method comprises the following steps: an original extract liquid permeates and extracts water molecules in raw milk through a forward osmotic process, and concentrated milk and a diluted extract liquid are obtained. The system comprises a raw milk tank, a concentrated forward osmotic membrane unit, a concentrated milk collection tank, a diluted extract liquid regeneration and reuse unit and an original extract liquid tank which are connected. By adopting of the concentrating forward osmoticmembrane unit, the effective ingredients in the milk can be concentrated, the water content of the milk can be reduced, the high-concentration milk can be prepared, and the product quality can be improved; the milk is concentrated by the forward osmotic technology, the solid content of about 60% (30%-70%) can be obtained, and the solid content is higher than that of other low-temperature concentrating technologies.

Owner:国初科技(厦门)有限公司

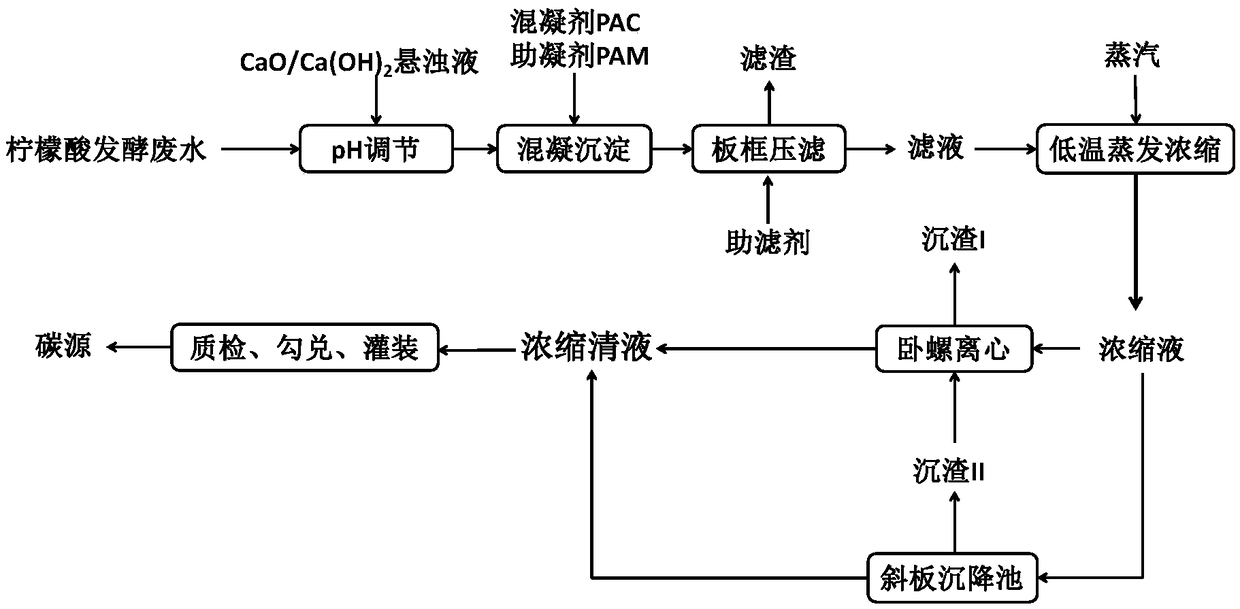

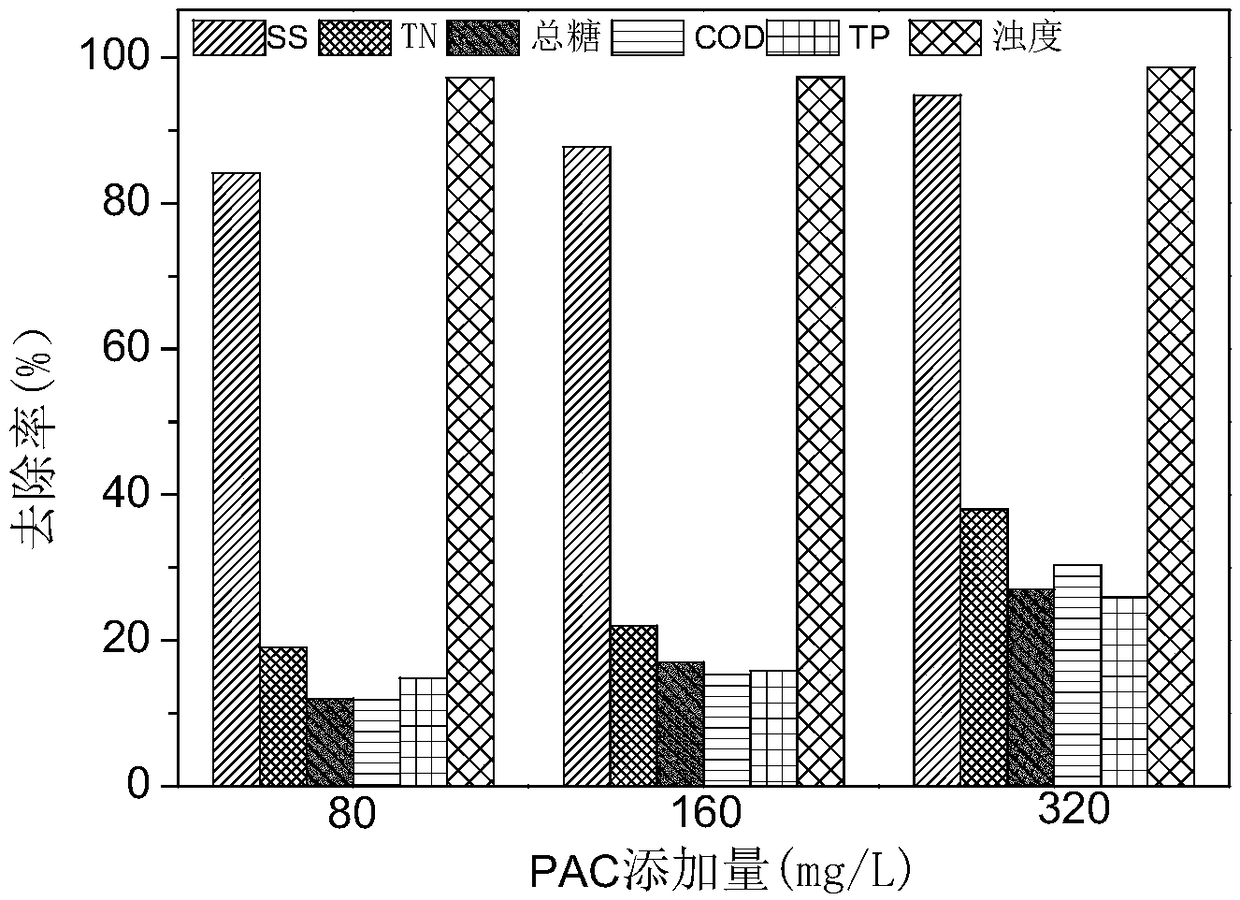

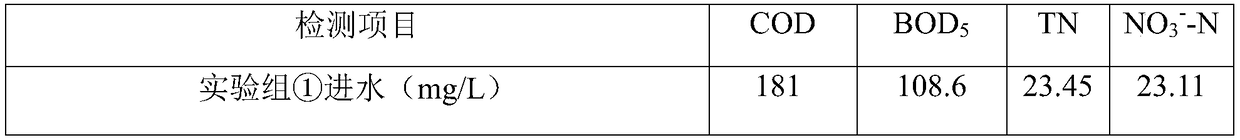

Method for utilizing critic acid fermentation wastewater

InactiveCN108947118AReduce processing costsGood effect of denitrification and denitrificationWater/sewage treatment by centrifugal separationTreatment using aerobic processesHigh concentrationPhosphor

The invention discloses a method for utilizing critic acid fermentation wastewater and belongs to the technical field of environmental engineering. Based on the characteristic that critic acid fermentation wastewater contains a large amount of degradation-resistant mycelia, high concentration BOD, total nitrogen, and total phosphor, nitrogen and phosphor are removed by a precipitation method, highconcentration BOD is taken as an auxiliary carbon source for a biological nitrogen-removing and phosphor-removing treatment of chemical wastewater, the wastes are converted into valuable resources, and the critic acid fermentation wastewater is utilized. The wastewater discharge of critic acid producing enterprises is reduced, the byproduct benefits are increased, and great economic benefits andsocial benefits are generated.

Owner:JIANGNAN UNIV +1

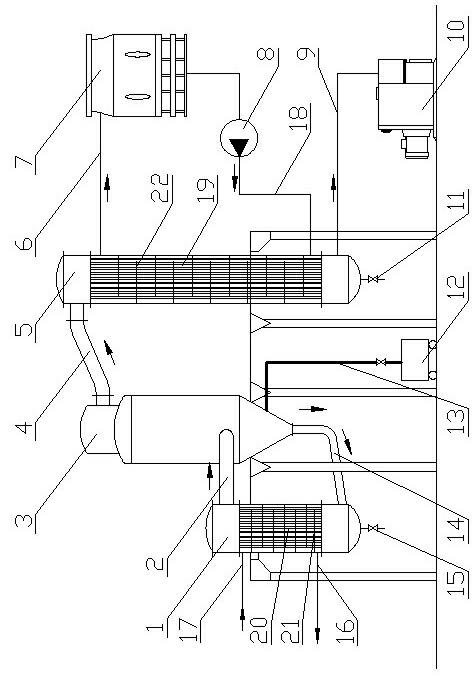

Adipic acid waste water evaporation and concentration process and device thereof

InactiveCN105923673AReduce processing costsReduce processing energy consumptionNature of treatment waterWater/sewage treatment by heatingVapor–liquid separatorConcentration ratio

