Production scheme and preparation method of converting biogas slurry into organic fertilizer

A technology of organic fertilizer and biogas slurry, which is applied in the field of waste reuse and high-quality organic fertilizer preparation, can solve the problems of low relative content of active ingredients, environmental pollution, waste of biogas slurry, etc., and achieve low concentration cost, high degree of automation, and easy to use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

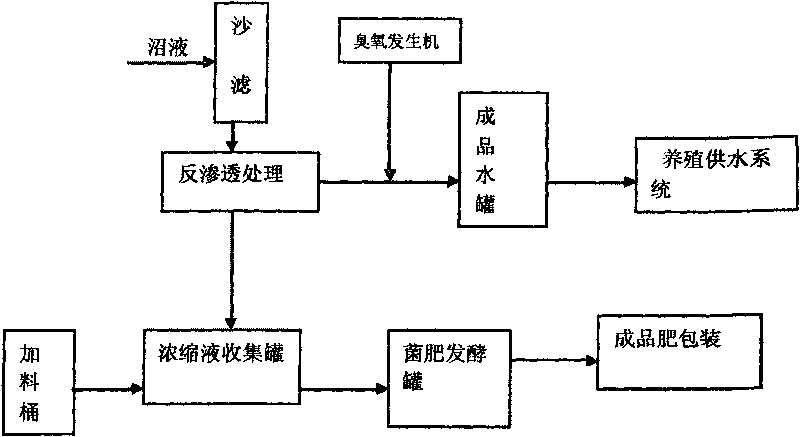

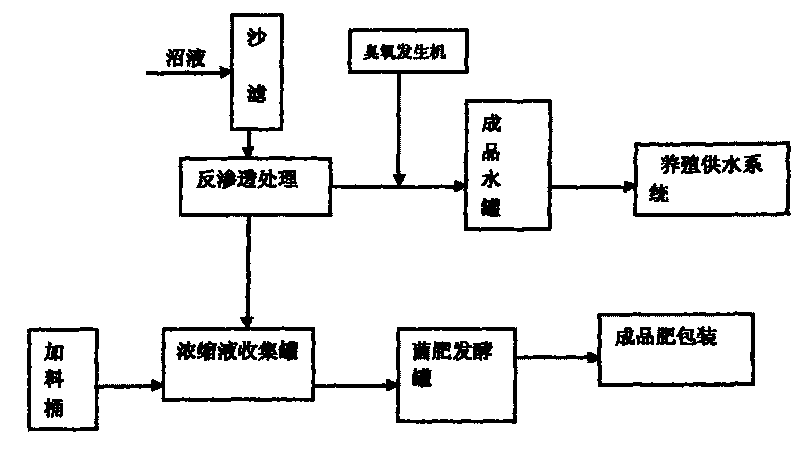

[0025] The production scheme and preparation method of converting biogas slurry to organic fertilizer includes the following steps:

[0026] A) Sand filtration treatment: pump the biogas slurry into a steel tank filled with quartz sand, and filter out large dross.

[0027] B) Reverse osmosis treatment: pressurize the biogas slurry, and use the principle of reverse osmosis to separate the water from the biogas slurry to obtain a biogas slurry concentrate.

[0028] C) Ozone disinfection and sterilization: recycle the water obtained by reverse osmosis after ozone disinfection and sterilization.

[0029] D) Adding active ingredients: recover the biogas slurry obtained from concentration, and add corresponding ingredients according to different usage requirements after testing.

[0030] E) Fermentation of beneficial bacteria: the prepared concentrated solution is fermented by effective bacteria and packaged.

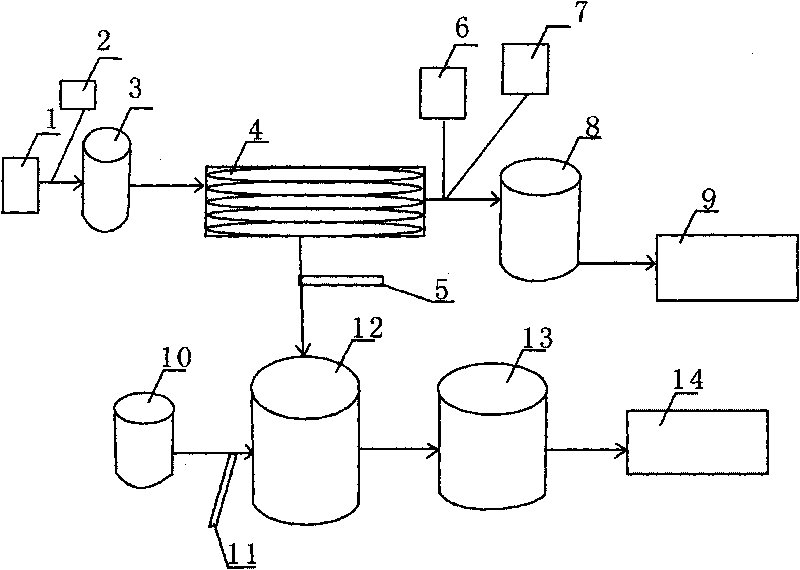

[0031] Equipment for biogas slurry to organic fertilizer production pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com