The invention relates to an adipic acid waste water evaporation and concentration process. The adipic acid waste water evaporation and concentration process comprises the following steps that firstly, a material is preheated; secondly, preheated material enters a film falling heat exchanger to be heated, and gas-liquid mixture is formed; thirdly, the gas-liquid mixture enters the film falling heat exchanger to be subjected to gas-liquid separation, and a concentrated solution returns to the film falling heat exchanger; fourthly, after the concentration ratio of the material in the film falling heat exchanger reaches a preset value, the material is transferred out, heated and concentrated by a forced circulation heat exchanger and then fed into the gas-liquid separator to be subjected to further gas-liquid separation; fifthly, the material is further concentrated in the gas-liquid separator, when the concentration ratio meets the requirement, the material is discharged, secondary steam enters a compressor to be compressed, and after the temperature is raised, the material continues to be heated. The concentration of adipic acid in the adipic acid waste water is effectively increased, the energy consumption is saved, and the concentration cost is reduced; after the concentration of the adipic acid solution is improved, oxalic acid crystals are separated out conveniently, and the environment pollution is reduced.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

Low-temperature vacuum thickener

InactiveCN102319516AMeet the requirements of enrichmentKeep the scentEvaporationVacuum pumpingEngineering

A low-temperature vacuum thickener relates to the technical field of liquid low-temperature concentration. The invention mainly comprises a heating pot, an evaporating pot, and a condensing pot; the heating pot, the evaporating pot, and the condensing pot of the invention respectively have negative-pressure sealing performance and are connected by pipelines; a steam system is connected to a hot steam inlet of the heating pot; a water-charging pump in series connection with a cooling pipe in the condensing pot is opened; a vacuum pump connected to a vacuum-pumping outlet of the condensing pot is opened; and the system can be used normally. The invention has a simple and reasonable structure, and can concentrate various liquid with different concentrations. The invention can meet the concentration requirements of liquid, maintain original fragrance and colors of the raw material, increase the quality of the concentrate, and reduce concentration cost.

Owner:江苏金叶机电设备有限公司

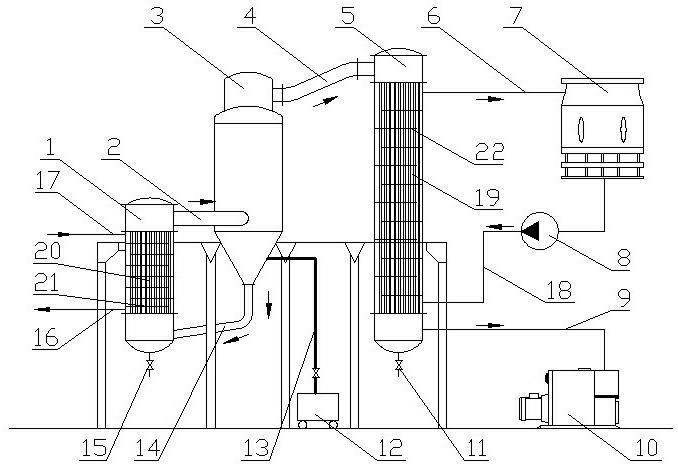

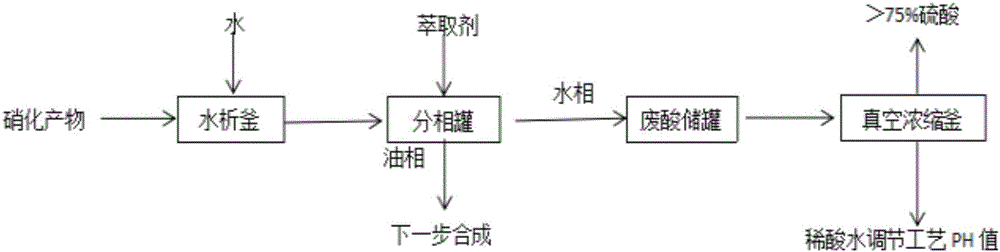

New technology for recycling sulfuric acid in production of 2-cyano-4-nitroaniline

ActiveCN105859580AEasy to useReduce enrichment costsOrganic compound preparationCarboxylic acid nitrile purification/separationChemical industryChlorobenzene

The invention belongs to the field of chemical industry, and relates to a new technology for recycling sulfuric acid in a technology of using concentrated sulfuric acid and concentrated nitric acid to nitrify o-chlorobenzonitrile so as to generate 2-cyano-4-nitro chlorobenzene. An extraction technology is used for extracting a product and nitration by-product impurities from waste acid of nitration, so that pure waste acid is obtained; dilute sulfuric acid is concentrated to 75% or more by using concentration equipment; therefore, the defects that the traditional technology is high in energy consumption, high in pollution and the like are overcome; the technology is free from generation of waste acid, thus being very environmentally friendly.

Owner:河北嘉泰化工科技有限公司

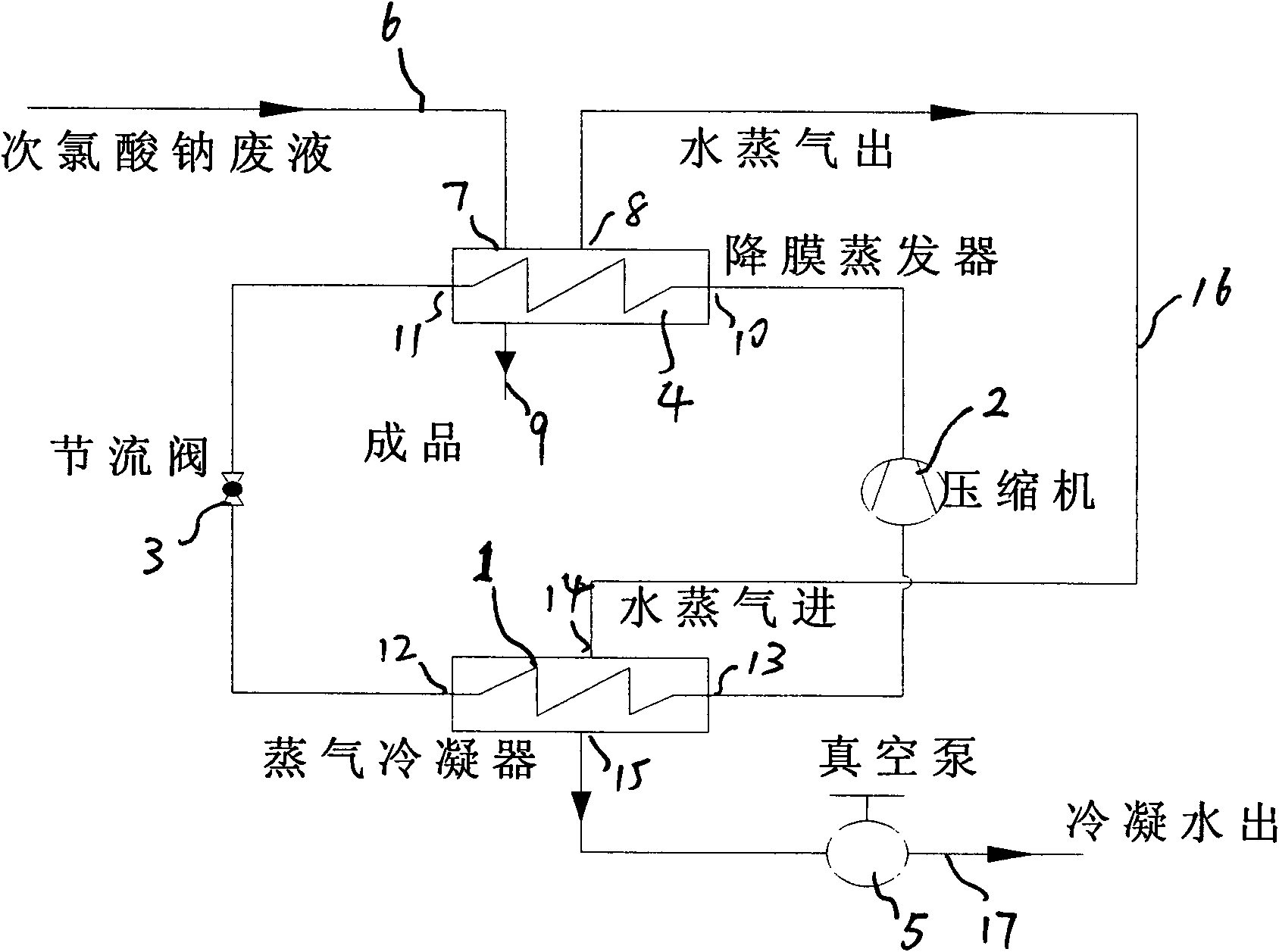

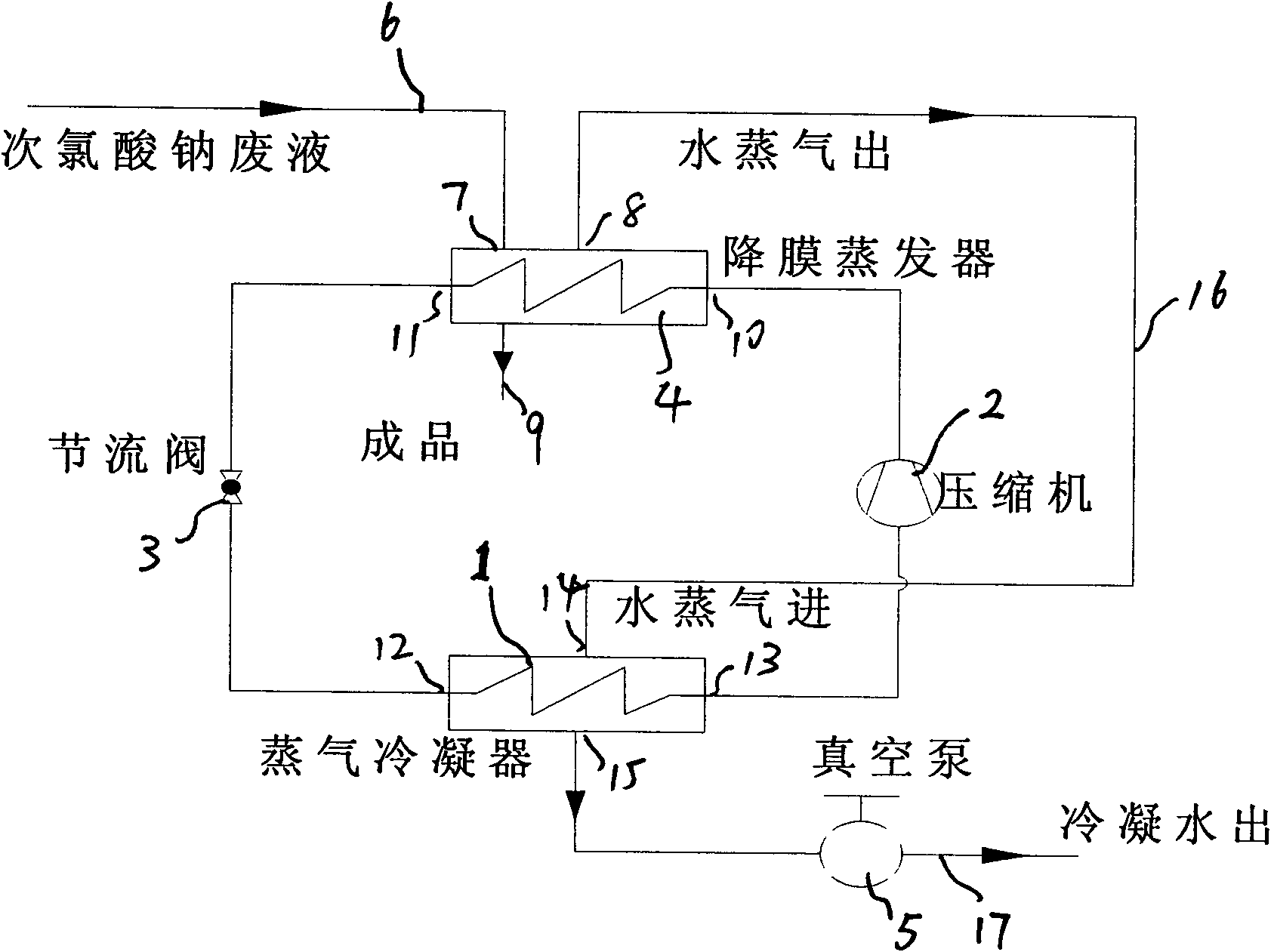

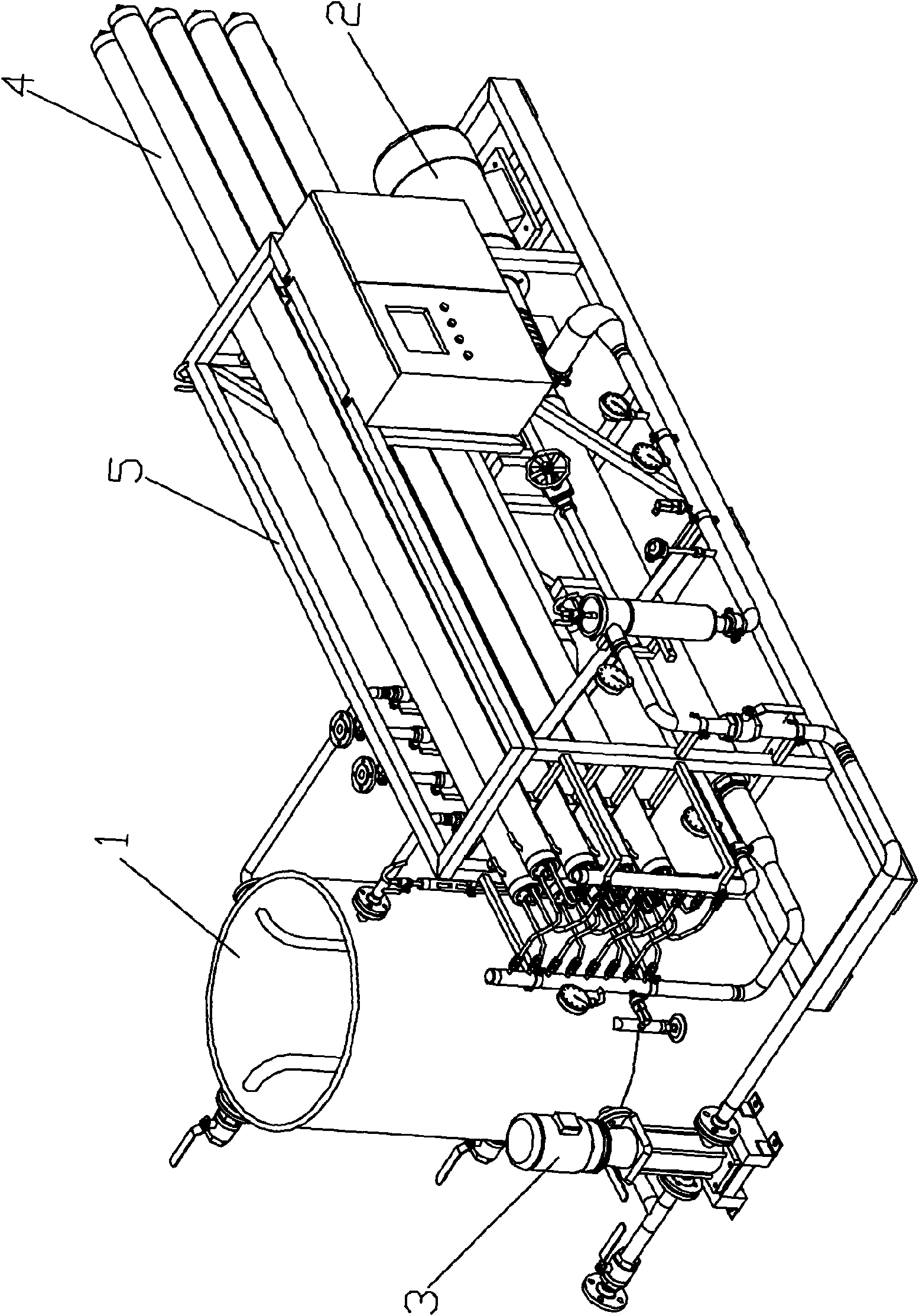

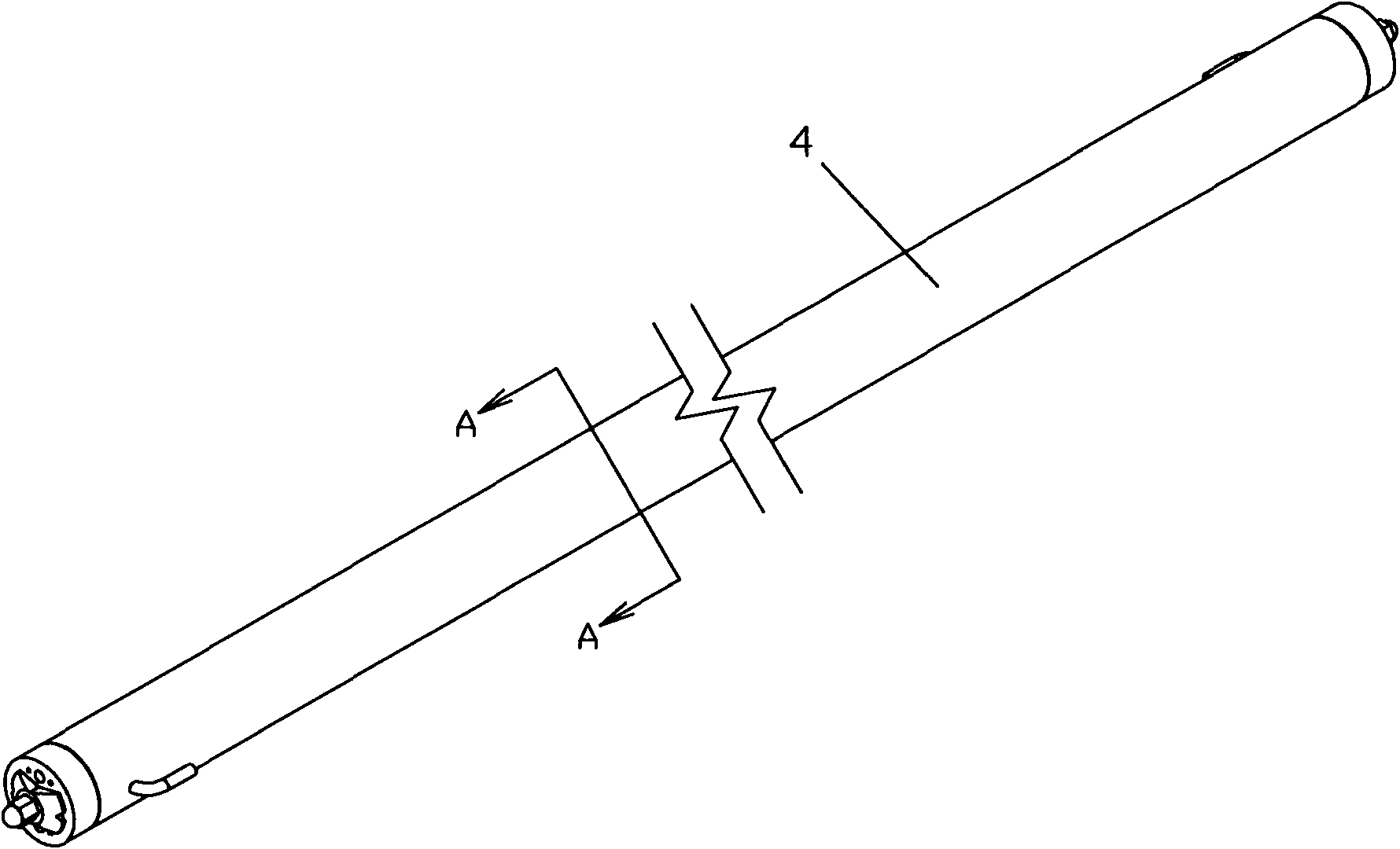

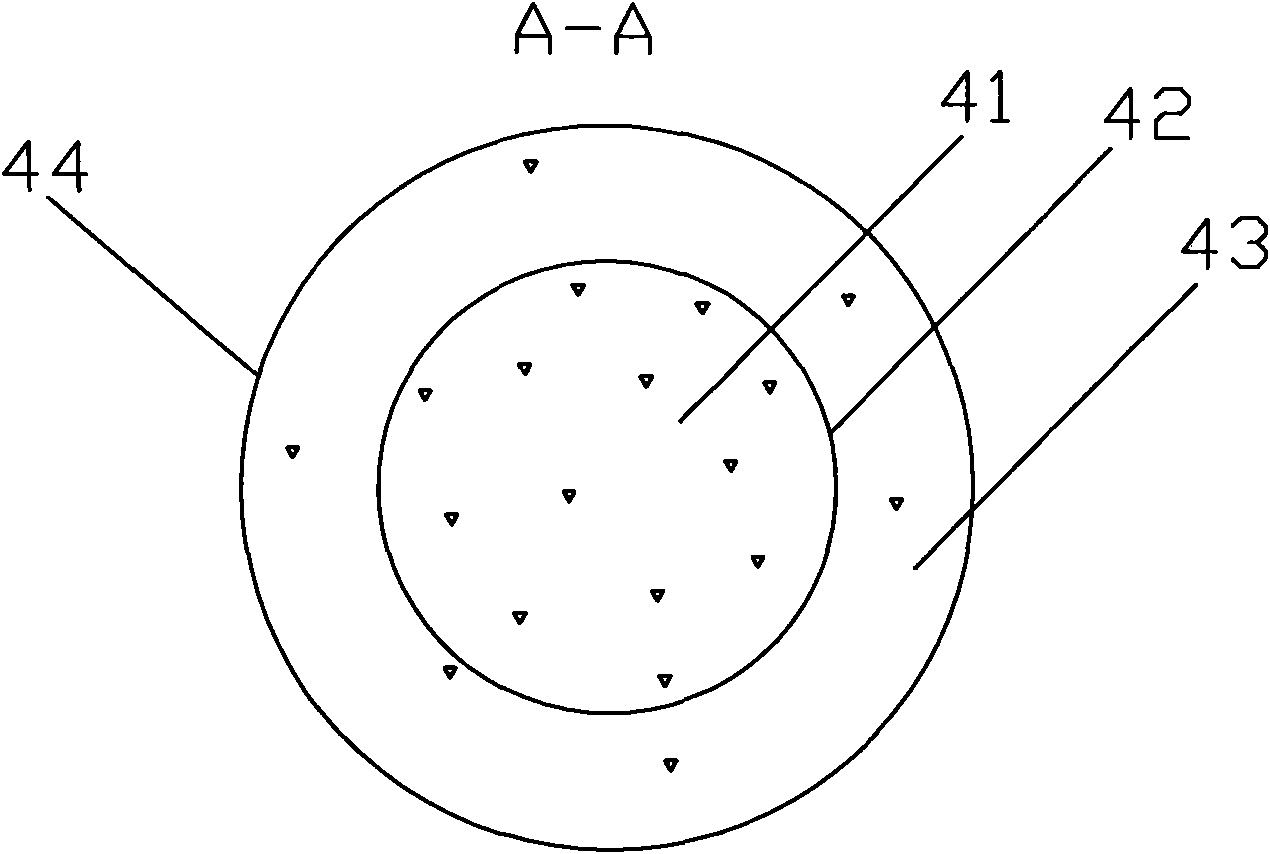

Evaporation and concentration device for corrosive liquid material

The invention discloses an evaporation and concentration device for a corrosive liquid material, which comprises a falling film evaporator, a compressor, a secondary vapor condenser and a water pump. The evaporation and concentration device is a set of chlorate waste liquid falling film evaporator and a set of medium cooling circulation system, wherein the chlorate waste liquid falling film evaporator is used for evaporating and concentrating chlorate waste liquidchlorates and consists of a medium cooling circulation system compressor, thea falling film evaporator and thea secondary vapor condenser. Cooler vapor with relatively high temperature behind the outlet of the compressor is used for heating the chlorate waste liquid to evaporate and concentrate diluted solution of a chlorate; a cooling medium evaporates and absorbs the heat during condensation of secondary vapor in the secondary vapor condenser; and the water pump is arranged at the outlet of the secondary vapor condenser and can quickly drain condensed water in a negative pressure state, and then the secondary vapor smoothly enters the secondary vapor condenser and is condensed.

Owner:JIANGSU LEKE THERMAL ENG EQUIP

Chinese medicine extract concentrated film device

InactiveCN101653698AExtended service lifeLow investment costSemi-permeable membranesPharmaceutical product form changeHigh concentrationMicrometer

The invention relates to a Chinese medicine extract concentrated film device comprising a material inlet pipe, wherein one end of the material inlet pipe is provided with a material inlet, and the other end is connected with a booster pump; the booster pump is connected with a tubular membrane set through a pipeline; the tubular membrane set comprises an outer pipe and a tubular film core arrangedin the outer pipe; the tubular film core is connected with one end of a return pipeline; and the outer pipe is connected with a discharge pipeline. The device can be widely used in the Chinese medicine extract after being simply processed by a 10-micrometer filter and carry out the concentration below 70 DEG C. The device has the advantages of low cost, high concentration capability and efficiency, easy washing and high temperature resistance.

Owner:SINOPHARM GRP DEZHONG (FOSHAN) PHARM CO LTD +1

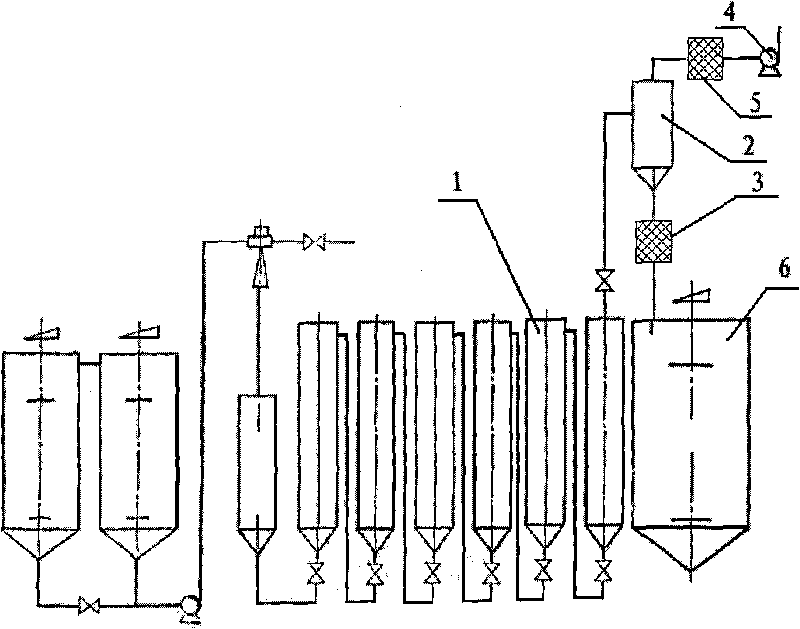

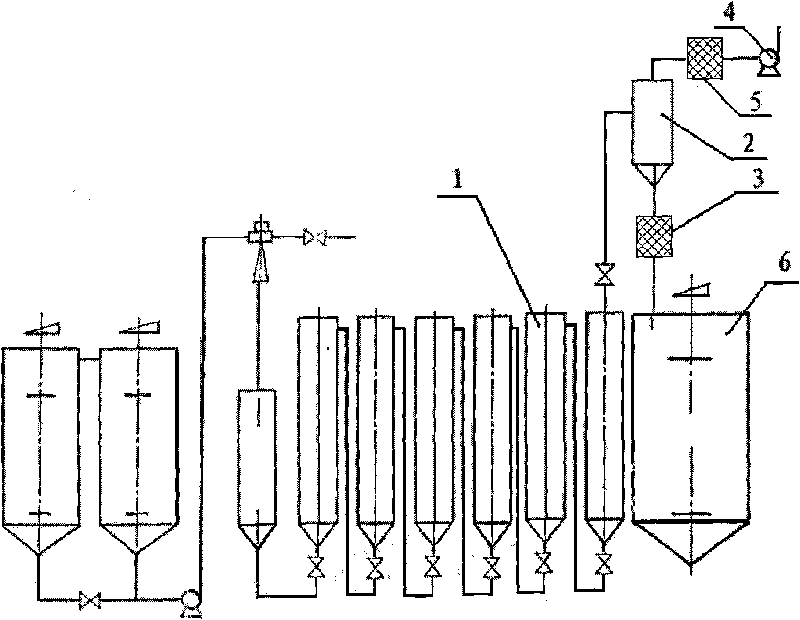

Method for continuously extracting erythritol

ActiveCN107556162AIncrease contentHigh light transmittanceHydroxy compound separation/purificationFiltrationUltrafiltration

The invention discloses a method for continuously extracting erythritol. The method is characterized by comprising the following steps: (1) carrying out ultrafiltration; (2) carrying out nano-filtration; (3) washing and filtering; (4) concentrating; (5) evaporating and crystallizing. The method disclosed by the invention has simple steps and is convenient to operate; impurities in an erythritol solution can be removed by adopting membrane filtration, so that the content and the light transmittance of the erythritol can be improved; the content can reach 99.1 percent, the light transmittance can reach 95 percent and the yield reaches 99 percent; the erythritol is evaporated and crystallized after membrane filtration and concentration are carried out, and the production cost also can be reduced, so that the method disclosed by the invention is suitable for being popularized and applied.

Owner:四川绿沃创新环保工程有限公司

Extraction method of stevioside

InactiveCN108659066AReduce difficultyReduce the amount of water addedSugar derivativesSugar derivatives preparationPectinaseDesorption

The invention discloses an extraction method of stevioside. The extraction method comprises the following steps: crushing dry stevia leaves, adding into an extraction tank, then adding water of whichthe mass is several times of that of the stevia, and stirring; adding cellulase, laccase and pectinase into the extraction tank, and extracting while stirring; adding a flocculant into the extractiontank, flocculating, and filtering to obtain a filtrate; adsorbing the filtrate by using macroporous adsorption resin, desorbing by using ethanol, concentrating a desorbed solution, and then performingdesalting desorption by using cationic resin to obtain a secondarily desorbed solution; concentrating the secondarily desorbed solution, and performing spray drying to obtain stevioside powder. Through addition of a mixed enzyme of the cellulase, the laccase and the pectinase into a stevia crushing solution, the addition amount of the water and the number of extractions in the extracting step arereduced, and the extracting yield is 13-32% higher than that when no enzyme is added, and the concentration cost and the operation complexity of a subsequent process are reduced.

Owner:HUAIYIN TEACHERS COLLEGE

Method for treating glyphosate mother liquor

InactiveCN103665035AContinuous processingHandle large scaleAmino compound purification/separationGroup 5/15 element organic compoundsGlyphosateChemical products

The invention provides a method for treating glyphosate mother liquor. The method comprises the following steps: introducing dimethylamine gas into the bottom of a gas-liquid countercurrent packed tower, absorbing the dimethylamine gas through taking the glyphosate mother liquor as an absorbent and collecting alkaline liquid at the bottom of the tower; introducing the liquid into a rectifying tower for rectification to obtain triethylamine and tower bottom liquid; dehydrating the tower bottom liquid at reduced pressure, adding hydrochloric acid to adjust the pH value of the tower bottom liquid to strong acidity, cooling, crystallizing and filtering to obtain glyphosate; and further distilling the filtered filtrate at reduced pressure to obtain dimethylamine hydrochloride. Compared with the prior art, the method provided by the invention has the advantages that the dimethylamine gas is utilized to replace other liquid alkalies to recover the catalyst triethylamine in the glyphosate mother liquor, the obtained glyphosate and the dimethylamine hydrochloride are useful chemical products and no waste is produced, so that the method is high in recovery rate, high in recovery product quality, friendly to environment and economic; in the meanwhile, the gas-liquid countercurrent packed tower is adopted in the method, so that the method is more safe in reaction and is beneficial to the continuous and large scale treatment of the glyphosate mother liquor.

Owner:HEBI NONGLIN PHARMA

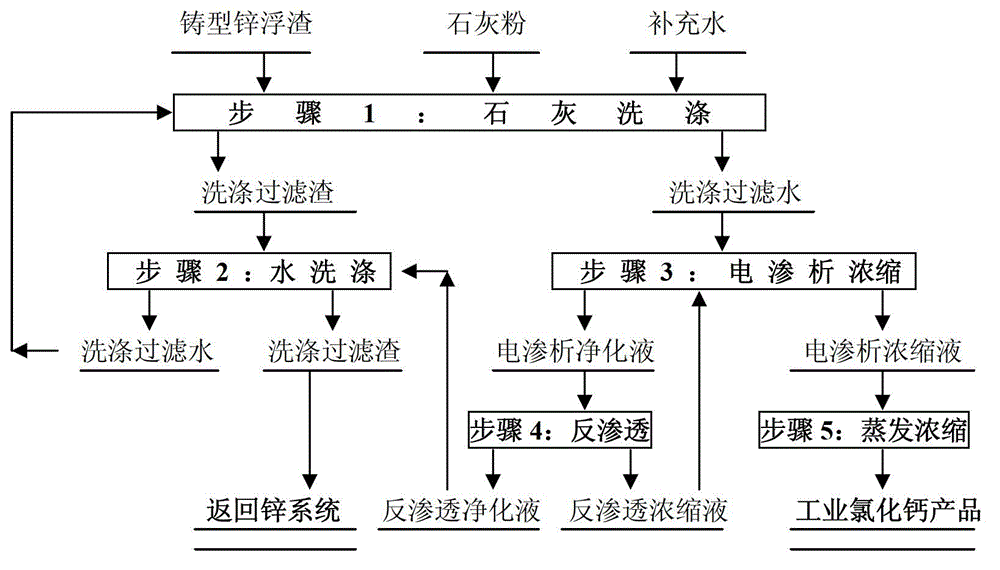

Processing method of casting zinc dross

InactiveCN102978418AAchieve separationEffective protectionProcess efficiency improvementFiltrationReverse osmosis

The invention discloses a processing method of casting zinc dross. The processing method comprises the steps of adding water and the casting zinc dross into a washing trough when stirring at room temperature, adjusting the final pH value of washing liquid to 9-11 using hydrated lime powder, washing the casting zinc dross for 10-30 minutes, filtering to obtain filtrate and filtration residue, washing the filtration residue using tap water at room temperature and in the liquid-solid ratio of (3:1):(5:1) for 10-30 minutes, filtering to obtain the filtrate and filtration residue, returning the filtration residue to a zinc system to produce electrodeposited zinc, returning the filtrate to the lime water washing procedure, subjecting the lime water washed filtrate to electrodialysis concentration,subjecting the electrodialysis purified liquid to the separation treatment by means of reverse osmosis membrane technology, returning the reverse osmosis concentrated liquid to the electrodialysis procedure for processing, returning the reverse osmosis membrane purified liquid to the tap water washing procedure, and vaporizing and concentrating the electrodialysis concentrated liquid to produce the product of calcium chloride. By adopting the processing method provided by the invention, chlorine can be fast removed from the casting zinc dross, the metal zinc can be recycled, the product of calcium chloride can be simultaneously produced, and the whole process procedures do not produce waste water.

Owner:LAIBIN CHINA TIN SMELTING

Method for preparing concentrated liquid fertilizer by using wastewater containing livestock excrement

InactiveCN107324850AImprove solubilityHigh organic contentCalcareous fertilisersBio-organic fraction processingLiquid wasteHigh concentration

The invention discloses a method for preparing a concentrated liquid fertilizer by using wastewater containing livestock excrement. The method comprises the following steps: adding acids to immobilize amino and keep fertilizers; adding quicklime to neutralize excessive acids; performing primary fermentation so as to increase the dissolution degree of organic fertilizers; performing solid-liquid separation; performing negative-pressure concentration; and performing secondary fermentation on a concentrated liquid, thereby obtaining a livestock excrement concentrated liquid fertilizer. The method is simple in concentration process, good in operability and low in concentration cost; the solution degree of fertilizer components in the organic liquid fertilizer is high; due to amino immobilization and fertilizer increase of acids, and alcohol for increasing the dissolution degree of livestock excrement in the wastewater, the organic fertilizers can be relatively thoroughly dissolved in the wastewater, the cost of negative pressure concentration is reduced, the alcohol and the water can be both recycled, and the utilization rate of the livestock excrement is effectively increased; and by adopting the method, wastewater containing livestock excrement generated in the on-scale livestock breeding process can be turned into a high-concentration organic fertilizer, so that wastewater treatment in the on-scale livestock breeding process is solved, and harmonious development of agriculture, on-scale livestock breeding and living environments of people is promoted.

Owner:朱和平

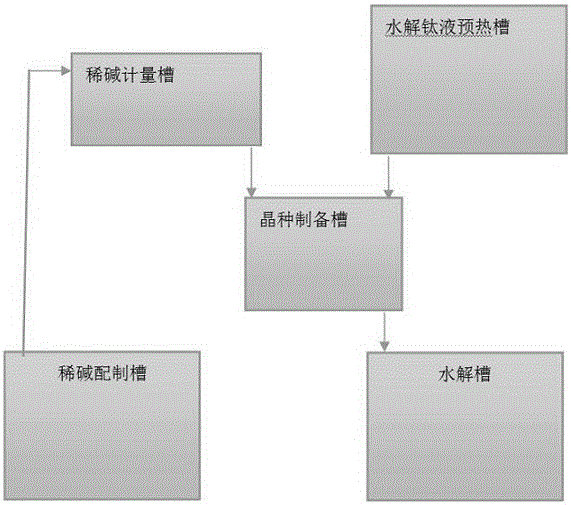

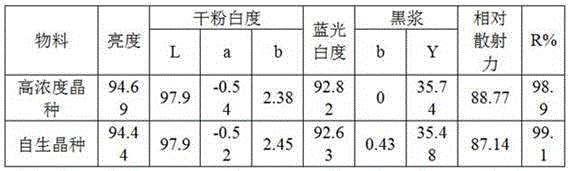

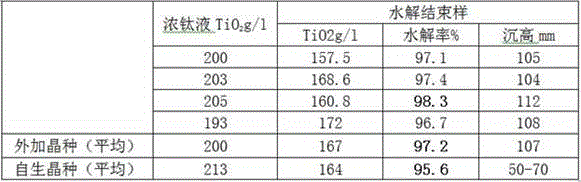

Method for preparing titanium white powder from high-concentration additional crystal seeds

ActiveCN106241866AIncrease hydrolysis rateReduce enrichment costsTitanium dioxideHigh concentrationWhite powder

The invention relates to the production of titanium white powder production, and particularly relates to a method for preparing titanium white powder from high-concentration additional crystal seeds. Compared with the existing spontaneous crystal seed method, high-concentration additional crystal seed hydrolysis can be increased by 1.5%, normal water washing can be performed for primary washing and secondary washing, and the pulping Fe content can be also well controlled; and meanwhile, the high-concentration additional crystal seed hydrolysis material has a certain effect of improving pigment performance.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

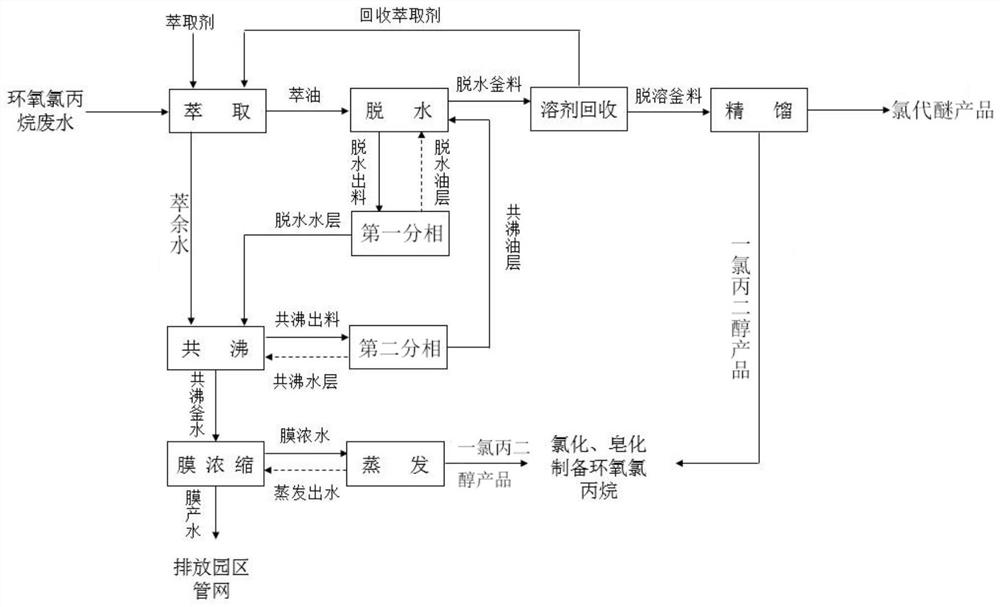

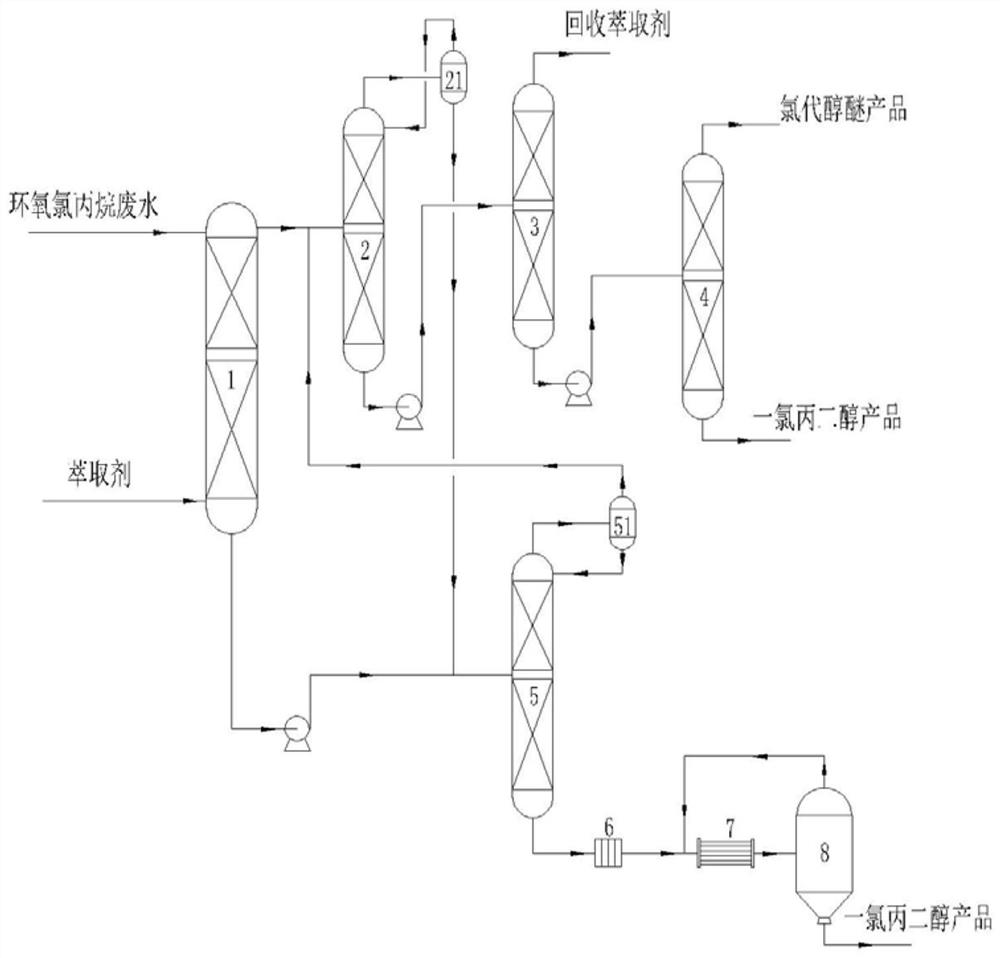

Device and method for separating and purifying by-products in epichlorohydrin wastewater

ActiveCN112374676AAchieve separationImprove economyEther separation/purificationGeneral water supply conservationEtherEpichlorohydrin

The invention provides a device for separating and purifying by-products in epichlorohydrin wastewater. The device comprises an extraction unit, a dehydration unit, a solvent recovery unit and a rectification unit which are connected in sequence. The device further comprises an azeotropic unit, a membrane concentration unit and an evaporation unit which are sequentially connected with the extraction unit. Separation, purification and resource recovery of by-products in the epichlorohydrin wastewater can be effectively achieved through a series of working sections such as combined extraction, rectification, membrane concentration and evaporation. The method using the device can effectively separate water and organic matters, realizes recovery, separation and purification of chlorohydrin ether and propylene glycol monochloride in wastewater, realizes up-to-standard discharge of effluent, and has a wide application prospect.

Owner:JIANGSU YANGNONG CHEM GROUP +3

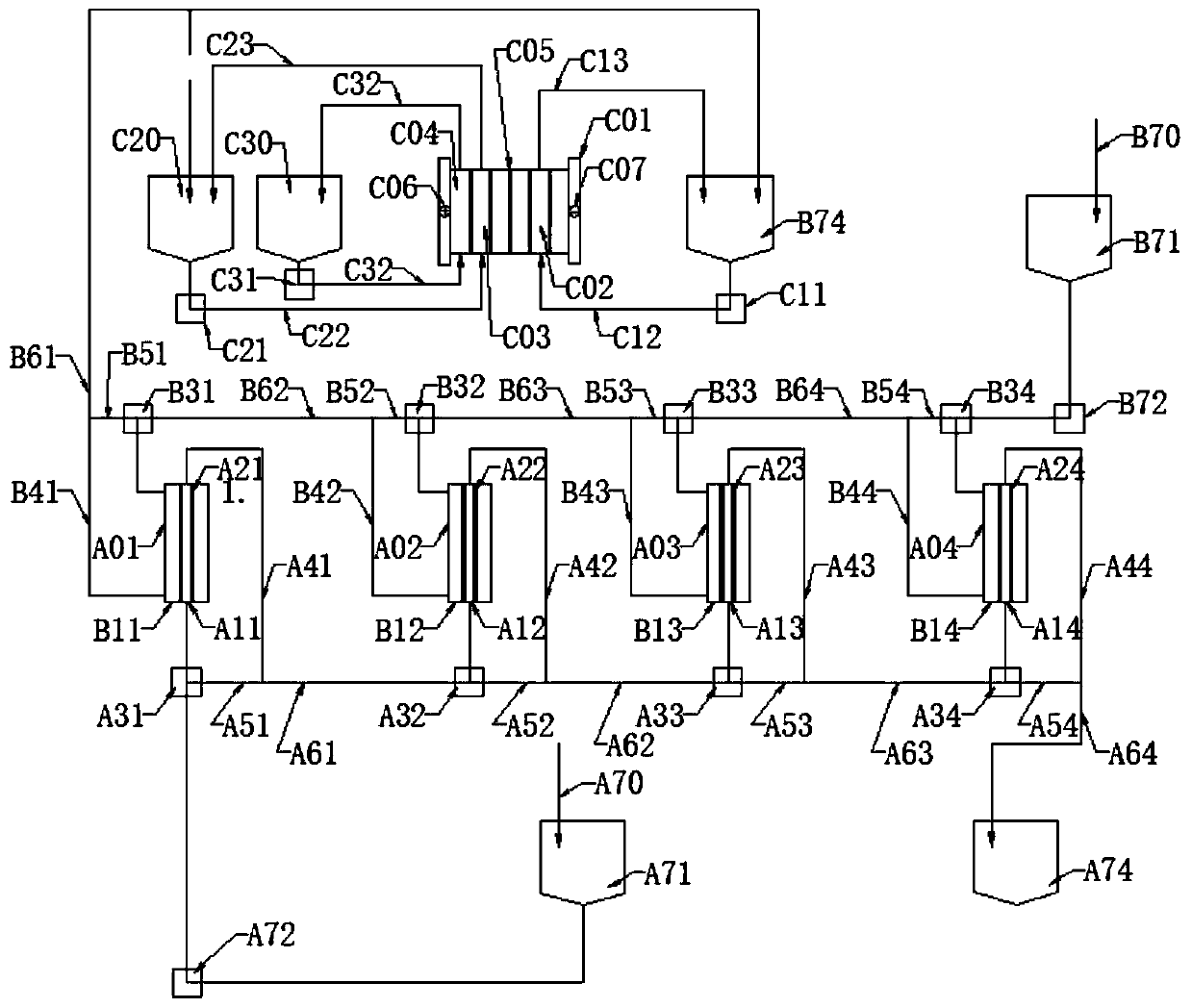

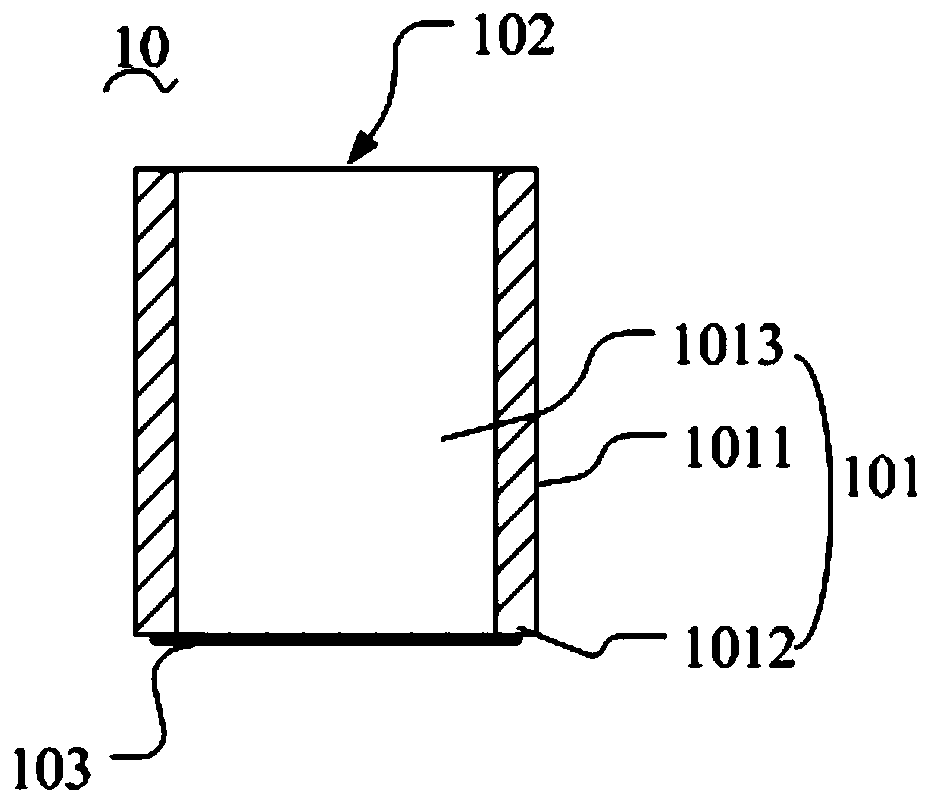

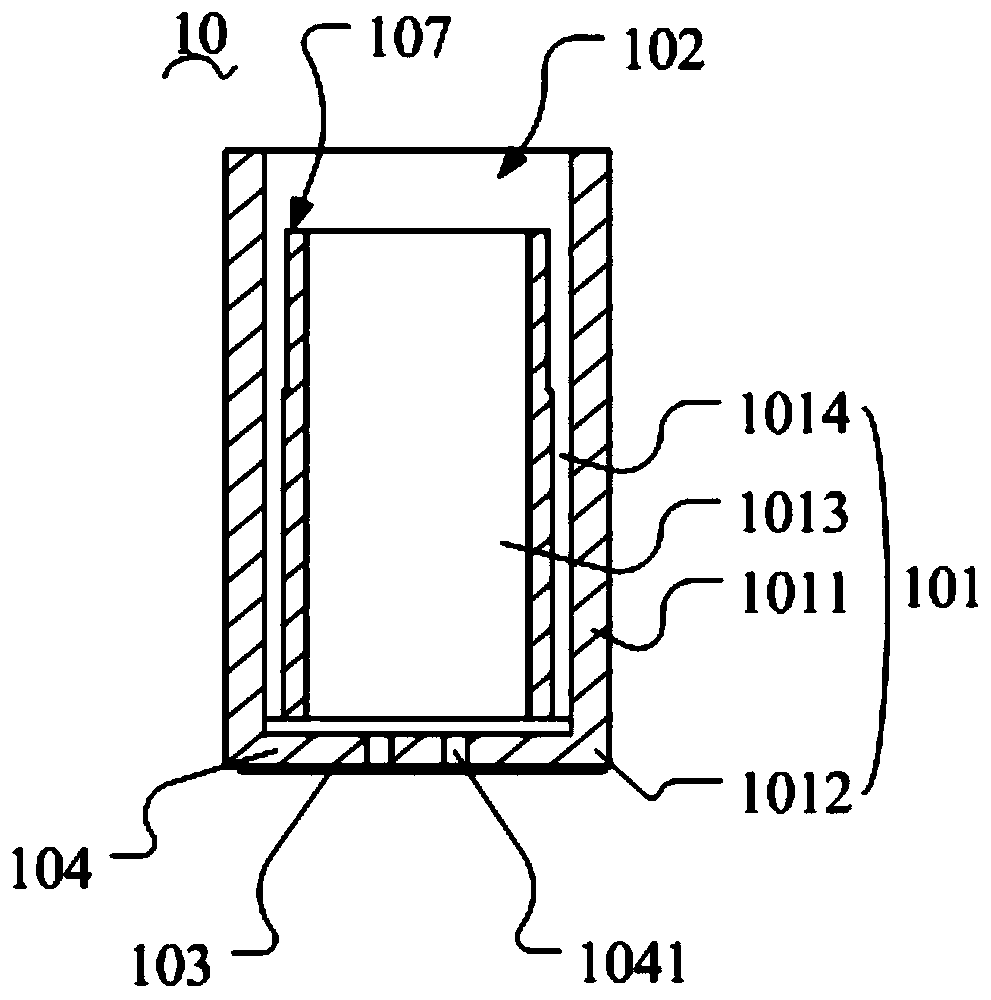

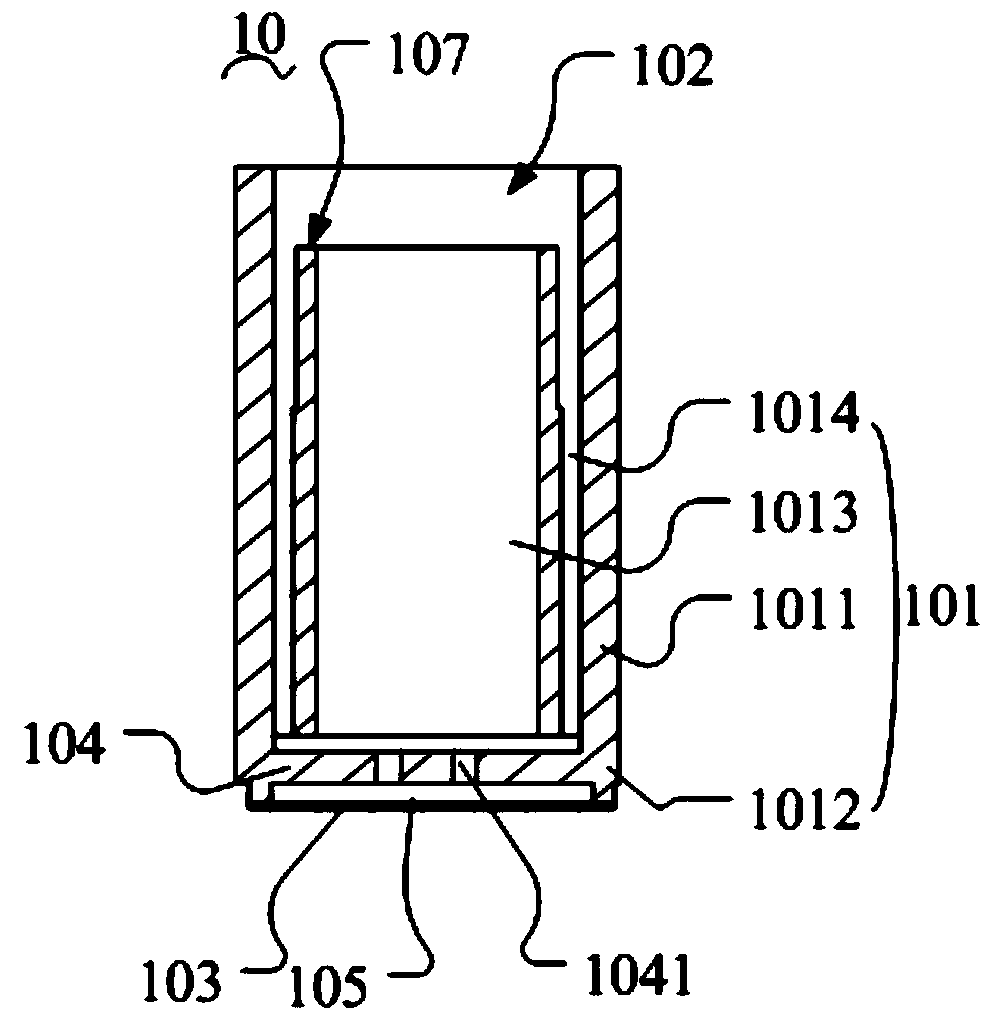

Enrichment device, enrichment system, sample manufacturing system and sample detection system

PendingCN111007238AReduce enrichment costsLow costMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPhysical chemistryEngineering

The invention discloses an enrichment device, an enrichment system, a sample manufacturing system and a sample detection system. The enrichment device comprises an enrichment housing, wherein the enrichment housing defines an enrichment cavity for accommodating suction liquid; a suction connecting part which is used for communicating the suction mechanism with the enrichment cavity, so that the enrichment cavity forms negative pressure under the action of a vacuumizing mechanism; and a separation part which is arranged on the enrichment housing, and when negative pressure is formed in the enrichment cavity, a sample can pass through the separation part and form the suction liquid to enter the enrichment cavity, and retentate is retained on the separation part.

Owner:AVE SCI & TECH CO LTD

A self-born crystal seed for hydrolysis in titanium dioxide production and a preparing method thereof

The invention relates to a self-born crystal seed for hydrolysis in titanium dioxide production and a preparing method thereof, and belongs to the technical field of chemical engineering. The method includes adding a titanium solution into base water and fully mixing the mixture to obtain self-born crystal seeds. The amount of the base water is calculated to control the total titanium concentration, calculated based on TiO2, of a hydrolysis system to be 155-175 g / L according to the concentration of the initial titanium solution. The base water is prepared by adding sulfuric acid or sodium hydroxide into water and fully mixing the mixture. The dosage of the sulfuric acid or sodium hydroxide meets a condition that when the titanium solution is added into the base water and the amount of theadded titanium solution is 3.0-3.5% of the volume of the total titanium solution, the concentration of sulfuric acid of the whole reaction system is 0.6 + / - 0.02 mol / L. A present process for producingtitanium dioxide self-born crystal seeds through a sulfuric acid method is utilized, the base water amount for initial formation of the self-born crystal seeds and the acidity of a critical point arecontrolled to obtain hydrolysis seeds of a proper amount and proper mass, and pigment titanium dioxide with good structures and excellent performance can be prepared.

Owner:攀枝花兴中钛业有限公司

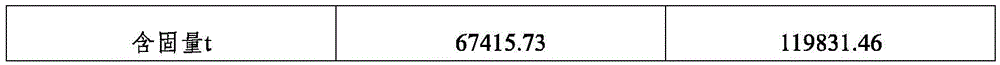

Concentration method and concentration apparatus for wet method phosphorus acid

InactiveCN105668535AThe concentrated effect is excellentConcentration effect is better than traditional wet-process phosphoric acid concentrationPhosphorus compoundsPhosphoric acidSolid content

The invention relates to the technical field of wet method phosphorus acid concentration and especially provides a concentration method and a concentration apparatus for wet method phosphorus acid. In the apparatus, a concentrated acid precipitation unit is connected to a secondary acid pump; the secondary acid pump is connected to a concentration mechanism; and the concentration mechanism is connected to a finish product acid precipitation unit. With limitation on concentration, specific gravity and solid content of the wet method phosphorus acid fed from a material inlet, and limitation on flow rate and processing time during the treatment process, the method has better wet method phosphorus acid concentration effect than a conventional method. When processing load is 750000 ton, solid content is reduced by 55675.85 ton, and meanwhile, 59140.87 ton of clear acid is avoided from being brought away by solid, so that the yield of concentrated clear acid is increased by about 8%. The method and the apparatus reduce the loss rate of the clear acid and reduce cost.

Owner:GUIZHOU KAILIN GRP CO LTD

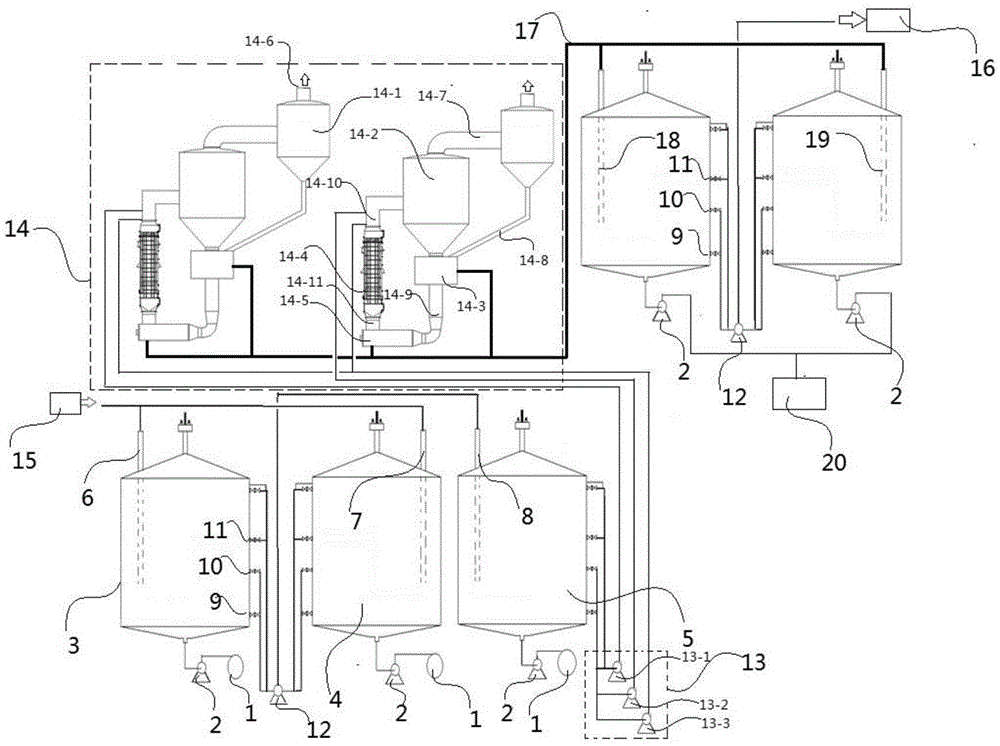

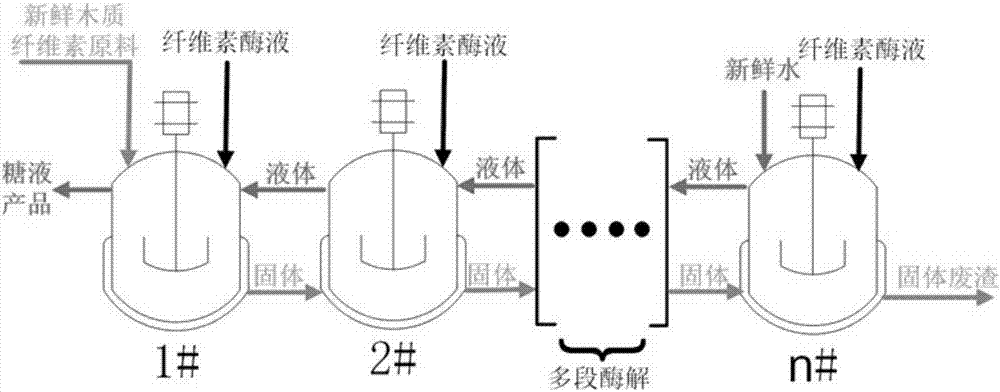

Multi-step efficient enzyme hydrolysis process method of lignocellulose

The invention discloses a multi-step efficient enzyme hydrolysis process method of lignocellulose. The method comprises the following steps of 1, feeding a fresh lignocellulose raw material, cellulase and water into a first enzyme hydrolysis tank, and performing hydrolysis under a condition of certain temperature and pH value; 2, after the first enzyme hydrolysis reaction in the step 1 is finished, performing solid-liquid separation, wherein the liquid obtained through separation is directly taken out to be used as a sugar product, and the solid obtained through separation is directly fed into a second enzyme hydrolysis tank to be reacted; 3, after the second enzyme hydrolysis reaction in the step 2 is finished, performing solid-liquid separation, wherein the liquid obtained through separation is conveyed into the first enzyme hydrolysis tank to continuously participate in the enzyme hydrolysis reaction, and the solid obtained through separation is directly fed into a third enzyme hydrolysis tank to be continuously reacted; etc.and n, after the (n-1)th enzyme hydrolysis reaction in the step (n-1) is finished, performing solid-liquid separation, wherein the liquid obtained through separation is conveyed into the (n-2)th enzyme hydrolysis tank to continuously participate in the enzyme hydrolysis reaction, and the solid obtained through separation is directly fed into an nth enzyme hydrolysis tank to be continuously reacted.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

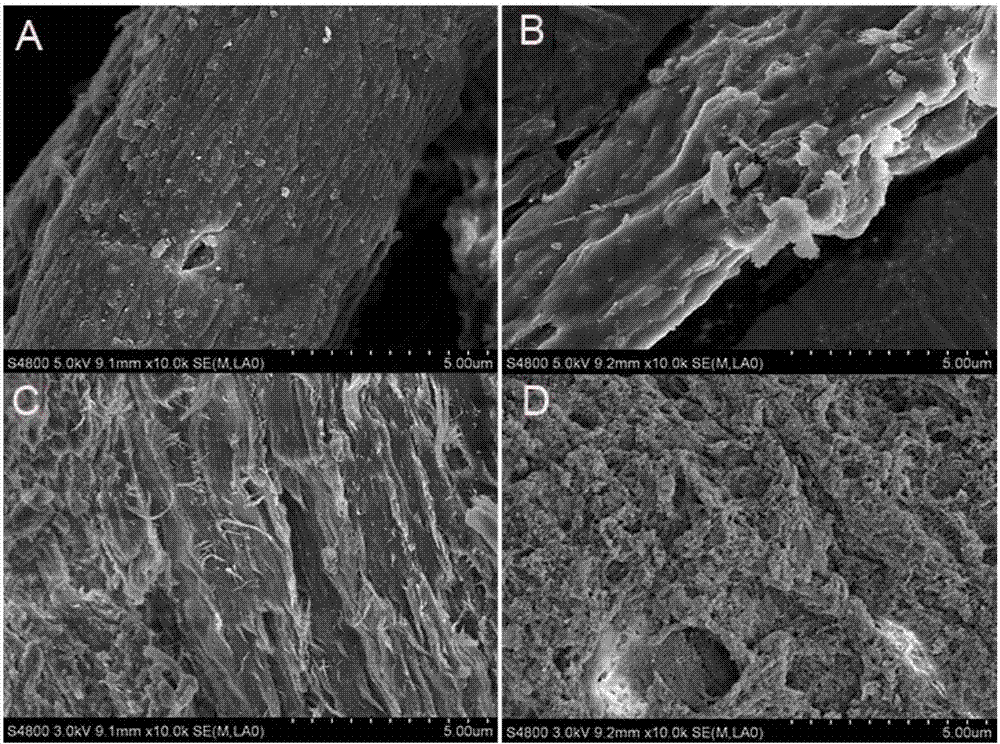

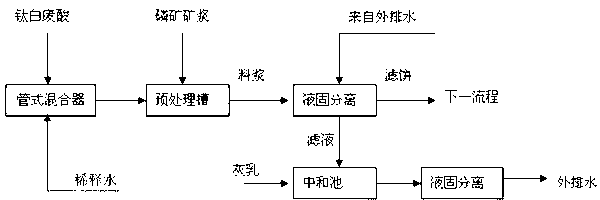

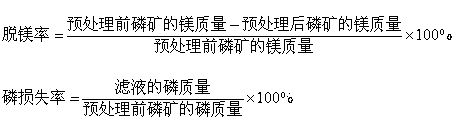

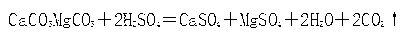

Method for pre-treating phosphorus rock by titanium dioxide waste acid

ActiveCN102674278BReduce processingQuality improvementPhosphorus compoundsLoss ratePretreatment method

The invention discloses a method for pre-treating phosphorus rock by titanium dioxide waste acid, comprising the following steps of: (1) collecting titanium dioxide waste acid to a waste acid storage tank, and controlling concentration of sulfuric acid in the titanium dioxide waste acid to be 20-30%, and concentration of ferrous sulfate to be 10-14%; (2) mixing and diluting the dilution water and the titanium dioxide waste acid according to the mass ratio of (4-10):1, and controlling content of the sulfuric acid to be 1-8%; and (3) adding diluted titanium dioxide waste acid and ground phosphorus rock to a reaction tank to react so as to obtain reaction slurry, and separating solid and liquid of the reaction slurry to obtain a solid phase, i.e.,, pre-treated phosphorus rock. The method not only has high magnesium removing rate and low phosphorus loss rate, but also solves the problem that the fluctuation of the acid concentration influences a pre-treatment pH (Potential Of Hydrogen) value, is suitable for wet-process phosphoric acid production of different scales, has high production efficiency and low operation cost, and is economic and practical.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com